Ultra-precision machining method of cerium lanthanum alloy

A technology of ultra-precision machining and cerium-lanthanum alloy, which is applied in the field of ultra-precision machining of cerium-lanthanum alloy, can solve problems such as difficulty in meeting ultra-precision machining requirements of cerium-lanthanum alloy, affecting surface machining accuracy, and difficulty in stable cutting, so as to improve the cutting surface. The effect of quality, improving machining accuracy and stable machining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

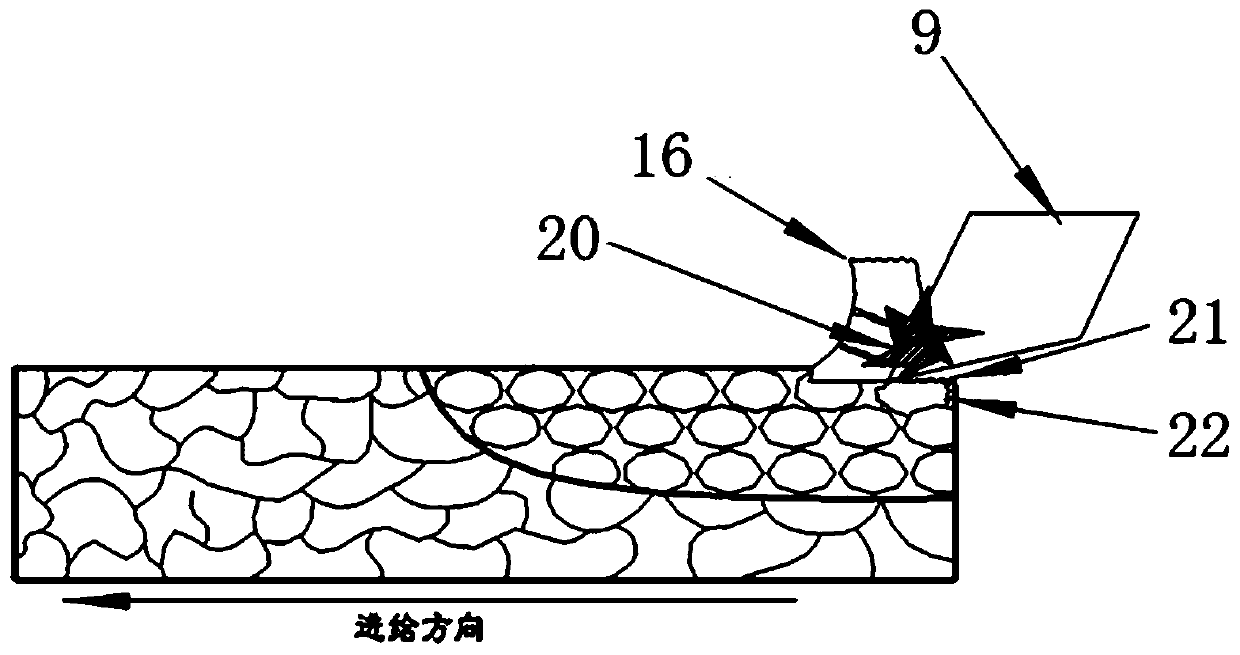

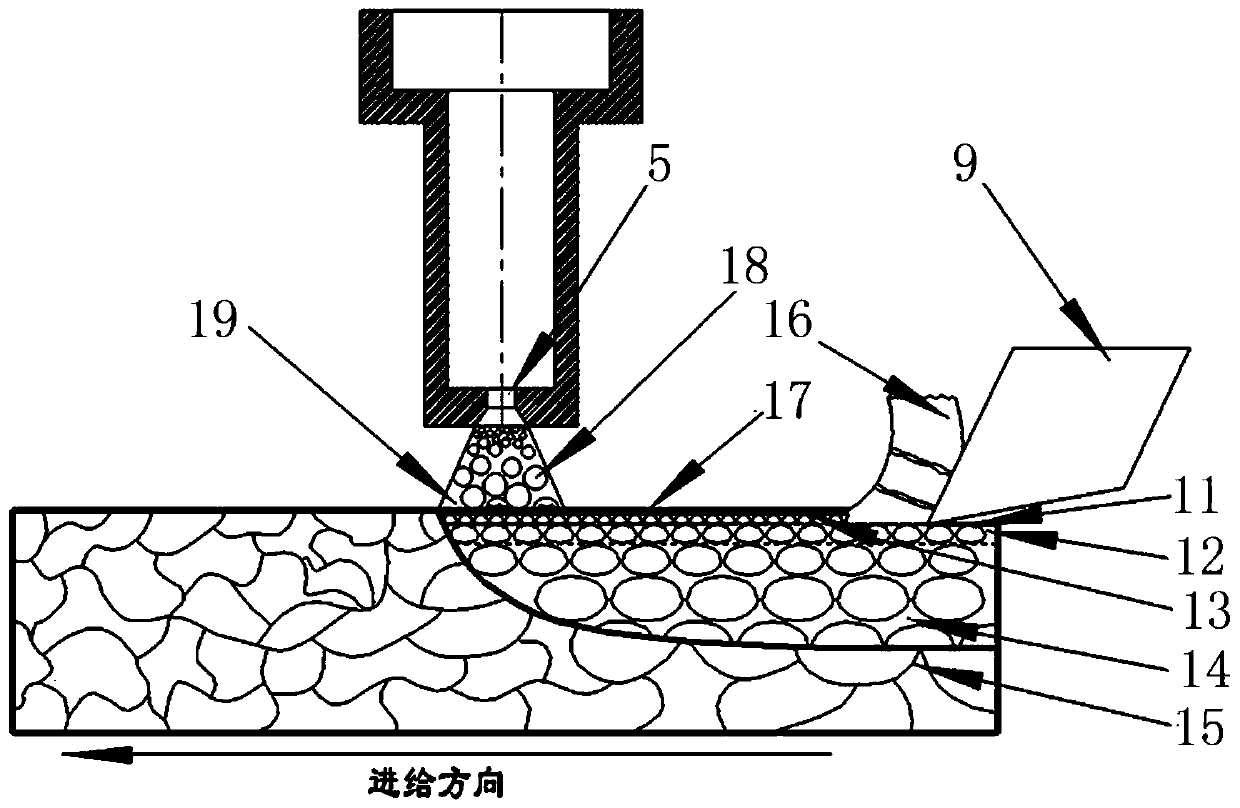

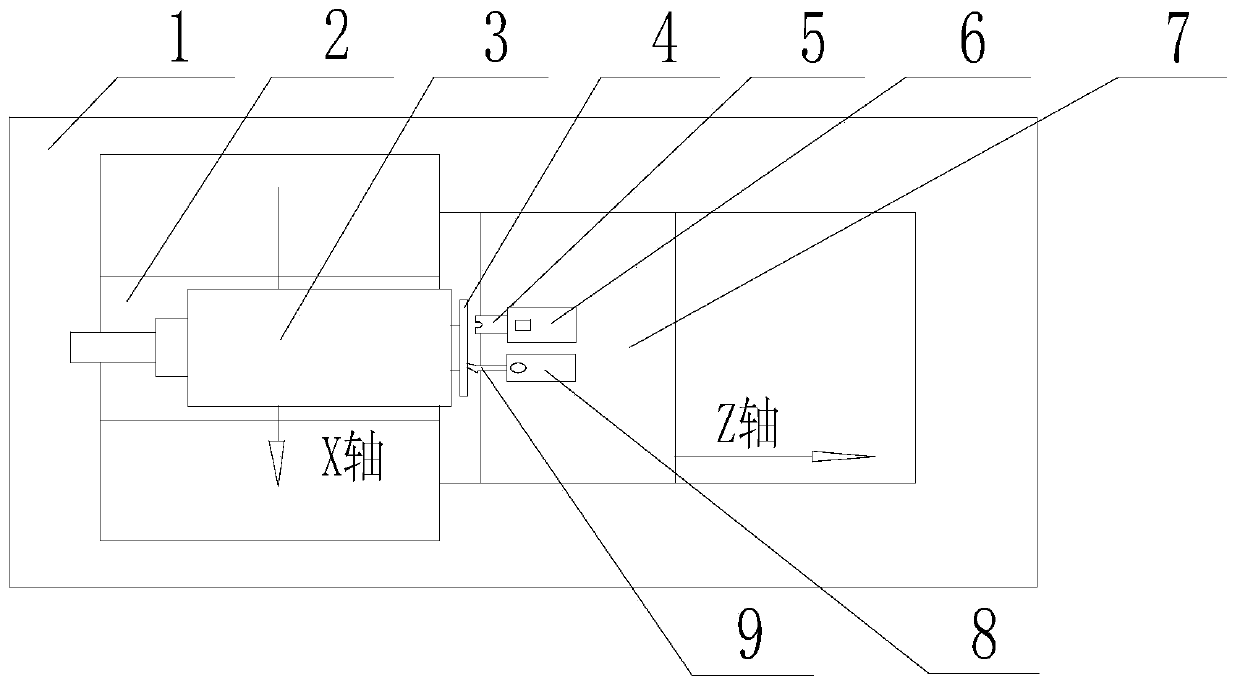

[0033] Such as figure 2 , image 3 As shown, an ultra-precision machining method of a cerium-lanthanum alloy of the present invention, the thickness of the cerium-lanthanum alloy used in this embodiment is about 5mm flake sample. The chemical properties of the cerium-lanthanum alloy are active, and the surface is easily oxidized. This example does not provide any anti-oxidation protection, so the surface of the sample has produced an oxide layer before processing. Moreover, the cerium-lanthanum alloy has not been subjected to any special treatment before processing, and its crystal grains are coarse, on the order of 200 μm. Select a cavitation jet system consisting of a water storage tank, feed pump, pressure regulating valve, cavitation container, nozzle, etc. to perform step 1). Select a three-axis ultra-precision single-point diamond lathe to perform step 2). Before processing, the equipment should be transformed so that it can meet the technological scheme provided by ...

Embodiment 2

[0040] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0041] The cavitation jet process parameters are selected from the parameter range provided by the patent of the present invention, specifically: the nozzle diameter is 2.5mm, the outlet flow area pressure is 30MPa, the nozzle moving speed is 6mm / min, the target distance is 15mm; the cutting depth is 1um, the spindle The rotational speed is 450rpm, and the feed rate is 6mm / min.

Embodiment 3

[0043] This embodiment is based on embodiment 1, and the difference with embodiment 1 is:

[0044]The cavitation jet process parameters are selected from the parameter range provided by the patent of the present invention, specifically: the diameter of the nozzle is 1.5mm, the pressure of the outlet flow area is 20MPa, the moving speed of the nozzle is 1mm / min, the target distance is 12mm, the cutting depth is 5um, the spindle The rotational speed is 450rpm, and the feed rate is 1mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com