Reaction force cone cutting device

A technology of cutting device and reaction force cone, applied in the directions of large fixed members, maintenance and safety accessories, milling machine equipment, etc., can solve problems such as low cutting efficiency, reduce cutting quality, avoid uneven force on cables, and improve cutting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

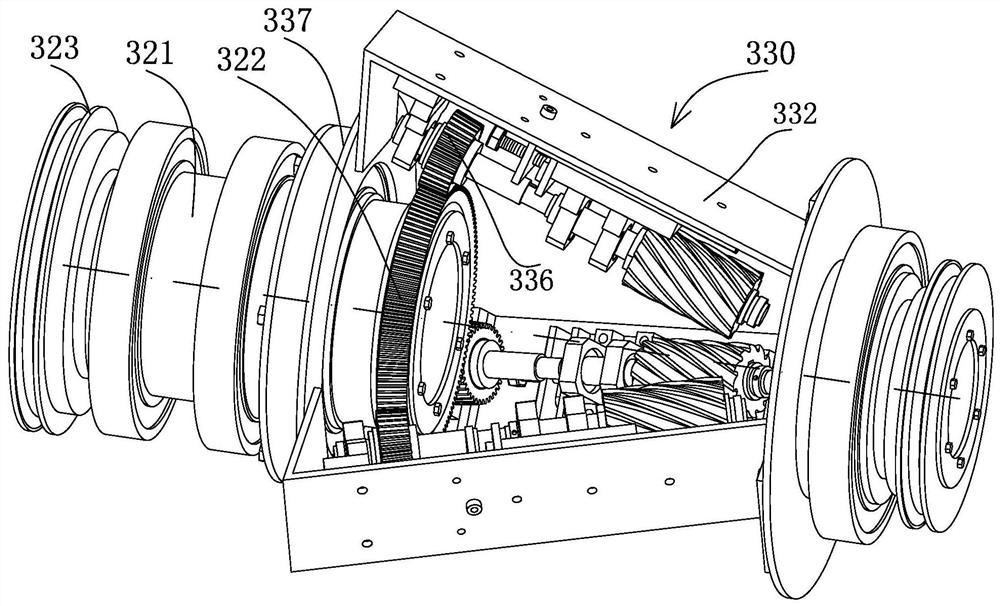

[0059] In the production of cable terminals, due to the cutting of the metal sheath and insulation, the original uniform radial distribution of the electric field gradient in the cable insulation is destroyed, and the power lines are concentrated at the shielding fracture of the outer semiconducting layer, where the electric field intensity distribution is the most uneven , the field strength is the highest, and breakdown accidents are most likely to occur. Due to the increase in the cross-section of the conductor joint, the thickness and dielectric constant of the additional insulation are different from the insulation of the cable body, the electric field distribution in the cable terminal and the intermediate joint is compared with that of the cable itself. This change is mainly manifested in the axial electric field strength along the direction of the cable insulation surface, or axial stress.

[0060] In order to improve the electric field distribution in this part, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com