Patents

Literature

54results about How to "Avoid corners" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

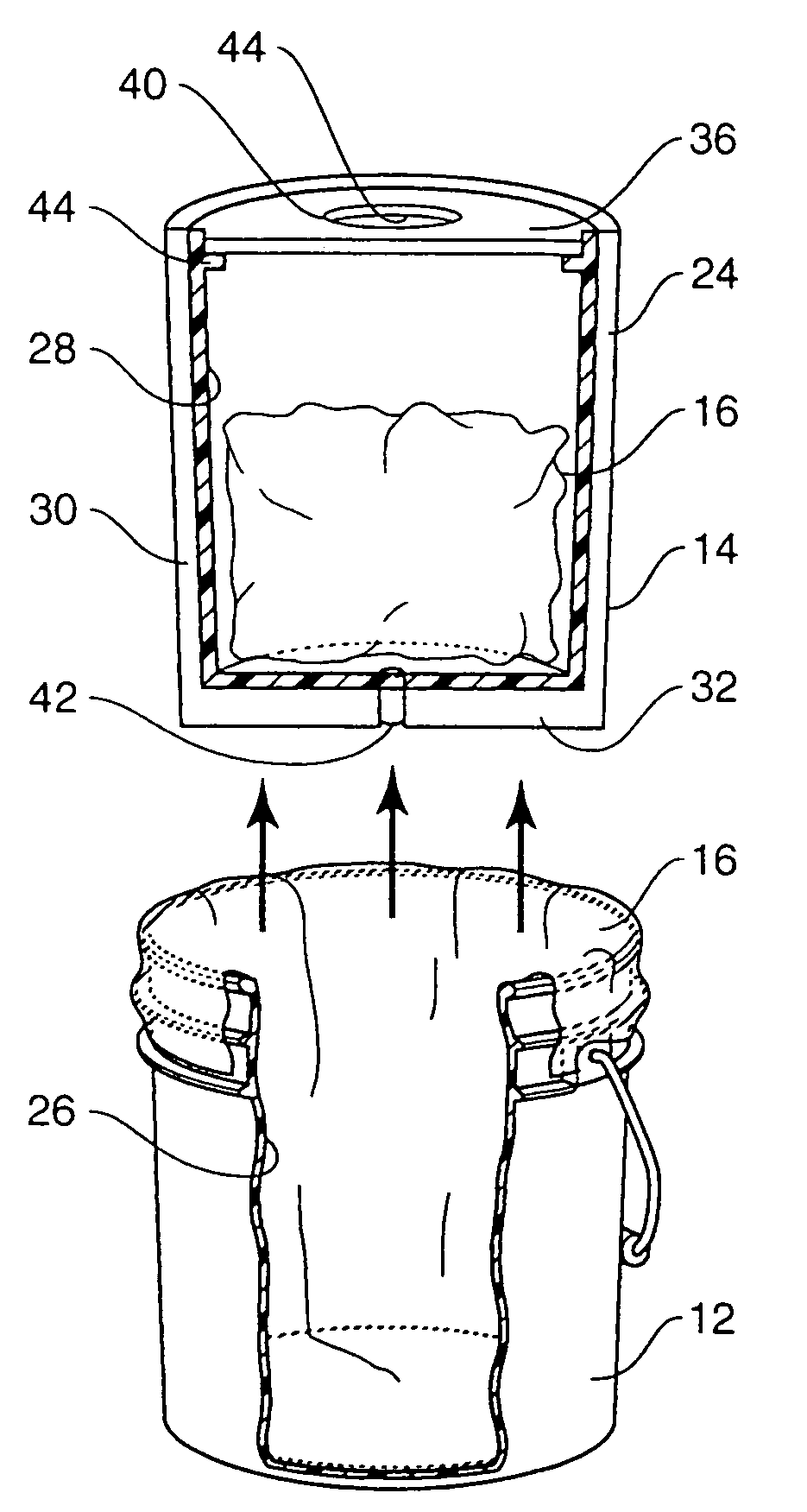

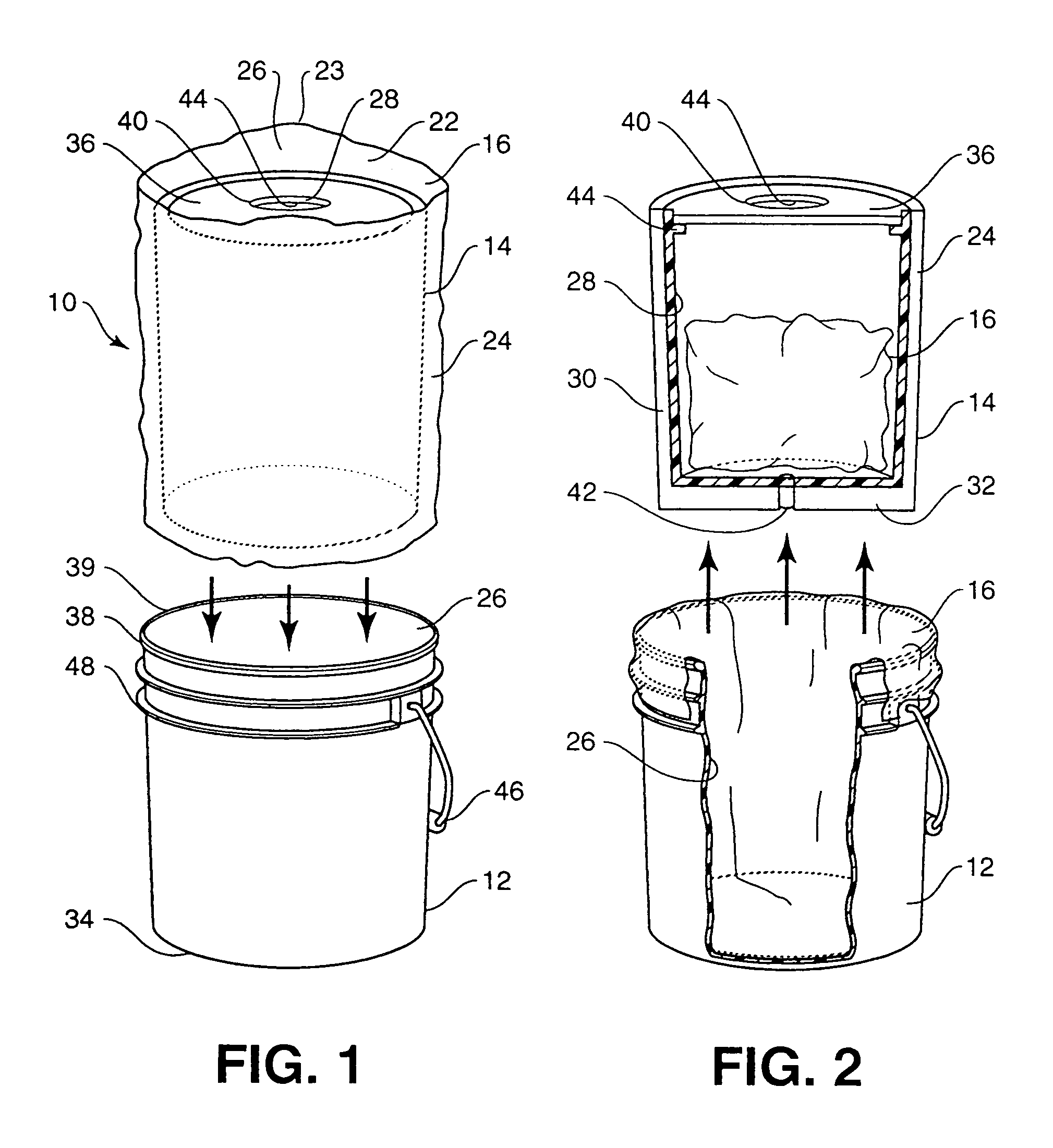

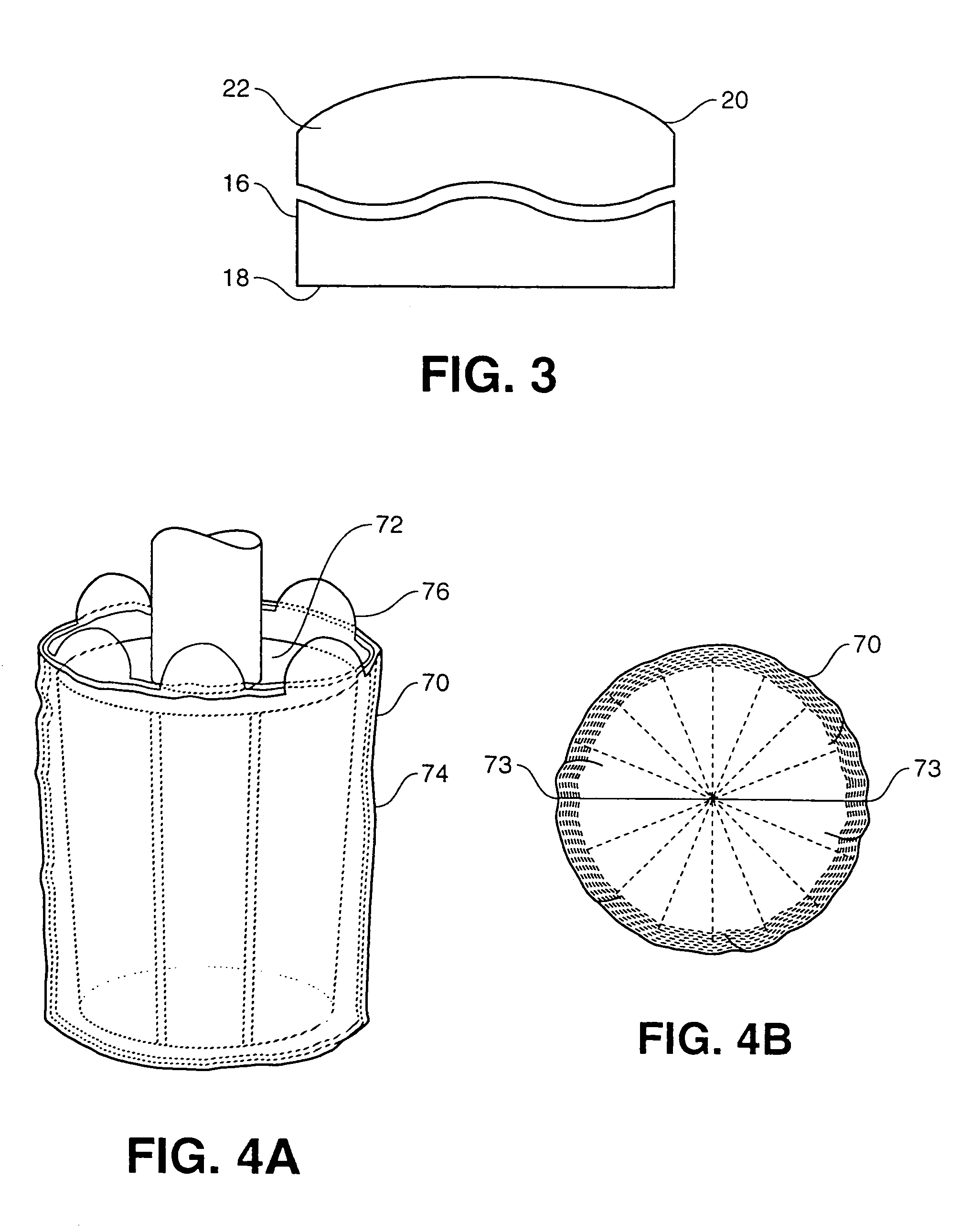

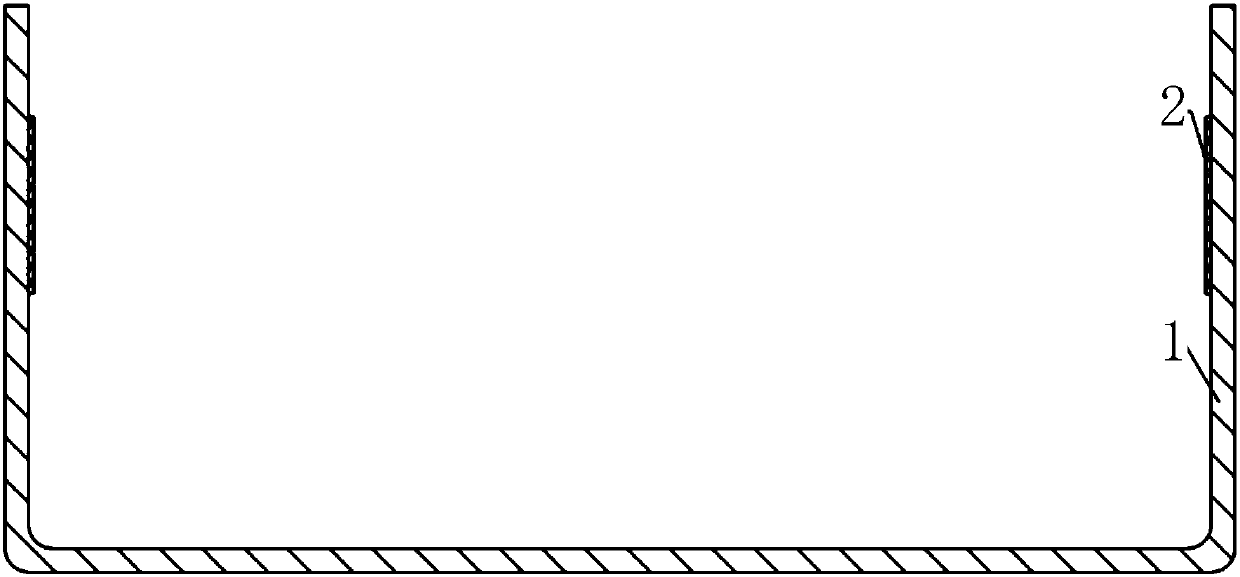

Paint container liner system

InactiveUS7159734B1Fit tightlyAvoid cornersLarge containersLinings/internal coatingsAdhesiveMechanical engineering

A paint container liner system including disposable liners and an open container for receiving at least one of the disposable liners, the liners being sized and configured to fit into the inside of the container and around the rim of the container, the liners being maintained in position in the container by a suction generated during installation in one embodiment and by a noncuring adhesive interposed between the liner and container in another embodiment, the liners also being stretched around the rim of the container and in another embodiment configured with a rounded bottom to retain the liner in place during use, the system also including a container cap with a slot for supporting a paint brush during periods of nonuse.

Owner:DRIPLESS

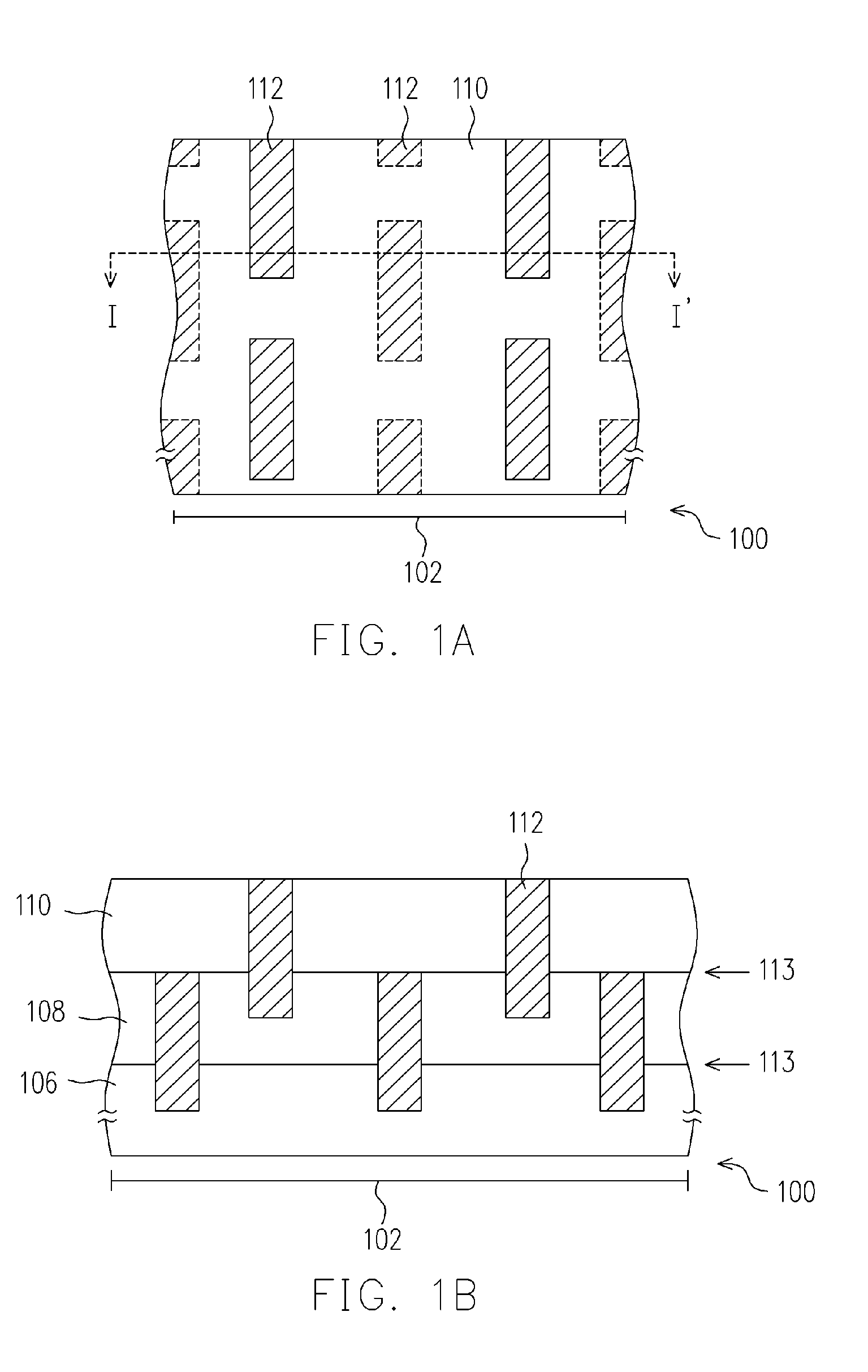

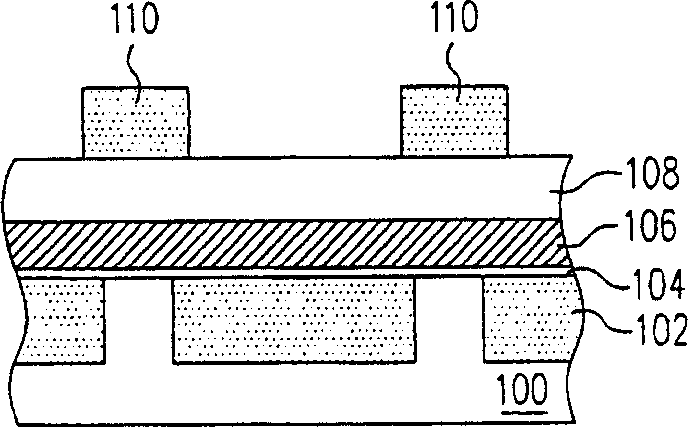

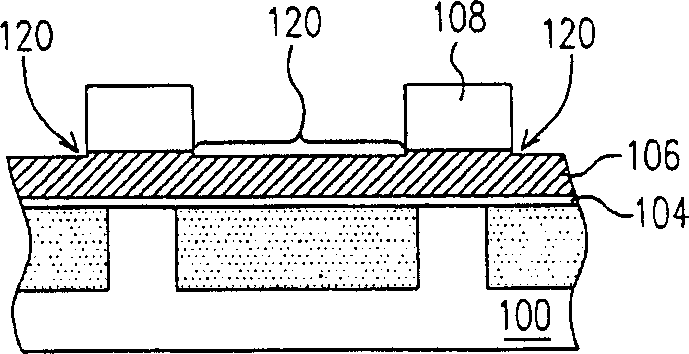

Semiconductor structure and fabricating method thereof

ActiveUS20070069337A1Avoid crackingAvoid cornersSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDielectric layer

A semiconductor structure is provided. The semiconductor structure is disposed on the scribe line of a wafer and is around the chip area of the wafer. The semiconductor structure includes a plurality of dielectric layers sequentially disposed on the scribe line and a plurality of metal patterns disposed in each dielectric layer. The metal patterns disposed in each dielectric layer extend to the next underlying dielectric layer.

Owner:MARLIN SEMICON LTD

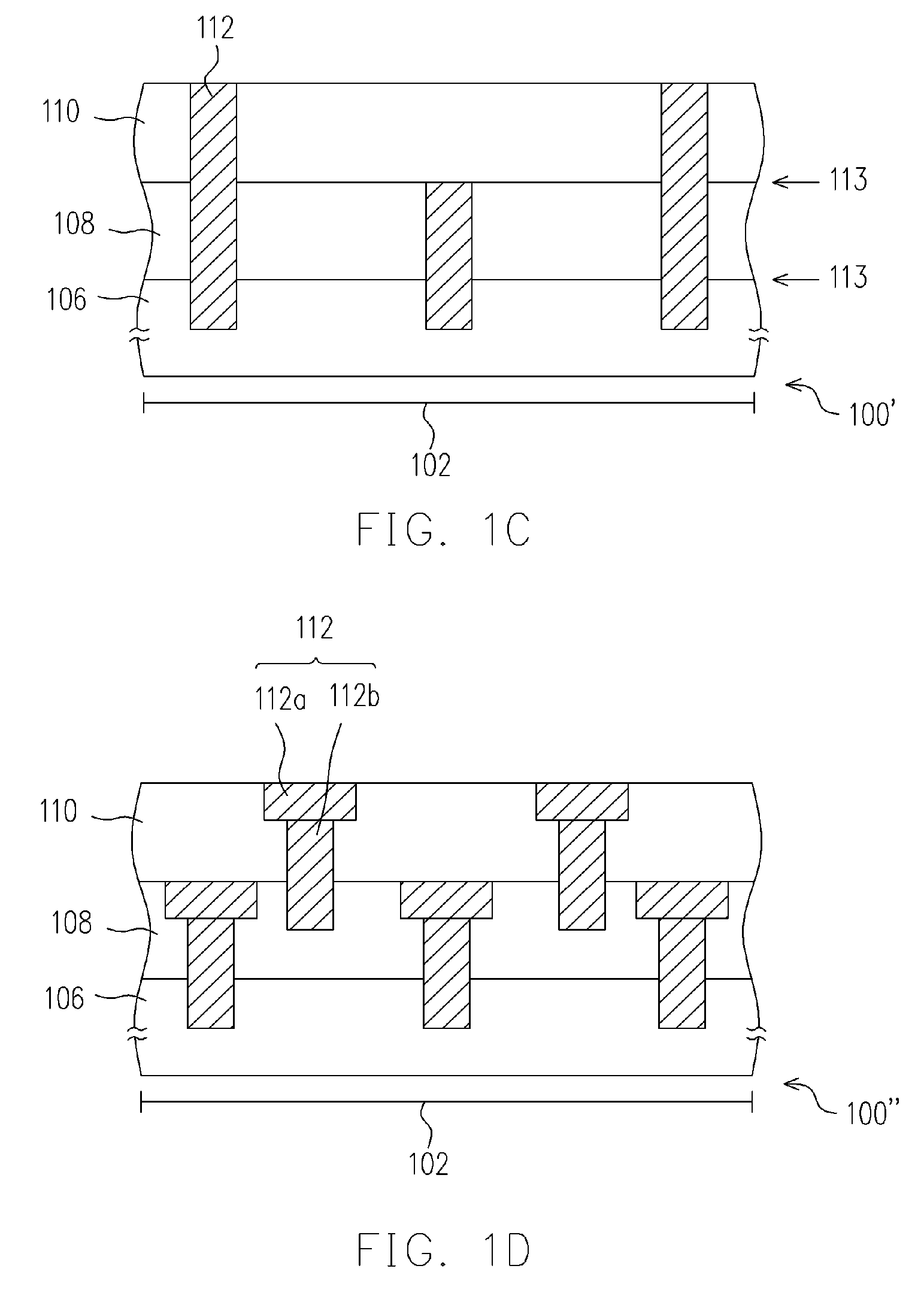

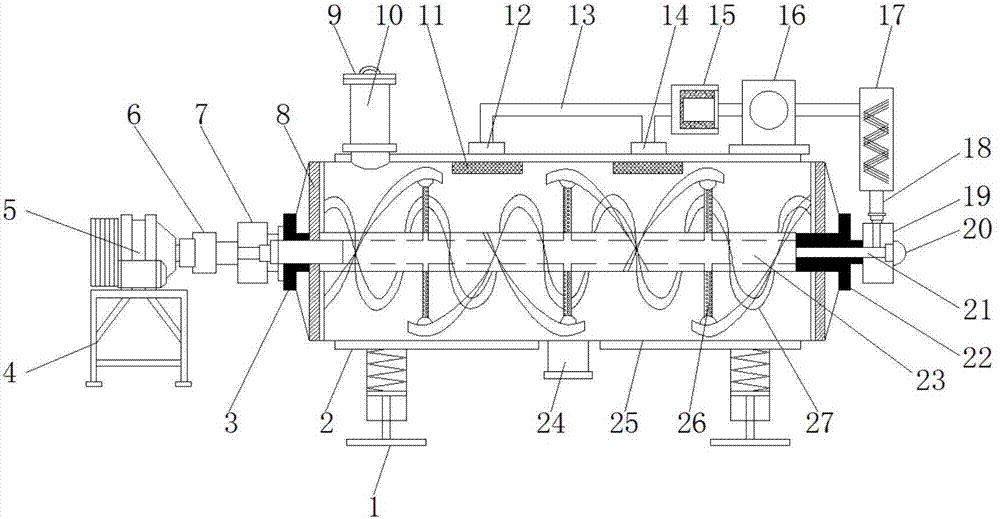

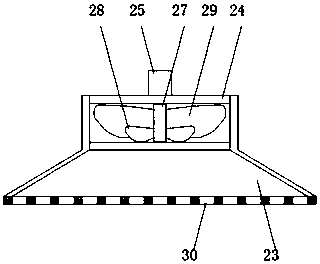

Low-air-pressure particle material drying equipment

InactiveCN107289757AImprove insulation effectEasy to addGranular material dryingDrying solid materials without heatBoiling pointHelical blade

The invention discloses a granular material drying equipment under low air pressure state, which comprises a suction pipe, a drying cylinder body and a blowing hole. Sleeve, shock-absorbing spring and T-shaped rod; both ends of the drying cylinder are welded with end sealing plates, and a closed drying chamber is formed between the drying cylinder and the end sealing plates, and the drying cylinder The top front end is welded with a material adding pipe; the heat preservation effect is good, the sealing effect is good, the spiral blade and the scraper blade stir the material in the drying cylinder to ensure the full mixing of the material in the drying cylinder, realize the circulation of hot air, and improve the heating of the material. The uniformity of the material, and in the low pressure environment in the drying cylinder, only a low heating temperature can make the water in the material reach the boiling point to evaporate and separate, which improves the efficiency of material drying, reduces the drying cost, and improves the quality of the material. Ease of drying.

Owner:惠安县长信机电科技有限公司

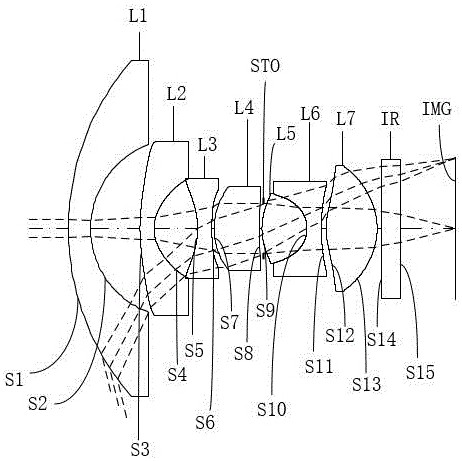

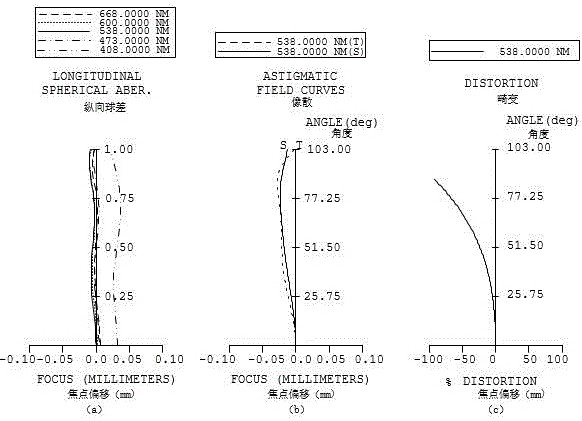

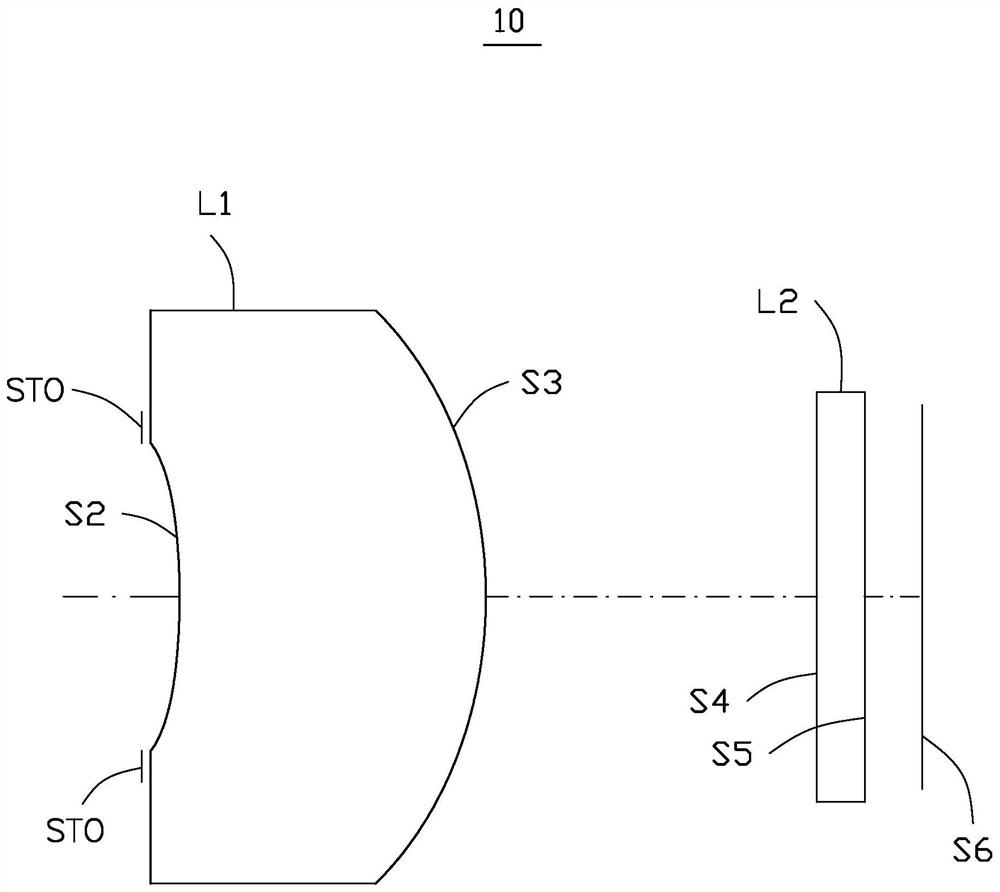

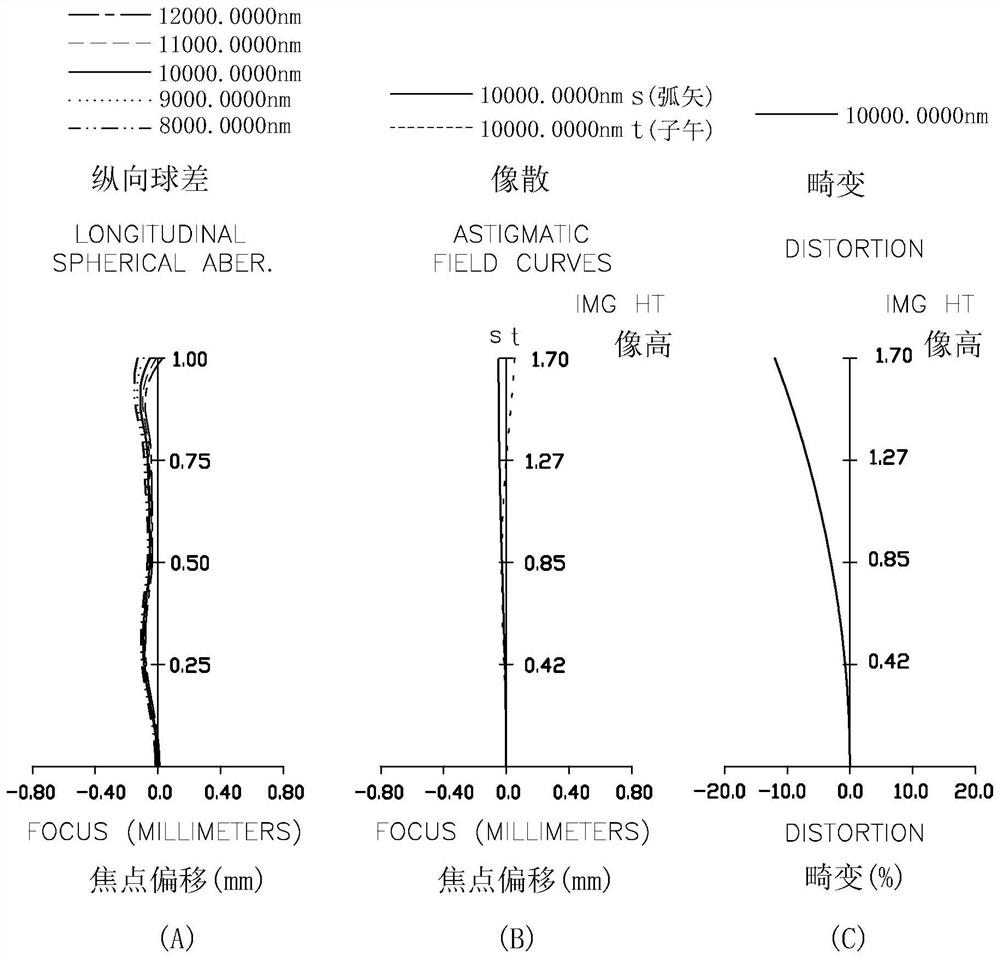

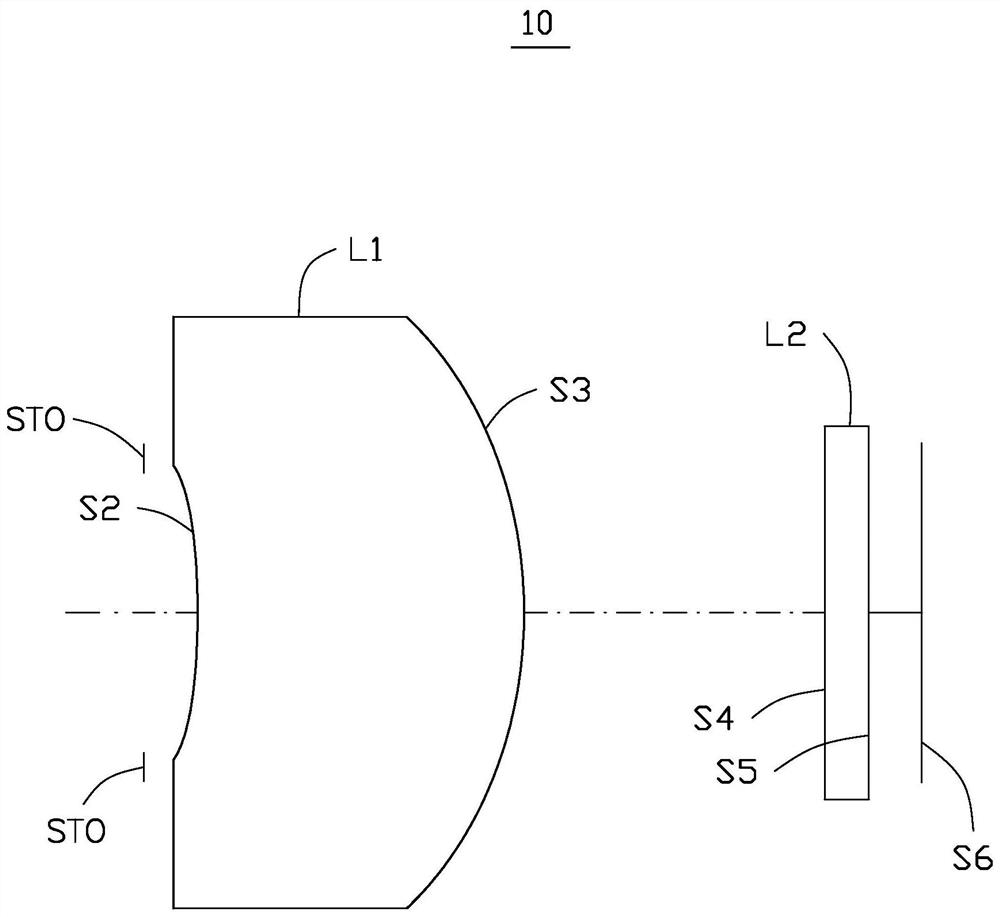

Optical system, lens module and electronic device

ActiveCN113433675AReduce processing difficultyGuaranteed image qualityOptical elementsOptical axisMiniaturization

The invention discloses an optical system, a lens module and an electronic device. The optical system sequentially comprises from an object side to an image side along an optical axis: a first lens to a seventh lens, in which the first, second, third and sixth lenses each have negative refractive power, the fourth, fifth and seventh lenses each have positive refractive power, the mirror surface of the third lens is a concave surface in a paraxial region, the mirror surfaces of the fifth lens and the seventh lens are convex in a paraxial region. The optical system satisfies the following relational expressions: 10.5<TTL / f<12, wherein TTL is the distance from the object side surface of the first lens to the imaging surface on the optical axis, and f is the effective focal length of the optical system. By reasonably designing the surface types and the refractive power of the first to seventh lenses and limiting the relationship between the total length of the optical system and the focal length of the optical system through the relational expression, the total length of the optical system is controlled while the field angle range of the optical system is met, so that the miniaturization characteristic of the optical system is met.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

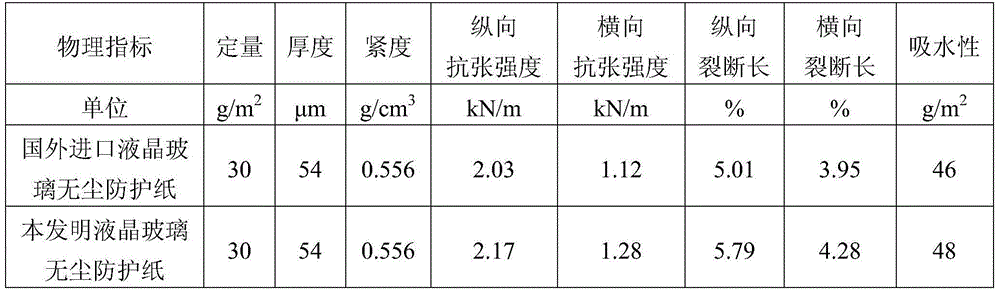

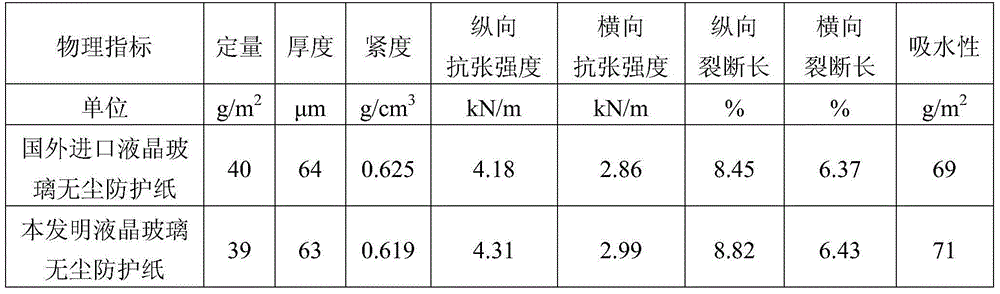

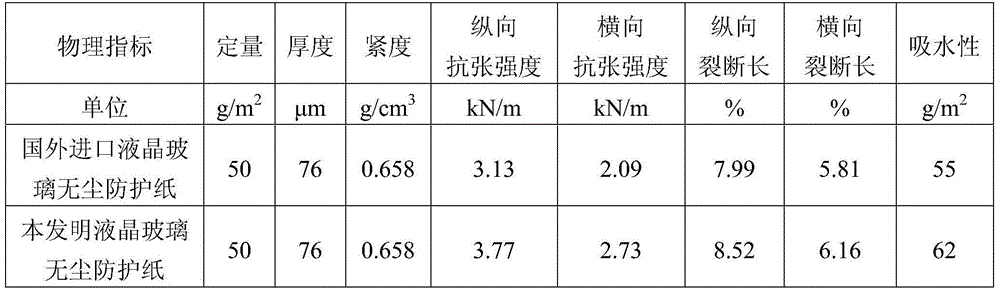

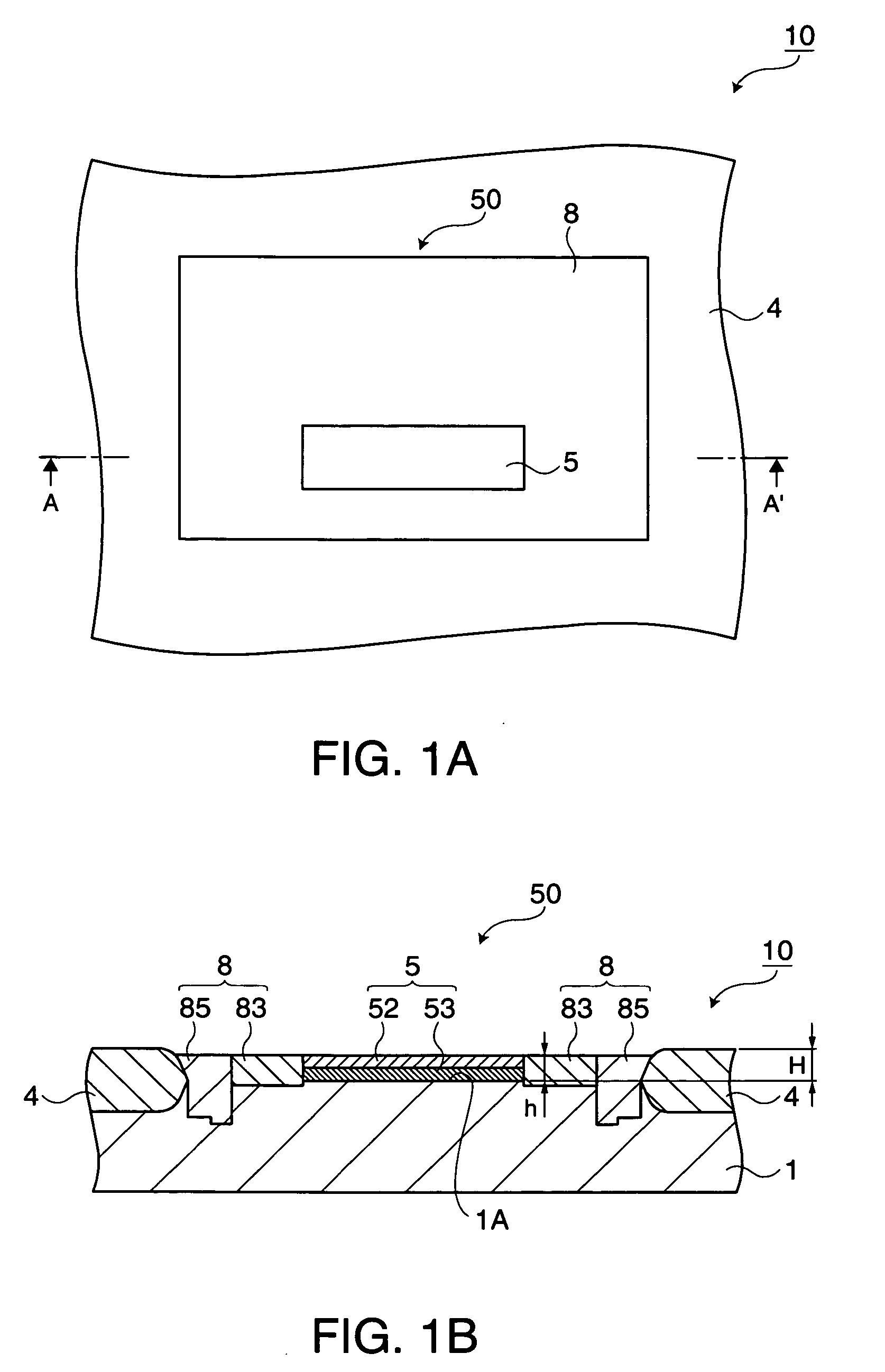

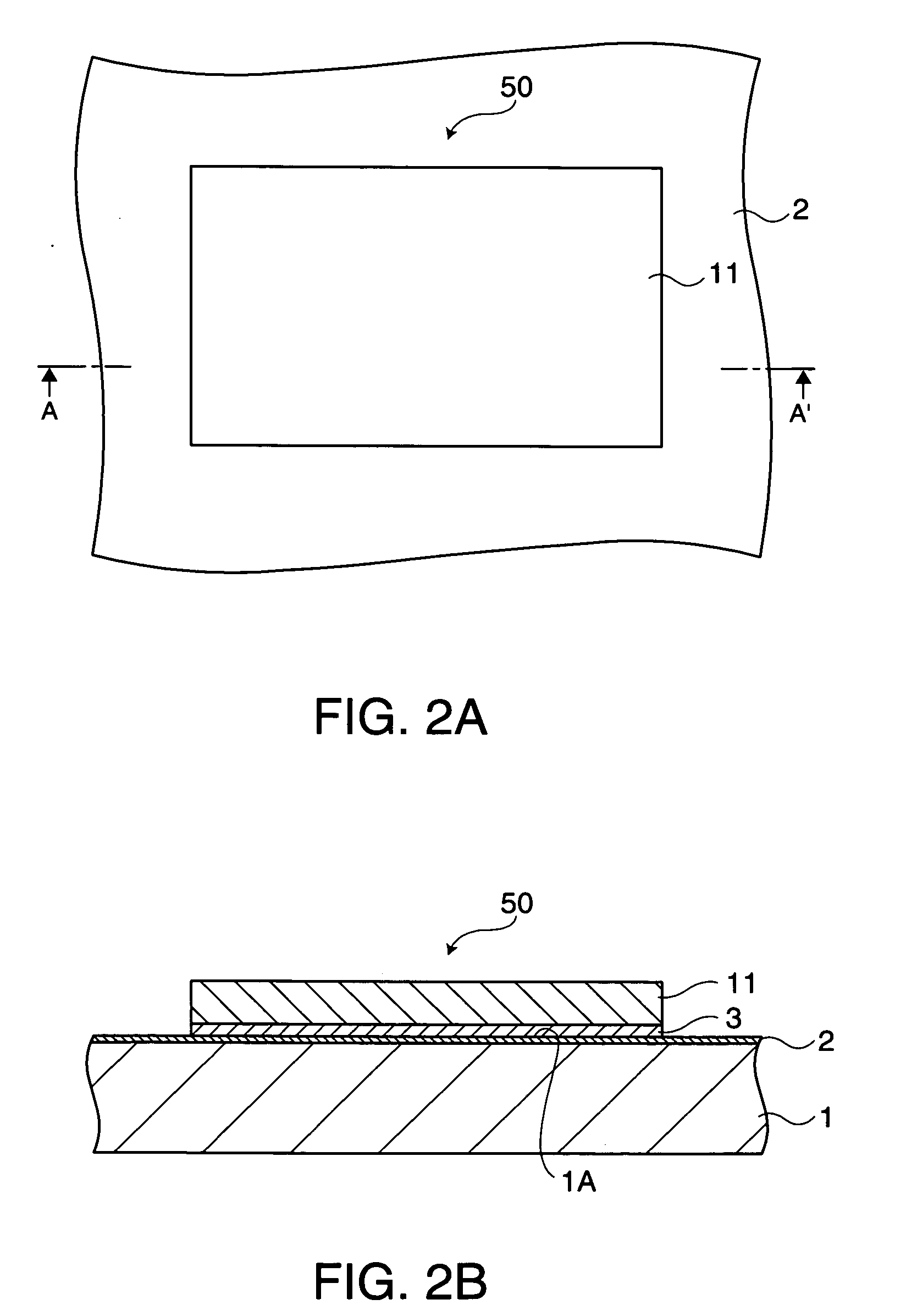

Liquid crystal glass dust-free protective paper

InactiveCN104631193AImprove heat resistanceImprove moisture resistancePaper coatingReinforcing agents additionFiberPapermaking

The invention relates to the technical field of papermaking, in particular to a piece of liquid crystal glass dust-free protective paper. The liquid crystal glass dust-free protective paper is prepared by the following steps: with bleached chemical softwood pulp as a raw material, conveying the raw material to a net cage with a destaticizing device via a feeing fan, wherein the net cage is used for removing static electricity on the surfaces of fibers and ensuring that the fibers are uniformly dispersed and free of flocculation; forming a paper web through an air supply system, an exhaust system and a forming net; and carrying out heat compressing, upper glue spraying, baking, lower glue spraying, rebaking and calendaring on the paper web, and then forming the liquid crystal glass dust-free protective paper, wherein the liquid crystal glass dust-free protective paper has good heat resistance, moisture resistance, anti-static property and anti-corrosion performance and can be applied to the processing or transporting process of coated glass, optical glass and liquid crystal glass substrates to play roles in backing and isolating. By virtue of a dry agglutination technique, the water consumption in the production process is greatly reduced, so that the problem of pollution of a natural water body is relieved; the capital expenditure is relatively low; the energy consumption in the production process is relatively low; and the production cost is reduced.

Owner:中国制浆造纸研究院衢州分院

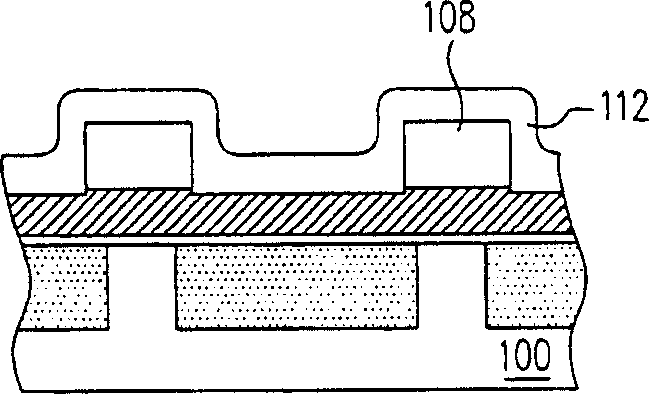

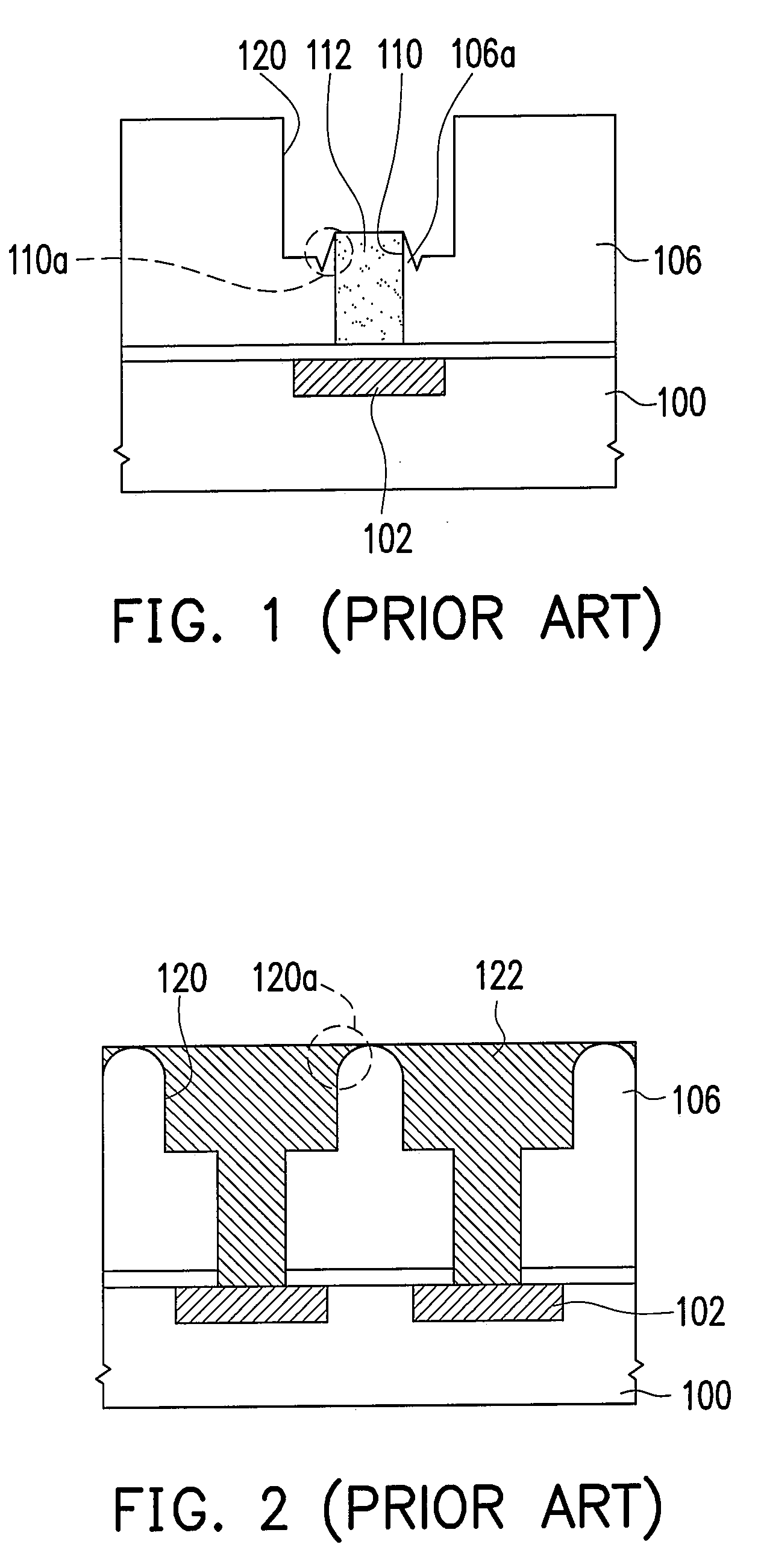

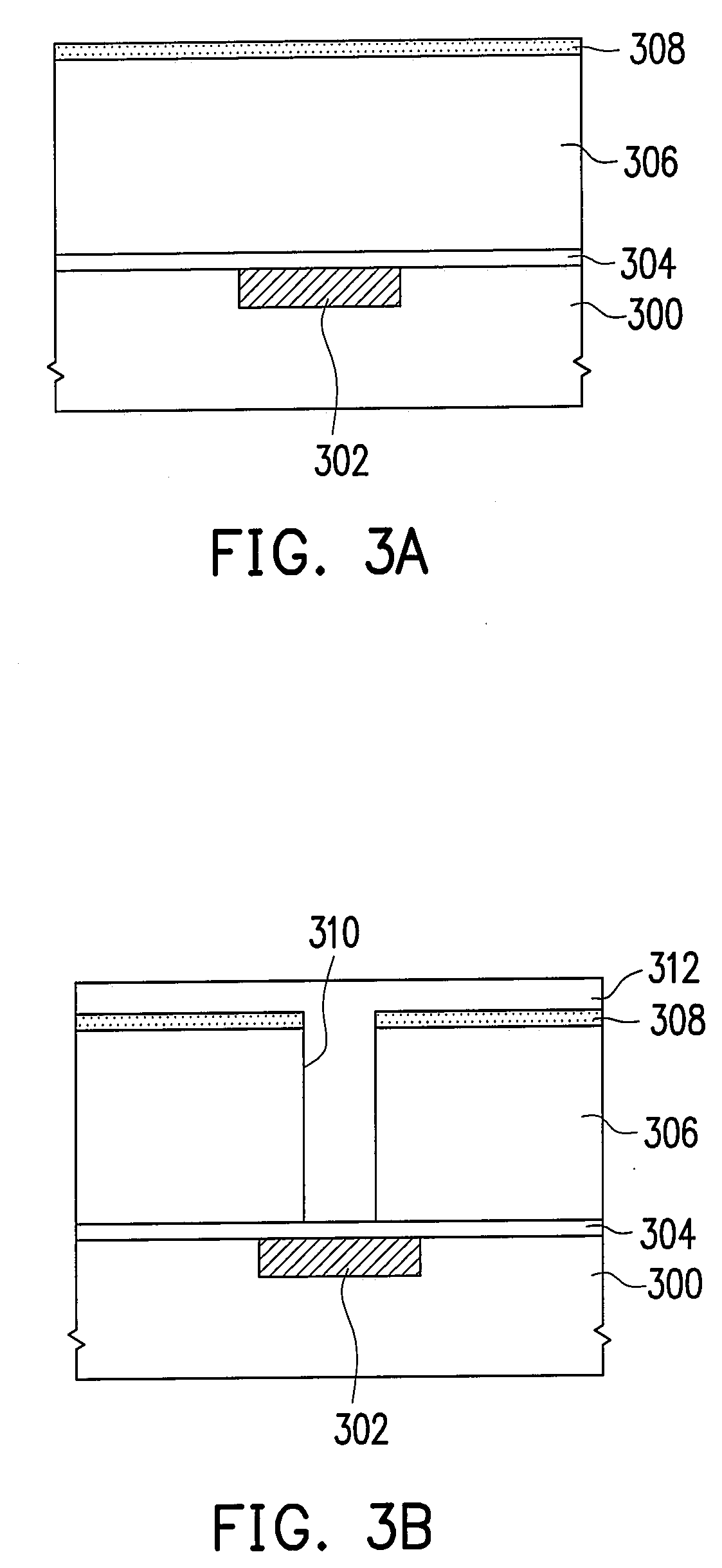

Grid and formation of fast-flashing memory therewith

InactiveCN1855372AIncrease widthOmit the planarization processSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorComputational physics

The method comprises: orderly forming a grid dielectric layer, a conducting layer, an isolation protective layer, a sacrificial layer and a patterned mask layer on a substrate; using the patterned mask layer as etching mask and using the isolation protective layer as etching stop layer to remove the exposed sacrificial layer, and then removing the patterned mask layer; forming a spacer on the sidewall of the sacrificial layer, and then using the spacer and the sacrificial layer as etching mask to remove the portion of isolation protective layer and conducting layer in order to form a grid; finally removing the sacrificial layer, spacer and isolation protective layer. The invention can avoid generation of edge and corner on the top surface of grid at the time of etching sacrificial layer.

Owner:POWERCHIP SEMICON CORP

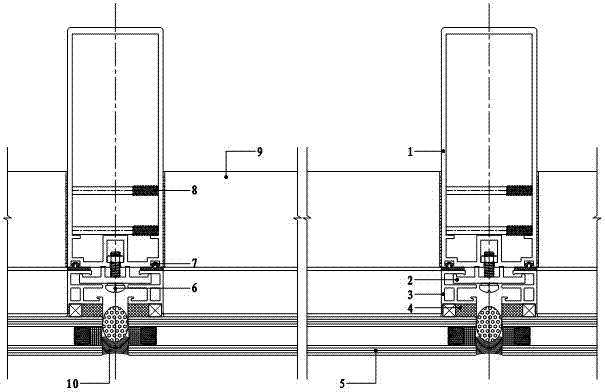

Hitching hidden-frame glass curtain wall

InactiveCN103397724ARapid positioningImprove on-site installation efficiencyWallsAdhesiveEngineering

The invention provides a hitching hidden-frame glass curtain wall comprising a main frame, an auxiliary frame, a cross beam, an opening frame, an opening sash and glass. Left and right vertical sides in the main and auxiliary frames are connected through pressure plates, and top and bottom horizontal sides in the main and auxiliary frames are connected through hooks. The cross beam is fixed on the main frame. The auxiliary frame is hitched to the cross beam, and a carrier strip is disposed at the lower end of the auxiliary frame. The glass is adhered to the auxiliary frame through silicone structural adhesive. The upper end of the opening frame is hitched to the cross beam. The opening frame is connected with the opening sash in a hitched structure. A channeled carrier strip is disposed at the upper end of the opening sash. The hitching hidden-frame glass curtain wall has the advantages that small-unit glass plates are positioned fast, field installation efficiency is improved, and the problems such as shedding of corners of the opening sash and frame-sash scratching are prevented effectively.

Owner:秦皇岛市中贤幕墙装饰工程有限公司

Composite binder for powder injection moulding and preparation and application method

ActiveCN105860886AImprove liquidityGood liquidity lowNon-macromolecular adhesive additivesTransportation and packagingMicrocrystalline waxInjection moulding

The invention discloses composite binder for powder injection moulding and a preparation and application method. The composite binder for powder injection moulding comprises raw materials including furfuryl alcohol, trimethylolpropane, polypropylene, o-hydroxybenzoic acid, polyacrylamide, palm wax, microcrystalline wax and epoxidized soybean oil and further comprises boric acid and water. The composite binder combining thermoplasticity and a thermosetting system is adopted, advantages of thermoplasticity and the thermosetting system are utilized, on one hand, the problems that conventional binder is excessively long in thermal degreasing time and low in production efficiency are solved, and the degreasing rate can reach 90% or above within 6 hours; on the other hand, the yield rate of a powder injection moulding product is raised, and quality of a finished product is improved.

Owner:ANHUI SANLIAN UNIV

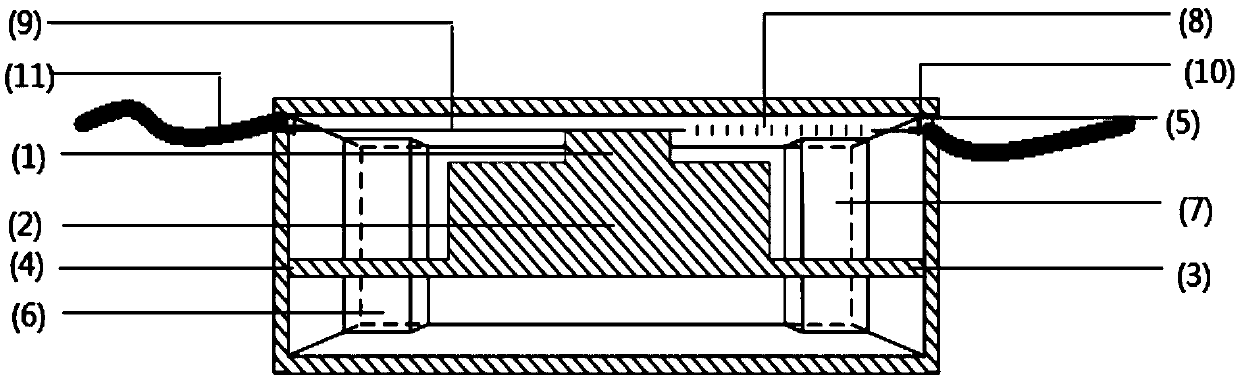

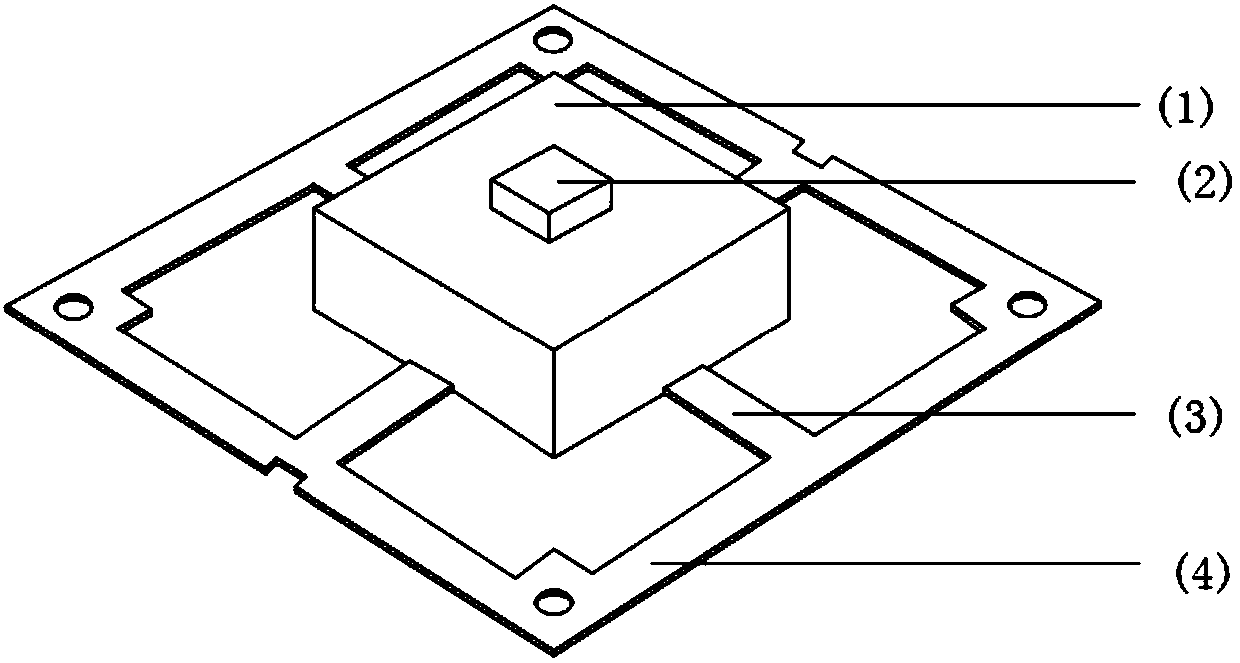

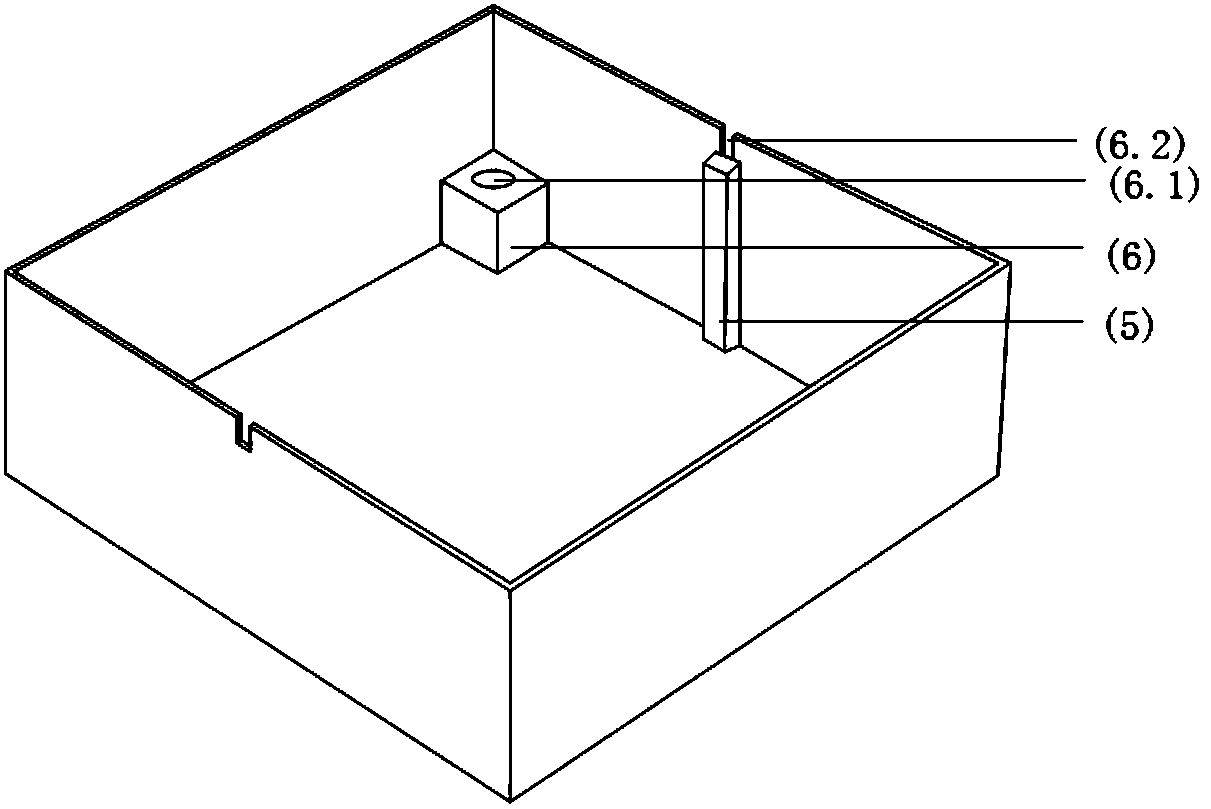

Optical fiber grating vibration sensor made of multi-cantilever beam all-insulation materials

PendingCN107860462ASimple structureEasy to installSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCantilevered beamAnti jamming

The invention discloses an optical fiber grating vibration sensor made of multi-cantilever beam all-insulation materials. The optical fiber grating vibration sensor comprises a vibration sensing system, a base and a top cover. The vibration sensing system comprises a mass block, four cantilever beams with equal lengths and a frame, and the frame is connected with the cantilever beams. The mass block is connected with the frame by the four slice cantilever beams and is supported and suspended by the cantilever beams. Four protruded quadrangular columns with equal heights are arranged at four corners of the base of a sensor, the vibration sensor is arranged in the base, and the frame of the sensor is exactly clamped on the surfaces of the four quadrangular columns, so that the vibration sensor can be suspended in the base. The optical fiber grating vibration sensor has the advantages that the cantilever beams can be driven by the mass block to vibrate along with the mass block when the sensor feels vibration, the wavelengths of a grating adhered on the mass block can vary, and vibration frequencies can be measured according to variation of the wavelengths of the grating; the mass block is fixed by the aid of the four cantilever beams, accordingly, the anti-jamming capacity can be enhanced, high-order modal resonance can be inhibited, vibration signals can be sensitively detected,and excellent insulation effects can be realized by the optical fiber grating vibration sensor owing to the insulation properties of the nonmetal materials.

Owner:ZHAOTONG POWER SUPPLYING BUREAU OF YUNNAN POWER GRID

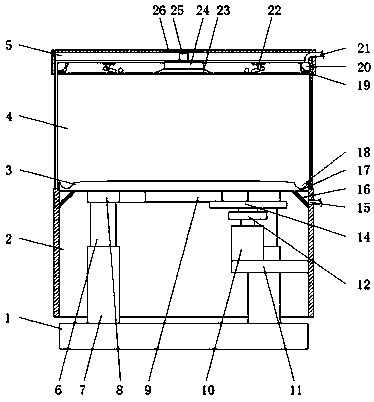

Display device convenient to regulate and clean for biotechnology promotion

InactiveCN109965613AEasy to display in all directionsConvenient for detailed observationShow cabinetsShow shelvesHydraulic cylinderDrive wheel

The invention discloses a display device convenient to regulate and clean for biotechnology promotion. The display device comprises a base, a box body and a display disc, wherein the box body is put above the base; the display disc is arranged in an inner cavity of the box body; a visual window is arranged at the top of the box body; a cover case is arranged at the top of the visual window; a hydraulic cylinder is arranged at the top of the base; a piston rod is inserted and connected with the top of the hydraulic cylinder; and a slide block is arranged at the top of the piston rod. A drivingwheel is driven to rotate through a first motor; a driven wheel is pulled to rotate intermittently, so that the display disc connected with the driven wheel generates time intervals during rotation; exhibitors can conveniently do careful observation; the height of the display disc can be regulated through the hydraulic cylinder and the piston rod which are arranged between the base and the displaydisc; the height regulation can be performed according to exhibit properties; the exhibits can be conveniently and comprehensively displayed; the display effect is enhanced; the biotechnology promotion is promoted; and the display device is suitable for being widely popularized and used.

Owner:滁州立天生物信息咨询有限公司

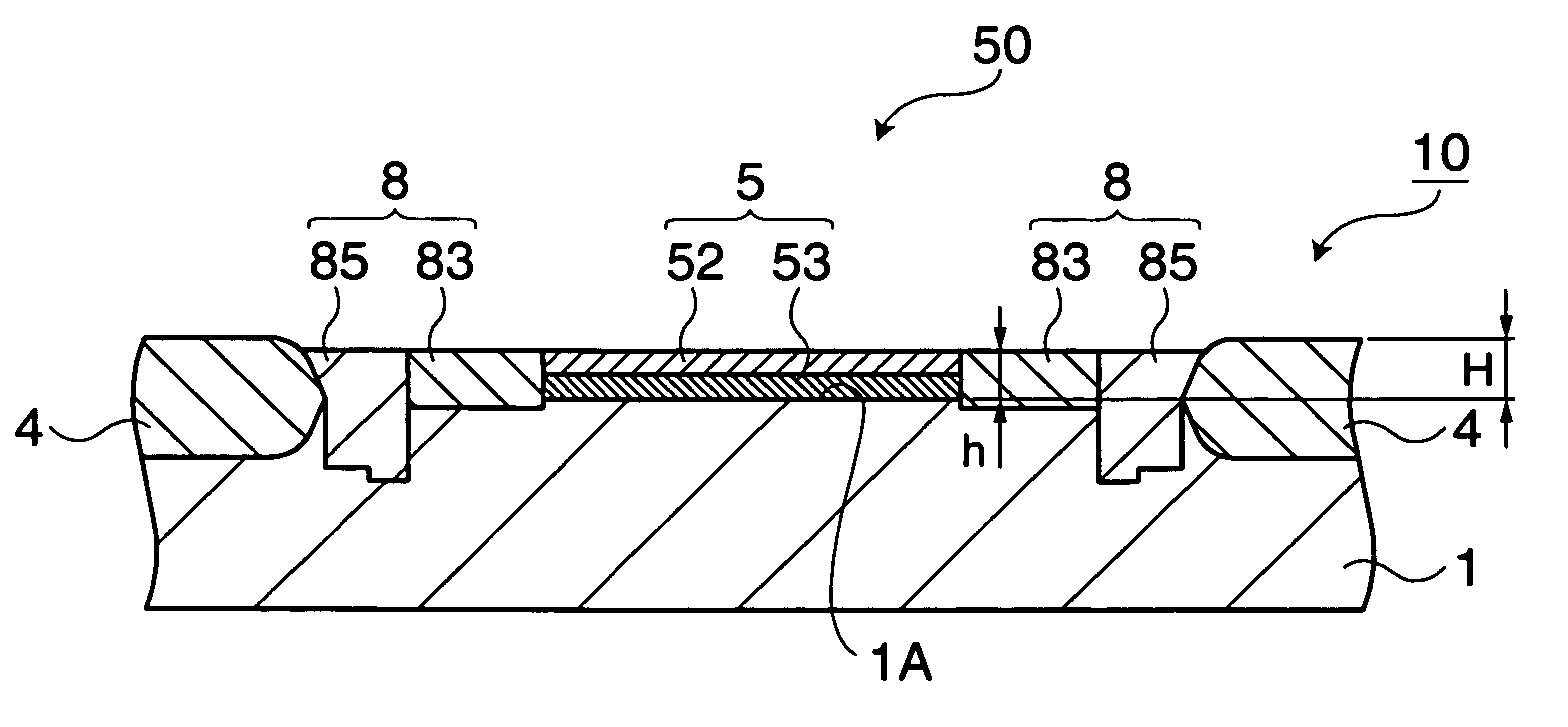

Method for manufacturing a semiconductor substrate, method for manufacturing a semiconductor device, and the semiconductor device

InactiveUS20070148832A1Reduce volatilityAvoid cornersSolid-state devicesSemiconductor/solid-state device manufacturingLOCOSPolycrystalline silicon

A method for manufacturing a semiconductor substrate having a silicon-on-insulator (SOI) structure region isolated by a local oxidation of silicon (LOCOS) film and an SOI structure in the region includes forming the LOCOS film so as to make a height from an uppermost surface of a semiconductor member to a top surface of the LOCOS film be higher than a height from the uppermost surface of the semiconductor member to a top surface of the SOI structure, forming a silicon germanium layer and a silicon layer on the SOI structure region on the semiconductor member by epitaxial growth and forming a polysilicon film on a surface of the LOCOS film, forming a recess for a support to support the silicon layer to be a part of the SOI structure, forming the support on the semiconductor member, exposing a side of the silicon germanium layer and the silicon layer underneath the support, forming a cavity by removing the silicon germanium layer having the side exposed, forming the SOI structure by embedding an insulating layer to be buried in the cavity, planarizing a covering insulating film formed to cover an entire of a top surface of the semiconductor member by using the polysilicon film as a stopper, and exposing a top surface of the silicon layer in the SOI structure by etching.

Owner:SEIKO EPSON CORP

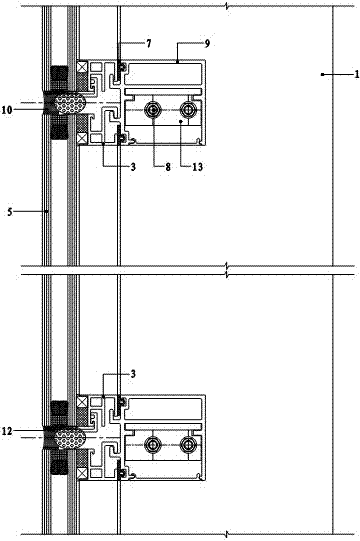

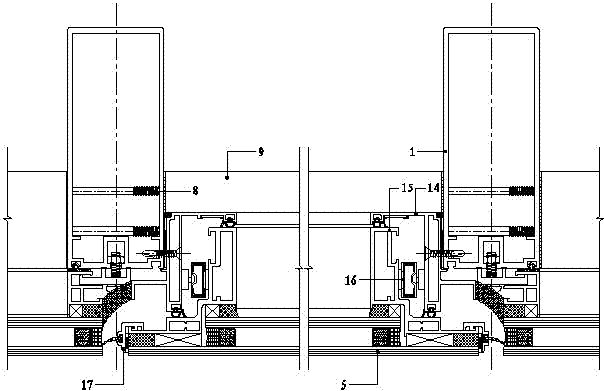

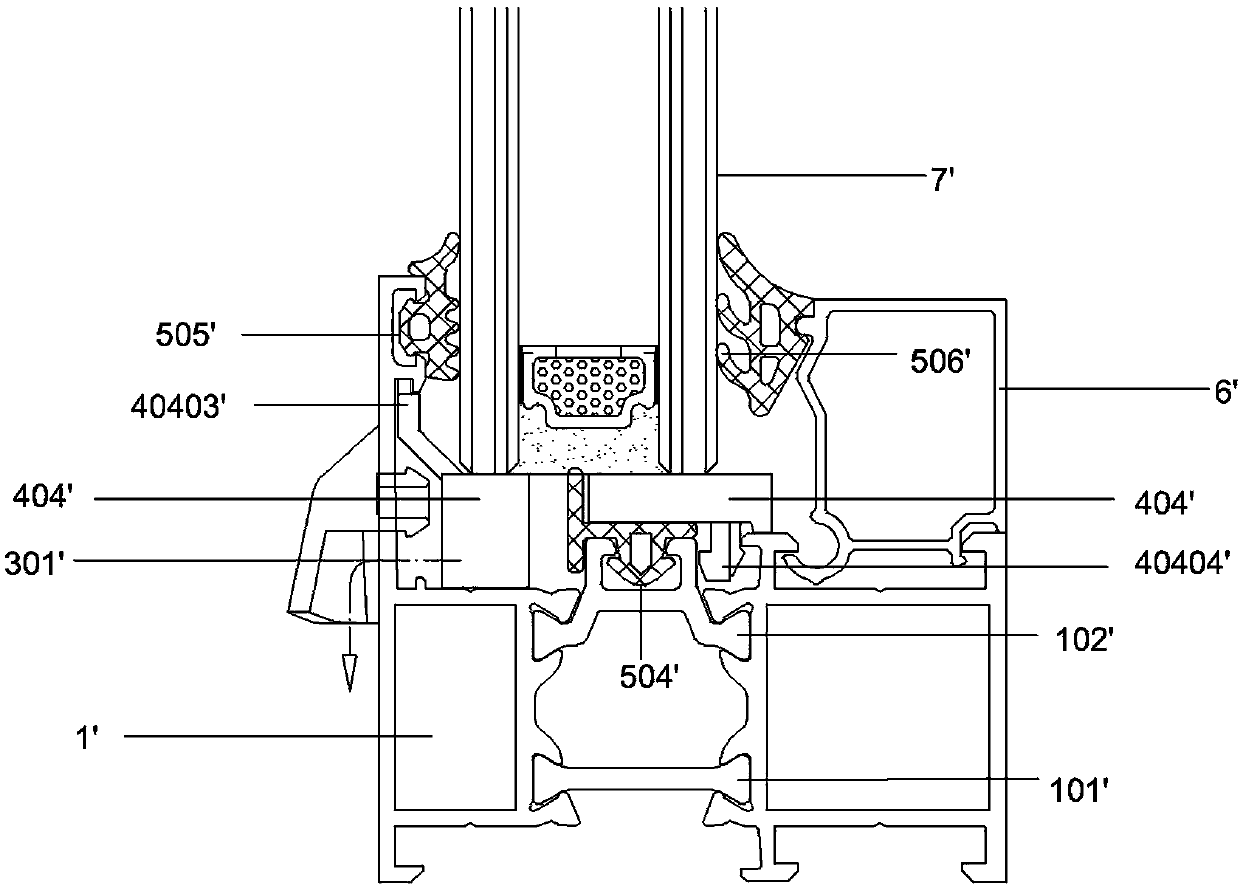

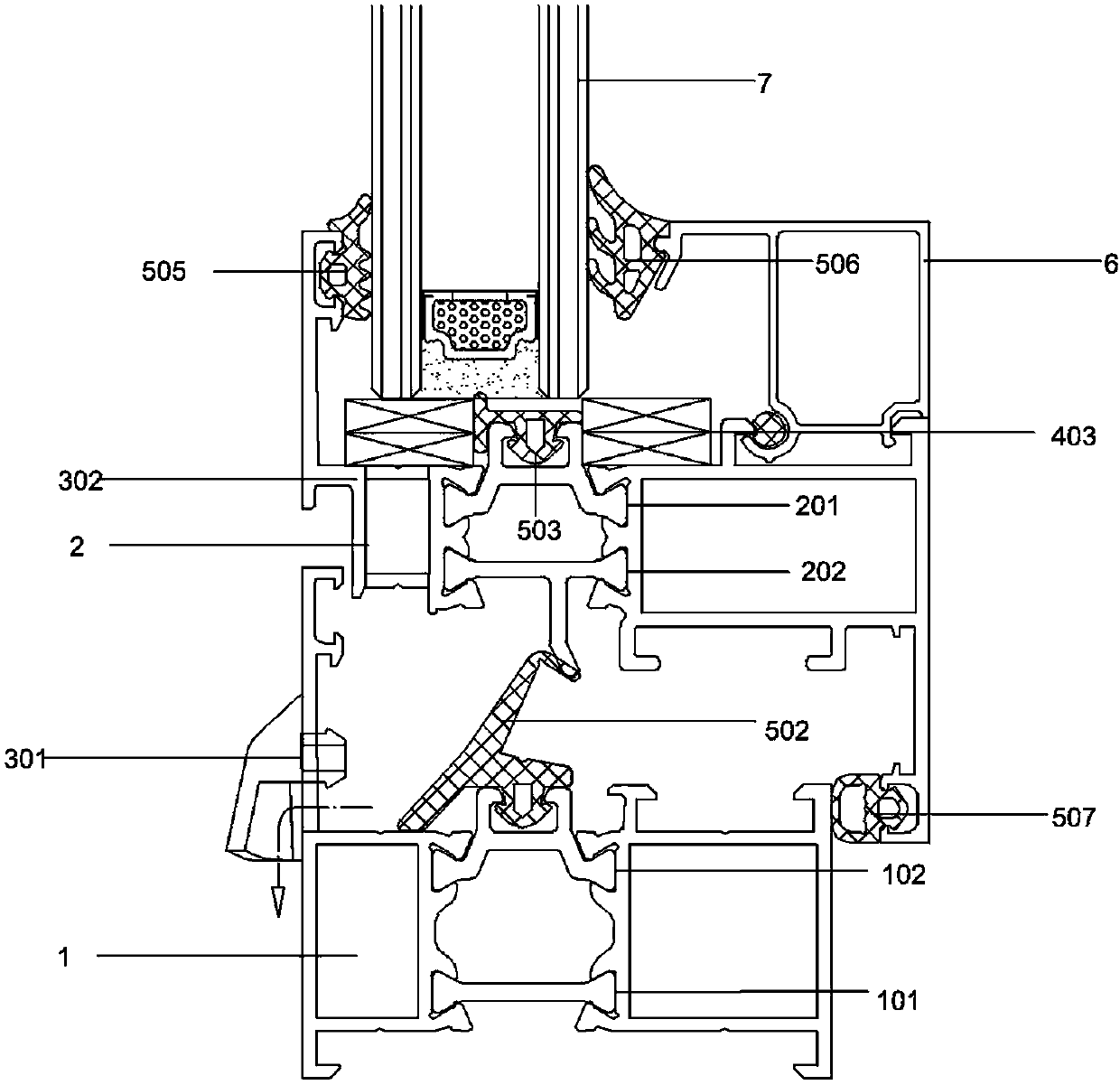

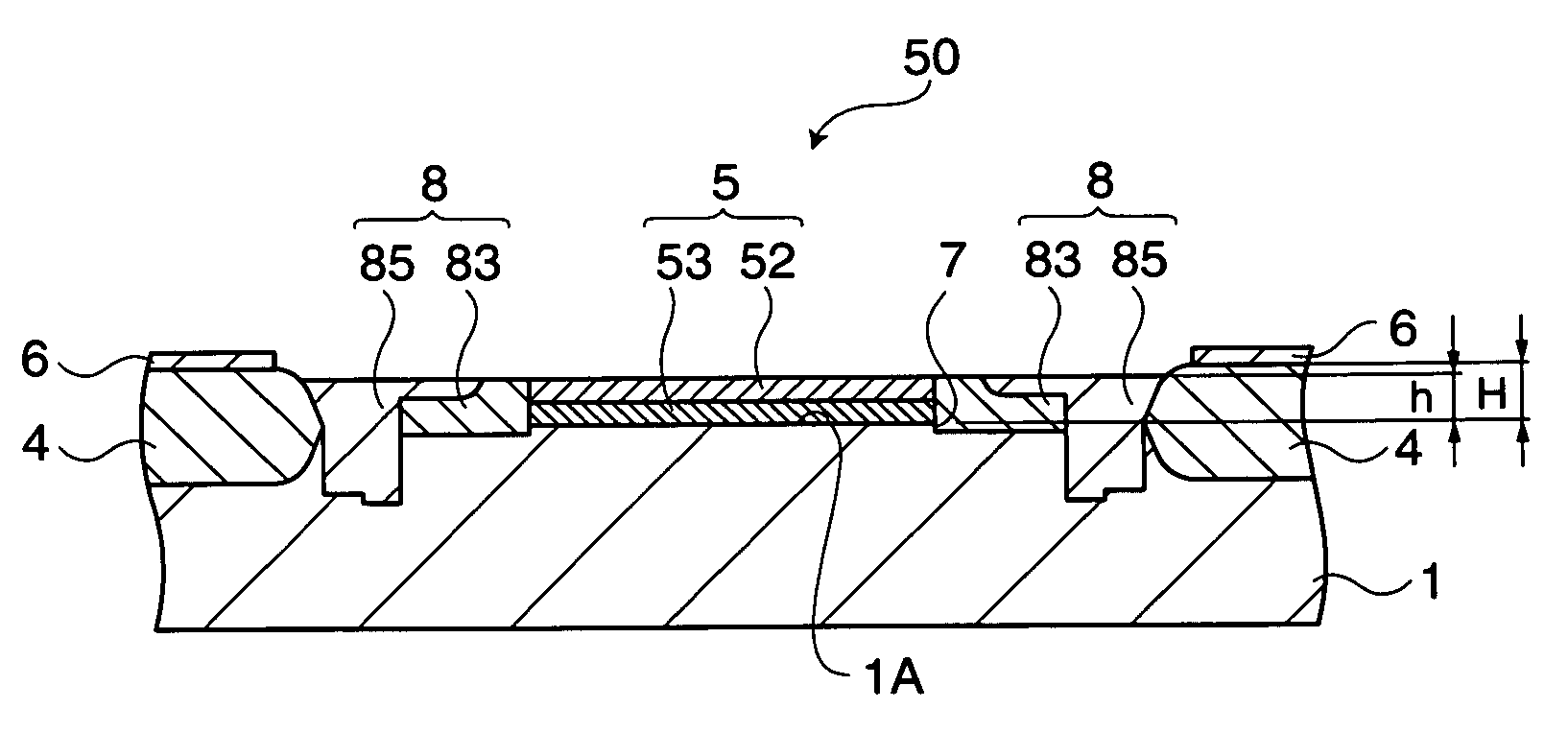

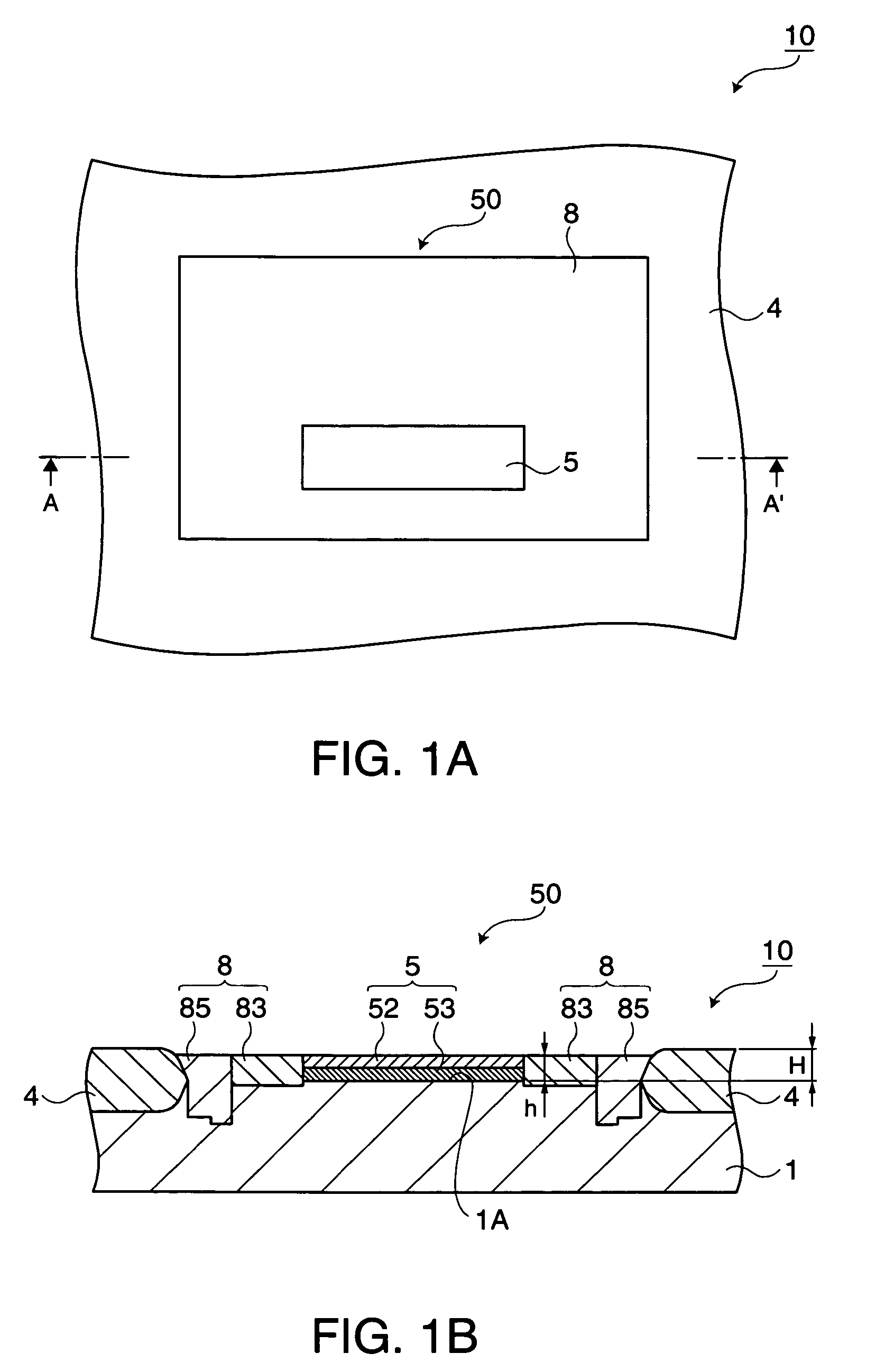

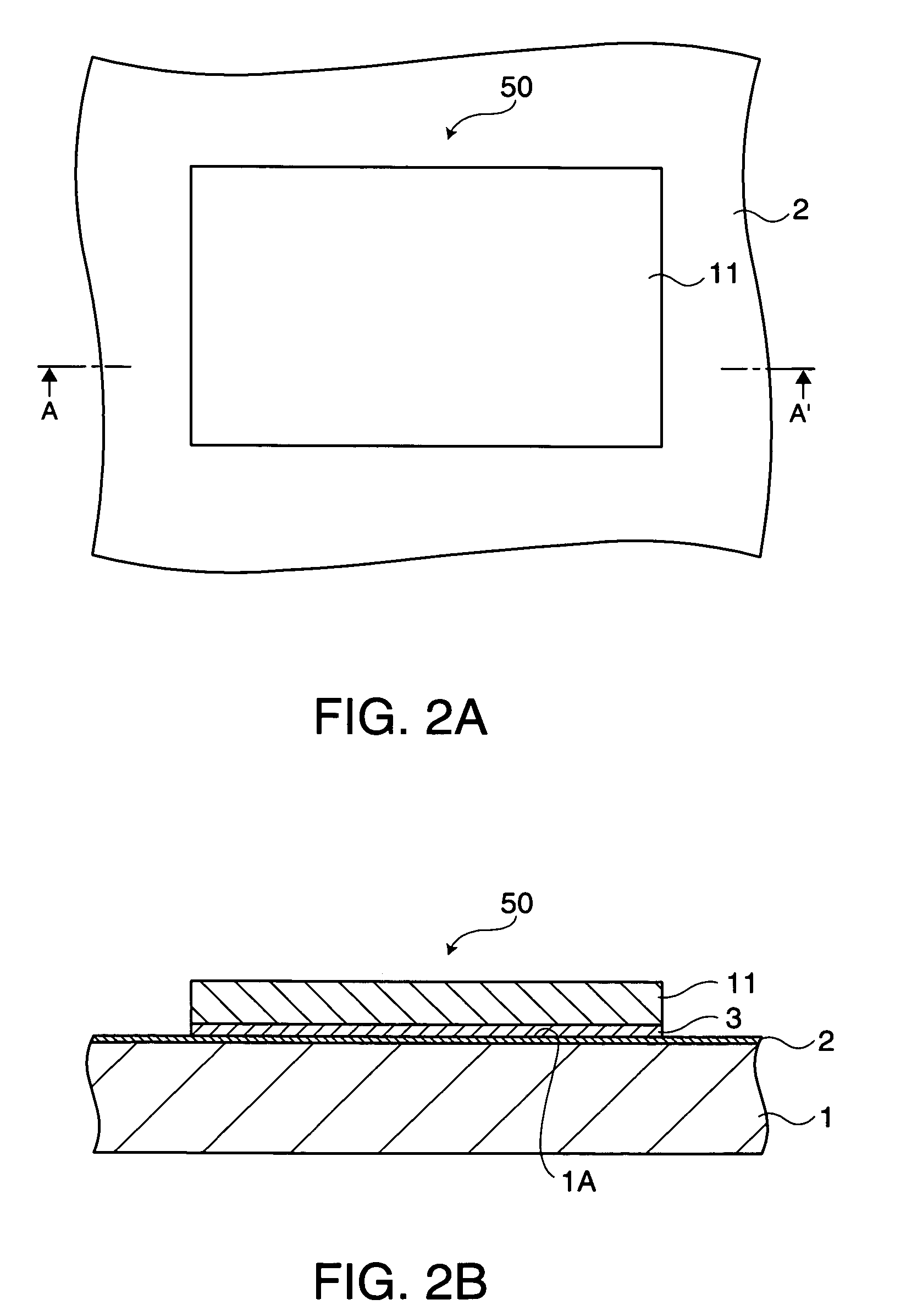

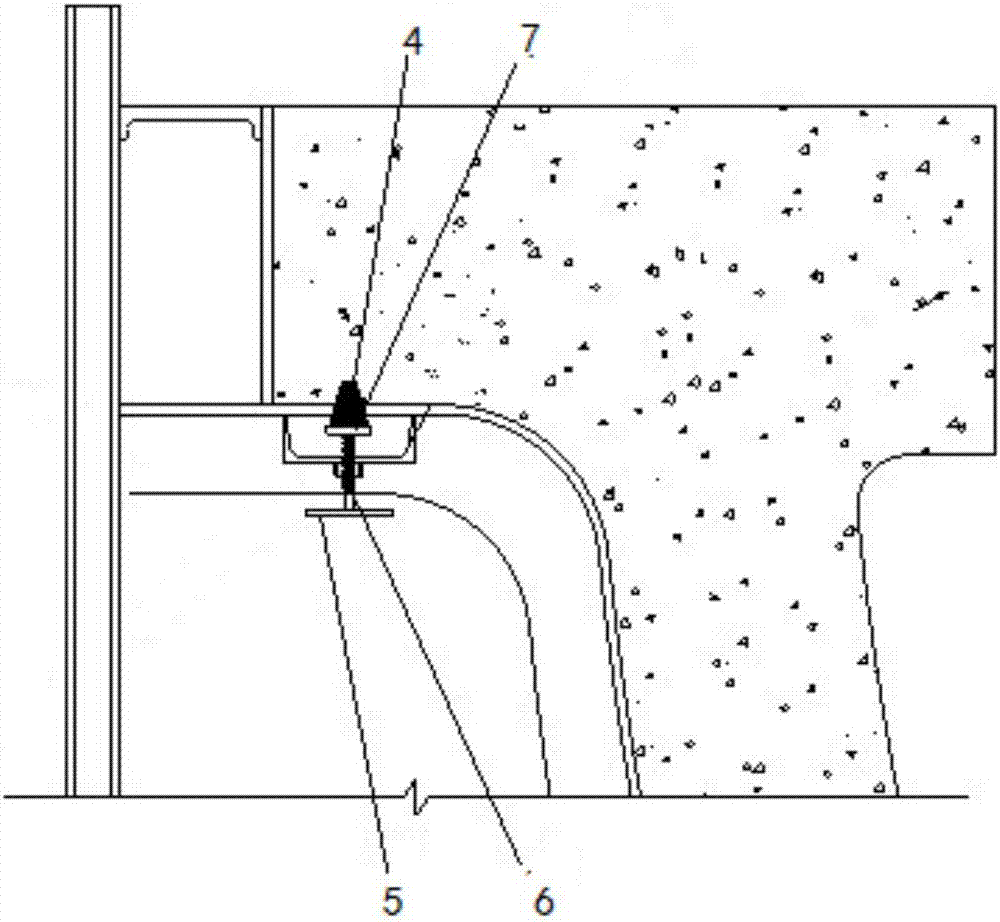

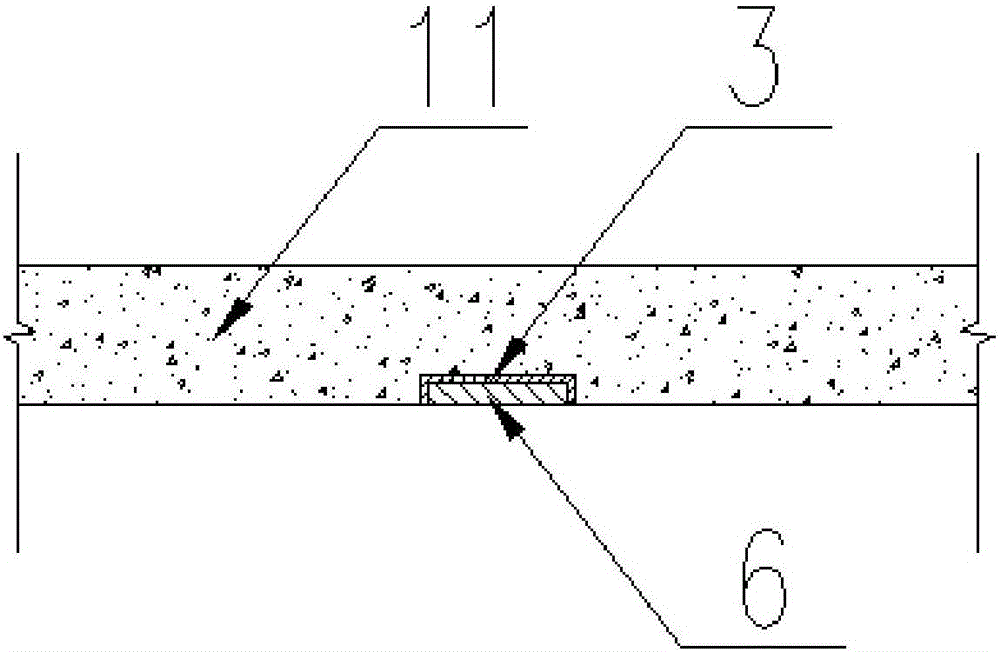

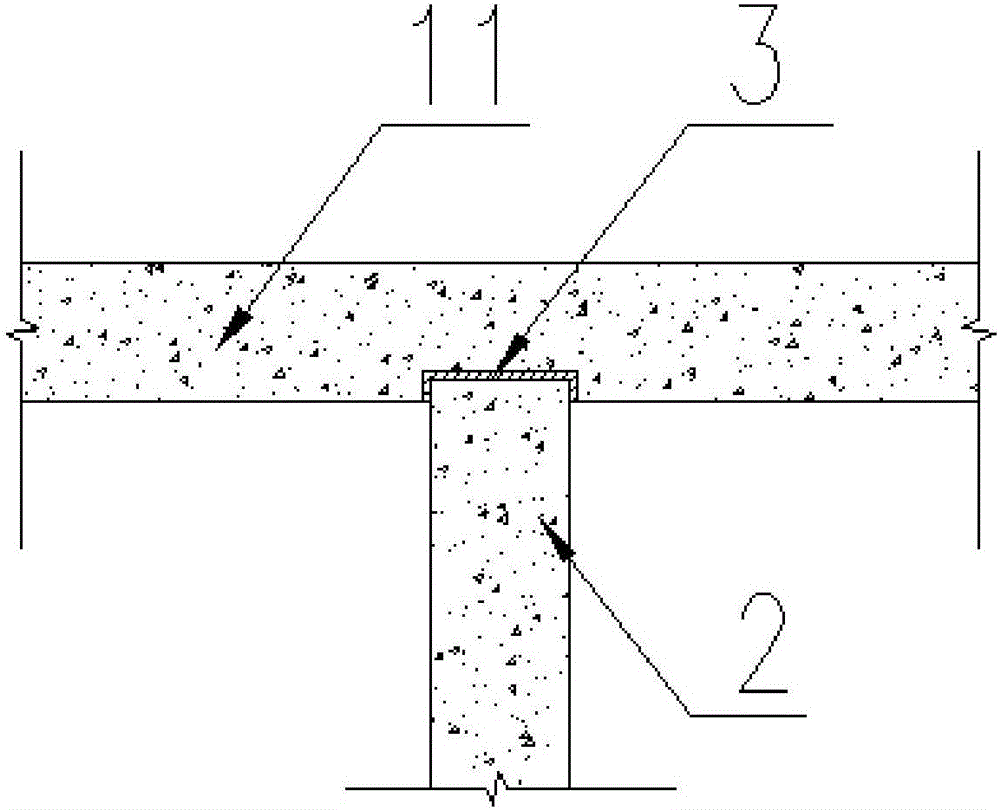

High-water tightness door/window system

The invention belongs to the field of a curtain wall of a building door / window, and particularly relates to a high-water tightness door / window system. The high-water tightness door / window system comprises a frame (1) and an opening window sash (2), wherein the frame (1) is fixedly provided with a CG-shaped heat insulation bar (102), the CG-shaped heat insulation bar (102) is fixedly provided with a long-tail water-vapor separating adhesive tape (502), the opening window sash (2) is fixedly provided with a T-shaped heat insulation bar (202), the end part of the long-tail water-vapor separating adhesive tape (502) is in lap joint with the end part of the T-shaped heat insulation bar (202), the opening window sash (2) is fixedly provided with a CG-shaped fan heat insulation bar (201), the CG-shaped fan heat insulation bar (201) is fixedly provided with a fan middle adhesive tape (503), the top part of the fan middle adhesive tape (503) is in lap joint with glass (7), and the bottom part of the fan middle adhesive tape (503) is embedded in the CG-shaped fan heat insulation bar (201). The high-water tightness door / window system disclosed by the invention has the advantages that the sealing performance and the heat preservation performance are good, the structure is stable and firm, the universality is high, and the waterproof performance of the building door / window can be met.

Owner:LIAONING JOYDON ALUMINUM BUILDING SYST

Production method of mechanically press-molded high-temperature baffle brick

ActiveCN104529480AImprove thermal shock resistanceHigh compressive strengthCeramic shaping apparatusHydraulic cylinderBrick

The invention relates to a production method of a mechanically press-molded high-temperature baffle brick. The method comprises the following steps: (1) a raw material is prepared; (2) a mold is mounted; (3) the prepared raw material is added into the mold; (4) pressure vibration is carried out with a vibration molding machine, wherein a work bench of the vibration molding machine performs high-frequency vibration under the driving of a motor, and at a same time a hydraulic pressure head applies forces to the raw material in the mold under the push of a hydraulic cylinder; (5) mold release is carried out; (6) an obtained baffle brick blank is fired in a high-temperature kiln; and (7) sorting and packaging are carried out. With the method for producing the high-temperature baffle brick through mechanical press molding, production efficiency can be greatly improved, and the produced baffle brick has high refractoriness and good thermal stability. Therefore, problems of low production efficiency, low refractoriness and poor thermal shock resistance of existing baffle bricks are effectively solved.

Owner:HENAN SANSONG CERAMICS IND

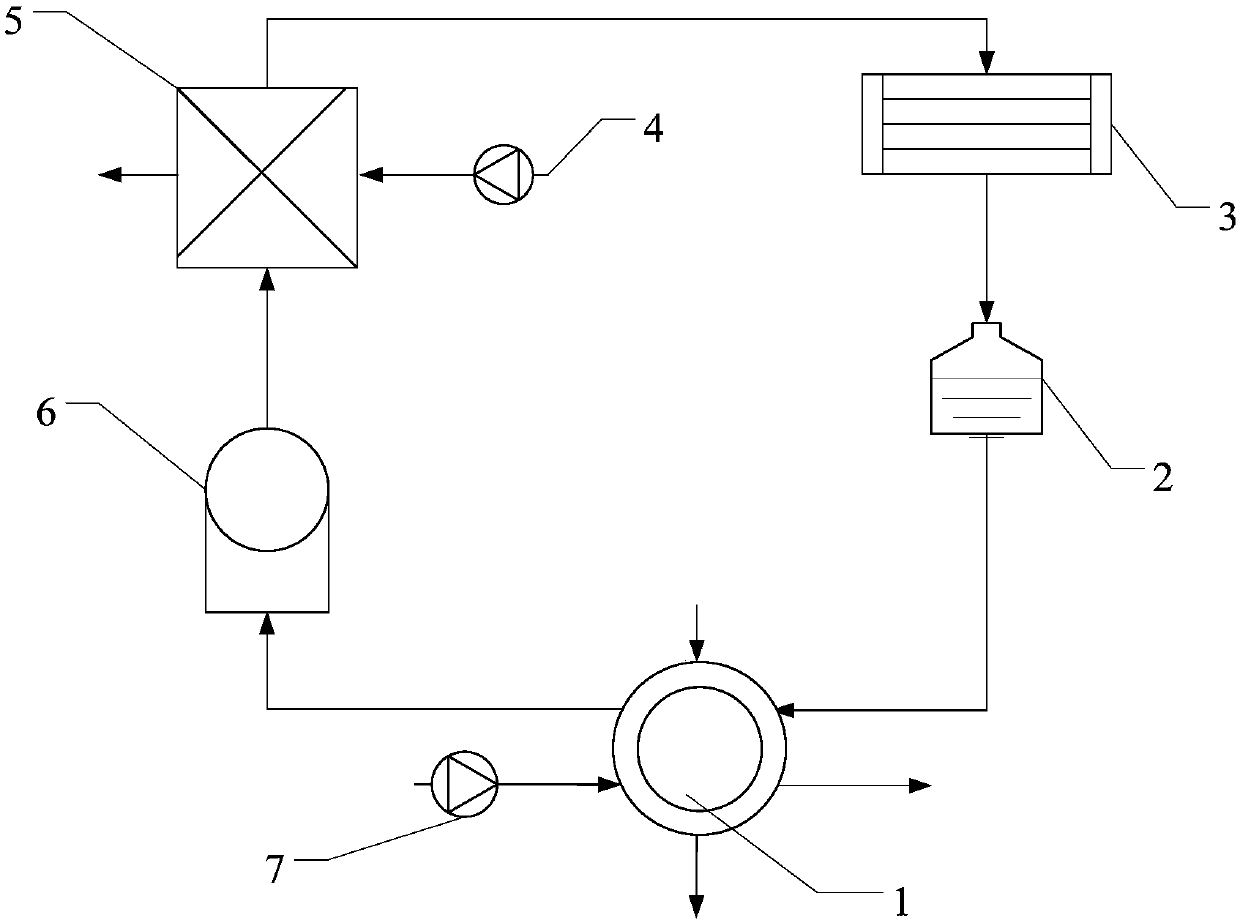

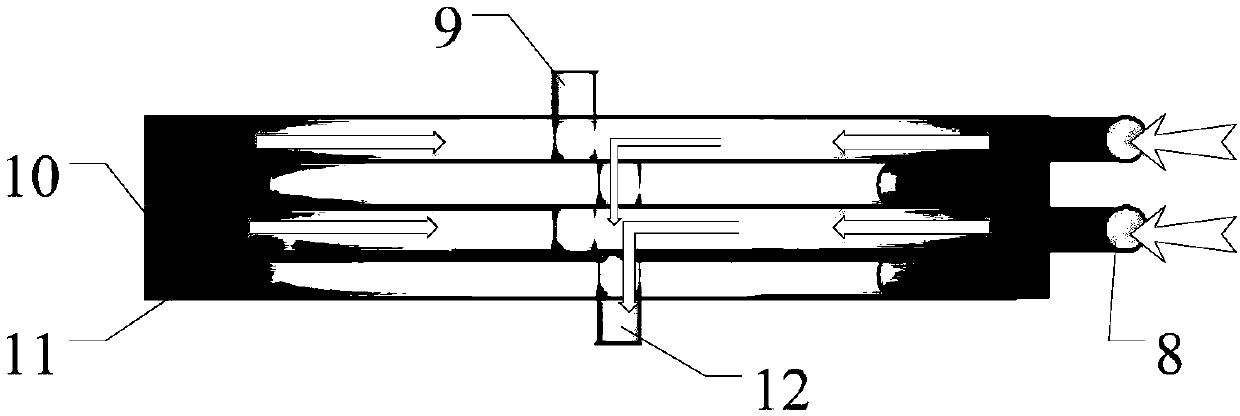

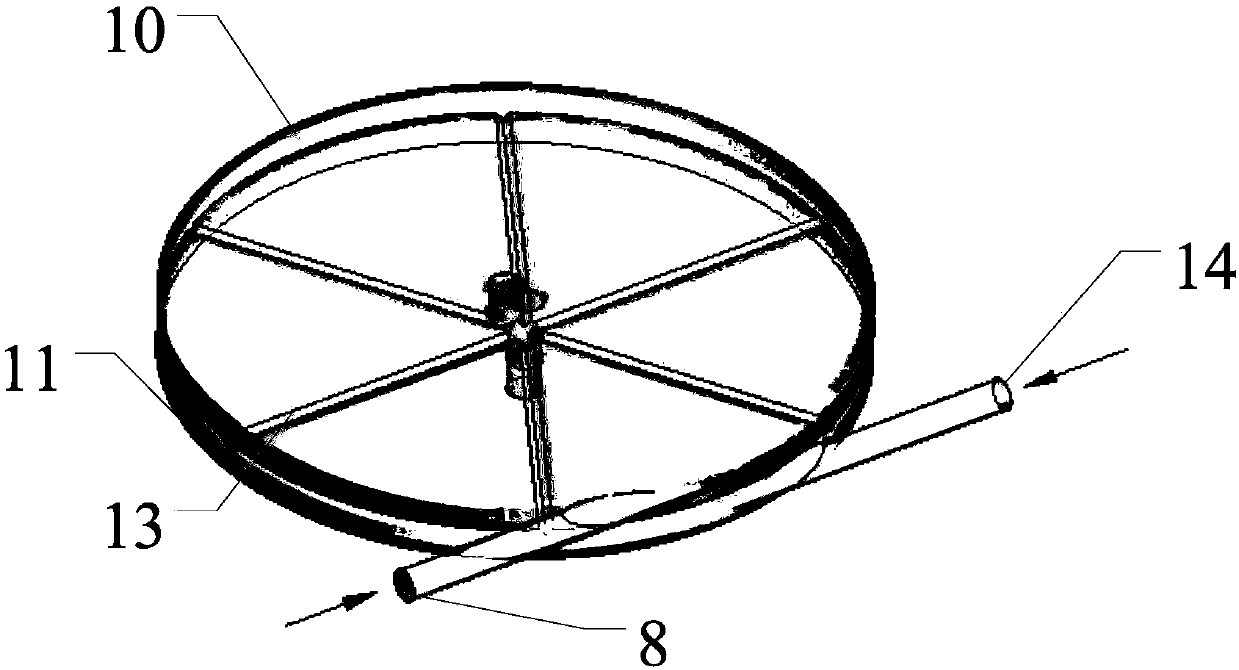

Disc film dehumidifier and dehumidifying system

ActiveCN107676889ASufficient heat exchangeFully communicateLighting and heating apparatusSpace heating and ventilation detailsCircular discChemistry

The invention discloses a disc film dehumidifier and a dehumidifying system. The dehumidifier comprises a shell, an air runner and a solution runner; the shell is disc-shaped; the air runner and the solution runner are both plane spiral pipes, are contacted, and are in parallel; and an included angle of projections of an intake port and a liquid feed port on a horizontal plane is 180 degrees, so that gas entering the air runner and liquid in the solution runner are opposite in flowing direction to form countercurrents or quasi countercurrents. The corresponding dehumidifying system comprises the disc film dehumidifier. The disc film dehumidifier and the dehumidifying system have such advantages as full heat exchange, good mass transfer effect and high moisture absorbing efficiency.

Owner:DONGGUAN UNIV OF TECH

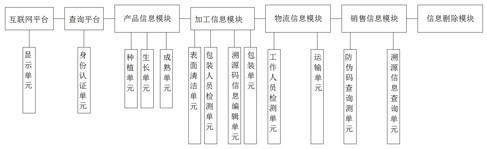

Agricultural product traceability management system based on block chain

InactiveCN113159801AEnsure safe handlingAvoid cornersDigital data information retrievalCo-operative working arrangementsLogistics managementThe Internet

The invention belongs to the technical field of agricultural product traceability management, particularly relates to an agricultural product traceability management system based on a block chain, and provides the following scheme for solving the problems that a traditional agricultural product traceability system does not inspect the physical state of a worker, the health state of the worker cannot be ensured, and information cannot be deleted and managed. The system comprises an Internet platform, a query platform, a product information module, a processing information module, a logistics information module, a sales information module and an information deletion module, the query platform is connected with the Internet platform, the product information module, the processing information module, the logistics information module, the product packaging module, the sales information module and the information deletion module are all connected with the Internet platform, and the product information module comprises a planting unit, a growing unit and a maturing unit. The system is convenient to operate, can inspect the physical state and identity of a worker, and can automatically store or delete agricultural product information.

Owner:浙江天演维真网络科技股份有限公司

Method for manufacturing a semiconductor substrate, method for manufacturing a semiconductor device, and the semiconductor device

InactiveUS7452781B2Reduce occurrenceLower Reliability RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingLOCOSSemiconductor

A method for manufacturing a semiconductor substrate having a silicon-on-insulator (SOI) structure region isolated by a local oxidation of silicon (LOCOS) film and an SOI structure in the region includes forming the LOCOS film so as to make a height from an uppermost surface of a semiconductor member to a top surface of the LOCOS film be higher than a height from the uppermost surface of the semiconductor member to a top surface of the SOI structure, forming a silicon germanium layer and a silicon layer on the SOI structure region on the semiconductor member by epitaxial growth and forming a polysilicon film on a surface of the LOCOS film, forming a recess for a support to support the silicon layer to be a part of the SOI structure, forming the support on the semiconductor member, exposing a side of the silicon germanium layer and the silicon layer underneath the support, forming a cavity by removing the silicon germanium layer having the side exposed, forming the SOI structure by embedding an insulating layer to be buried in the cavity, planarizing a covering insulating film formed to cover an entire of a top surface of the semiconductor member by using the polysilicon film as a stopper, and exposing a top surface of the silicon layer in the SOI structure by etching.

Owner:SEIKO EPSON CORP

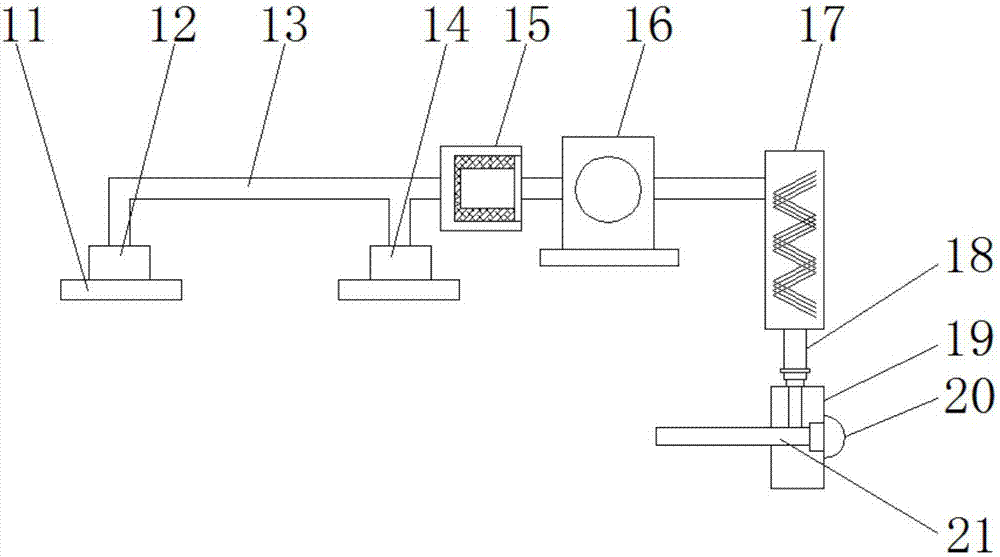

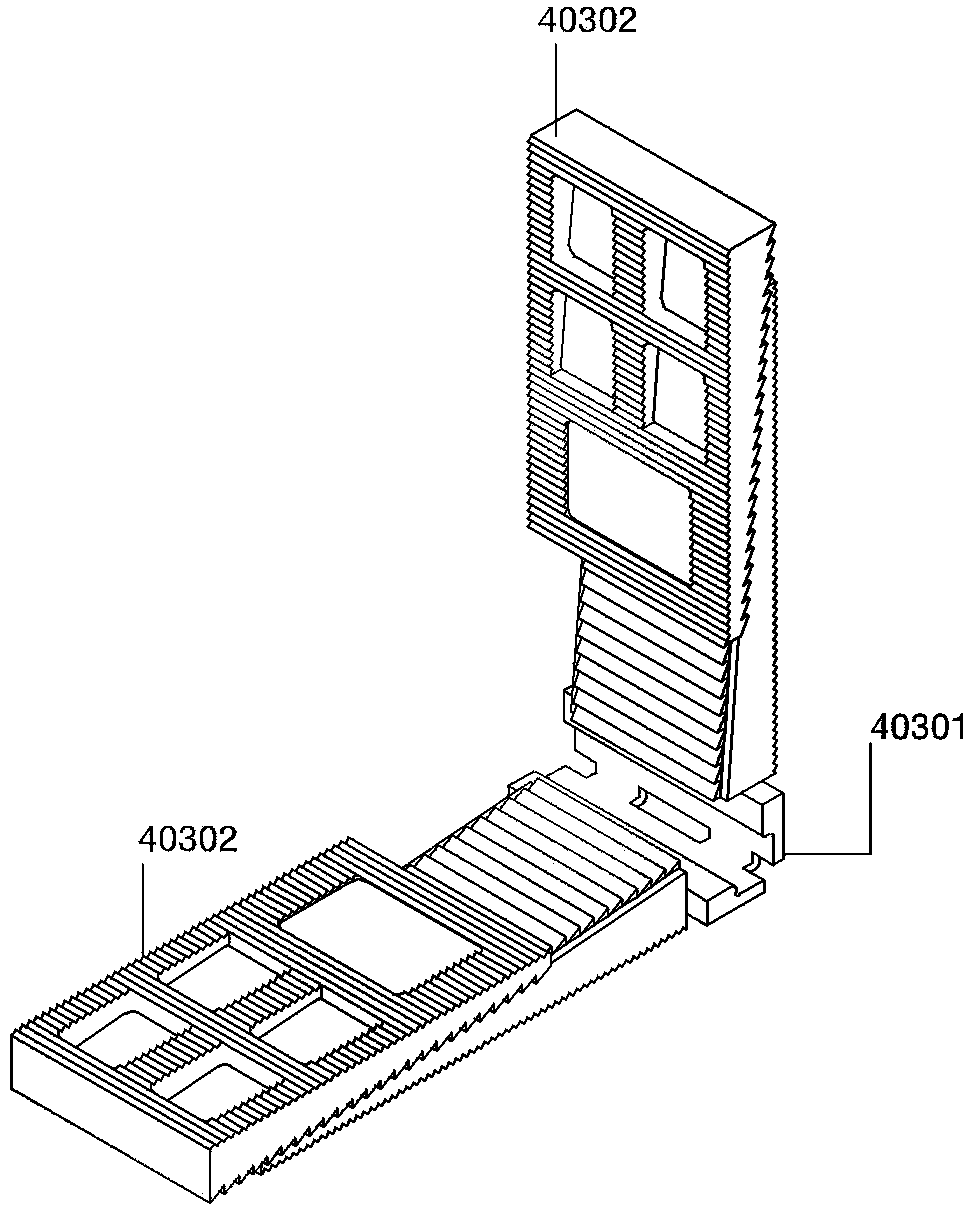

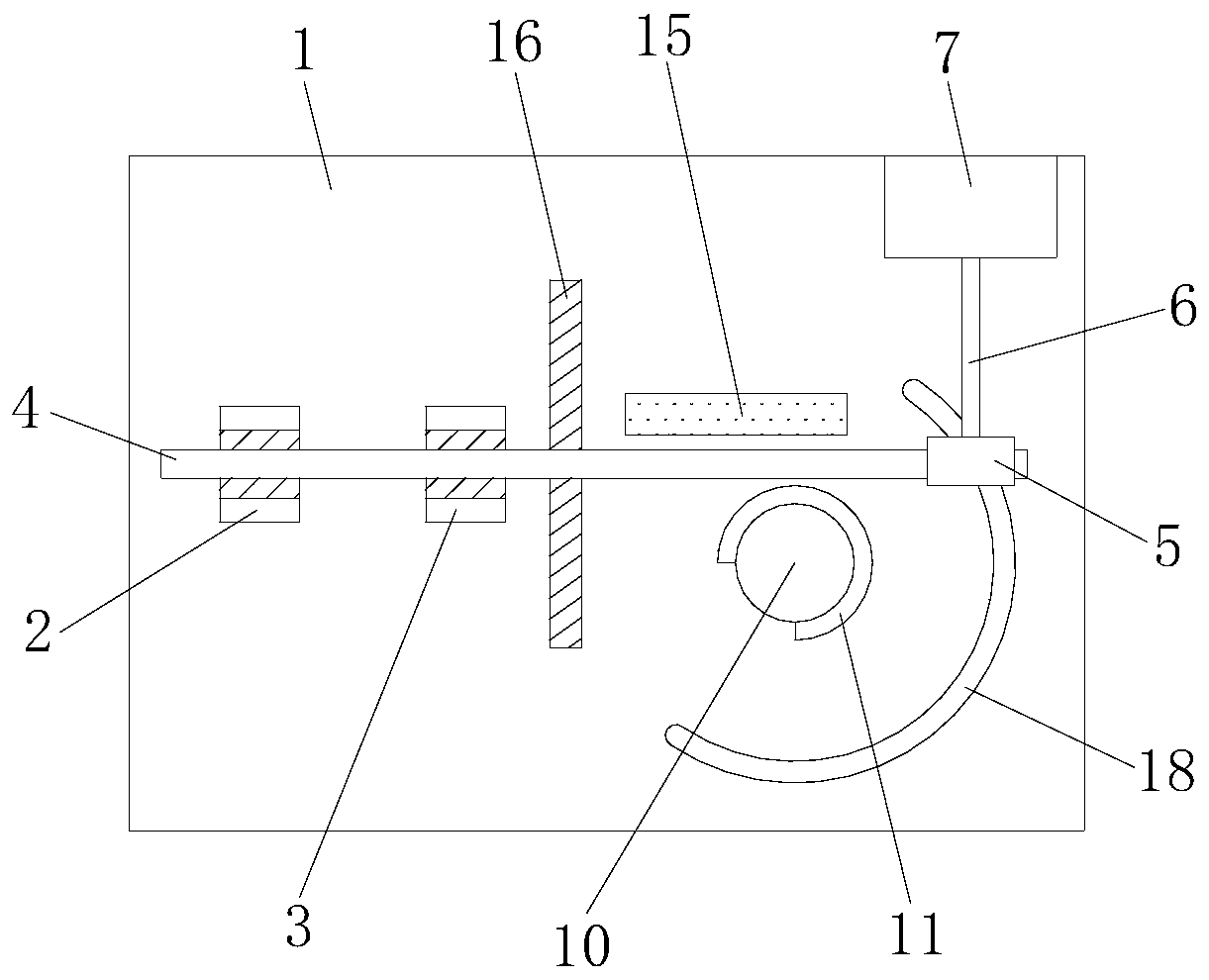

Lifting type drip edge molding system

ActiveCN107090976APrecise positioningGuaranteed positioning accuracyForms/shuttering/falseworksElectrical and Electronics engineeringInsertion depth

The invention discloses a lifting type drip edge molding system. The lifting type drip edge molding system comprises a fixing part, an inner core and a variable-section insert block, wherein a guide hole for guiding the inner core is formed in the fixing part, and the inner core is glidingly arranged in the guide hole; at least one first penetration through hole is formed in the fixing part; second penetration through holes in equal quantity to the first penetration through holes are formed in the inner core, and the variable-section insert block is arranged in a penetration manner by means of the first penetration through holes and the second penetration through holes. With adoption of the technical scheme, position precision of a molding bar is guaranteed effectively, the height of the inner core relative to the fixing part can be adjusted by controlling the insertion depth of the variable-section insert block, and the height of the molding bar can be adjusted; according to the technical scheme, positioning of the variable-section insert block is reliable, and problems caused by thread failure are solved effectively.

Owner:JIANGSU SHENGLE MACHINERY

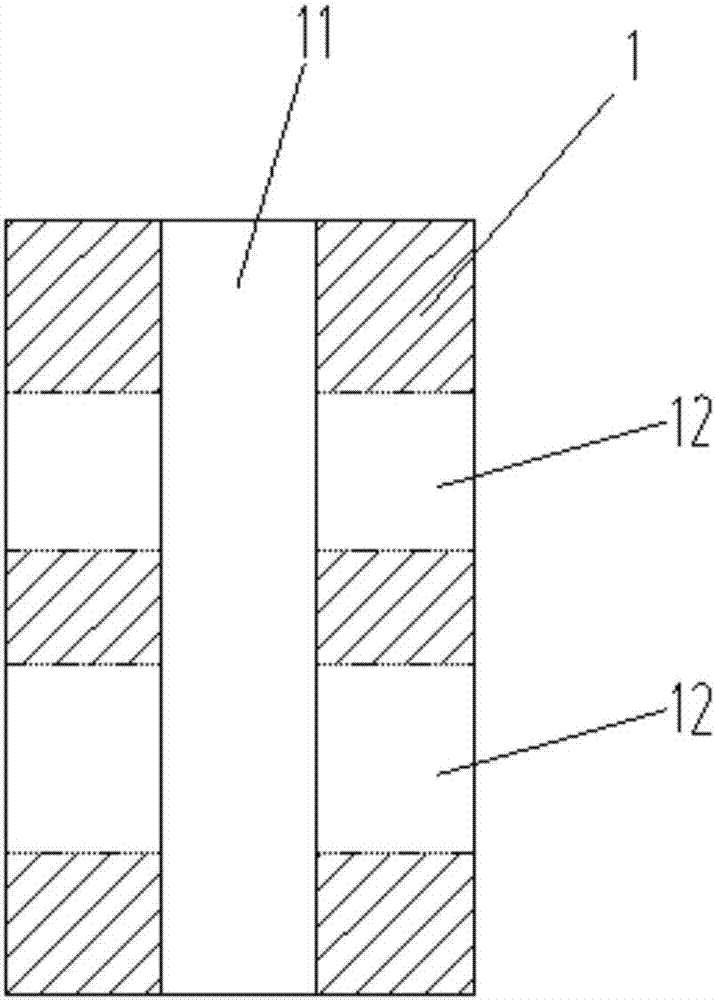

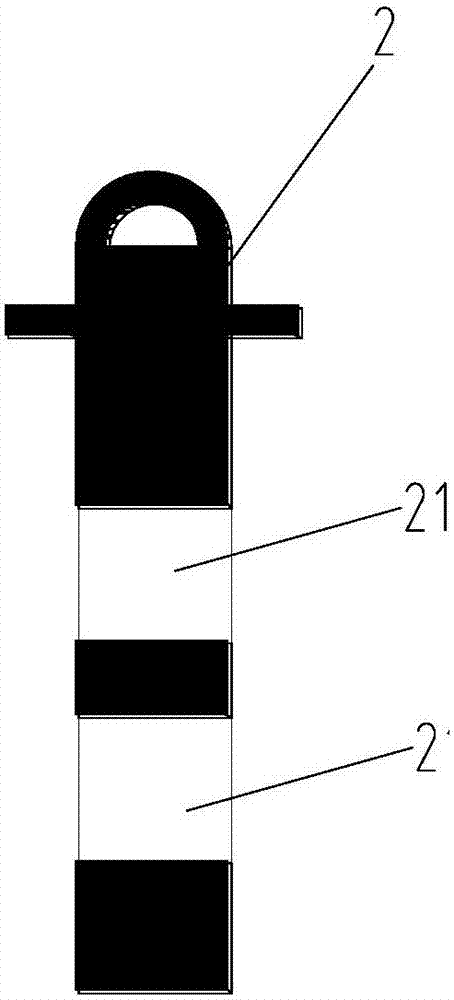

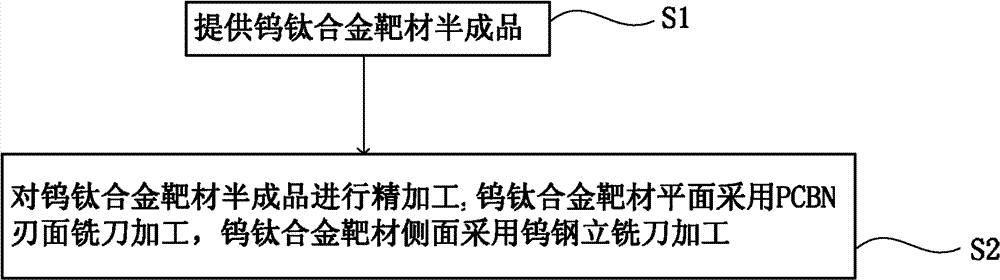

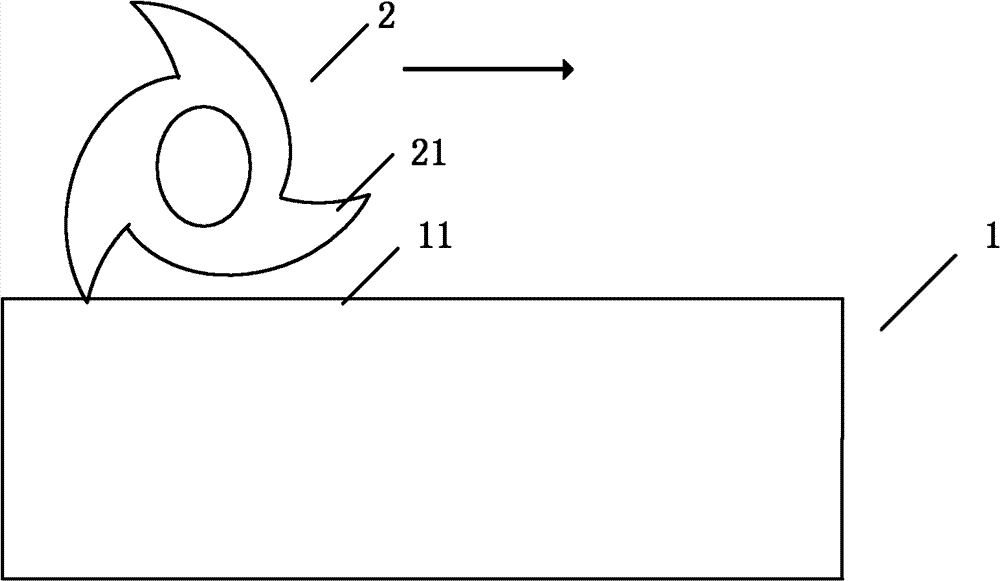

Machining method for milling tungsten alloy target material

ActiveCN102145403BUniform cutting forceAvoid cornersMilling equipment detailsMilling cutterBoron nitride

The invention discloses a machining method for a tungsten alloy target material, which comprises the steps of providing a semi-finished product of the tungsten alloy target material and carrying out finish machining on the semi-finished product of the tungsten alloy target material, wherein in the finish machining step, the plane of the tungsten alloy target material is machined by a PCBN (Polycrystalline Cubic Boron Nitride) face mill, and the side face of the tungsten alloy target material is machined by a tungsten steel end mill. By adopting the machining method for the tungsten alloy target material provided by the invention, the arris defect in the machining process is avoided, the machining of the tungsten alloy target material with complex curved surface can be realized, and the problems of long machining cycle and low production efficiency are solved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

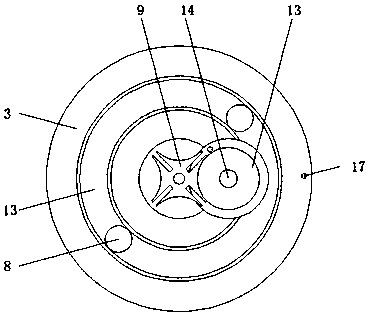

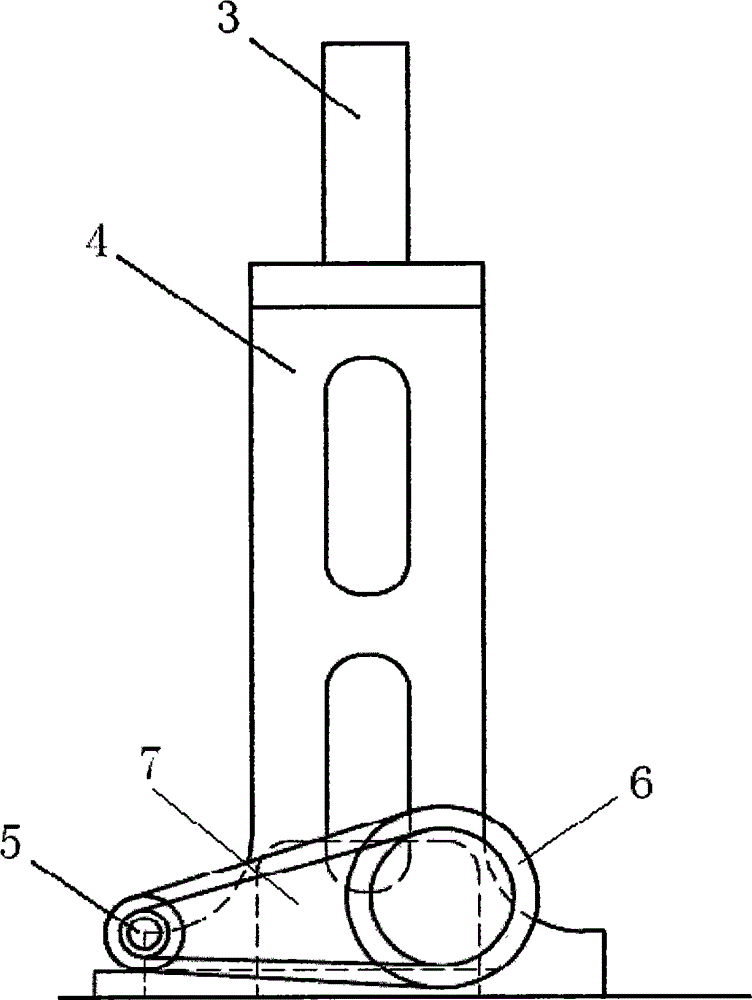

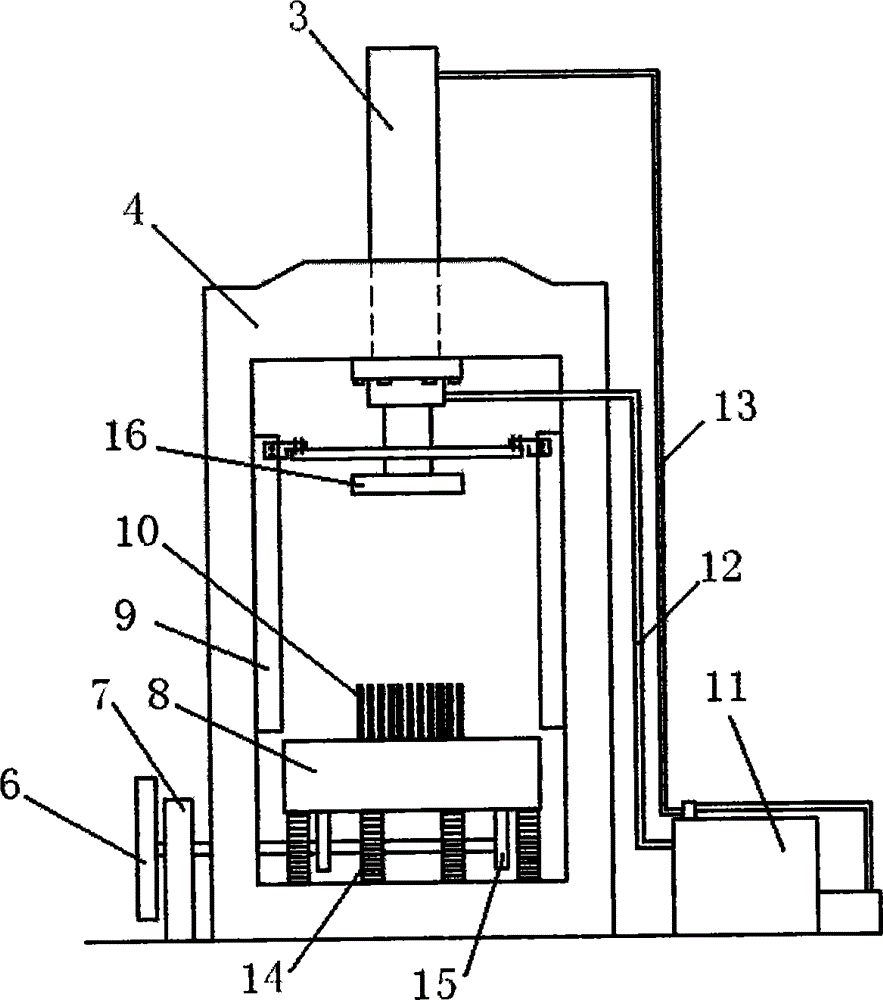

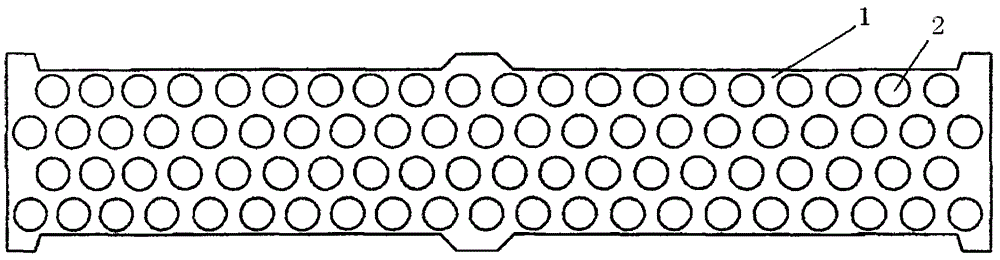

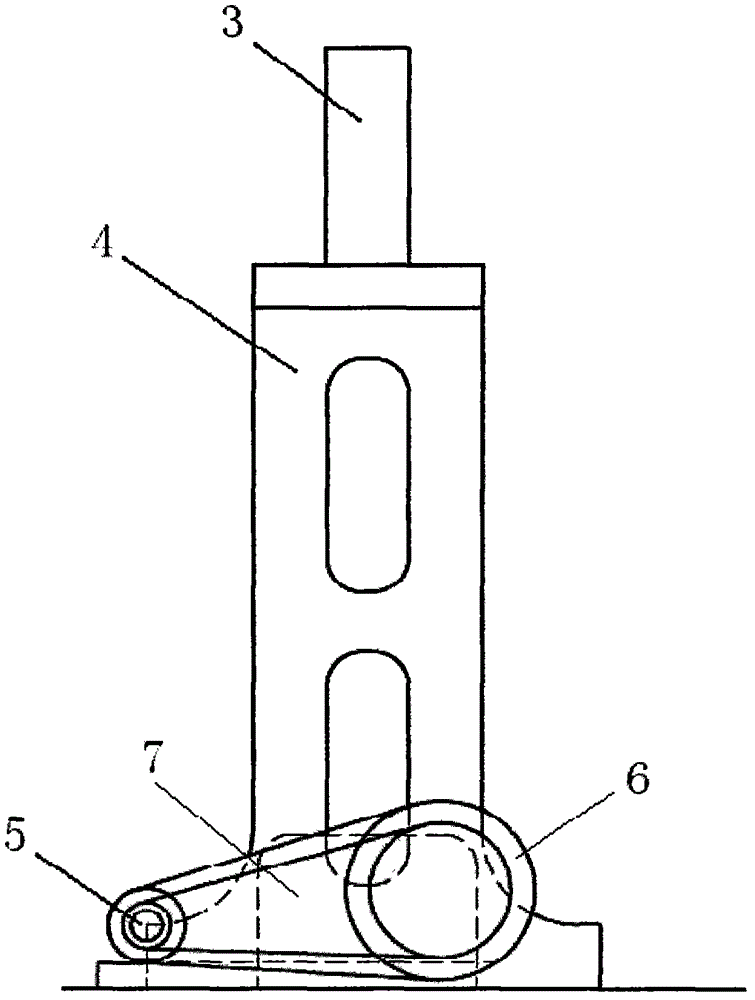

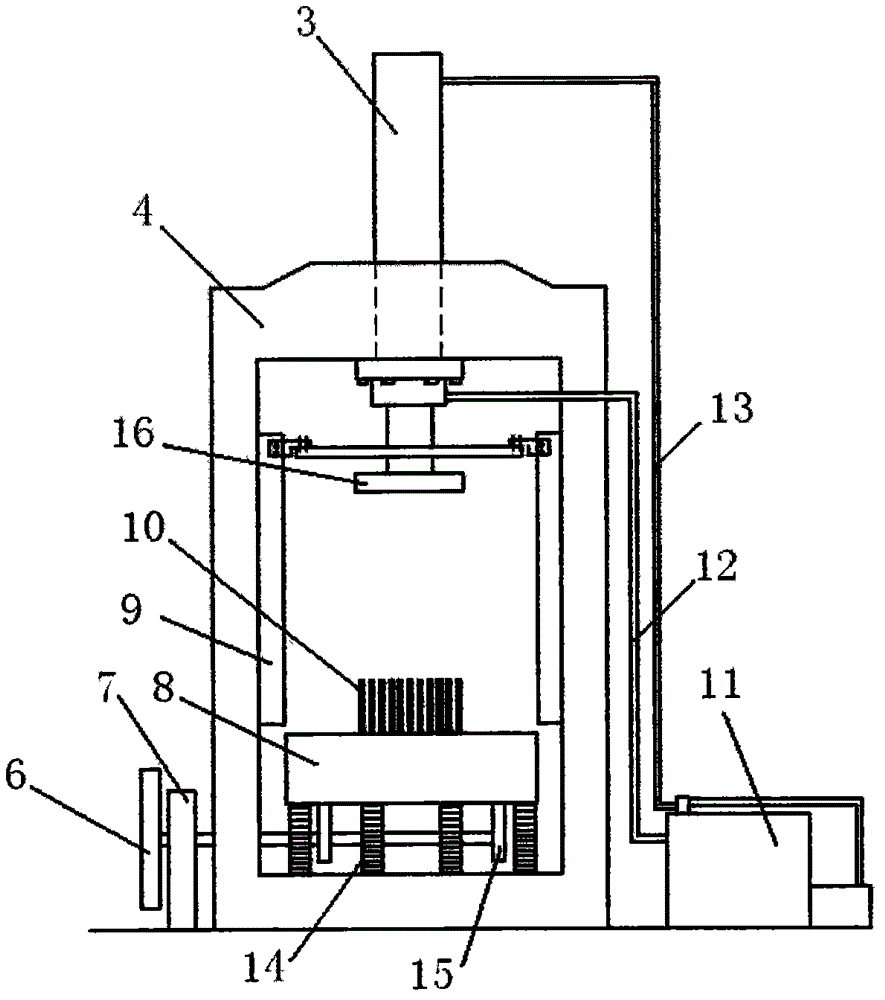

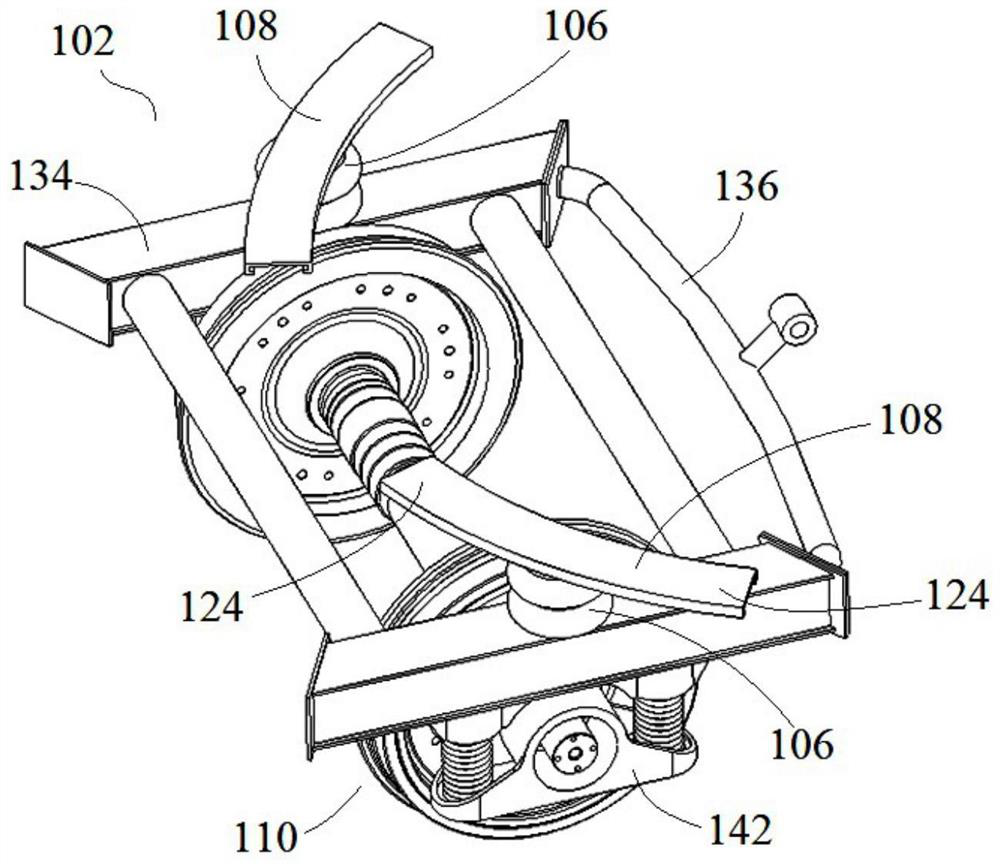

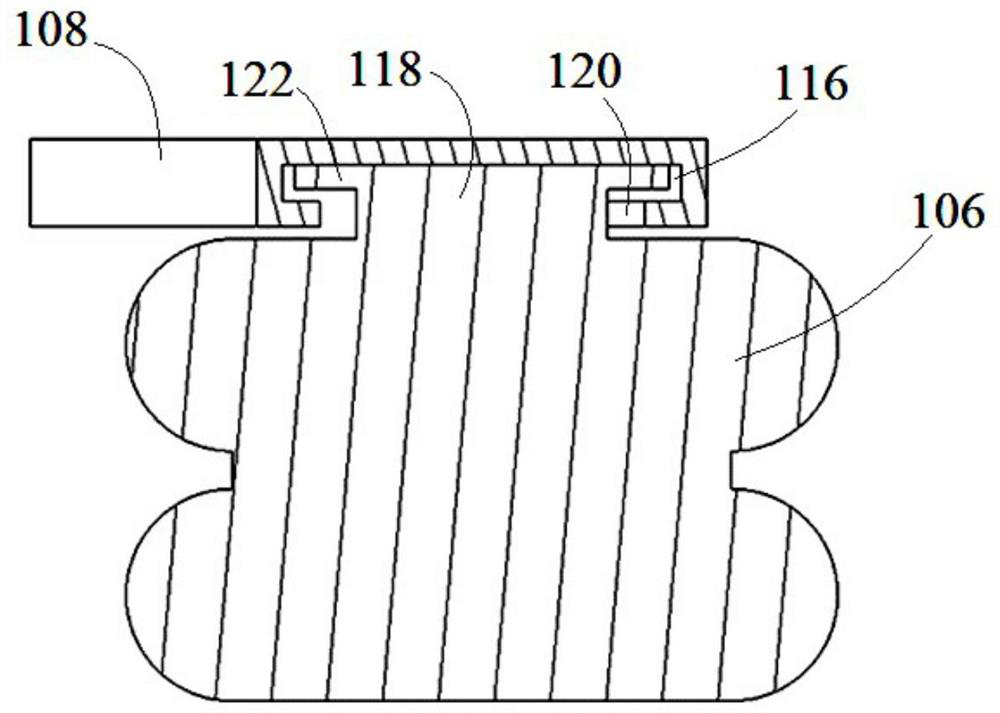

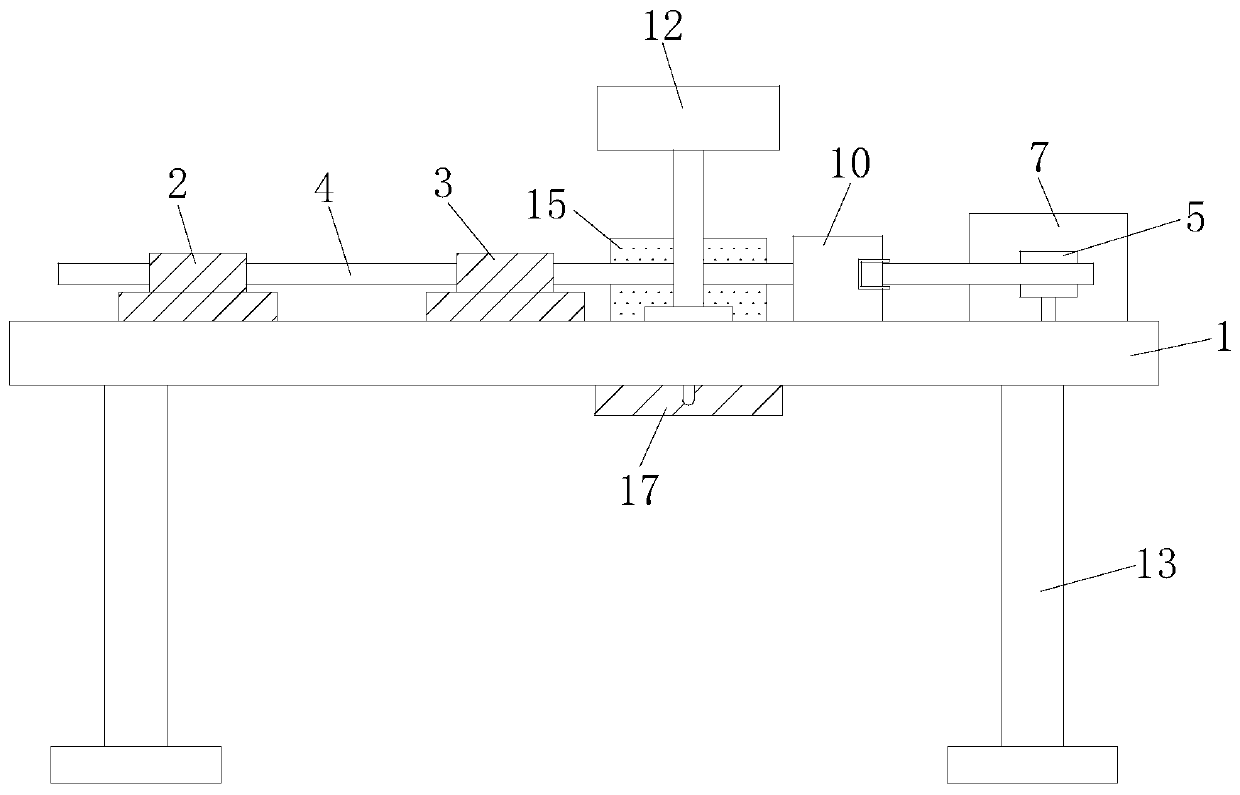

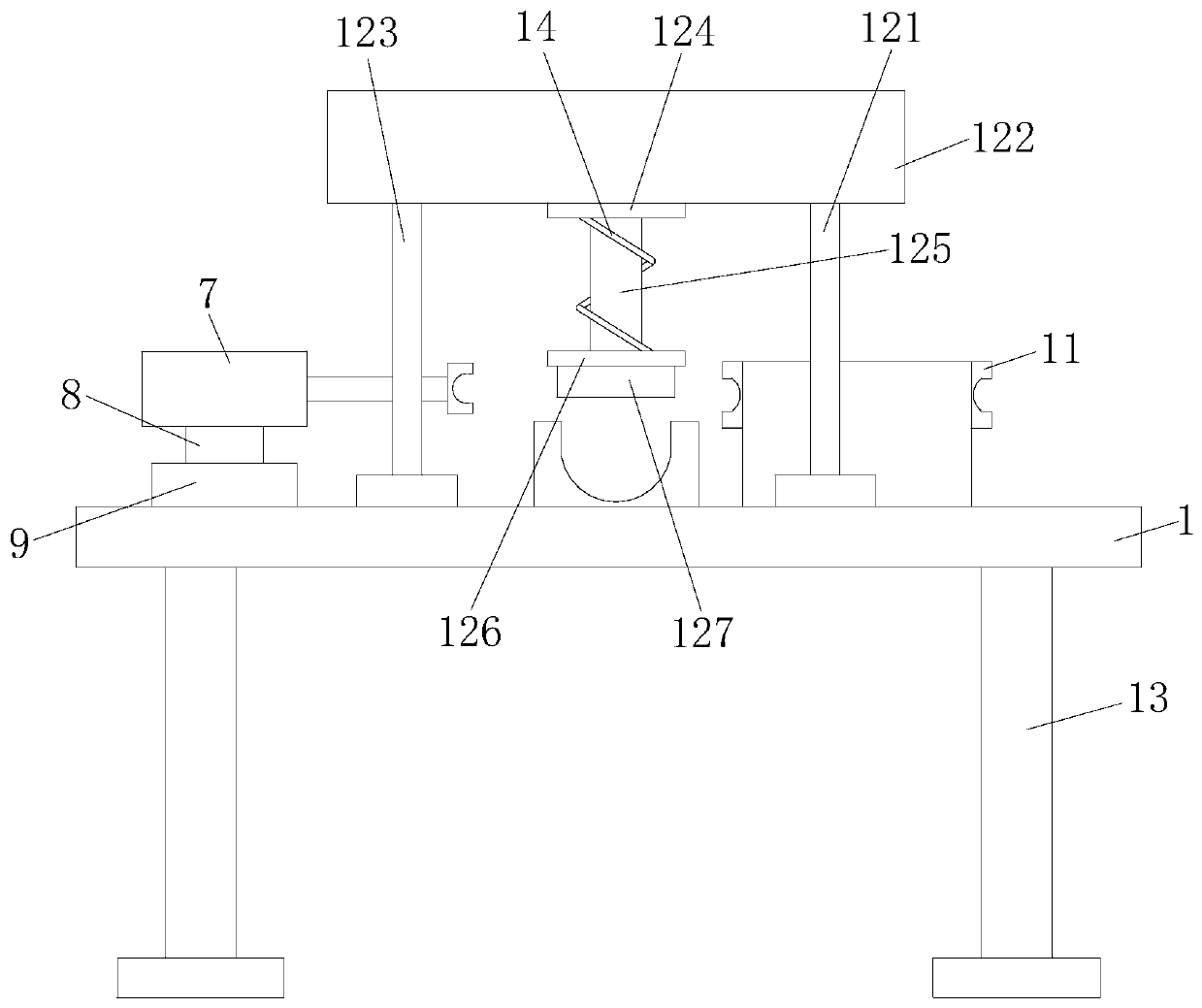

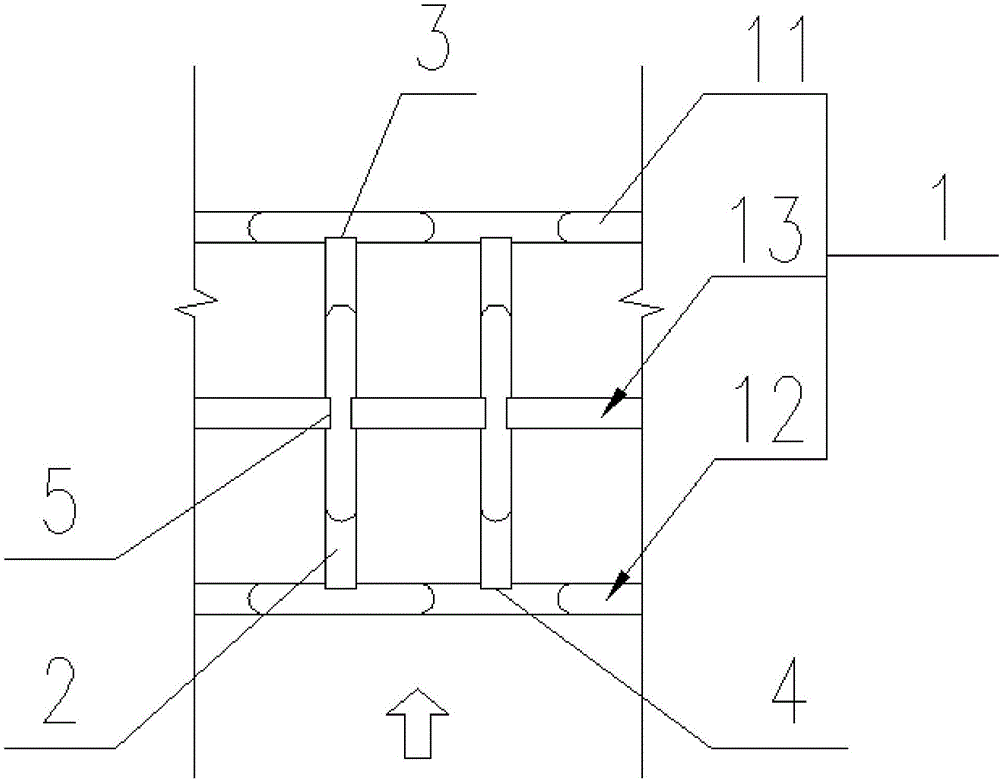

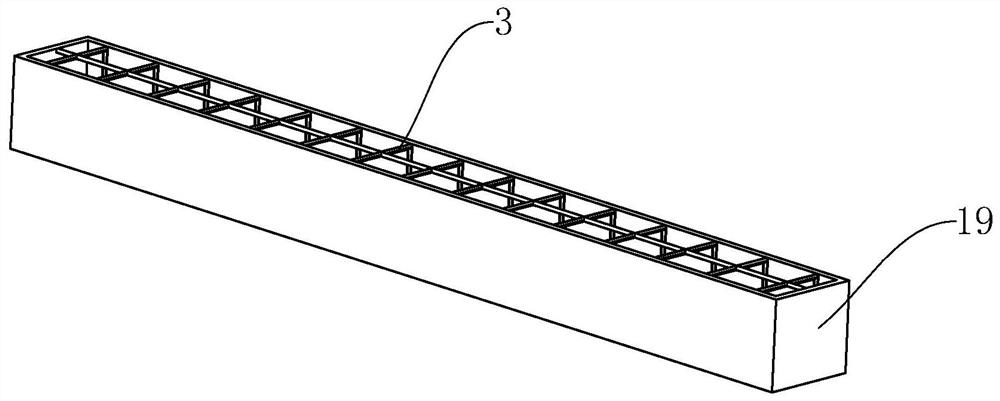

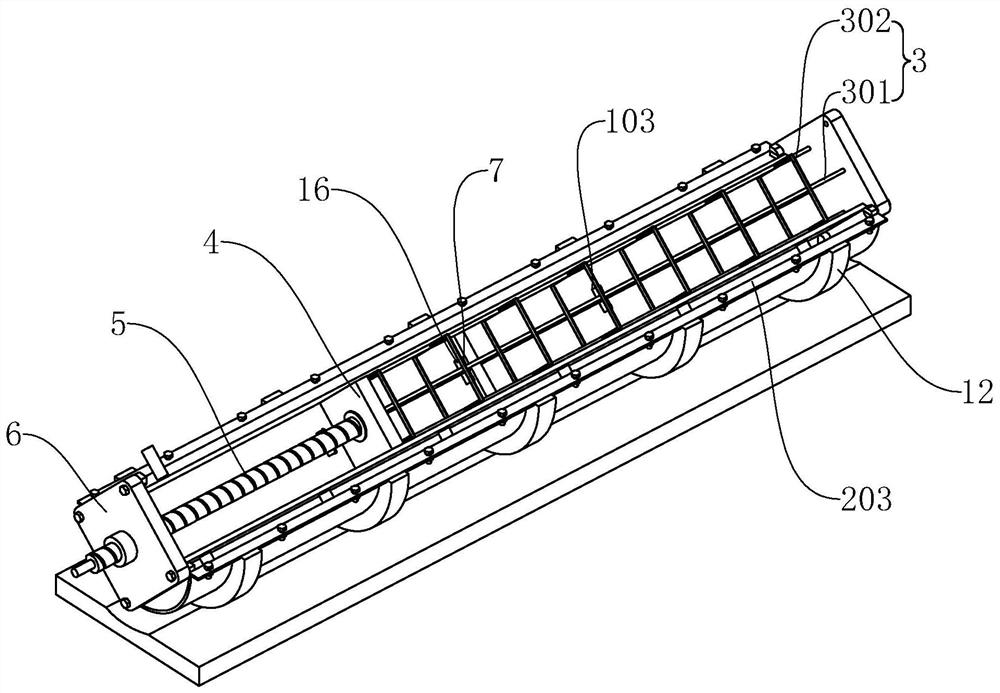

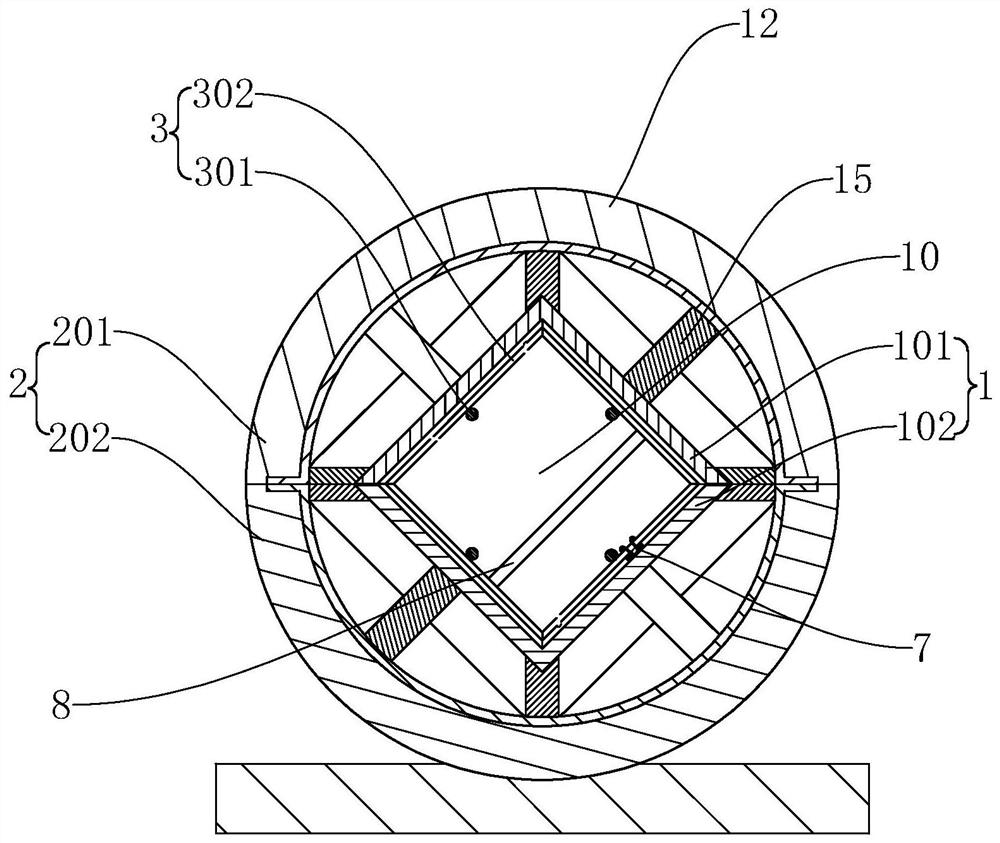

Vibration molding machine for producing high-temperature baffle bricks

InactiveCN104354219AImprove thermal shock resistanceHigh compressive strengthShaping press ramHydraulic cylinderBrick

The invention relates to a vibration molding machine for producing high-temperature baffle bricks. The vibration molding machine comprises a machine body (4), a hydraulic pressure system and a vibration table system, wherein the hydraulic pressure system comprises an oil tank (11), an oil inlet pipe (13), an oil returning pipe (12), a hydraulic cylinder (3) and a hydraulic pressure head (16); the vibration table system comprises a motor (5), a synchronous gearbox (7), a vibration assembly (15), a worktable (8) and a damping spring (14); a perforation shaft (10) is fixedly arranged on the upper surface of the worktable (8); the hydraulic cylinder (3) of the hydraulic pressure system is arranged on the machine body (4) and is used for connecting the oil inlet pipe (13) with the oil returning pipe (12); the other end of the oil inlet pipe (13) and the other end of the oil returning pipe (12) are respectively connected with the oil tank (11); the hydraulic pressure head (16) is arranged at one end of the hydraulic cylinder (3); the motor (5) applies power to the worktable (8) through the synchronous gearbox (7) and the vibration assembly (15); the motor (5) and the damping spring (14) are matched together for enabling the worktable (8) to vibrate at high frequency. According to the vibration molding machine disclosed by the invention, the production efficiency of the baffle bricks can be greatly improved; in addition, the produced baffle bricks are high in refractoriness and good in thermal stability.

Owner:HENAN SANSONG CERAMICS IND

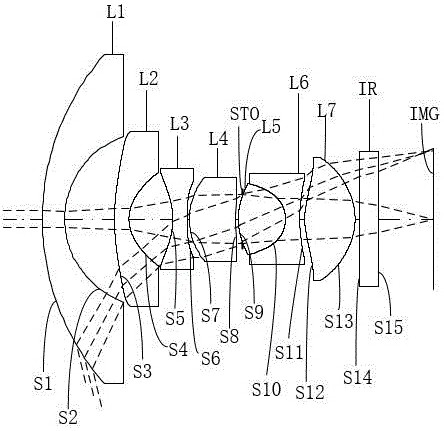

Optical image capturing system, image capturing module and electronic device

ActiveCN112698476AImprove wide-angleAffect image qualityOptical elementsOphthalmologyImaging quality

The invention provides an optical imaging system, an image capturing module and an electronic device. The optical imaging system sequentially comprises a diaphragm, a lens and a protection flat plate from the object side to the image side along the optical axis. The lens has positive refractive power, the object side surface of the lens is a concave surface at a paraxial region, the image side surface of the lens is a convex surface at a paraxial region, and the object side surface and the image side surface of the lens are aspheric surfaces; and the optical imaging system satisfies the following relational expressions that 9<SDs1 / the absolute value of sags1<12 , wherein SDs1 is the maximum clear aperture of the object side surface of the lens, and sags1 is the distance from the maximum clear aperture of the object side surface of the lens to the central point of the object side surface of the lens, which is parallel to the optical axis. According to the optical imaging system, the aspheric lens with positive refractive power is adopted, the total optical length is small, a large field angle range can be obtained, the wide angle of the optical imaging system can be improved, and the imaging quality is improved by reasonably configuring the curvature of the object side face of the lens.

Owner:TIANJIN OFILM OPTO ELECTRONICS CO LTD

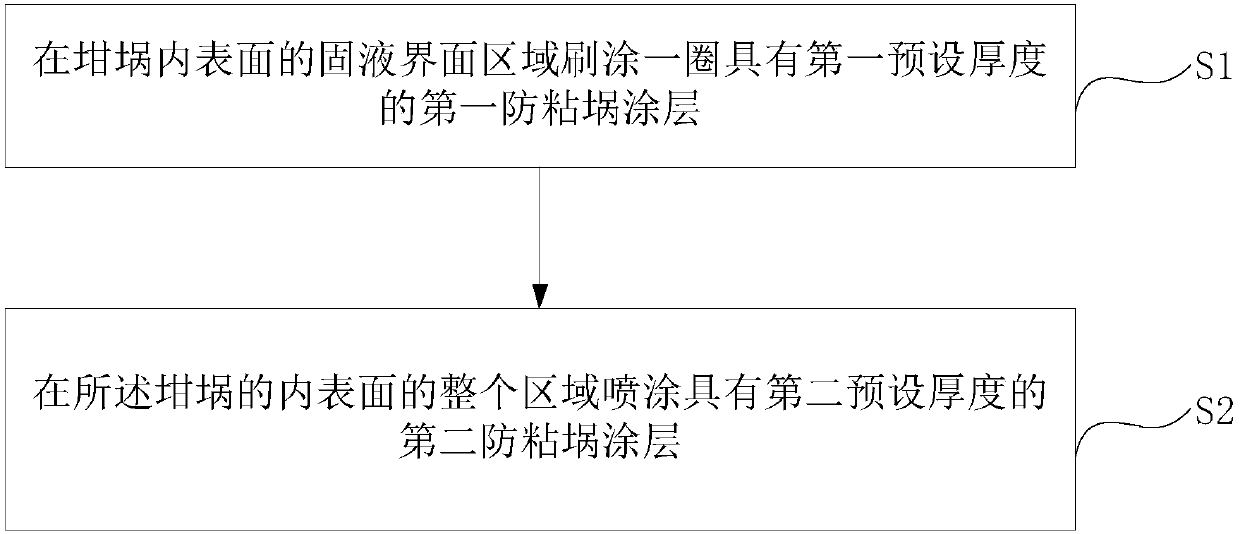

Crucible adhesion preventing method of polycrystalline ingot casting

InactiveCN107747124AAvoid cornersAvoid crackingPolycrystalline material growthSingle crystal growth detailsIngot castingCrucible

The invention discloses a crucible adhesion preventing method of polycrystalline ingot casting. The method comprises coating a solid-liquid interface area of the inner surface of a crucible by a circle of a first crucible adhesion preventing coating with a first preset thickness, and spraying the whole area of the inner surface of the crucible by a second crucible adhesion preventing coating witha second preset thickness. According to the crucible adhesion preventing method of polycrystalline ingot casting, the crucible can be prevented from being adhered, a silicon ingot is prevented from edge failure and cracking, the quality of the silicon ingot is improved, and the production cost is reduced.

Owner:JINKO SOLAR CO LTD +1

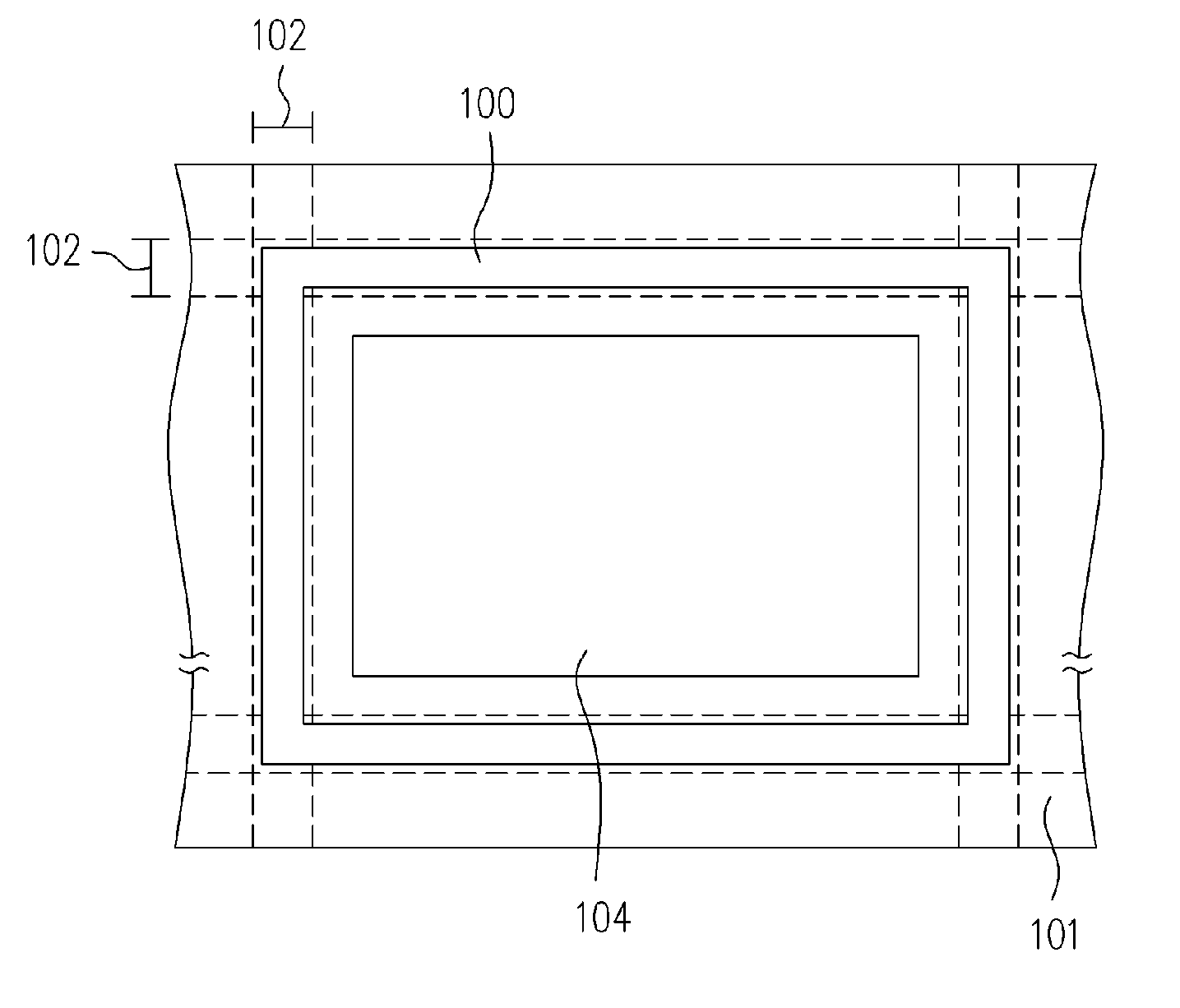

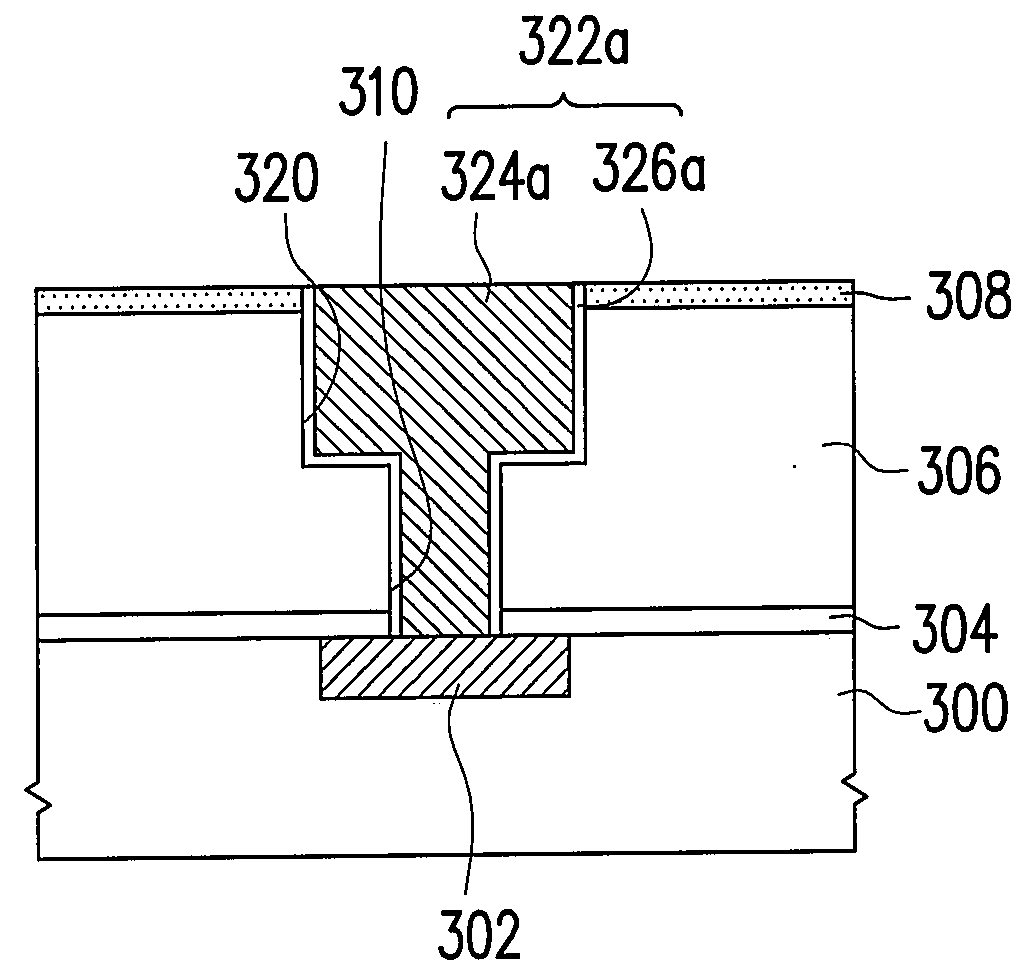

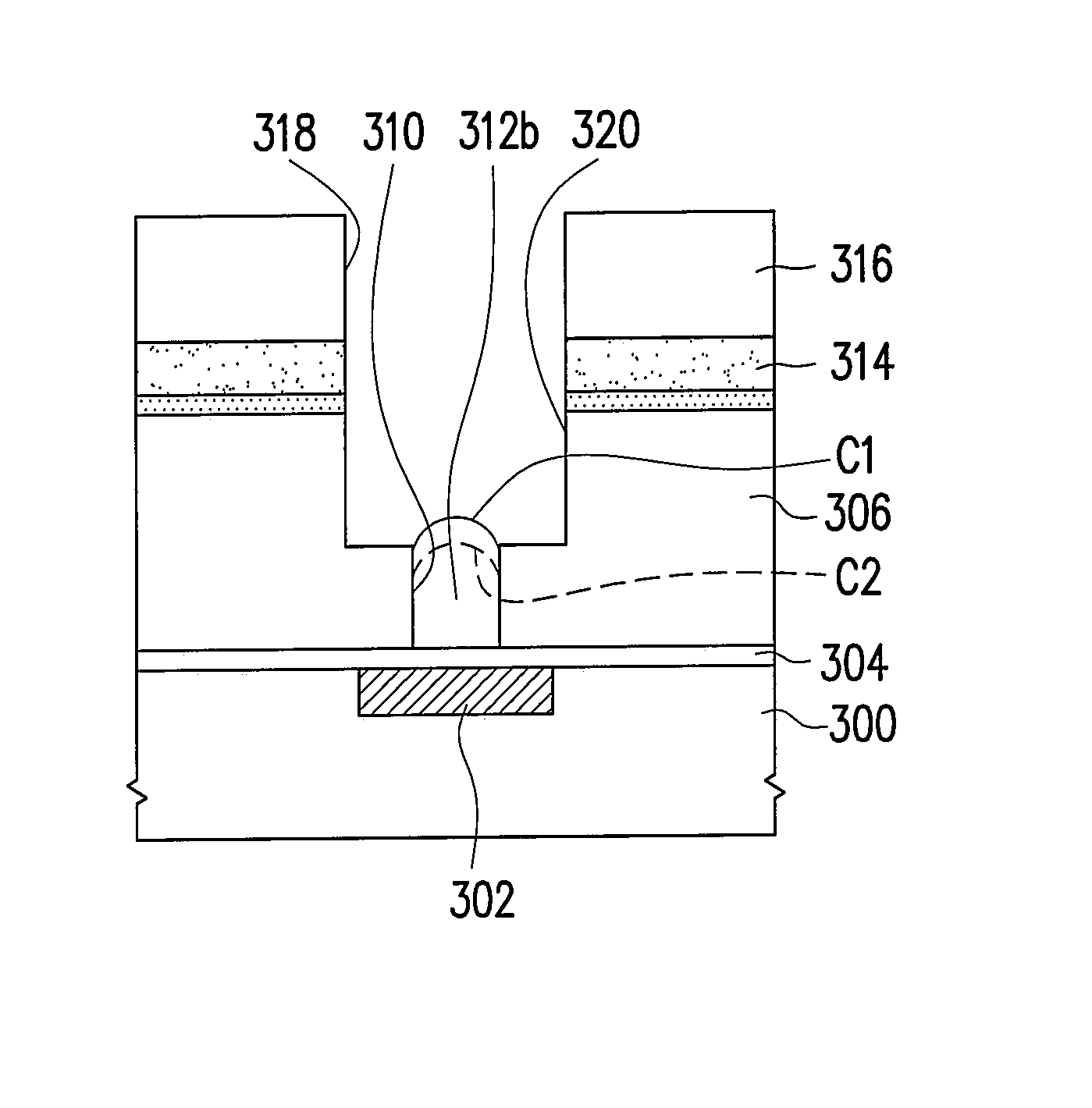

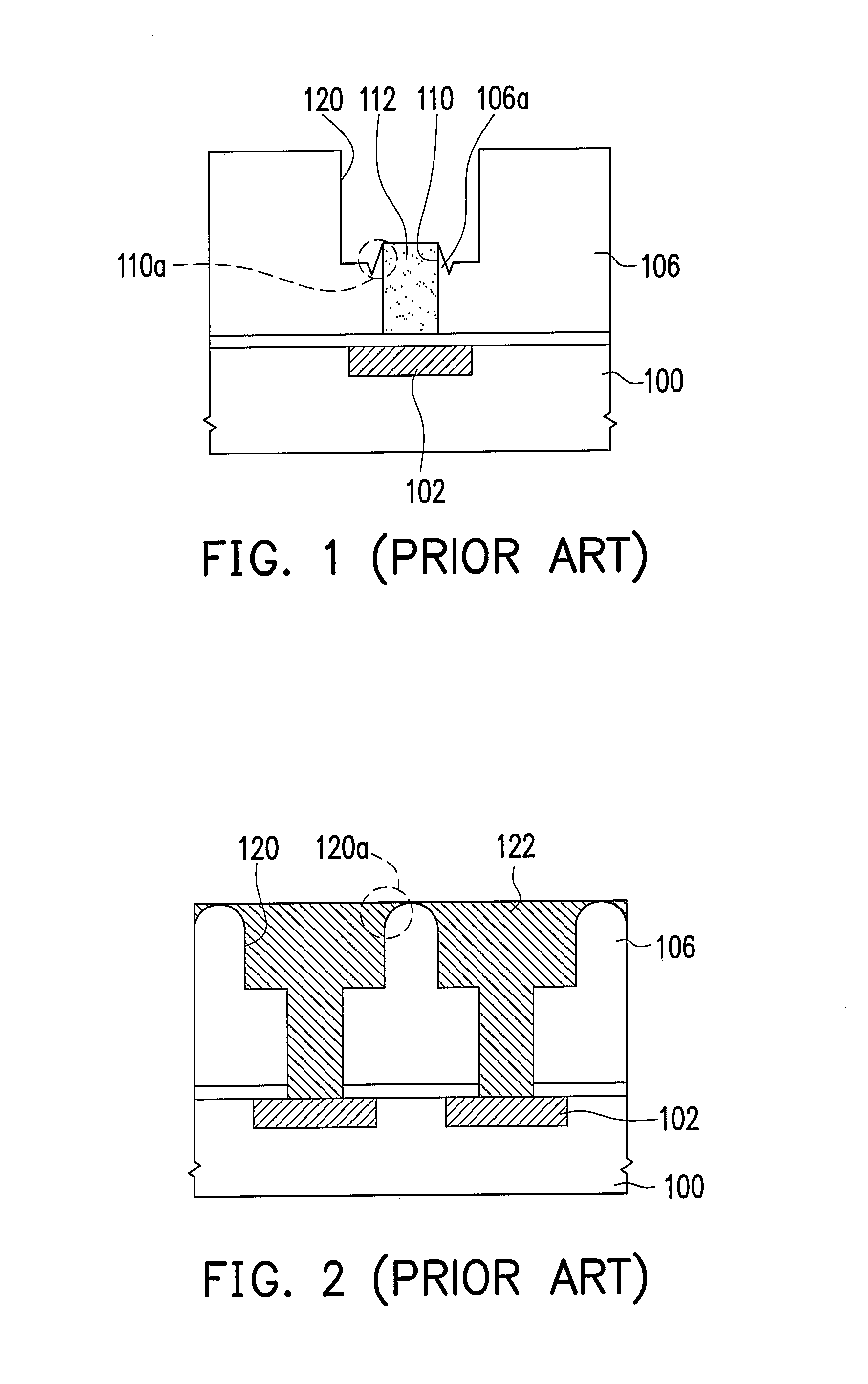

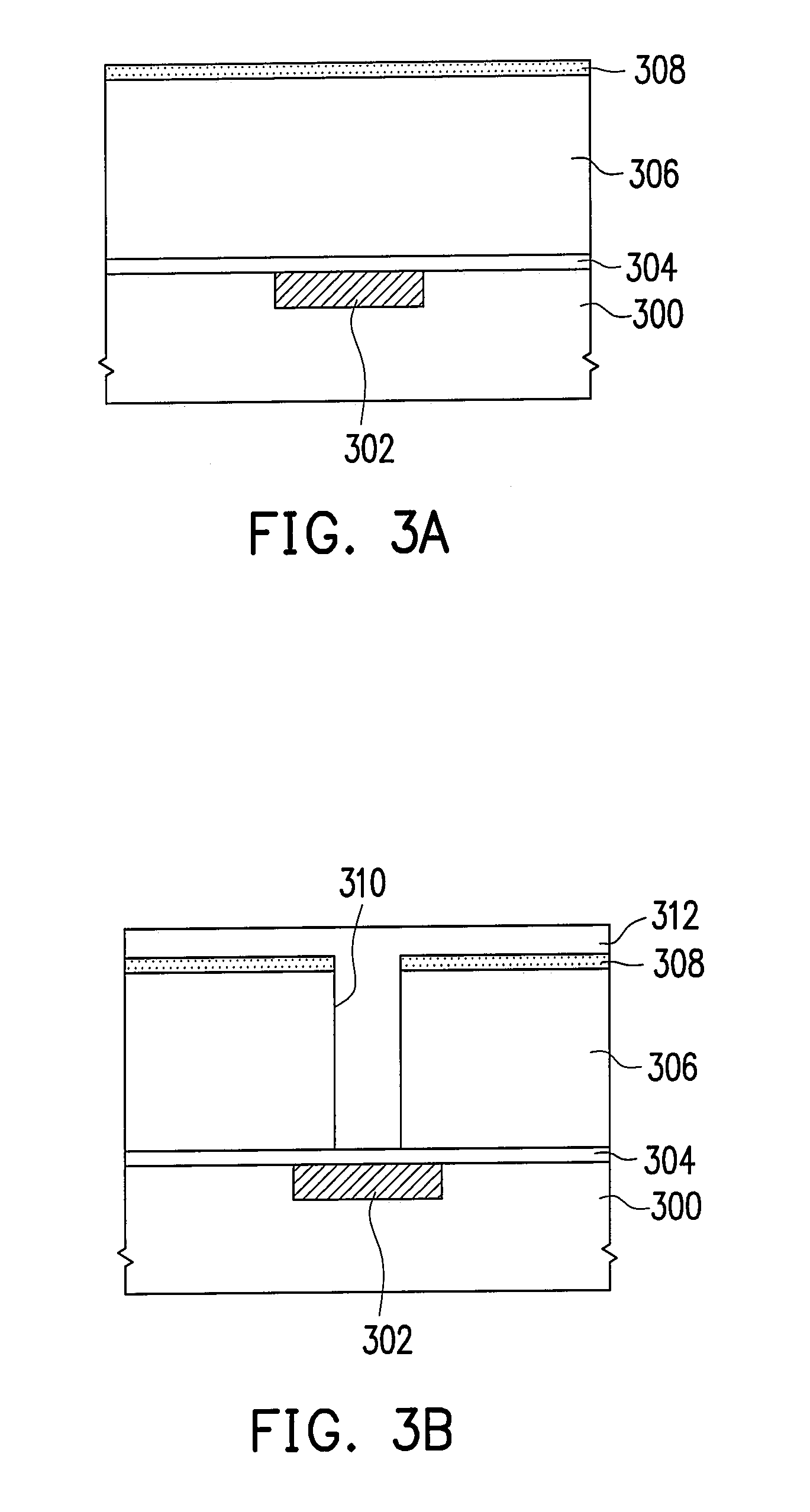

Method of forming composite opening and method of dual damascene process using the same

ActiveUS20080200025A1Avoid cornersAvoid formingSemiconductor/solid-state device manufacturingFilling materialsDielectric layer

A dual damascene process is provided. A dielectric layer is formed on a substrate and then a via opening is formed in the dielectric layer to expose a liner formed on the substrate. A gap fill (GF) layer is filled into the via opening and a resistant layer is formed on the substrate. A photolithographic process and an etching process are performed to form a trench in the dielectric layer and to remain the gap fill material having a top surface with a convex shape. In the etching process, an etching rate of the gap fill material layer is larger than that of the resistant layer. The gap fill material, the resistant layer, and the liner exposed by the via opening are removed. A conductive layer fills out the trench and the via opening. This invention is focusing on controlling etch-rate to avoid shielding effect when forming the composite opening.

Owner:UNITED MICROELECTRONICS CORP

Method of forming composite opening and method of dual damascene process using the same

ActiveUS7482266B2Avoid cornersAvoid formingSemiconductor/solid-state device manufacturingFilling materialsDielectric layer

A dual damascene process is provided. A dielectric layer is formed on a substrate and then a via opening is formed in the dielectric layer to expose a liner formed on the substrate. A gap fill (GF) layer is filled into the via opening and a resistant layer is formed on the substrate. A photolithographic process and an etching process are performed to form a trench in the dielectric layer and to remain the gap fill material having a top surface with a convex shape. In the etching process, an etching rate of the gap fill material layer is larger than that of the resistant layer. The gap fill material, the resistant layer, and the liner exposed by the via opening are removed. A conductive layer fills out the trench and the via opening. This invention is focusing on controlling etch-rate to avoid shielding effect when forming the composite opening.

Owner:UNITED MICROELECTRONICS CORP

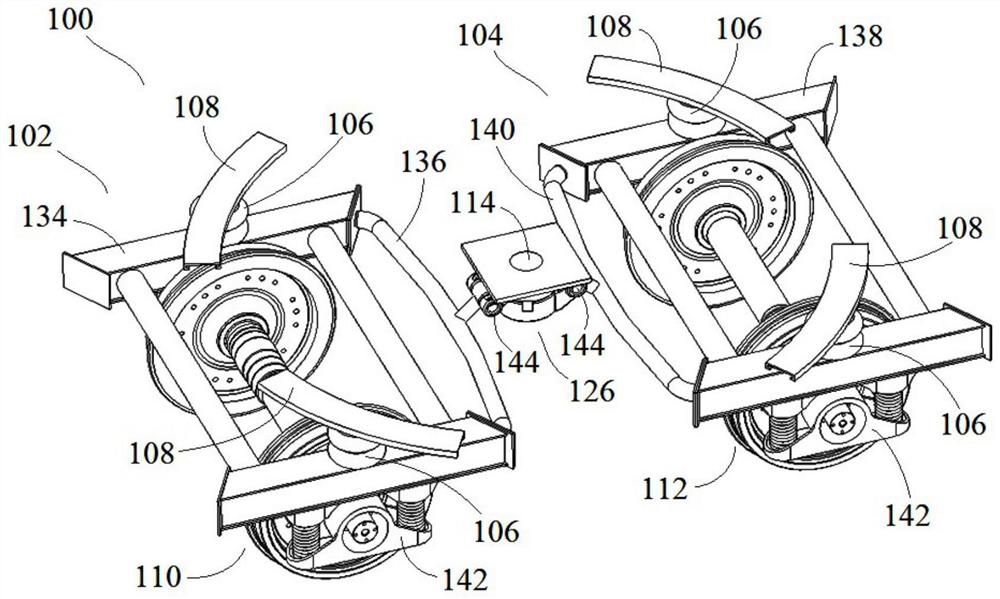

Radial bogie and rail vehicle

PendingCN111824197ARealize self-guiding radial adjustment functionAvoid cornersBogiesBogie-underframe connectionsBogieEngineering

The invention relates to the technical field of rail transit, and provides a radial bogie and a rail vehicle. The radial bogie includes a first framework, a second framework, a secondary damping device and a guide component, wherein a first wheel set is mounted on the first framework; the second framework is rotatably connected with the first framework and is provided with a second wheel set; thesecondary damping device is mounted on the first framework and the second framework; and the guide component is installed on a vehicle body of the railway vehicle, and the secondary damping device makes contact with the guide component and can slide along the guide component along with relative rotation between the first framework and the second framework. According to the radial bogie and the rail vehicle, at least swinging and fluctuation of the bogie in the running process can be improved, and therefore the snakelike running stability and the curve passing performance of the radial bogie can be better balanced.

Owner:CRRC IND INST CO LTD

Hardware steel bar bending device

InactiveCN111283030AInhibit sheddingImprove stabilityMetal-working feeding devicesShaping safety devicesStructural engineeringThermal treatment

The invention discloses a hardware steel bar bending device, and relates to the field of hardware steel bar bending devices. The hardware steel bar bending device comprises a table body, a first steelbar fixing seat is fixedly connected to the left side of the top end of the table body, a second steel bar fixing seat is arranged on the right side of the first steel bar fixing seat, one end of thesecond steel bar fixing seat is fixedly connected to one side of the top end of the table body, a hardware steel bar is connected to one end of the first steel bar fixing seat and one end of the second steel bar fixing seat in a clamped mode, a push block is connected to the other end of the hardware steel bar in a clamped mode, a semicircular sliding groove is connected to one end of the push block in a clamped mode, an electric push rod is fixedly connected to one end of the push block, the other end of the electric push rod is sleeved with a ground hole push rod box, and the bottom end ofthe electric push rod box is fixedly connected with a circular rotating block. According to the hardware steel bar bending device, micro-heating treatment can be carried out on hardware steel bars, sothat the hardware steel bars are soft and high in plasticity, and bending and cutting the hardware steel bars are conveniently carried out.

Owner:田清

Arrangement structure of lattice-form underground continuous wall

ActiveCN106087973AGood overall performanceEasy constructionArtificial islandsUnderwater structuresRebarSlurry wall

Owner:POWERCHINA CHENGDU ENG

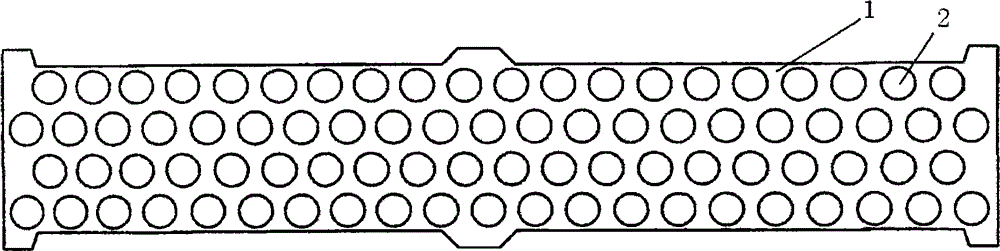

Preparation method of pre-tensioning method prestressed centrifugal concrete solid square pile

ActiveCN113478612AHigh pile strengthImprove durabilityCeramic shaping apparatusBulkheads/pilesPre stressCentrifugation

The invention discloses a preparation method of a pre-tensioning method prestressed centrifugal concrete solid square pile, which comprises the following steps: preparing a mold, and brushing a parting agent on the mold; mounting a reinforcement cage in the mold, and arranging a tensioning end plate; feeding prepared concrete into the mold; conducting prestressed tensioning on the reinforcement cage according to the designed tensioning stress, and then carrying out locking and anchoring; putting the mold which is fed with the concrete on a centrifugal machine for centrifugal forming treatment; after centrifugation is completed, forming a central hollow core in the center of the square pile, and pouring out residual slurry separated from the concrete completely; conducting secondary filling on the center of the pile through high-strength-grade concrete, filling the center hollow core through secondary material pumping, and forming the square pile; performing steam curing on the formed solid square pile; and releasing and demolding the cured solid square pile. According to the method, the strength of the pile body of the solid square pile is high, and the phenomena that the four corners of the solid square pile in a non-centrifugal production process fall off and are unfilled and the strength difference of the upper section and the lower section of the pile body is large due to concrete vibration are avoided.

Owner:南京汇联建材科技发展有限公司

Construction method of Larsen steel sheet pile

PendingCN114108601AThe layout is straight and tidyAvoid cornersBulkheads/pilesArchitectural engineeringRebar

The invention discloses a construction method of a Larsen steel sheet pile. The construction method comprises the following steps of determining a base line, determining a pile position, driving the steel sheet pile, taking measures before earth excavation, completing civil construction and pulling out the steel sheet pile. The plane arrangement shape of the foundation pit dado steel sheet pile needs to be straight and tidy as much as possible, irregular corners are avoided, and utilization and supporting arrangement of standard steel sheet piles are facilitated. All peripheral sizes accord with the sheet pile modulus as much as possible. During the whole construction period, in the construction operations of earth cutting, hoisting, reinforcing steel bar tying, concrete pouring and the like, collision of the support is strictly prohibited, the support is prohibited from being dismantled at will, cutting and electric welding on the support are prohibited at will, and heavy objects are not required to be placed on the support.

Owner:NANTONG UNIVERSITY

High-strength foam brick and preparation method thereof

The invention discloses a high-strength foam brick. The high-strength foam brick is characterized by being prepared from the following raw materials in parts by weight: 30-40 parts of waste glass, 6-8 parts of rutile titanium dioxide, 5-10 parts of high aluminum powder, 8-12 parts of zircon power, 4-8 parts of alumina silicate fiber, 2-4 parts of triisopropanolamine, 4-6 parts of ethylene diamine tetraacetic acid, 1-2 parts of erythritol, 1-2 parts of citric acid, 1-2 parts of bone glue, 0.5-1 part of seaweed gel, 1-2 parts of sodium lignosulphonate, 0.5-1 part of sodium lignin sulfonate, 2-4 parts of coconut oil fatty acid glycine potassium, 6-10 parts of composite filler and 40-60 parts of water. According to the foam brick disclosed by the invention, through strength improvement, the crushing resistance and the fracture resistance are improved; the phenomena such as edge failure and fracture are avoided; the product quality is relatively good; and the durability is relatively high.

Owner:HEFEI KANGLING HEALTH TECH

Intelligent forming, stacking and coking production method

ActiveCN111187634ASignificant energy savingSignificant emission reductionStacking articlesSpecial form destructive distillationCoal briquetteCoal

The invention relates to an intelligent forming, stacking and coking production method, which specifically comprises the steps of coal sample pretreatment, forming, stacking, coal charging and coke quenching, wherein the forming and stacking processes are intelligent, the forming in the intelligent forming specifically comprises the steps of raw material metering feeding, homogenizing, mold filling, forming and demolding to form a set of intelligent control system, the length, the width and the height of the formed coal briquettes are 500-1000 mm, 400-600 mm and 400-650 mm respectively, the precision of the size of the formed coal briquettes is within + / -2 mm, the intelligent stacking adopts gantry type stacking, the gantry type stacking is composed of a stacking bracket, a stacking lifting table and plural sets of stacking grippers, and the length, the width and the height of the stacked coal walls are 12000-2500 mm, 400-3400 mm and 1000-10000 mm. The method has the characteristics ofsimple process flow and high automation degree, and has advantages of remarkable energy saving, environment protection, emission reducing, yield increasing and social and economic benefits.

Owner:山西博嘉慧科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com