Disc film dehumidifier and dehumidifying system

A dehumidifier and disc type technology, applied in the field of disc type membrane dehumidifier and dehumidification system, can solve the problems of pipeline and equipment corrosion, reduce heat exchange efficiency, air entrainment of hygroscopic agent, etc., to avoid corrosion, enhance disturbance, Avoid heat transfer efficiency and hygroscopic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

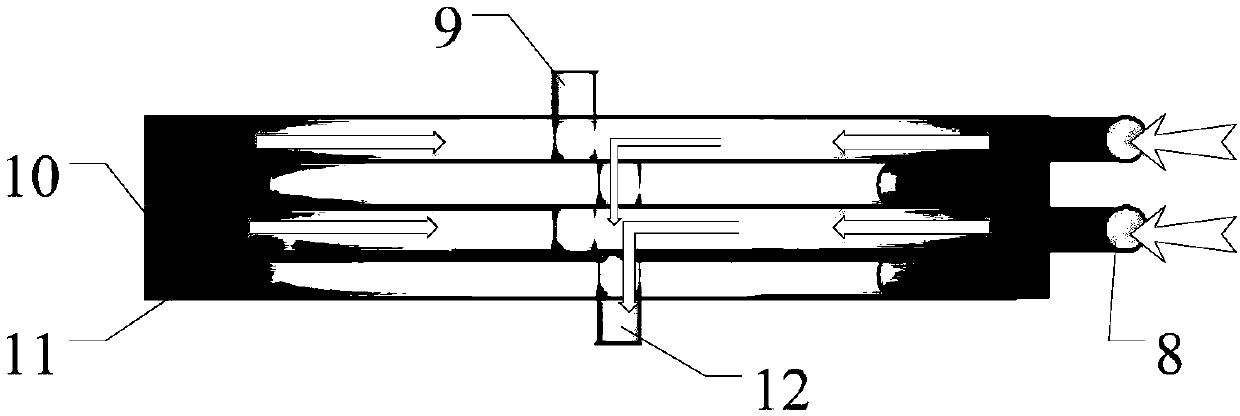

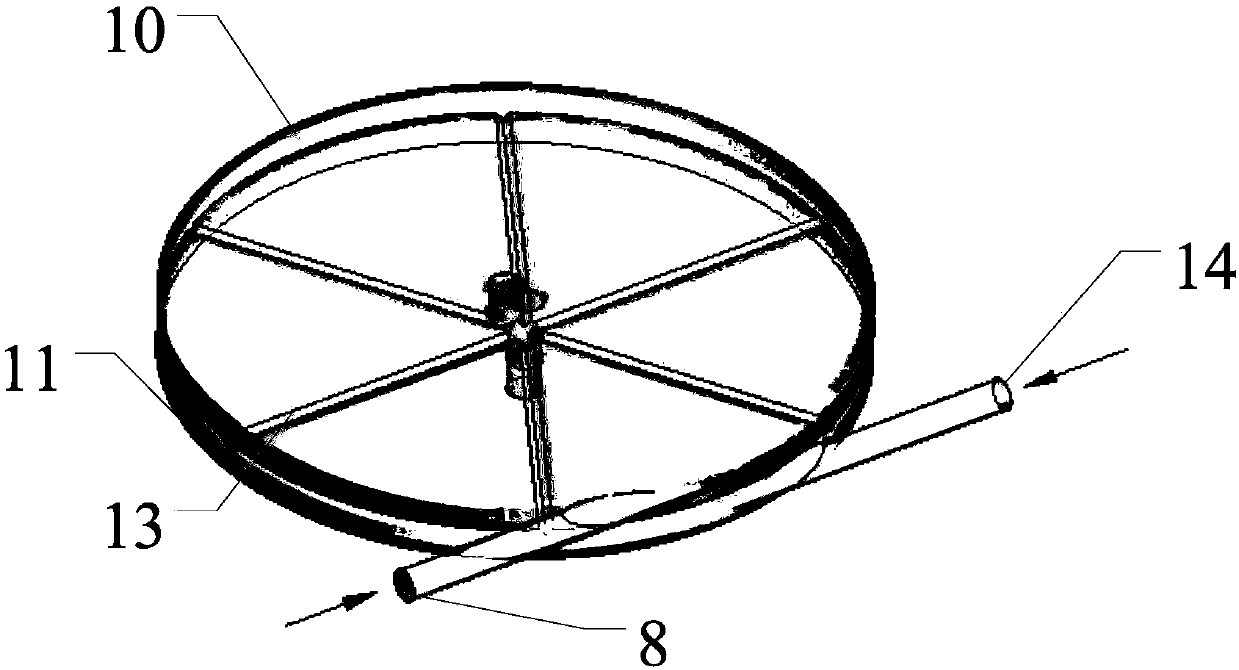

[0049] Such as figure 2 ,with image 3 As shown, the disc membrane dehumidifier is composed of multiple solution channels and air channels alternately arranged and combined. Two adjacent channels are separated by a semi-permeable membrane, and a solution channel 10 and an air flow A unit composed of channel 11 will be explained. When dehumidifying, the dehumidifying solution enters the solution flow channel 10 from the liquid inlet 8, and the dehumidifying solution flows in a vortex counterclockwise direction in the flow channel, and finally flows out of the flow channel at the center of the flow channel. Then it flows through the next solution flow channel or flows out of the disc membrane dehumidifier from the liquid outlet 12; at the same time, the outdoor fresh air flows into the air flow channel 11 from the air inlet 14 and the inlet direction of the air inlet 14 is in the direction of the liquid inlet 8 At 180°, the air enters the flow channel and flows clockwise in a vor...

Embodiment 2

[0054] The main technical solution in this embodiment is the same as that in Embodiment 1. For the features that are not explained in this embodiment, the explanation in Embodiment 1 is adopted, which will not be repeated here. Such as Figure 5 As shown, the difference between this embodiment and the first embodiment is that a coil-type cooling tube 15 is installed in each solution flow channel 10.

[0055] When working, the dehumidifying solution absorbs water vapor in the air, and the latent heat of water vapor causes the temperature of the dehumidifying solution to rise and the dehumidification efficiency to decrease. Therefore, when the dehumidifier is working, cooling water or cooling is passed into the coiled cooling pipe 15 at the same time. The gas takes away the dehumidification heat of the dehumidification liquid, which is the dehumidification liquid to restore higher dehumidification efficiency.

Embodiment 3

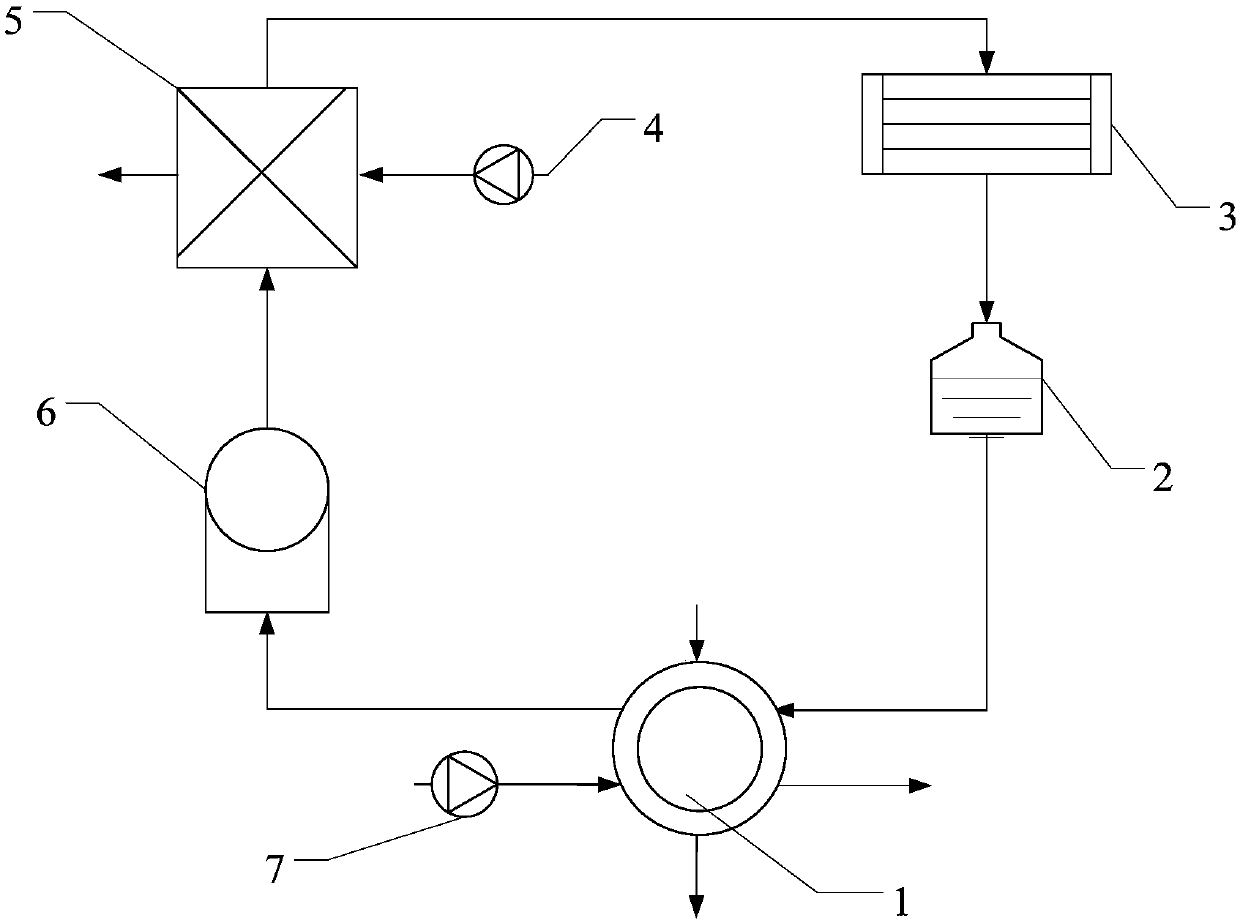

[0057] Such as figure 1 As shown, a dehumidification system includes a disc membrane dehumidifier 1, a liquid storage tank 2, a cooler 3, a second induced draft fan 4, a regenerator 5, a heater 6 (a solar heater is selected), and an induced draft fan 7. . During operation, the concentrated dehumidifying solution in the liquid storage tank 2 flows into the disc membrane dehumidifier 1. The dehumidified dehumidifying solution absorbs water vapor so that the concentration becomes low, and it flows through the heater 6 for heating, which is required for regeneration. After reaching the temperature, it flows into the regenerator 5 for concentration regeneration. The dehumidifying solution after the regenerator 5 is restored to a concentrated solution. At this time, the solution temperature is higher and the dehumidification efficiency is lower. It flows through the cooler 3 for cooling, and finally flows into the liquid storage tank 2 is stored in the dehumidifier 1 again for dehumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com