Ceramic-matrix high-temperature fused-salt phase-change heat-storage type off-peak electricity utilizing and steam generating device

A technology of steam generating device and ceramic substrate, which is applied in the field of non-oxide ceramic substrate molten salt phase change high-temperature heat storage valley electricity utilization and steam generating device, steam generating device, which can solve the problem that heat transfer oil is not suitable for high temperature conditions, Unstable release process, low heat storage temperature, etc., to achieve good corrosion resistance, reduce heat dissipation loss, and high heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical principles, technical solutions and advantages of the present invention more clearly in detail, the present invention will be described more comprehensively below in conjunction with the accompanying drawings.

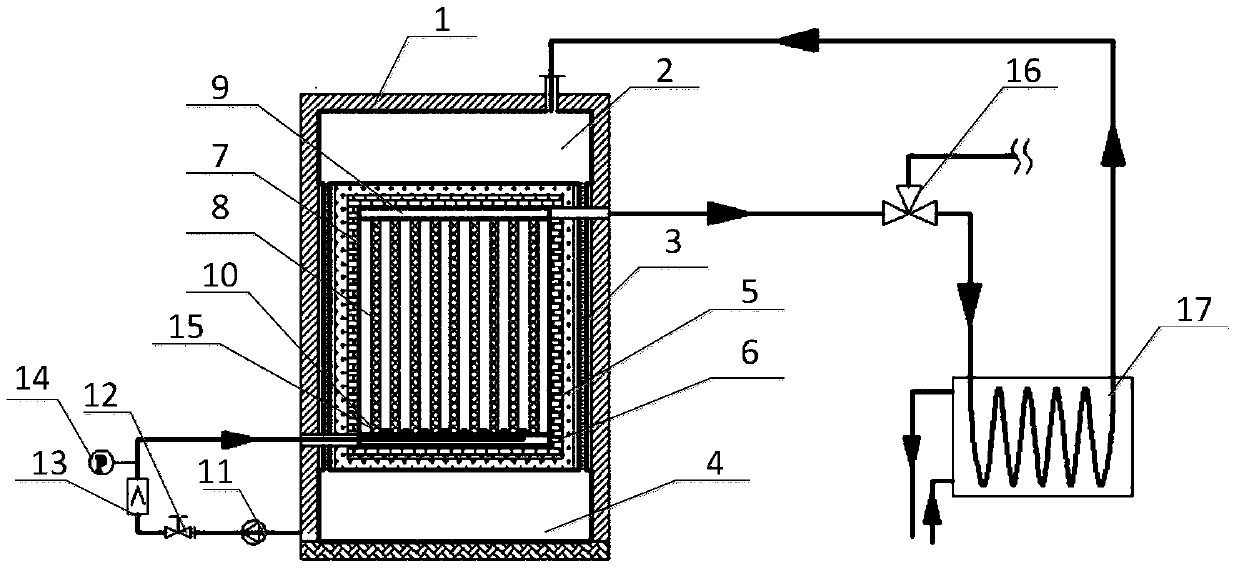

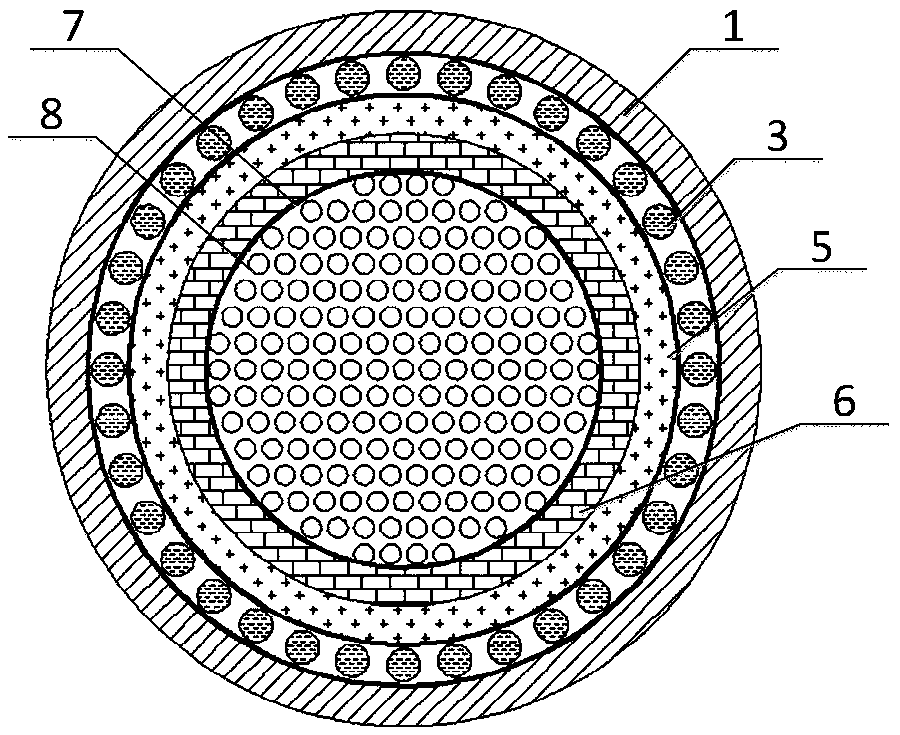

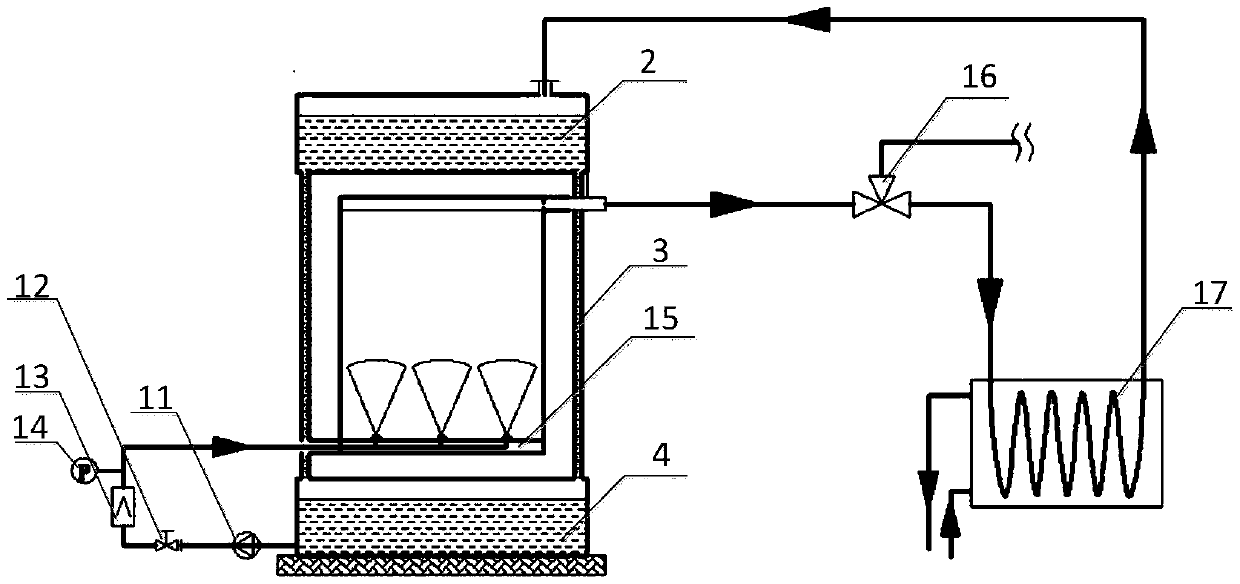

[0020] Such as figure 1 , figure 2 and image 3 As shown in this embodiment, one of the ceramic matrix molten salt phase change high-temperature heat storage type valley electricity utilization steam generating devices disclosed in the embodiment of the invention mainly includes the main body of the heat storage pile, the heat preservation structure of the heat storage pile, the heat transfer medium system and the heat exchanger. heat system. The heat storage reactor is connected to the heat exchange system through steam pipes, and the high-temperature saturated steam in the steam pipes is adjusted through the three-way valve to adjust the flow distribution, which can meet the domestic hot water and steam supply for process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com