Patents

Literature

121results about How to "Achieve reasonable utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

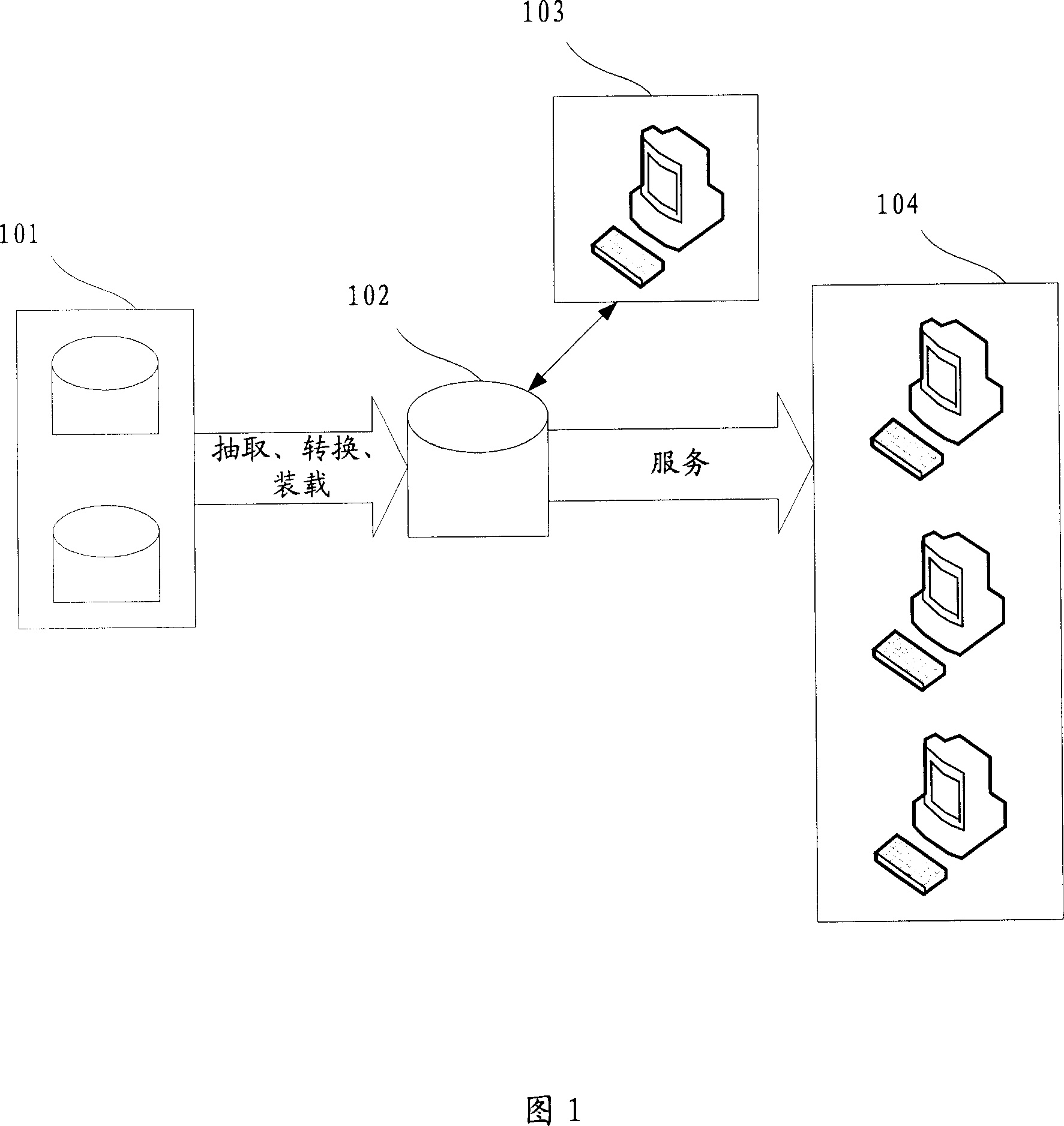

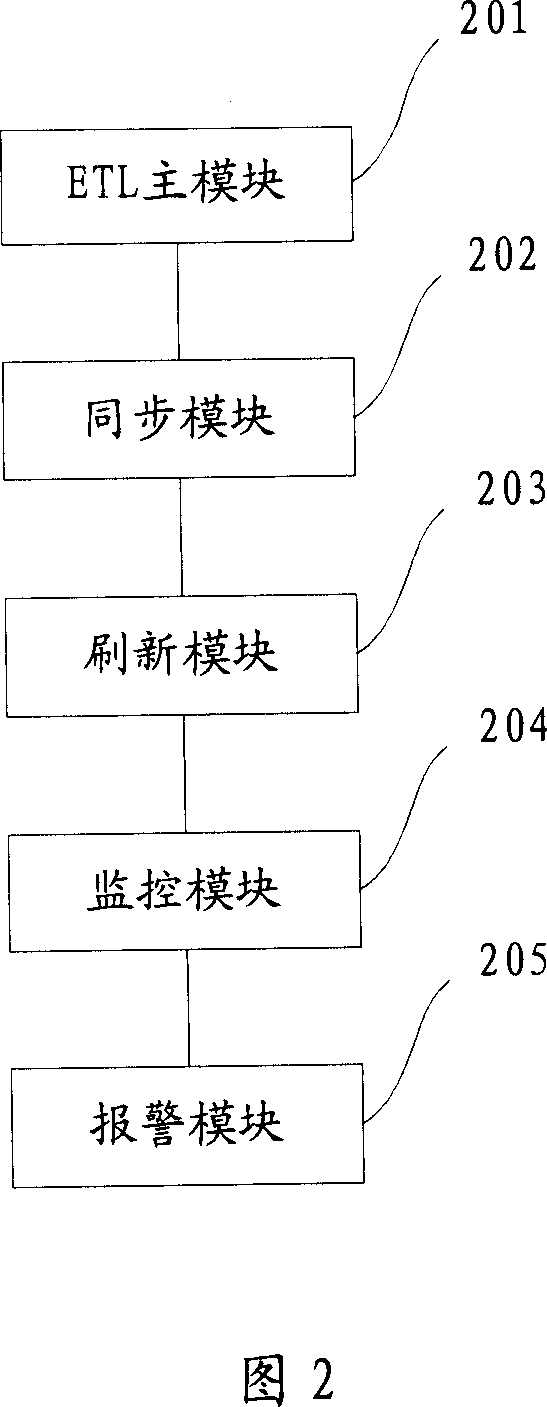

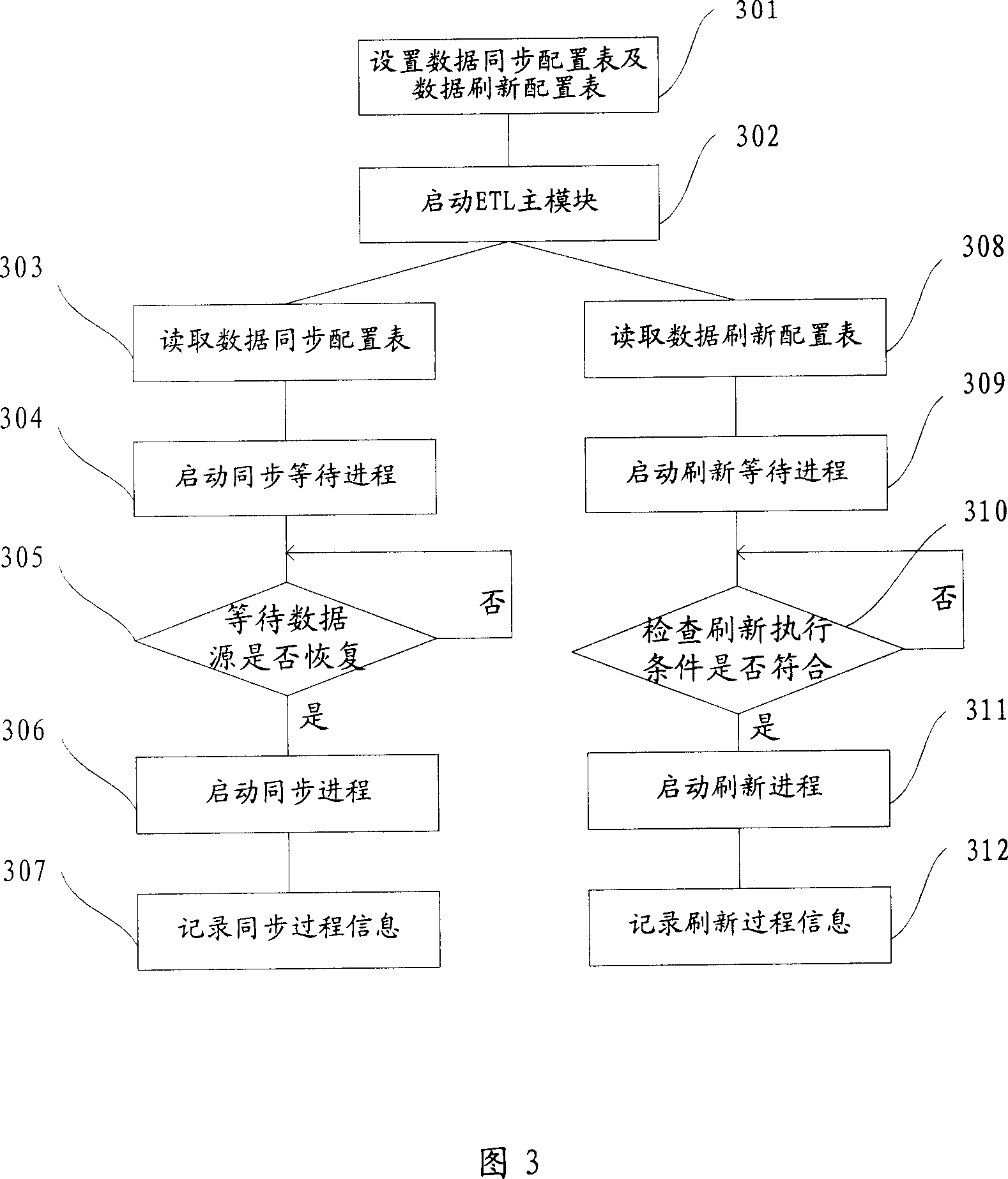

Data processing method and system of data library

InactiveCN101105793ASolve the problem of inconsistent synchronization timeGuaranteed processing timeMultiprogramming arrangementsSpecial data processing applicationsData synchronizationData warehouse

The invention discloses a data handling method and a system in database to solve the problem that the single course treatment requires great amount of time and manpower cost and can not handle abnormities in ETL process. The method includes: arrange data synchronous configuration table and data refreshing configuration table; configuration information of the corresponding data source, start up a plurality of synchronous courses in parallel; refreshing grades, and start up a plurality of refreshing courses to make sequential synchronous and refreshing treatment on a plurality of data sources. The invention also includes parallel monitoring treatment; periodically checking synchronous refreshing information table; any abnormity discovered should be recorded in the alarm information table; the invention also includes parallel alarm treatment: Periodically checking alarm information table; alarm information should be sent immediately for new abnormities. The invention enhances the efficiency of synchronization and refreshing and saves a great deal of time and manpower cost. Real-time monitoring ensures timely handling of problems and safe, reasonable, and stable operation of database.

Owner:ALIBABA GRP HLDG LTD

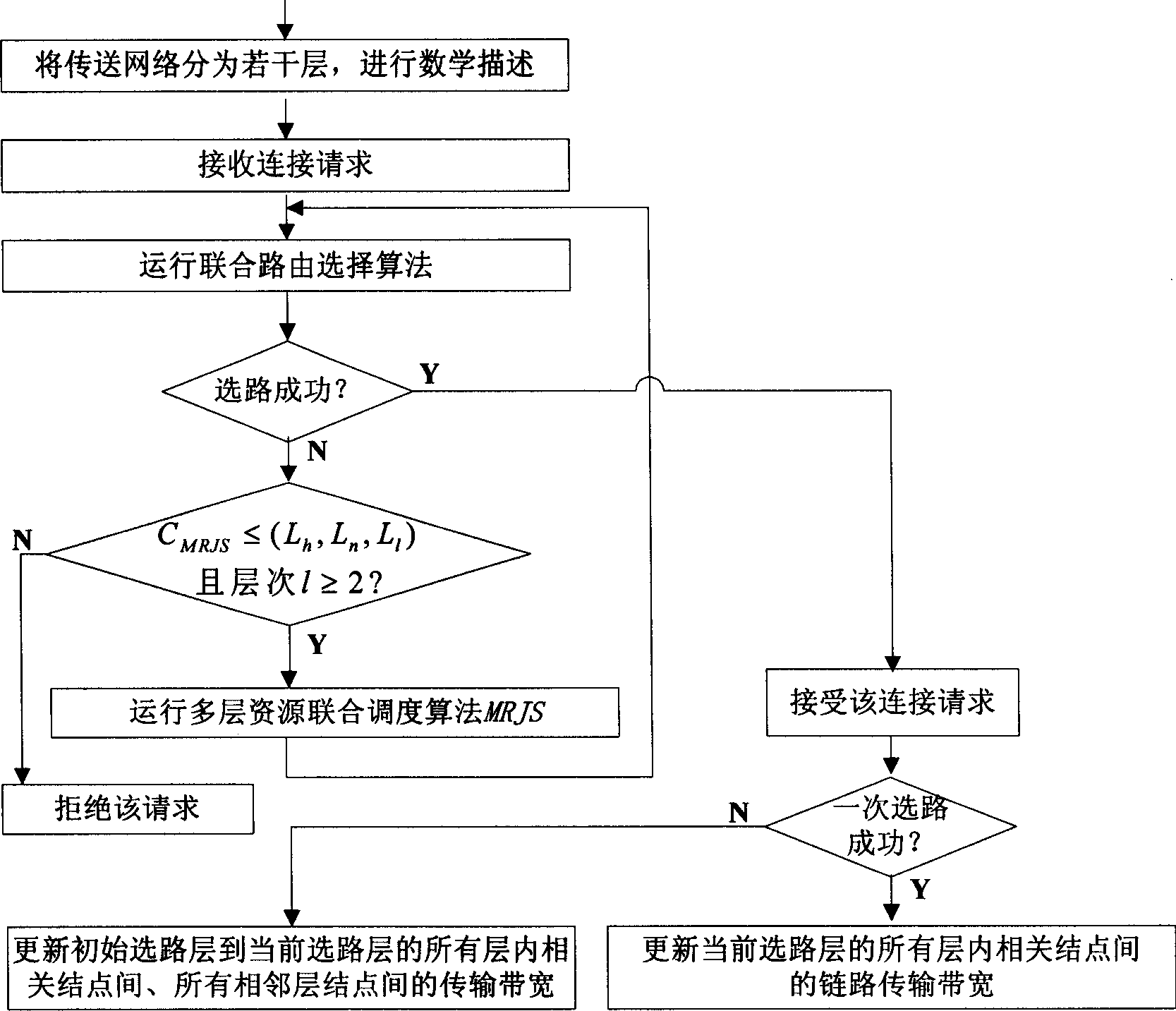

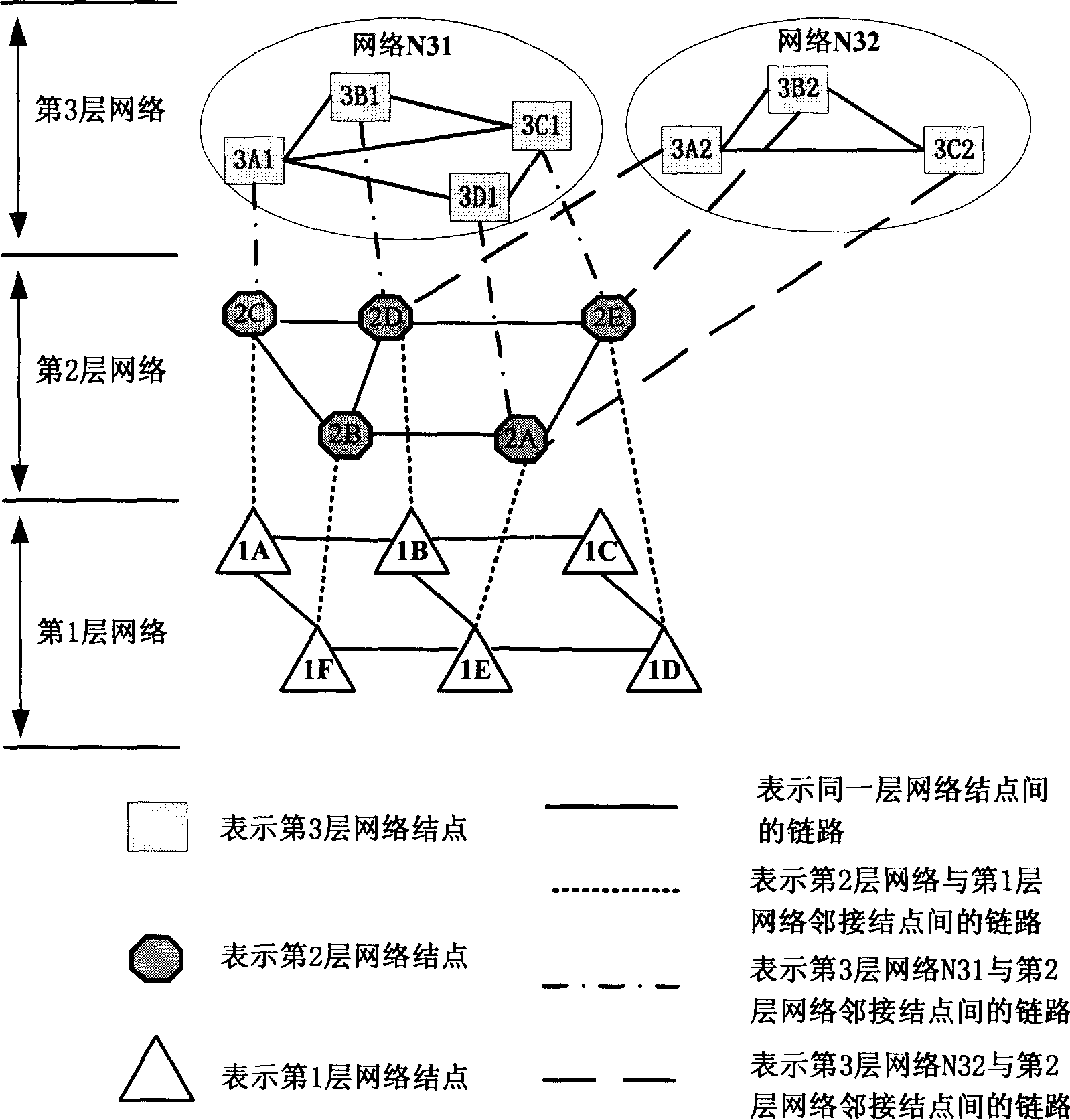

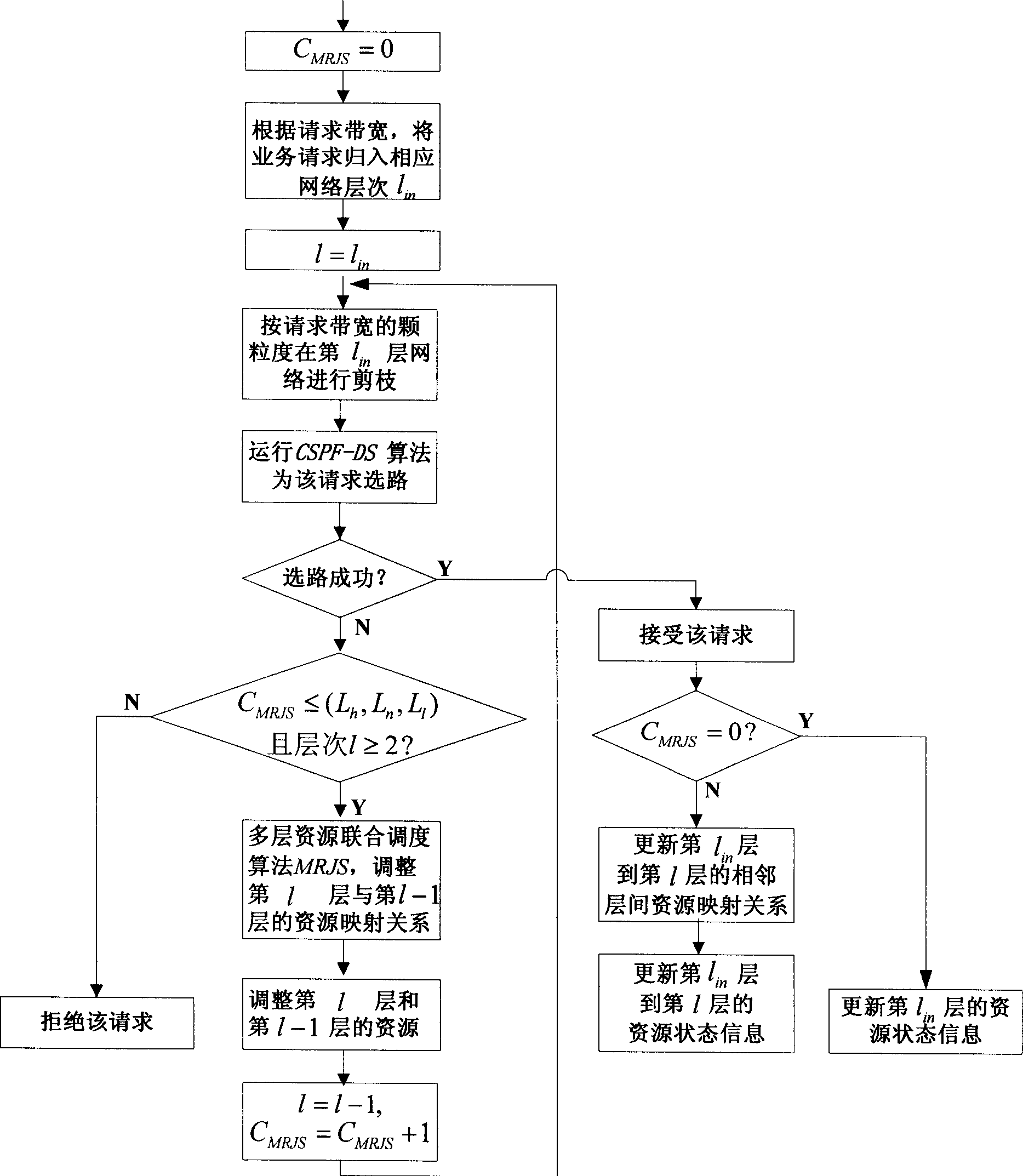

Resource utilization optimization method for transfer network

InactiveCN1688133AAchieve mutual coordinationMeet business needsData switching networksBandwidth utilizationTransmission delay

This invention discloses a method for laminating transmission nets, selecting joint routes and jointly optimizing multi-layer resource including the following steps: 1, expressing layering to the network, 2, jointly selecting routes according to the parameters of service request bandwidth and grade, link bandwidth usability, adjacent inter layer link transmission rate and hops, 3, calling the MRIS method based on the result of jointly selecting routes, 4, periodically calling the MRJS method to optimize the resource configuration, 5, carrying out the algorithm operation.

Owner:XIDIAN UNIV +1

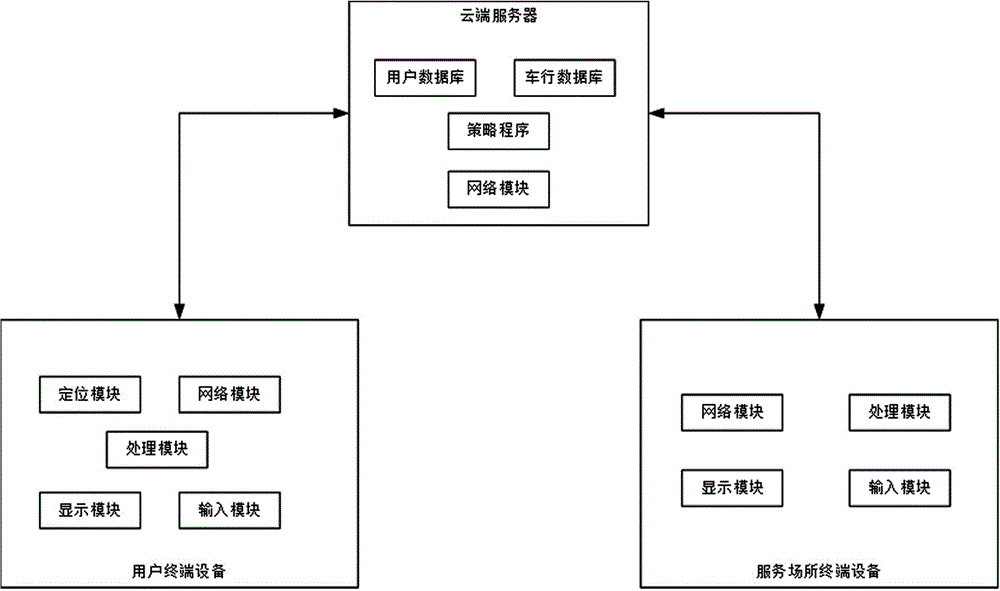

Field service reservation intelligent queuing system and method thereof based on Internet and geographic position

InactiveCN104598975ARational use of resourcesStrong economic and social significanceReservationsChecking apparatusGeolocationTime information

Provided is a field service reservation intelligent queuing system and method thereof based on Internet and geographic position. The system comprises a cloud server and user remote terminals and service field remote terminals which are connected with the cloud server. The plurality of user remote terminals and service field remote terminals are provided, the user remote terminals achieves information real-time interaction with the service field remote terminals through a cloud server, the cloud server arranges users into a service field service queue according to the less-time-consuming principle on the basis of information of the user remote terminals and the service field remote terminals, and publishes the queue information to the user remote terminals and the service field remote terminals in real time. By means of the system and method, real-time information interaction between the users and the service field is achieved, the resources of two parties are configured in real time, reasonable utilization of the resources is achieved in the most reasonable mode, great convenience is provided for the users, and the system and method has high economical and social meanings.

Owner:XIAN SITEPLANES NETWORK TECH

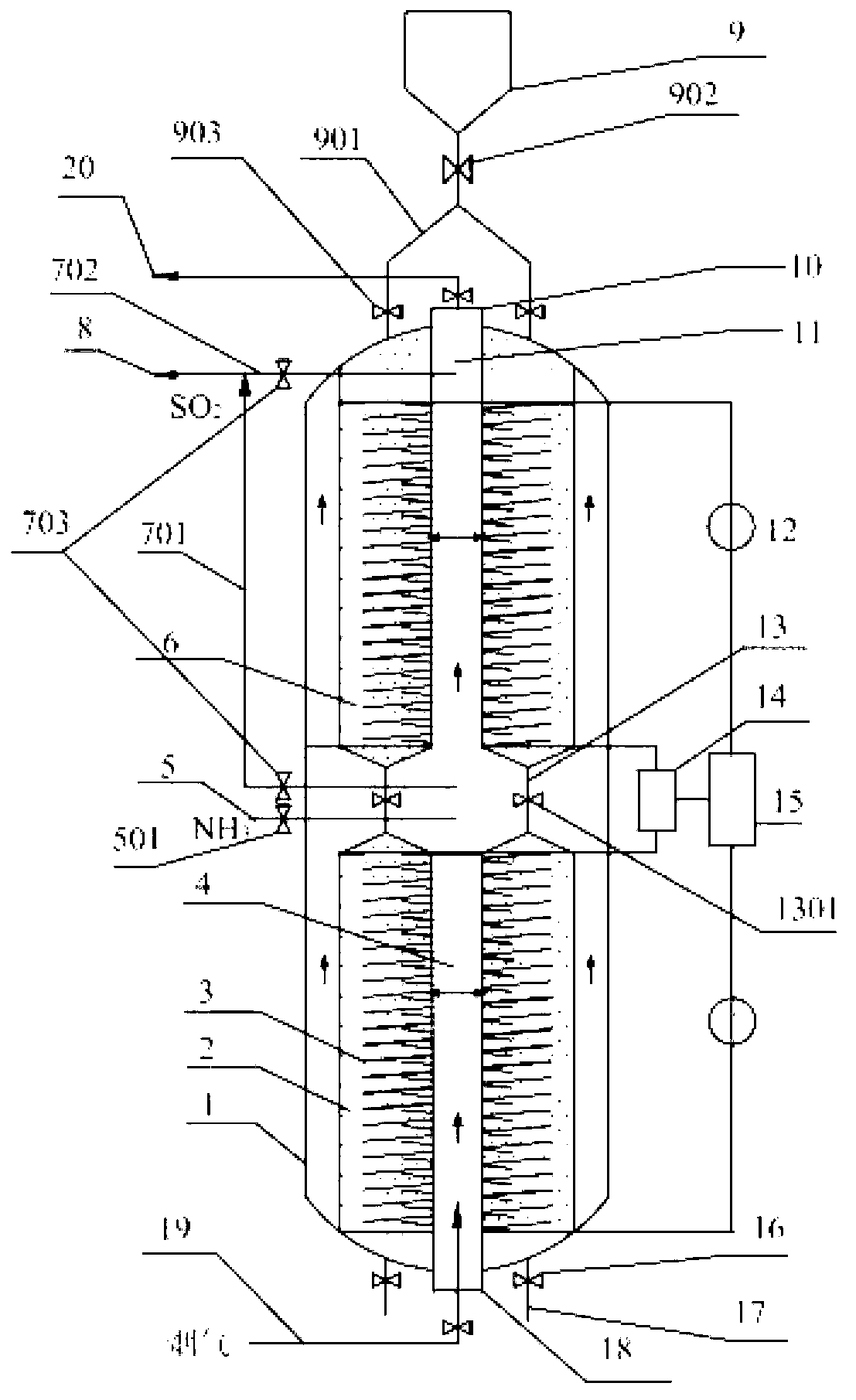

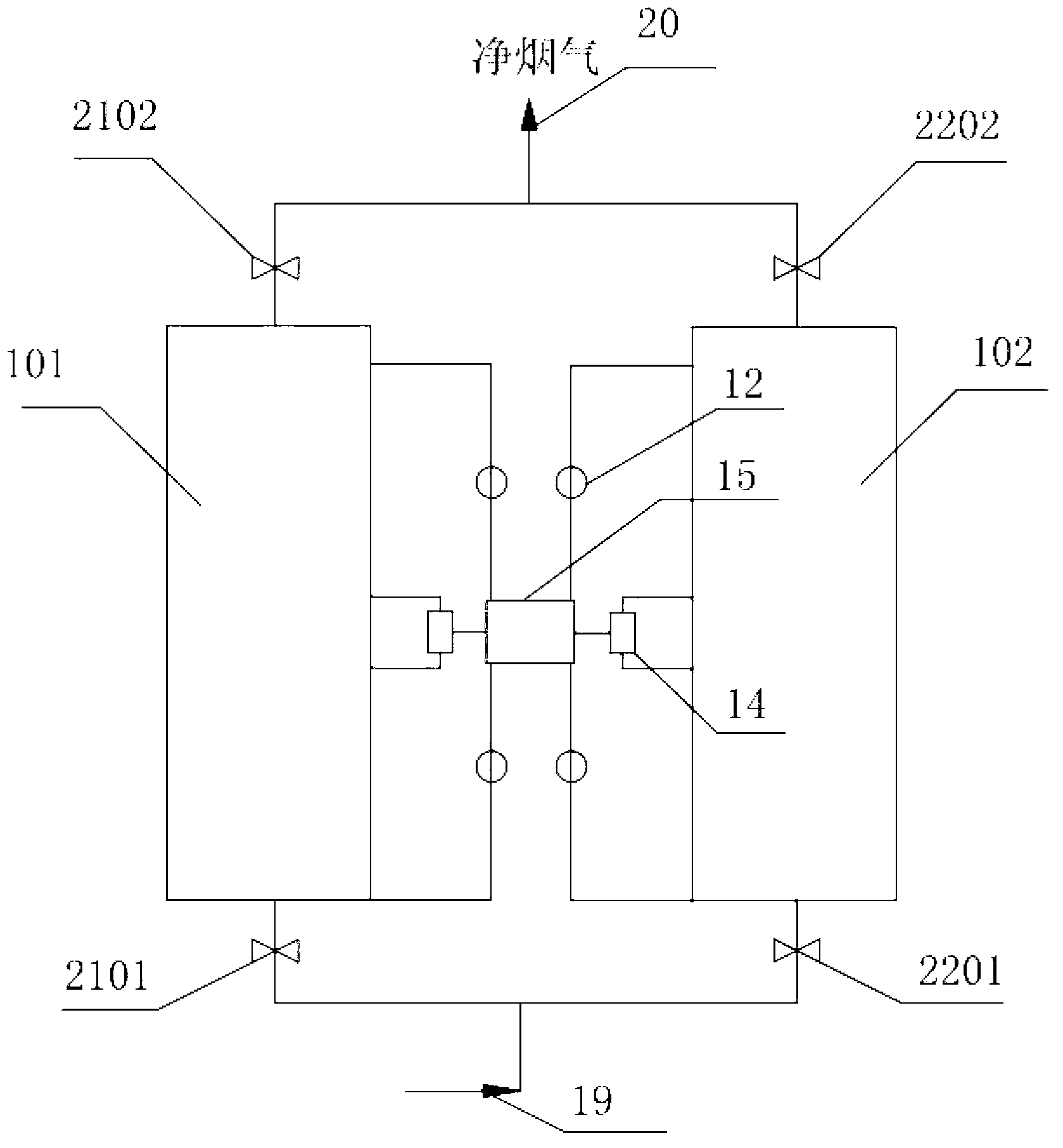

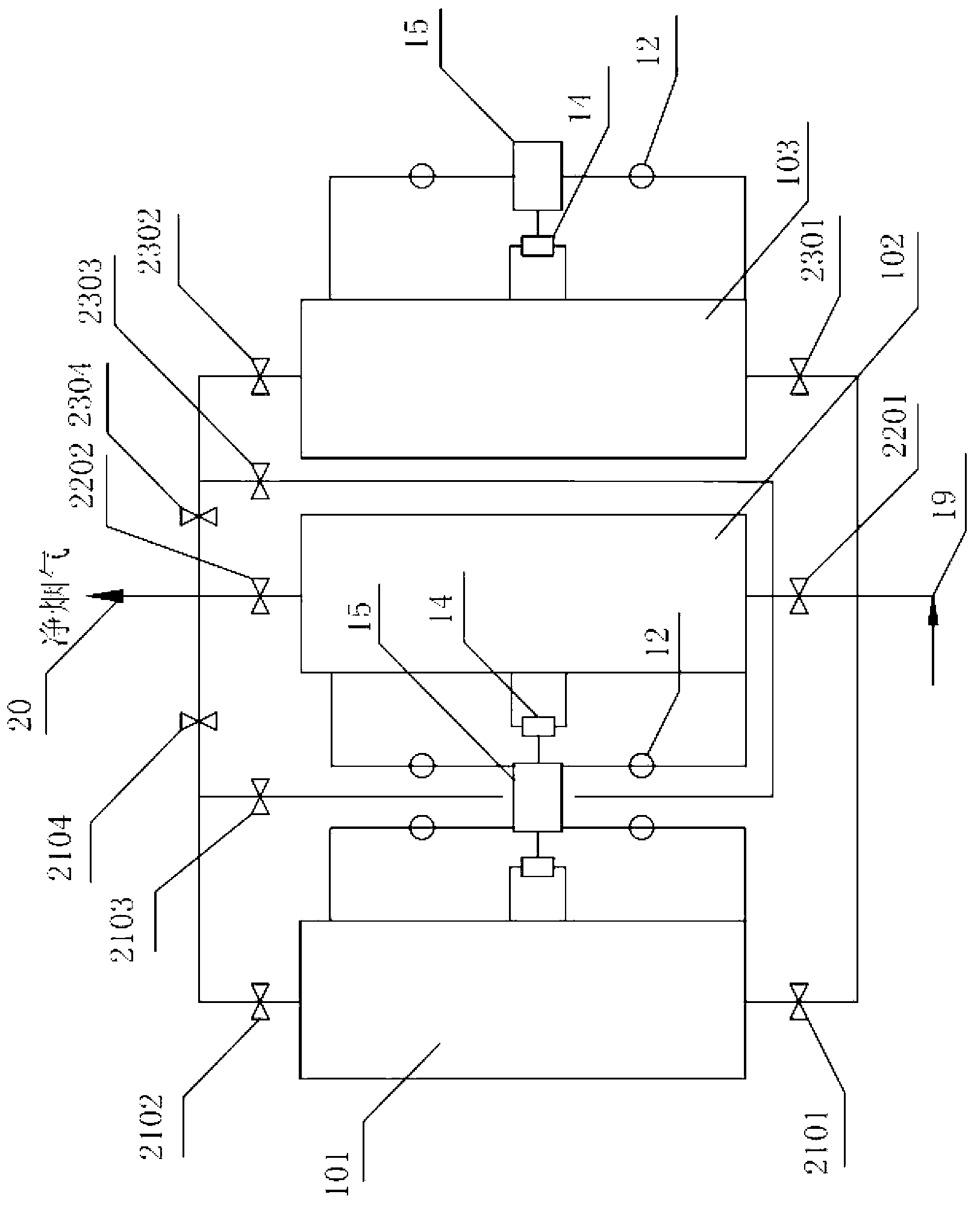

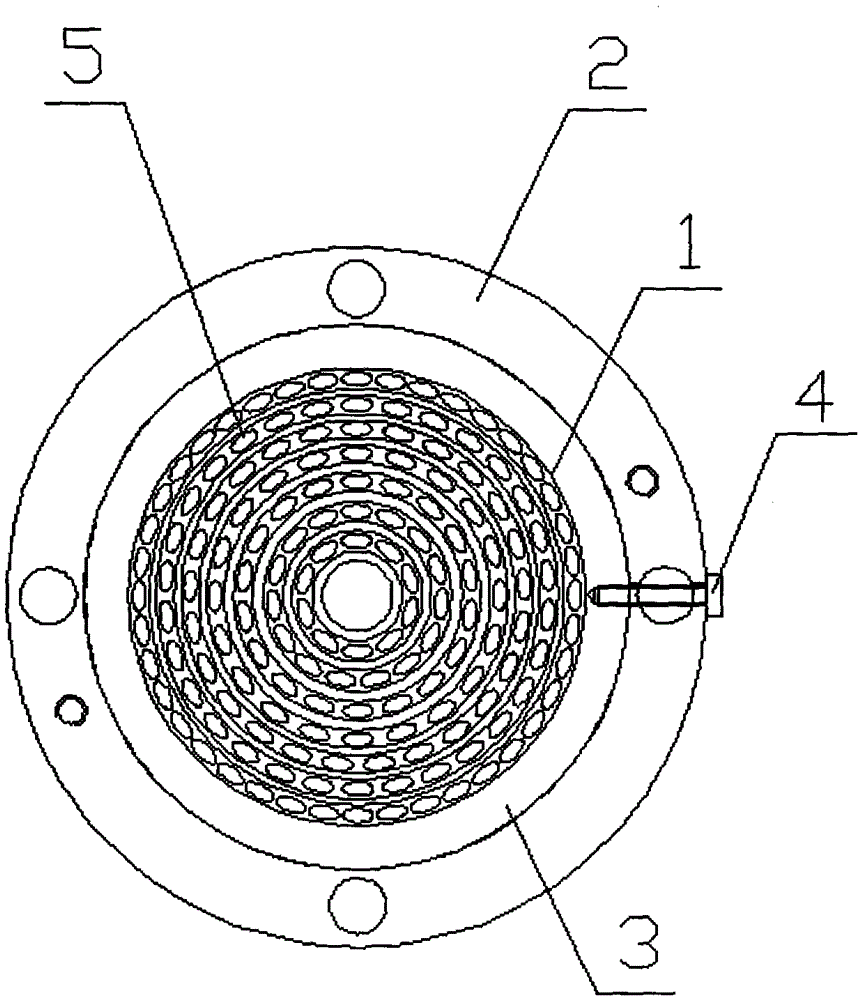

Flue gas cleaning system capable of switching pollutant desorption technology and adsorbent regeneration technology and method thereof

ActiveCN103007679AIncrease investment costNot easy to repairDispersed particle separationFlue gasDesorption

The invention provides a flue gas cleaning system capable of switching a pollutant desorption technology and an adsorbent regeneration technology. The system comprises two or more fixed bed reactors, a regenerative heating device which is used for adsorbent regeneration, and a to-be-cleaned flue gas valve and a flue gas cleaning valve which are used for controlling switching between the pollutant desorption technology and the adsorbent regeneration technology, wherein each of the fixed bed reactor is internally provided with a central tube connected with a flue gas inlet, as well as a first adsorption layer and a second adsorption layer which are used for cleaning flue gas and arranged on the outer side of the central tube; and the upper end of the central tube is connected with a flue gas outlet. The invention further discloses a flue gas cleaning method using the system. The system can be used for performing the flue gas pollutant desorption technology and the adsorbent regeneration technology in one fixed bed reactor, and achieve the switching between the pollutant desorption technology and the adsorbent regeneration technology in the different fixed bed reactors.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Method for producing high-purity nano-zinc oxide by ammonia method using electrolytic zinc acid-leaching residues

ActiveCN102863007AGrowth inhibitionSmall particle sizeZinc oxides/hydroxidesNanotechnologyElectrolysisZno nanoparticles

The invention discloses a method for producing high-purity nano-zinc oxide by an ammonia method using electrolytic zinc acid-leaching residues. The method comprises the following steps of: adding slaked lime being 1-5% of the mass of electrolytic zinc acid-leaching residues before a leaching step to perform activation, then leaching with ammonia-ammonium bicarbonate solution, adding 0.3-0.5kg of sodium fluorosilicate to per cubic meter of ammonia-ammonium bicarbonate solution, and refining after performing purification and impurity removal. According to the method for producing high-purity nano-zinc oxide by ammonia method using electrolytic zinc acid-leaching residues, the electrolytic zinc acid-leaching residues can be leached efficiently, the high-purity nano-zinc oxide with the purity up to above 99.7% can be obtained, and the high-purity nano-zinc oxide has high practical value and economic value; all the valuable and harmful heavy metals in the electrolytic zinc acid-leaching residues are leached and utilized, so that the obtained final leaching residues are converted from electrolytic zinc acid-leaching residues as high hazard wastes into ordinary solid wastes, the environment is protected, and the resources are rationally utilized.

Owner:SICHUAN JUHONG TECH

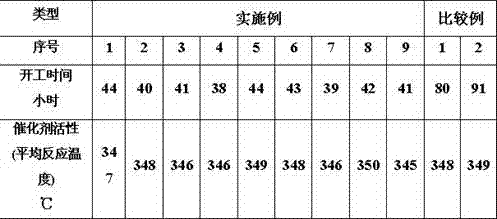

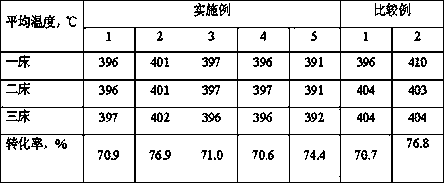

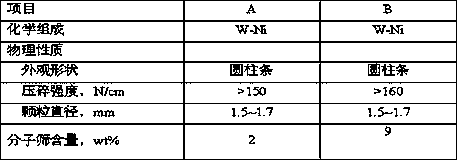

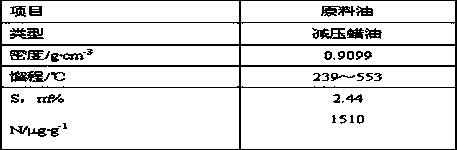

Hydrocracking startup method

ActiveCN107446616AIntensified vulcanization process inside the extenderHigh activityCatalyst protectionMolecular sieve catalystsHydrogenLow nitrogen

The invention discloses a hydrocracking startup method. The hydrocracking startup method comprises the following steps: introducing low-nitrogen startup oil, hydrogen and a sulfurizing reagent into a hydrocracking unit; then carrying out sulfuration on a hydrocracking catalyst at a constant temperature of 220 to 260 DEG C; after the content of hydrogen sulfide in to-be-cycled hydrogen reaches 3000 to 5000 ppm, reducing the adding rate of the sulfurizing reagent and increasing the bed temperature of the hydrocracking catalyst; when the bed temperature of the hydrocracking catalyst reaches 310 to 330 DEG C, increasing the adding rate of the sulfurizing reagent; and continuing constant-temperature sulfuration, then allowing the temperature to rise to 340 to 350 DEG C and introducing raw oil for a reaction, wherein the amount of the hydrocracking catalyst is 0.5 to 8% by weight. The method provided by the invention is short in time for startup, raw material switching and entry into a stable production state, avoids the consumption of a passivating agent and potential hazards during ammonia injection in the startup process, reduces energy consumption, and decreases pollution of the passivating agent to environment and harm of the passivating agent to human beings.

Owner:CHINA PETROLEUM & CHEM CORP +1

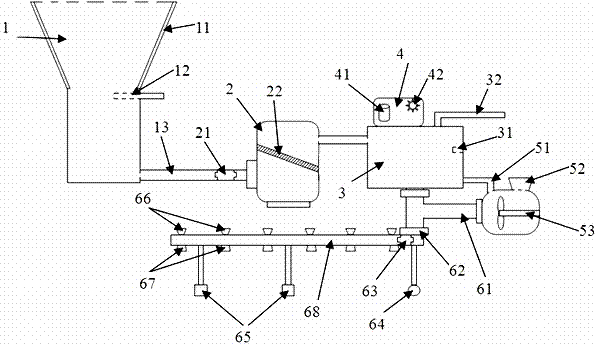

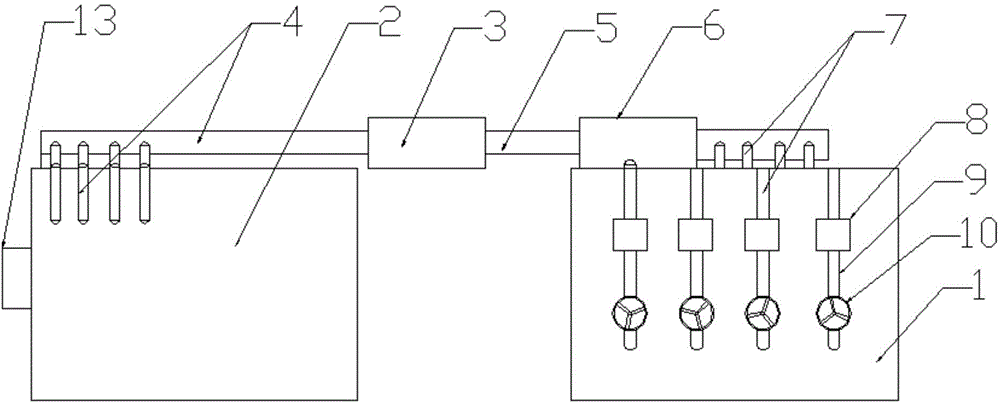

Irrigation device based on Internet of Things

ActiveCN107295953AImprove mixing efficiencyRelieve pressureGeneral water supply conservationWatering devicesFertilizerRainwater harvesting

The invention relates to an irrigation device based on Internet of Things. The irrigation device comprises a rainwater collecting chamber, a filtering chamber, a water storage cavity, a control part, a water mixing chamber and a spraying part. The irrigation device has the advantages that by arranging the rainwater collecting chamber, a water resource can be furthest utilized by the irrigation device; by arranging a solar power generation device on the rainwater collecting chamber, energy can be reasonably utilized; by arranging the control part and the spraying part, and setting a specific setting manner, the water-saving efficiency is improved, and the irrigation, fertilizer applying and pesticide spraying can be realized in one device.

Owner:NINGBO YILIN AGUATECH CO LTD

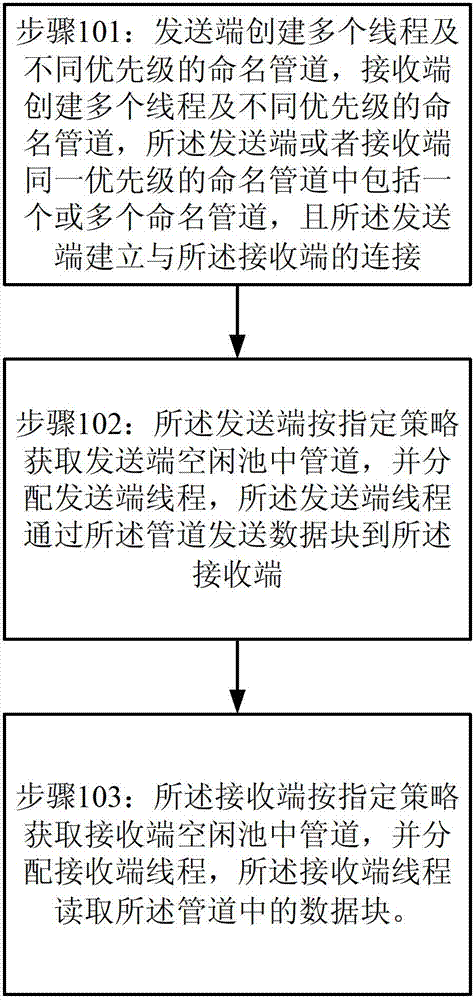

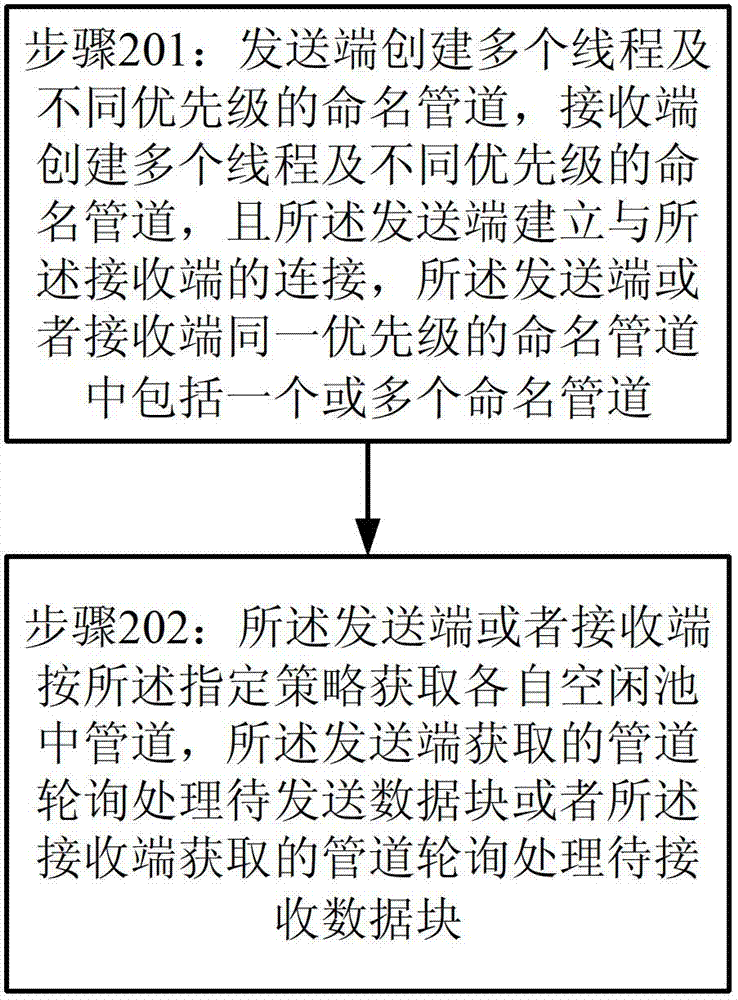

Inter-process communication method and system

InactiveCN102739567AImprove communication efficiencyAchieve reasonable utilizationData switching networksTelecommunicationsNamed pipe

The invention provides an inter-process communication method and system. The method comprises the following steps of: creating a plurality of threads and named pipes of different priorities at a sending terminal, creating a plurality of threads and named pipes of different priorities at a receiving terminal, the named pipe of the same priority at the sending terminal or the receiving terminal comprising one or a plurality of named pipes, and the sending terminal being connected with the receiving terminal. The sending terminal obtains a pipe in an idle pool according to the specified policy and distributes the threads of the sending terminal, and the threads of the sending terminal send data blocks to the receiving terminal through the pipe. The receiving terminal obtains a pipe in an idle pool of the receiving terminal according to the specified policy and distributes the threads of the receiving terminal, and the threads of the receiving terminal read the data blocks in the pipe.

Owner:SUZHOU CODYY NETWORK SCI & TECH

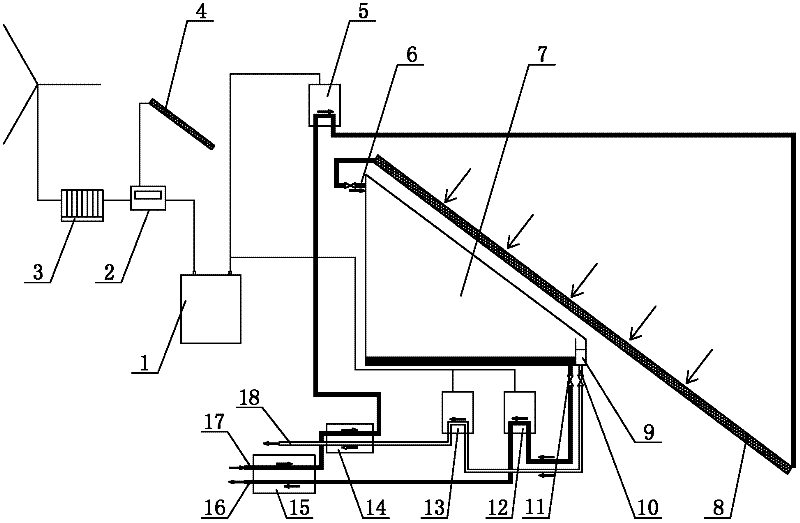

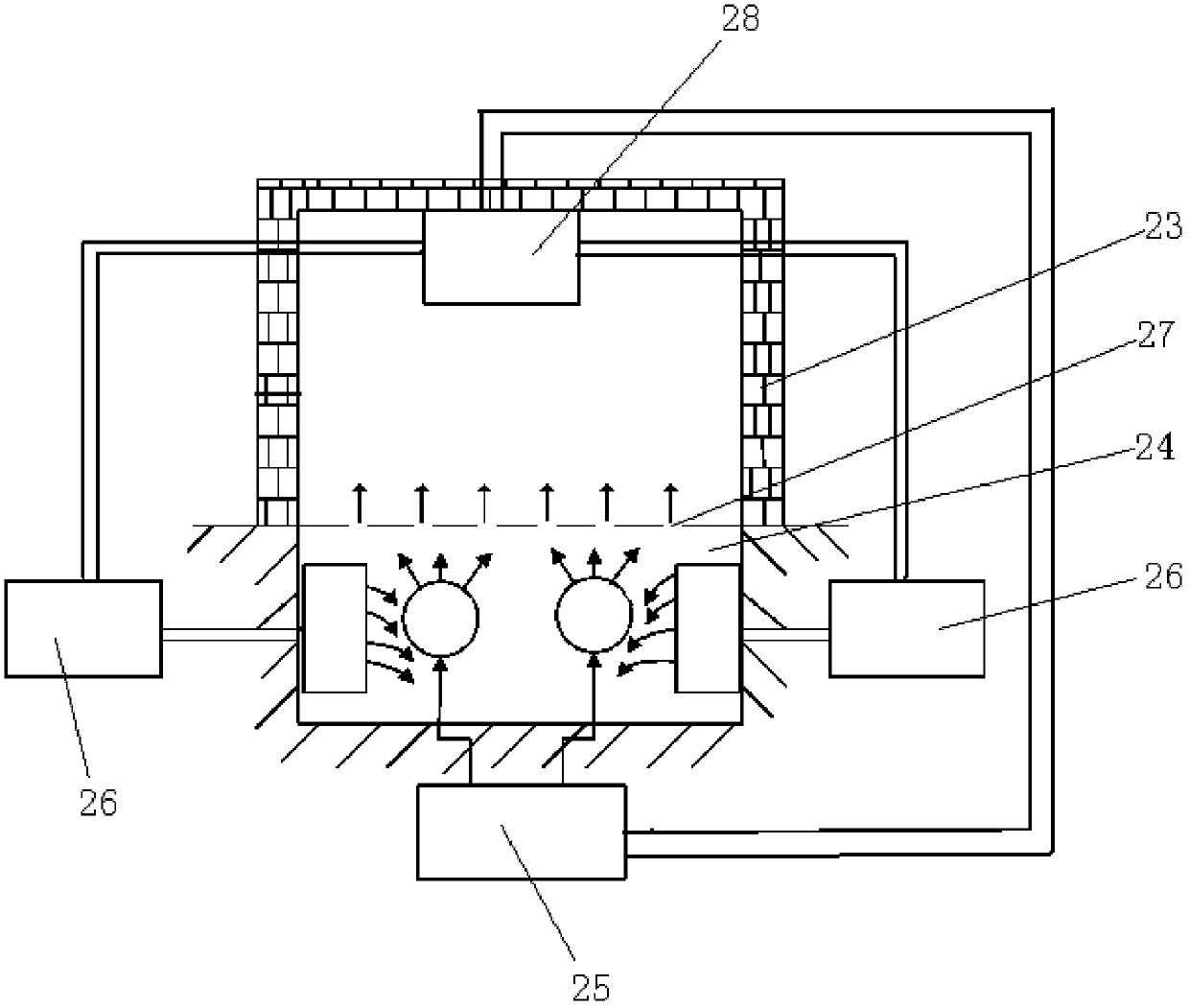

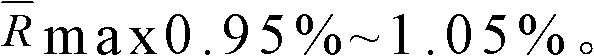

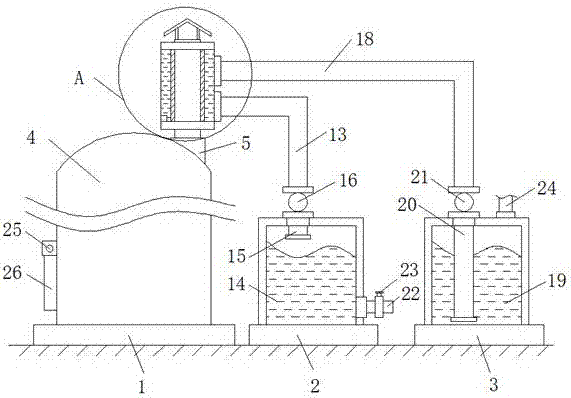

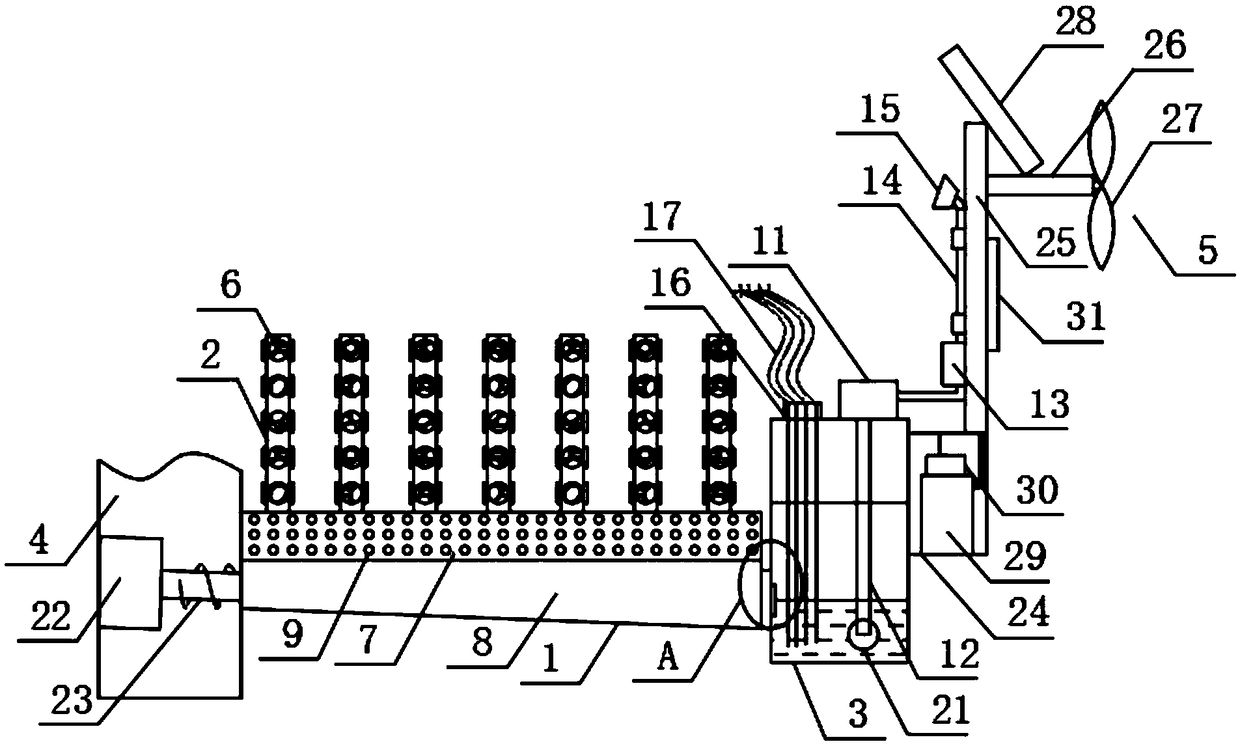

Active solar energy and wind energy coupling seawater desalination plant

InactiveCN102351263AExtended working hoursPrevent heat lossGeneral water supply conservationSeawater treatmentWind forceCharge controller

The invention discloses an active solar energy and wind energy coupling seawater desalination plant. A solar cell panel and a wind driven generator are connected with a storage battery through a charging controller; the storage battery drives a vacuum pump to work; an original seawater inlet pipe is connected to a solar heat collector through a heat exchanger and enters into a seawater evaporator, which is equipped with a fresh water outlet and a condensed seawater outlet; the fresh water outlet is connected with a fresh water outlet pipe passing through a heat exchanger; and the condensed seawater outlet is connected with a condensed seawater outlet pipe passing through a heat exchanger. The invention can collect electric energy generated by solar energy and wind energy in the storage battery and prolong a vacuum pump working time in breezeless and dark weather; besides condensed seawater, steam and fresh water mixture with large enthalpy respectively pass heat of their own to the original seawater through the heat exchanger, so as to fully utilize waste heat and realize reasonable energy utilization.

Owner:TIANJIN UNIV

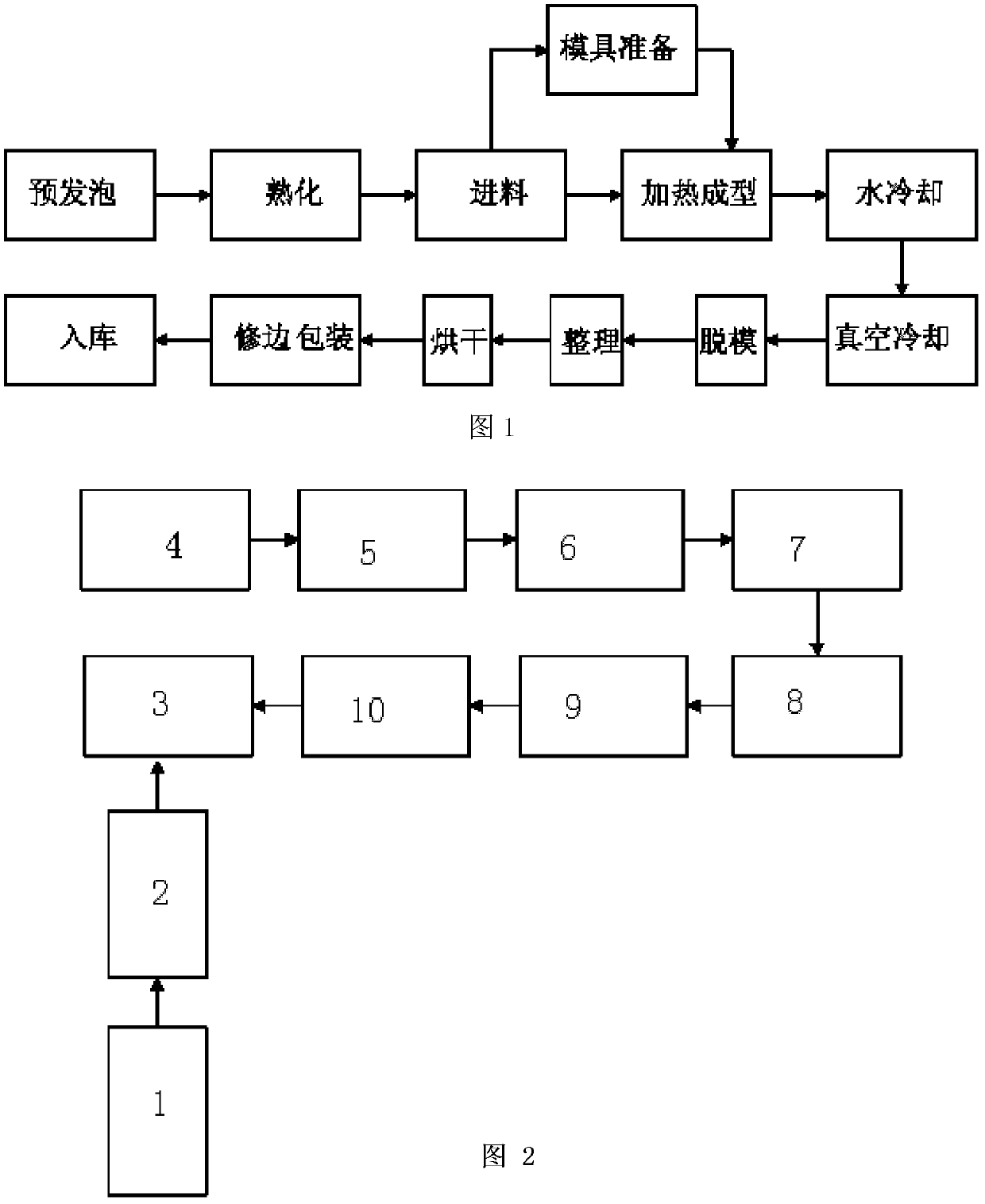

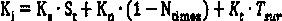

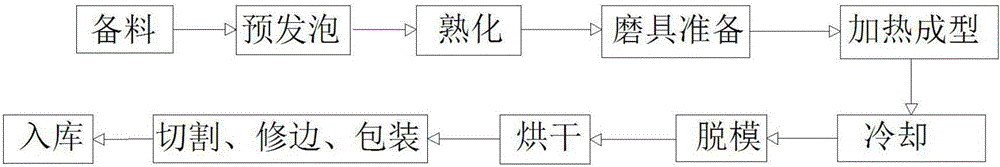

Production technique of EPS (expandable polystyrene) foam articles

The invention discloses a production technique of EPS (expandable polystyrene) foam articles. The production technique is characterized by comprising the following steps: pre-foaming, curing, feeding, preparing mould, heating and forming, water cooling, vacuum cooling, demoulding, trimming, drying, trimming, packaging and storing in warehouse, and the production technique improves the compressed air, water circular cooling and drying process. The technique disclosed by the invention has simple and reasonable technique procedures and utilizes two paths of compressed air supply systems, so that the pipeline pressure is very stable, an electromagnetic valve acts flexibly, a cylinder switching valve quickly and reliably acts, and a cooling water circulating system can quickly cool to improve the cooling efficiency, save the electric energy and vapor and reasonably utilize the energy sources; besides, a mixed mode of high and low temperature air is used, so that the articles are not deformed or expanded irrespective to the foaming density, the drying time is shortened and the resources are reasonably utilized.

Owner:安徽艾柯泡塑股份有限公司

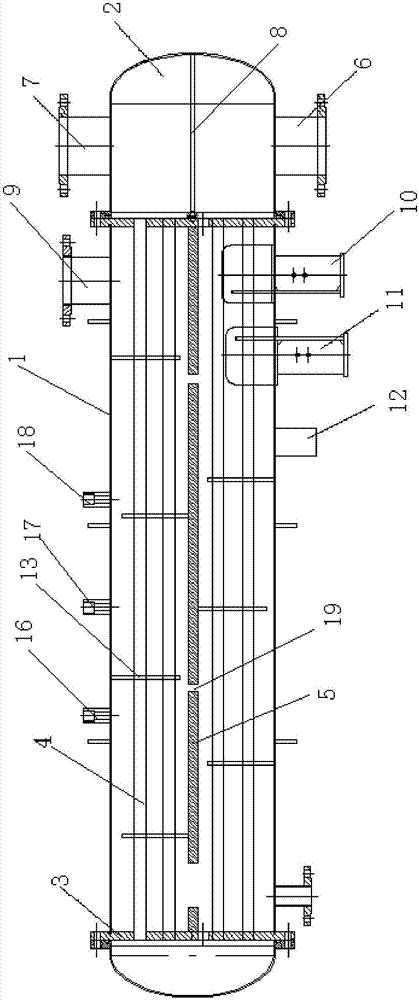

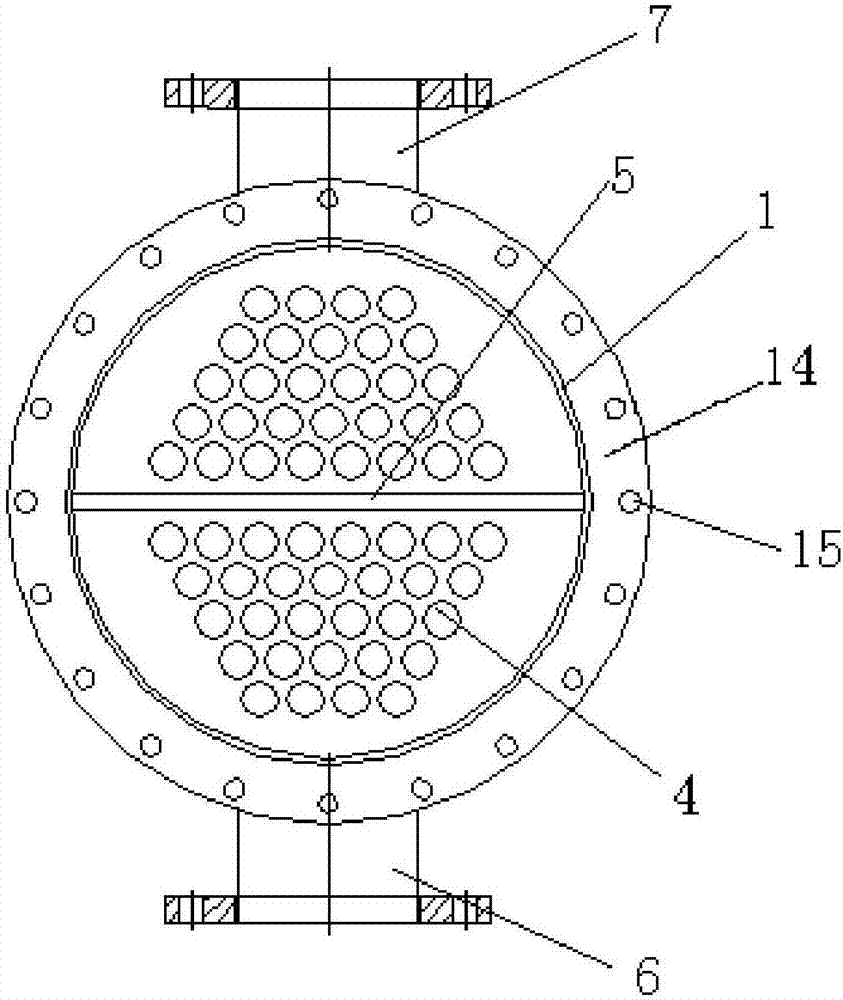

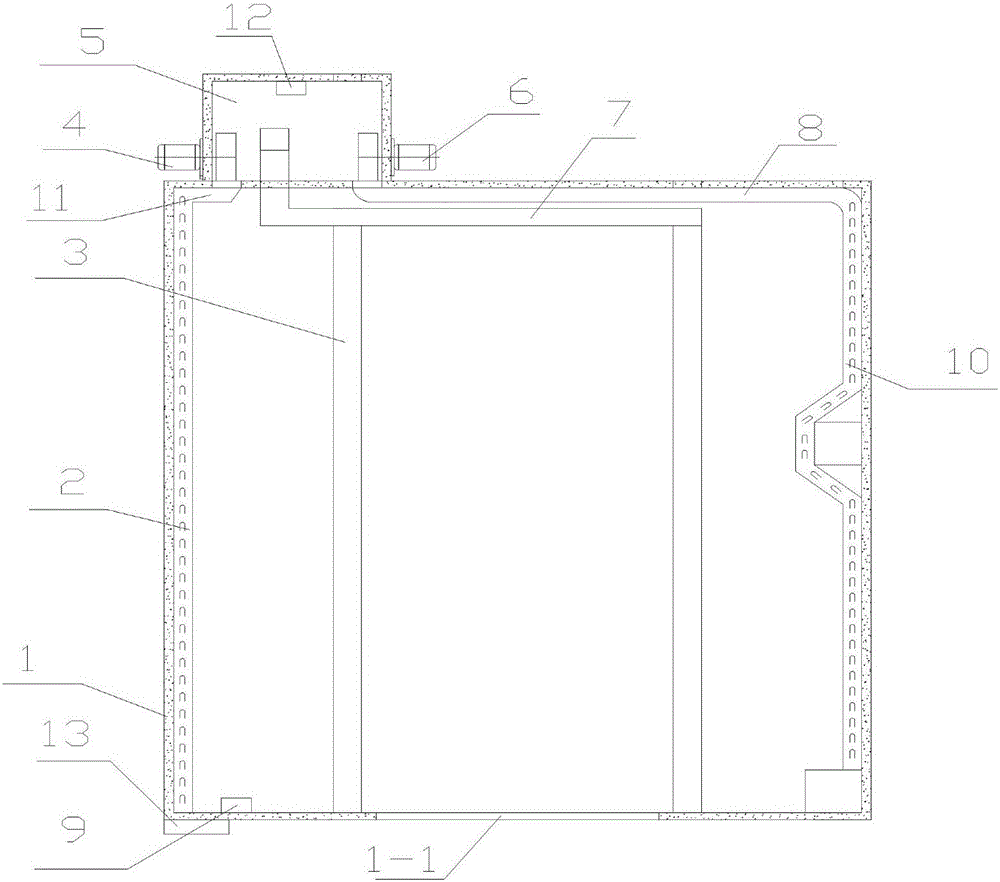

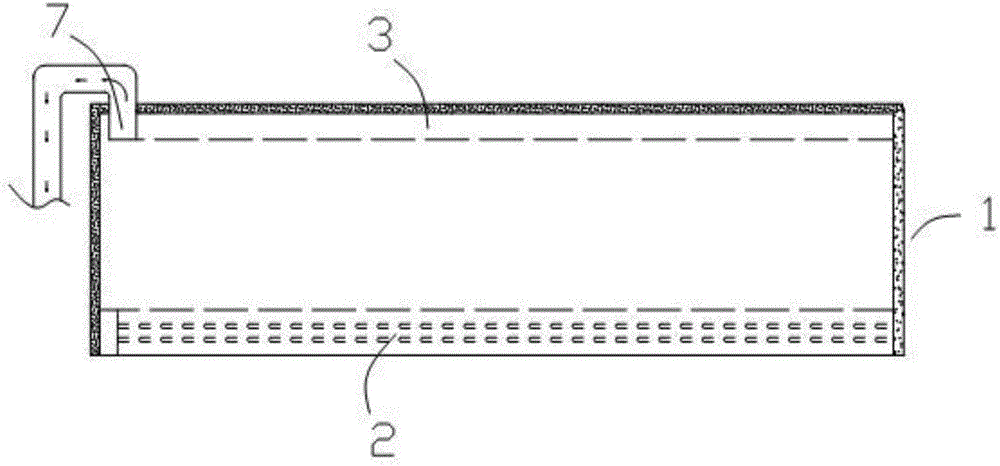

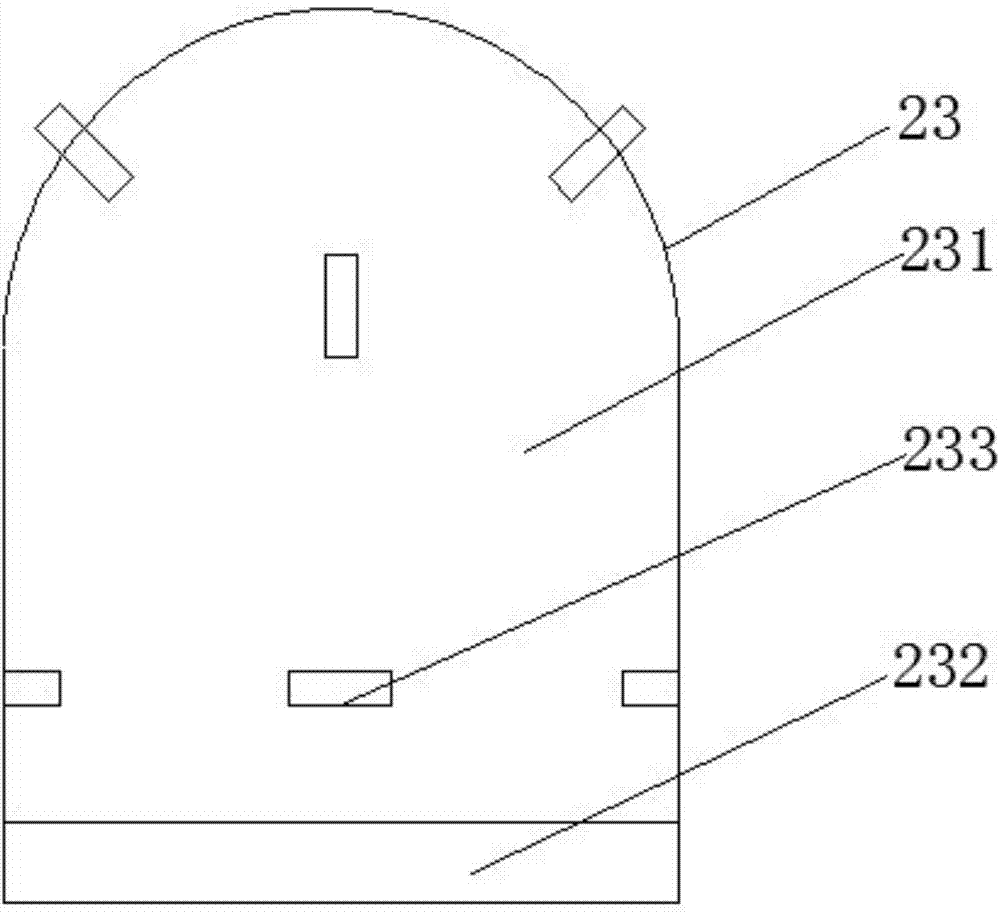

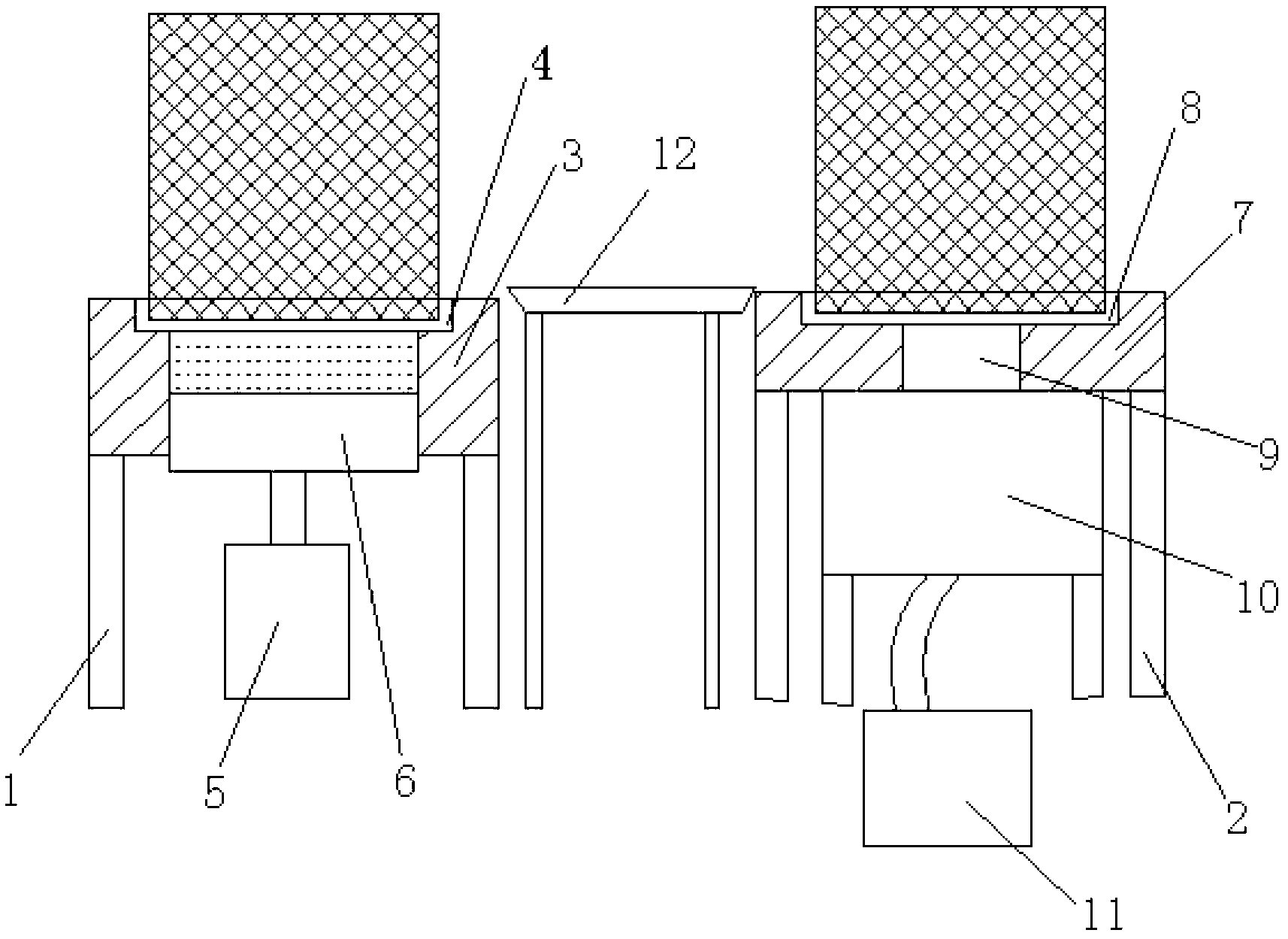

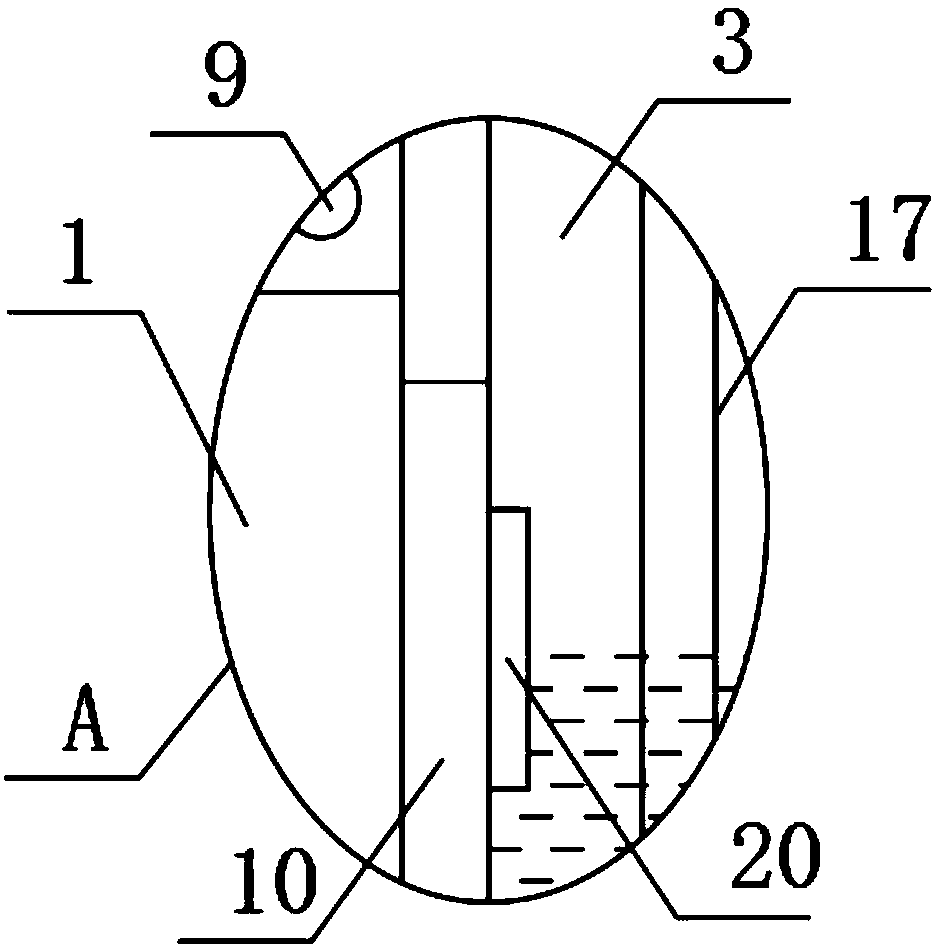

Horizontal heater structure with high heat utilization rate

InactiveCN107490303AReasonable useAchieve reasonable utilizationSteam/vapor condensersHeat exchanger casingsThermal energyEngineering

The invention discloses a horizontal heater structure with the high heat utilization rate. The horizontal heater structure comprises a horizontal and straight tank body. The tank body is composed of a cylinder body and oval sealing heads matched with the two ends of the cylinder body. Heat exchange conveying pipes are mounted in the cylinder body through flange pipe plates at intervals. Partitions for partitioning the heat exchange conveying pipes are mounted in the middles of the flange pipe plates, a feeding opening and a discharging opening are formed in the oval sealing head at the same end, the feeding opening is located in the lower end, the discharging opening is located in the upper end, and the feeding opening and the discharging opening are partitioned by a pass partition plate. A steam inlet is formed in the end, where the discharging opening is located, of the cylinder body. A steam outlet, a condensate outlet and an exhaust opening are formed in the end, where the feeding opening is located, of the cylinder body. Steam through holes are formed in the partitions near the oval sealing head at the other end, and baffle plates are distributed on the discharging pipes below the partitions and the feeding pipes above the partitions. By the adoption of the horizontal heater structure with the high heat utilization rate, the requirement that mother liquid is heated gradually in the conveying process is met, the steam heat energy is used reasonably, the sufficient heat exchange effect is achieved, and the reasonable utilization of resources is met.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

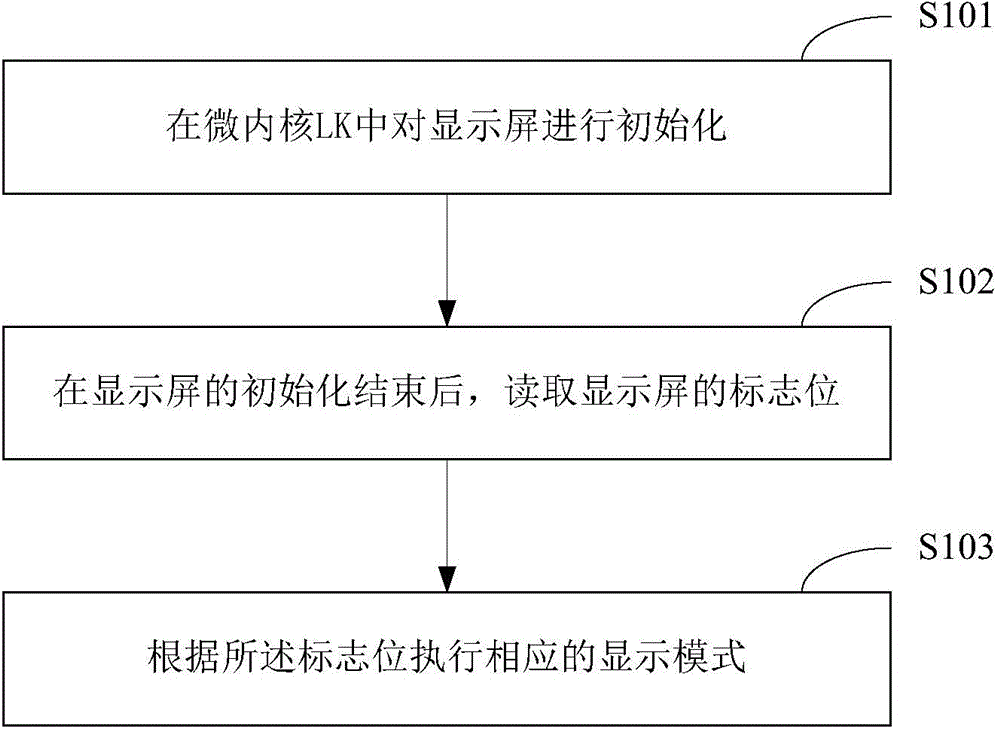

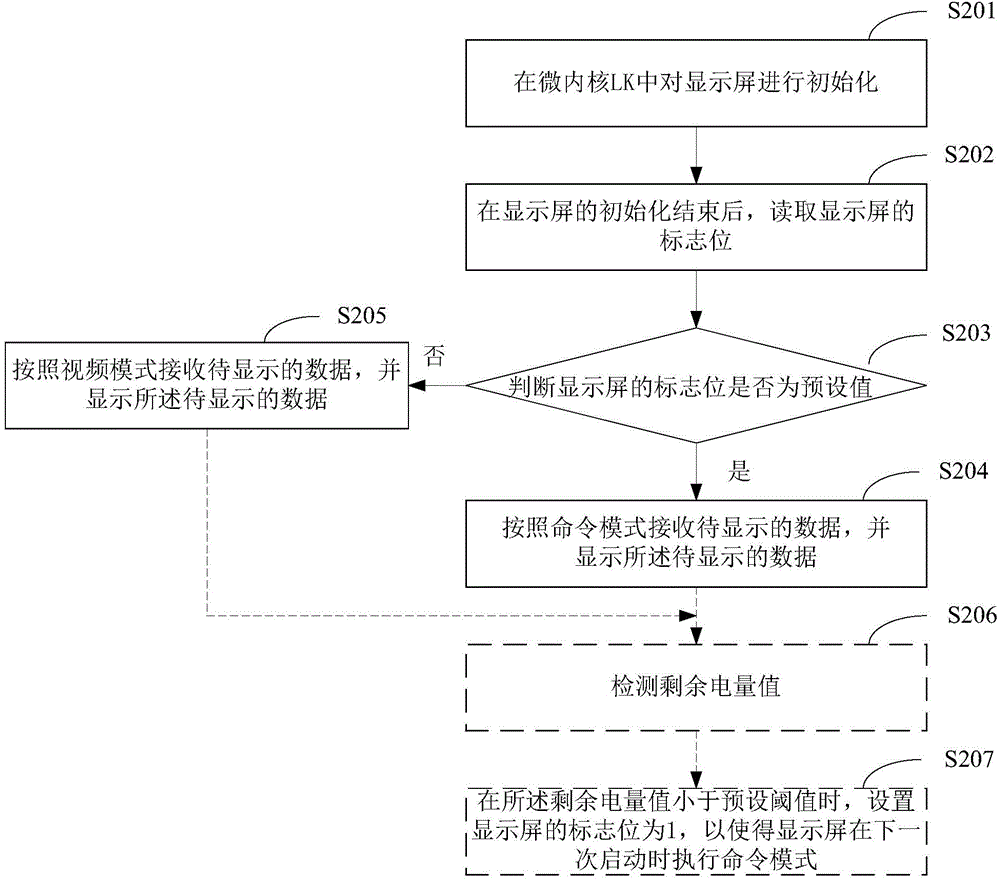

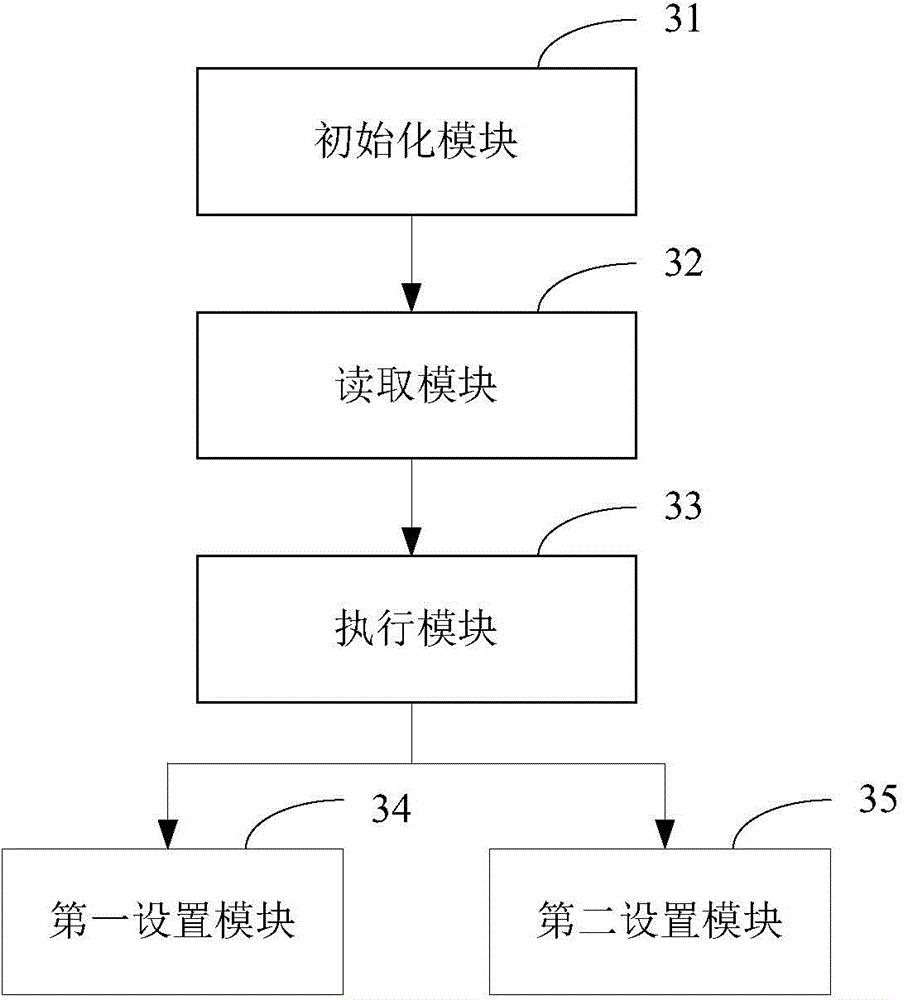

Method and device for dynamically switching display modes of display screen

InactiveCN104156189AAchieve reasonable utilizationReduce manufacturing costDigital output to display deviceMicrokernelComputer engineering

The invention belongs to the technical field of display screens and provides a method and device for dynamically switching display modes of a display screen. According to the method and the device, a zone bit is additionally arranged in the display screen supporting a video mode and a command mode and used as the identification for switching the video mode and the command mode. In the starting process of the display screen, at first, the display screen is initialized in a microkernel LK; after initialization of the display screen is finished, the identification of the display screen is read; finally, the corresponding display mode is executed according to the zone bit. Accordingly, the display modes of the display screen are dynamically switched by reading the identification so that the display screen of the same type can be switched into another display mode when one mode is damaged, and can be utilized reasonably; moreover, the production cost of the display screen is lowered.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

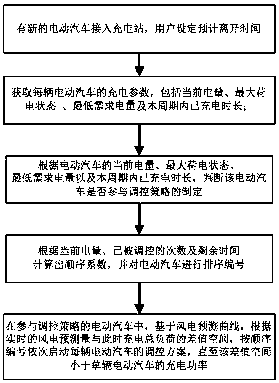

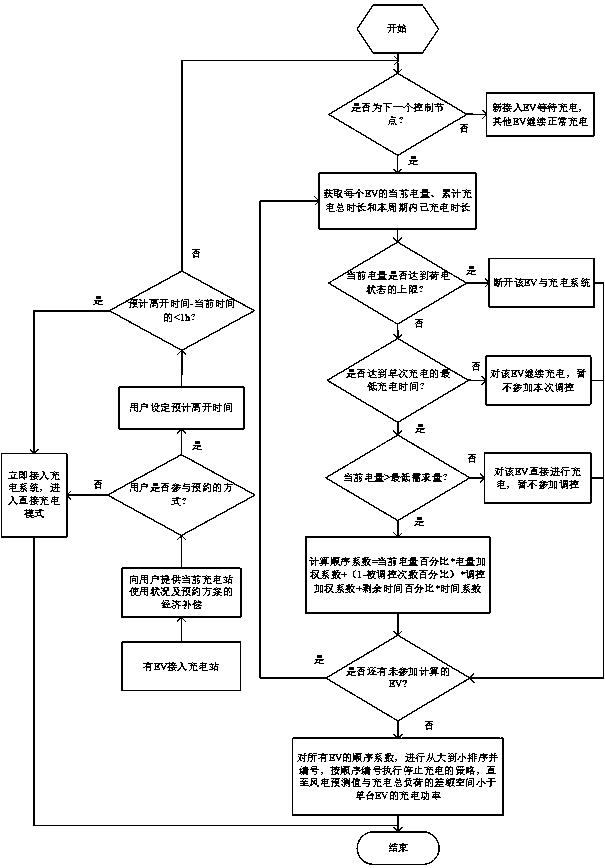

Electric-vehicle orderly charging control method facing wind power consumption

InactiveCN107867187APromote digestionAchieve reasonable utilizationCharging stationsElectric vehicle charging technologyElectricityState parameter

The invention relates to an electric-vehicle (EV) orderly charging control method facing wind power consumption. The method includes the following steps that 1, a new EV is switched in a charging station, and a user sets expected departure time; 2, charging parameters and state parameters of every EV are obtained; 3, according to the relates state parameters of the EV, whether the EV participatesin formulating of the control strategy or not is judged; 4, order coefficients are calculated according to the charging parameters, and the EV is sorted and numbered; 5, based on a wind-power forecasting curve, according to the real-time wind-power forecasting amount and the difference value space of a this-moment charging total load, control formulas of every EV are sequentially carried out according to the order number till the difference value space is smaller than the charging power of a single EV. According to the electric-vehicle (EV) orderly charging control method facing wind power consumption in the technical scheme, based on maximized consumption wind-power resources, in the control process, the lowest charging requirement of the user is considered, and the control fairness is also considered, so that the win-win effect of consuming wind power and meeting the user requirements is achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +3

High-efficiency production process of EPS (Expandable polystyrene) foam product

The invention discloses a high-efficiency production process of an EPS foam product and relates to the technical field of foam processing. The production process comprises the following steps: preparing materials; pre-foaming; ageing; preparing a mold; performing heating formation; cooling; demolding; drying; cutting; trimming; packaging; and putting in storage, wherein compressed air and a drying procedure are improved. The production process disclosed by the invention is simple and reasonable in technological procedure; compressed air supply systems are adopted; a drying room body, a combustion chamber, a hot air system and an air returning system of a drying room form a circulation system; most of hot air is circulated inside the drying room, so high thermal efficiency is realized, energy is saved, and reasonable utilization of resources is realized.

Owner:泸州市青林包装有限公司

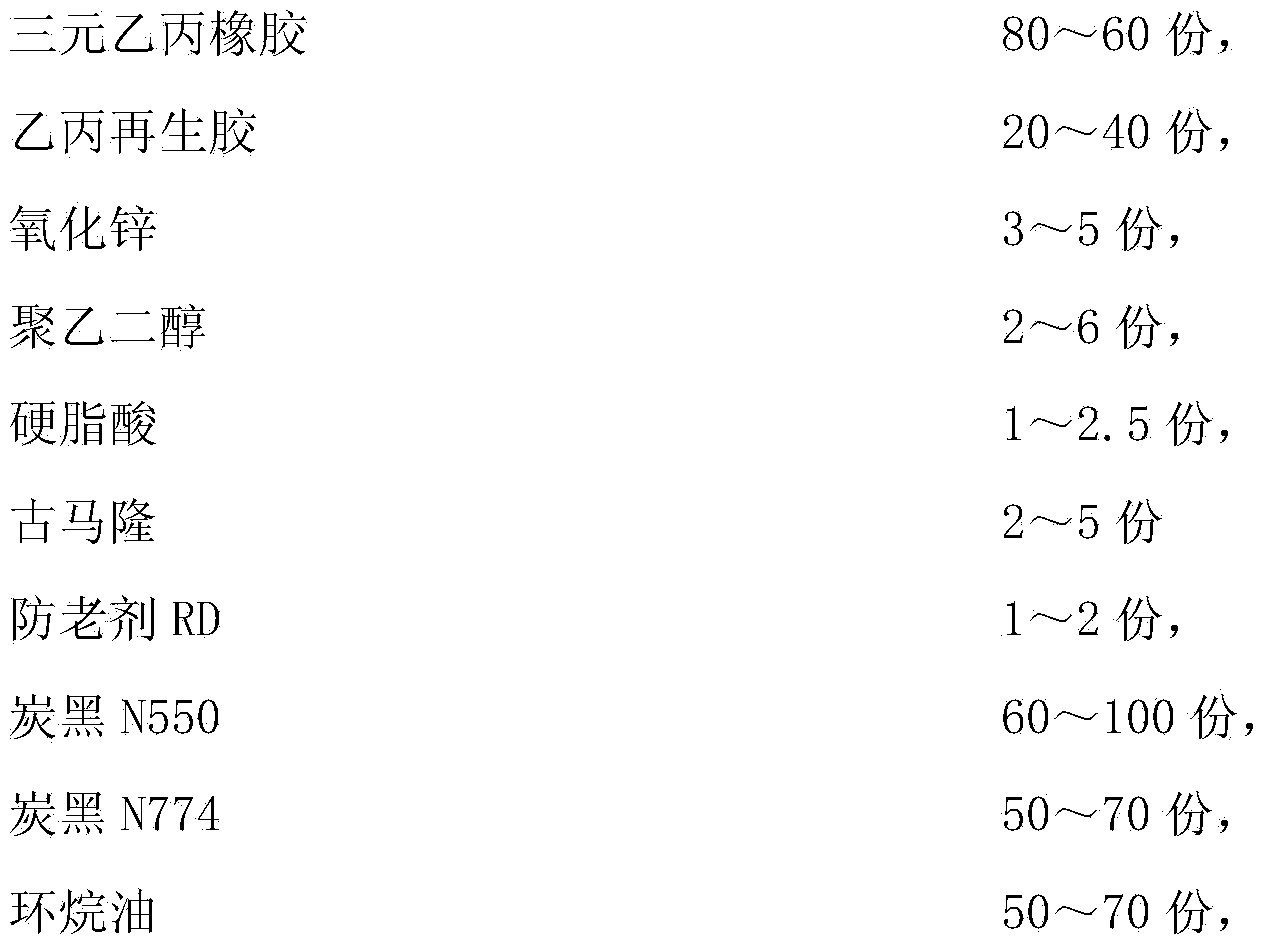

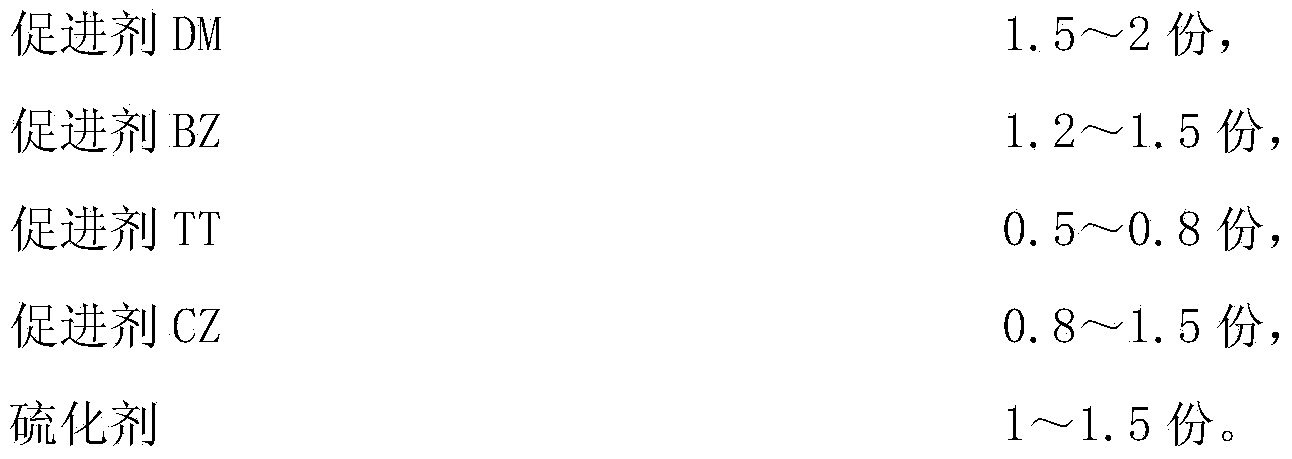

Rubber composition using both EPDM and reclaimed rubber

The invention relates to a rubber composition using both EPDM and reclaimed rubber. The rubber composition comprises 80 to 60 parts of EPDM, 20 to 40 parts of ethylene propylene reclaimed rubber, 3 to 5 parts of zinc oxide, 2 to 6 parts of polyethylene glycol, 1 to 2.5 parts of stearic acid, 2 to 5 parts of coumarone, 1 to 2 parts of an antioxidant RD, 60 to 100 parts of carbon black N550, 50 to 70 parts of carbon black N774, 50 to 70 parts of naphthenic oil, 1.5 to 2 parts of a promoter DM, 1.2 to 1.5 parts of a promoter BZ, 0.5 to 0.8 part of a promoter TT, 0.8 to 1.5 parts of a promoter CZ and 1 to 1.5 parts of a vulcanizing agent. The rubber composition using both EPDM and EP reclaimed rubber is used to replace EPDM rubber in a rubber product, can meet requirements of a material for heat resistance, weatherability and ozone resistance, substantially alleviates the problem of scarcity of EPDM rubber in China, turns the waste into the valuable and realizes reasonable utilization of resources.

Owner:TIANJIN PENGYI GRP CO LTD

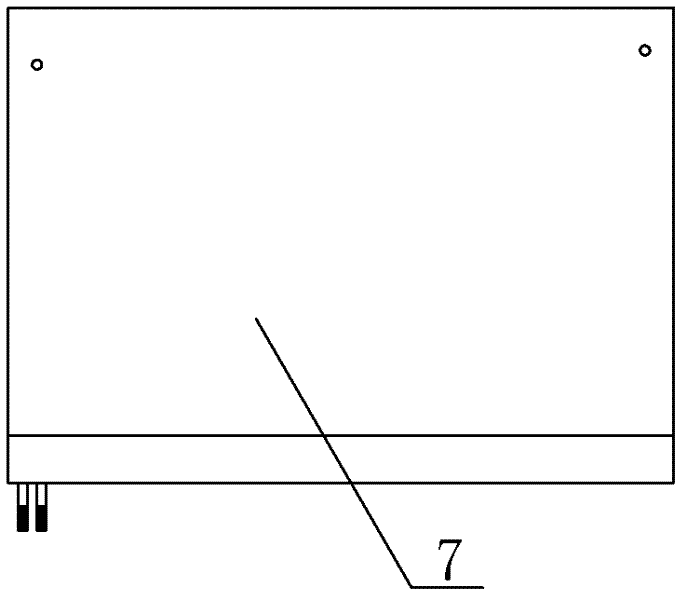

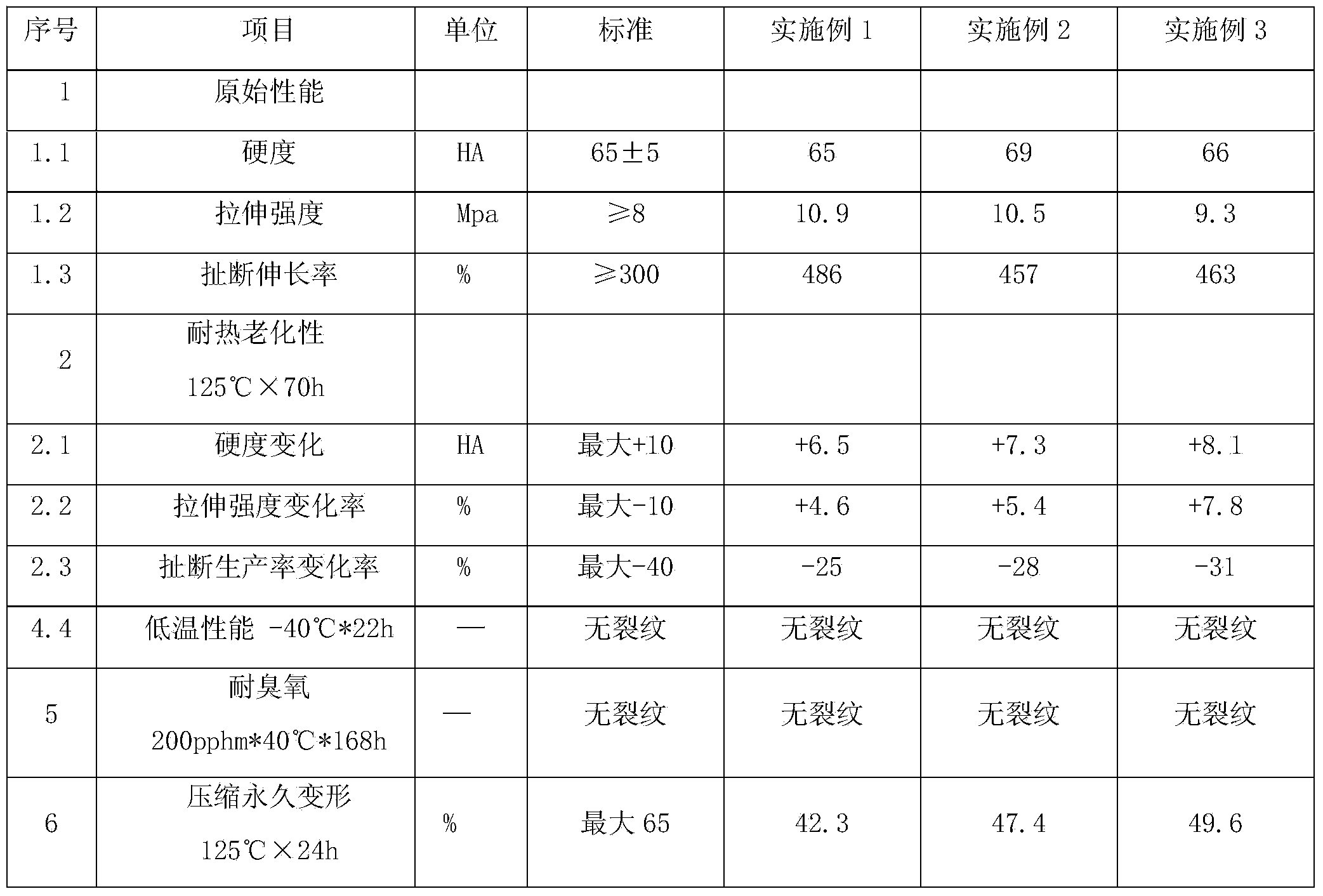

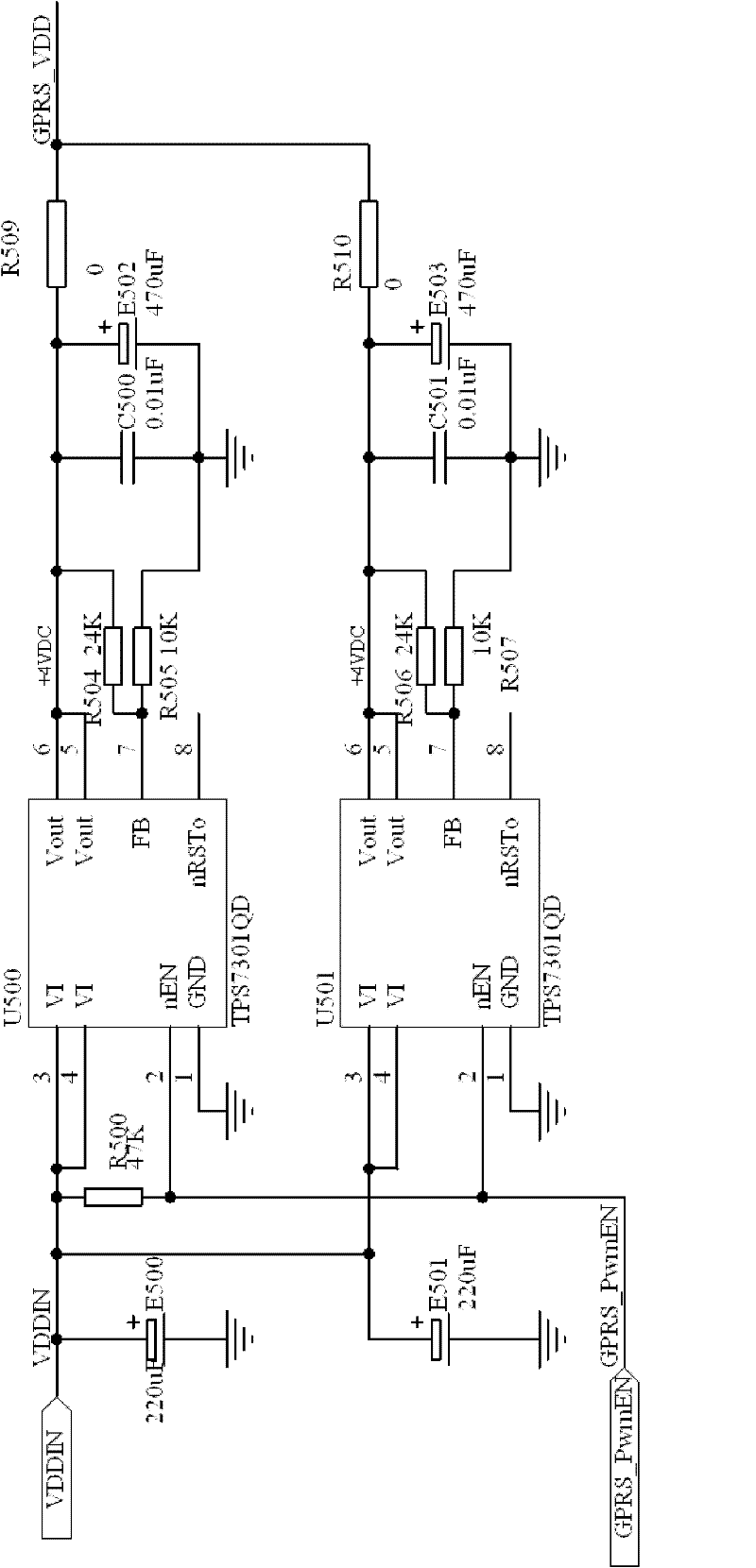

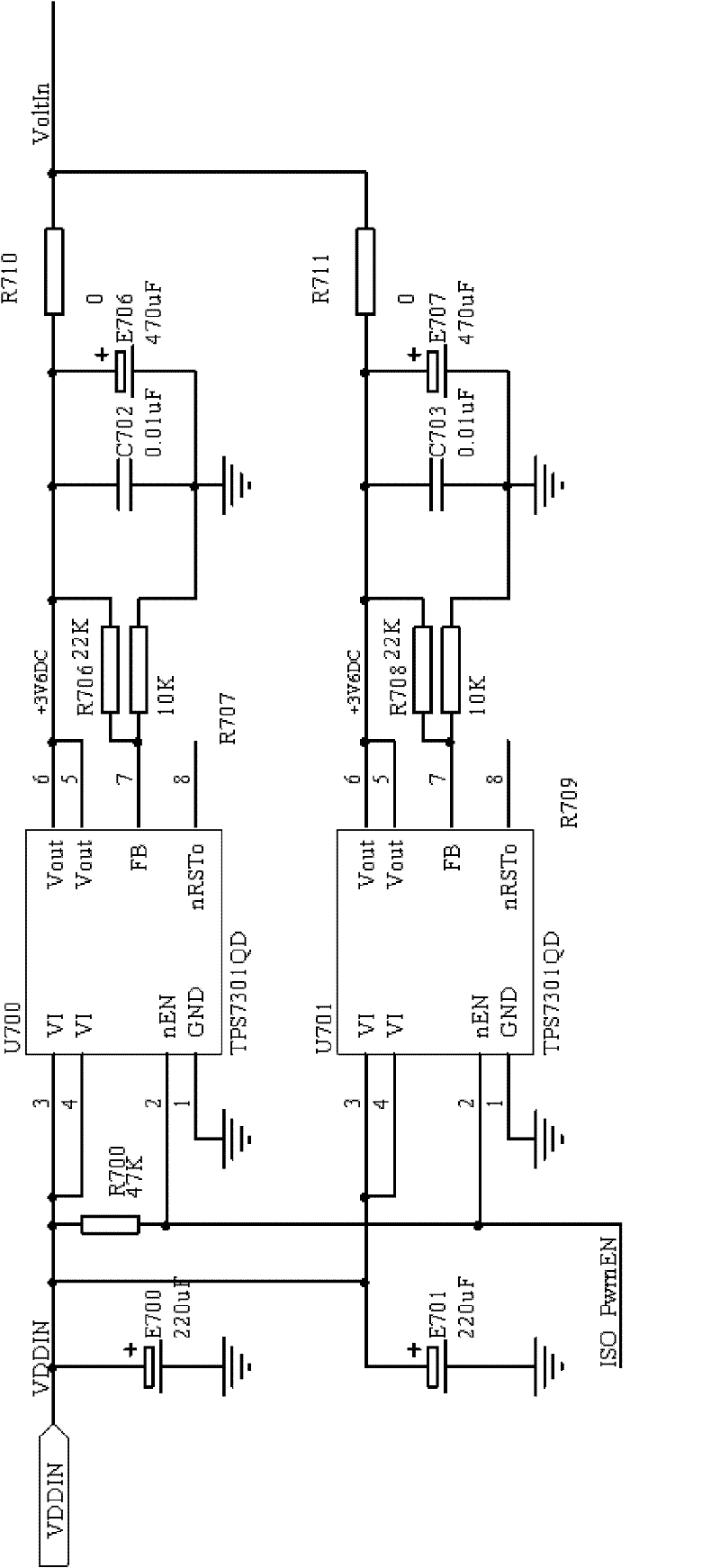

Power supply control system of field on-line monitoring device

InactiveCN102520626AAchieve reasonable utilizationReduce energy consumptionDc-dc conversionProgramme control in sequence/logic controllersGeneral Packet Radio ServiceControl signal

The invention discloses a power supply control system of a field on-line monitoring device. The power supply control system comprises a control unit, a GPRS (General Packet Radio Service) module, a plurality of loads connected in parallel and isolated power supply modules. The GPRS module is connected with the control unit through a first voltage-stabilizing circuit, and receives a control signal of the control unit; the load in each path is provided with a second voltage-stabilizing circuit, and each second voltage-stabilizing circuit is respectively connected with one isolated power supply module, and each isolated power supply module is connected to the control unit, so as to receive the control signal of the control unit; the load connected in parallel of each path is connected to one isolated power supply module, and the isolated power supply module is connected with the control unit so as to receive the control signal of the control unit.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

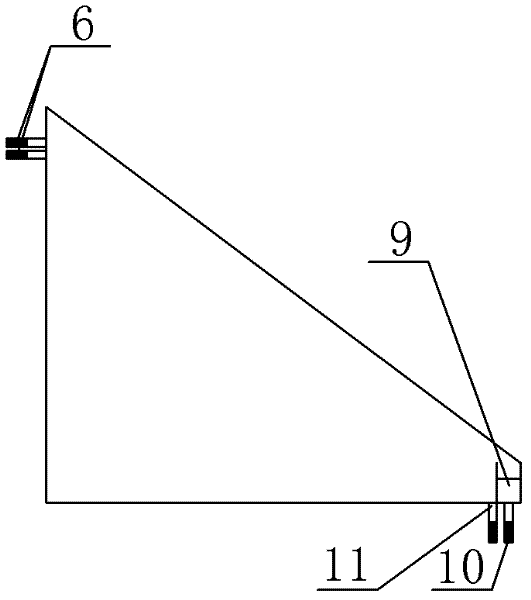

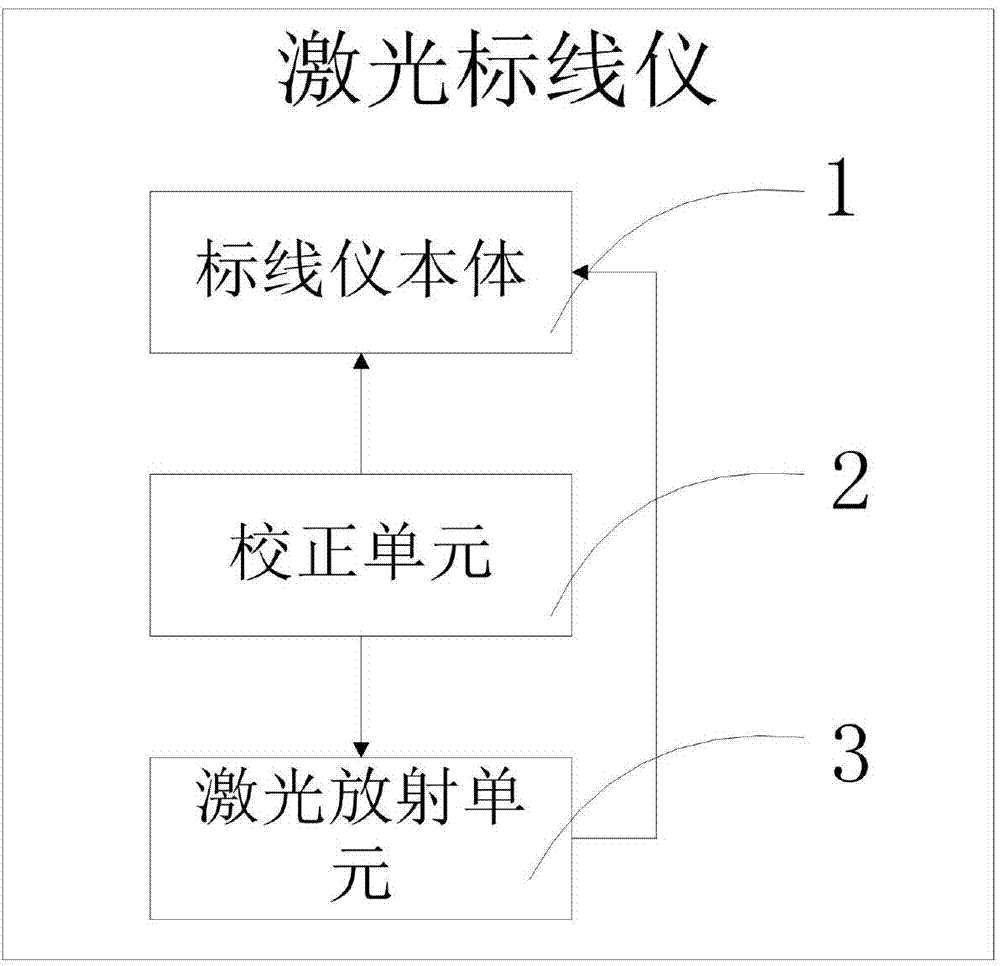

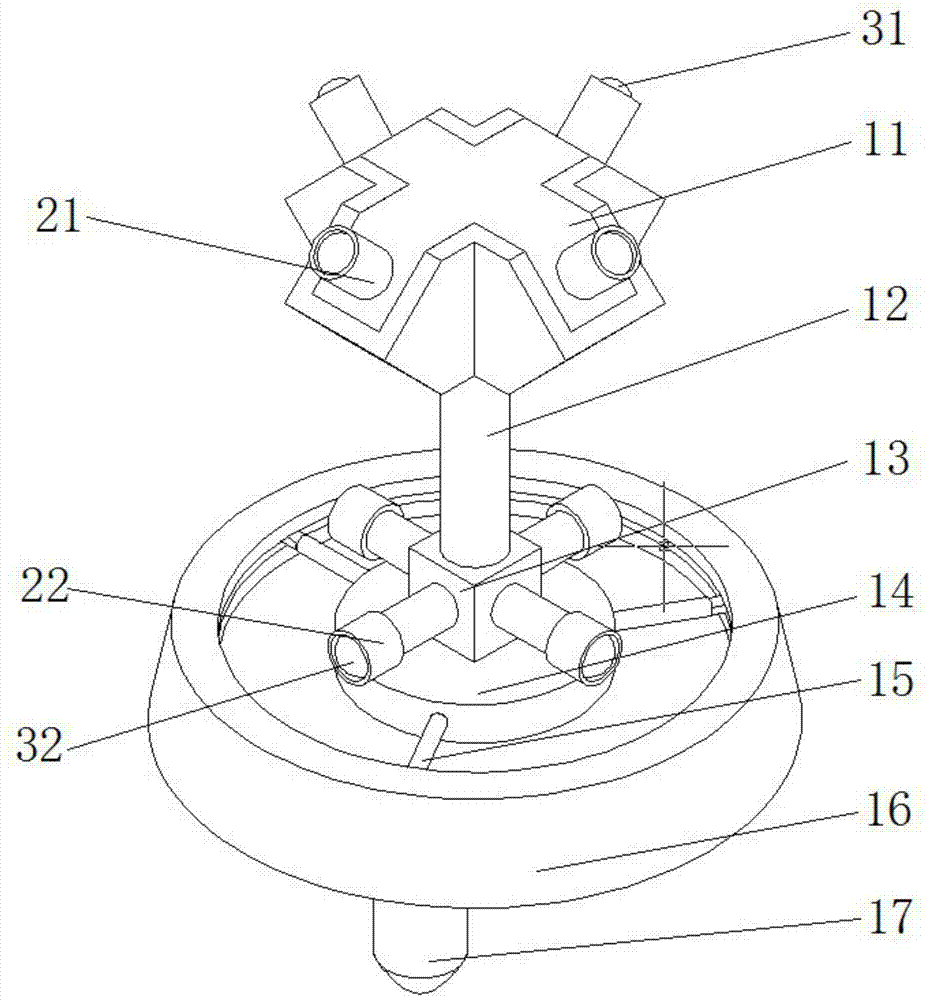

Laser marking instrument with automatic correcting function

InactiveCN104713532AImprove practicalityHigh measurement accuracyReference line/planes/sectorsOptoelectronicsMeasurement precision

The invention provides a laser marking instrument with the automatic correcting function. The laser marking instrument comprises a laser marking instrument main body, a correcting unit and a laser emitting unit, wherein the correcting unit and the laser emitting unit are both mounted on the laser marking instrument main body; the correcting unit is used for correcting the laser emitting unit. The laser marking instrument disclosed by the invention has the automatic correcting function, so that the data obtained in actual surveying and mapping are higher in reference value and practicability, and the measurement precision of the laser marking instrument can be correspondingly improved; furthermore, the laser marking instrument is simple in structure and convenient to operate; the correcting unit can be replaced at any time, so that the practicability of the laser marking instrument can be improved.

Owner:浙江新蓝达实业股份有限公司

Inorganic flame retardant surface modification method

InactiveCN103265826AReasonable useImprove flame retardant effectPigment treatment with non-polymer organic compoundsSurface modificationFire retardant

The invention discloses an inorganic flame retardant surface modification method which comprises the following steps: filling an inorganic flame retardant in a surface pretreatment device for heating and preheating, adding a coupling agent into an organic solvent, dissolving the coupling agent in a container, spraying the dissolved coupling agent into a reaction container in the respective container in a high-pressure spraying mode, mounting a stirring rod for fully stirring in the reaction container, and fusing to obtain the surface modified inorganic flame retardant. According to the mode, the aluminum hydroxide and other inorganic flame retardants can be modified through surface treatment and are used for enhancing the adhesion force to polymers and improving the affinity to an interface, so that the dehydration reaction is finished in a certain temperature range.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Outer Mongolia coking coal-participant coking coal blending method

InactiveCN102517060AEfficient use ofNo deterioration in qualityCoke ovensProcess engineeringBriquette

The invention discloses an Outer Mongolia coking coal-participant coking coal blending method. The method comprises a step of blending of all single coking coals, and the single coking coals comprise, by weight, 3-8% of gas-rich coal, 5-15% of rich coal, 15-20% of 1 / 3 coking coal, 15-20% of the Outer Mongolia coking coal, 30-38% of coking coal and 10-15% of lean coal. According to the invention, the Outer Mongolia coking coal participates in the coking coal blending according to a 1 / 3 coking coal application method, so the effective utilization of the Outer Mongolia coking coal resource can be realized under non-grading fragmentation and briquette technology or tamping coking technology conditions, and the coke quality is not deteriorated.

Owner:武汉钢铁有限公司

Heat recycling device of smelting furnace

InactiveCN107990745AExtended service lifeIncrease profitCharge treatment typeIncreasing energy efficiencyEngineeringWater collection

The invention relates to the technical field of smelting furnaces, and discloses a heat recycling device of a smelting furnace. The heat recycling device of the smelting furnace comprises a first base, a second base and a third base, wherein a furnace body is fixedly connected to the top part of the first base; a chimney fixedly communicates to the top part of the furnace body; a first fixing ringis fixedly sleeved on the bottom part of an outer surface of the chimney; a heat exchange guide plate located above the first fixing ring is fixedly sleeved on the outer surface of the chimney; and ahot water collection tank is fixedly sleeved on an outer surface of the heat exchange guide plate. According to the heat recycling device of the smelting furnace, the heat exchange guide plate can beused for heating water in the hot water collection tank through collecting heat on the chimney, and water is conveyed to a hot water tank through the pumping of the first pump and is then dischargedfrom a drainage pipe for the use by people, so that the outer wall of the chimney can be cooled, the service life of the chimney is prolonged, meanwhile, an effect on recycling waste heat is achieved,the energy is saved, and the energy utilization ratio is improved.

Owner:佘峰

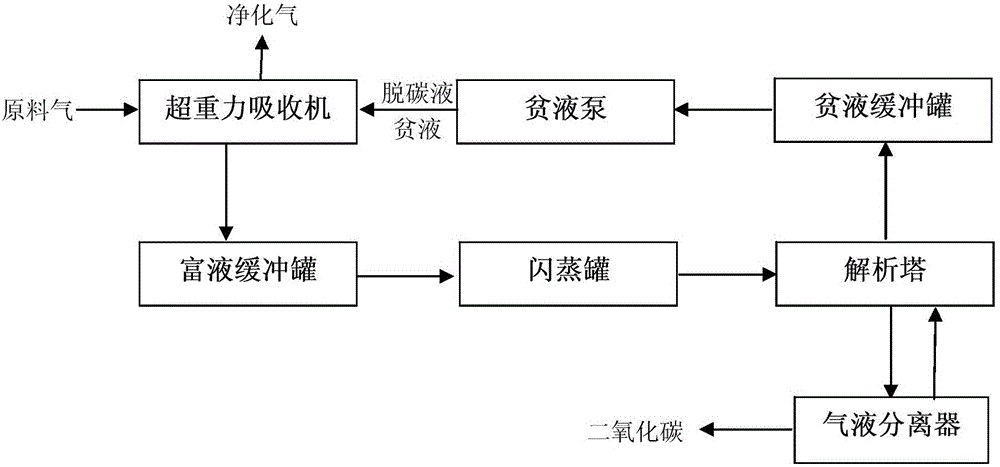

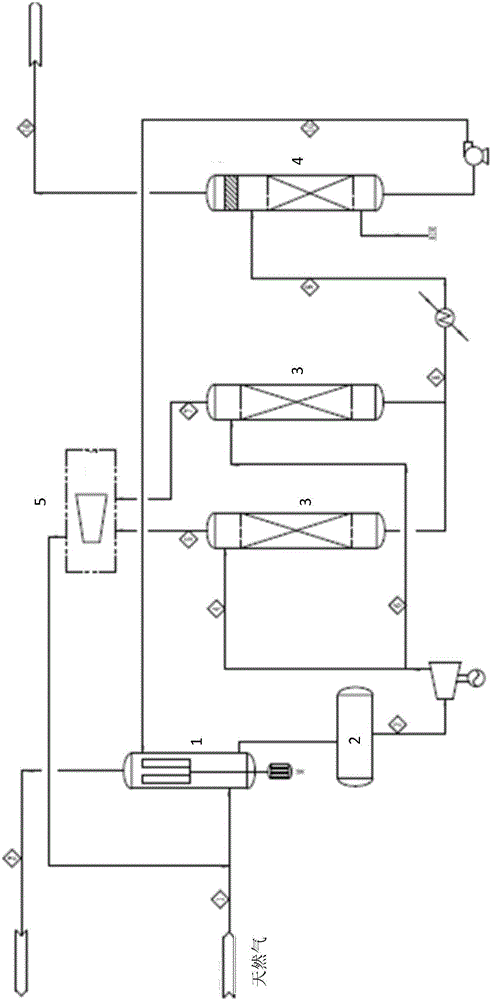

Skid-mounted carbon dioxide gas absorption method and apparatus applicable to offshore platform

InactiveCN106334412AReduce volumeImprove conversion rateDispersed particle separationAir quality improvementDesorptionHigh pressure

The invention provides a skid-mounted carbon dioxide gas absorption method and apparatus applicable to an offshore platform. The method comprises the following steps: conveying high-pressure gas (feed gas) with high carbon dioxide content and a barren decarburization solution (a barren solution) into a hypergravity absorption machine and allowing the barren solution to absorb CO2 in the feed gas to form a rich decarburization solution ( a rich solution) so as to realize purification of the feed gas; and allowing the rich solution to enter a desorption tower after flash evaporation and pressure reduction so as to realize release of CO2 and regeneration into a barren solution, allowing CO2 to enter a post-treatment system after treatment by a gas-liquid separator and re-inputting the regenerated barren solution into the hypergravity absorption machine for cyclic utilization. The hypergravity absorption machine and the like are integrally arranged to form a detachable skid-mounted integrated system. The apparatus provided by the invention employs a skid-mounting design, and is small in size, light in weight and applicable to space-limited occasions like an offshore platform; and through a combination of the method and the apparatus provided by the invention, CO2 in feed gas like natural gas and oilfield associated gas can be highly and environment-friendlily removed at low cost, low consumption and low discharge, and rational utilization of resources is realized.

Owner:北京化工大学苏州(相城)研究院 +2

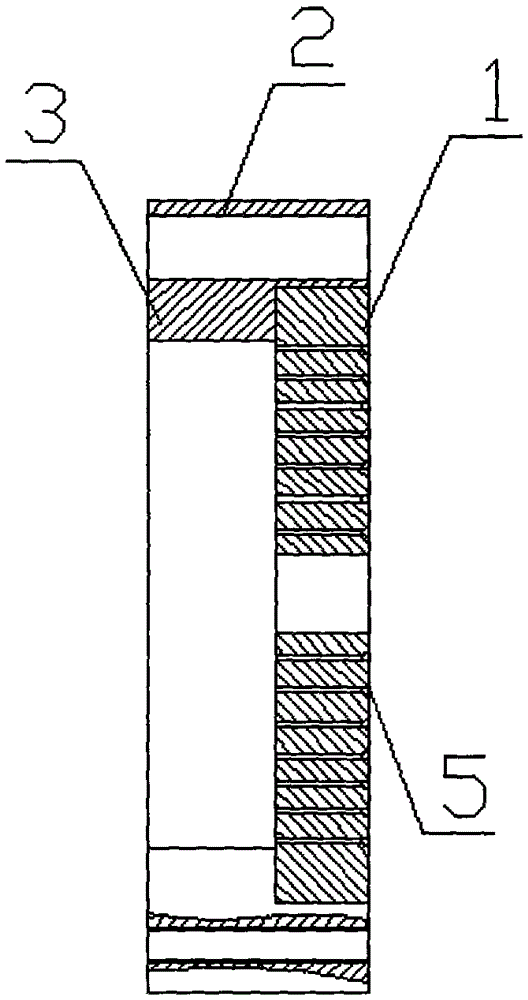

Carbonized husk thermal insulation and heat reserving brick

ActiveCN103922693AAchieve consumptionAchieve reasonable utilizationSolid waste managementAdhesiveThermal insulation

The invention relates to a carbonized husk thermal insulation and heat reserving brick which is characterized by being processed by taking a black husk prototype material husk carbon as a raw material, mixing 1 part of magnesium chloride with 2 parts of water to obtain a magnesium chloride diluent, mixing 2-2 parts of magnesium chloride diluent with 1 part of magnesium oxide to obtain an adhesive, mixing 3-5 parts of husk carbon with 1 part of chlorine and magnesium oxide adhesive to prepare brick blank, compressing in a die and the like. According to the invention, a brick kiln is not needed to be built, soil is not used instead of waste husk carbon, so that production cost is low, the pollution of husk on environment is governed because a large amount of husk wastes are consumed, and the prepared brick is porous, low in density and rough in texture, has the advantages of light weight, thermal insulation, heat reservation, sound insulation, shock absorption and the like, and is a novel environment-friendly indoor partition wall material.

Owner:嘉兴久珥科技有限公司

Method of using low-grade zinc oxide ore to produce high-purity nano zinc oxide by means of ammonia process

ActiveCN102863011AEvenly distributedEfficient leachingZinc oxides/hydroxidesNanotechnologyEnvironmental resistanceZno nanoparticles

The invention discloses a method of using low-grade zinc oxide ore to produce high-purity nano zinc oxide by means of the ammonia process. The method includes: using slaked lime of 3-5% mass of the low-grade zinc oxide ore for activating before leaching, using ammonia water-ammonium bicarbonate solution as leaching agent, adding 0.3-0.5kg of sodium fluorosilicate into per stere of the leaching agent for leaching, purifying for impurity removal, and refining. On one hand, efficient leaching of the low-grade zinc oxide ore is realized, high-purity zinc oxide with large specific surface area can be obtained at low calcinations temperature, and extremely high practical value and economic value are obtained; and on the other hand, the treatment method is low in energy consumption and high in efficiency. Valuable and poisonous heavy metal in the low-grade zinc oxide ore can be leached out for use and cleaned by means of water washing, and accordingly economy, environment friendliness and reasonable utilization of renewable resources are realized.

Owner:SICHUAN JUHONG TECH

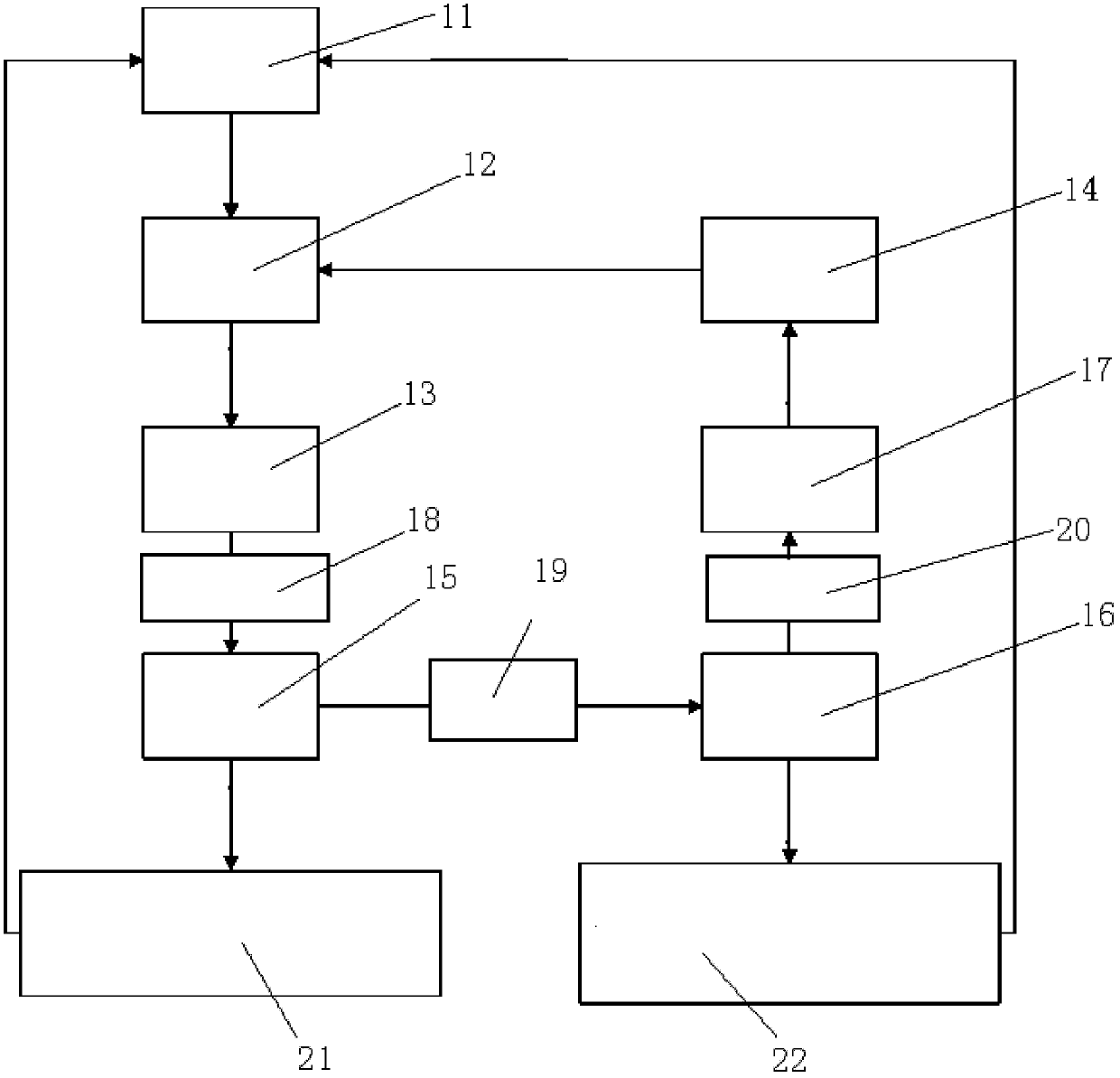

Freshness keeping device for fruits and vegetables in supermarkets

InactiveCN104970088AInhibition of respiratory metabolic activityStay hydratedFruits/vegetable preservation by irradiation/electric treatmentEngineeringHigh pressure

The invention discloses a freshness keeping device for fruits and vegetables in supermarkets, and belongs to the technical field of freshness keeping devices for fruits and vegetables. The freshness keeping device comprises a temperature detection unit, a humidity detection unit, a carbon dioxide concentration detection unit, a control unit, a temperature control unit, a humidity control unit, an ozone generation unit and a high-pressure electrostatic generation unit, wherein the high-pressure electrostatic generation unit comprises a direct-current high-voltage power supply, a positive-negative high-voltage filter circuit, a positive-negative ionic discharge electrode, a frequency producing module and a frequency selection module. According to the device disclosed by the invention, a high-voltage electrostatic field is adopted, so that the respiratory metabolism activity of the vegetables and the fruits is restrained, moisture content in the vegetables and the fruits is effectively maintained, and a freshness keeping effect is achieved.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Combustor for high/low-calorific-value gas

InactiveCN102679344AImprove combustion effectImprove combustion intensityIndirect carbon-dioxide mitigationGaseous fuel burnerAir volumeCombustor

The invention relates to a combustor for high / low-calorific-value gas, which comprises a central burner and 3-8 peripheral burners, wherein the central burner is provided with a central fuel nozzle and a central air nozzle, and each peripheral burner is provided with a peripheral fuel nozzle and a peripheral air nozzle; the central fuel nozzle and the peripheral fuel nozzles are respectively provided with an air inlet pipe, the central air nozzle and the peripheral air nozzles are respectively provided with an air inlet, and the air inlet is provided with an air-quantity regulating mechanism; the air inlet is selectively connected with an oxygen-enriched preparation device, and the oxygen-enriched preparation device is an oxygen-enriched film or a PSA (pressure swing adsorption) oxygenerator; and each burner is provided with an independent fuel nozzle and an independent air nozzle, thereby ensuring the fully mixing of fuel gas and combustion-supporting gas, improving the combustion effect of the combustor, and improving the operation flexibility. The combustor provided by the invention has the advantages that: (1) an effect of combustion is performed through a plurality of nozzles, so that the fuel flows of the nozzles are fine, and fuels are fully mixed with air; (2) the air quantity is regulated by using a regulating mechanism, so that fuels with different calorific values can be combusted; and (3) different type of gas can be combusted simultaneously, thereby facilitating the reasonable application of gas resources.

Owner:中科为宇(北京)科技发展有限公司

Device and method for uploading soldering paste of metal honeycomb carrier

ActiveCN103212766AAchieve reasonable utilizationReasonable structural designSoldering auxillary devicesHoneycombAtmospheric pressure

The invention discloses a device and method for uploading a soldering paste of a metal honeycomb carrier. The device comprises an air pressure propelling device used for uploading the soldering paste, and a soldering paste negative pressure recovery device. The method is a method that brazing is carried out by coating the soldering paste after rolling and forming, and the method comprises the following steps: rolling a flat wave strip into the metal honeycomb carrier; placing the formed metal honeycomb carrier on the air pressure propelling device used for uploading the soldering paste, so as to push the soldering paste into the metal honeycomb carrier; placing the metal honeycomb carrier filled with the soldering paste upside down to be delivered into the soldering paste negative pressure recovery device to recycle redundant soldering paste; and finally placing the metal honeycomb carrier containing small amount of soldering paste in clearance into a vacuum brazing room to be welded. The device for uploading the soldering paste of the metal honeycomb carrier is reasonable in structure design, and the method is simple and feasible, so that not only the soldering paste cannot generate plugged holes in a carrier pore canal, but also the condition that the soldering paste is discharged and pressed can be reduced, and soldering flux is saved, thereby rational utilization of resources can be achieved, and meanwhile, the welding strength is improved, and the quality of products is guaranteed.

Owner:浙江欧信环保科技有限公司

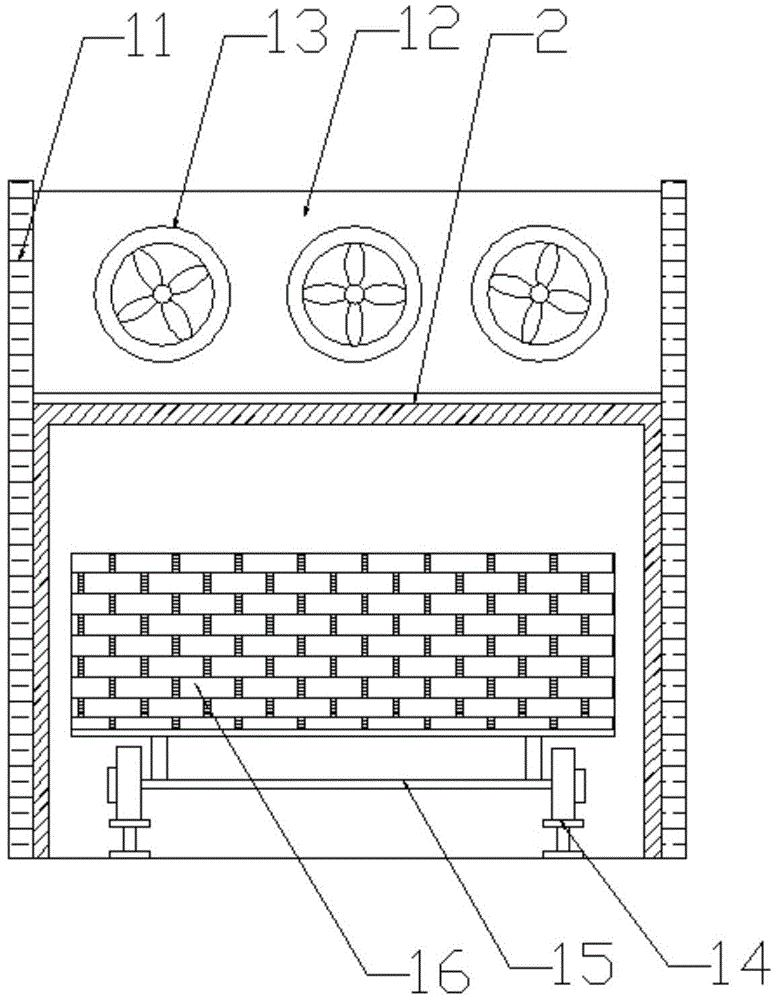

Calcining-kiln waste-heat utilization device for high-void rate shale hollow blocks

InactiveCN104315869AReasonable layoutLess occupied spaceDrying gas arrangementsFurnace typesTunnel kilnHeating energy

The invention discloses a calcining-kiln waste-heat utilization device for high-void rate shale hollow blocks. The calcining-kiln waste-heat utilization device comprises a drying tunnel kiln and a calcining tunnel kiln, a primary air supplying mechanism is arranged between the drying tunnel kiln and the calcining tunnel kiln, air inlets of the primary air supplying mechanism are communicated with a cooling section of the calcining tunnel kiln through air draft pipelines, an air outlet of the primary air supplying mechanism is connected with a secondary air supplying mechanism through a primary air supplying pipeline, the secondary air supplying mechanism is mounted on the drying tunnel kiln, an air outlet of the secondary air supplying mechanism is connected with at least two tertiary air supplying mechanisms through secondary air supplying pipelines, and air outlets of tertiary air supplying mechanisms are communicated with the cavity of the drying tunnel kiln through tertiary air supplying pipelines. The calcining-kiln waste-heat utilization device has the advantages of simple structure, heat energy is reasonably utilized by using waste heat generated from an existing cooling section for blank drying, and the problem about waste in heat energy of tunnel kilns is solved.

Owner:CHONGQING FUXI BUILDING MATERIALS

Method for improving operation safety of hydrocracking unit

ActiveCN111100687AAvoid remodeling workCatalyst activity is stableTreatment with hydrotreatment processesChemistryProcess engineering

The invention discloses a method for improving the operation safety of a hydrocracking device. The hydrocracking unit at least comprises two hydrocracking catalyst beds. The method comprises the following steps: cooling to 200-340 DEG C and switching the hydrocracking feed oil with the nitrogen content of 300 to 500 ppm when the weight percentage content of nitrogen in the hydrocracking catalyst in the first hydrocracking catalyst bed is 0.15-0.35%; switching the hydrofined oil with the nitrogen content of less than 40ppm when the nitrogen content in the hydrocracking effluent is constant at 50-80ppm; simultaneously adjusting the reaction temperature of the hydrocracking section until the mass yield of the light oil of less than 360 DEG C is finally kept constant at 35-40% and the total constant time is 48-96 hours; and then adjusting to the hydrocracking reaction condition for hydrocracking reaction. By the method, the problem that the activity of part of the hydrocracking catalyst isdamaged due to frequent startup and shutdown and then the mismatching of reaction temperatures among different catalyst beds in the reactor is influenced is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

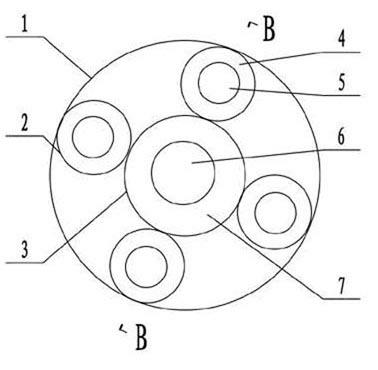

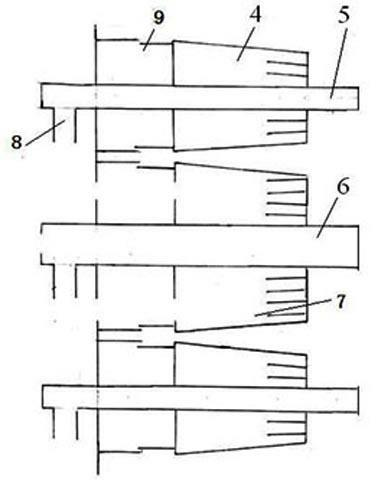

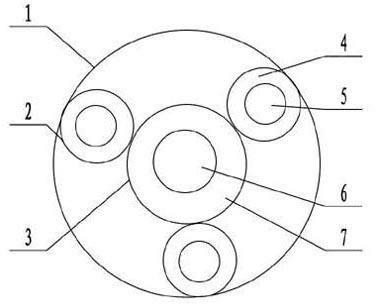

Detachable type spinneret plate

InactiveCN105525365ASimple structureEasy to assemble and disassembleSpinnerette packsBiochemical engineering

The invention relates to a detachable type spinneret plate. The detachable type spinneret plate comprises a spinneret plate body and a fixed plate body, wherein the fixed plate body adopts a hollow round structure, a step surface is arranged on the inner ring of the fixed plate body, and the spinneret plate body is arranged on the step surface. The detachable type spinneret plate is simple in structure and convenient to dismount and mount, all that is required is to replace the spinneret plate bodies with different specifications when products with different specifications are produced, the fixed plate body is not required to be replaced, so that resources are reasonably utilized, and production and manufacture cost is reduced.

Owner:刘静兰

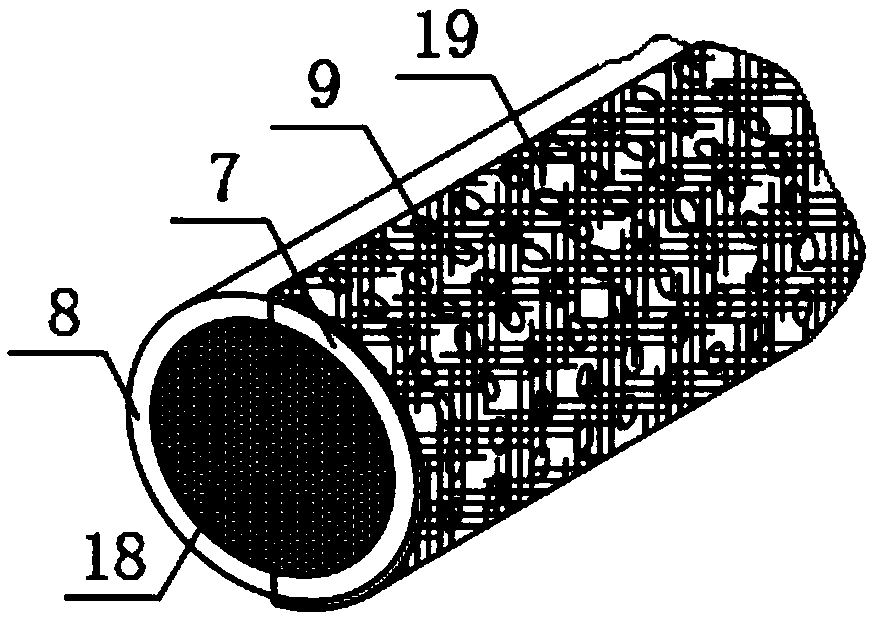

Pipeline device for improving saline-alkali soil

ActiveCN109392343AImprove dissolution efficiencyHigh salinitySoil lifting machinesWind motor with solar radiationAlkali soilWater storage tank

The invention discloses a pipeline device for improving saline-alkali soil. The pipeline device comprises a salt discharge pipe, an osmotic pipe, a water storage tank, a saline-alkali storage tank anda power generation system, wherein the osmotic pipe is fixedly arranged at the top of the salt discharge pipe, the bottom end of the osmotic pipe extends to the inner cavity of the salt discharge pipe, two ends of the salt discharge pipe are respectively provided with the water storage tank and the saline-alkali storage tank, the power generation system is arranged at the top end of one side of the osmotic pipe, and first osmotic holes are fixedly arranged around the outer wall of the osmotic pipe. The saline-alkali in the saline-alkali land is dissolved through clean water or rainwater to obtain dissolved water, the dissolved water enters the salt discharge pipe through the first osmotic holes or the second osmotic holes, then the dissolved water is filtered by using the salt discharge pipe, so that the filtered clean water enters the water storage tank for reuse, and residual filtered saline-alkali and minerals in the soil are transported to the saline-alkali storage tank for centralized collection by rotating of a screw conveyor, thereby improving the dissolving efficiency of the saline-alkali and greatly improving the saline-alkali property of the saline-alkali soil.

Owner:兴安盟隆华农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com