Calcining-kiln waste-heat utilization device for high-void rate shale hollow blocks

A hollow block and porosity technology, which is applied in the field of brick production, can solve problems such as heat energy waste in tunnel kilns, and achieve the effects of simple structure, solving heat energy waste and sufficient heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

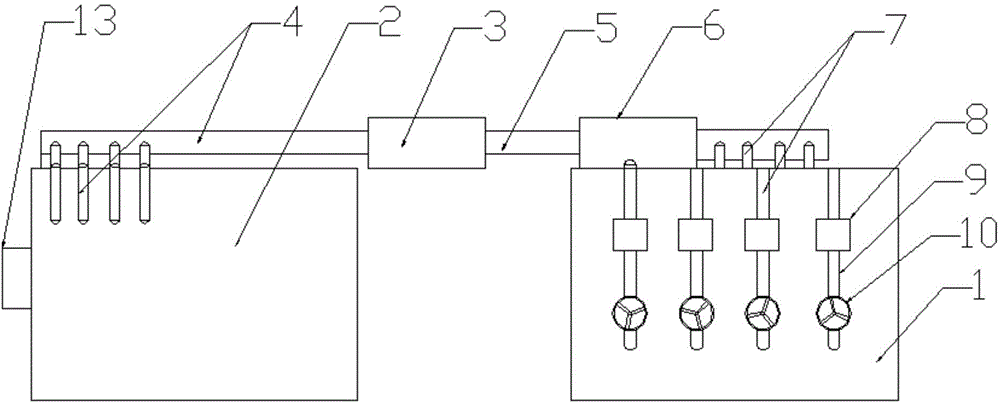

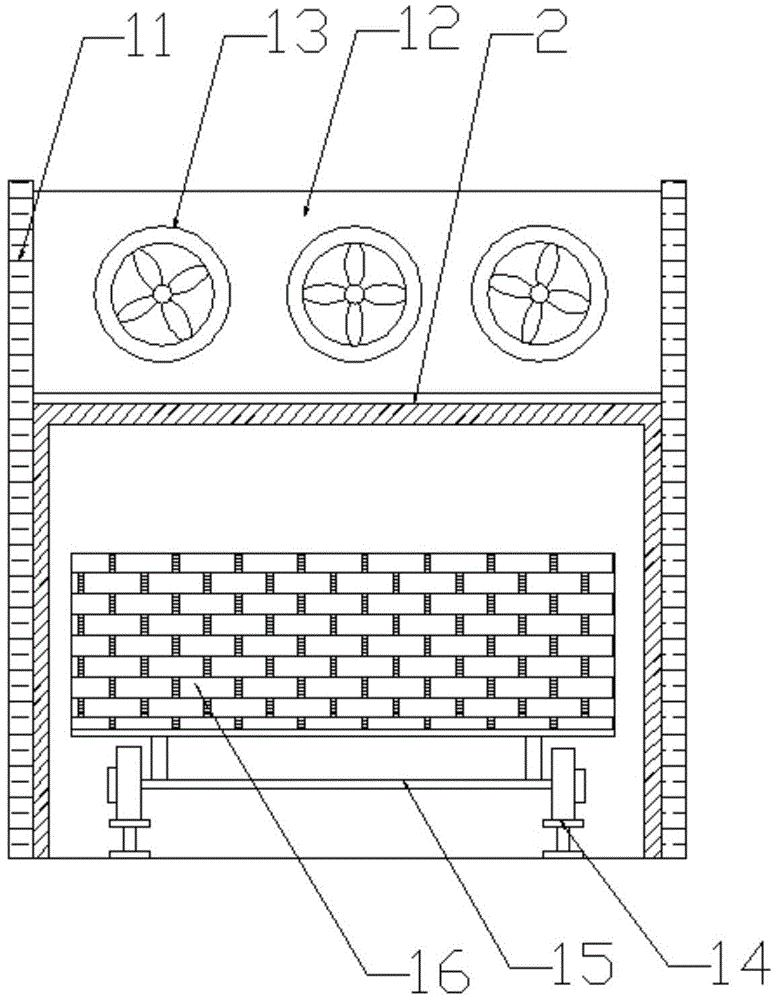

[0020] Such as Figure 1-Figure 2 As shown, a high porosity shale hollow block roasting kiln waste heat utilization device includes a drying tunnel kiln 1 and a roasting tunnel kiln 2. The roasting tunnel kiln 2 is divided into a roasting section and a cooling section. The cooling section is close to At the outlet end of the roasting tunnel kiln 2, a primary air supply mechanism 3 is arranged between the drying tunnel kiln 1 and the roasting tunnel kiln 2, and the air inlet of the primary air supply mechanism 3 is connected with the exhaust duct 4, and the exhaust duct 4 communicate with the cooling section of the roasting tunnel kiln 2 through eight air inlets respectively, the air outlet of the primary air supply mechanism 3 is connected with the secondary air supply mechanism 6 through the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com