Rubber composition using both EPDM and reclaimed rubber

A technology of EPDM rubber and rubber composition, which is applied in the field of rubber, can solve problems such as large gaps, achieve excellent mechanical properties, excellent fluidity, and alleviate the effects of resource scarcity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

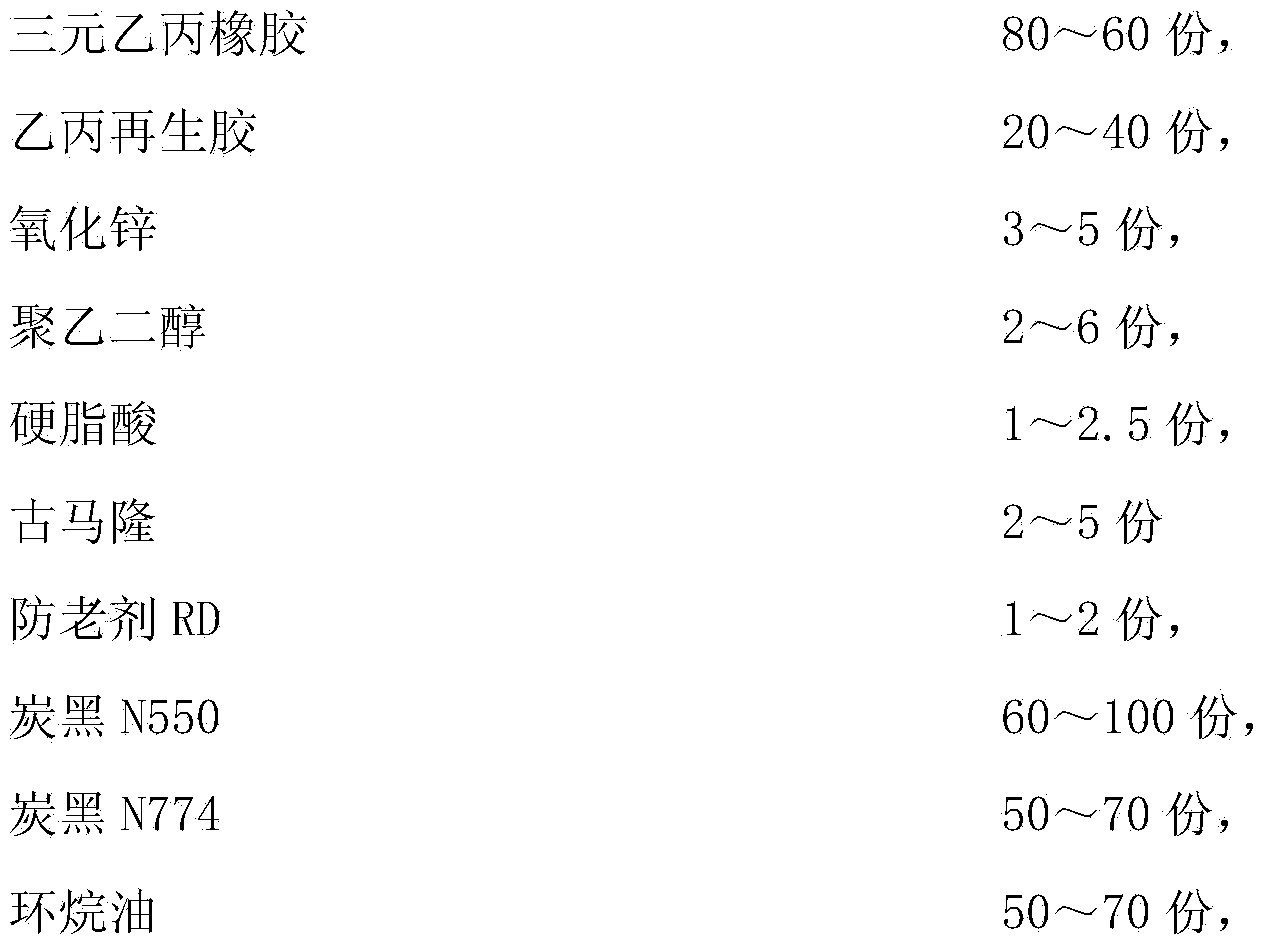

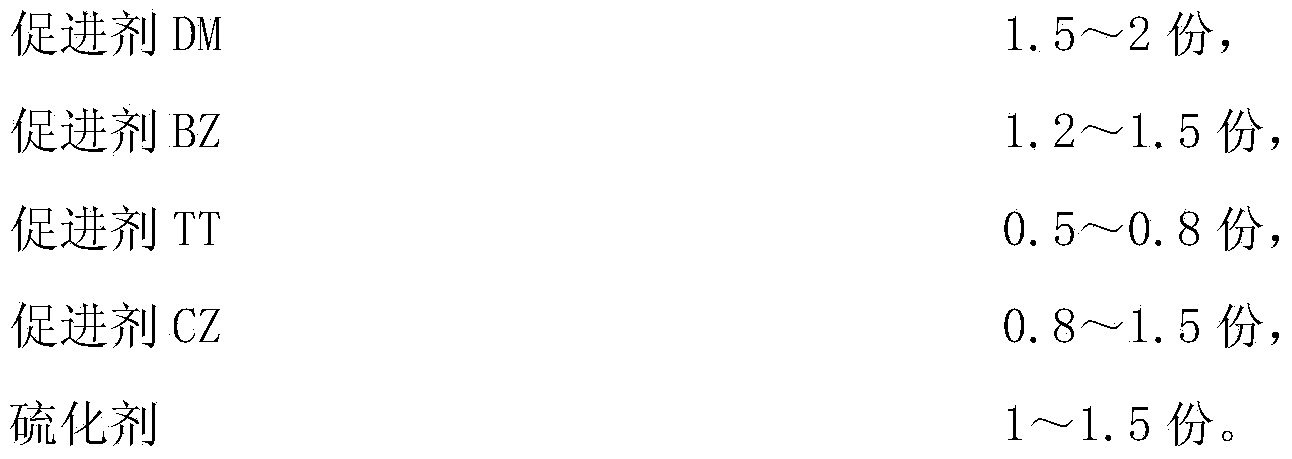

[0015] Embodiment of the rubber composition using EPDM and EPDM reclaimed rubber in combination:

[0016] In parts by mass

[0017] components

Example 1

Example 2

Example 3

EPDM

80

70

60

Ethylene Propylene Reclaimed Rubber

20

30

40

5

3

4

polyethylene glycol

4

6

2

1

1.5

2.5

Coumaron

4

2

5

[0018] Antiaging agent RD

1.5

2

1

Carbon black N550

80

100

60

Carbon black N774

50

60

70

naphthenic oil

70

60

50

accelerator DM

1.5

2

1.8

Accelerator BZ

1.5

1.5

1.2

Accelerator TT

0.6

0.5

0.8

Accelerator CZ

1.1

0.8

1.5

Vulcanizing agent

1.5

1.2

1

total

321.7

340.5

300.8

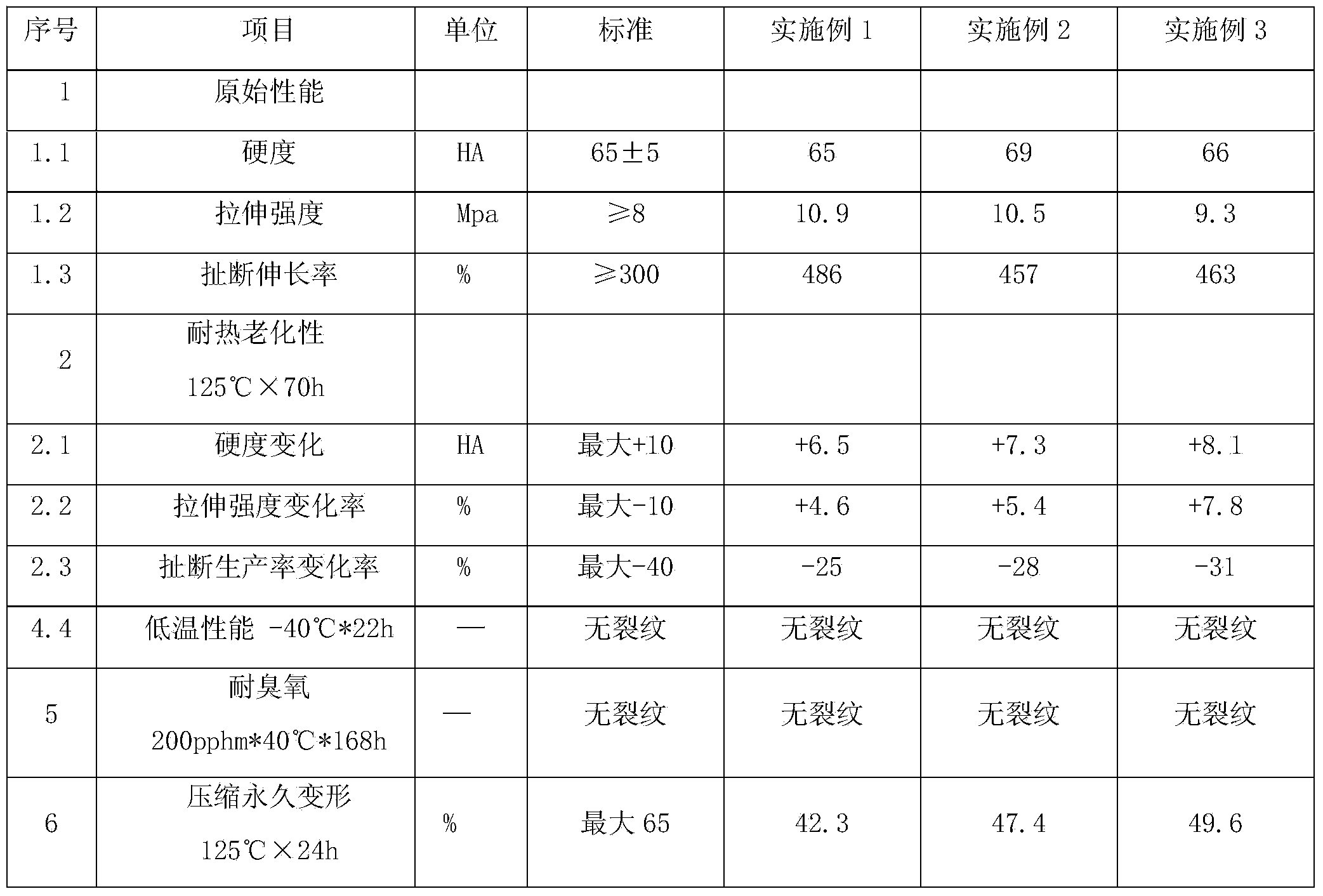

[0019] According to the raw material in the embodiment formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com