Combustor for high/low-calorific-value gas

A burner and gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., to achieve the effects of sufficient mixing, improved performance, and increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

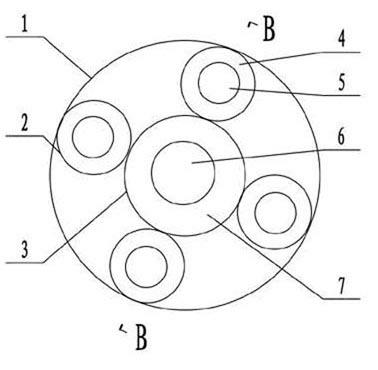

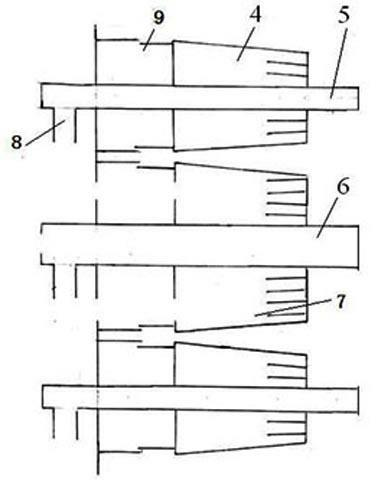

[0022] The burner for high and low calorific value gas of the present invention, such as figure 1 , figure 2 As shown, it includes a central burner 3 and four peripheral burners 2. The central burner is provided with a central fuel nozzle 6 and a central air nozzle 7 , and the peripheral burner is provided with a peripheral fuel nozzle 5 and a peripheral air nozzle 4 . The central fuel nozzle and the peripheral fuel nozzles are respectively provided with air intake pipes 8, the central air nozzle and the peripheral air nozzles are respectively provided with air inlets 9, and the air inlets are provided with an air volume regulating mechanism.

[0023] The combustion process of the high and low calorific value gas burner is that the low calorific value fuel water gas enters the central fuel nozzle 5 through the air intake pipe 8 of the central burner, and enters the peripheral fuel nozzle 5 through the air inlet of the peripheral burner. Air enters the central air nozzle 7 ...

Embodiment 2

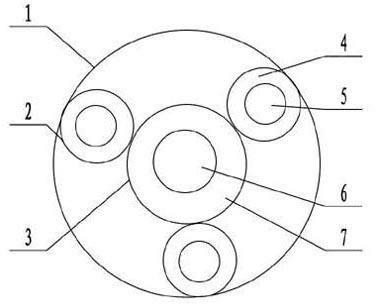

[0025] Another embodiment of the present invention is as image 3 As shown, it includes a central burner 3 and three peripheral burners 2. The central burner is provided with a central fuel nozzle 6 and a central air nozzle 7 , and the peripheral burner is provided with a peripheral air nozzle 4 and a peripheral fuel nozzle 5 . The central fuel nozzle and the peripheral fuel nozzles are respectively provided with air intake pipes 8, the central air nozzle and the peripheral air nozzles are respectively provided with air inlets 9, and the air inlets are provided with an air volume regulating mechanism. The air inlet is connected to the oxygen-enriched preparation equipment. The oxygen-enriched preparation equipment is an oxygen-enriched membrane, and the oxygen content in the oxygen-enriched air provided is 30%.

[0026] In this embodiment, heavy oil pyrolysis gas is used as fuel with a high calorific value, and the heavy oil pyrolysis gas enters the central fuel nozzle 6 and ...

Embodiment 3

[0028] Another embodiment of the present invention is as Figure 4 As shown, including central burner 3 and 5 peripheral burners 2. The central burner is provided with a central fuel nozzle 6 and a central air nozzle 7 , and the peripheral burner is provided with a peripheral fuel nozzle 5 and a peripheral air nozzle 4 . The air inlet pipe 9 of the central air nozzle 7 is connected with the pressure swing adsorption oxygen generator to provide oxygen-enriched air with an oxygen content of 50%.

[0029] In this embodiment, two fuels with high and low calorific value are used, and the high calorific value fuel has a calorific value of 18250kj / m 3 coke oven gas, the fuel with low calorific value is kj / m with a calorific value of 5900 3 Producer gas. The fuel with high calorific value enters the central fuel nozzle 6 through the feed port, and the fuel with low calorific value enters the peripheral fuel nozzle 5 through the feed port. Air enters the peripheral air nozzle 4 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com