Dual-cooling-head slit-cooling coaxial neamal tube refrigerating machine

A pulse tube refrigerator and slit technology, which is applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problem of affecting gas laminarization, increasing the radial size of coaxial pulse tubes, and poor compatibility requirements High-level problems, to achieve the effect of simple and convenient processing, exemption from flatness, and guaranteed sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

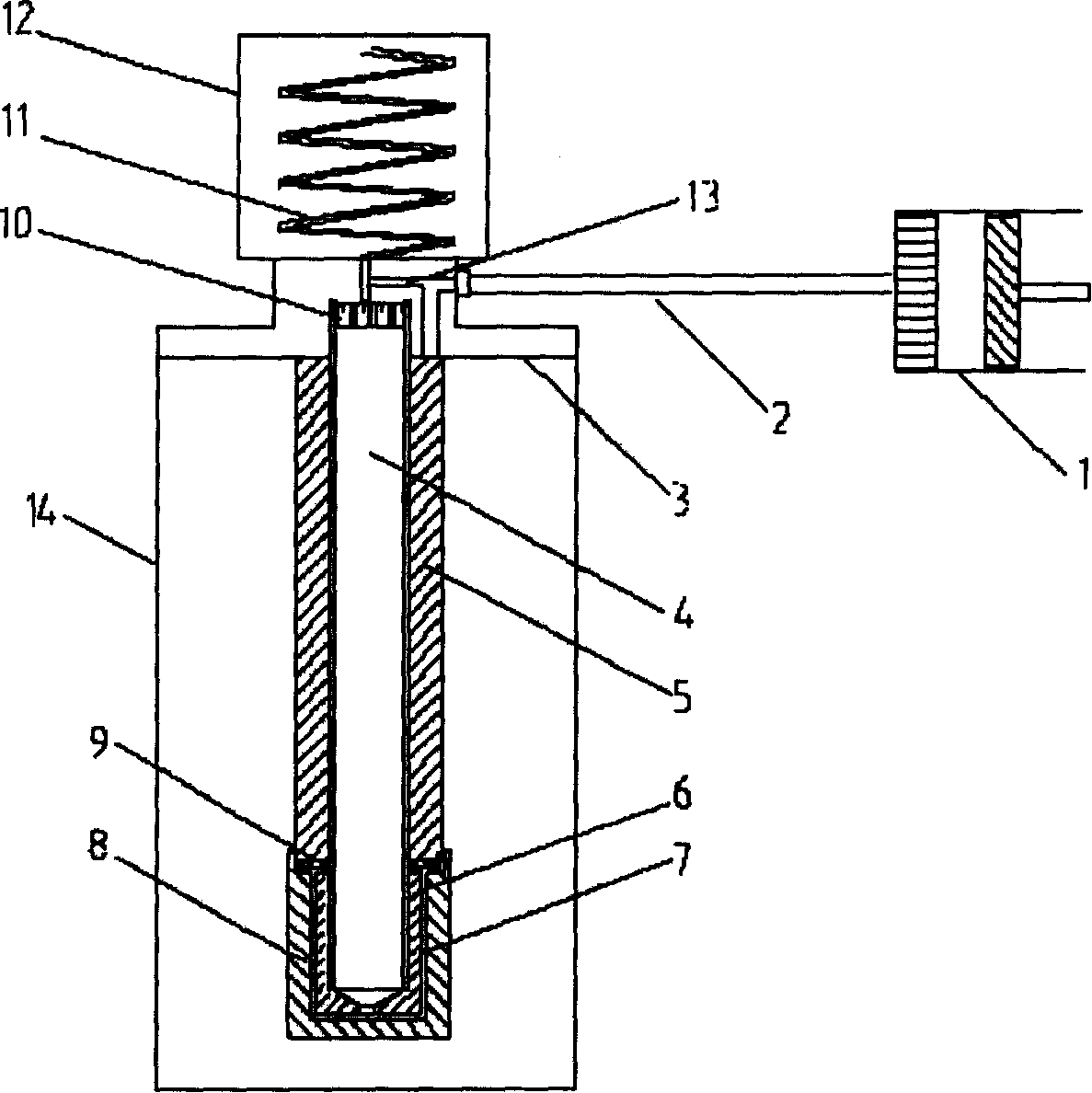

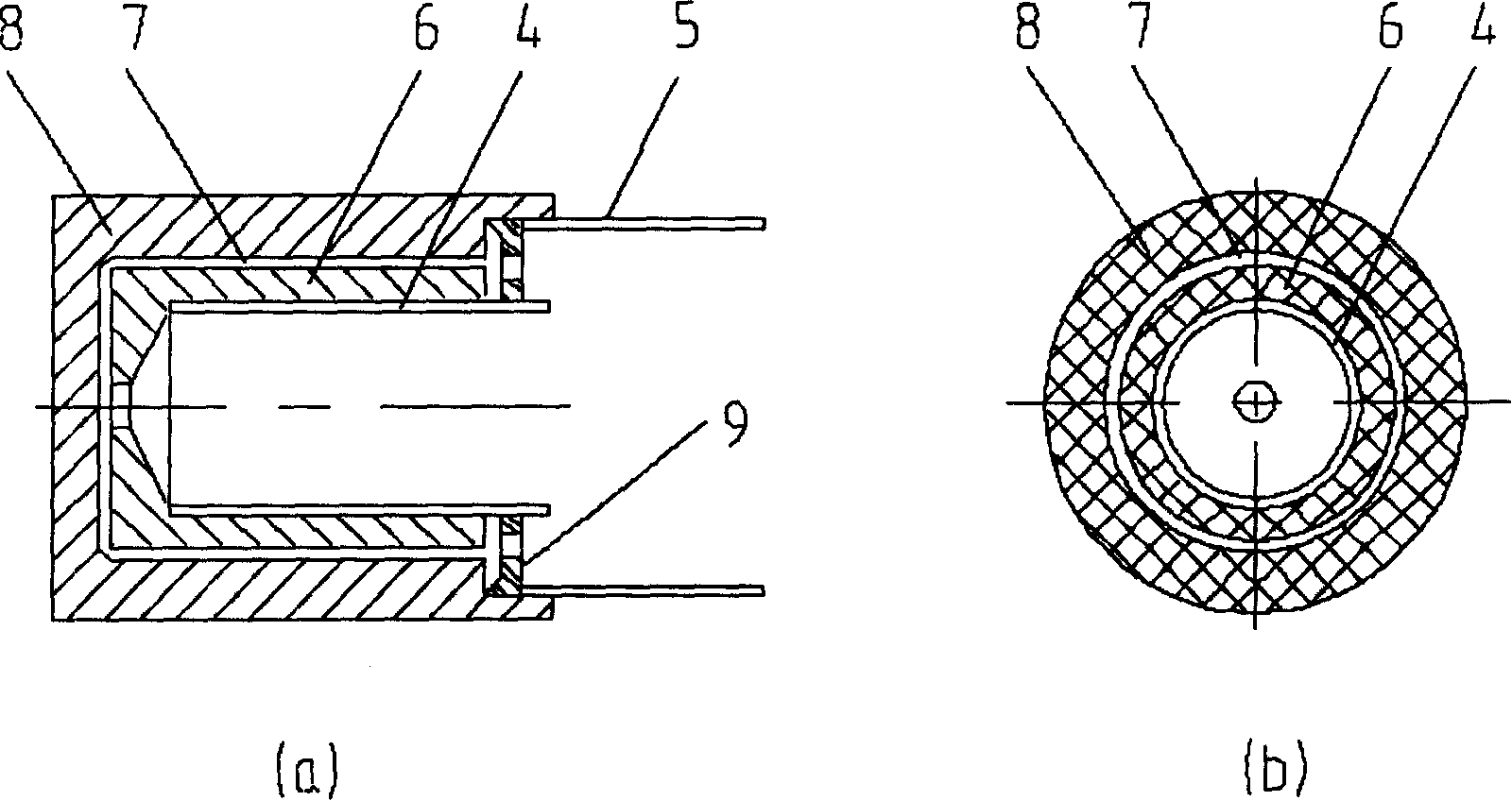

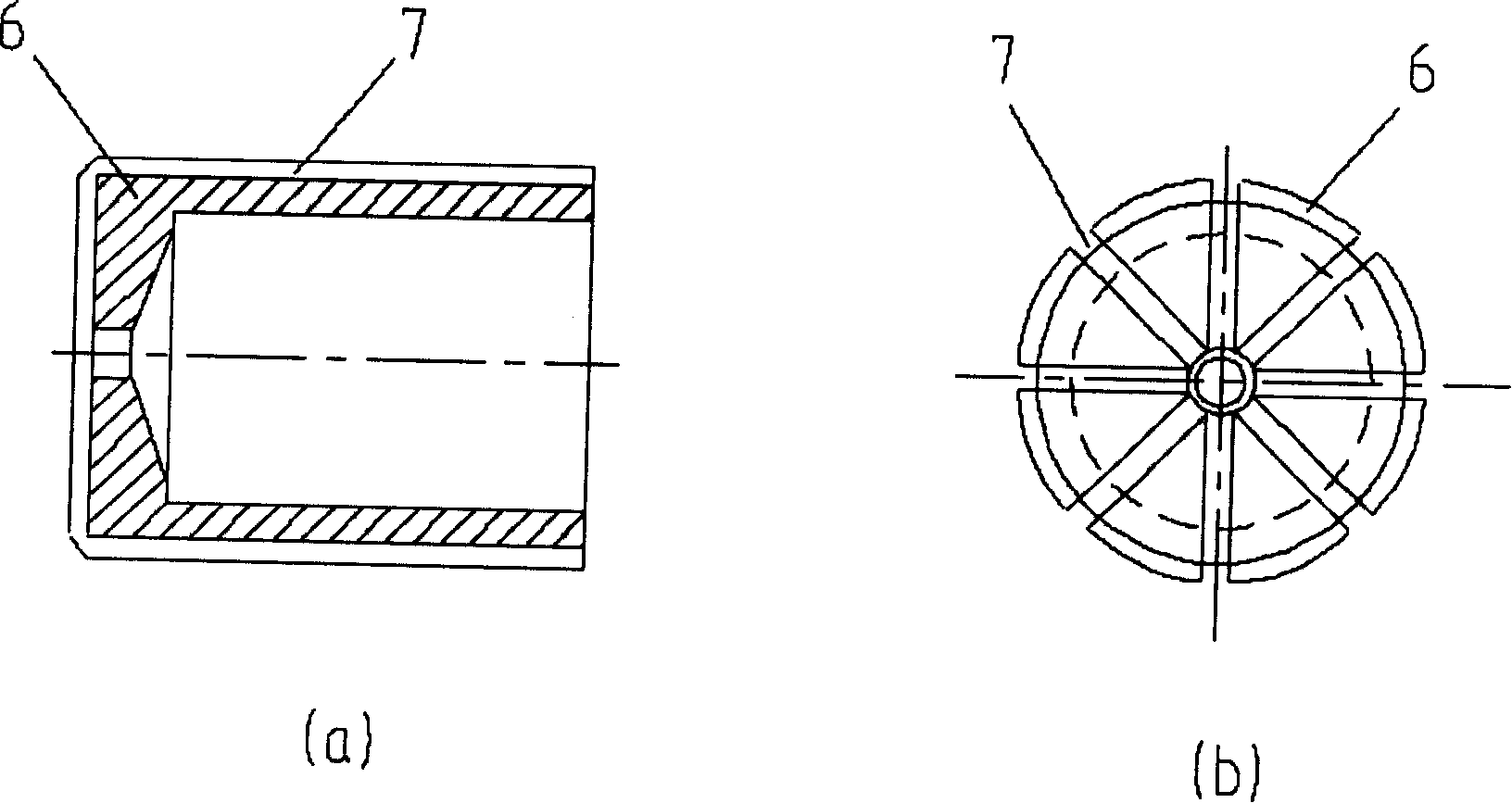

[0013] Such as figure 1 As shown, the present invention includes: a linear compressor 1, an air intake pipeline 2, a hot-end gas distribution flange 3, a pulse tube 4, a cold storage device 5, a slit-type cold finger 6, a channel 7, a cold-end jacket 8, a cold End deflector 9, hot end deflector 10, long neck pipe 11, gas storage 12, two-way air intake channel 13, vacuum cover 14.

[0014] A linear compressor 1 provides pressure fluctuations, and is connected to the hot end of the regenerator 5 coaxially sleeved outside the pulse tube 4 through the air intake pipeline 2 and the gas distribution flange 3 at the hot end. The cold end of the pulse tube 4 extends Out of the cold end of the regenerator 5, the outer wall of the protruding part closely fits a slit-type cold finger 6, and the bottom surface and the outer wall of the slit-type cold finger 6 are axially symmetrically provided with grooves 7, and a high-heat The cold end jacket 8 made of conductive material covers the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com