Arrangement structure of lattice-form underground continuous wall

An underground diaphragm wall and structure layout technology, which is applied to underwater structures, foundation structure engineering, sheet pile walls, etc., can solve the problems of difficult hoisting of steel cages, difficult processing of steel bars, and high project investment, so as to reduce construction risks , small amount of work, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

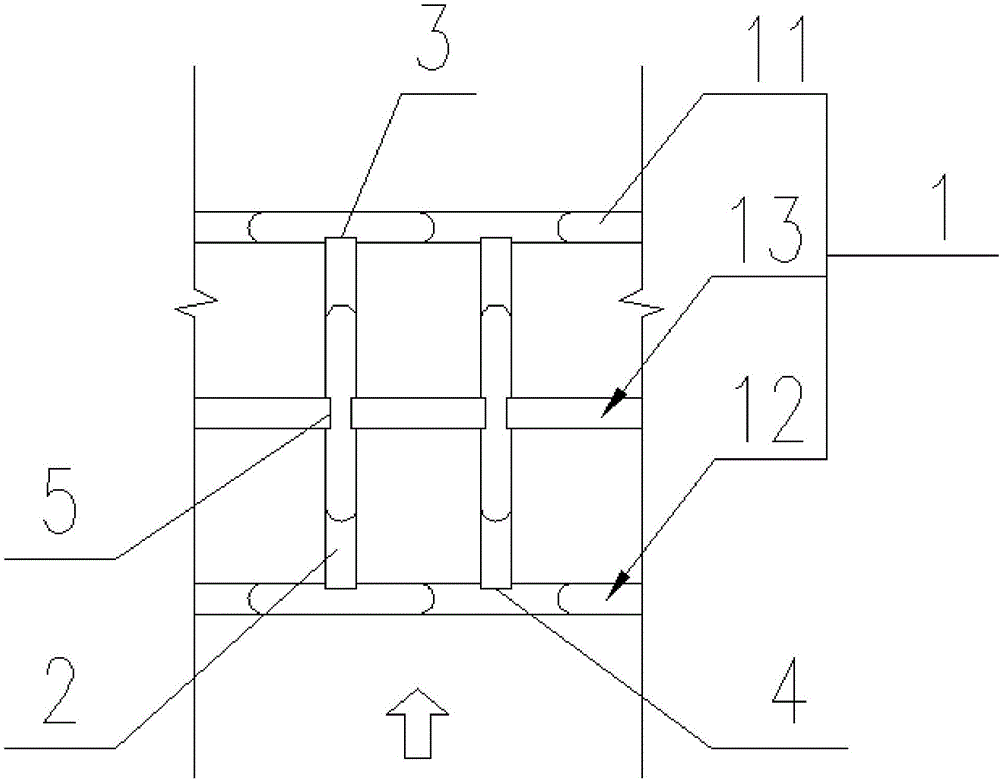

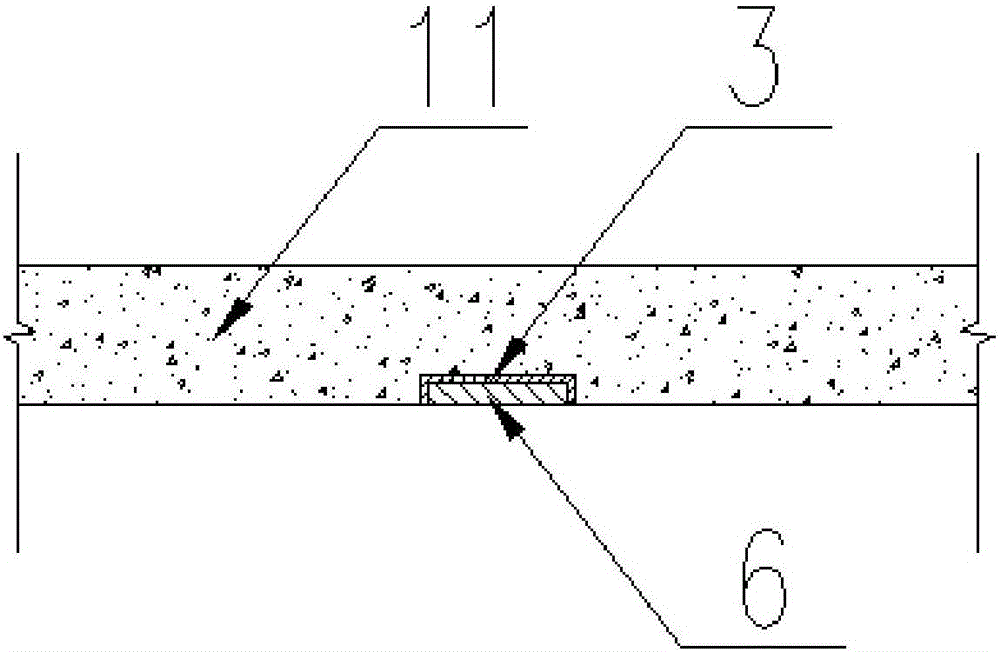

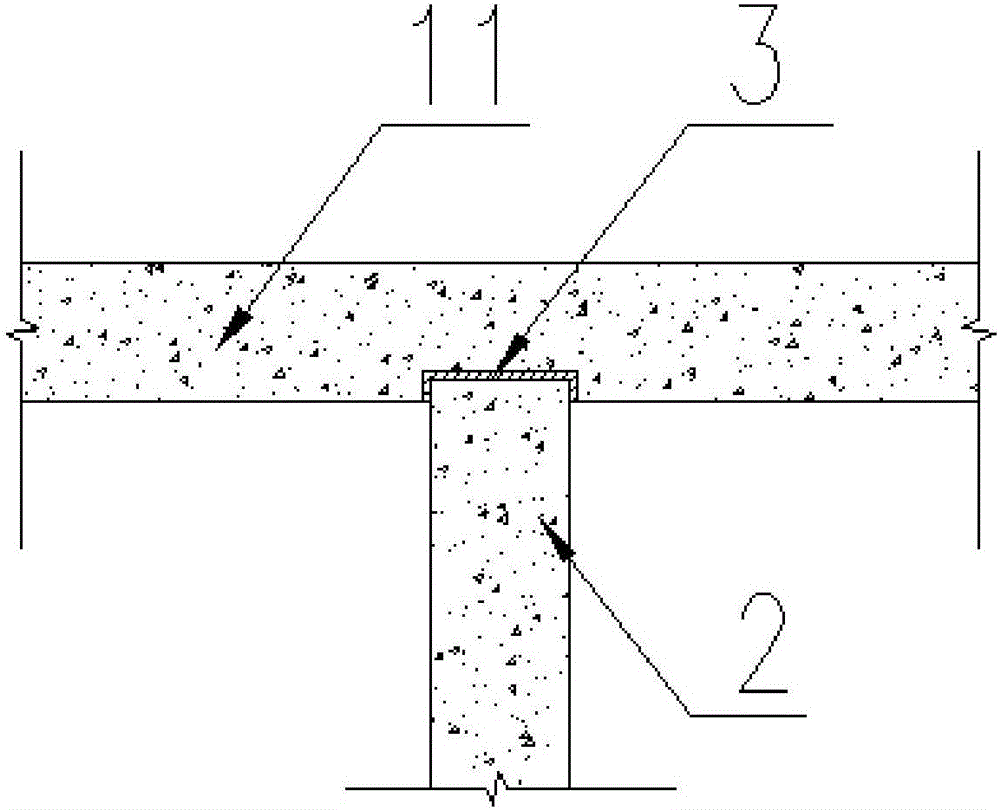

[0013] The present invention will be further described below in conjunction with the accompanying drawings, and the direction shown by the arrow in the figure is the main load direction.

[0014] Such as figure 1 As shown, the present invention includes a longitudinal wall 1 and a transverse wall 2, the axis of the longitudinal wall 1 is perpendicular to the main load direction, the axis of the transverse wall 2 is the same as the main load direction, and the longitudinal wall 1 includes an inner longitudinal wall 11 and an outer longitudinal wall 12, One end of the transverse wall 2 is connected to the inner longitudinal wall 11, and the other end is connected to the outer longitudinal wall 12. The inner longitudinal wall 11 is provided with a U-shaped joint 3 on the side facing the outer longitudinal wall 12, and the U-shaped joint 3 is embedded in the inner longitudinal wall 11. And it is fixedly connected with the steel cage in the inner longitudinal wall 11, the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com