Optical fiber grating vibration sensor made of multi-cantilever beam all-insulation materials

A vibration sensor, fiber grating technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve single problems, reduce costs, simplify processing procedures, and prevent loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

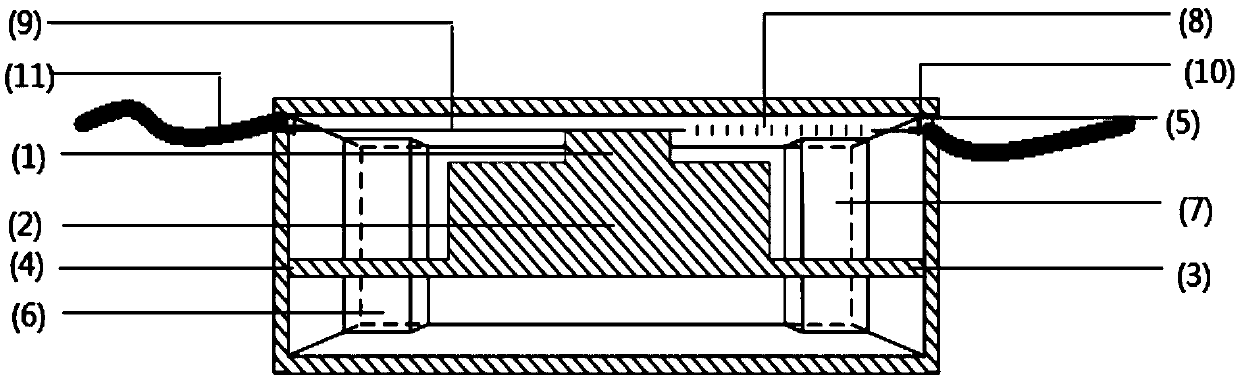

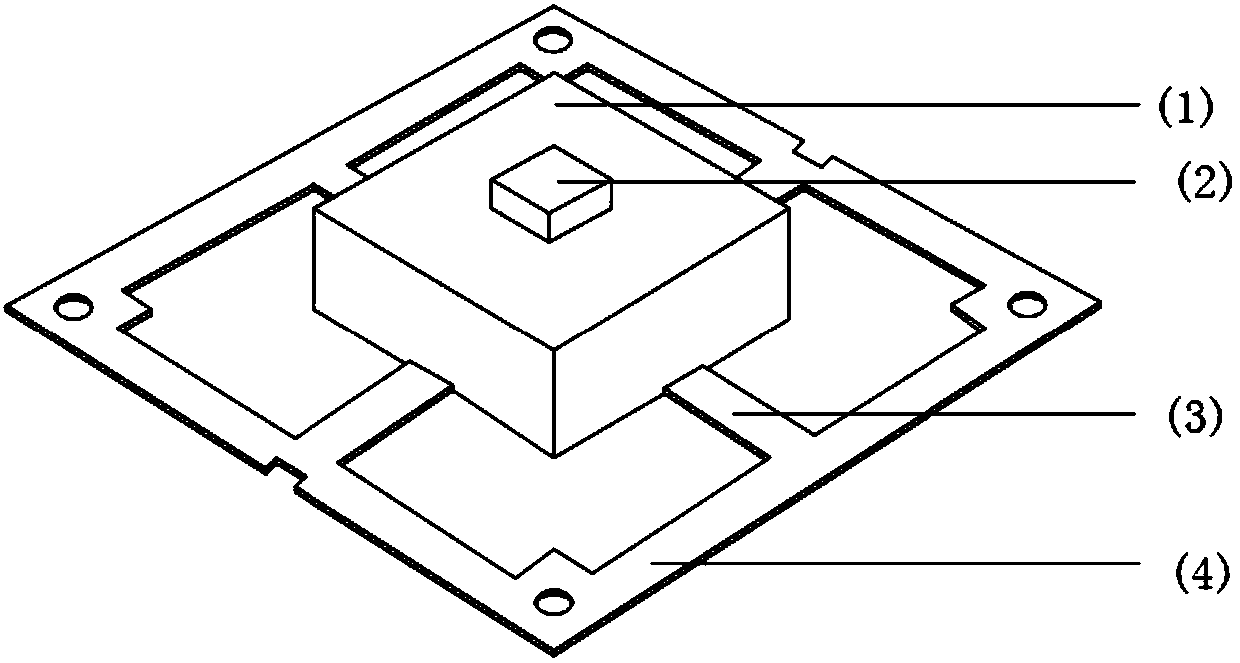

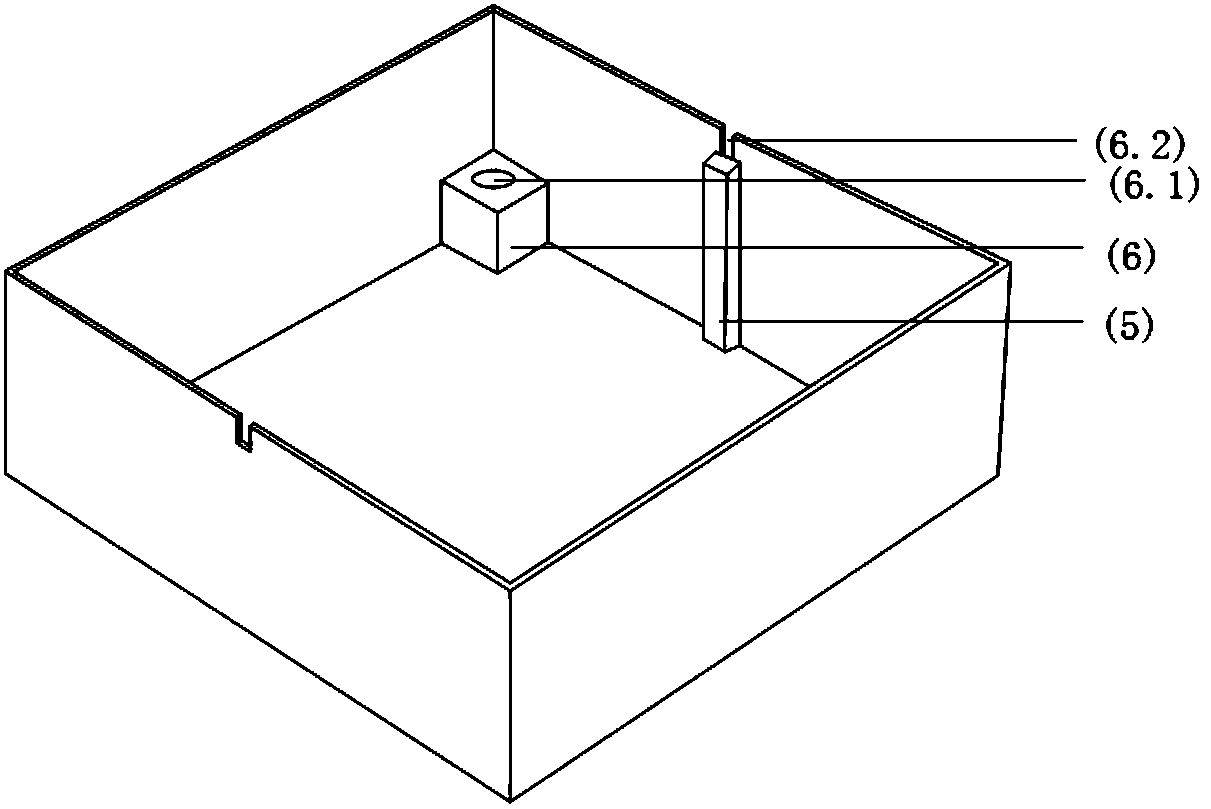

[0016] The structure of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0017] See figure 1 , a multi-cantilever full insulating material fiber grating vibration sensor, comprising a rectangular box-type base, a vibration sensor connected to the base, and a top cover on the base; wherein the vibration sensor includes a Rectangular mass block 1, four equal-length cantilever beams 3 symmetrically connected to the four sides of the mass block 1, and a frame 4 ring-connected to the four cantilever beams 3; The raised quadrangular prism 6 is provided with connection holes 6.1, the four corners of the frame 4 are provided with perforations 4.1, and the perforations 4.1 are correspondingly connected with the connection holes 6.1 to realize the suspension of the mass block 1, and the four corners of the top cover are also provided with Four equal-height quadrangular prism protrusions 7, the four prism protrusions 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com