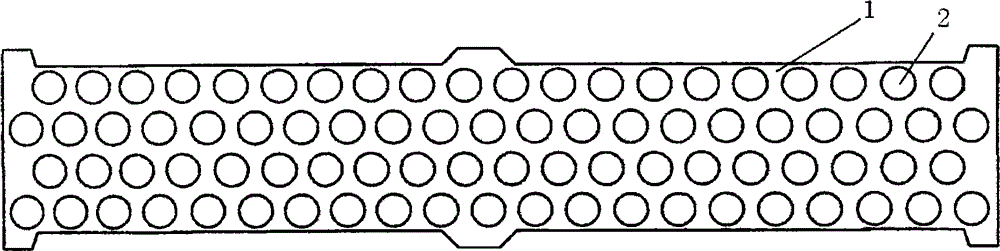

Production method of mechanically press-molded high-temperature baffle brick

A machine press molding and production method technology, applied in the field of refractory material manufacturing, can solve the problems of low refractoriness, low production efficiency of baffle bricks, poor thermal shock resistance, etc., achieve high refractoriness, avoid slow production, and heat resistance The effect of improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

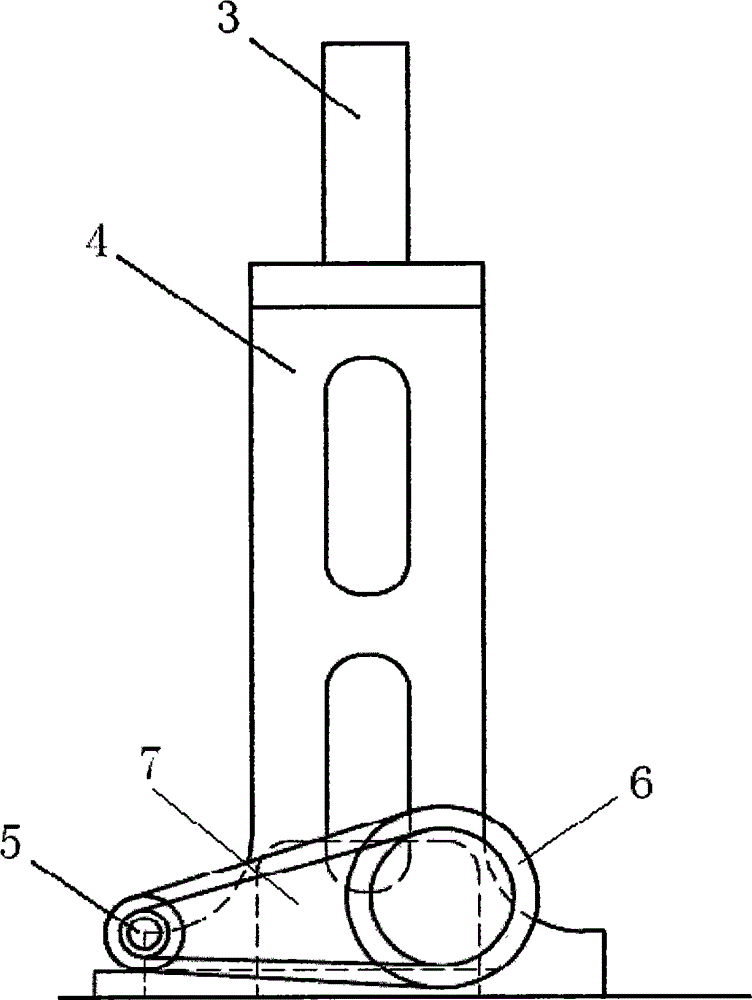

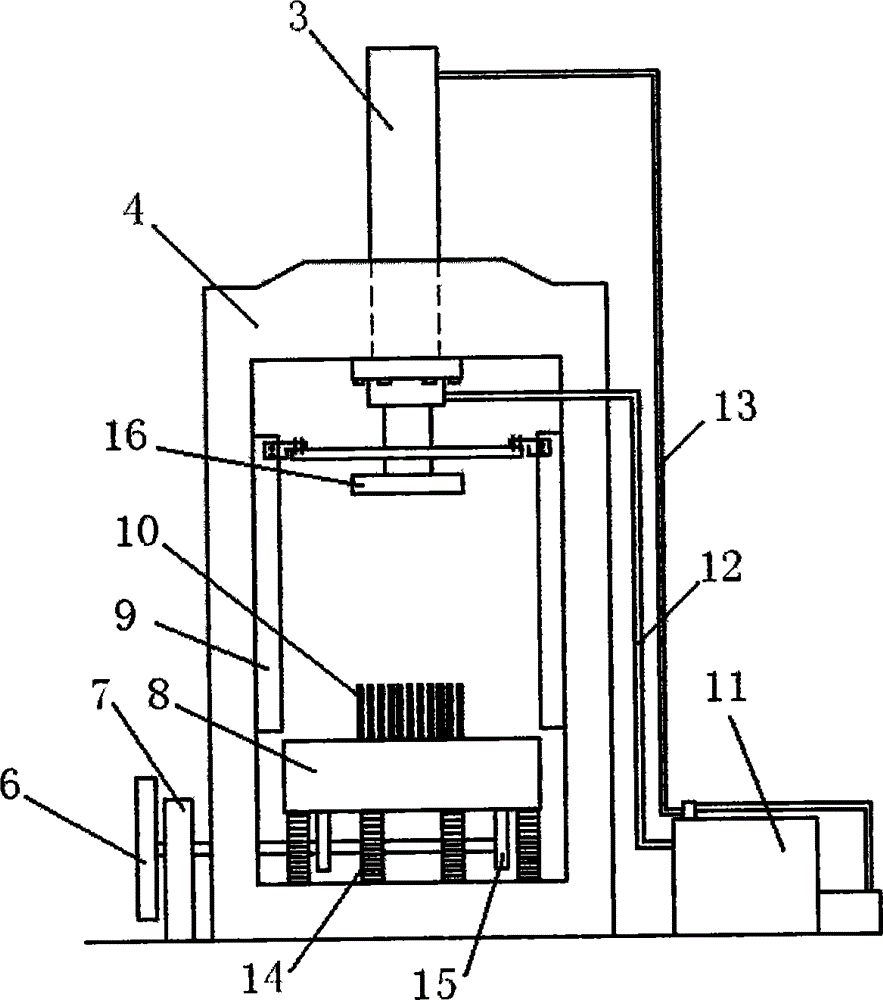

Method used

Image

Examples

Embodiment 1

[0049] A high-temperature baffle brick formed by machine pressing of the present invention is made of a base material and a binder. The base material is calculated by weight: 60% of high alumina material, 10% of mullite material, and 10% of Guangxi white clay. % and corundum powder 20%, the binder is composed of 30% of 180 mesh mullite material, 20% of 180 mesh high alumina material and 50% of water, the binder is added to the base material by weight as the base material 10% by weight (ie base material: binder = 100:10 or written as 10:1).

[0050] Such as 1000kg of base material, including 600kg of high alumina material, 100kg of mullite material, 200kg of corundum powder and 100kg of white clay, the binder is composed of 30kg of mullite material, 20kg of corundum powder and 50kg of water, that is, the baffle brick is composed of 1000kg It is made of materials composed of the base material and 100kg of binder.

[0051] The production method that realizes embodiment 1 is, at ...

Embodiment 2

[0053] A machine-pressed high-temperature baffle brick of the present invention can also be composed of a base material composed of 55% of high-alumina material, 12% of corundum powder, 18% of mullite and 15% of white mud by weight: Mo It is made of a binder consisting of 30% of stone powder, 30% of corundum powder and 40% of water. The amount of binder added is 12% of the base material. It is composed of 1800kg of stone and 1500kg of white clay, and the binder is composed of 360kg of mullite powder, 360kg of corundum powder and 480kg of water. The process step of present embodiment 2 is the same as embodiment 1.

[0054] Because the components of the baffle bricks produced by the machine press molding method of the present invention are different from those of the traditional cast-molded baffle bricks, the components are scientific and reasonable, and the binder does not use existing lignin or simple water, and is made at 1480°C It is fired at a high temperature above -1580°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com