Patents

Literature

39results about How to "High pile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

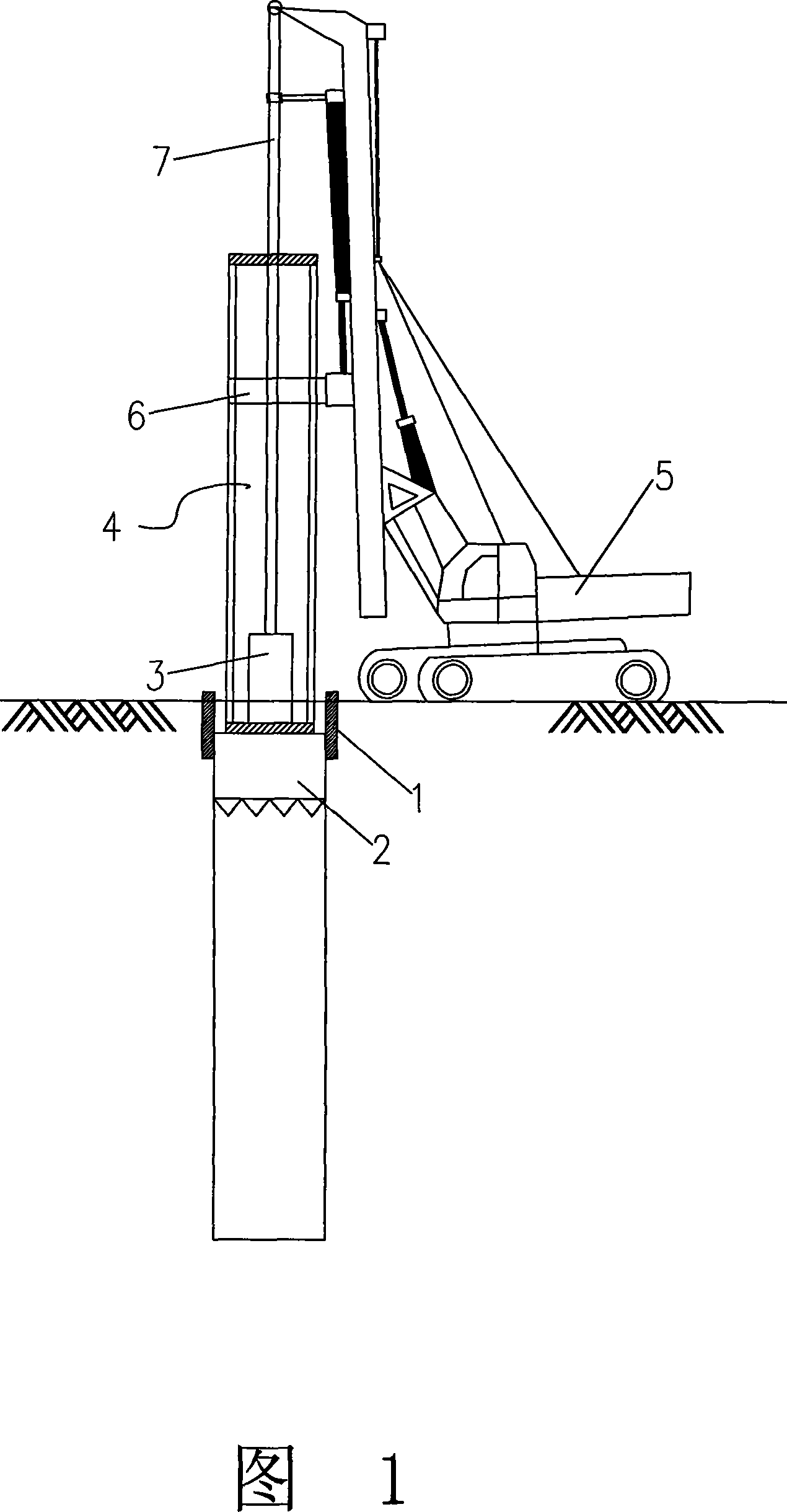

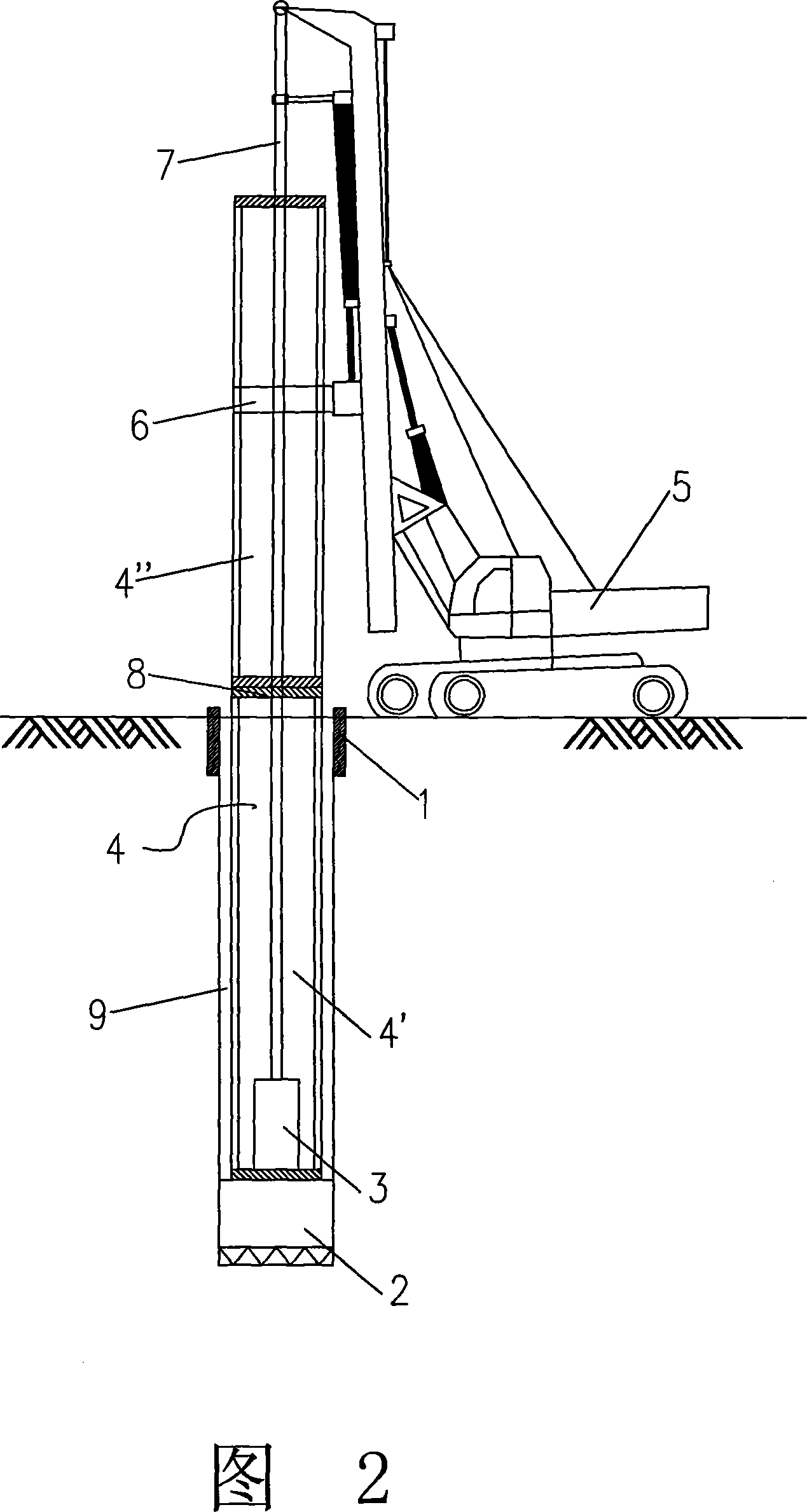

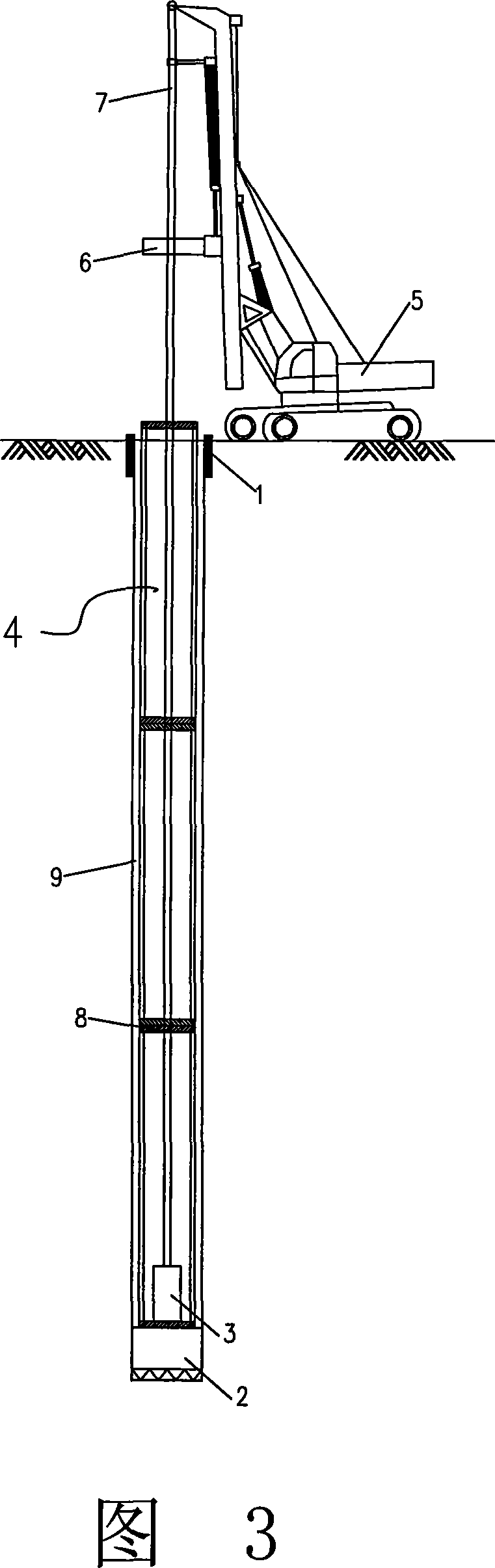

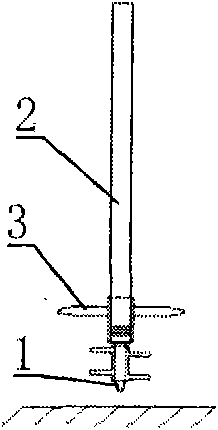

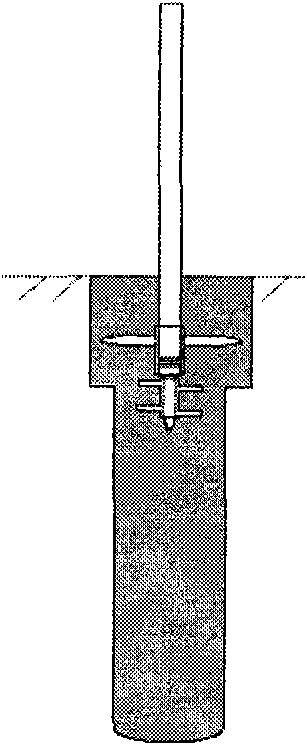

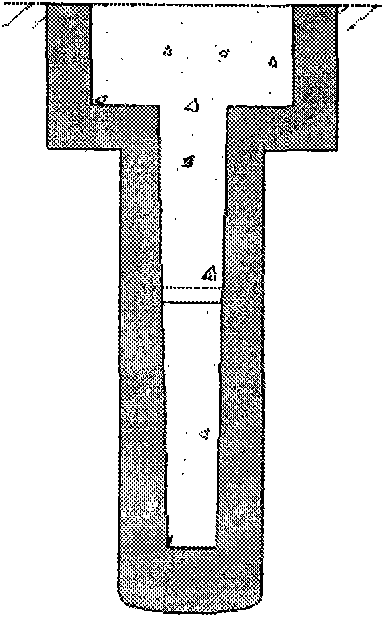

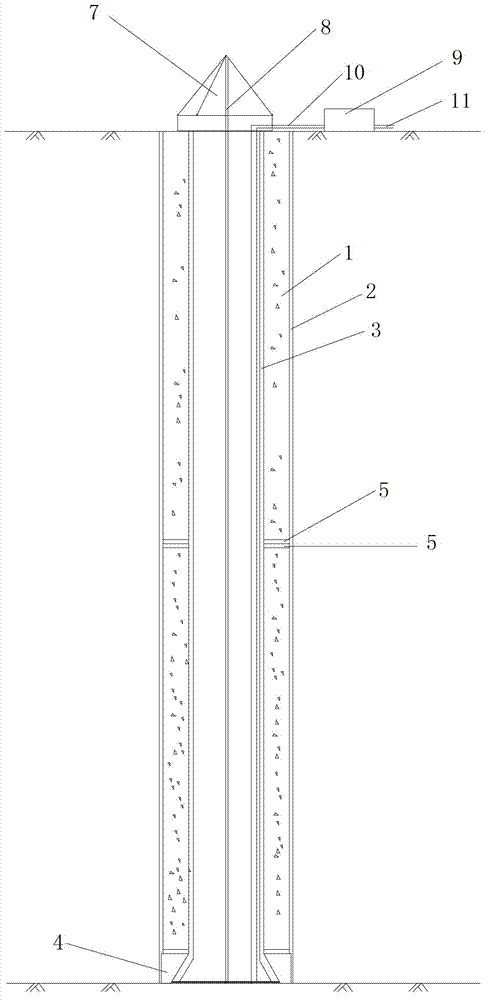

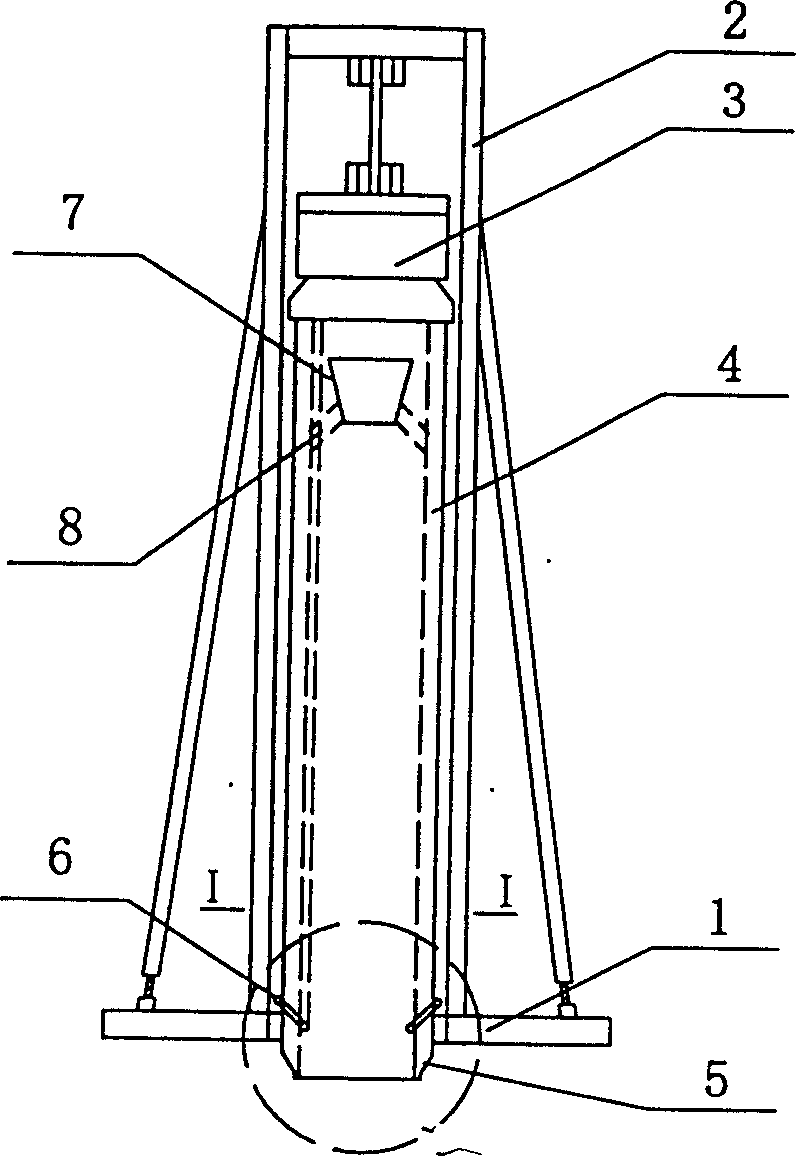

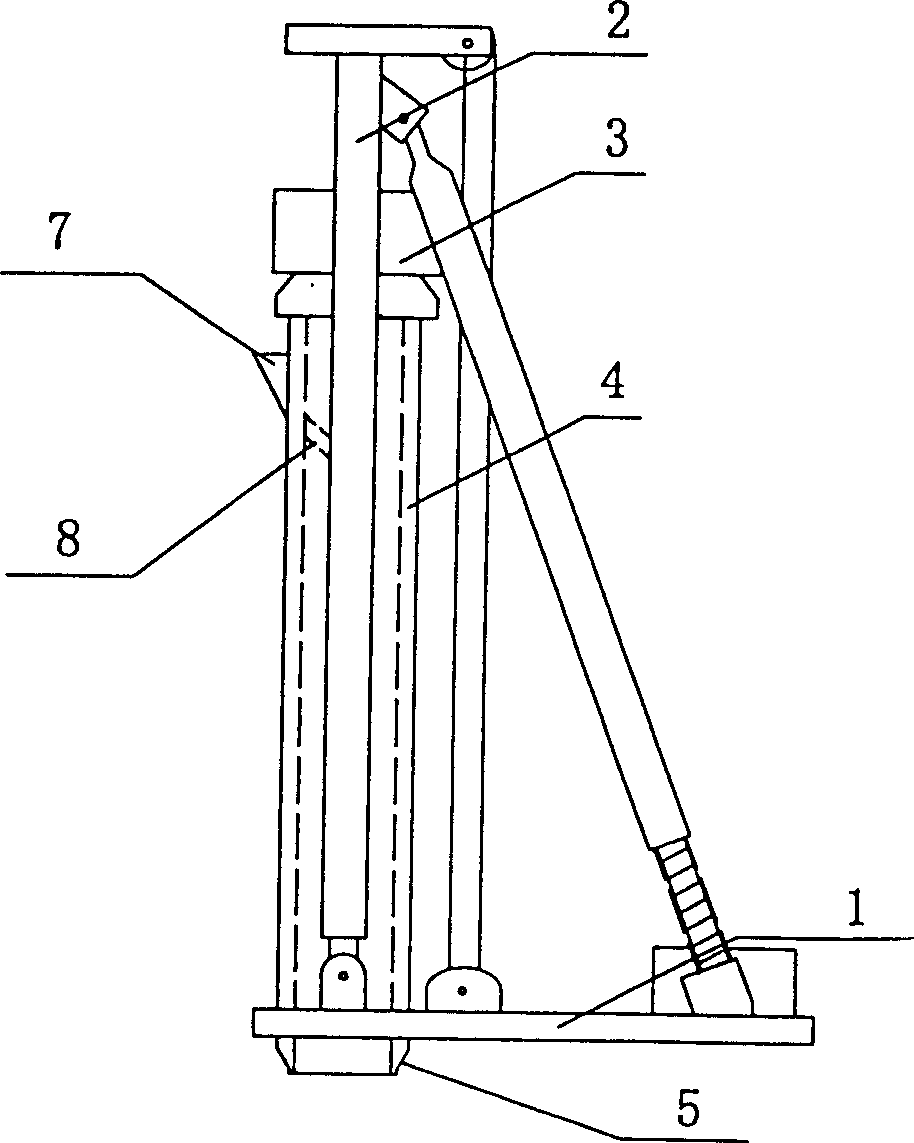

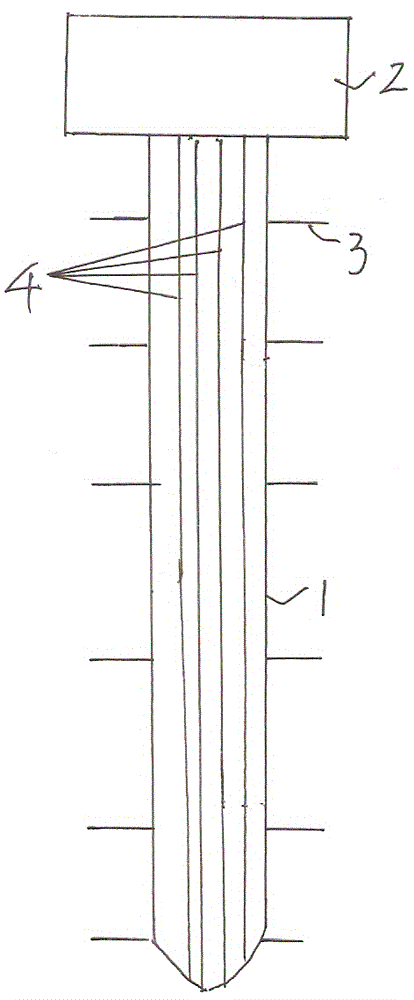

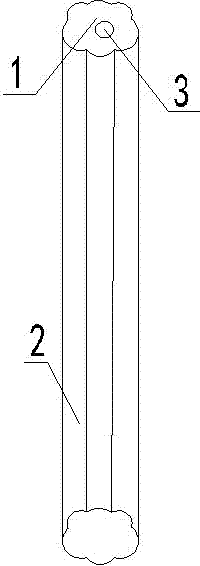

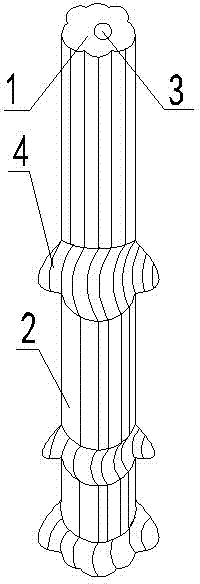

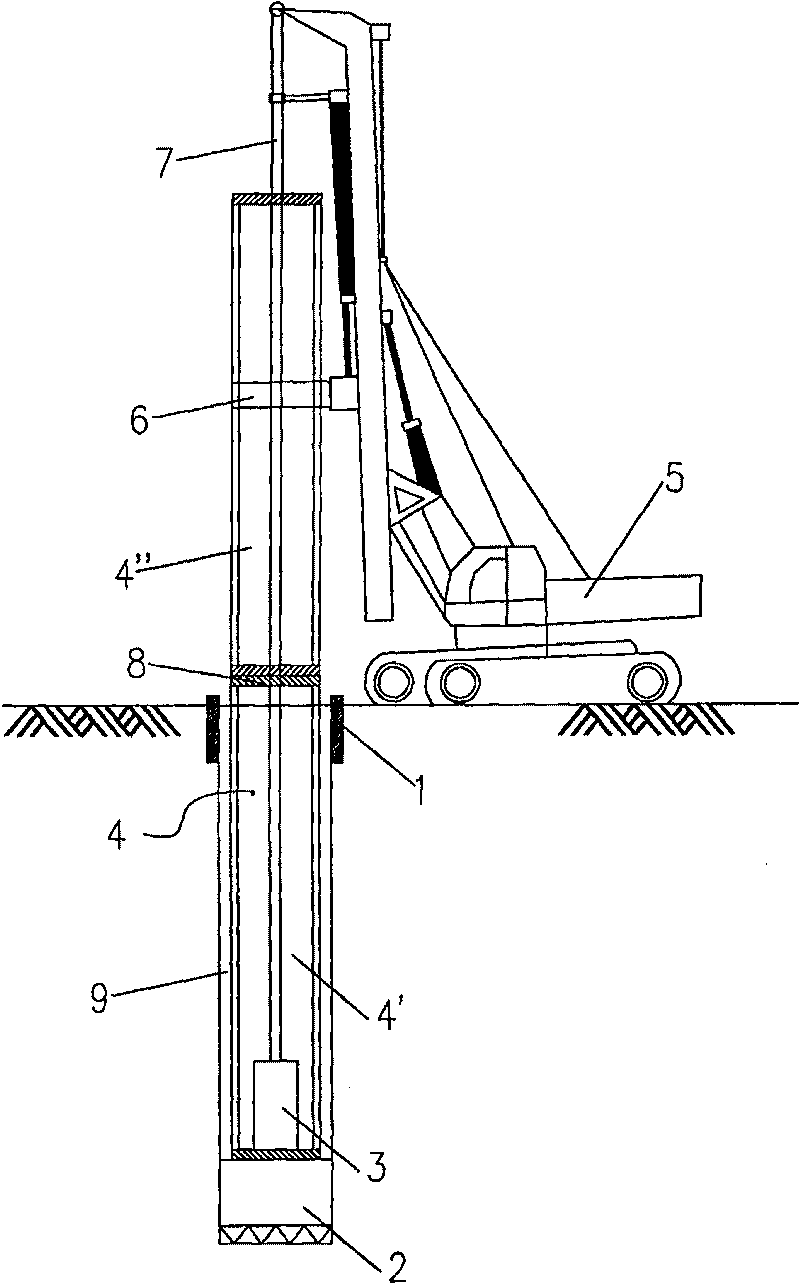

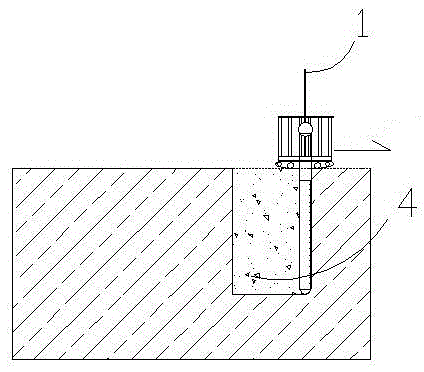

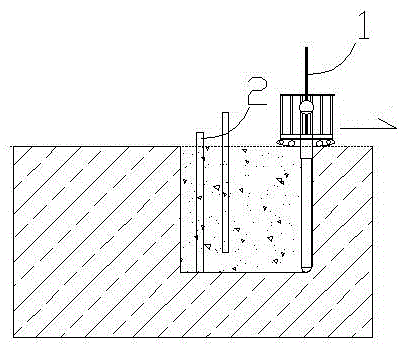

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

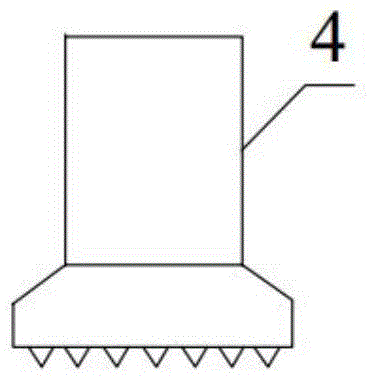

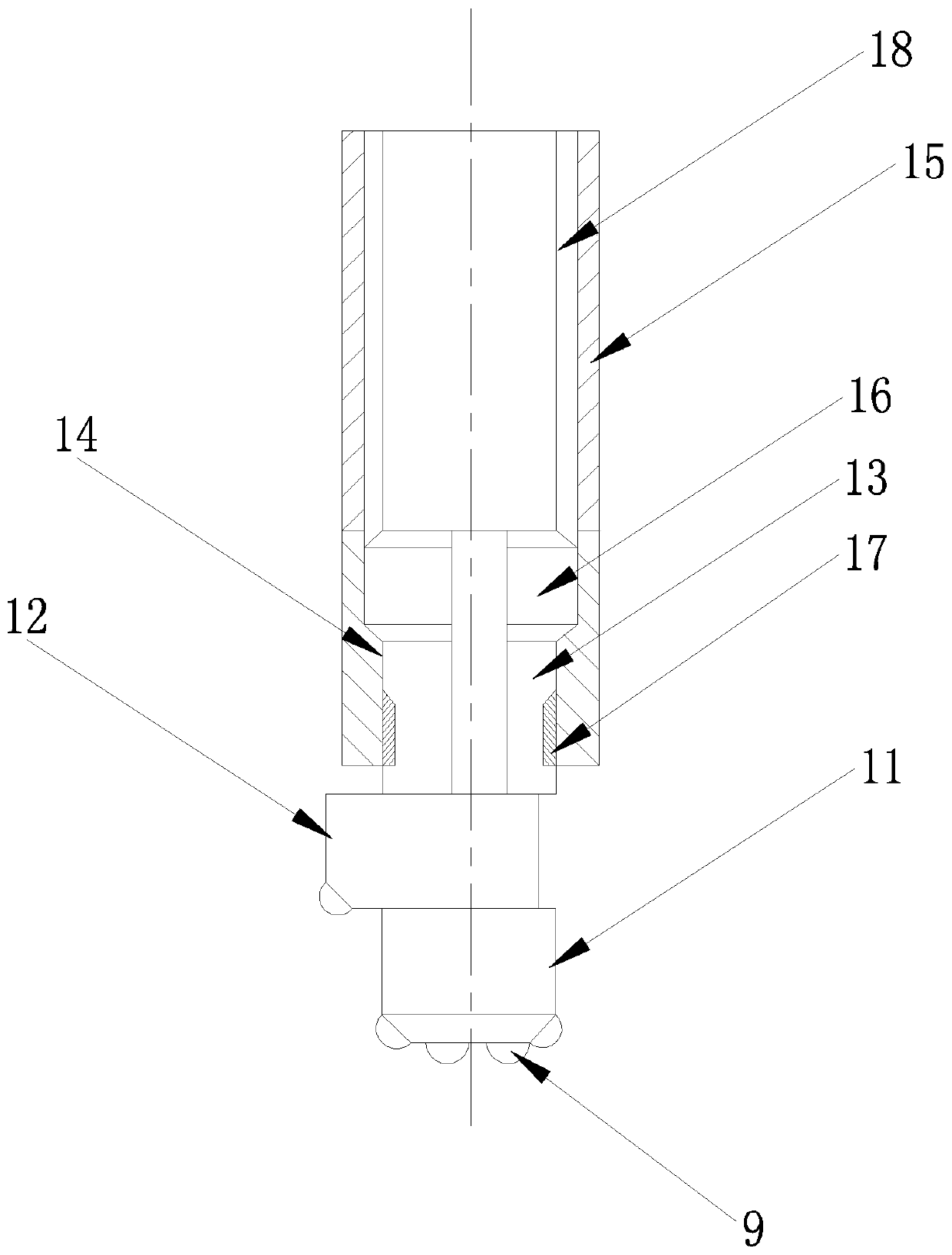

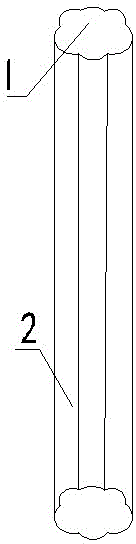

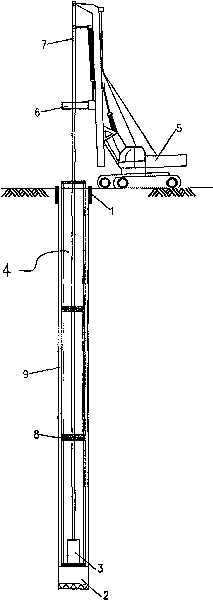

Pile-forming method for cement paste spraying multi-directional core entraining mixing pile

The invention provides a pile-forming method for a cement paste spraying multi-directional core entraining mixing pile, which is characterized in that (1) a mixing pile machine is in position and leveled, and a bit aims at a pile position; (2) a drill pipe downward stirs and cuts soil along a guide frame until the designed depth; (3) after the drill pipe reaches the predetermined design depth, concrete are locally and continuously sprayed and stirred at the tip of the pile for more than 10 to 30 seconds; (4) the drill pipe is lifted; (5) concrete spraying is carried out while stirring; the drill pipe is lifted to the surface of earth or the designed elevation to finish the construction of a signal multi-directional mixing pile; (6) the tip of the pile of a core pile passes through a central hole of a jacking pile platform and is inserted into the center of the finished multi-directional mixing pile; (7) after the core pile sinks by self-weight and is penetrated into a certain depth of the mixing pile, the core pile is collated along two directions and the verticality of the core pile is regulated; the core pile is continuously sunken without any unmistakable; and (8) the core pile is pressed by hydraulic static force until the designed appointed depth. The method can realize the synchronous implementation of the mixing pile and the core pile operation, has high working efficiency, convenient construction, and low construction noise; the stress of the pile body is more reasonable and the pile shaft has high strength.

Owner:武汉谦诚桩工科技股份有限公司

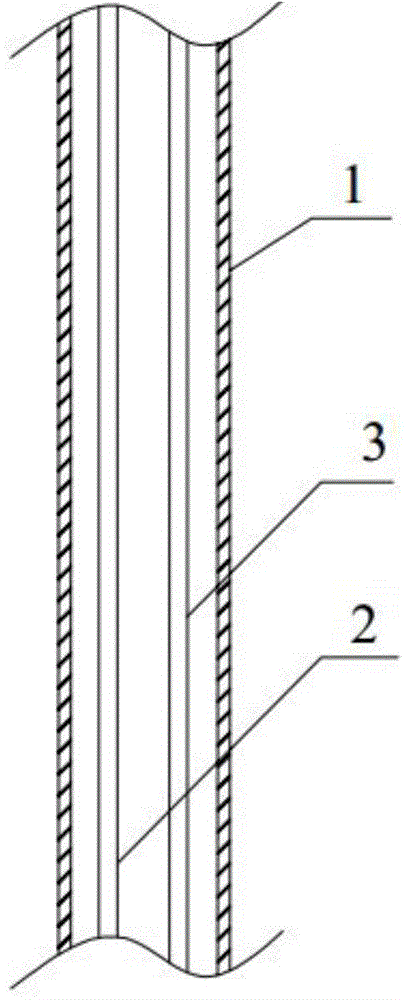

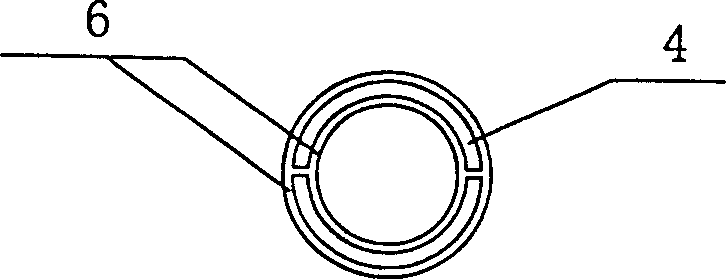

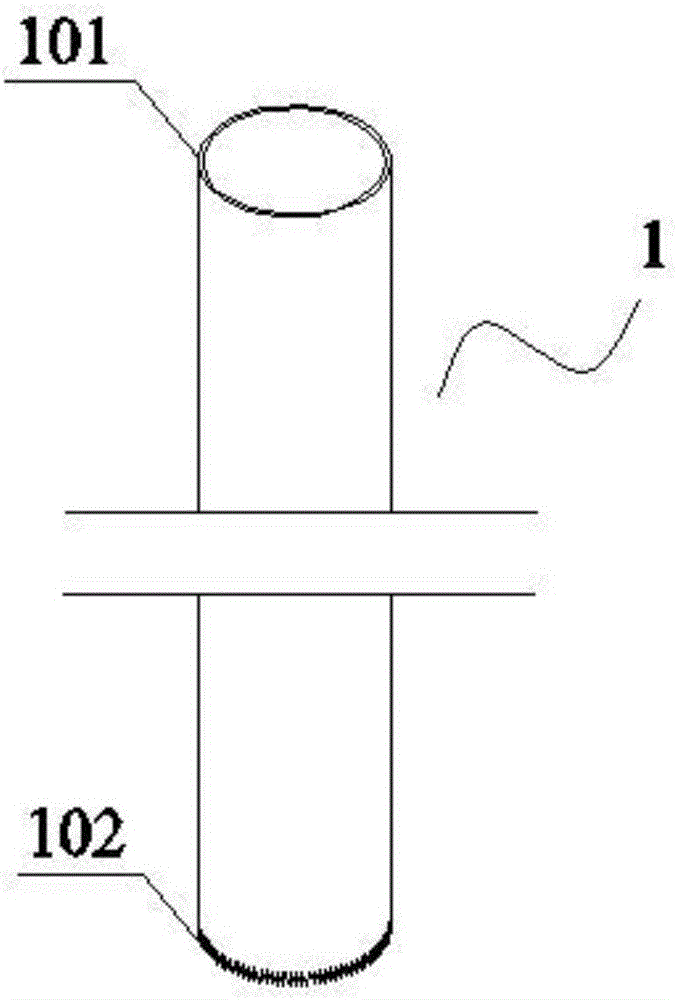

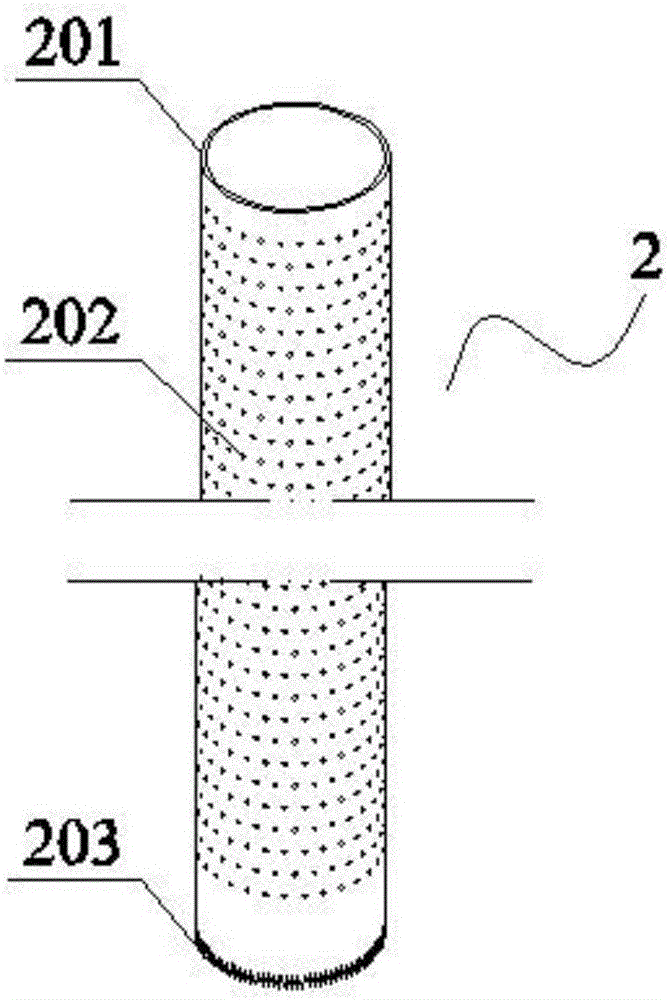

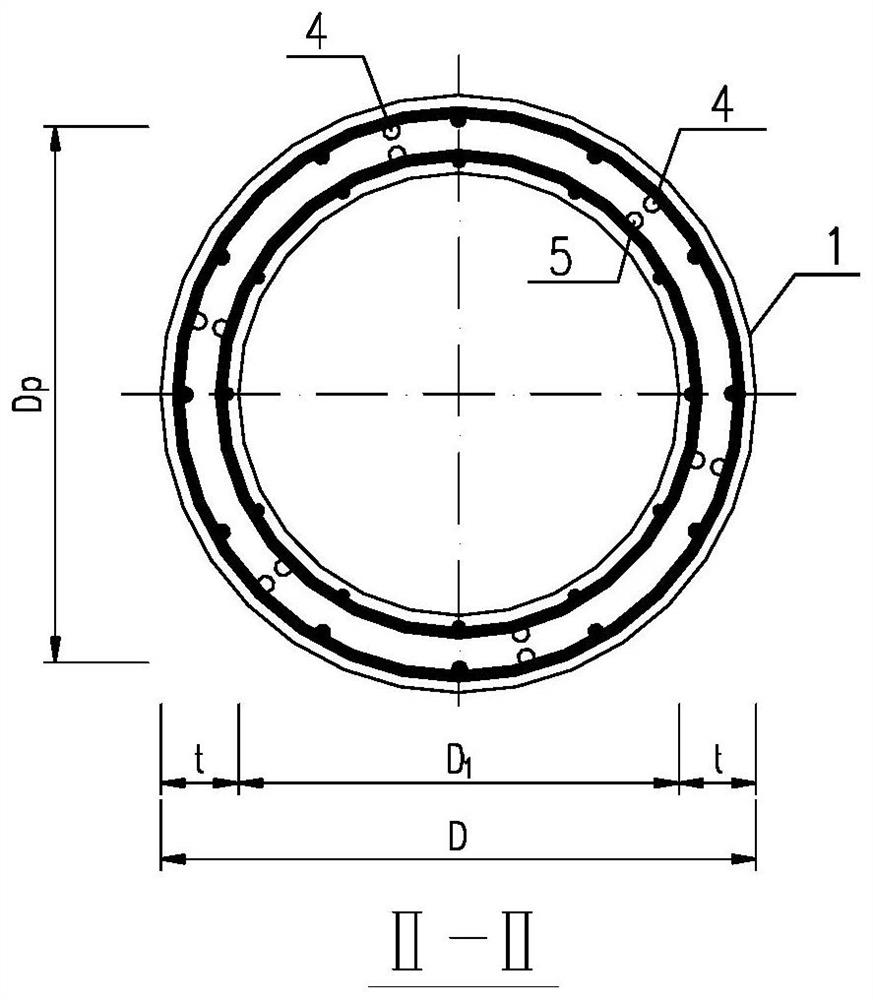

Rock-socketed pipe pile foundation with pile core by concrete pouring and pile side by static pressure grouting and construction method for rock-socketed pipe pile foundation

The invention discloses a rock-socketed pipe pile foundation with a pile core by concrete pouring and a pile side by static pressure grouting and a construction method for the rock-socketed pipe pile foundation. The pipe pile foundation comprises a prestressed concrete pipe pile, a pile shoe, concrete for pouring the pile core and cement mortar formed during static pressure grouting of the pipe side, and the pile shoe is connected with a lower end of a section of a pipe pile at the downmost of the pipe pile foundation. Before pouring the concrete for pouring the pile core, clean water is jetted by high-pressure jet grouting equipment to clean an inner wall of the pipe pile and rock-soil dregs retained in the pile core to be pumped out by a mortar pump. The cement mortar formed during static pressure grouting of the pipe side is formed by using a drilling machine to drill a plurality of holes close to the periphery of the pipe pile to a pile bottom and respectively statically pouring cement paste when the pipe pile is constructed to a designed elevation and the pile core is poured with underwater concrete for a certain time. The rock-socketed pipe pile foundation with the pile core by concrete pouring and the pile side by static pressure grouting and the construction method for the rock-socketed pipe pile foundation are especially suitable for rock-socketed pipe pile foundations, can increase force bearing area of a section of the pipe pile, and improve pipe pile strength and bearing capability of the pipe pile foundation, and the construction method is simple and reliable.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

Ground strengthening cement mortar rotary-spraying pile and construction method

The present invention discloses a foundation reinforced cement mortar rotary-spraying pile and the construction method thereof. The conventional rotary-spraying pile uses the slurry as the neat cement grout and the cement is added with fine powder sand. The slurry has obvious effect for improving the character of the clay foundation and increasing the pile forming quality of the rotary-spraying pile. The phenomenon of low pile-forming strength of conventional rotary-spraying pile in the clay formation is overcome. The same formation adopts a cement mortar rotary-spraying pile. The strength of the cement-treated soil after pile forming is increased for about 30% compared with the conventional neat cement group rotary-spraying pile and the cement is saved for more than 20%.

Owner:徐玉杰

Foundation reinforcing mode

The foundation reinforcing method for loose and soft soil includes depositing straight sunken tube into loose and soft soil through vibration or other process, throwing stuffing, such as sand and stone, mine refuse, clay, etc. mixed with cement and water, into the sunken tube, hammering to density and form piles, and final spreading stuffing cushion in the top of the piles to form composite foundation with high strength cement piles. The method is simple in construction and low in cost, and has wide application range and no environmental pollution.

Owner:王光明 +1

Method for performing deep foundation pit waterproof curtain construction by adopting high-pressure jet grouting pile machine

ActiveCN104631480ASolve the problem of difficulty in forming holes with a large number of bouldersHigh pile strengthBulkheads/pilesSludgeHigh pressure

The invention discloses a method for performing deep foundation pit waterproof curtain construction by adopting a high-pressure jet grouting pile machine. According to the method and for sludge, clayey soil, loess, sandy soil, artificial filling, a pebble bed, a mud rock layer and other geological layers large in pore-forming difficulty, a grouting pipe and a gas injection pipe are installed inside a CFG pile machine drill rod, a drill bit of a CFG pile machine is refit into a down-hole hammer drill bit, a construction technology that gunite pile forming is directly performed after pore forming is adopted, and constructive technical parameters are optimized, so that pore-forming quality is improved, a construction period is shortened, and construction cost is reduced.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

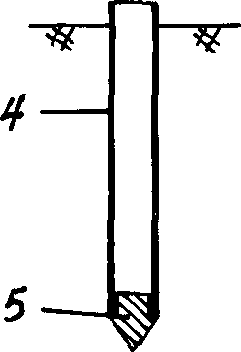

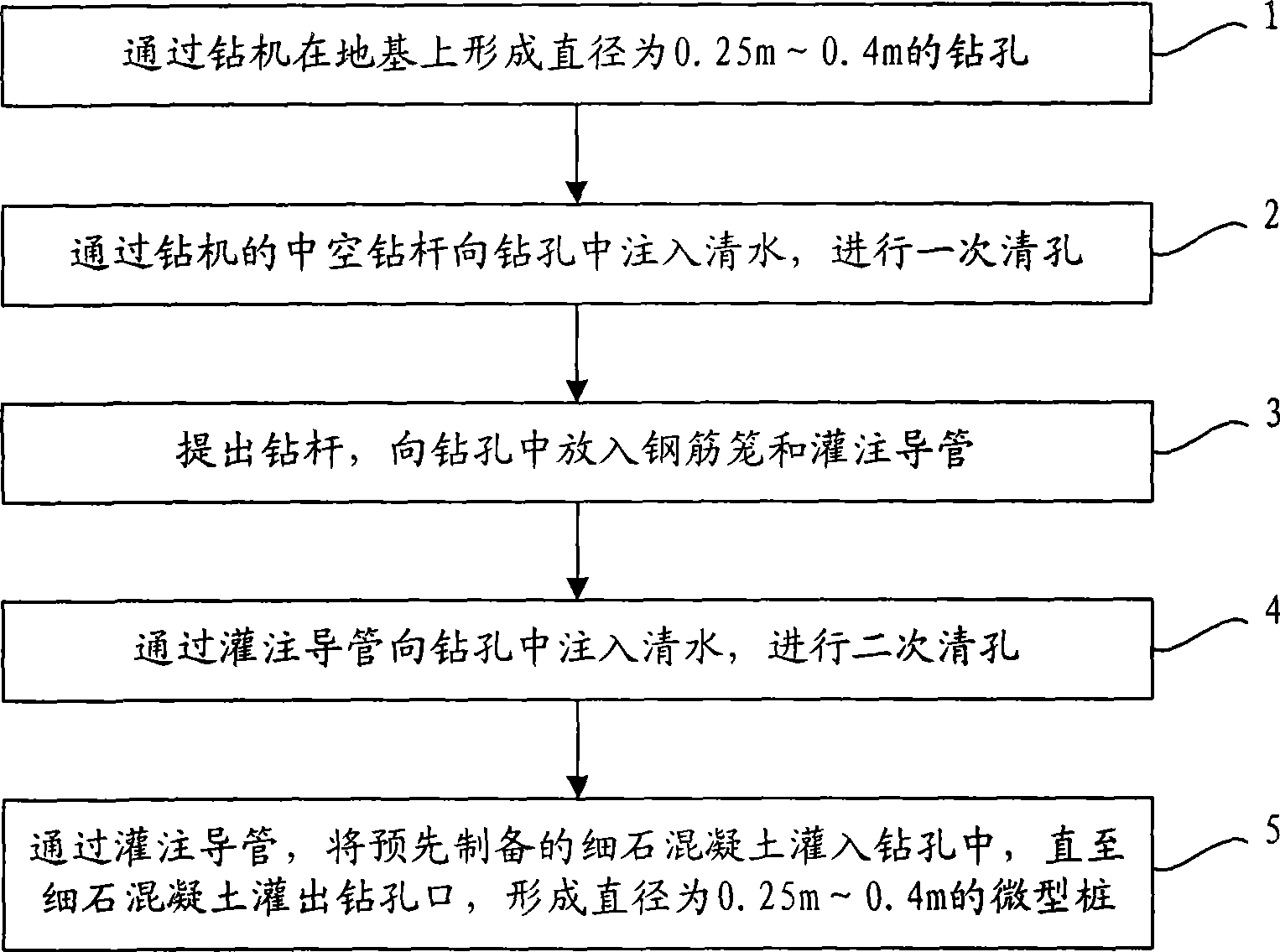

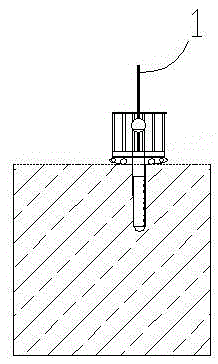

Novel miniature pile construction method

InactiveCN101424081AEasy to budget and final accountsSave the amount of pile materialBulkheads/pilesUltimate tensile strengthGuide tube

The invention relates to a method for constructing a novel mini-pile, which comprises the following steps: step one, using a drilling machine to form drill holes of which the diameter is between 0.25 and 0.4 meter on a groundwork; step two, pouring clear water in the drill holes through a hollow drill pipe of the drilling machine to perform a primary hole cleaning; step three, lifting out the drill pipe and putting reinforcing cages and pouring guide tubes into the drill holes; step four, pouring clear water into the drill holes through the pouring guide tubes to perform a secondary hole cleaning; and step five, pouring prepared fine gravel concrete into the drill holes through the pouring guide tubes until the fine gravel concrete pours out of the drilling holes so as to form the mini-pile of which the diameter is between 0.25 and 0.4 meter. The method adopts a mode of directly pouring the fine gravel concrete to form the mini-pile, thereby saving pile-making materials, facilitating engineering budget and final account and benefiting the popularization and the application of the mini-pile; besides, the method is convenient to control the pile body strength of the mini-pile so as to be advantageous for improving the pile body strength and the bearing capacity of the mini-pile.

Owner:CHINA ELECTRIC POWER RES INST

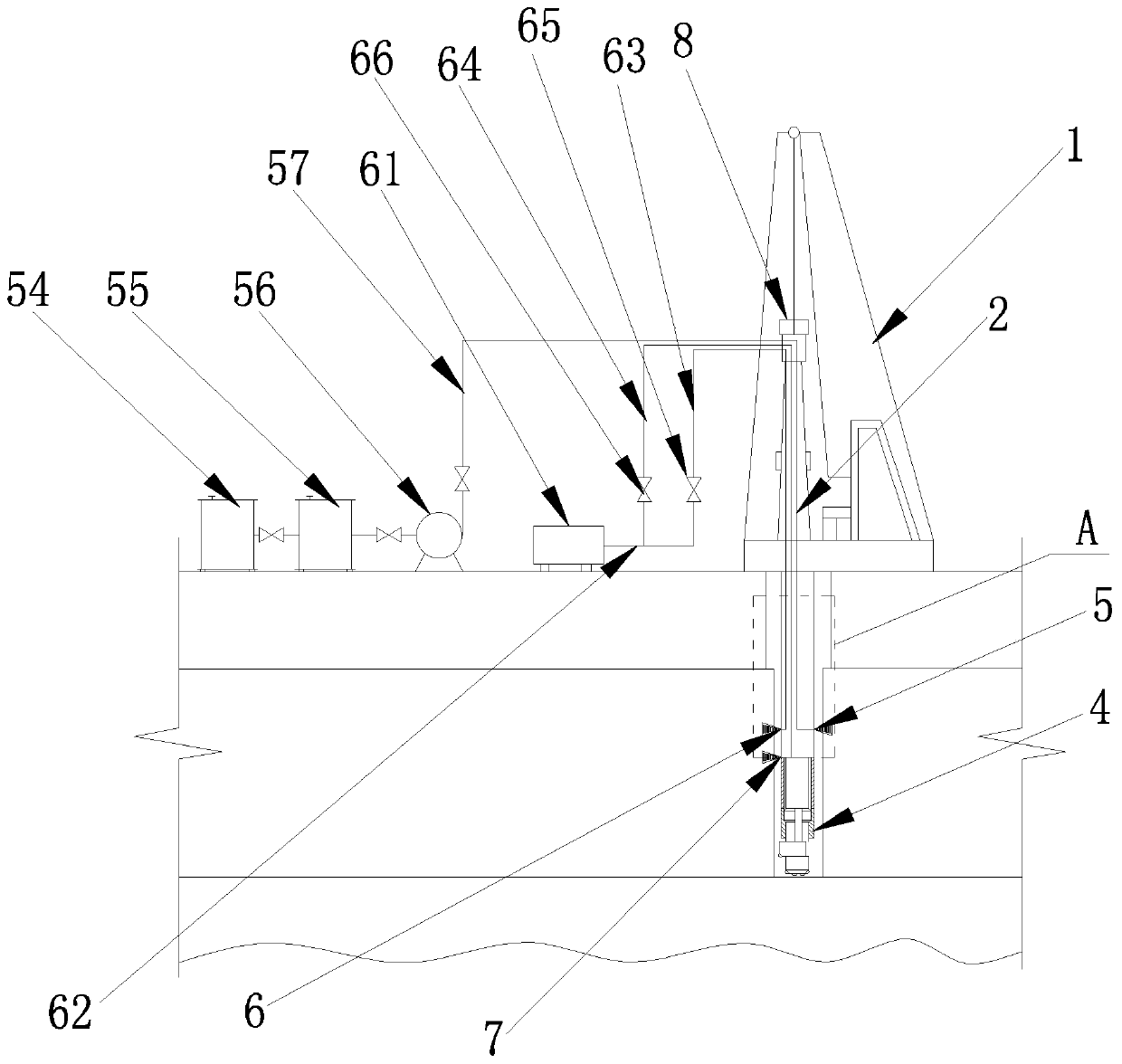

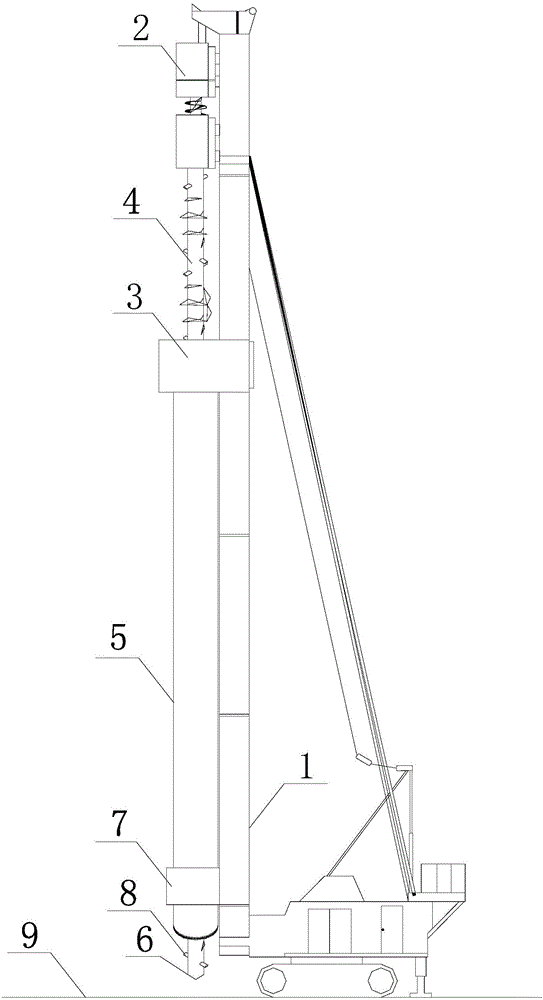

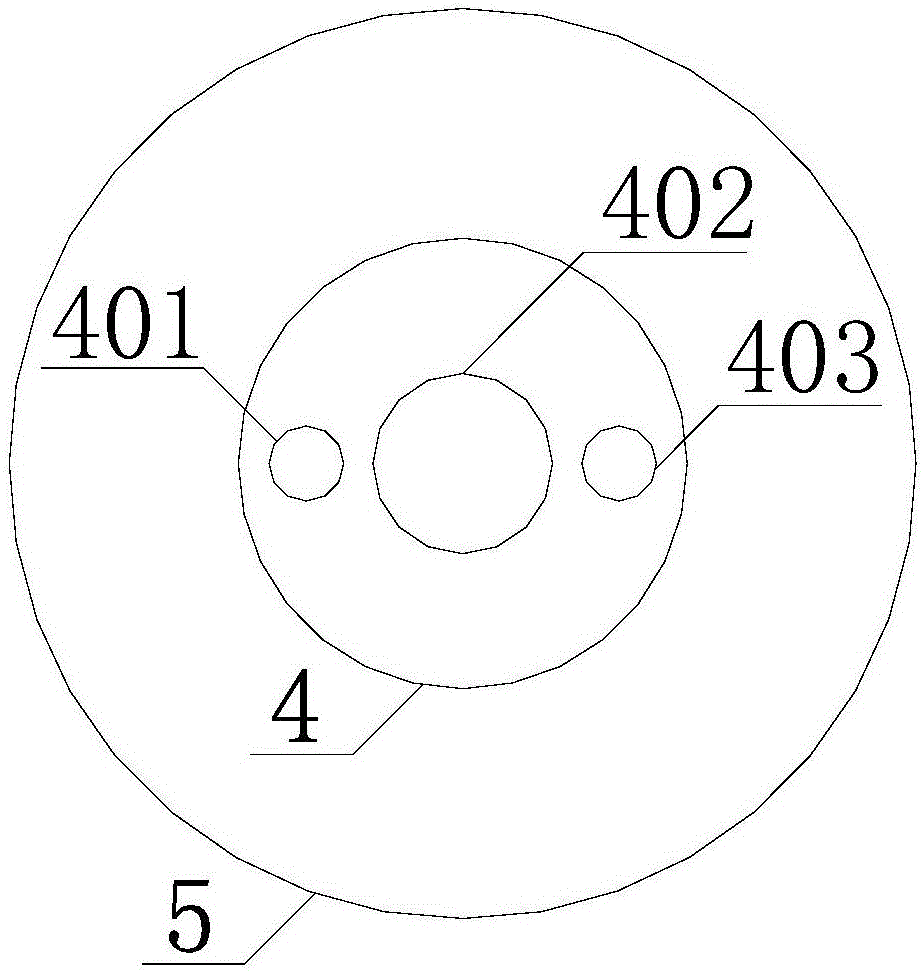

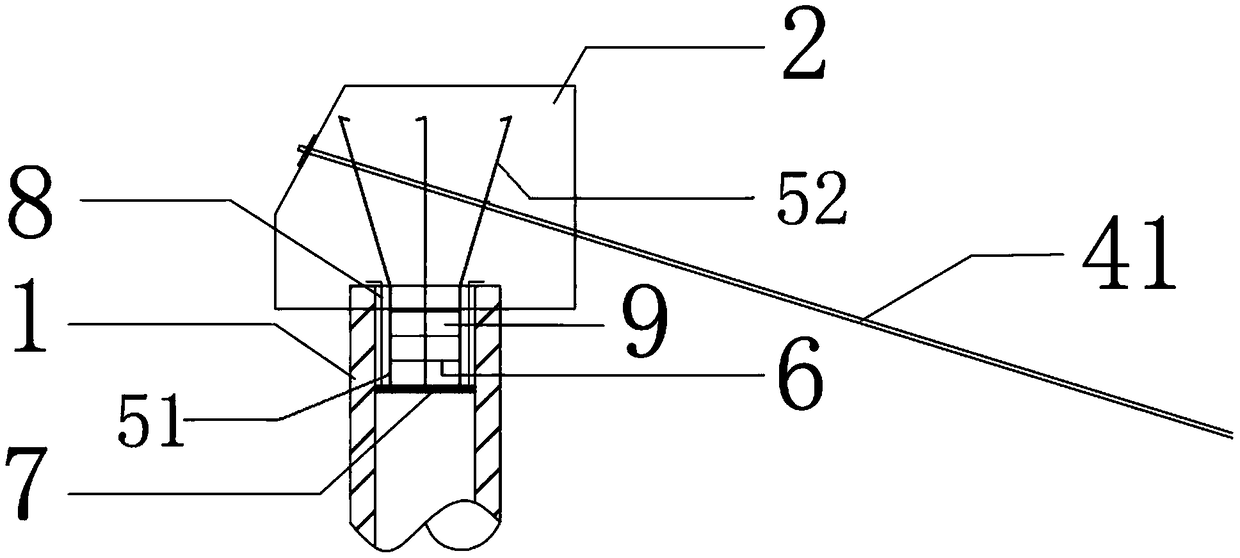

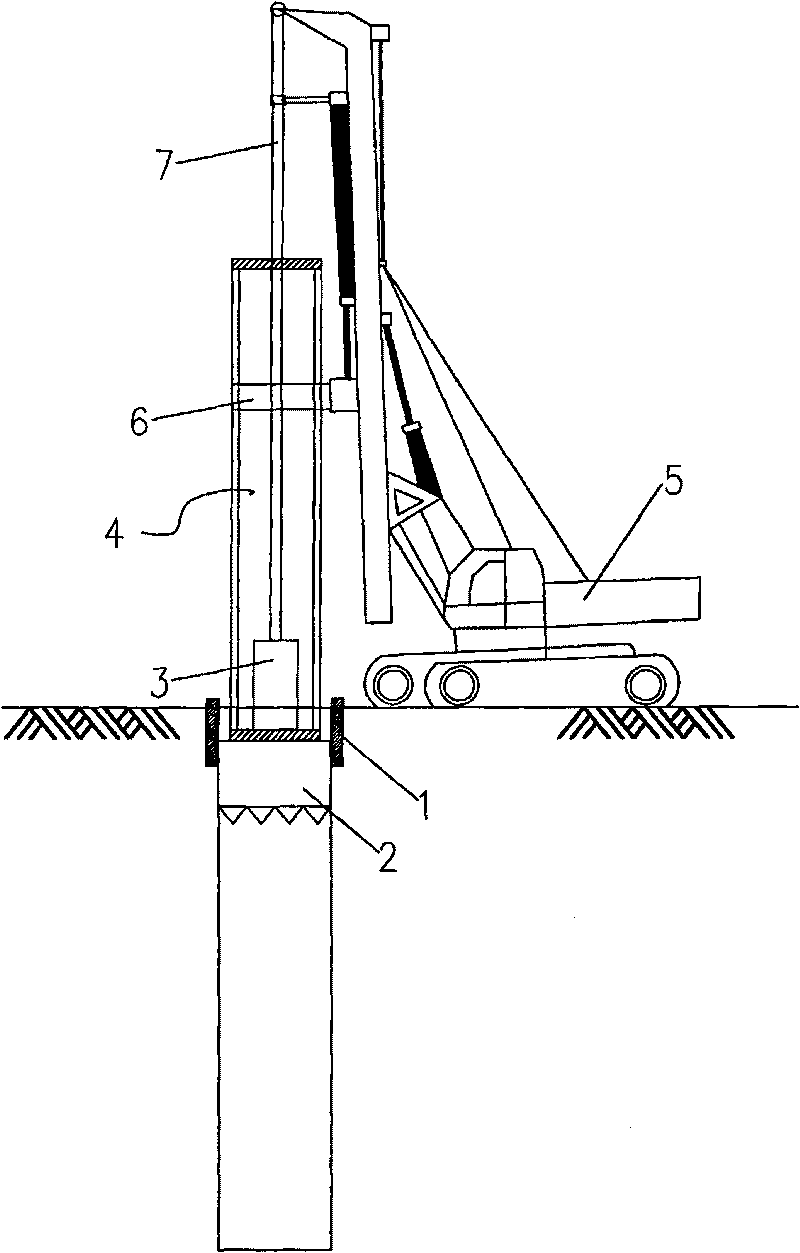

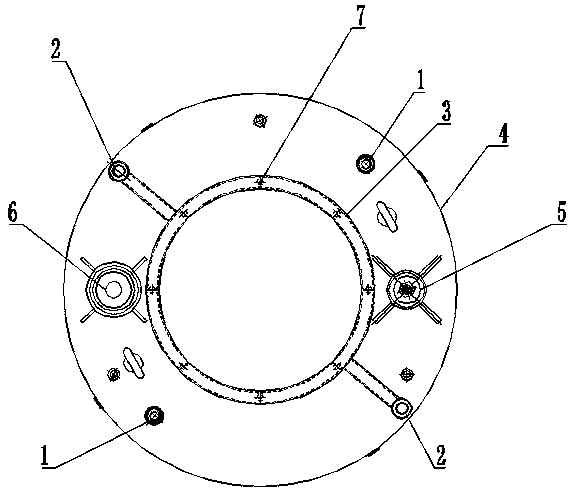

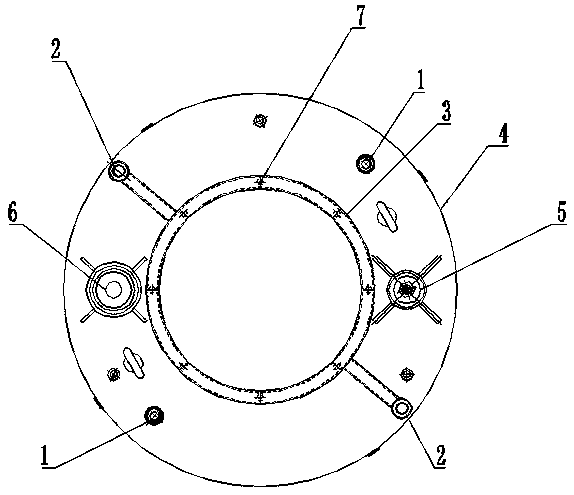

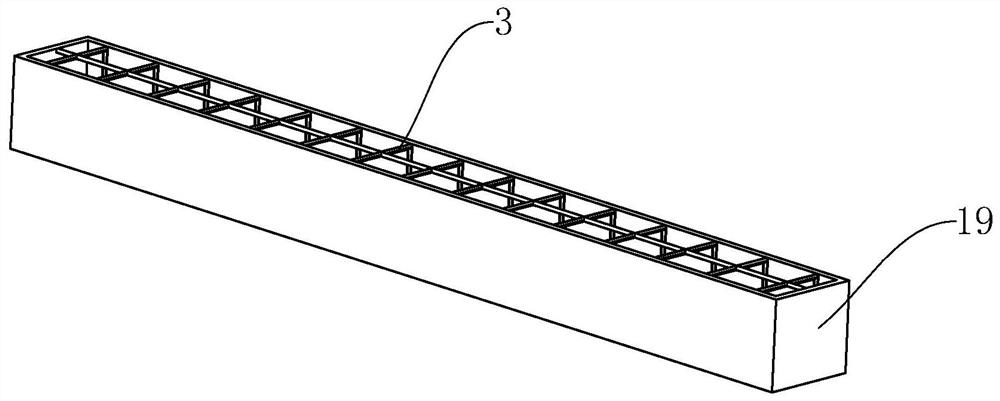

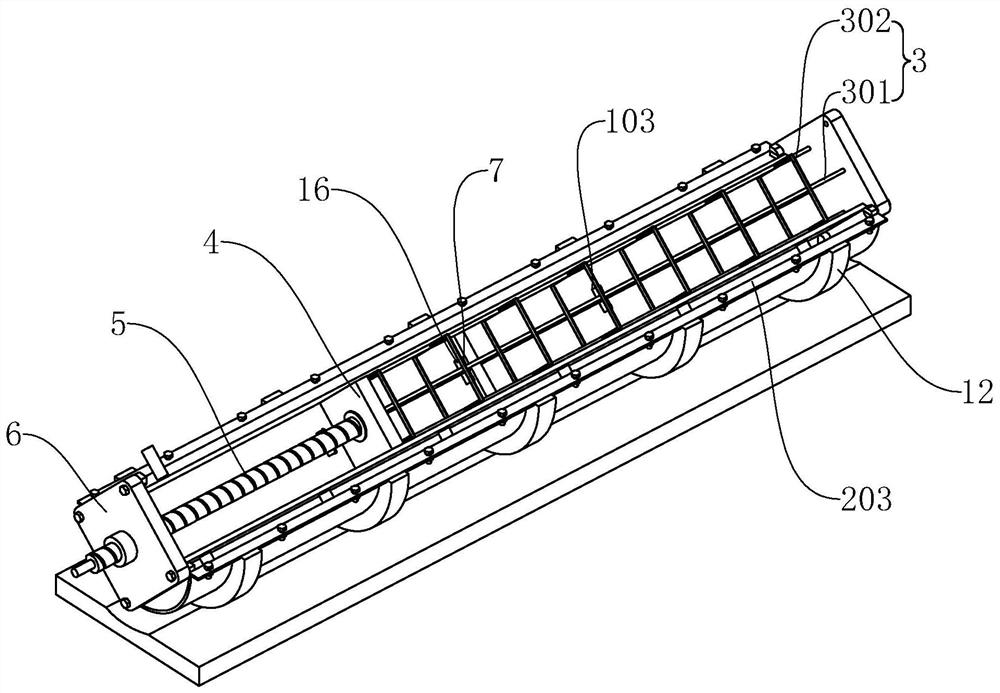

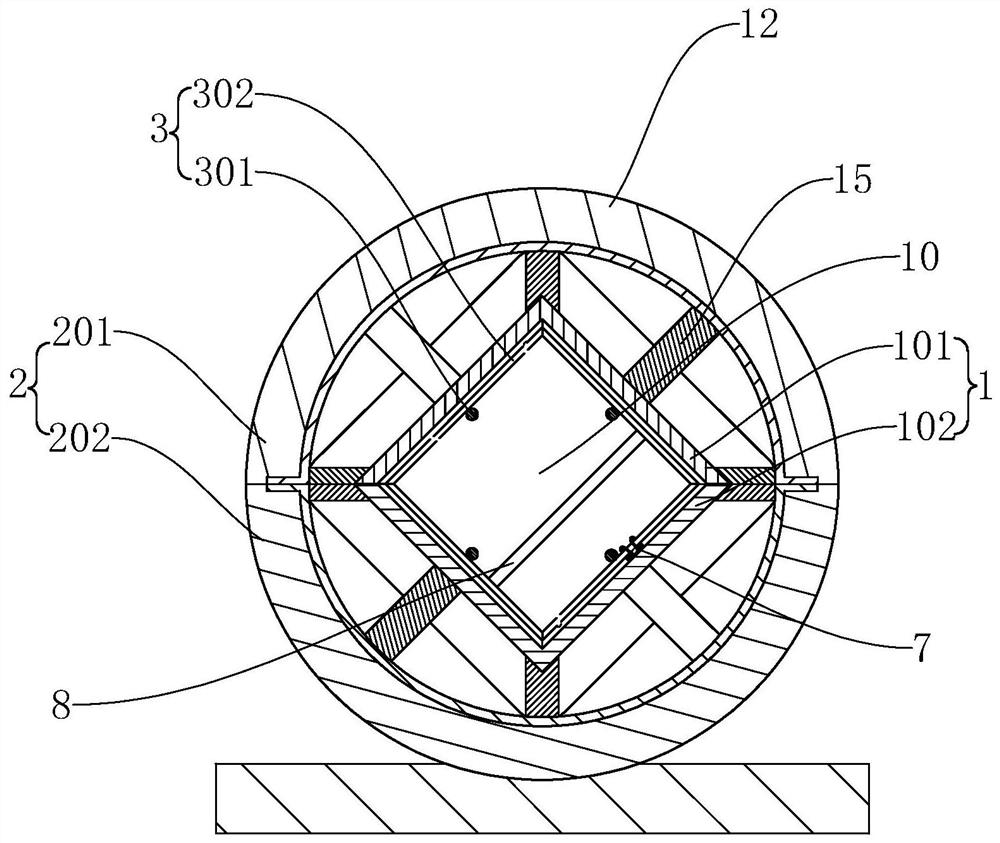

High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

PendingCN111577136ASimple structureHigh pile strengthDirectional drillingBorehole drivesPipeUltimate tensile strength

The invention relates to a high-pressure jet grouting pile hole leading construction integrated device and a construction method thereof. The high-pressure jet grouting pile hole leading constructionintegrated device comprises a jet grouting drilling machine, a high-pressure jet grouting drill rod and a triple pipe, wherein the triple pipe is fixedly arranged at the bottom of the high-pressure jet grouting drill rod, and a down-the-hole hammer is fixedly arranged at the bottom of the triple pipe; and the triple pipe comprises a grout outlet ejector, an inner air outlet ejector and an outer air outlet ejector which are sequentially arranged from inside to outside. The high-pressure jet grouting pile hole leading construction integrated device is simple in structure, convenient to use and practical, the construction technology of combining the triple pipe and the down-the-hole hammer is adopted for the environment of a complex geological layer, and by optimizing construction technical parameters, an obtained pile body is high in strength and good in construction quality. Compared with a traditional high-pressure jet grouting pile construction method, the input mechanical materials are few, the cost is low, construction is safe, and construction is rapid.

Owner:浙江岩科建设有限公司

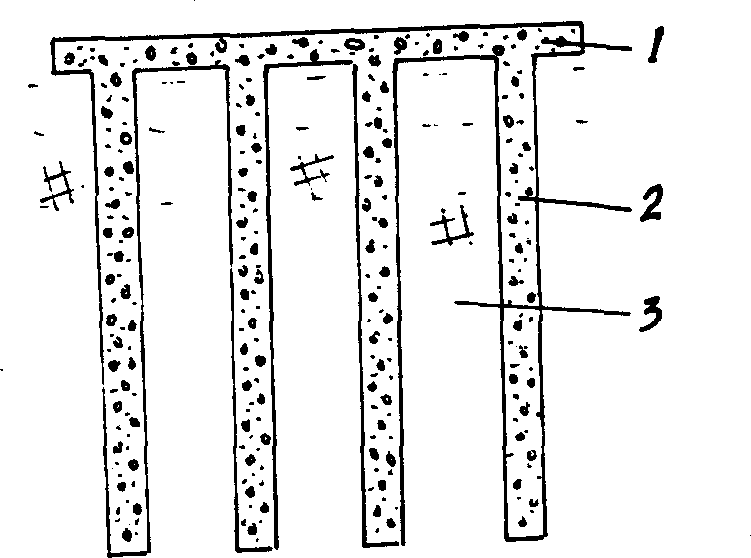

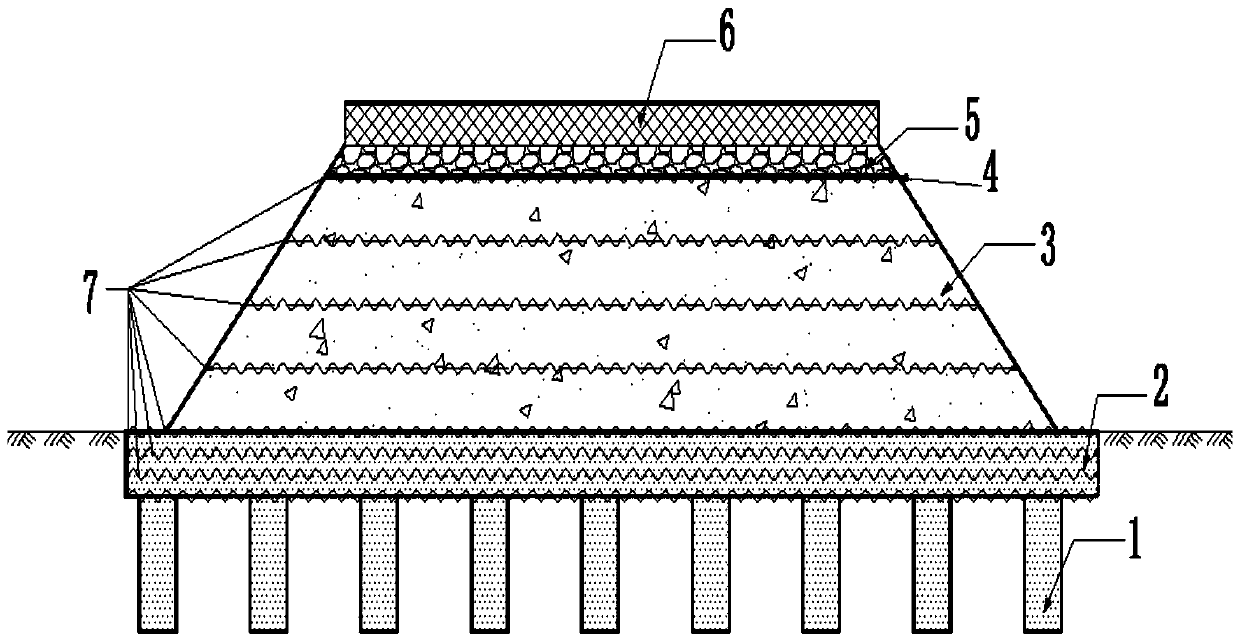

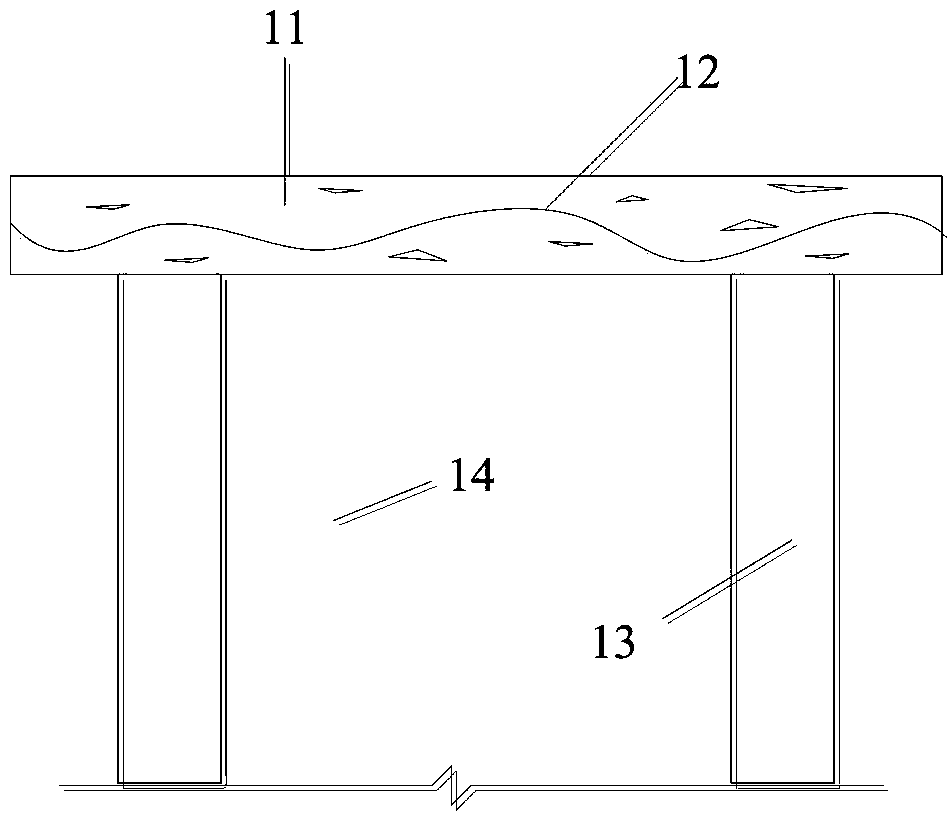

Soft foundation composite ground base construction method for field pouring pipe pile with large diameter

InactiveCN1158434CImprove stabilityStrong pile bodyBulkheads/pilesEngineeringUltimate tensile strength

A method for constructing cast-in-place pipe pile composite ground base on the soft ground is characterized by that a hollow structure with internal and external casing pipes is adopted and draven into the ground base, and a specially-designed casing pipe forming large-diameter in-situ pipe pile casting machine is used, then the concrete is placed in-situ so as to obtain the large-diameter cast-in-place pipe pile, and on its top portion, a sandstone layer and geotechnical grille and laid. This invention is a thin-wall pipe pile, belonging to the rigid pile, and its trength is high.

Owner:HOHAI UNIV

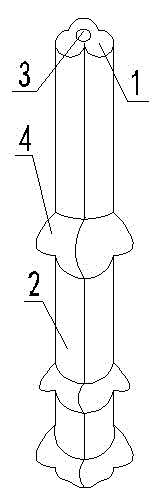

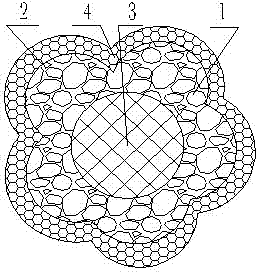

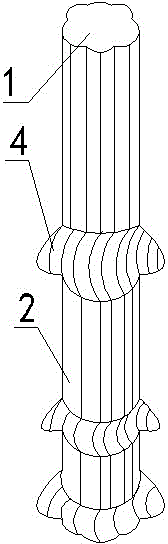

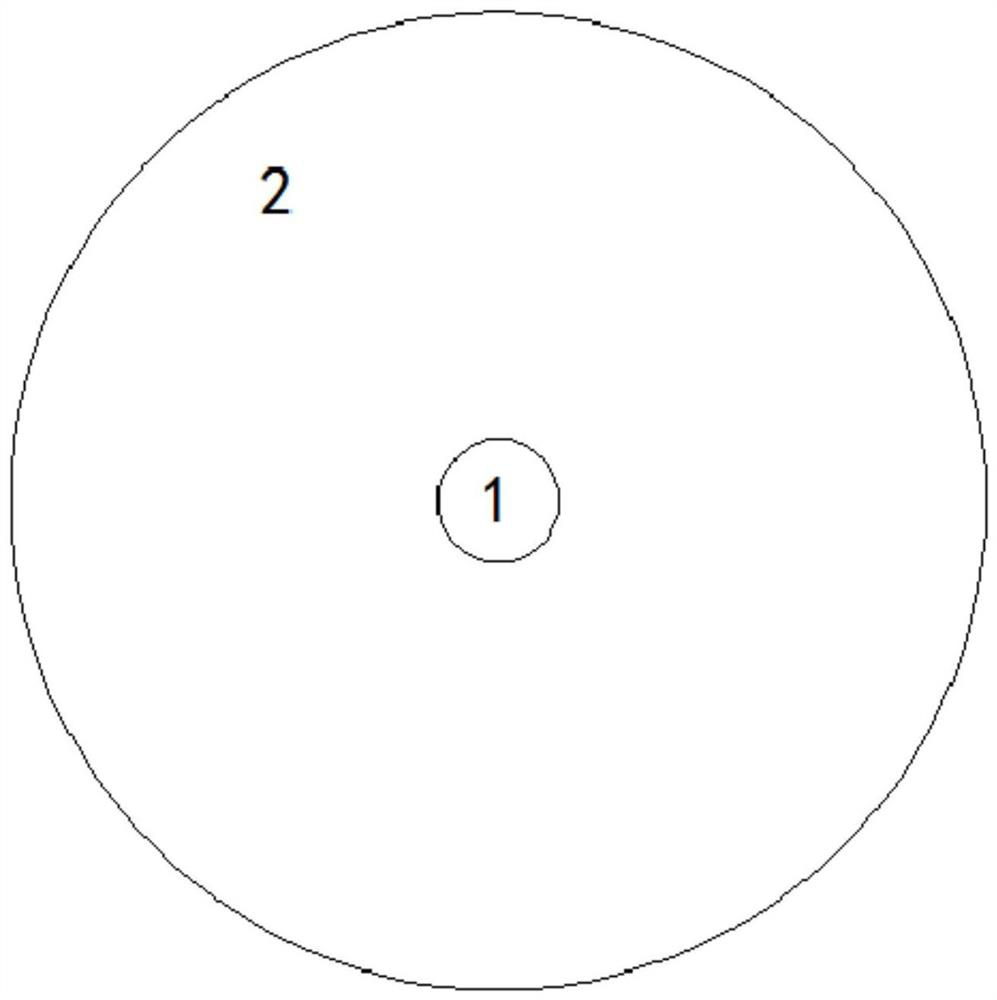

High-strength triangular plum-blossom-shaped cement soil mixing bearing pile and forming method thereof

The invention relates to a high-strength triangular plum-blossom-shaped cement soil mixing bearing pile and a forming method thereof. The high-strength triangular plum-blossom-shaped cement soil mixing bearing pile is good in perpendicularity, incline resisting capability and full in full-load bearing capacity. The cement soil mixing pile comprises a cement soil mixing pile, two end faces and a cement soil mixing pile body are formed by connection of three plum-blossom-shaped petals, and one or more concrete cement piles are positioned in a high-strength triangular plum-blossom-shaped cement soil mixing bearing pile body. The high-strength triangular plum-blossom-shaped cement soil mixing bearing pile has the advantages that a pile foundation of the triangularly distributed plum-blossom-shaped cement soil mixing pile is large in bearing capacity, bearing and supporting points are triangularly distributed, and the pile foundation is good in stability; when the pile foundation formed by the triangular plum-blossom-shaped petals is positioned in a soft soil foundation, the three plum-blossom-shaped petals identical in inclined angles act on a wall of the soft soil foundation like three projected ejection posts, so that the cement soil pile is ensured not to incline but perpendicularly stand in the soft soil foundation; due to the fact that a three-axis drilling rod sinks along a guiding frame, stirs and sprays cement paste at the same time, and the sinking direction and the stirring direction are opposite, so that the cement paste and soil can be fully mixed integrally, and high strength of the cement soil pile is ensured.

Owner:周兆弟

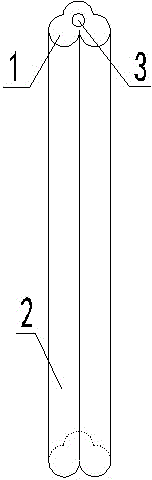

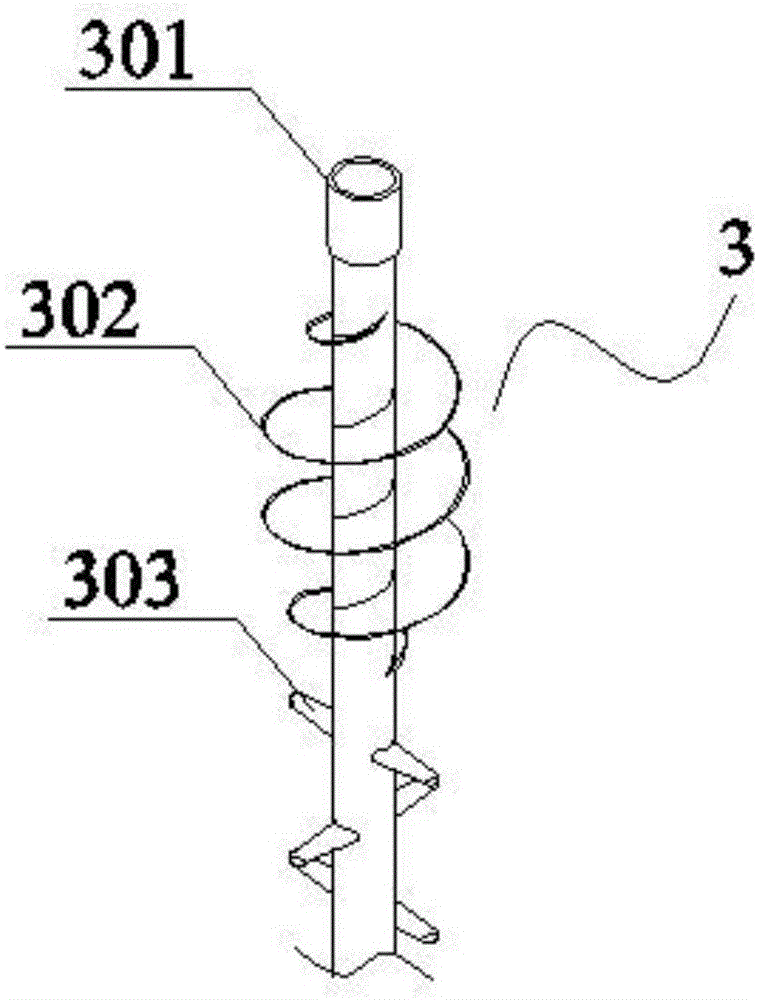

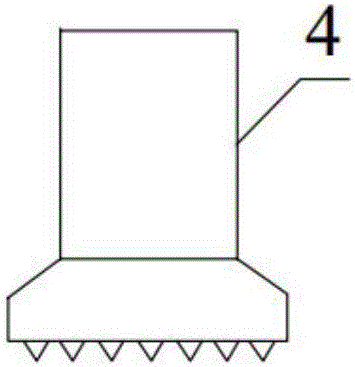

Construction method of ultrahigh bearing capacity stiff composite pile

InactiveCN104674801AImprove construction efficiencyHigh pile strengthBulkheads/pilesEngineeringDry powder

The invention discloses a construction method of an ultrahigh bearing capacity stiff composite pile. According to the method, a cement soil peripheral pile is firstly constructed, and then, an inner core pile is constructed and driven in the peripheral pile. The construction method is characterized in that when the peripheral pile is constructed, a cement stirring device with blades in holoaxial arrangement is adopted for the cement stirring, and the simultaneous stirring is carried out in the whole pile length range; the cement stirring device with blades in holoaxial arrangement comprises a stirring shaft, the stirring shaft is connected with a power head, and a layer of stirring blades is arranged every 20 to 50cm in positions below the power head of the stirring shaft; a plurality of spray pipes are arranged in an inner cavity of the stirring shaft and are used for spraying water, dry powder, sand or curing agents, and spray openings of the plurality of spray pipes are positioned at the bottom of the stirring shaft; during the construction, the materials are sprayed through the spray pipes and are stirred for forming the pile. The construction method has the advantages that the construction efficiency is high, the intensity of the pile formed through construction is high, the bearing force is great, the bearing pressure of a pile body is more than 8000KN, the horizontal bearing force is more than 300KN, and the pulling resistant bearing force is more than 2000KN.

Owner:邓亚光

Pile forming operation method for protection barrel type cement soil mixing pile

The invention relates to a pile forming construction method for a protection barrel type cement soil mixing pile machine. The pile forming operation method is suitable for treatment of sludge, mucky soil and other soft soil foundations. The protection barrel type cement soil mixing machine is mainly composed of a crawler belt type mixing machine pile frame, a mixing machine power head, a protection barrel power head, a mixing shaft, a protection barrel, a drill bit, a supporting frame, mixing blades and the like. A slurry spraying pipe, a water spraying pipe and a material spraying pipe which are arranged in parallel are arranged in the protection barrel. When a cement soil mixing pile is formed, the protection barrel conducts cutting and drilling under the action of the protection barrel power head, the mixing machine power head carries a drill rod for rotary jet grouting following, and in the sinking mixing process of the mixing shaft, the slurry spraying pipe sprays slurry, the material spraying pipe sprays materials, and the water spraying pipe sprays water or slurry according to the stratum condition and the construction need. In the elevating mixing process of the mixing shaft, the protection barrel power head is closed, and the stirring shaft conducts mixing during slurry spraying to the preset slurry stopping face. The mixture and the slurry liquid are sufficiently mixed with an in-situ soil body in the closed protection barrel, the uniform degree and strength of a pile body are improved, and diffusion and flowing away of the slurry liquid of a curing agent are avoided.

Owner:ANHUI UNIV OF SCI & TECH

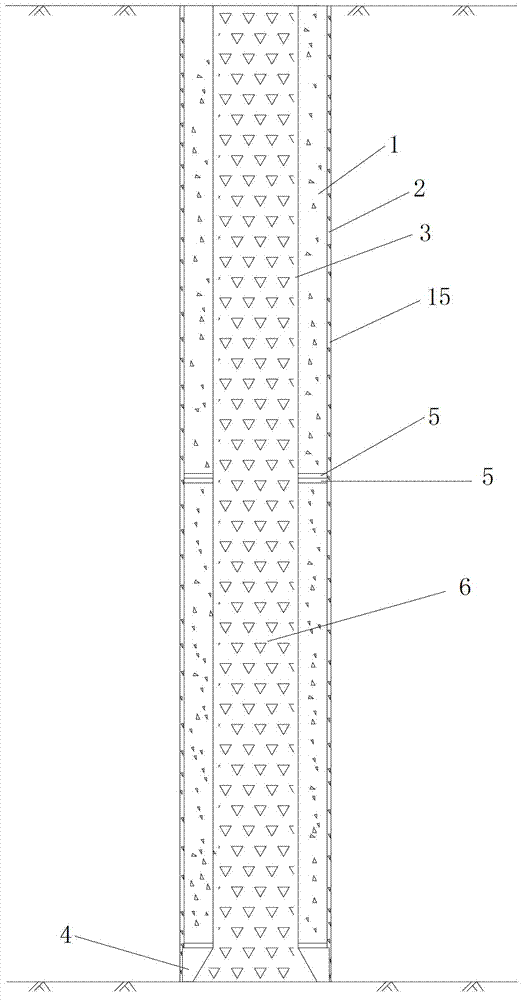

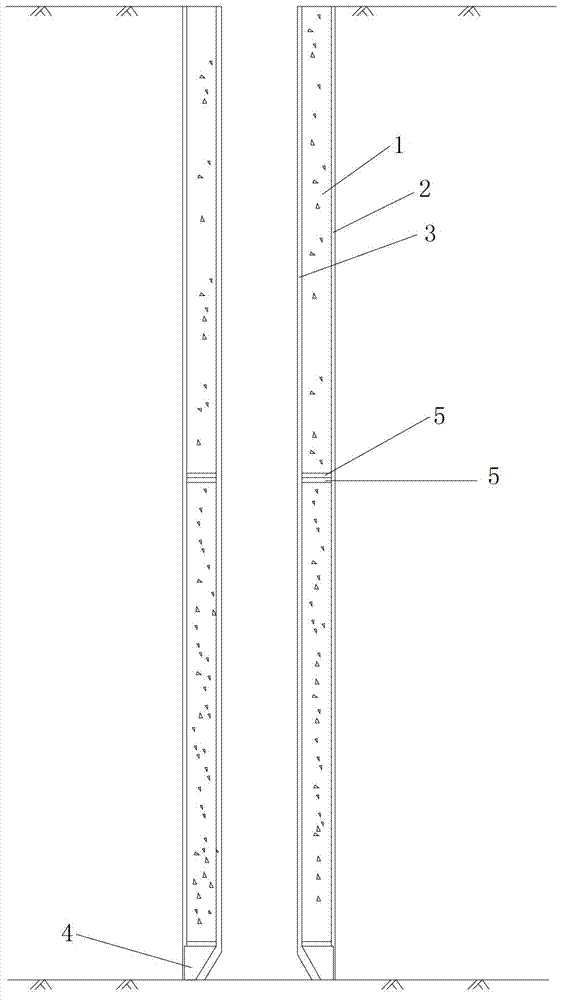

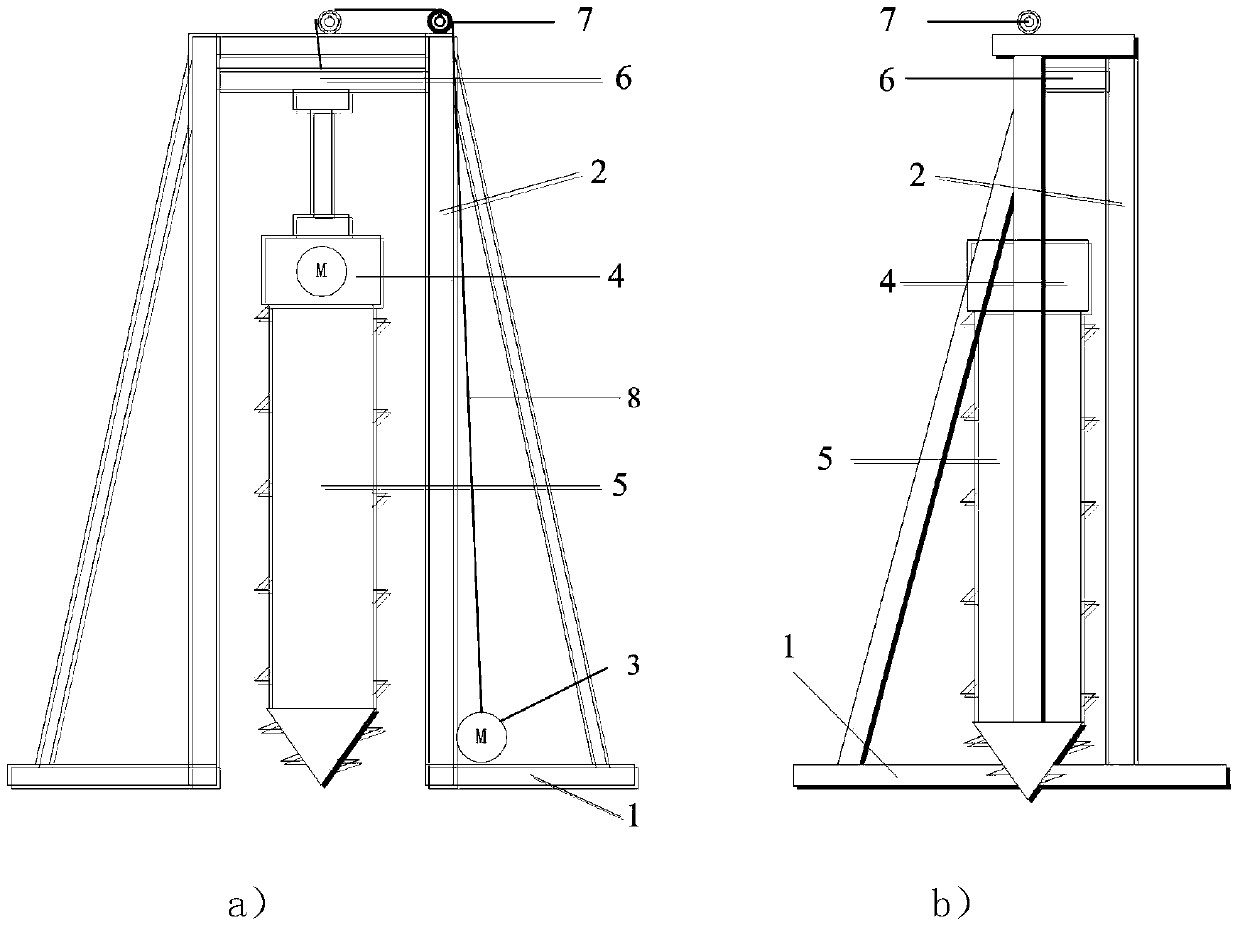

Construction device and construction method for deep or ultra-deep rock-embedded precast pile

The invention discloses a construction device and construction method for a deep or ultra-deep rock-embedded precast pile and relates to the technical field of precast pile construction. The construction device comprises a full cylinder drilling machine, a non-polished cylinder or a plum-blossom-shaped cylinder, a drill rod, a drill bit and a grout spraying nozzle. The full cylinder drilling machine is connected with the non-polished cylinder or the plum-blossom-shaped cylinder and the drill rod. The drill rod is connected with the drill bit. The drill bit is connected with the grout spraying nozzle. The construction technique used for the deep or ultra-deep precast pile in soft soil areas can also be used for construction of a deep or ultra-deep rock-embedded precast pile comprising a slightly-weathered, moderately-weathered or hard underlying stratum foundation, soil sampling is not needed in the construction process, the construction speed is high, hole collapse and hole shrinkage are avoided, slag in holes does not need to be removed, the side form resistance of a soil body and the end resistance of bed rocks can be brought into full play, the pile body strength of the precast pile is improved, and the bearing capacity of a single pile is improved substantially; meanwhile, the construction speed of a finished pile can be increased substantially, industrial production is facilitated, and the construction cost is reduced; and furthermore, deep, ultra-deep or rock-embedded cast-in-place piles in the soft soil areas can be replaced to a certain extent.

Owner:陈亮

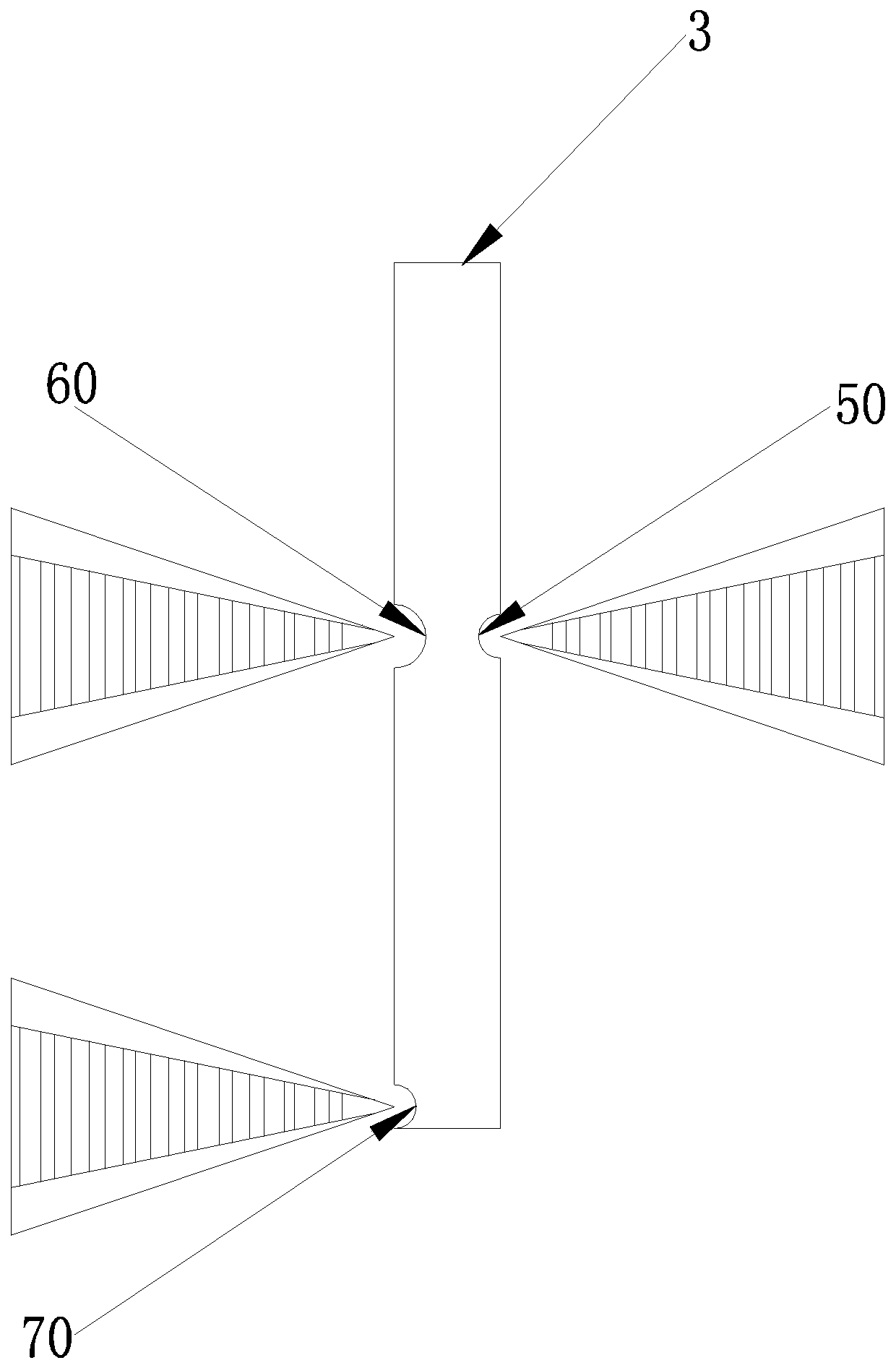

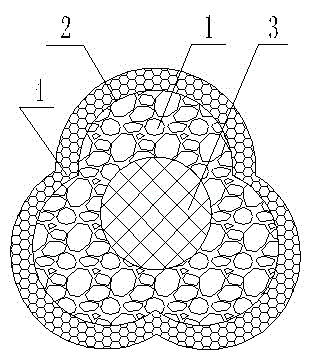

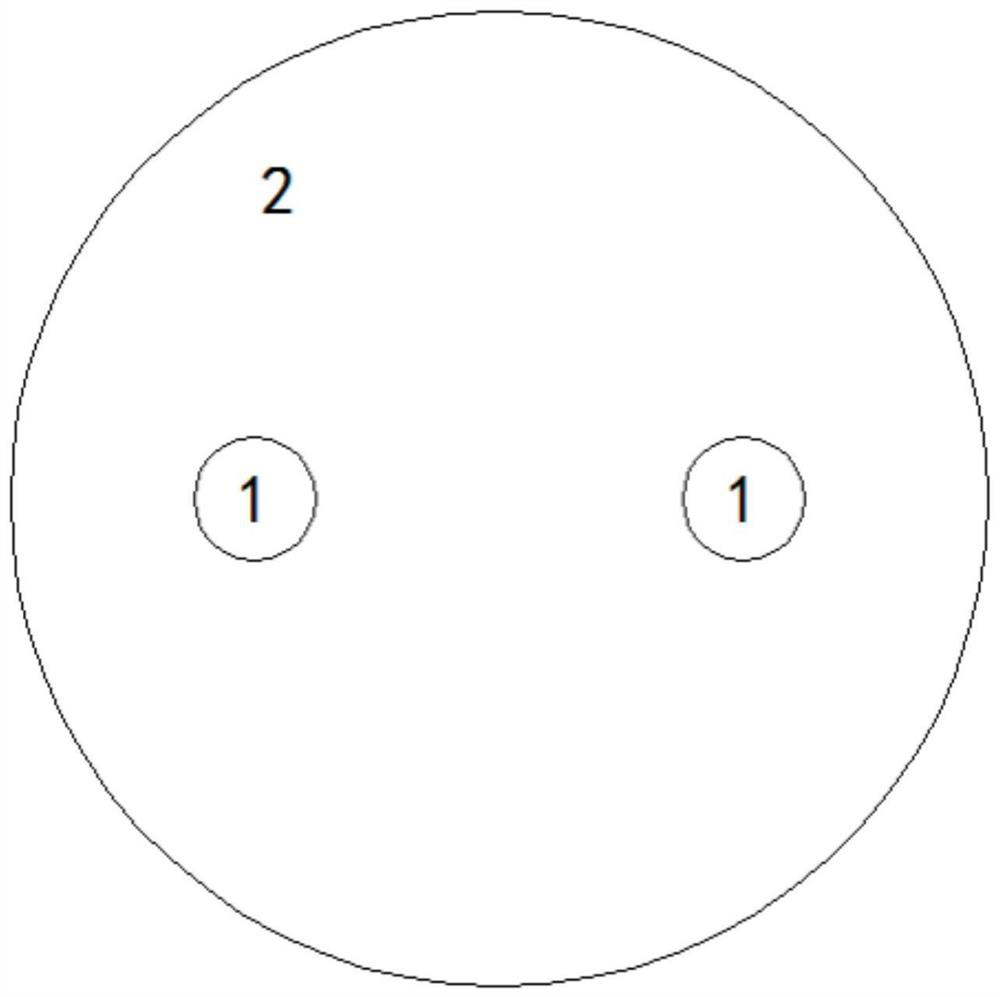

Quincunx cement soil mixing high-strength bearing pile and forming method

The invention relates to a quincunx cement soil mixing high-strength bearing pile and a forming method. The quincunx cement soil mixing high-strength bearing pile is good in perpendicularity and inclination-resisting capability and has the full-load bearing capacity. The quincunx cement soil mixing high-strength bearing pile comprises a cement soil mixing pile. The two end faces and the pile body of the cement soil mixing pile are formed by connecting a plurality of quincunx petals together. One or more concrete cement piles are arranged in the pile body of the quincunx cement soil mixing high-strength bearing pile. The quincunx cement soil mixing high-strength bearing pile has the advantages that firstly, due to the fact that the bearing area of a pile foundation of the multiangular-distribution quincunx cement soil pile is large, and bearing supporting points are distributed in a quincunx mode, the stability of the pile foundation is good; secondly, when the pile body composed of the multiangular quincunx petals is in a soft soil foundation, the pile body which is composed of the quincunx petals with equal included angles acts on the wall of the soft soil foundation like a three-column protruding jack column, and it can be ensured that the cement soil pile does not incline and is perpendicularly erected in the soft soil foundation; thirdly, due to the fact that a drill bit of a multi-axis drill pipe sinks while stirring and guniting along a guide frame, and the direction of sinking is opposite to the direction of stirring, cement paste and soil can be fully and evenly integrated, and it can be ensured that the strength of the pile body of the formed cement soil pile is high.

Owner:周兆弟

Collapsible loess area highway reinforced bridgehead roadbed and construction method

ActiveCN111549598AHigh pile strengthIncreased compaction effectRoadwaysSoil preservationRiver sandSoil science

The invention discloses a collapsible loess area highway reinforced bridgehead roadbed and a construction method. The roadbed sequentially comprises a sand-doped lime-soil pile composite foundation, areinforced sand-doped lime-soil mattress layer, a reinforced sand-stone-ash-doped improved loess backfill layer, a composite geomembrane, a graded broken stone hardcore and a bridgehead approach slabfrom bottom to top. According to the sand-doped lime-soil pile composite foundation, sand-doped lime soil serves as a pile body material to be filled into pile holes in a layered mode. The reinforcedsand-doped lime-soil mattress layer is formed by mixing river sand, lime and loess in proportion to form a filler; bidirectional geogrids are evenly laid at the vertical interval of 0.2 m for reinforcement, the reinforced sand-gravel-ash-doped improved loess backfill layer is formed by mixing river sand, lime and loess in proportion to form filler, and bidirectional geogrids are evenly laid at the vertical interval of 0.6 m in the filling process. The bridgehead roadbed is high in compression resistance, tensile strength, shearing strength and stability, the problem of 'bridgehead bump' caused by differential settlement and deformation of the bridgehead roadbed can be eliminated to the maximum extent, and meanwhile, the water stability and the frost resistance of the bridgehead roadbed are enhanced.

Owner:WUHAN UNIV OF TECH

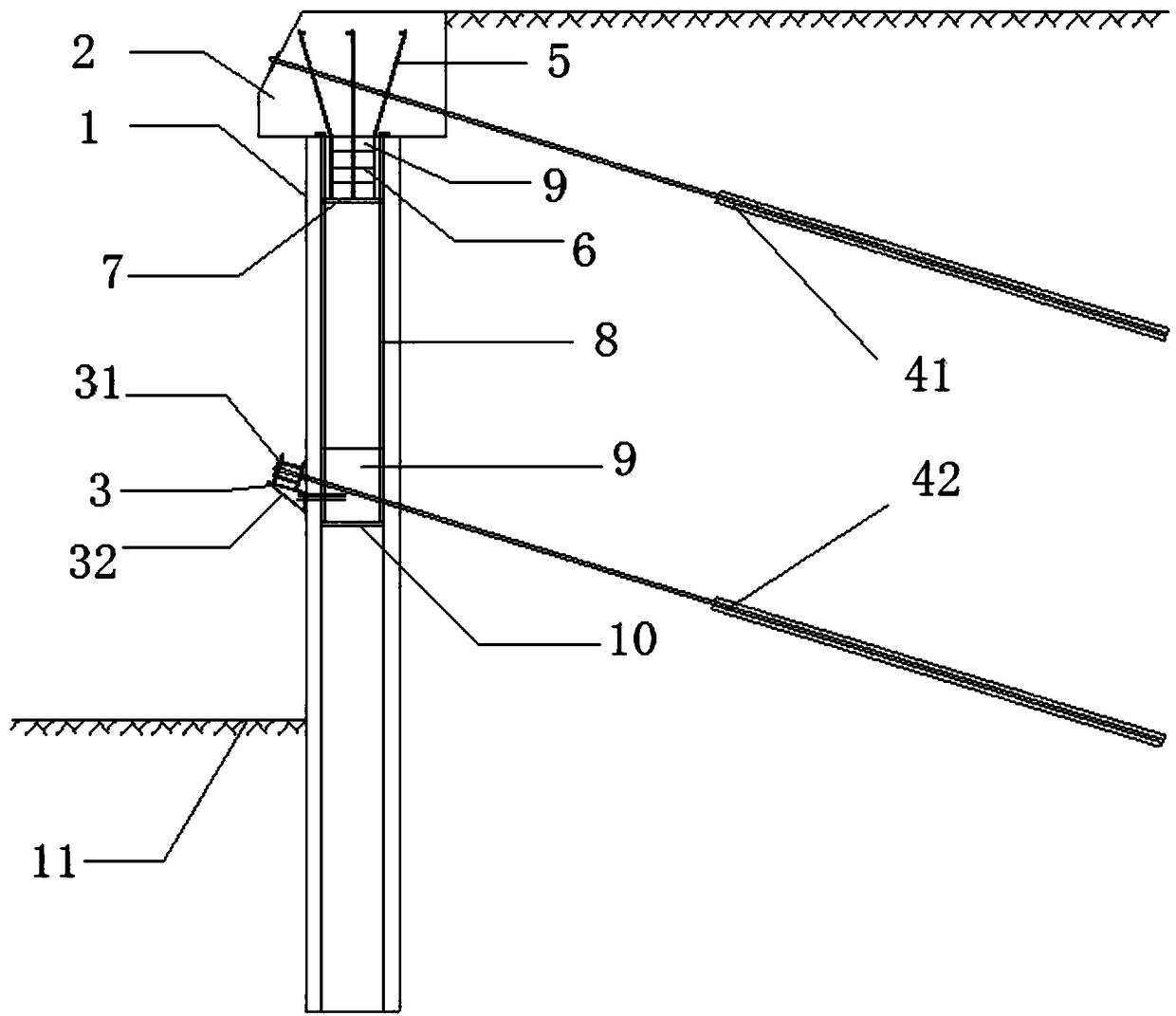

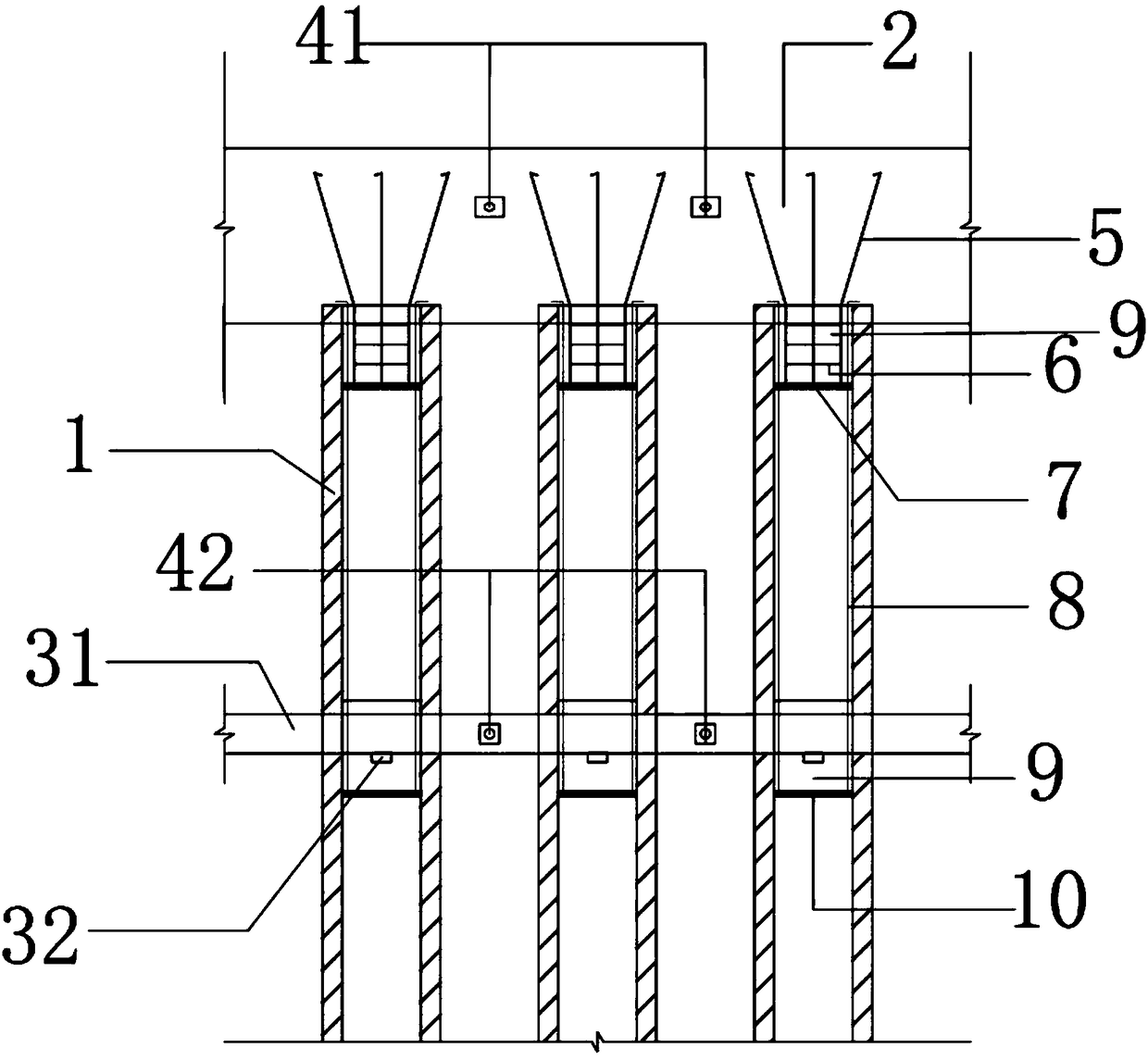

Anti-deformation supporting structure of foundation pit and construction method thereof

PendingCN108360534AImprove stabilityControl deformationExcavationsBulkheads/pilesPre stressBuilding energy

The invention discloses an anti-deformation supporting structure of a foundation pit and a construction method thereof. The anti-deformation supporting structure comprises a plurality of pre-stressedconcrete pipe piles vertically and parallelly arranged around the foundation pit, wherein the pile tops of the two adjacent pre-stressed concrete pipe piles are connected through crown beams; first supporting plates are fixed in the tops of the pre-stressed concrete pipe piles in the radial direction, a plurality of main steel bars are fixed on the first supporting plates through fill core concrete, all the main steel bars are arranged in a circle evenly around the inner walls of the pre-stressed concrete pipe piles, and the main steel bars are connected into a whole through stirrups; each main steel bar is formed by connecting a vertical section and an inclined section, wherein each vertical section is fixed inside each pre-stressed concrete pipe pile and each inclined section is fixed inside each crown beam; and the inclined sections incline toward the outer sides of the pile walls of the pre-stressed concrete pipe piles, and bend inward at the top ends of the pre-stressed concrete pipe piles. The anti-deformation supporting structure can meet the stability requirement of foundation pit deformation in the case of reducing building energy consumption and the use of building materials, the noise and pollution to the environment produced by construction machinery are very little, and construction is green and environment-friendly.

Owner:广西建工集团土木工程有限公司

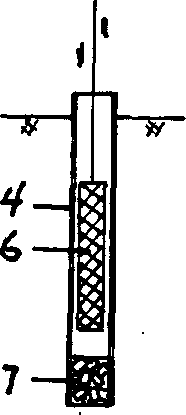

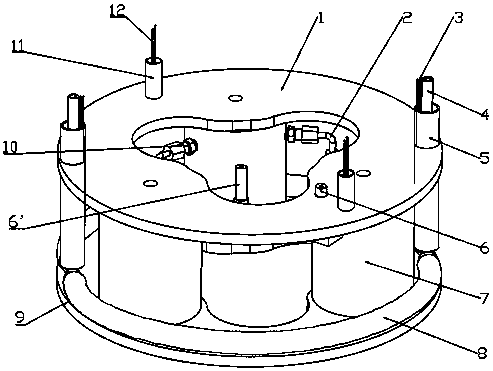

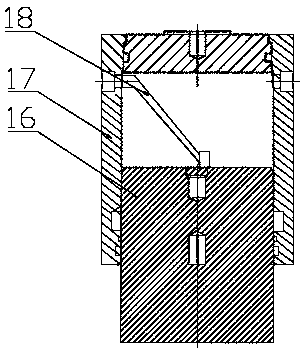

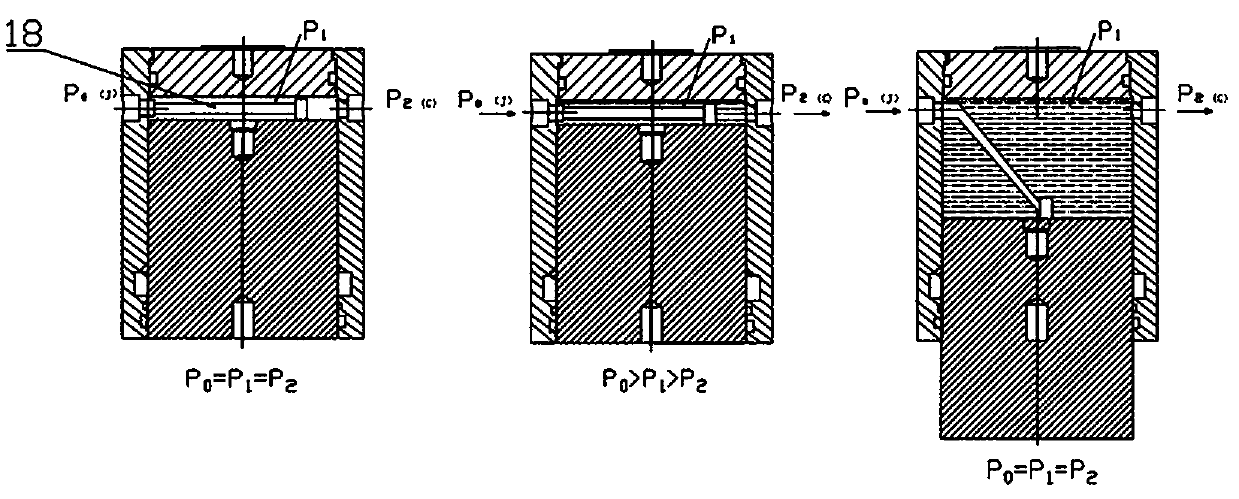

Load box integrating test force application and engineering pile reinforcement

PendingCN110387912AImprove effectivenessUniform output thrustFoundation testingFilling rateEngineering

The invention relates to a novel self-balancing load box, in particular to an integrated load box which provides load application force during static load test pile detection and reinforces an engineering pile after a detection test is finished, and belongs to the field of civil engineering. A load box integrating test force application and engineering pile reinforcement comprises a connecting base, hydraulic pipes and a jack structure, wherein a connecting plate comprises an upper base and a lower base which are oppositely arranged; the jack structure is arranged between the upper base and the lower base to move; there are a plurality of hydraulic pipes, and one hydraulic pipe communicates with an liquid inlet and an liquid inlet device to form a loading liquid path passage, another hydraulic pipe communicates with an liquid outlet and an slurry inlet device to form a grouting liquid path passage, and other hydraulic pipes communicates with the liquid inlets and liquid outlets adjacent the jack structure. The invention has the following advantages: firstly, the effectiveness of grouting in a cylinder is improved; secondly, the compactness of the grouting in the cylinder can be ensured; thirdly, the filling rate of the grouting in the displacement clearance of the upper and lower section piles are ensured; fourthly, the pile body strength of the pile foundation is improved, andthe foundation pile reinforcing effect is achieved; and finally, the vertical bearing capacity of the foundation pile can be continuously transmitted.

Owner:NANCHANG YONGQI TECH DEV +1

Plum-blossom-shaped cement soil mixing pile and forming method thereof

The invention relates to a triangular plum-blossom-shaped cement soil mixing pile and a forming method thereof. The plum-blossom-shaped cement soil mixing pile is good in perpendicularity, incline resisting capability and full in full-load bearing capacity. The cement soil mixing pile comprises a cement soil mixing pile, and two end faces and a cement soil mixing pile body are formed by connection of three plum-blossom-shaped petals. The plum-blossom-shaped cement soil mixing pile has the advantages that a pile foundation distributed in multiple angles is large in bearing capacity, bearing and supporting points are triangularly distributed, and the pile foundation is good in stability; when the pile foundation formed by the plum-blossom-shaped petals is positioned in a soft soil foundation, a plurality of plum-blossom-shaped petals identical in inclined angles act on a wall of the soft soil foundation like three projected ejection posts, so that the cement soil pile is ensured not to incline but perpendicularly stand in the soft soil foundation; due to the fact that a multiple-axis drilling rod sinks along a guiding frame, stirs and sprays cement paste at the same time, and the sinking direction and the stirring direction are opposite, so that the cement paste and soil can be fully mixed integrally, and high strength of the cement soil pile is ensured.

Owner:周兆弟

Construction method of drilling follow casting pile used for building or bridge foundation

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

Small-diameter cast-in-place tube pile composite foundation treatment method for permafrost foundation of Qinghai-Tibet highway

The invention relates to a technology of adopting a small-diameter cast-in-place tube pile composite foundation for treating a permafrost foundation of the Qinghai-Tibet highway, in particular to a specially designed steel tube mold forming small diameter (50 cm-80 cm) cast-in-place tube pile machine. The method includes the steps that steel tube cavity structures are driven into the permafrost foundation in a rotating mode; heat preservation hollow steel protective tubes are driven into holes formed after the steel tube cavity structures are pulled out, then freshly mixed concrete is cast in place, and the steel protective tubes are pulled out after certain strength is reached; a gravel layer and soil engineering grilles are laid at the tops of formed small diameter cast-in-place tube piles. The previous thought of protecting the permafrost foundation passively is broken through, the problems of hot melting and sinking of the permafrost foundation of the Qinghai-Tibet highway are expected to be solved fundamentally, and meanwhile the small diameter cast-in-place tube piles belong to rigid piles, are high in strength, simple in technology and low in cost, and the treatment depth can reach 10 m-30 m.

Owner:SOUTHEAST UNIV

Load box gap reinforcing device after self-balancing detection and reinforcing method thereof

PendingCN109914495AEnsure pressureEnsure grout densityFoundation testingStructural engineeringWelding

The invention relates to a load box gap reinforcing device after self-balancing detection and a reinforcing method thereof, and belongs to the technical field of building foundation piles. The load box gap reinforcing device after self-balancing detection comprises a load box device, an upper displacement pipe, lower displacement pipes and a grouting annular loop pipe. The load box device comprises a grouting load box, a grouting one-way valve and a hydraulic pipe; the grouting annular loop pipe is fixed to the center of an upper plate of the grouting load box through indirect welding. The center line of the grouting annular loop pipe is coaxial with the center of the grouting load box, the diameter of the grouting annular loop pipe is the same as that of a middle hole of the grouting loadbox, two ends of the grouting annular loop pipe are connected with lower displacement pipes symmetrically arranged on two sides of the grouting load box respectively to form an annular channel, and the grouting one-way valve and the hydraulic pipe are symmetrically installed on two sides of the grouting annular loop pipe respectively.

Owner:NANCHANG YONGQI TECH DEV

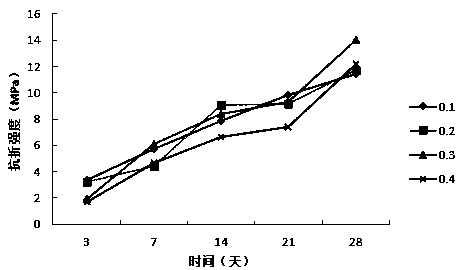

Cement production and preparation method

The invention discloses a cement production and preparation method. Raw materials include 50-100 parts of silicate cement, 60-120 parts of coal ash, 40-80 parts of fine sand, 20-40 parts of graphite powder, 1-7 parts of polyvinyl alcohol fiber, 0.5-2 parts of water reducer, 0.1-0.2 part of additive and 20-40 parts of gypsum powder; calculated by volume fraction, the graphite powder accounts for 5-15% of total volume of the raw materials, and the polyvinyl alcohol fiber accounts for 1-2% of the total volume of the raw materials; the additive is composed of 5-10 parts of nano silicon dioxide, 15-20 parts of triethanolamine, 10-15 parts of water glass, 10-15 parts of dispersant, 5-8 parts of calcium carbonate, 1-1.5 parts of excitant and water. Cement has higher tensile strength and high tenacity, is suitable for damage restoring and reinforcing of structural tensioned parts and structure paving layers having high requirements on ductility and has special solidification enhancing effect on improving pile forming performance of engineering of organic matter soil, peat soil and pond-river sludge.

Owner:顾广才

Foundation pit supporting construction technology combining equal-thickness cement-soil diaphragm wall and tubular piles

InactiveCN105544556ASmall footprintImprove integrityExcavationsBulkheads/pilesSlurry wallEngineering

The invention relates to a foundation pit supporting construction technology combining an equal-thickness cement-soil diaphragm wall and tubular piles. The foundation pit supporting construction technology is characterized in that according to the technological process, a plurality of supporting structures are manufactured along the side boundary of a foundation pit and connected end to end to form a whole surrounding the foundation pit, wherein the specific construction technology of each supporting structure comprises the steps that a, after pile position surveying and setting out are carried out, drilling down is carried out, and cutting is carried out downwards till cutting is carried out at the preset depth; b, after cutting is carried out downwards at the preset depth, transverse cutting is started, and meanwhile grouting is carried out to form the equal-thickness cement-soil diaphragm wall; c, after transverse cutting is carried out for a certain distance, transverse cutting and grouting continue to be kept, and the prefabricated tubular piles are sequentially and vertically lowered into the diaphragm wall in the length direction of the diaphragm wall; and d, a top beam is poured to completely cover the prefabricated tubular piles and the diaphragm wall. The supporting structures with high integrality are formed, and construction speed is high.

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

Concrete for precasting magnesium oxide carbonized pile and application thereof

InactiveCN110218061AGood quality and stabilityLow priceCeramic shaping apparatusBulkheads/pilesCarrying capacityMold filling

The invention discloses concrete for precasting a magnesium oxide carbonized pile and application thereof, belonging to the field of building materials. Through improving a raw material ratio, namelythe ratio of powder obtained by mixing magnesium oxide and coal ash in the raw materials, a novel concrete formula for the precast pile is obtained. A precasting method includes 1) assembling a steelbar cage; 2) cleaning a mold and coating the inner wall of the mold with a layer of engine oil before mold filling; 3) paving concrete on the bottom of the mold, putting the steel bar cage into the mold to vibrate for compaction, uniformly pouring and feeding, and then performing segmented pouring and vibrating for compaction; 4) curing a molded semi-finished product pile in a carbonization case for 24 h, and then demolding to obtain the magnesium oxide carbonized pile. The pile is good in quality stability and cheap, the production cost is easy to control, and the pile has adequate carrying capacity, small transport and pouring amounts, and reduced material and energy consumption.

Owner:扬州邗江中科南工建设工程与信息化研究中心

Reinforced CFG pile mixture suitable for soft soil area, CFG pile, composite foundation and construction method of composite foundation

PendingCN113213879AReduce dosageIncrease dosageProtective foundationBulkheads/pilesAggregate (composite)Soil science

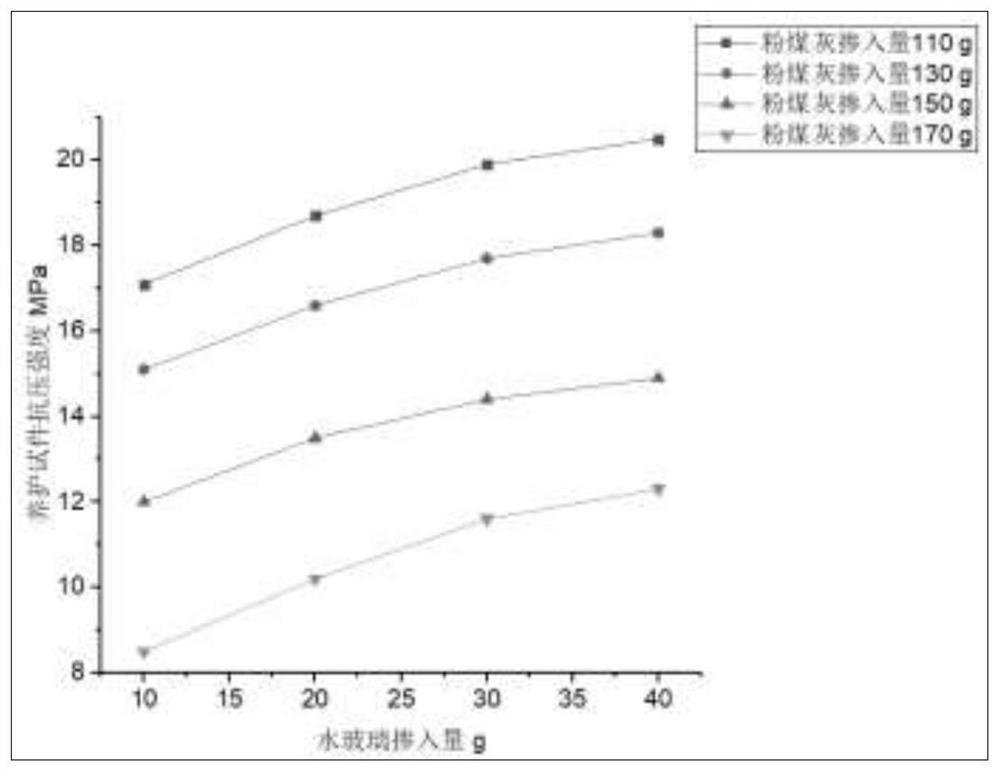

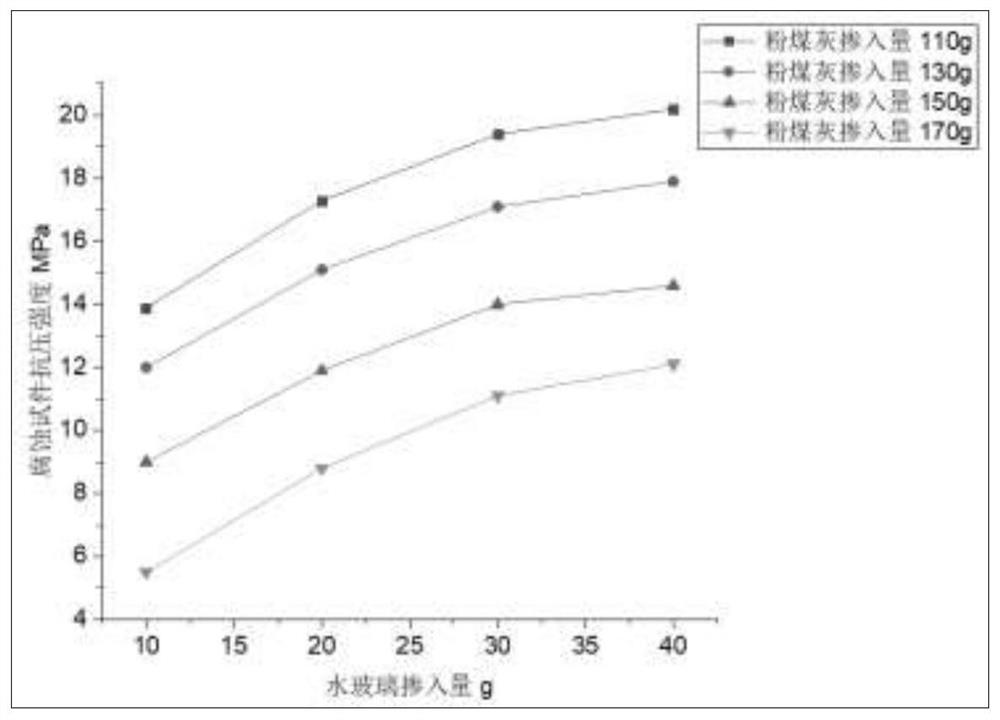

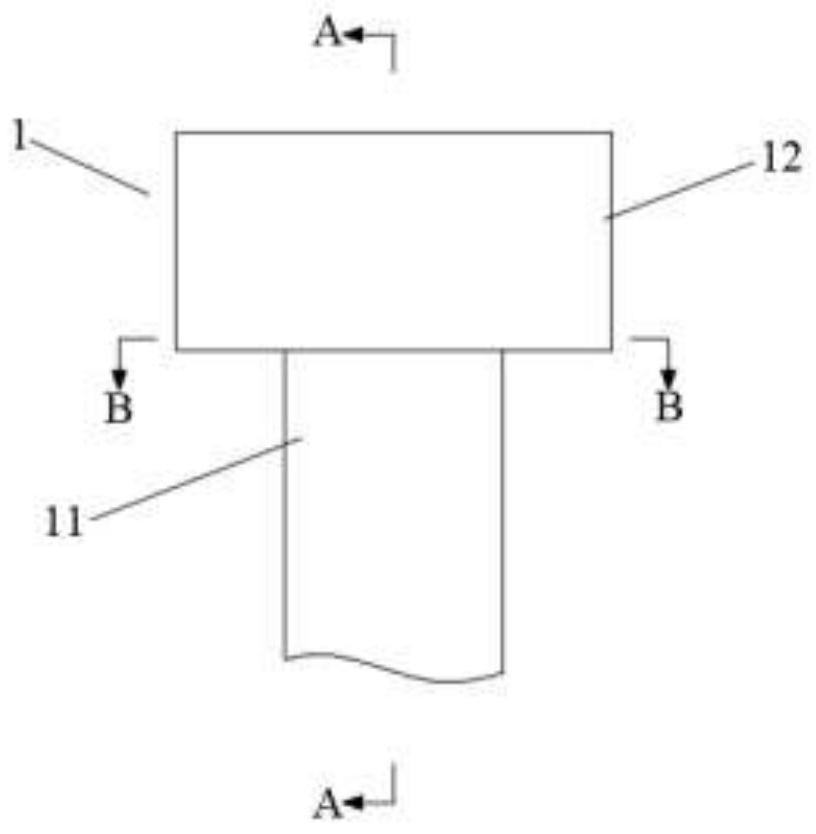

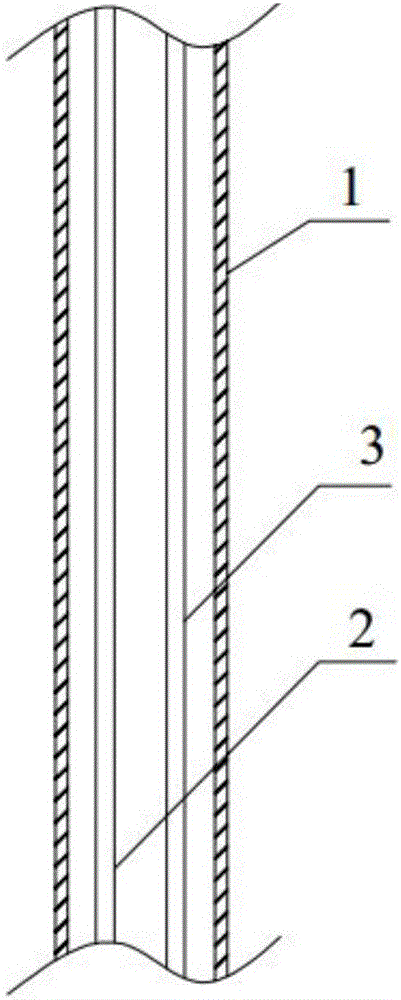

The invention provides a reinforced CFG pile mixture suitable for a soft soil area, a CFG pile, a composite foundation and a construction method of the composite foundation. The CFG pile mixture is prepared from cement, fly ash, fine aggregate, coarse aggregate, water, silicon powder, water glass and a polycarboxylic acid water reducing agent, and the mass ratio of the cement to the fly ash to the fine aggregate to the coarse aggregate to the water to the silicon powder to the water glass to the polycarboxylic acid water reducing agent is (180-220):(110-130):(750-900):(950-1200):(110-150):(10-20):(20-40):(1.3-1.5). By reducing the use amount of the cement in the mixture, increasing the use amount of the fly ash and adding the high-efficiency polycarboxylic acid water reducing agent, the water glass and the silicon powder, the CFG pile poured by adopting the mixture with the mixing ratio has good durability and corrosion resistance, the pile body strength and the bearing capacity of the CFG pile in the soft soil area can be effectively improved, and the pile forming quality is improved; and meanwhile, the material cost can be reduced by increasing the use amount of the fly ash, and efficient utilization of industrial byproducts is realized.

Owner:中建湛江大道投资建设有限公司 +1

Construction method of water-stop curtain for deep foundation pit by using high-pressure rotary grouting pile machine

ActiveCN104631480BSolve the problem of difficulty in forming holes with a large number of bouldersHigh pile strengthBulkheads/pilesSoil sciencePile driver

The invention discloses a method for constructing a water-stop curtain for a deep foundation pit by using a high-pressure rotary grouting pile machine. The method of the present invention aims at silt, cohesive soil, loess, sandy soil, artificial filling, pebble layer, mudstone layer and other geological layers that are difficult to form holes, by installing the grouting pipe and gas injection pipe on the CFG pile driver drill Inside, the drill bit of the CFG pile driver is converted into a down-the-hole hammer drill bit, and the construction technology of directly spraying grout into piles after hole formation is adopted.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Preparation method of pre-tensioning method prestressed centrifugal concrete solid square pile

ActiveCN113478612AHigh pile strengthImprove durabilityCeramic shaping apparatusBulkheads/pilesPre stressCentrifugation

The invention discloses a preparation method of a pre-tensioning method prestressed centrifugal concrete solid square pile, which comprises the following steps: preparing a mold, and brushing a parting agent on the mold; mounting a reinforcement cage in the mold, and arranging a tensioning end plate; feeding prepared concrete into the mold; conducting prestressed tensioning on the reinforcement cage according to the designed tensioning stress, and then carrying out locking and anchoring; putting the mold which is fed with the concrete on a centrifugal machine for centrifugal forming treatment; after centrifugation is completed, forming a central hollow core in the center of the square pile, and pouring out residual slurry separated from the concrete completely; conducting secondary filling on the center of the pile through high-strength-grade concrete, filling the center hollow core through secondary material pumping, and forming the square pile; performing steam curing on the formed solid square pile; and releasing and demolding the cured solid square pile. According to the method, the strength of the pile body of the solid square pile is high, and the phenomena that the four corners of the solid square pile in a non-centrifugal production process fall off and are unfilled and the strength difference of the upper section and the lower section of the pile body is large due to concrete vibration are avoided.

Owner:南京汇联建材科技发展有限公司

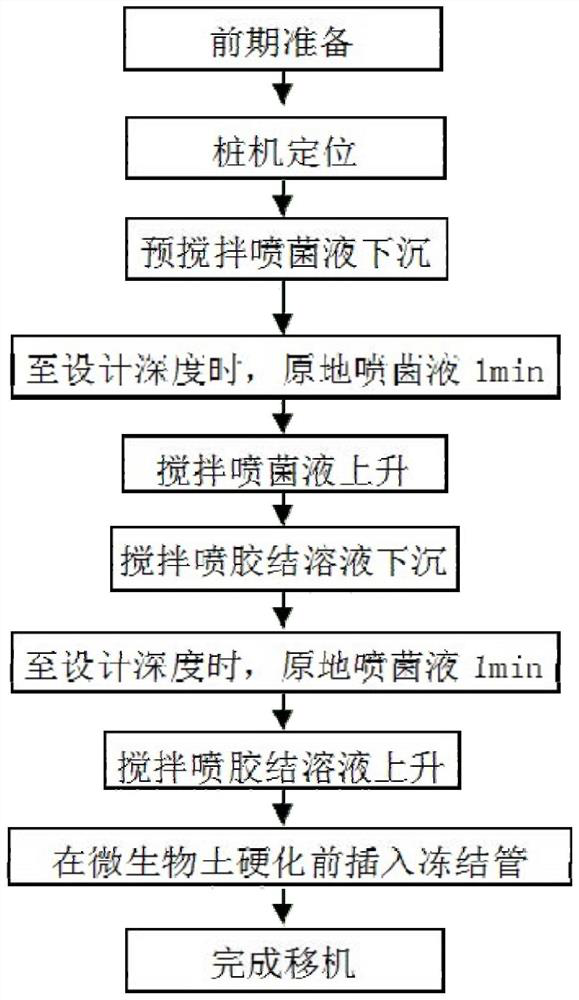

Frozen microorganism soil mixing pile

ActiveCN113235579AImprove bearing capacityIncreased shear strengthBacteriaMicroorganism based processesMicroorganismSoil science

The invention provides a frozen microorganism soil mixing pile. Soft soil is forcibly mixed with a water reducing agent, a bacterial liquid and a cementing solution on site in a foundation, so that the soft soil is hardened into foundation soil; and then a freezing method is implemented, so that the phenomena of frost heaving and thaw collapse of surrounding stratums can be effectively inhibited, and the bearing capacity, the shear strength, the pile body strength and the impermeability of the microorganism soil mixing pile are enhanced. According to the frozen microorganism soil mixing pile, soft soil gaps are filled with the cementing solution, and the bacterial liquid containing bacillus pasteurii and pseudomonas oryzihabitans is added, so that cracks generated when the mixing pile is frozen are repaired, and the bearing capacity of the mixing pile is improved; and by adding the water reducing agent, the impermeability of the microorganism soil mixing pile is improved, and the influence of water on the freezing effect is reduced.

Owner:HAINAN UNIVERSITY

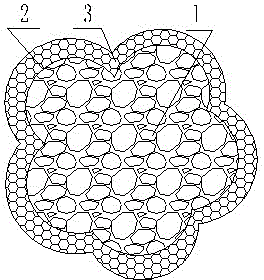

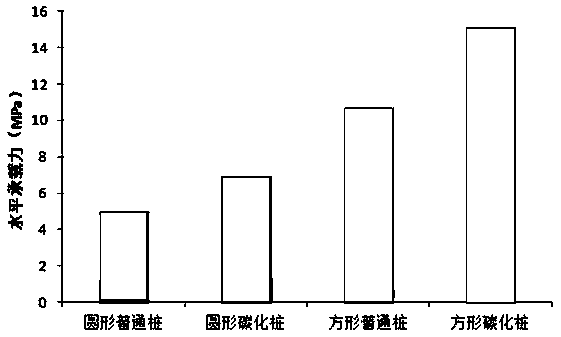

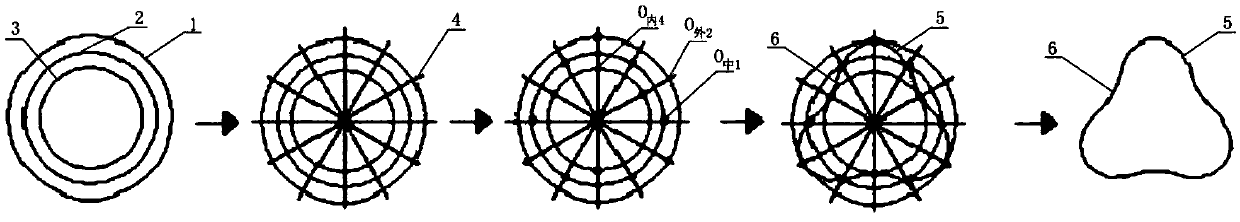

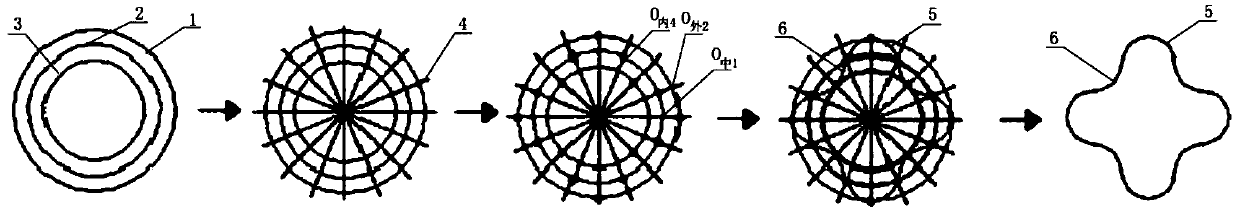

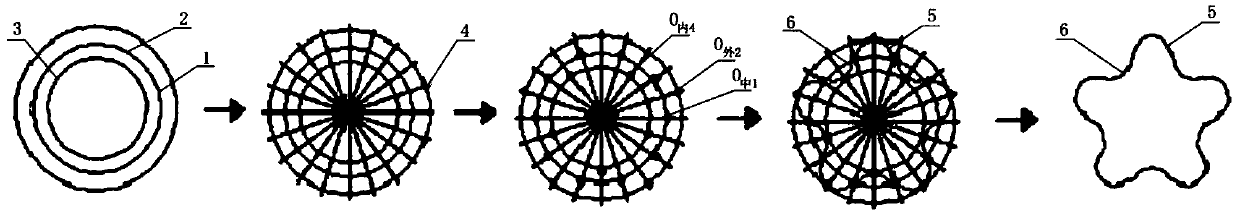

A cross-sectional construction method of a multi-petal plum blossom-shaped pile, a special-shaped pile and a manufacturing method

ActiveCN107386271BImprove bearing capacityHigh pile strengthCeramic shaping apparatusBulkheads/pilesStress concentrationPetal

The invention provides a cross section construction method for multi-petal quincuncial piles. The cross section construction method for multi-petal quincuncial piles comprises the following steps: setting the number of petals of a quincuncial pile as n, and taking three circles which are different in radius and are concentric; guiding out 4n radials from the centers of the circles, wherein 4n intersection points of the 4n radials and the outer circle are O outside 4n, 4n intersection points of the 4n radials and the middle circle are O middle 4n, 4n intersection points of the 4n radials and the inner circle are O inside 4n, and O inside 4(k-1)+i, O middle 4 (k-1)+i and O outside 4(k-1)+i are positioned on the same radial; taking a three-point concyclic principle, and drawing convex arcs by taking intersection point O middle 4(n-1)+1, O outside 4(n-1)+2 and O middle 4(n-1)+3 as reference points; and drawing concave arcs by taking intersection point O middle 4 (n-1)+3, O inside 4n and O middle 4n+1 as reference points. By streamed connection between the n convex arcs and the N concave arms, stress concentration can be prevented effectively, and the bearing capacity of the pile and the strength of a pile body are greatly improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

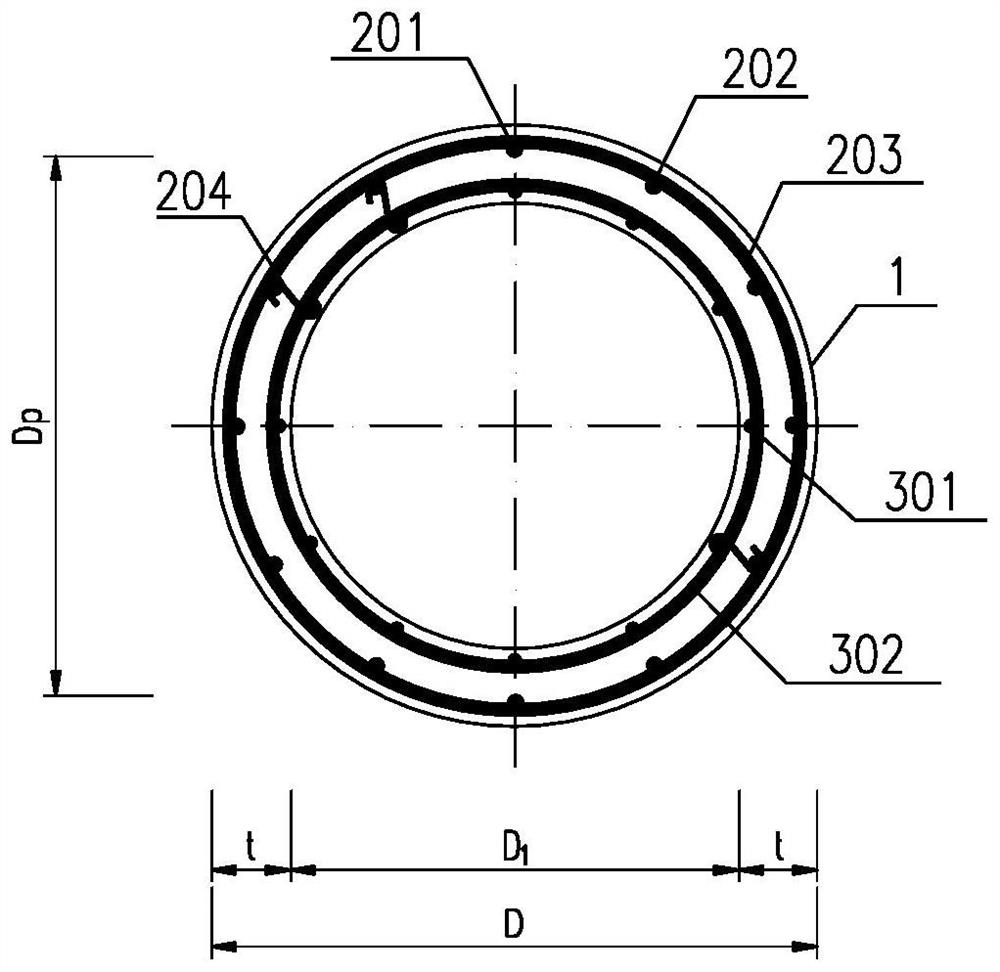

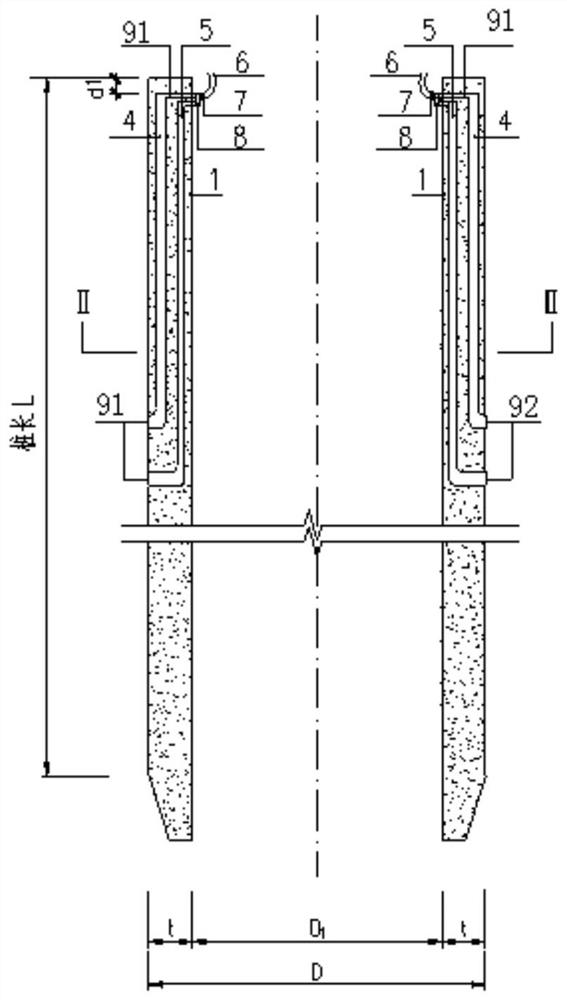

Super-large-diameter prestressed concrete tubular pile for offshore wind power and construction method thereof

ActiveCN114351697AImprove stabilityImprove bending abilityWind motor assemblyWind motor supports/mountsPre stressArchitectural engineering

The invention discloses a super-large-diameter prestressed concrete tubular pile for offshore wind power and a construction method thereof.The concrete tubular pile comprises a reinforcement cage framework, and the reinforcement cage framework adopts a double-layer bidirectional mixed reinforcement mode and comprises an outer ring layer, an inner ring layer and a connecting layer connecting the outer ring layer and the inner ring layer into a whole; the outer ring layer comprises outer ring layer longitudinal bars and outer ring layer stirrups, and the inner ring layer comprises inner ring layer longitudinal bars and inner ring layer stirrups; the outer ring layer longitudinal bars and the inner ring layer longitudinal bars are tied through tie bars, and the tie bars form the connecting layer. Therefore, the corrosion of seawater and salt mist to the fan foundation and the damage of marine organisms to the structural foundation can be effectively reduced, the problem of corrosion resistance of the fan foundation is well solved, and the concrete base material is adopted, so that the engineering cost can be reduced, the construction is convenient, and the operation and maintenance cost is reduced and the operation and maintenance efficiency is improved under the pressure of reducing the cost on average price.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com