Load box integrating test force application and engineering pile reinforcement

A technology of load boxes and engineering piles, which is applied in foundation structure engineering, foundation structure testing, construction, etc., can solve problems such as engineering pile breakage, unquantifiable acceptance, disconnection, etc., to ensure filling rate, ensure compactness, and improve The effect on success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Attached below Figure 1-8 The present invention is further described:

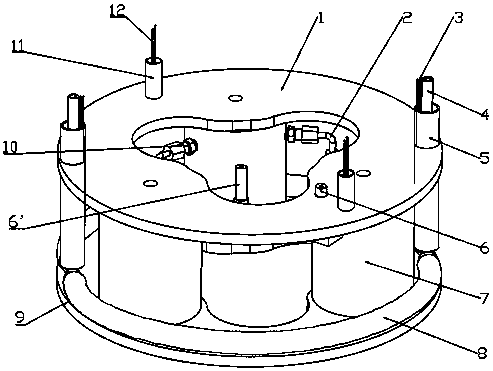

[0032] An integrated load box integrating test force and engineering pile reinforcement, including a load box device and a detection device;

[0033] Such as figure 1 , 6 As shown, the load box device includes: upper base 1, hydraulic pipe 2, lower displacement wire 3, outer grouting pipe 4, outer grouting pipe sheath 5, hydraulic pipe 6, hydraulic pipe 6', jack 7, U-shaped bottom Pipe 8, lower base 9, hydraulic pipe and cylinder connecting piece 10, upper displacement wire sheath 11, upper displacement wire 12, joint 13, lower displacement wire fixing ring 14, joint base 15.

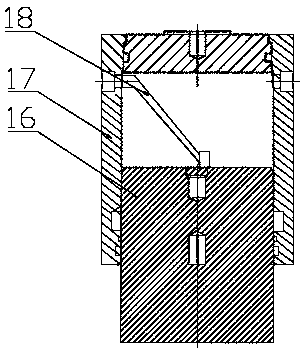

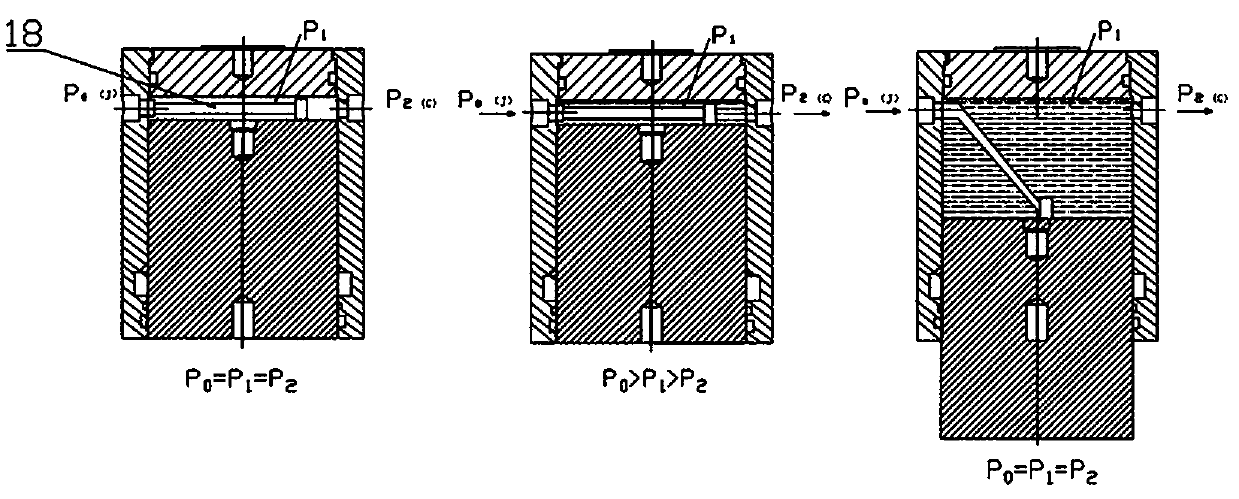

[0034] Such as figure 2 As shown, the upper base 1 is arranged opposite to the lower base 9, and can move up and down under the action of the jack 7; the upper base 1 is provided with a through hole for the upper displacement wire sheath 11 and the outer grouting pipe sheath 5 to pass through , the upper displacement w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com