Patents

Literature

65results about How to "Overcome the polluted environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

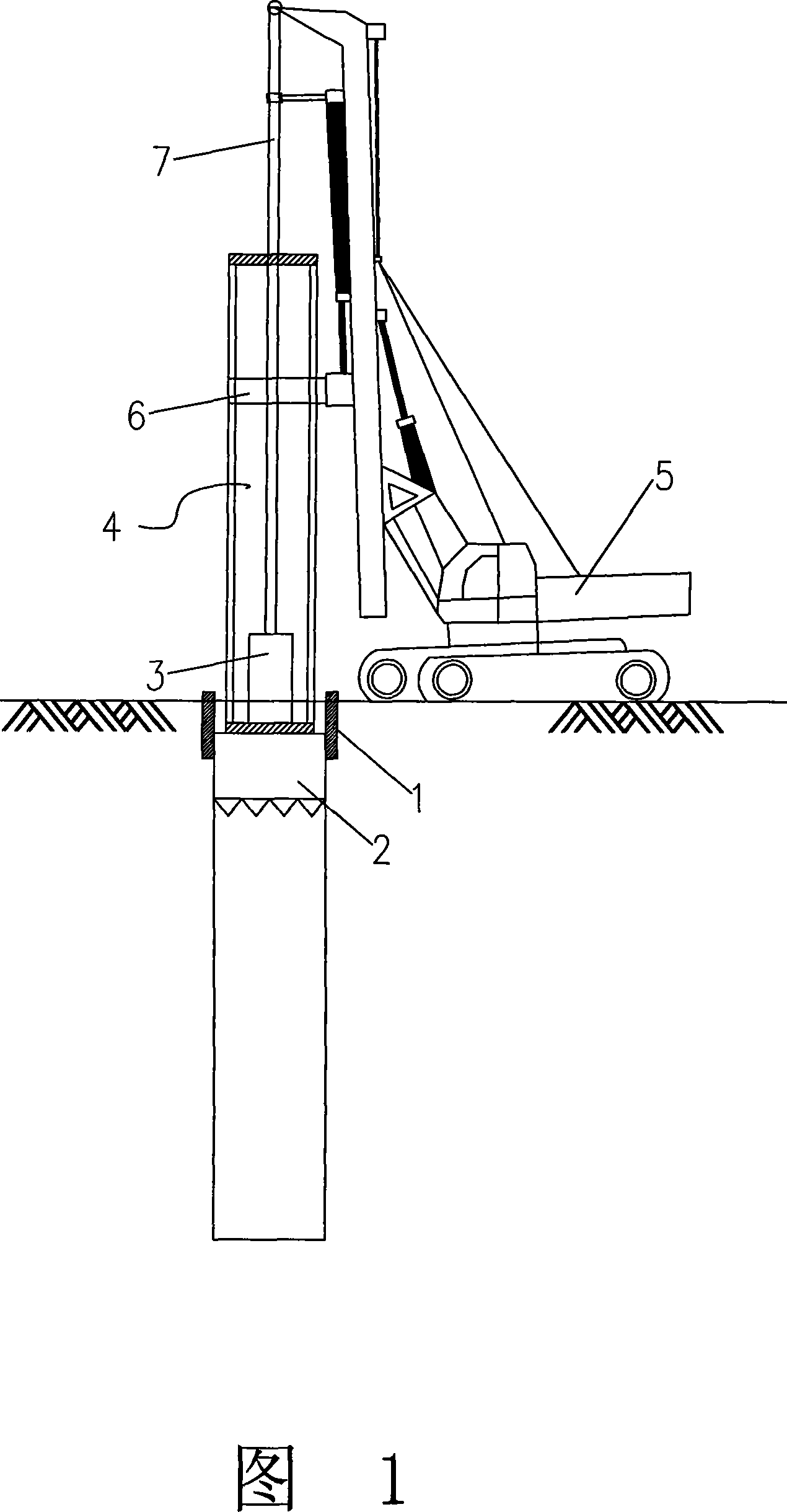

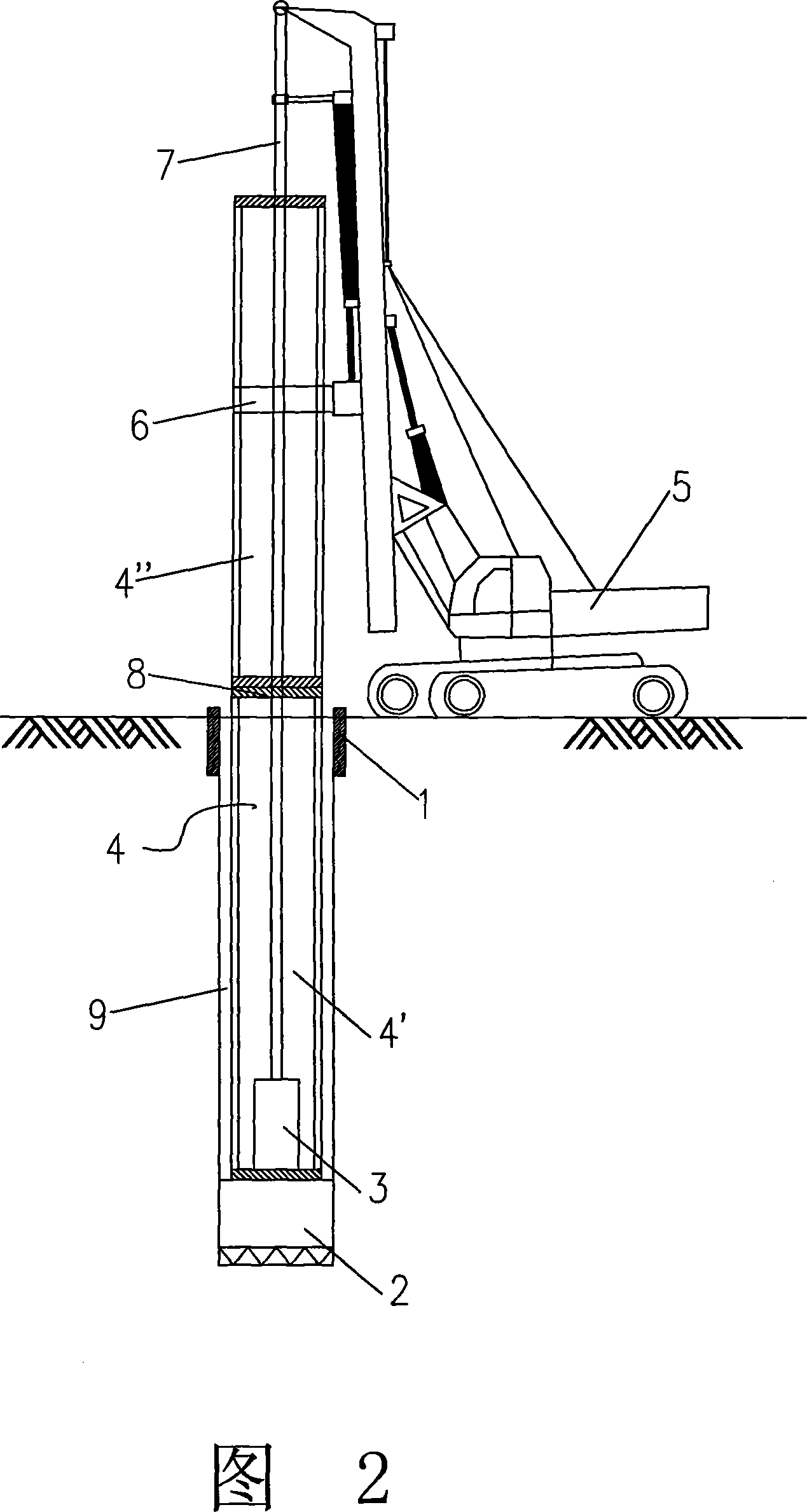

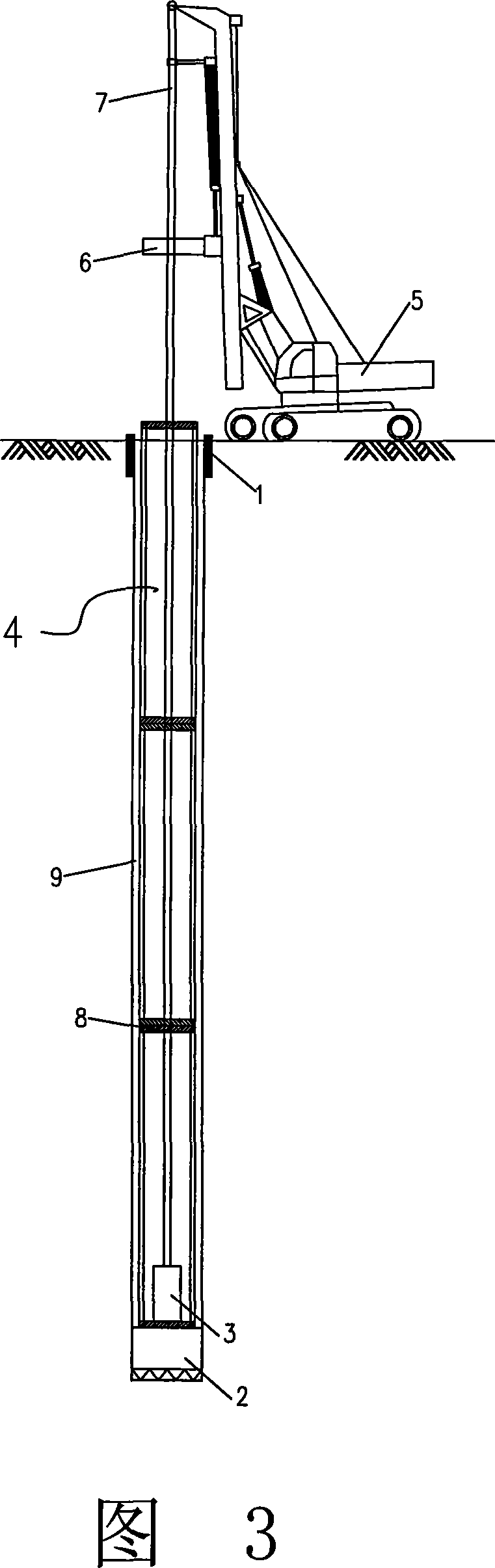

Construction method of drilling follow casting pile used for building or bridge foundation

A method for constructing pipe piles while drilling for building or bridge foundations. The construction steps are to cover high-strength prestressed concrete pipes or steel pipes with drill pipes on the ground first, and install impactors and reaming retractable drill bits at the front ends of the drill pipes. , Follow the pipe while drilling, follow the pipe retaining wall, drill to the design elevation, stop drilling, withdraw from the reaming to shrink the drill bit, use the mud pump to clean the mud and sediment, pour concrete into the pipe, and simultaneously inject pressure grout to the outside of the pipe wall , stop when concrete and grout reach the ground; the object of the invention is to propose a construction method with fast construction speed, reliable quality, less material consumption, high bearing capacity of piles, mechanized operation, and environmental protection. In the construction method of bored cast-in-place piles, the use of mud retaining walls pollutes the environment, the hole is easy to collapse during the drilling process, the quality of concrete pouring is unstable, and the prestressed pipe piles are easy to cause the soil to rise. The strength of the pile body constructed by the invention is high. , There is no sediment at the bottom of the pile, and the pile end is completely rock-socketed, which can reach more than 2 times the bearing capacity of the same diameter bored pile.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

Environment Protection type bioactive plant-growing container

InactiveCN1408205ANo pollution in the processGrow vigorouslyCultivating equipmentsNatural organic matterPlant fibre

The environment protection type bioactive plant-growing container for growing seedlings in planting consists of plant fiber powder 20-75 wt%, natural organic matter 10-60 wt%, bioactive nutrient 0.5-20 wt%, non-toxic adhesive 10-50 wt% and stuffing 3-10 wt%. The said plant fiber powder is husk powder, rice straw powder, corn straw powder, wheat straw powder, etc; the natural organic matter includes turf and sphagna; and the bioactive nutrient is algin. The plant-growing container is produced through mixing the said material and press molding at 80-160 deg.c.

Owner:金绿汀

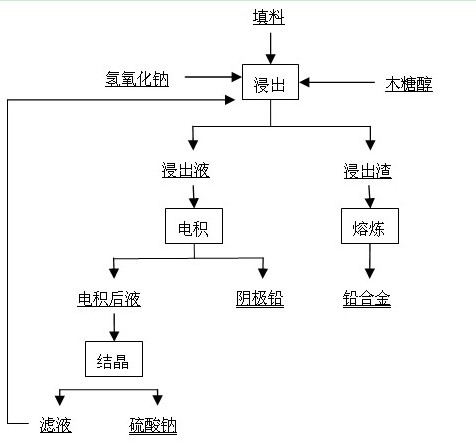

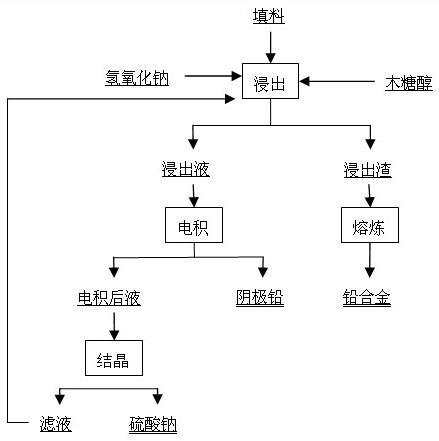

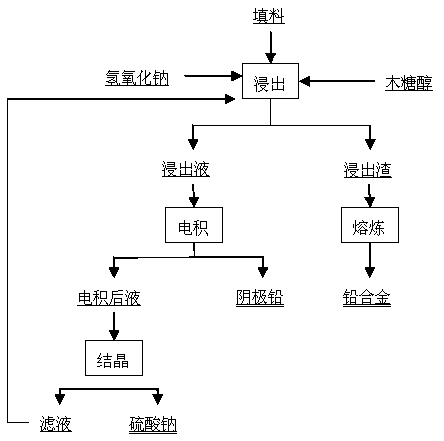

Method for recovering lead in waste lead-acid storage battery filler by using wet process

InactiveCN102560535AElectrolytic smoothImprove electrolysis efficiencyPhotography auxillary processesProcess efficiency improvementElectrolysisHuman health

The invention relates to a method for recovering lead in a waste lead-acid battery filler by using a wet process, which comprises the following steps of: taking and adding sodium hydroxide and xylitol into water, agitating and dissolving at a normal temperature to prepare mixed solution; adding obtained lead paste powder in the mixed solution, reacting for 1-5 hours and taking a filtered filtrate as an electrolyte; adopting a pure lead plate or a stainless steel plate as a cathode; and adopting the stainless steel plate as an anode and switching on direct current for electrolysis. The method has the beneficial effects that the method of directly leaching lead paste is adopted; the processes of desulfurization and reductive transformation are not required, so that the process flow is simplified; the sodium hydroxide and xylitol solution are adopted when the lead paste is leached and can form a compound with lead oxide to leach the lead in the lead paste to a utmost extent, so that the sulfur dioxide and various smoke and dust generated in the pyrometallurgical recovery process are avoided, and the straight yield of the lead is improved; and volatile smoke and dust or acid mist can not be generated, so that the defect that a silicon fluorine acid electrolyte pollutes the environment and is harmful to human health is overcome.

Owner:HENAN UNIV OF SCI & TECH

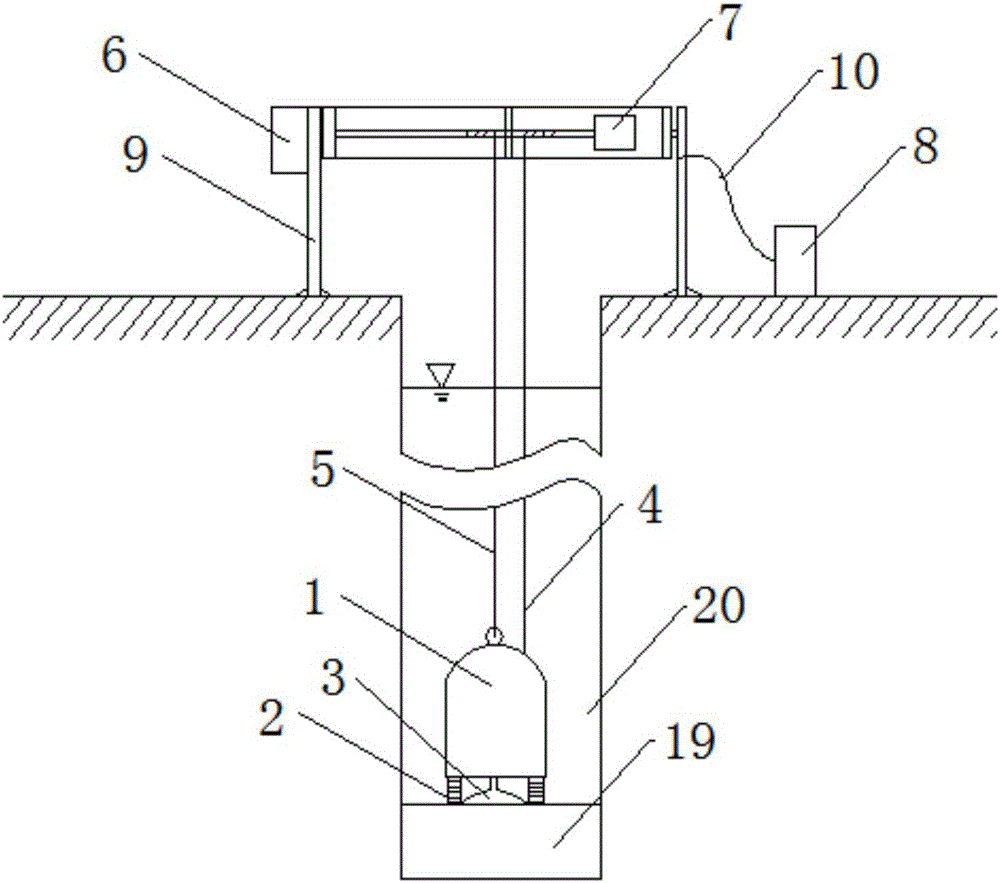

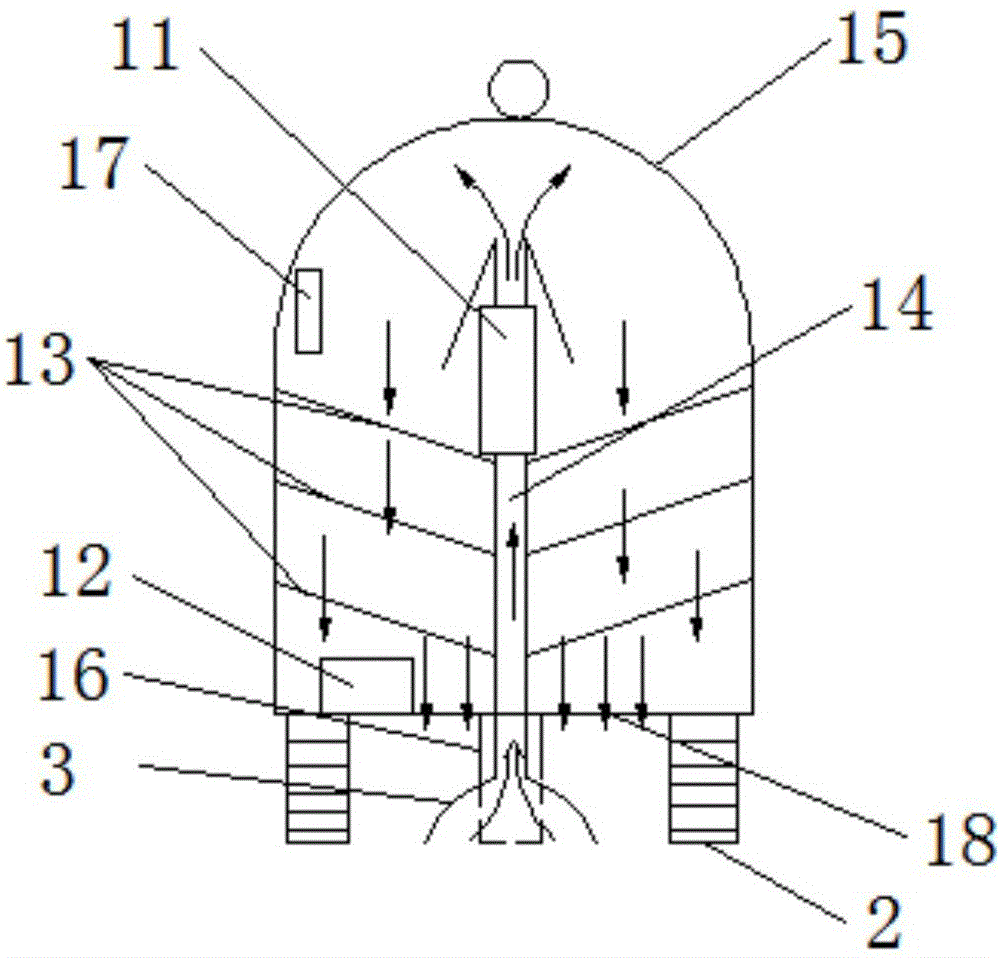

Sediment removal machine for removing sediment at bottom of pile and working method thereof

ActiveCN105821881AThorough slag removalAvoid the risk of hole collapseBulkheads/pilesSediment FilterDischarge return

The invention discloses a sediment removal machine for removing sediment at the bottom of a pile and a working method thereof. The sediment removal machine comprises a sediment removal device and a main controller for controlling work of the sediment removal device. The sediment removal device comprises an outer cover, a sediment suction tube for sucking the sediment is arranged in the outer cover, and the bottom end of the sediment suction tube extends out of the outer cover so that the sediment at the bottom of the pile can be sucked into the outer cover. At least one layer of sediment filter screen is arranged between the outer cover and the sediment suction tube. The positions where the sediment filter screens are located are lower than an outlet of the sediment suction tube. A water outlet is formed in the bottom surface of the outer cover so as to discharge return mud flowing down the sediment filter screens. A sediment amount sensor is arranged on the upper portion of the inner side face of the outer cover and connected with the main controller. Mud displacement does not exist, mud pouring is not needed, the automation degree is high, operability is high, the sediment removal efficiency and effect are improved, the hole collapse risk caused by mud displacement is avoided, and the problem that the environment is polluted because a large amount of mud is used is solved.

Owner:SHANDONG UNIV

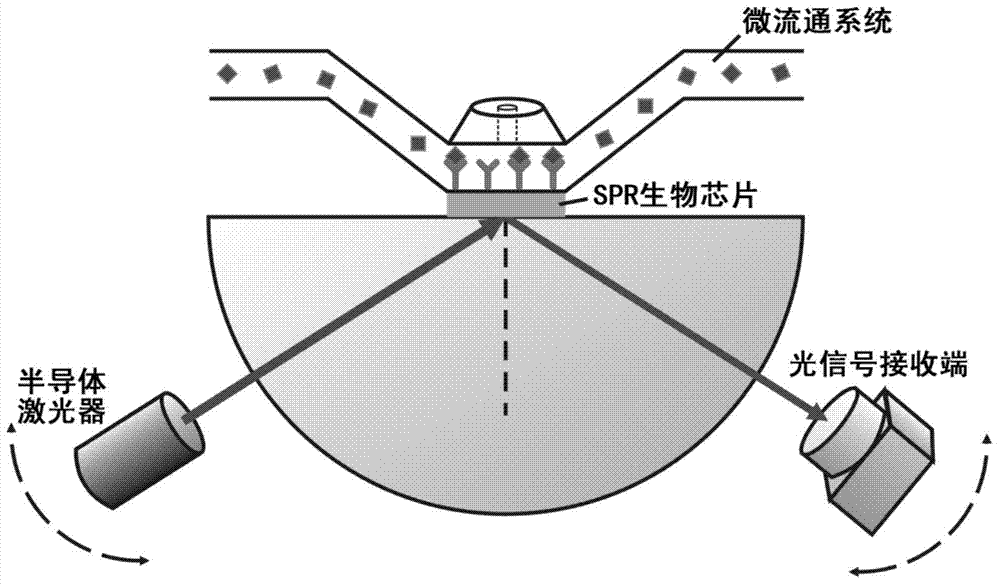

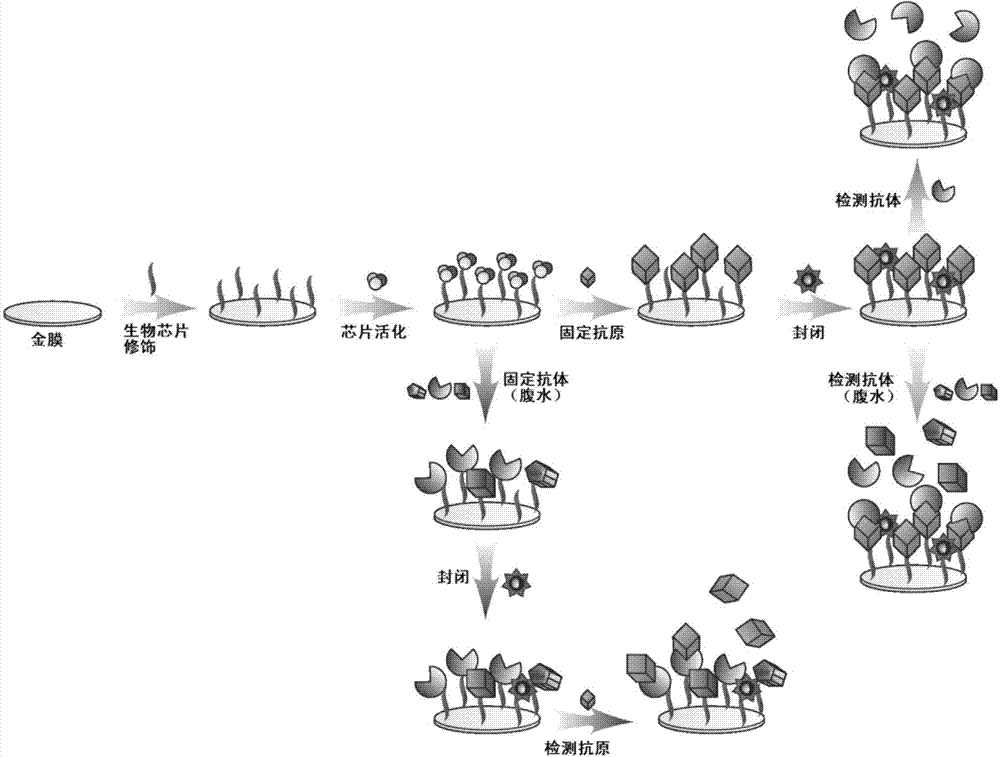

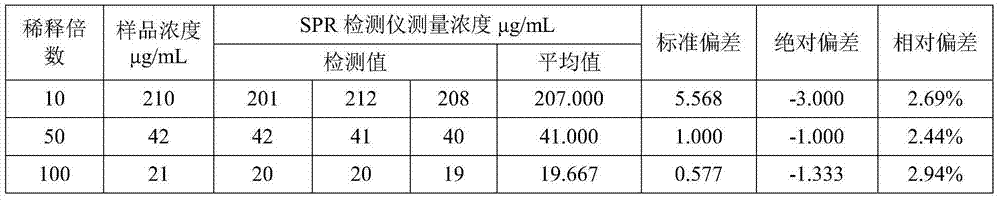

Surface plasma resonance immunosense chip as well as preparation method and application thereof

InactiveCN103792368ANo pollution in the processOvercome the polluted environmentBiological material analysisMaterial analysis by optical meansShrimpMonoclonal antibody

The invention relates to the field of biochips, and particularly relates to a surface plasma resonance immunosense chip as well as a preparation method and application thereof. The surface plasma resonance immunosense chip is prepared by the following steps: fixing a shrimp tropomyosin, shrimp tropomyosin monoclonal antibody ascites or a shrimp tropomyosin monoclonal antibody on a solid phase carrier as a bioprobe; generating surface plasma resonance response by utilizing a gold membrane; modifying sulfydryl on the surface of the gold membrane by utilizing a self-assembly monomolecular layer technique; and fixing the probe on the biochip after the chip is activated. The biochip can be applied to detection of the shrimp tropomyosin monoclonal antibody or the shrimp tropomyosin monoclonal antibody ascites, and detection of the allergen (shrimp tropomyosin), has the advantage of simplicity and convenience in operation, rapidity, high flexibility, no need of being labeled, low cost, simple device, no pollution to the environment and the like, and is hopeful to realize the field real-time detection of a great amount of samples.

Owner:JINAN UNIVERSITY

Chinese medicinal herb feed additive capable of reinforcing reproduction ability of yellow catfish

InactiveCN101057631AIncrease intestinal lipase and protease activityPromote digestion and absorptionAnimal feeding stuffSexual disorderFecundityMedicinal herb

The invention discloses a compound Chinese herbal feed addictive for enhancing fecundity of Richardson, wherein the constituents include (by weight percent) matrimony vine 15-25%, ligustrum japonicum 15-25%, motherwort 15-25%, magnolia bark 5-15%, poria cocos wolf 10-20% and nutgrass flatsedge rhizome 2-8%.

Owner:王吉桥 +1

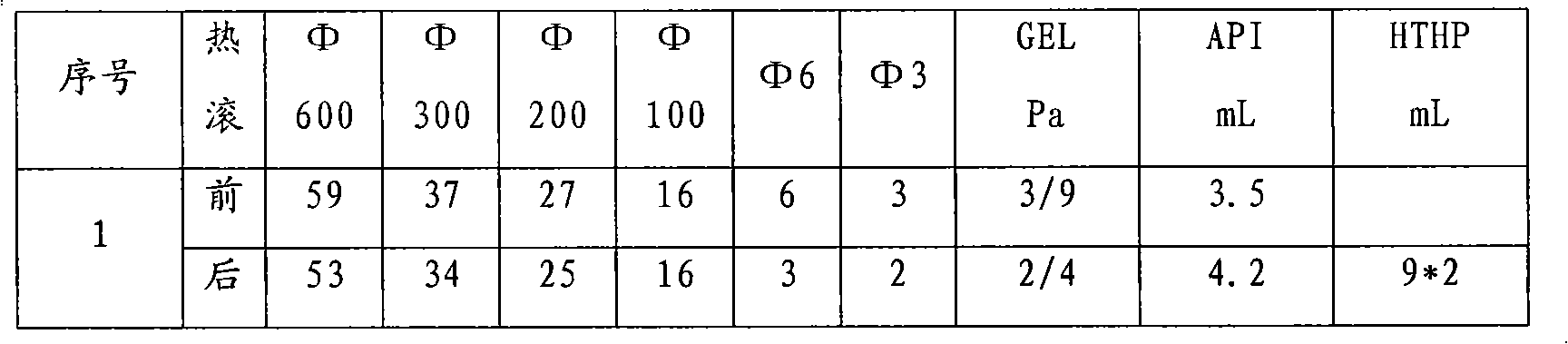

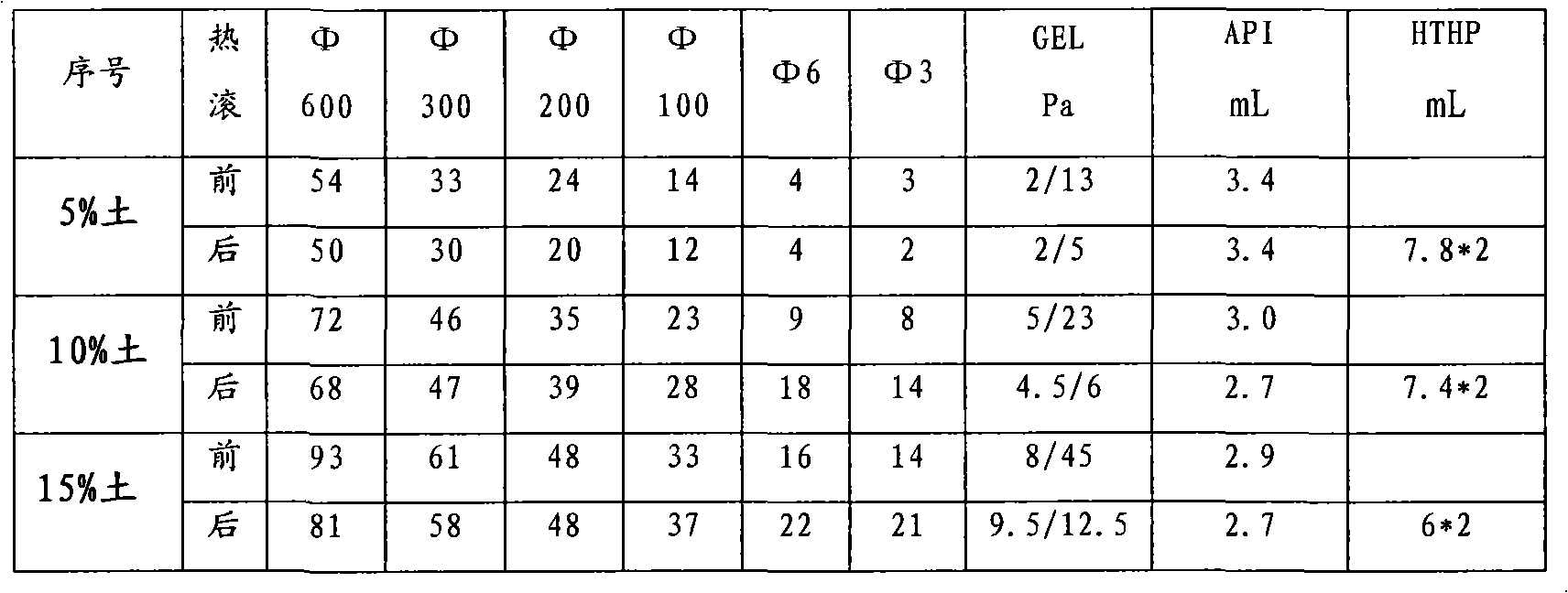

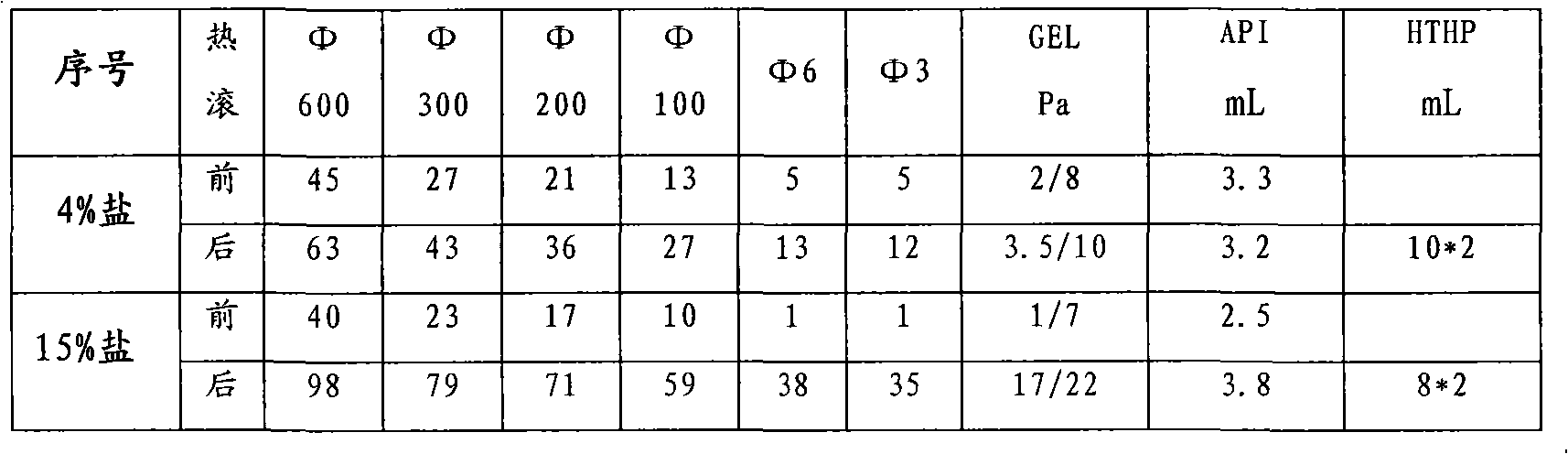

Method for preparing high temperature-resistant and salt resistant fluid loss agent for drilling fluid

ActiveCN101955565APrevent hydrationNo pollution in the processDrilling compositionWater basedFiltration

The invention relates to a method for preparing a high temperature-resistant and salt resistant fluid loss agent for drilling fluid. The method comprises the following steps of: (1) raw material preparation, wherein a mass ratio of 2-acrylamide-2-methylpropanesulfonic to acrylamide to lignitous coal to water to an initiator to an auxiliary material is 2-3:5-7:7-10:15-20:0.1-0.2:0.1-0.2:25-30; (2) mother solution preparation: adding the 2-acrylamide-2-methylpropanesulfonic and the acrylamide into the water respectively, and when keeping the temperature of the solution between 50 and 70 DEG C, adding the lignitous coal; (3) polymerization: adding an oxidative initiator into the mother solution under stirring to react for 1 hour, and then adding a reduction initiator to react for 1 hour; (4) addition of the auxiliary material; and (5) drying and crushing: drying the mixture obtained in the step (4) at the temperature of between 95 and 105 DEG C. The high temperature-resistant and salt resistant fluid loss agent for the drilling fluid has high heat stability and temperature resistance and salt resistance, can effectively reduce filtration, and is suitable for various water-base drilling fluid systems, particularly water-base drilling fluid systems with the high temperature resistance and salt resistance requirements.

Owner:北京奥凯立科技发展股份有限公司

Method for electrolytically refining crude lead

InactiveCN102534660AImprove direct yieldOvercome the polluted environmentPhotography auxillary processesProcess efficiency improvementIonLead plate

The invention discloses a method for electrolytically refining crude lead. The method comprises the following steps of: adding sodium hydroxide and tartaric acid into water in turn, and stirring to dissolve at normal temperature to obtain a mixed solution; adding lead oxide powder into the mixed solution, dissolving and filtering to obtain filtrate, namely electrolyte; and adding the prepared electrolyte into an electrolytic cell, and switching on direct current for electrolysis by taking a stainless steel plate or a pure lead plate as a cathode and crude lead to be refined as an anode. By the method, smoke and middle slag generated in pyro-refining are avoided, the direct recovery rate of lead and comprehensive recovery rate of valued metals in the refining process are improved, volatile smoke or acid mist cannot be generated, and a defect that electrolyte in a silicofluoric acid system pollutes environment is overcome; meanwhile, the sodium hydroxide and the tartaric acid are added into the electrolyte, so that the sodium hydroxide and the tartaric acid can form a complex with the lead oxide, the concentration of lead ions in the electrolyte is greatly increased and the electrolysis efficiency is improved.

Owner:HENAN UNIV OF SCI & TECH

Water-based graphene conductive ink

Belonging to the field of functional materials, the invention relates to conductive ink, particularly to a water-based graphene conductive ink. The water-based graphene conductive ink specifically comprises the following components by mass: 50-70 parts of a graphene composite slurry, 30-55 parts of connection resin, 5-10 parts of a solvent, and 2-10 parts of an assistant. The water-based graphene conductive ink provided by the invention adopts deionized water as the dispersion medium to replace traditional organic solvents, and through connection resin screening and proportion adjustment, the adhesion and flexibility of the ink both meet the requirements, also the added graphene component effectively improves the conductive stability and reduces the resistivity. The water-based graphene conductive ink provided by the invention overcomes the defects of environmental pollution during use and high cost of traditional solvent type conductive ink. The detection result shows that water-based graphene conductive ink not only has the advantages of safety and environmental protection, but also has good conductivity.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

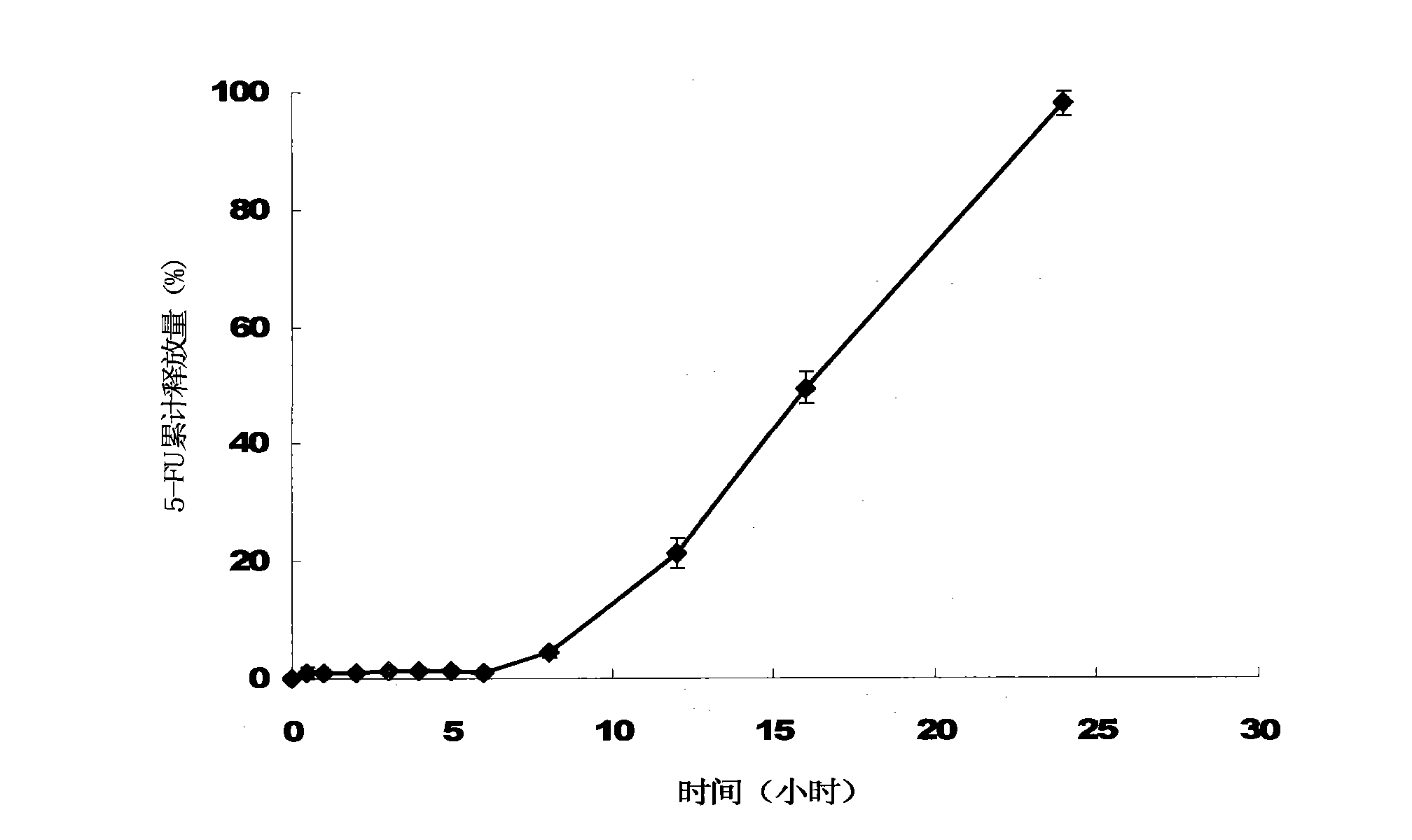

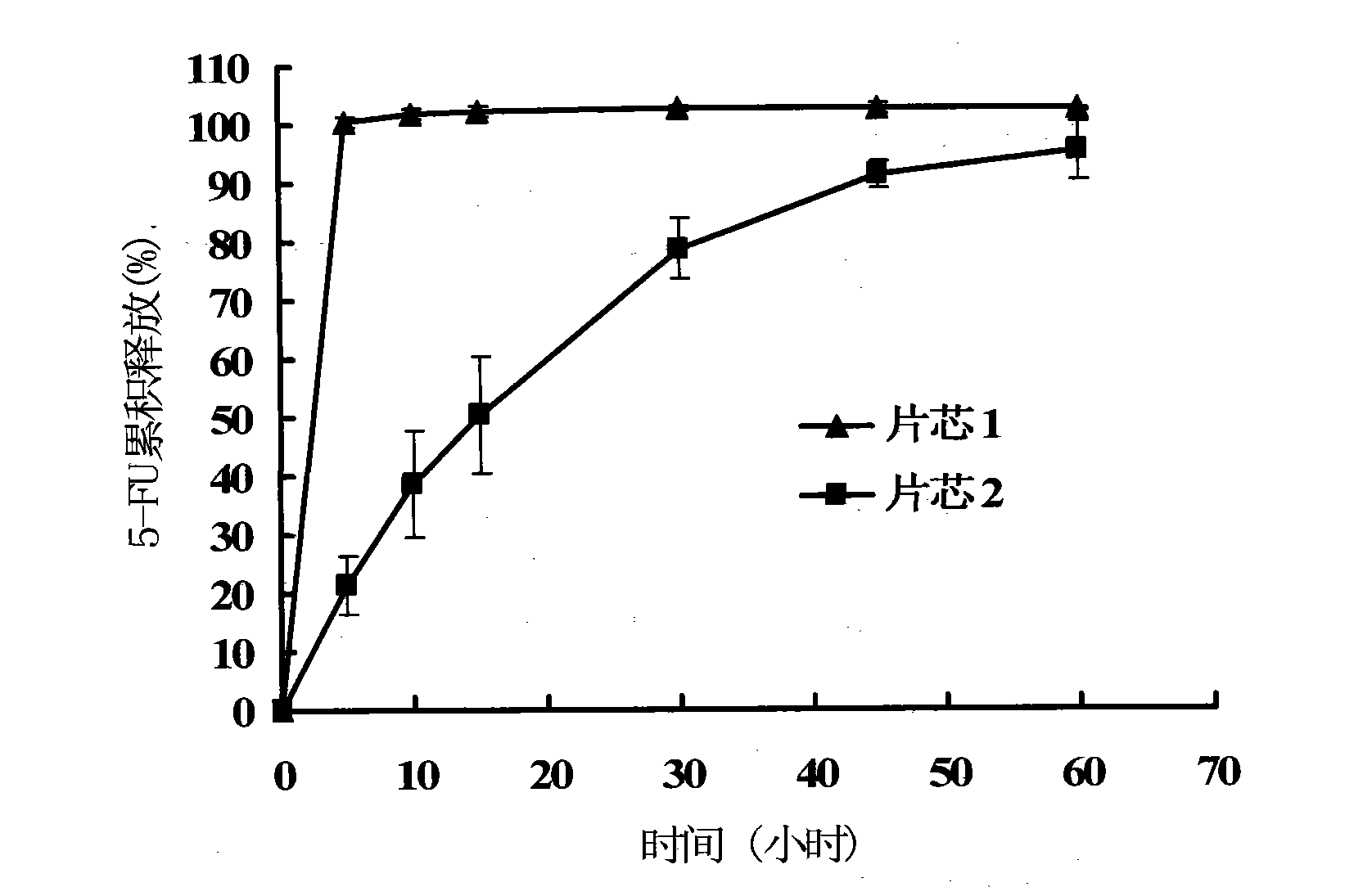

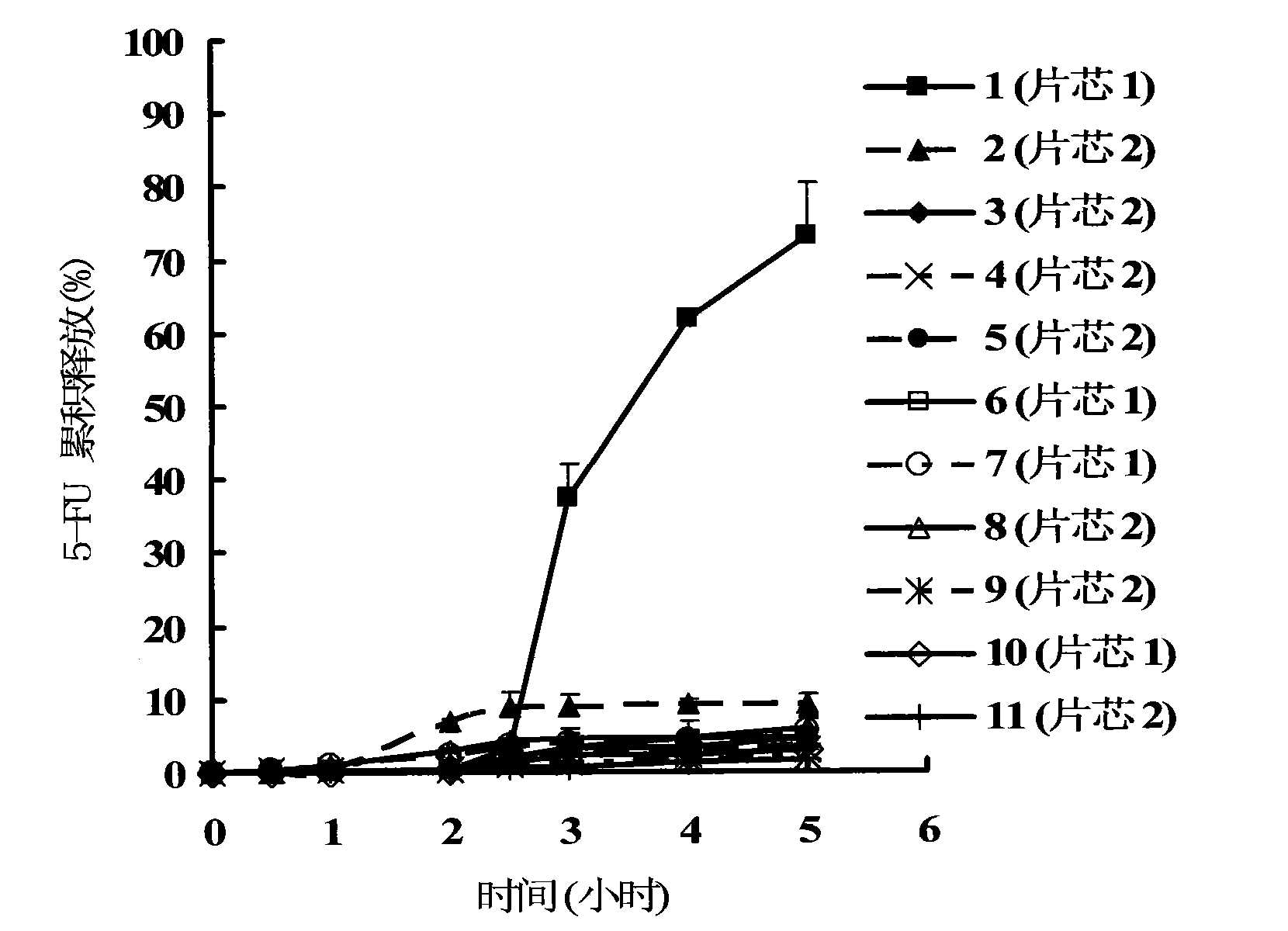

Colon delivery tablet by using pectin / corn protein as coating

InactiveCN101791298AOriginalityOvercome the polluted environmentPharmaceutical delivery mechanismPharmaceutical non-active ingredientsControlled releaseMedicine

The invention discloses a colon delivery tablet by using pectin / corn protein as a coating, which is prepared by a tablet core containing an active drug and a coating layer, wherein the tablet core is prepared by the following components by weight part: 50.0 + / - 20 parts of active drug, 28.0 + / - 10 parts of medicinal microcrystalline cellulose, 14.0 + / - 6 parts of pharmaceutical lactose, 5.0 + / - 2 parts of medicinal sodium carboxymethyl starch and 2.0 + / - 1 parts of medical talc powder, and the coating layer is prepared by the following components by weight part: 160 + / - 40 parts of corn protein, 80 + / - 20 parts of pectin and 60 + / - 15 parts of medicinal microcrystalline cellulose. A colon drug delivery system formed by the colon delivery tablet realizes the purposes of accurate positioning of colon and controlled-release release of drug, and the colon delivery table has simple and convenient preparation process, easy industrialization, and great development and application prospects.

Owner:XUZHOU HONGKANG TECH

Method for extracting iron ore concentrate from flyash

The invention relates to a method for extracting iron ore concentrate from flyash. According to the technical scheme, flyash undergoes dry magnetic separation in a spiral dry magnetic separator with its magnetic field intensity being 0.3-0.5 T so as to obtain rough concentrate and dry tailings; after addition of water, the rough concentrate is put into a wet magnetic separator with its magnetic field intensity being 0.16-0.2 T to undergo wet magnetic separation so as to obtain wet magnetic concentrate; the wet magnetic concentrate or a mixture of the wet magnetic concentrate and second-stage tailings obtained in a subsequent process is put into a ball mill, water is added and then ball-milling is carried out until granularity of 70-90 wt% of the ball-milling product is less than 0.045 mm so as to obtain fine-ground ore slurry; the fine-ground ore slurry is added into a wet magnetic separator with its magnetic field intensity being 0.06-0.1 T so as to obtain first-stage concentrate; the first-stage concentrate is added into a wet magnetic separator with its magnetic field intensity being 0.04-0.08 T to undergo second-stage weak magnetic separation so as to obtain iron ore concentrate and second-stage tailings; and the second-stage tailings return to the step 3. The method of the invention has characteristics of simple process, low energy consumption, high iron grade of iron concentrate powder and high iron recovery rate.

Owner:WUHAN UNIV OF SCI & TECH

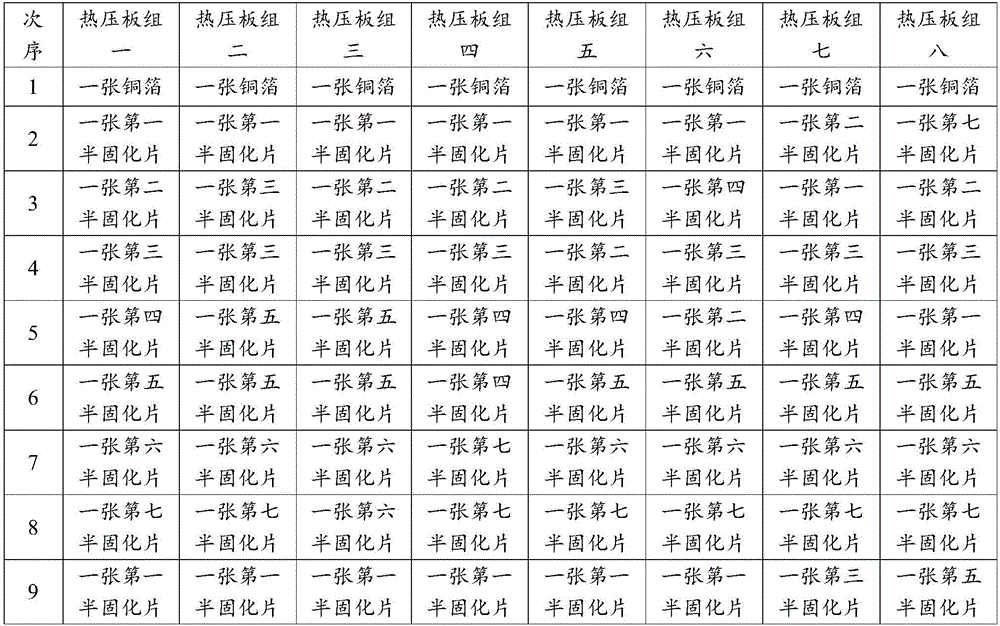

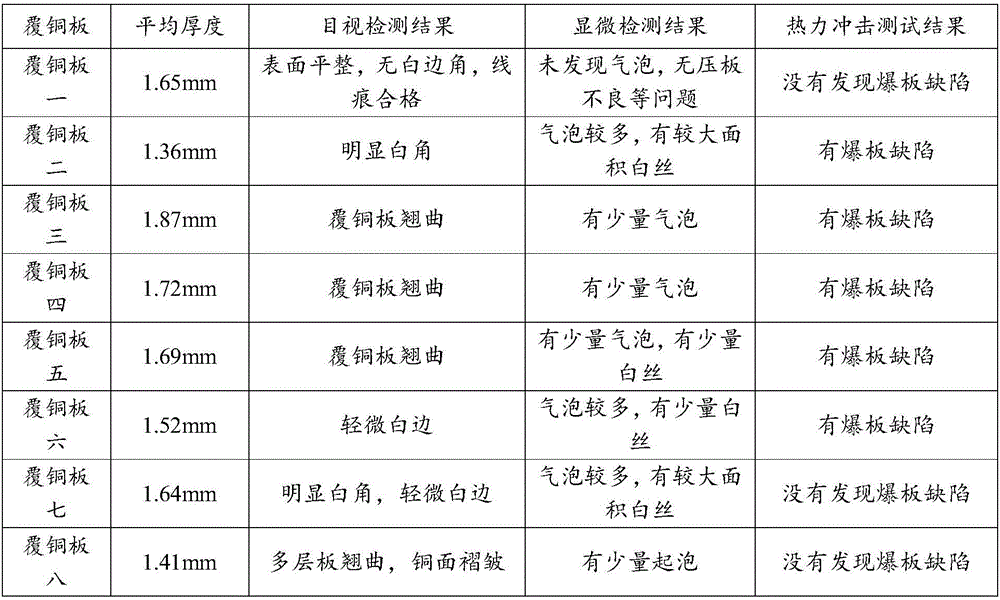

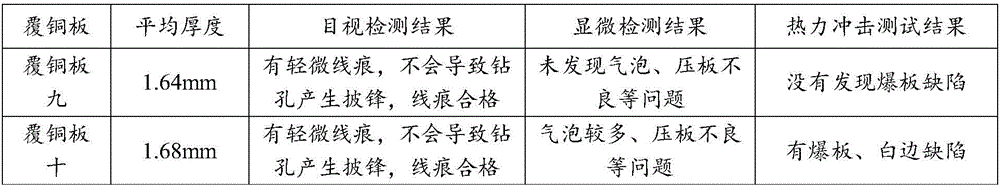

Method of reusing sampling material, edge cutting material and disqualified prepreg and copper-clad plate manufactured by using method

ActiveCN106494033AImprove performanceEasy to prepareLaminationLamination apparatusSocial benefitsEconomic benefits

The invention provides a method of reusing a sampling material, an edge cutting material and disqualified prepreg and a copper-clad plate manufactured by using the method. The copper-clad plate comprises copper foil and a mixed curing layer, wherein the copper foil is placed at least one side face of the mixed curing layer, and the mixed curing layer is formed by sequentially stacking the sampling material and edge cutting material of qualified prepreg and the disqualified prepreg and carrying out hot pressing molding on the materials. The copper-clad plate made of the sampling material, the edge cutting material and the disqualified prepreg is high in flame retardant level, surface resistance and peel strength. The method of reusing the sampling material, the edge cutting material and the disqualified prepreg is low in production cost and simple in process operation and has remarkable social benefits and economic benefits.

Owner:江门市龙兴电子材料有限公司

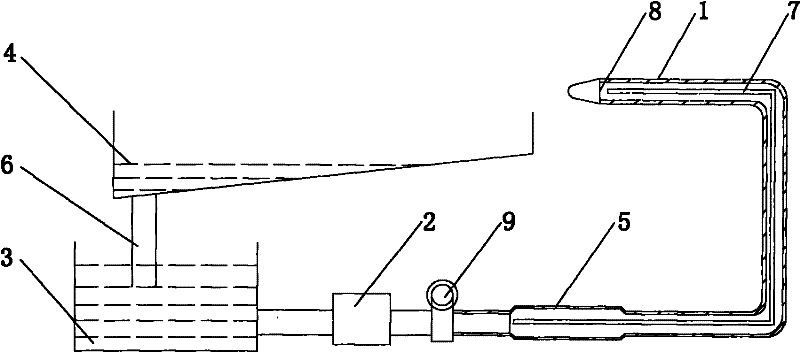

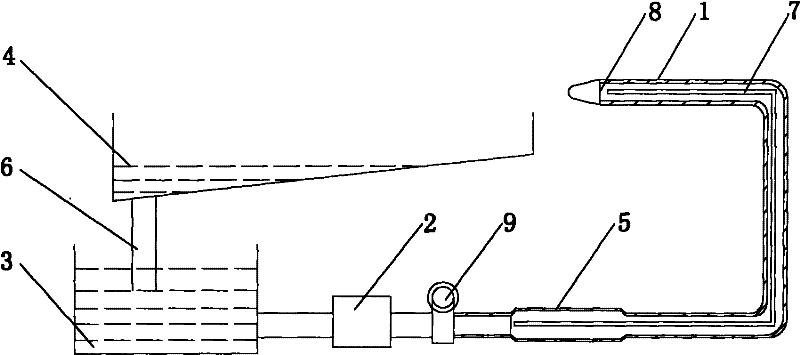

Circular cooling device for magnetic shoe inner-outer arc grinding machine

InactiveCN102189488AReduce water consumptionOvercome the polluted environmentGrinding/polishing safety devicesWater collectionWaste management

The invention relates to a circular cooling device for a magnetic shoe inner-outer arc grinding machine. The device is characterized by comprising a cooling nozzle, a water pump, a water tank and a water collection channel, wherein the water collection channel is arranged below the cooling nozzle; the water tank is arranged below the water collection channel; the water collection channel and the water tank are communicated through a pipeline; a water inlet of the water pump is communicated with the water tank; and a water outlet of the water pump is connected with the cooling nozzle through a communication piece. The circular cooling device for the magnetic shoe inner-outer arc grinding machine has a simple structure and can not be easily damaged; and meanwhile, water in the water tank can circularly cool the grinding head under the great combined effect of the water pump and a reduced-pressure regulation valve, and the problems of high water consumption and environmental pollution of the grinding machine are overcome.

Owner:常州亚邦捷宇自控成套设备有限公司

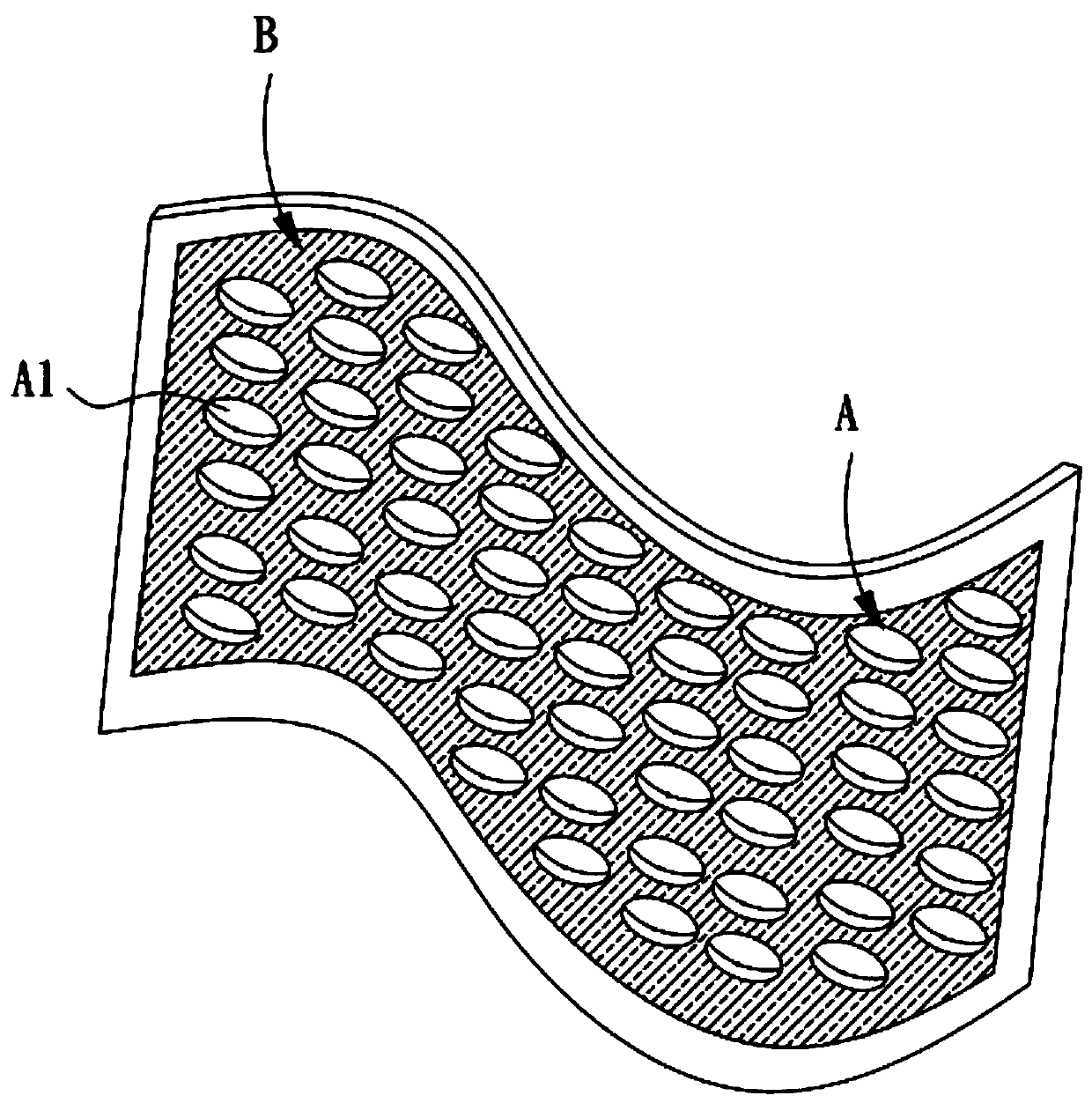

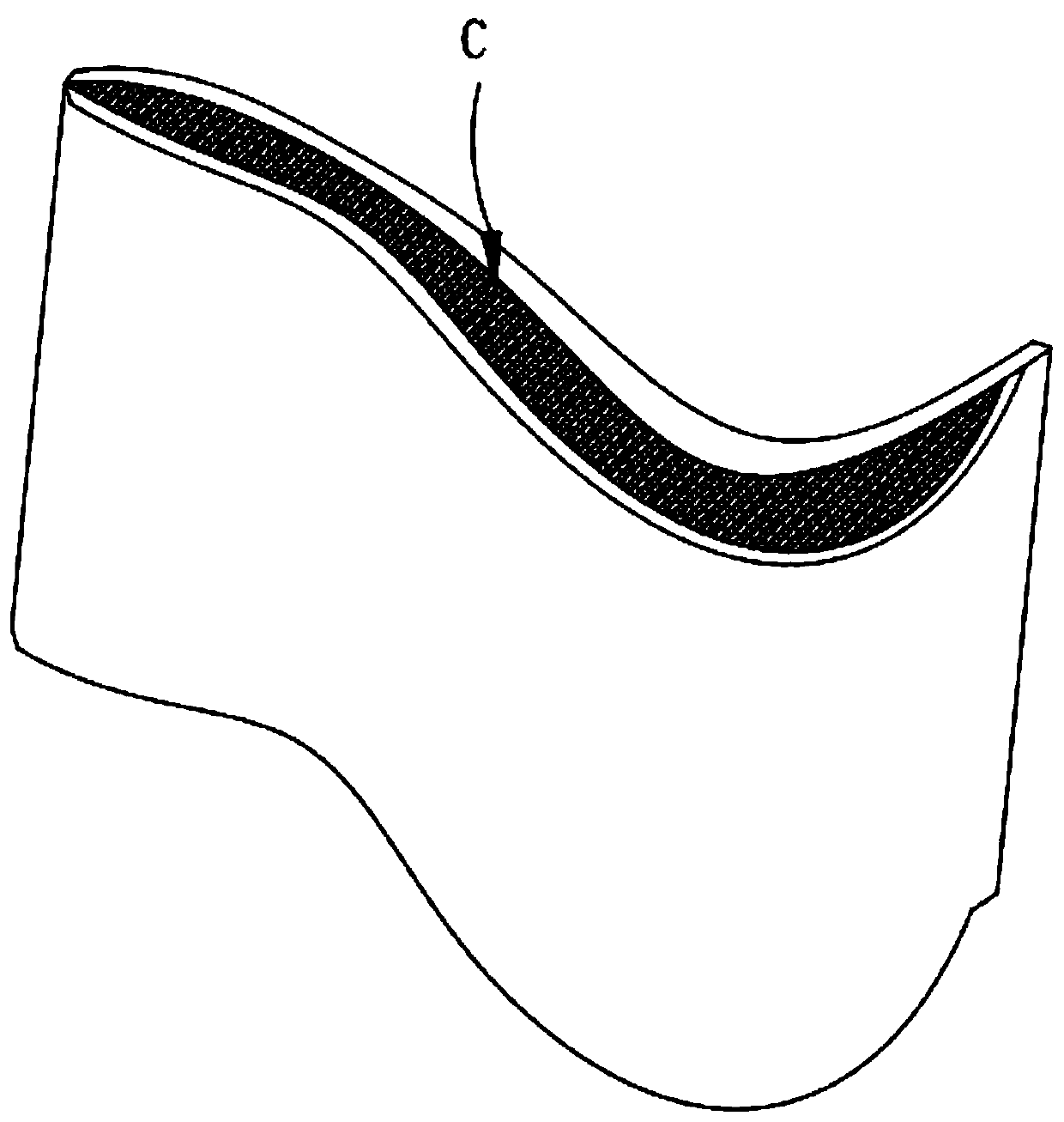

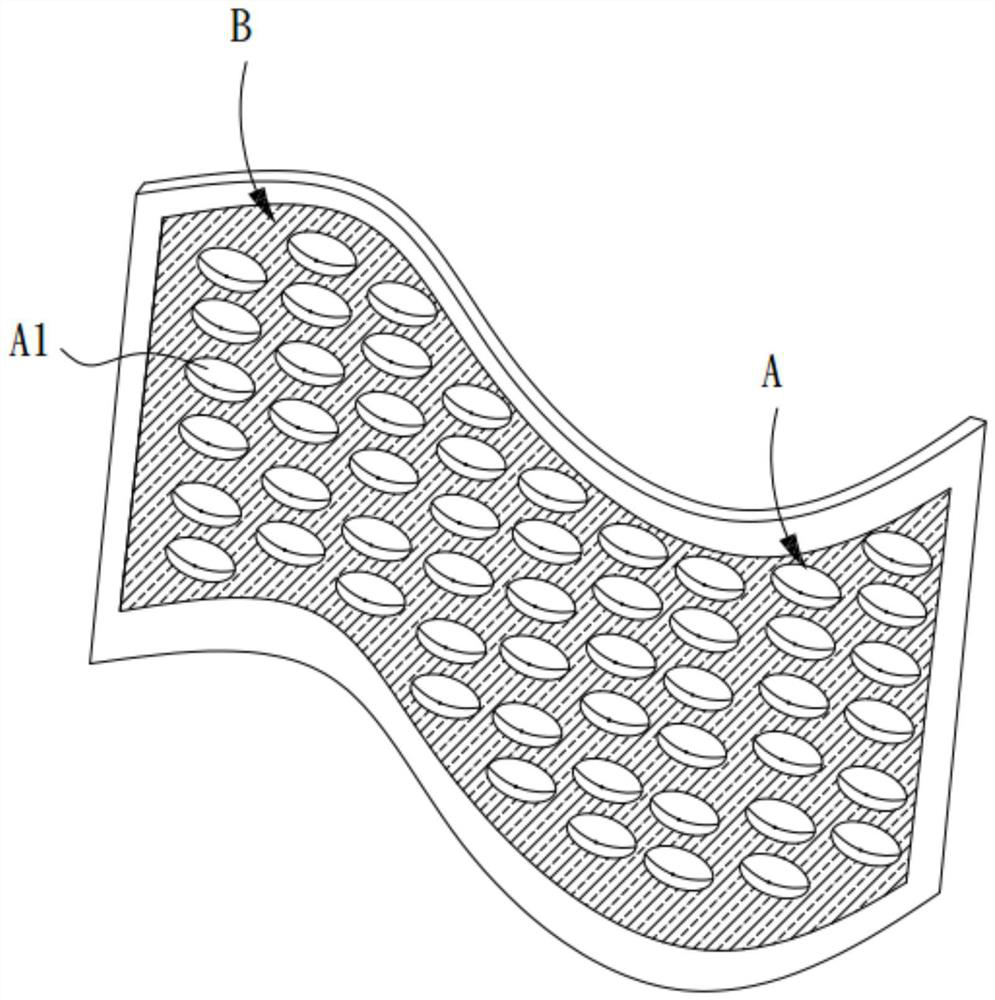

Full-recovery environment-friendly packaging structure and manufacturing method thereof

PendingCN110435219AAct as a protective bufferOvercoming problems that require separationPackage recyclingWrappersFull recoveryEngineering

The invention discloses a full-recovery environment-friendly packaging structure and a manufacturing method thereof. The packaging structure is applied to the packaging of express delivery, postal service and logistics and is composed of a paper plane structure, the plane structure comprises a first surface and a protective layer which is overlapped on the first surface, the protective layer comprises at least one layer of liner, and the liner is of a net structure formed by stretching paper materials after die cutting. The packaging structure provided by the invention overcomes the problems that in the prior art, for kraft paper bubble bags or envelopes, paper and plastic cannot be separated and recycled, and the environment is polluted. Meanwhile, the technical problems of environmentaldust pollution and poor air quality caused by adopting a powdery and granular soft structure as a buffer liner in the prior art are solved.

Owner:BETA SHENZHEN PACKAGE PRODS +1

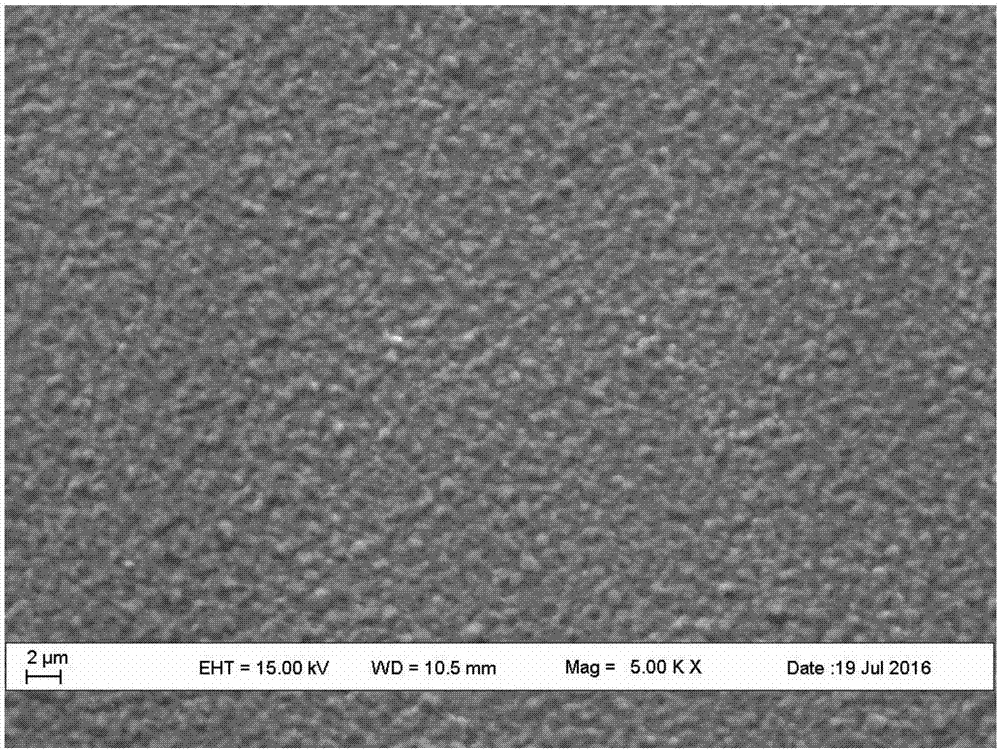

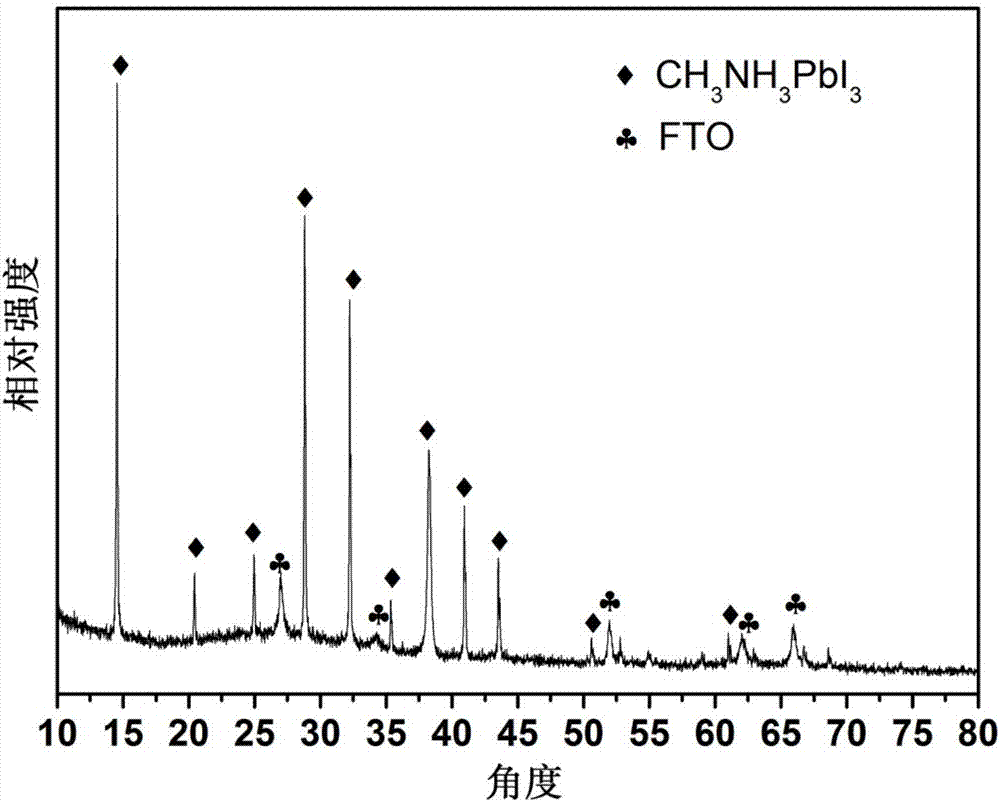

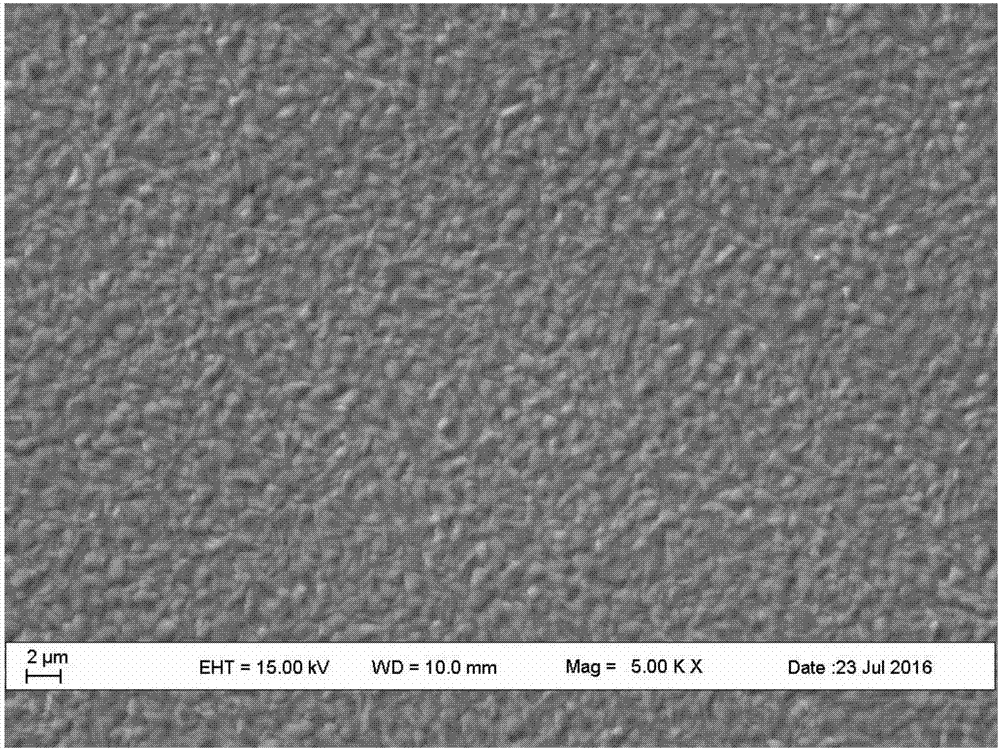

Chemical method for preparing halogenation methylamine lead photoelectric thin film in large-area manner

The invention relates to a chemical method for preparing a halogenation methylamine lead photoelectric thin film in a large-area manner. The method comprises the steps that a substrate deposited with a simple substance lead thin film and halogenation methylamine are heated under the vacuum or negative pressure condition, a reaction vessel is filled with halogenation methylamine, under the condition at the temperature of 200 DEG C to 300 DED C, the reaction is carried out, the reaction time is smaller than or equal to 50 min, and the halogenation methylamine lead semiconductor thin film material CH3NH3PbX3 with the large grain, good crystallinity and the uniform surface is prepared on the surface of the substrate material in an original manner, X is equal to Cl, Br, I or combination of one or two. According to the method, the halogenation methylamine lead thin film can be rapidly prepared in the large-area manner, the prepared halogenation methylamine lead thin film is good in thickness uniformity, halogenation methylamine lead is good in crystal and large in crystal size, the diameter can reach 0.5 to 2 micrometers, preferably, the diameter can reach one to three micrometers, the problem that in the traditional method, the film formation grain is small is solved, and the method has the wide experiment device research and industrial application prospect.

Owner:XUCHANG UNIV

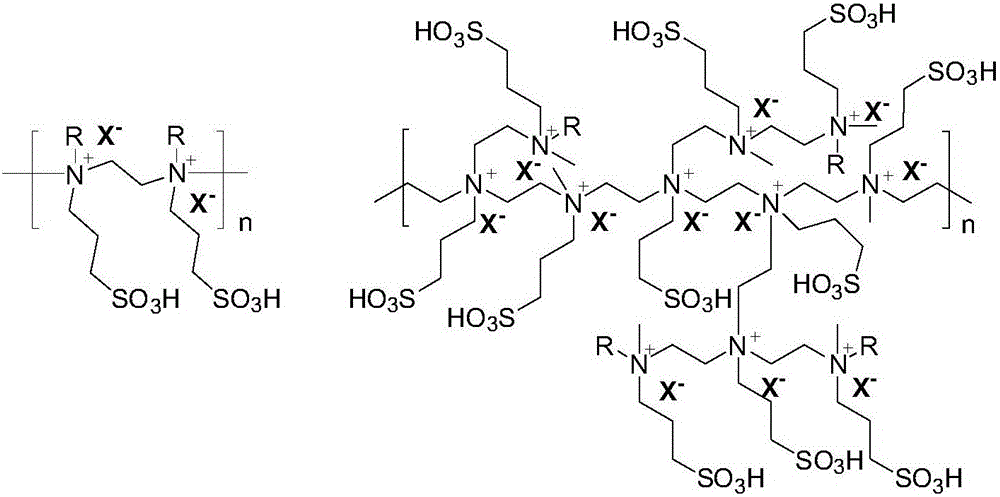

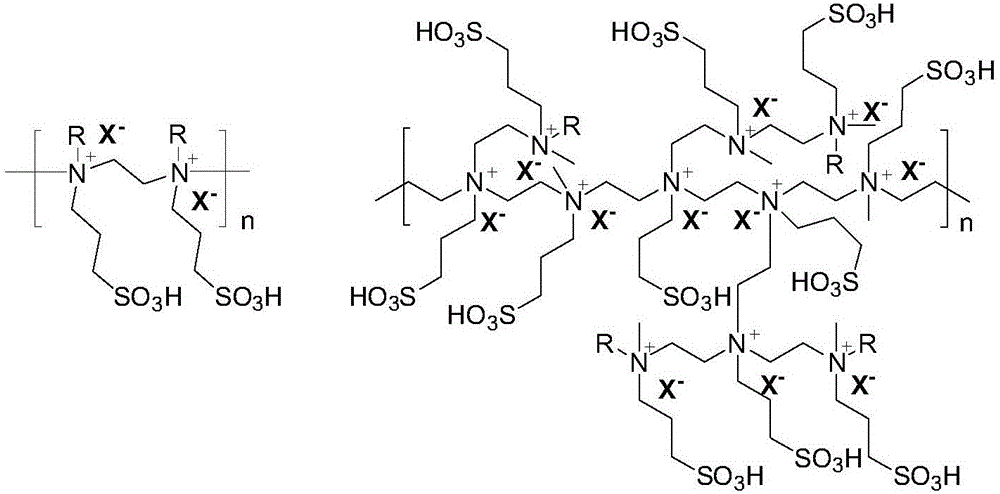

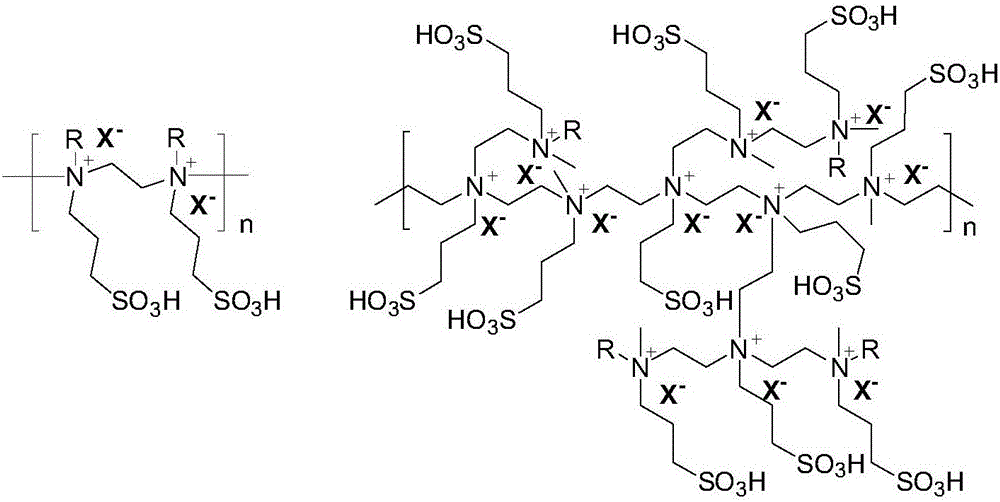

Polymerized ionic liquid catalysis method for preparing biodiesel

ActiveCN106433994AWide range of raw materialsMild reaction conditionsFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsBiodieselAlcohol

The invention discloses a polymeric ionic liquid catalysis method for preparing the biodiesel. The method comprises the steps of A) adopting an acid-functionalized polymeric ionic liquid as a reaction catalyst for catalyzing the reaction of fatty acids and short-chain alcohols for 3-6 hours at 40-65 DEG C, wherein the molar ratio of fatty acids to short-chain alcohols is 1: 1 to 1: 4, and the weight ratio of the above acid-functionalized polymeric ionic liquid to the total weight of reactants is 1: 4 to 1: 55; B) layering the reaction liquid obtained in the step A), decompressing the supernatant liquid to remove short-chain alcohols and then obtaining a product. The acid-functionalized polymeric ionic liquid is composed of sulfonic acid group-functionalized alkyl-substituted polyoxyalkylene ammonium cations and inorganic or organic anions. The method is free of environmental pollution and belongs to the environment-friendly process.

Owner:HEBEI LONGHAI BIOENERGY TECH

Skin core fiber composite paper new material

ActiveCN107336498ALess consumablesLow costSpecial paperSynthetic resin layered productsAdhesiveHazardous substance

The invention relates to a skin core fiber composite paper new material which is obtained by compounding skin core structure fiber and paper, a skin material of the skin core structure fiber is a low melting point heat-sealable polymer material, the melting point of the skin material is 52 to 180 DEG C, the melting point of a core material is higher than the melting point of the skin layer material, the tensile and the tear strength of the finally-prepared skin core fiber composite paper new material are high, and the skin core fiber composite paper new material has excellent economic value and popularization value. The skin core fiber composite paper new material is obtained by compounding reinforced fiber with paper surface, has the advantages of little material consumption, low cost and low requirements on materials of the paper before the compounding, at the same time an adhesive can play an adhesive role by hot pressing, and overcomes the problems of use inconvenience, high cost and easy production of toxic and harmful substances in traditional adhesives.

Owner:上海毅珂新材料科技有限公司

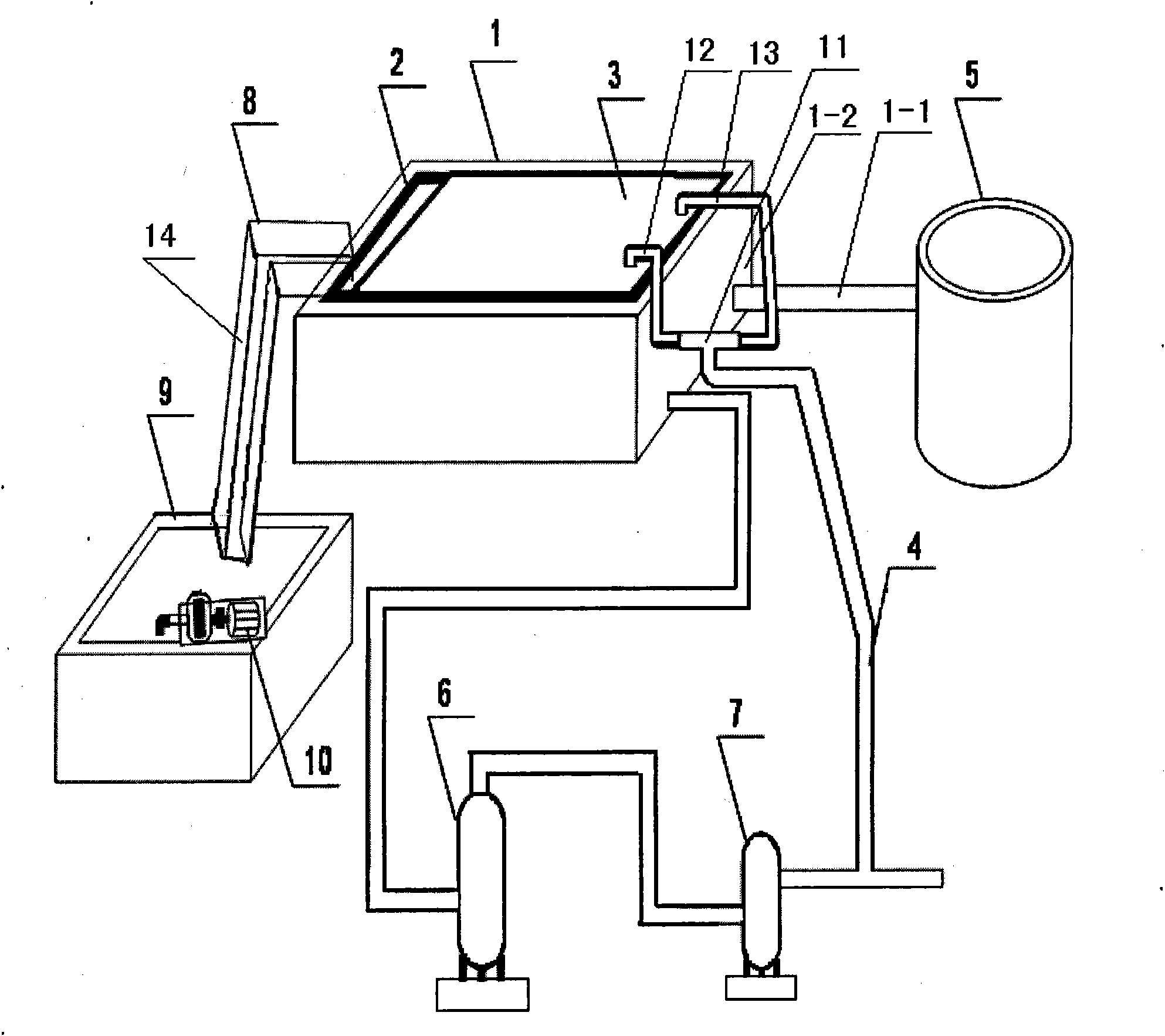

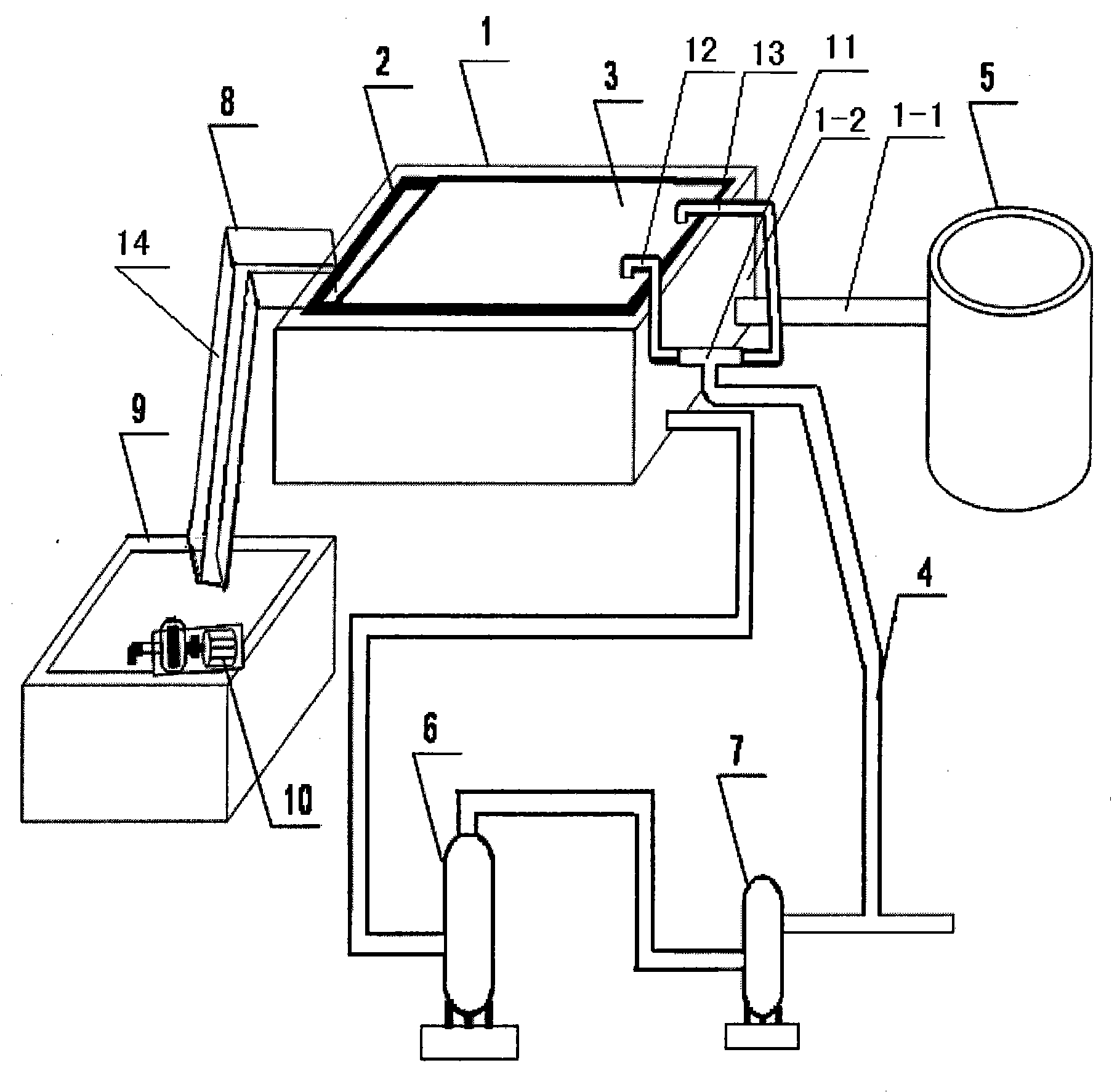

Closed flotation system with dross blowing device

InactiveCN101913672AOvercoming Scum SpillsOvercome the polluted environmentWater/sewage treatment by flotationDrossWastewater

The invention relates to a flotation device, in particular to a closed flotation system with a dross blowing device, which is used for blowing dross in the pretreatment stage of phenol-cyanogen wastewater treatment plants. The system solves the problem that dross scrapers in the existing floatation devices easily have failure. The system comprises a flotation tank, a compressed air pipe, a tee pipe coupling, a No.1 blowpipe, a No.2 blowpipe, a seal plate, a dross removal tank, a dross tank, a chute and a water pump, wherein one end of the compressed air pipe is communicated with one end of the tee pipe coupling; other two ends of the tee pipe coupling are respectively communicated with one end of the No.1 blowpipe and one end of the No.2 blowpipe; the other end of the No.1 blowpipe and the other end of the No.2 blowpipe are respectively inserted into the seal plate and are distributed along a side wall on which a wastewater inlet pipe of the flotation tank is positioned; the dross removal tank and the flotation tank are communicated; the upper and lower ends of the chute are respectively communicated with the dross removal tank and the dross tank; and a pumping pipe of the water pump is arranged in the dross tank. The system omits the dross scrapers, thus solving the problem that dross scrapers in the floatation devices easily have failure.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

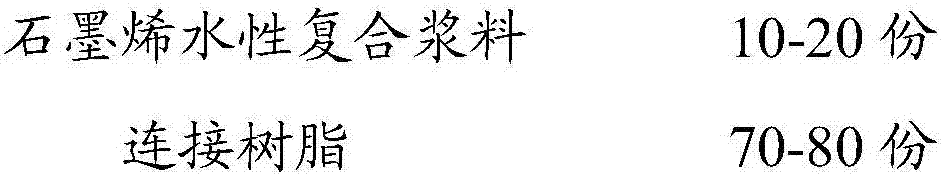

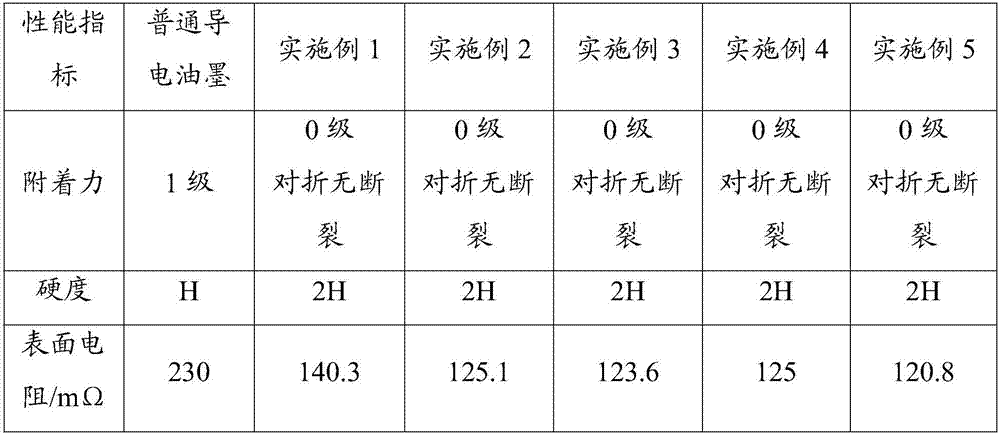

Waterborne graphene colorful conductive ink

InactiveCN107022244AImprove stabilityOvercome the polluted environmentInksDispersed mediaOrganic solvent

The invention belongs to the field of function materials, and relates to conductive ink, in particular to waterborne graphene colorful conductive ink. The waterborne graphene colorful conductive ink is specifically prepared from the following components in parts by mass: 10 to 20 parts of graphene waterborne composite slurry, 70 to 80 parts of connecting resin, 5 to 15 parts of a solvent, 1 to 5 parts of an aid, and 1 to 5 parts of color paste. A traditional organic solvent is replaced with deionized water serving as a dispersing medium, inorganic waterborne dye is used, and the adhesive force and the flexibility meet requirements by filtering the connecting resin and adjusting the proportion; meanwhile, graphene components are added, thereby effectively improving the conductive stability, reducing the electrical resistivity, and overcoming the defects of environmental pollution and high cost in a usage process of traditional solvent-type colorful conductive ink. A detection result shows that the waterborne graphene colorful conductive ink not only has the advantages of safety and environmental protection, but also has great conductivity.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

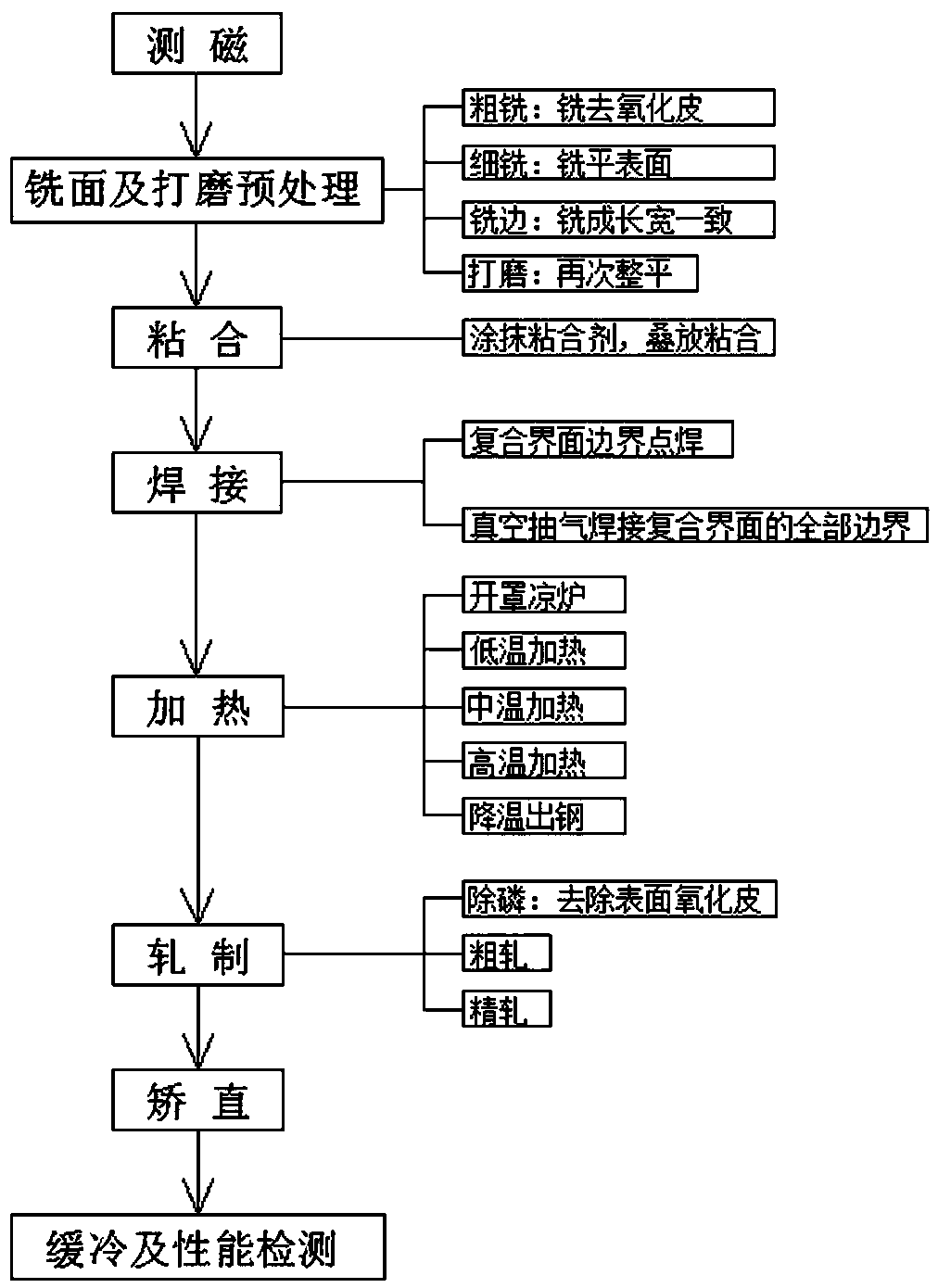

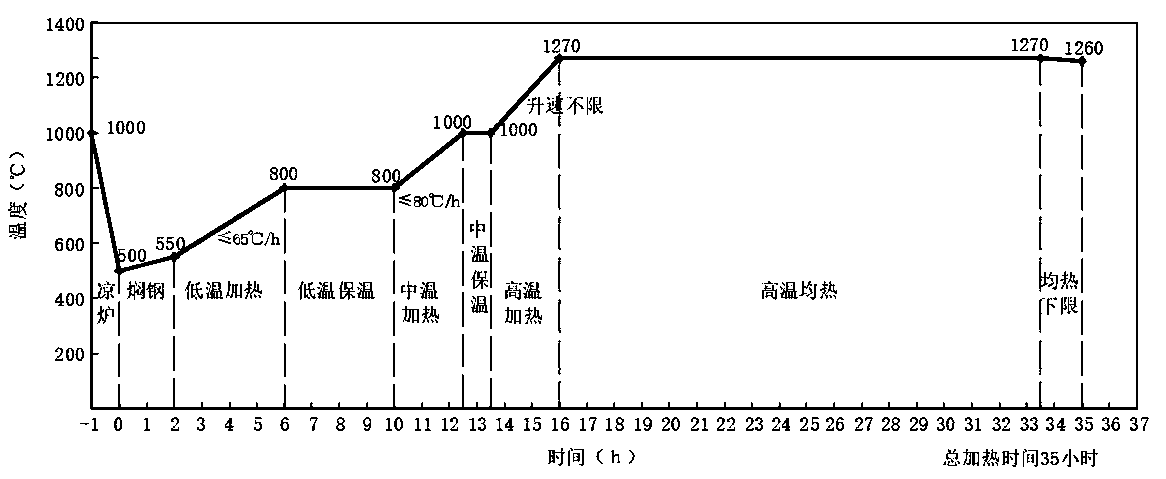

Manufacturing method of three-layer metal clad steel plate

PendingCN111331965AImprove yieldGuaranteed welding effectRoll force/gap control deviceTemperature control deviceVacuum pumpingAdhesive

The invention provides a manufacturing method of a three-layer metal clad steel plate. The manufacturing method comprises the following specific steps: measuring the magnetic content; conducting surface milling and polishing pretreatment on composite blank steel plates; daubing an adhesive and stacking and bonding the composite blank steel plates; conducting welding and sealing of the clad steel plate through spot welding in combination with vacuum pumping welding; heating the welded clad steel plate in three stages of low-temperature heating, medium-temperature heating and high-temperature heating by a soaking pit furnace; removing an oxide skin on the surface of the discharged clad steel plate through a phosphorus removal box, and then respectively performing rough rolling and finish rolling; straightening the rolled clad steel plate; and stacking the delivered clad steel plate for slow cooling, and performing flaw detection. The method provided by the invention can manufacture high-performance and high value-added clad steel plates without environmental pollution, is high in safety coefficient, and belongs to a green and environment-friendly process.

Owner:REFINE INVESTMENT CO LTD

Method for recovering lead in waste lead-acid storage battery filler by using wet process

InactiveCN102560535BAvoid it happening againImprove direct yieldPhotography auxillary processesProcess efficiency improvementElectrolysisHuman health

The invention relates to a method for recovering lead in a waste lead-acid battery filler by using a wet process, which comprises the following steps of: taking and adding sodium hydroxide and xylitol into water, agitating and dissolving at a normal temperature to prepare mixed solution; adding obtained lead paste powder in the mixed solution, reacting for 1-5 hours and taking a filtered filtrate as an electrolyte; adopting a pure lead plate or a stainless steel plate as a cathode; and adopting the stainless steel plate as an anode and switching on direct current for electrolysis. The method has the beneficial effects that the method of directly leaching lead paste is adopted; the processes of desulfurization and reductive transformation are not required, so that the process flow is simplified; the sodium hydroxide and xylitol solution are adopted when the lead paste is leached and can form a compound with lead oxide to leach the lead in the lead paste to a utmost extent, so that the sulfur dioxide and various smoke and dust generated in the pyrometallurgical recovery process are avoided, and the straight yield of the lead is improved; and volatile smoke and dust or acid mist can not be generated, so that the defect that a silicon fluorine acid electrolyte pollutes the environment and is harmful to human health is overcome.

Owner:HENAN UNIV OF SCI & TECH

Novel compound paper material and preparation method thereof

InactiveCN107100041ALower requirementLess consumablesPaper/cardboard layered productsAdhesivesFiberCompression molding

The invention relates to a novel compound paper material and a preparation method thereof. The preparation method includes: compounding an adhesive and reinforcing fibers to obtain a compound, placing the compound on an unwinding device, placing paper on another unwinding device, using one hot roller to perform hot rolling on the paper and the compound at the same time, and using a winding device to wind the compound paper after the hot compression molding. The prepared novel compound paper material is high in tensile strength and tear strength and extremely good in economic value and popularization value. The preparation method has the advantages that the reinforcing fibers are compounded with the surface of the paper, low material consumption, low cost and low requirements on the paper material before the compounding are achieved, the adhering effect of the adhesive can be brought into play after the hot compression, and the problems that a traditional adhesive is inconvenient to use and high in cost and easily generates toxic and harmful substances are solved.

Owner:上海海冰新材料科技有限公司

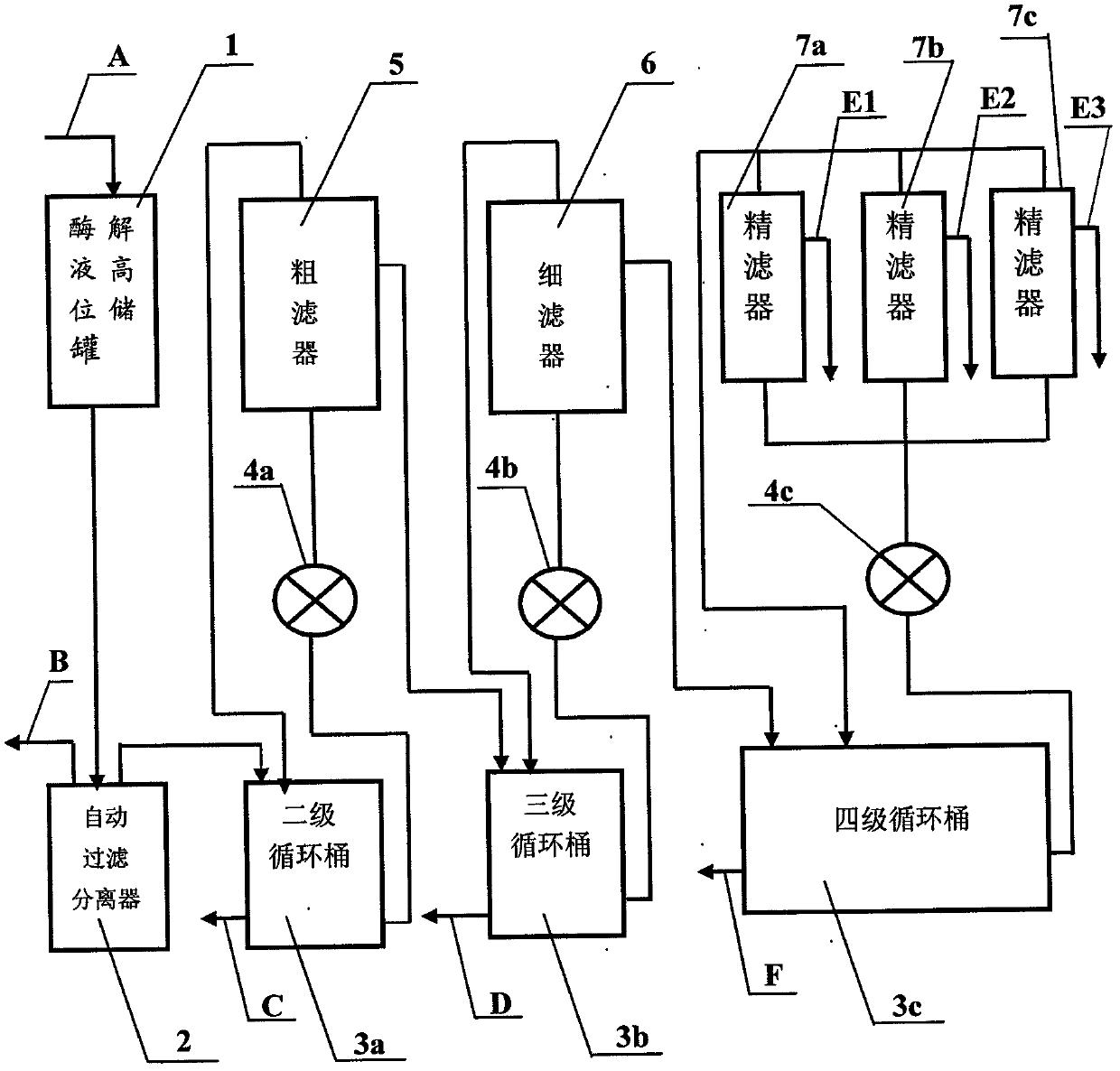

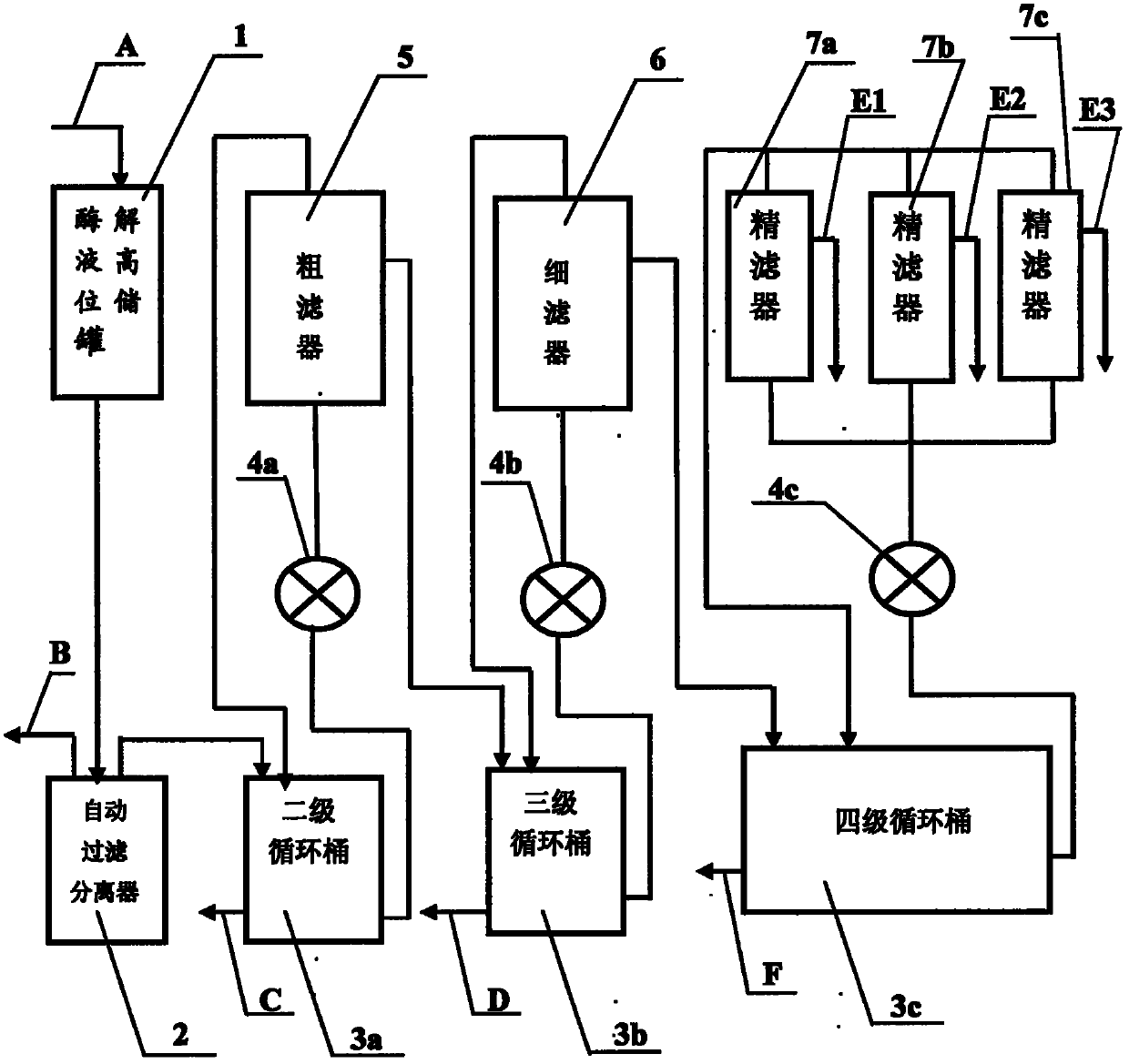

Method for extracting heparin sodium from cattle lungs

The invention relates to a method for extracting heparin sodium from cattle lungs. The method comprises the following steps of: (1), slurring: (2), enzymolysis; (3), enzyme removing; (4) purification; and (5), freeze drying. The method can be used for overcoming the difficulties in filtration of an enzymolysis liquid in the production of the heparin sodium from the cattle lungs, avoiding the trivial procedures of long-time resin adsorption, washing elution, resin regeneration and the like, solving the problems of environment pollution caused by acid-base waste liquor and the like, simplifying the production process, reducing the production cost, improving the yield and quality of products, reducing the environment pollution and providing an effective production guarantee for the scale production of the lung heparin sodium. The yield of the products can reach 42,000u / kg (of the lungs), and the titer reaches 70-120u / mg.

Owner:BAIYIN FURUIKANG BIOLOGICAL PRODS

Wheat seed dressing fertilizer and preparation method thereof

InactiveCN106220454ANutritional diversityIncrease productionCalcareous fertilisersAlkali orthophosphate fertiliserVitamin CSulfate

The invention discloses a wheat seed dressing fertilizer and a preparation method thereof. The wheat seed dressing fertilizer is prepared from, by weight, 30-42 parts of fulvic acid, 20-27 parts of monopotassium phosphate, 2-7 parts of zinc sulfate, 4-9 parts of ammonium molybdate, 3-8 parts of anhydrous cupric sulfate, 4-8 parts of boracic acid, 0.5-3 parts of chlormequat chloride, 3-6 parts of drought-resistant agent, 0.01-0.1 part of phytocytomine, 1-4 parts of vitamin C, 10-20 parts of dolomite powder, 7-13 parts of xenothime powder and 17-22 parts of conditioner. The wheat seed dressing fertilizer can be used for pretreatment of soil before wheat is sowed, the wheat seed dressing fertilizer can be sprayed on the leaf surfaces in the growth process of the wheat, and the wheat seed dressing fertilizer has the advantages of being comprehensive in nutrition, green, environmentally friendly, good in yield increasing effect and high in disease resistance.

Owner:宿松县华峰农机服务专业合作社

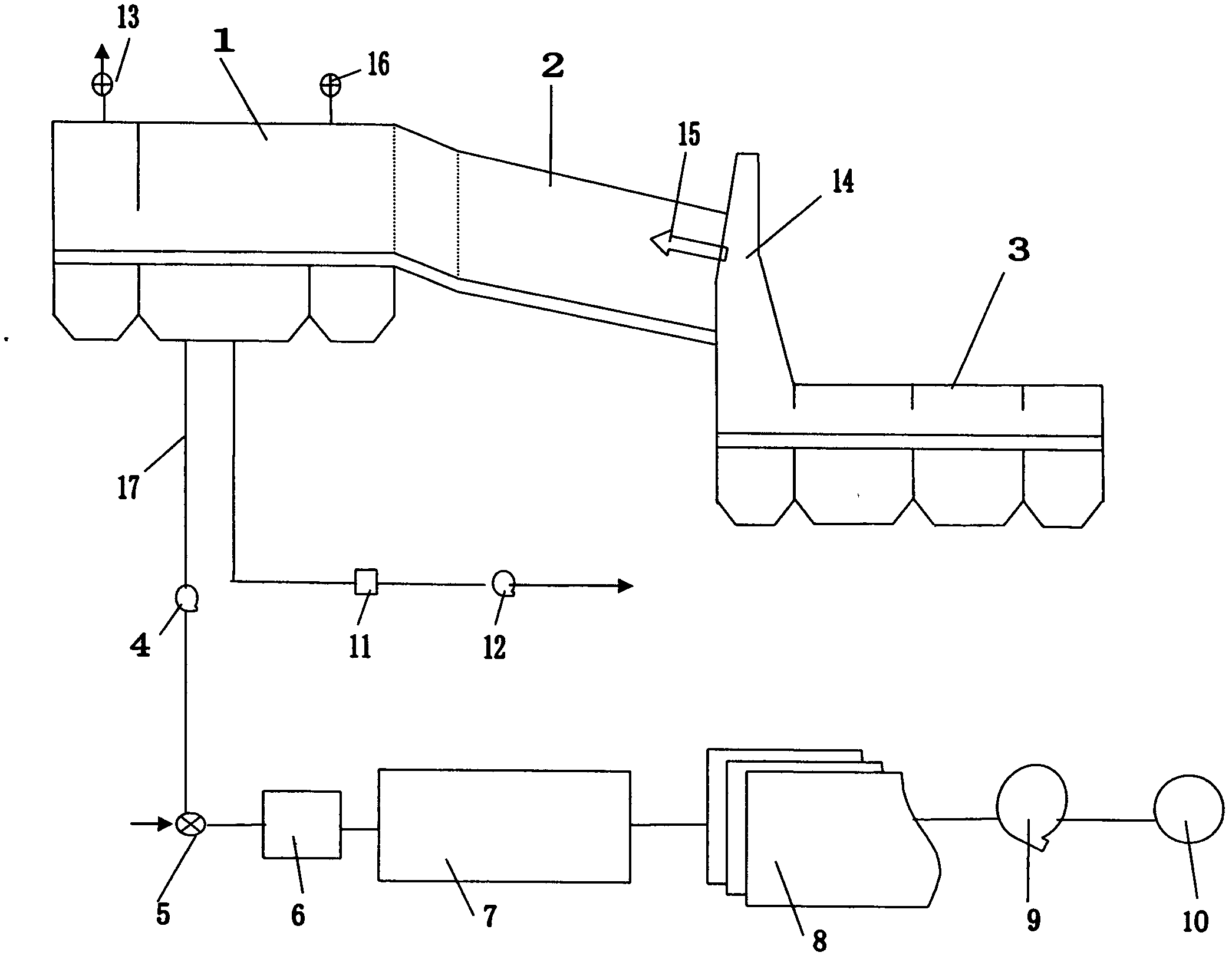

Method for disposing pallet oily black smoke and reducing consumption in production process

InactiveCN103206864AOvercome the polluted environmentHigh thermal efficiencyWaste heat treatmentCombustion systemCombustion

The invention provides a method for eliminating exhausted oily black smoke generated by furnace baking with heavy oil in the process of ignition temperature-rise period of a pallet plant and reducing energy consumption. The technique method comprises the steps that a smoke suction cover absorbs incompletely-combusted oily smoke in the ignition furnace baking process, a combustion system of a concentrate drying system or a coal making system of the pallet plant is utilized to carry out secondary combustion on the black smoke, so that the incompletely-combusted oil and carbon in the smoke are sufficiently combusted. Meanwhile, the high-temperature (about 300 DEG C) smoke residual heat of a roasting system is utilized to reduce the energy consumption of the concentrate drying system or the coal making system, and the energy resource is saved.

Owner:张廷 +2

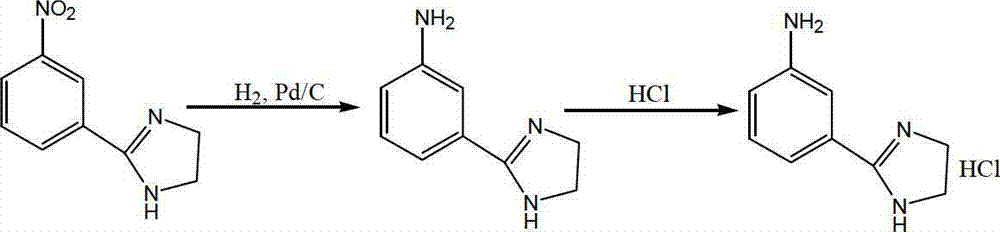

Preparation method of 2-(3-aminophenyl) imidazoline hydrochloride

ActiveCN102898375AReduced activityOvercome operabilityOrganic chemistryHydrogenation reactionSolvent

The invention relates to a preparation method of 2-(3-aminophenyl) imidazoline hydrochloride. the method comprises the steps of: adding 2-(3-aminophenyl) imidazoline to a solvent according to a mass-volume ratio of 1:(2-1); then adding palladium carbon with the palladium content of 0.5-10wt% in the proportion of 1-10% of the weight of the 2-(3-aminophenyl) imidazoline; carrying out reducing hydrogenation reaction for 2.5-6 hours under the conditions that the temperature is 10-100 DEG C, the atmosphere is hydrogen and the pressure of 0.01-0.95MPa; filtering, adjusting the pH of a filtrate to be at 1.0-3.0, reducing the temperature to -2-3 DEG C, standing for crystallization for 0.5-2h, filtering to obtain a precipitate, and drying the precipitate to prepare the 2-(3-aminophenyl) imidazoline hydrochloride. The preparation method is easy to control, small in energy consumption, low in cost, environment-friendly, and good in industrialization prospect.

Owner:QILU ANIMAL HEALTH PROD

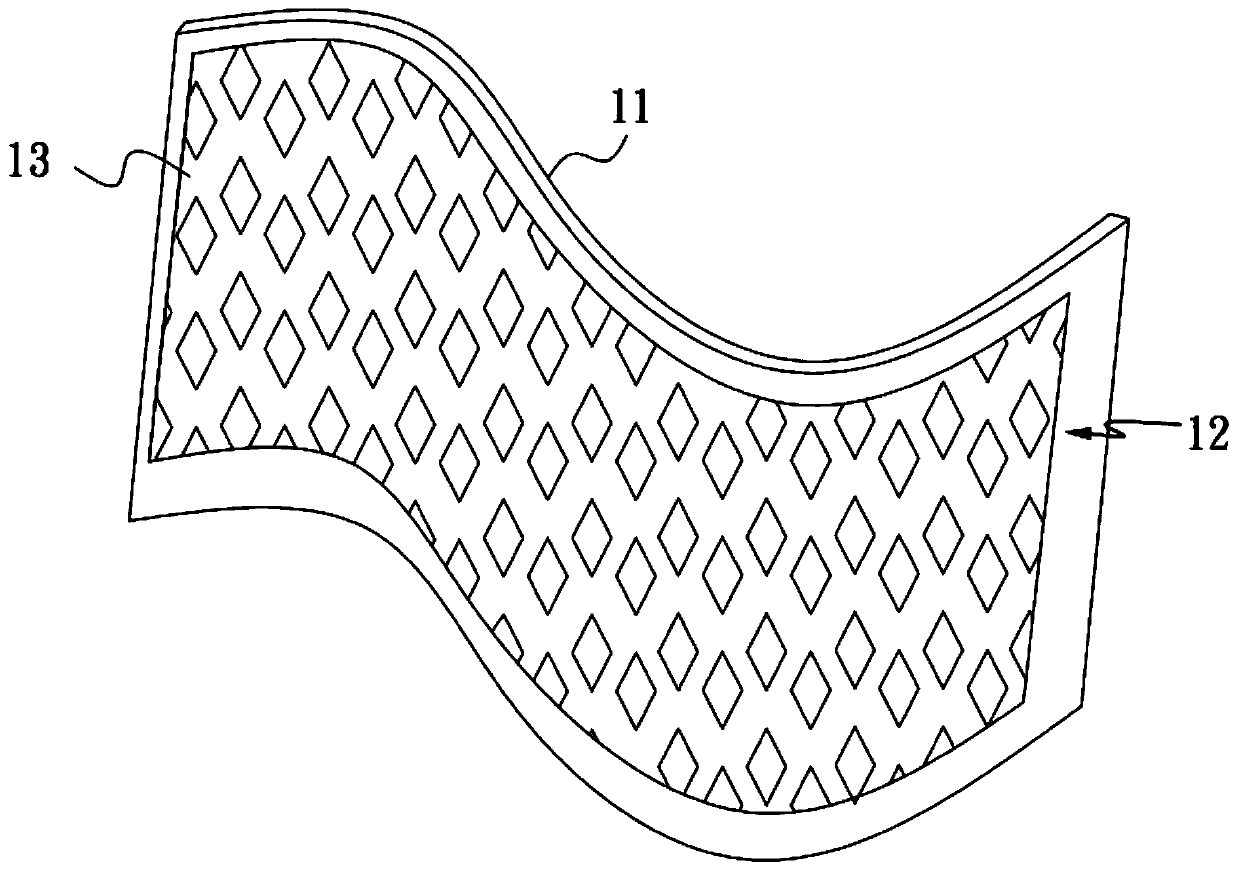

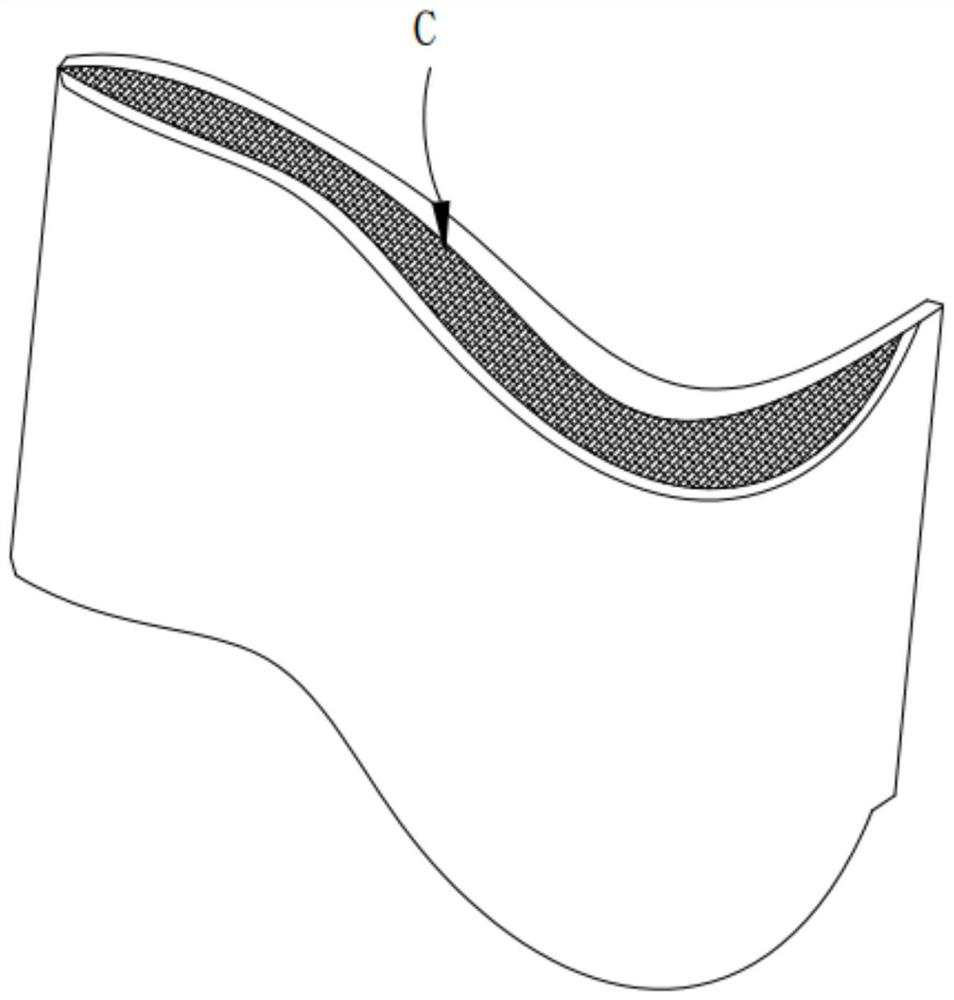

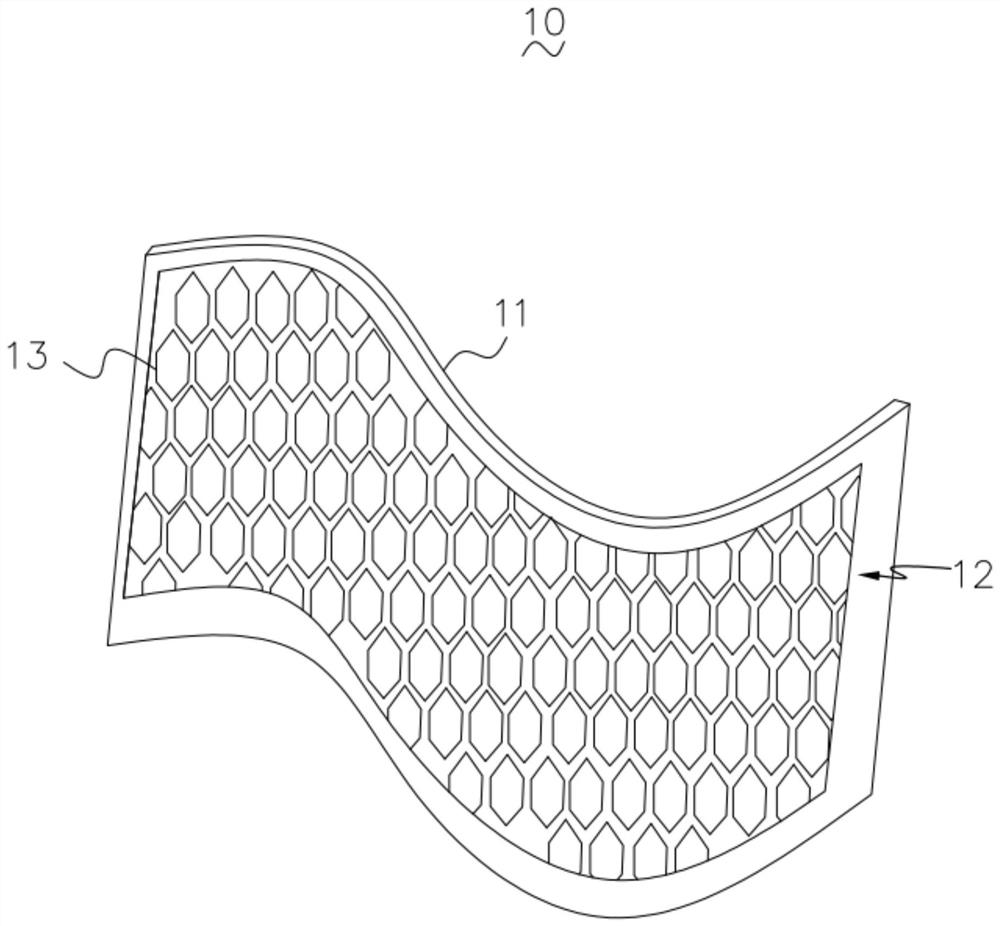

Fully recycled environment-friendly packaging structure

PendingCN113104398AAct as a protective bufferOvercoming problems that require separationFlexible coversWrappersLogistics managementProcess engineering

The invention discloses a fully recycled environment-friendly packaging structure. The packaging structure is applied to packaging of express delivery, postal service and logistics. The packaging structure is composed of a paper plane structure, wherein the plane structure comprises a first surface and a protective layer overlapped on the first surface; the protective layer comprises at least one layer of gasket; and the gasket is of a three-dimensional net structure. According to the packaging structure, the problem that in kraft paper bubble bags or envelopes in the prior art, paper and plastic cannot be separated and recycled, so that the environment is polluted is solved; and meanwhile, the technical problems of environmental dust pollution and poor air quality caused by the adoption of a powdery and granular soft structure as a buffer gasket in the prior art are solved.

Owner:BETA SHENZHEN PACKAGE PRODS +1

Method for preparing chitosan through chitin liquefaction

PendingCN113372467AOvercome the polluted environmentGood application traitsBulk chemical productionHigh concentrationDegradative enzyme

The invention discloses a method for preparing chitosan through chitin liquefaction. The method solves the problem that the environment is polluted by waste liquid and waste residues generated by high-concentration acid and alkali treatment needed in existing chitin preparation. The method comprises the following steps: 1) degrading chitin; 2) performing enzymolysis; and 3) purifying. The method comprises the steps: by taking fan-shaped squid bones as raw materials, soaking the fan-shaped squid bones in hydrogen peroxide, performing oxidative degradation on the fan-shaped squid bones by utilizing the explosion concentration of the hydrogen peroxide and using a controllable explosion technology to obtain degraded chitin, adding compound enzyme, further decomposing the oxidized and degraded chitin, and removing impurities through carbon dioxide supercritical fluid to obtain the chitosan. The chitosan extraction rate of the process is 42%. The hydrogen peroxide blasting combined enzyme method is adopted, the prepared chitosan is large in molecular weight, the product is good in biocompatibility and water solubility, and the technological process is simple, efficient, green and free of pollution.

Owner:荣成万盈水产科技有限公司

Mugwort essence oil synergistic chlorpyrifos microcapsule with soil caking resisting function and preparation method thereof

InactiveCN106818730AOvercome the polluted environmentLong durationBiocideDead animal preservationMaleic anhydrideSodium polyacrylate

The invention discloses a mugwort essence oil synergistic chlorpyrifos microcapsule with a soil caking resisting function and a preparation method thereof. The mugwort essence oil synergistic chlorpyrifos microcapsule is characterized in that the microcapsule is prepared from the following raw materials in parts by weight: 1 to 2 parts of sodium pyrophosphate, 15 to 25 parts of chlorpyrifos active compound, 30 to 50 parts of bentonite, 2 to 3 parts of rice bran, 3 to 8 parts of mugwort essence oil, 30 to 40 parts of urea, 60 to 70 parts of formaldehyde, a proper amount of hydrochloric acid, 2 to 3 parts of silicon dioxide, 10 to 20 parts of methyl alcohol, a proper amount of sodium hydroxide, 2 to 5 parts of sodium hydrated poly (styrene-alt-maleic anhydride), 2 to 3 parts of sodium polyacrylate and 250 to 800 parts of distilled water. The bentonite is introduced as a carrier into the microcapsule, the purpose of delaying chemical release is achieved, the stability of a microcapsule suspending agent is improved, and the service life of the farm chemical is prolonged; and bentonite treated with the sodium pyrophosphate can be used for preventing soil caking.

Owner:严帝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com