Water-based graphene conductive ink

A technology of water-based graphene and conductive ink, which can be used in ink, household utensils, applications, etc., can solve the problem of low conductivity, achieve the effect of improving stability, overcoming pollution environment, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

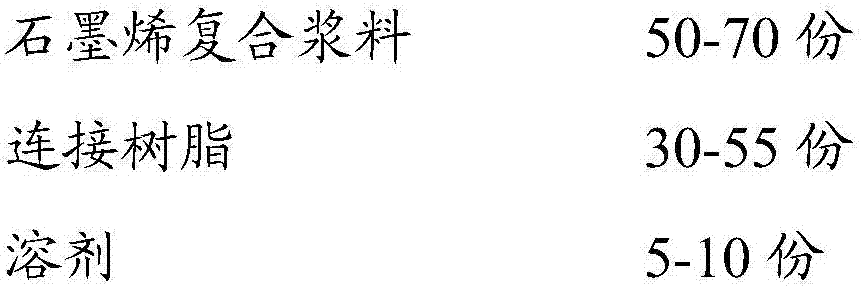

[0019] A water-based graphene conductive ink, including mass parts: 50 parts of graphene composite slurry, 30 parts of connecting resin, 5 parts of solvent, and 2 parts of auxiliary agent. Mix to prepare Conductive Ink 1.

Embodiment 2

[0021] A water-based graphene conductive ink, including mass parts: 60 parts of graphene composite slurry, 45 parts of connecting resin, 8 parts of solvent, and 8 parts of auxiliary agent. Mix to prepare Conductive Ink 2.

Embodiment 3

[0023] A water-based graphene conductive ink, including mass parts: 70 parts of graphene composite slurry, 55 parts of connecting resin, 10 parts of solvent, and 10 parts of auxiliary agent. Mix to prepare conductive ink 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com