Patents

Literature

45results about How to "Play the role of environmental protection and energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

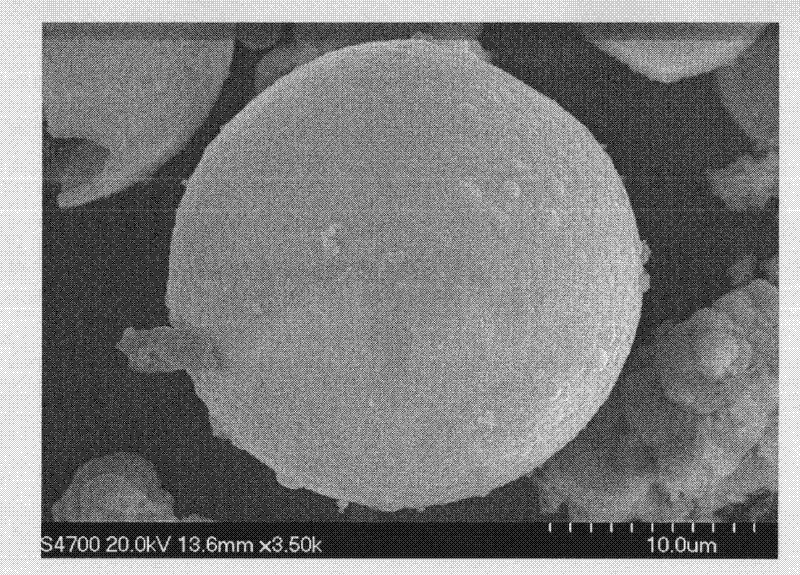

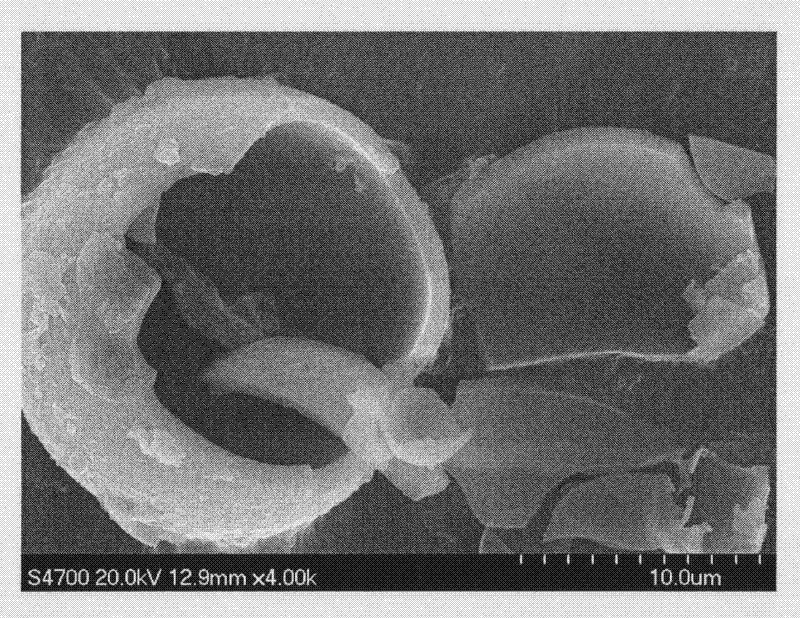

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

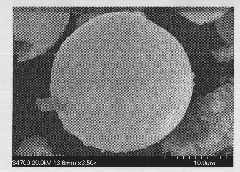

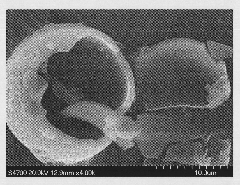

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

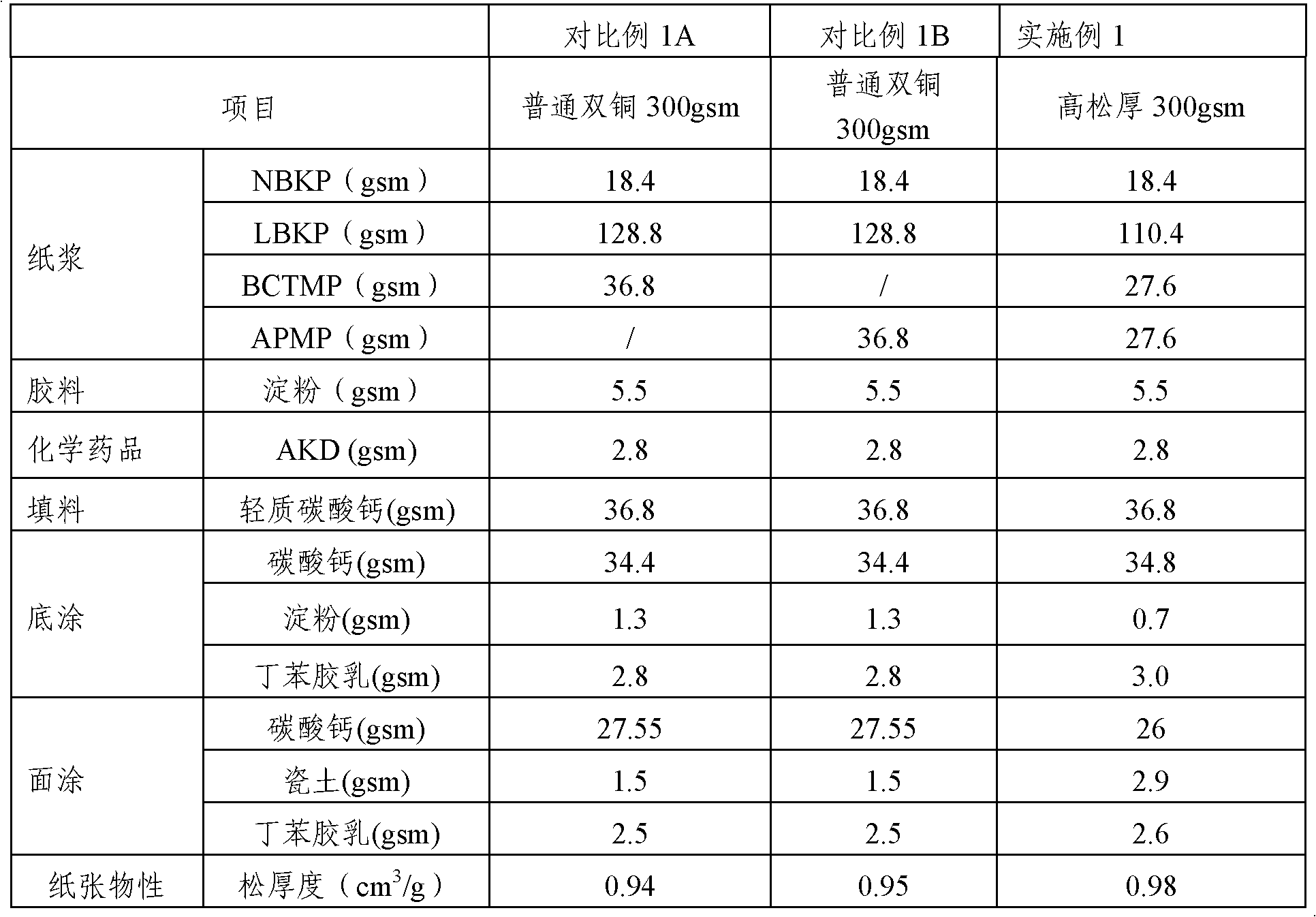

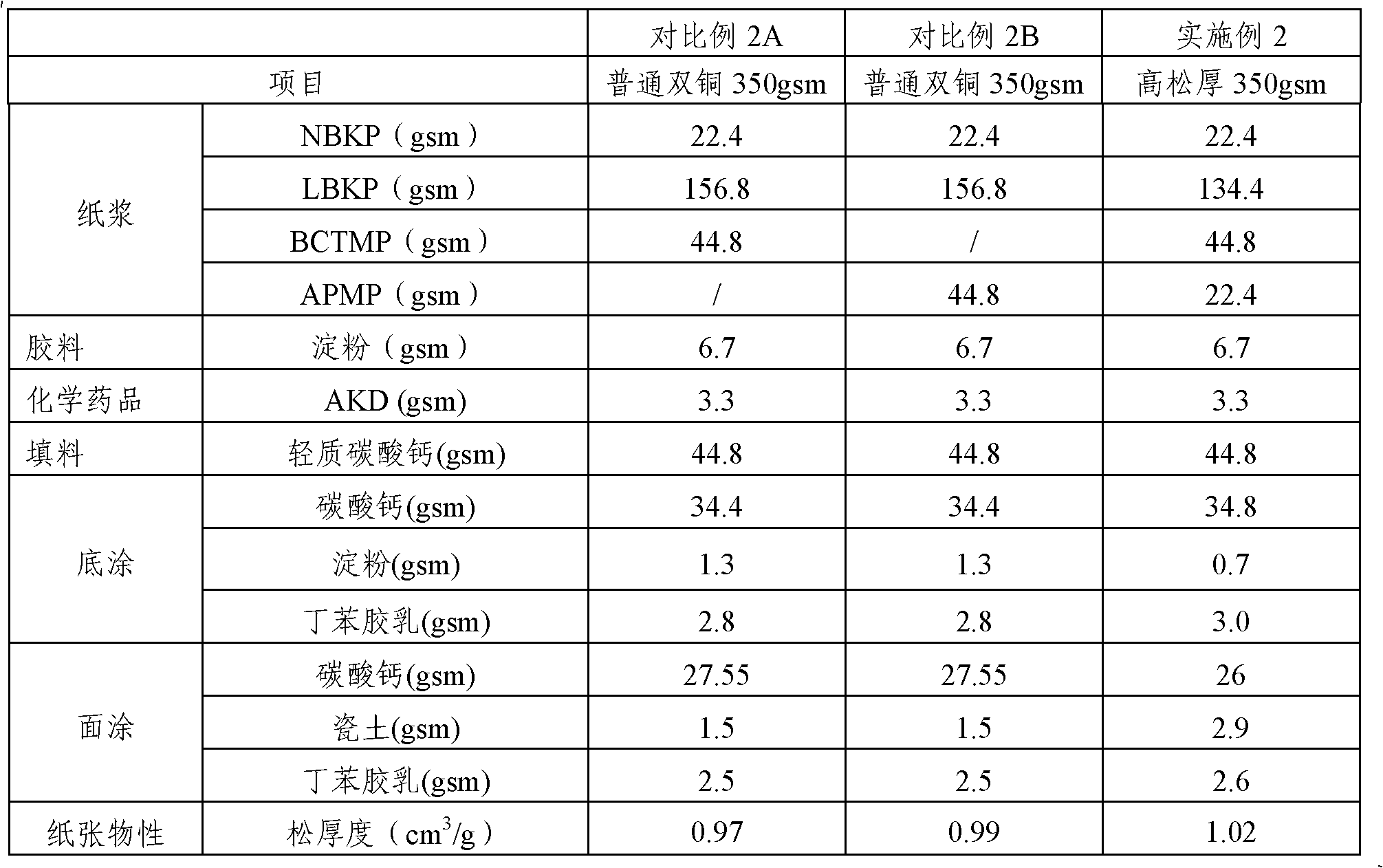

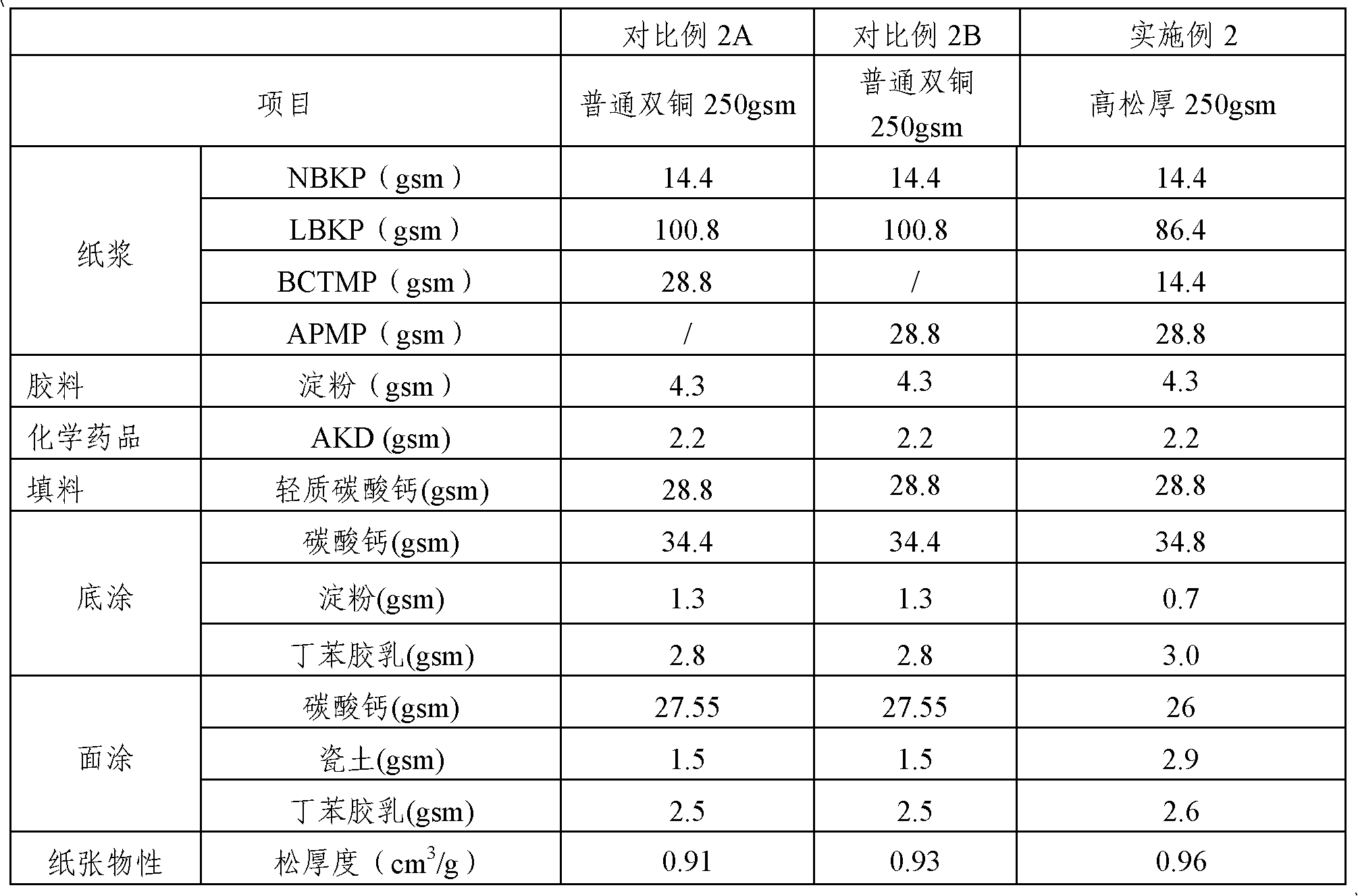

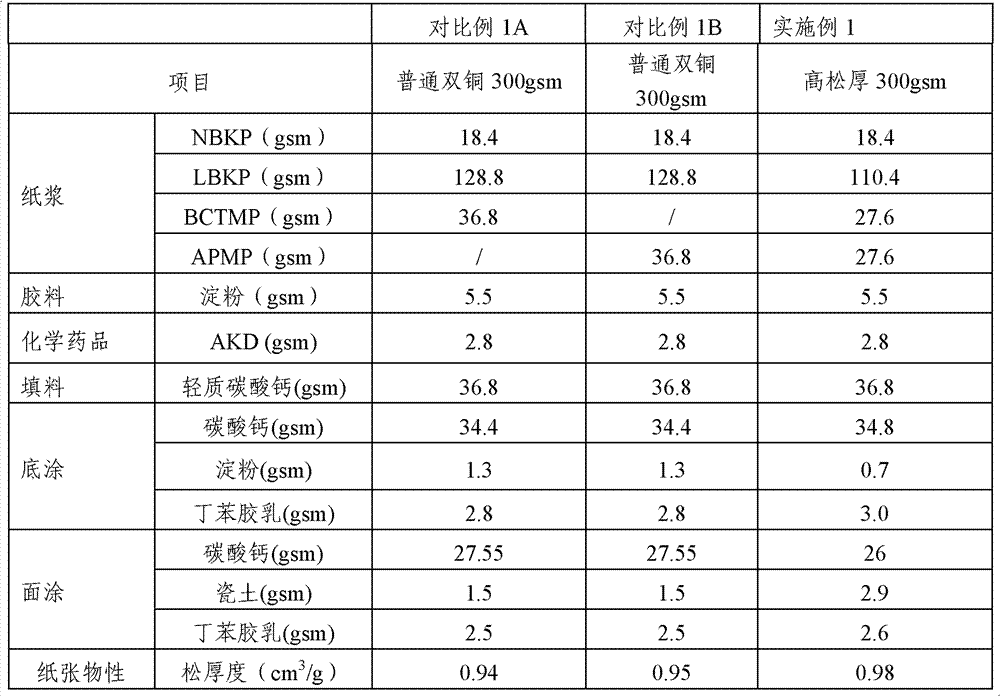

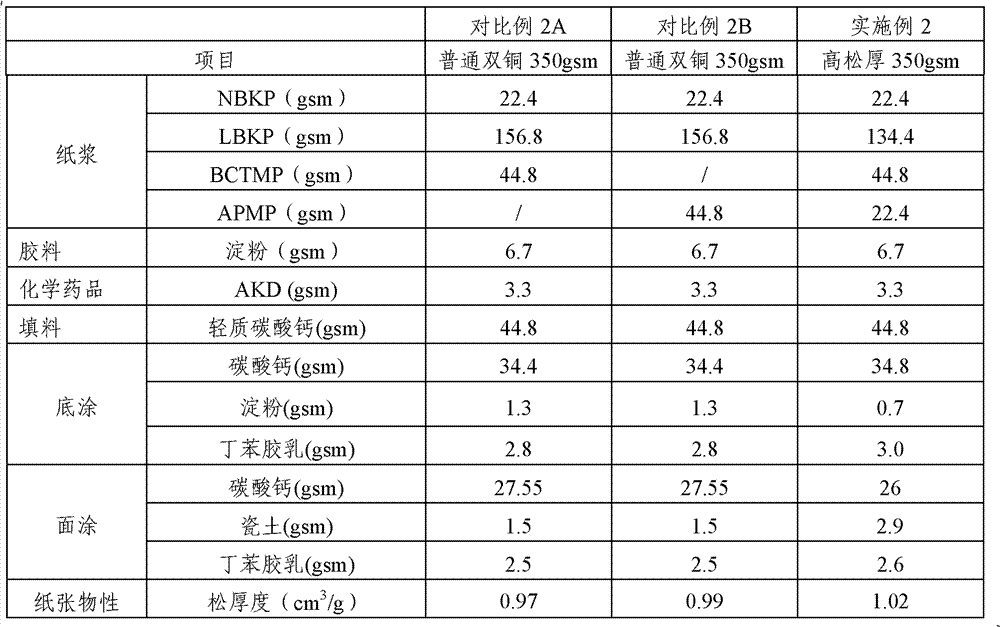

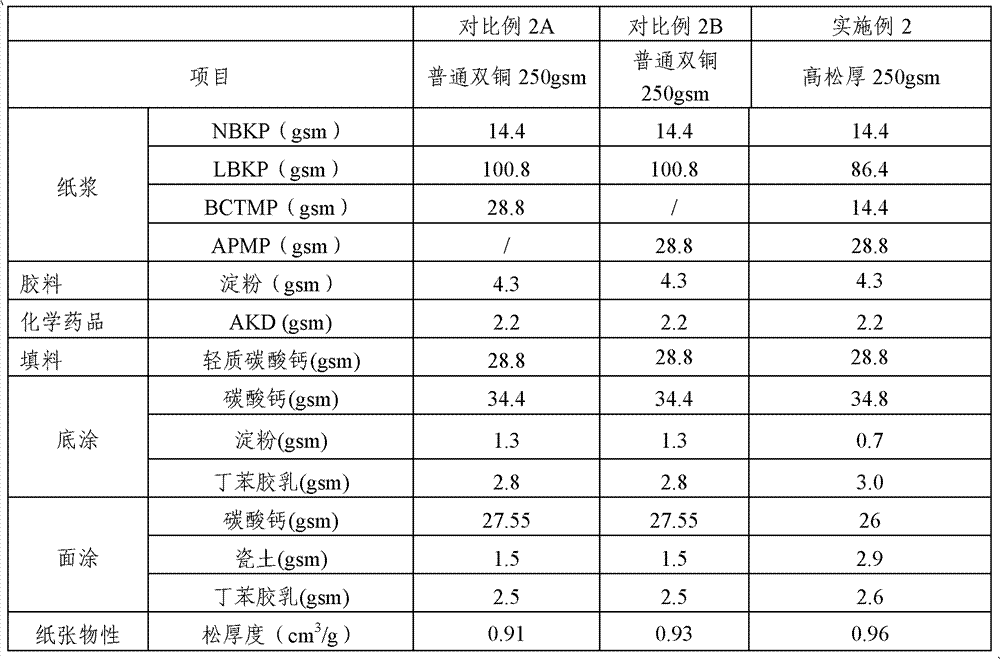

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

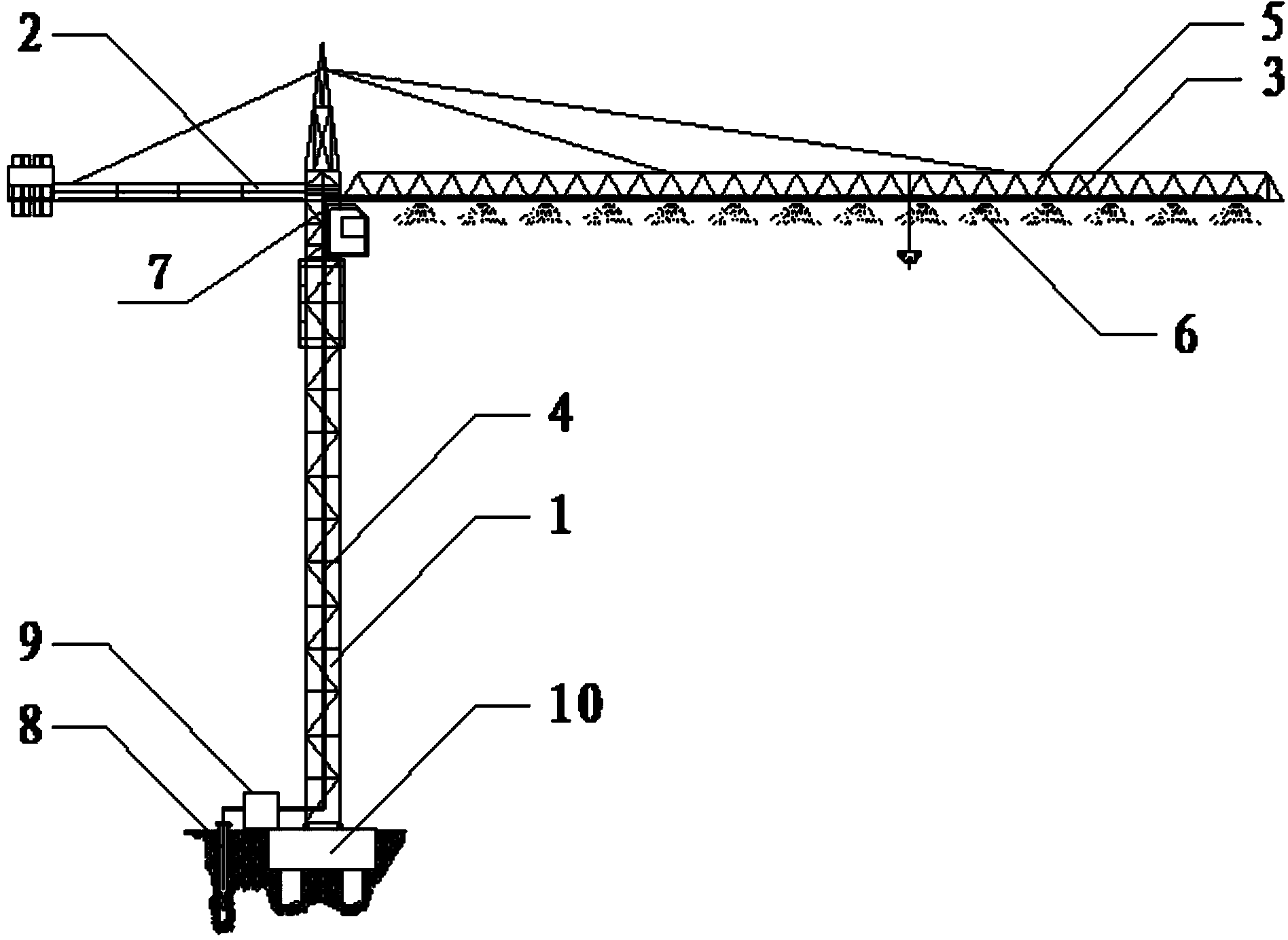

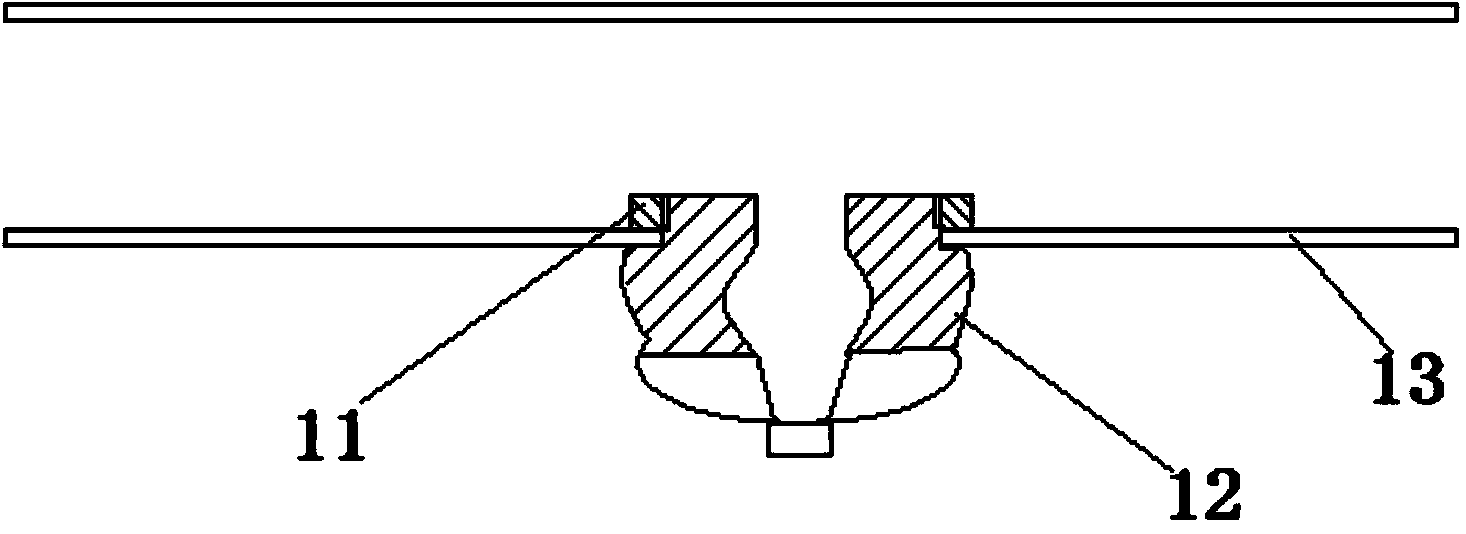

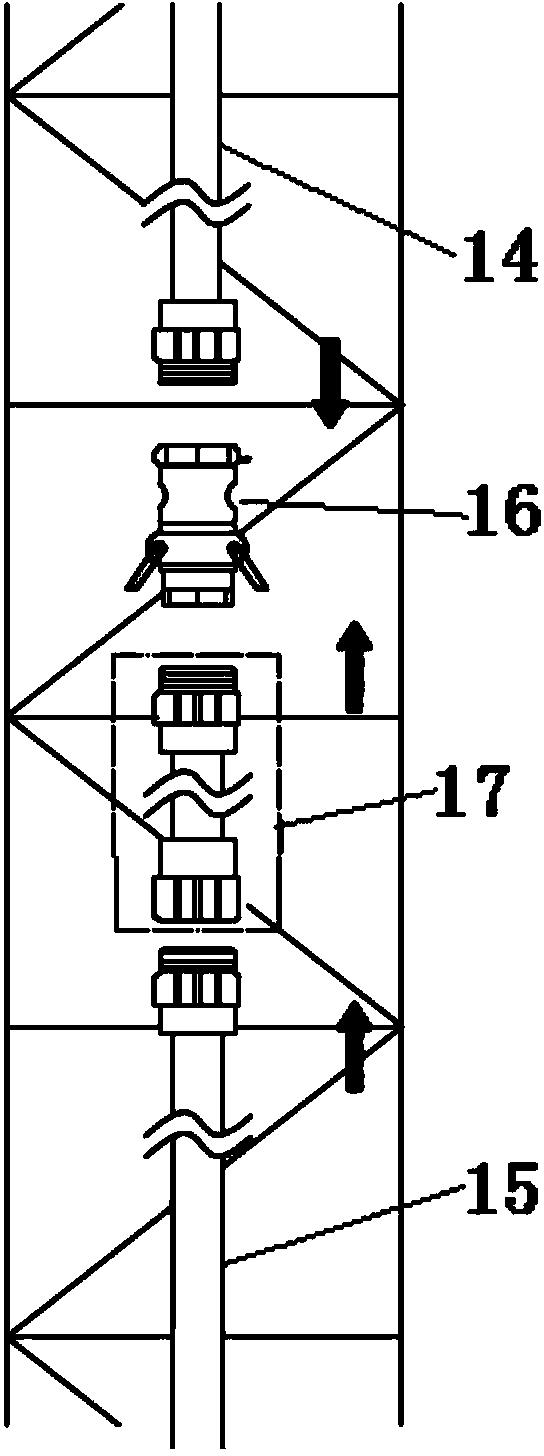

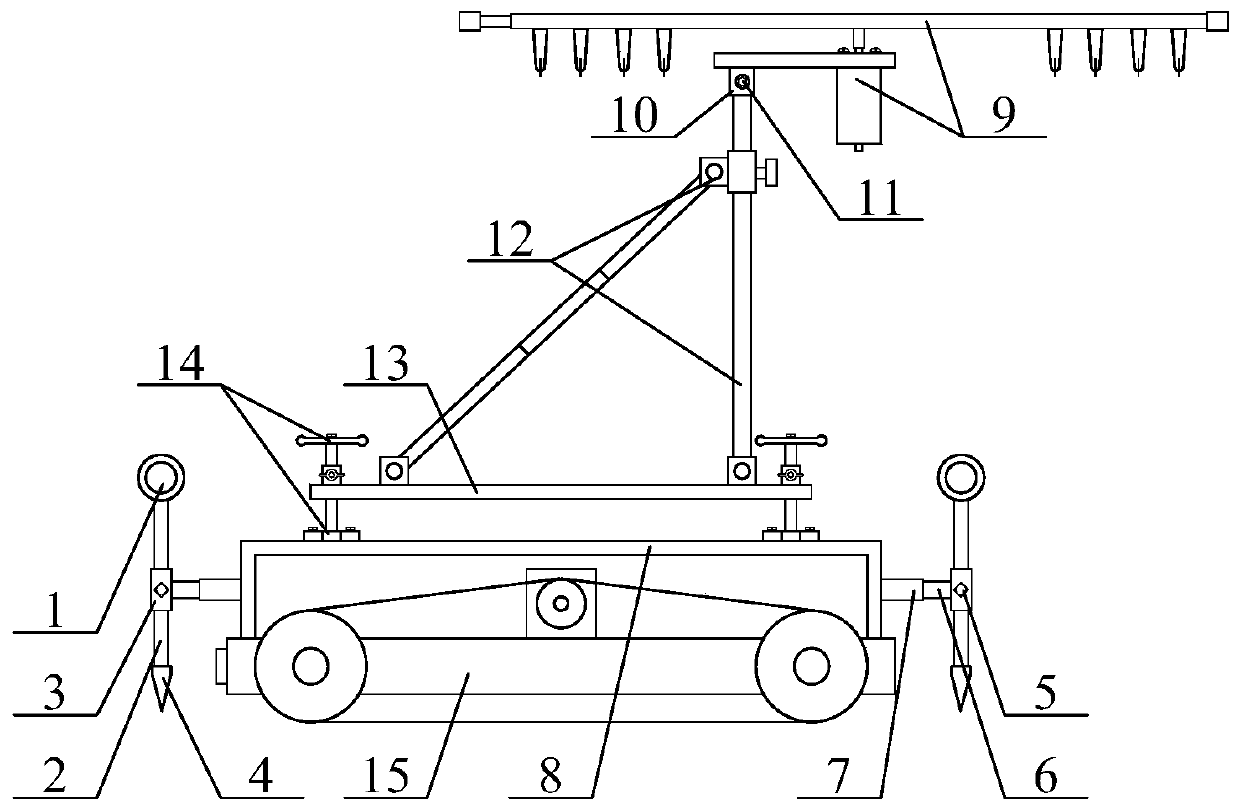

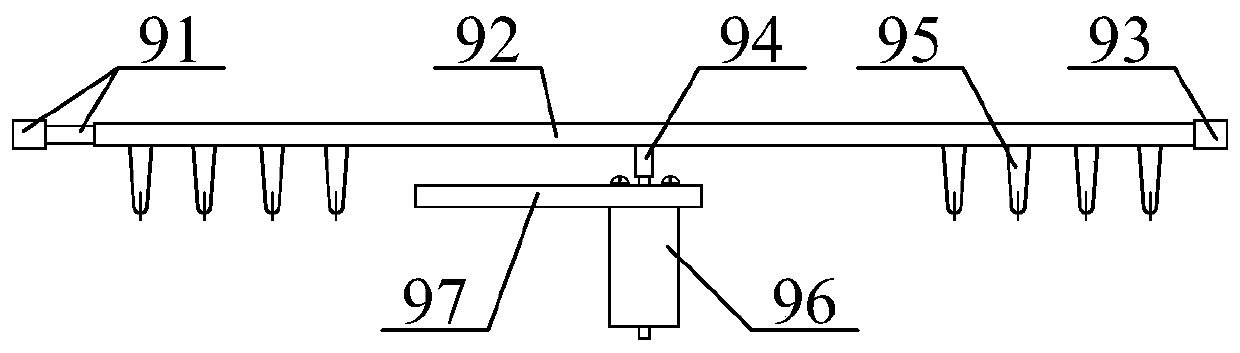

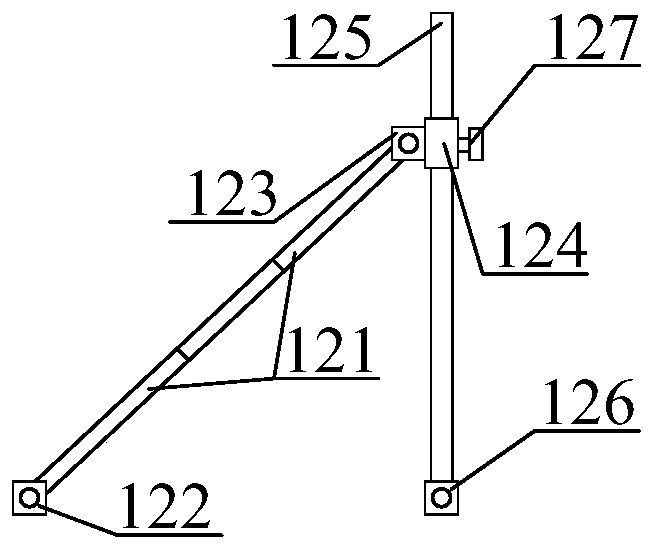

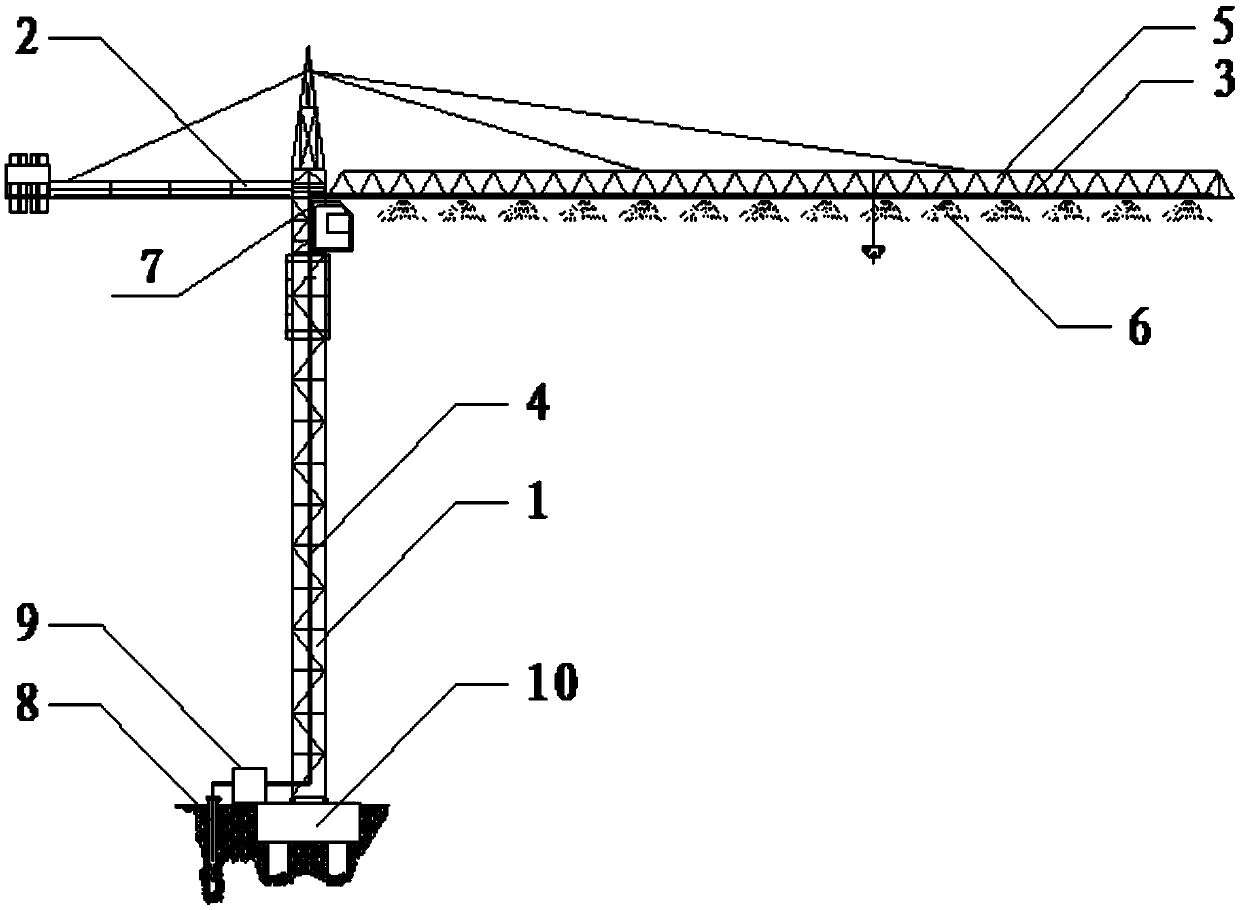

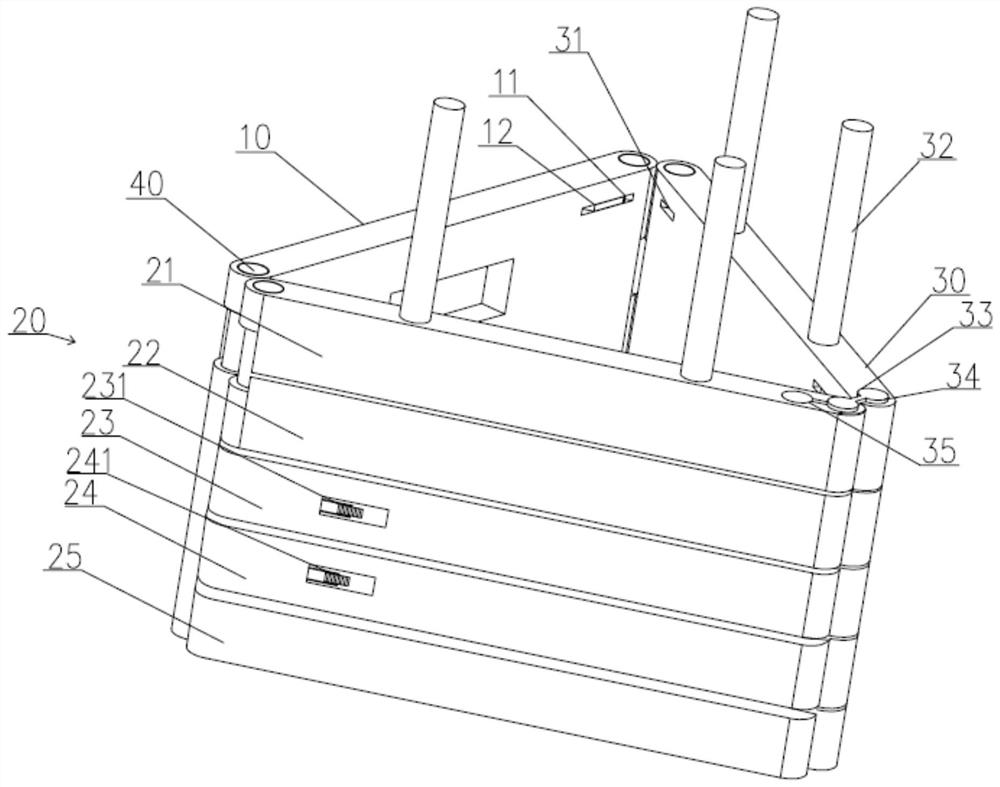

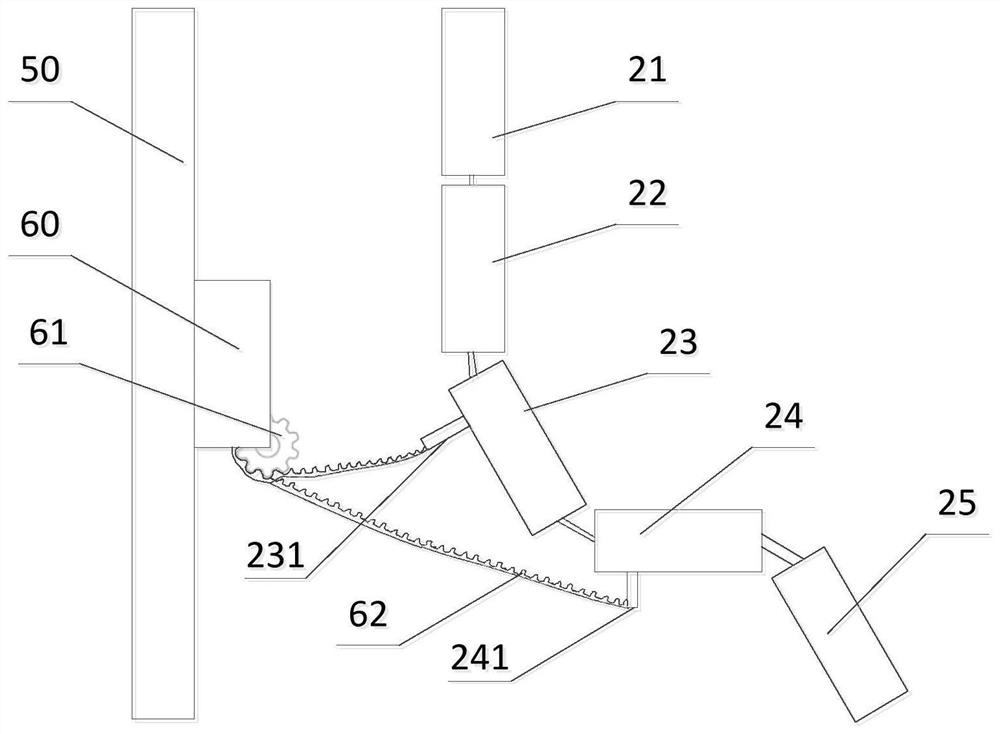

Tower crane spraying device having automatic control function

The invention provides a tower crane spraying device having an automatic control function. The tower crane spraying device comprises, at least, a base, a tower crane frame, a balancing arm and a hoisting arm, wherein the balancing arm and the hoisting arm are horizontally connected onto the tower crane frame, a vertical pipe is arranged on the tower crane frame, a horizontal water supply pipe is arranged on the hoisting arm, and spraying heads are evenly distributed on the horizontal water supply pipe. The horizontal water supply pipe and the vertical pipe are connected through a rotating connector. A control box and a water pump are arranged on the vertical pipe, the control box is located on the base, a flow meter, a water pressure gauge and a controller are arranged in the control box, and a flow control knob, a time control knob and a water pressure control knob are arranged on the controller. The shortcomings in the prior art are overcome, and the tower crane spraying device is simple in structure, convenient to install and use and capable of automatically controlling the spraying time and water volume.

Owner:WUHAN CUIYU ENVIRONMENTAL TECH

Vanadium-titanium nodular cast iron smelting method

The invention discloses a vanadium-titanium nodular cast iron smelting method which comprises the steps of weighing furnace burden, smelting, spheroidizing and inoculating, wherein the smelting step comprises the sub-steps: adding oxide scale of which the addition amount is 0.5-1.5 percent of the weight of the furnace burden, and adding the oxide scale at the bottom of the furnace burden during smelting and charging; in the smelting step, after the furnace burden is molten down, adding silicon iron into molten iron for regulating the components, so as to achieve the deoxidation effect. The method has the beneficial effects that the low-price oxide scale is added into the bottom of the furnace burden during charging, and the element Ti is oxidized preferentially, so that the titanium content is reduced, the inverse spheroidizing effect of titanium is weakened, nodularizing in vanadium-titanium ductile iron is guaranteed, and a good dephosphorization effect is achieved when the oxide scale is added during smelting; the oxide scale is wide in source and low in price, the oxide scale is reasonably utilized, the production cost can be reduced, and the environment-friendly energy-saving effects are achieved. According to the method, the process is simple, the operation is convenient and the cost is low, and the comprehensive performance of the vanadium-titanium nodular cast iron is guaranteed.

Owner:XIHUA UNIV

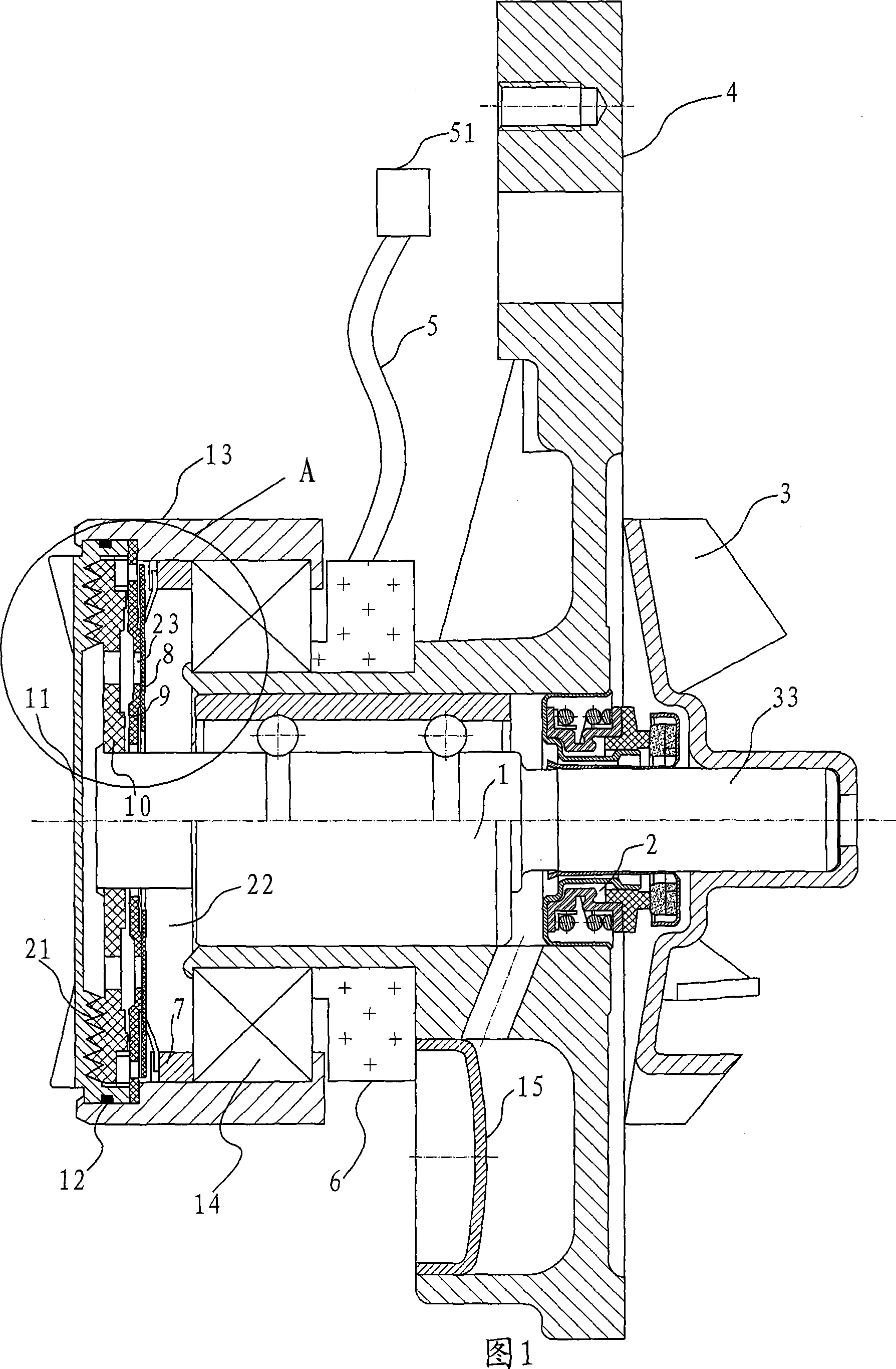

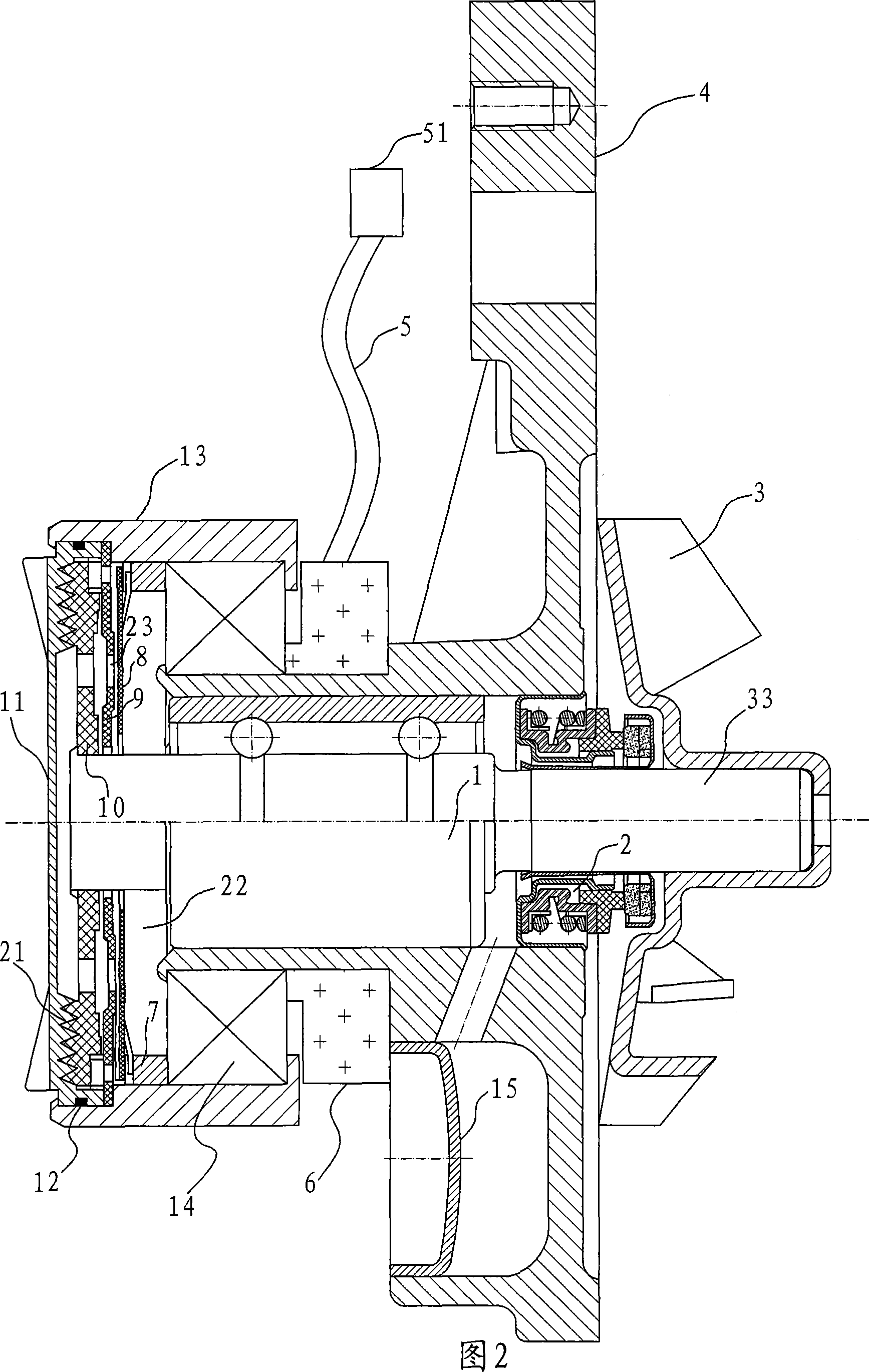

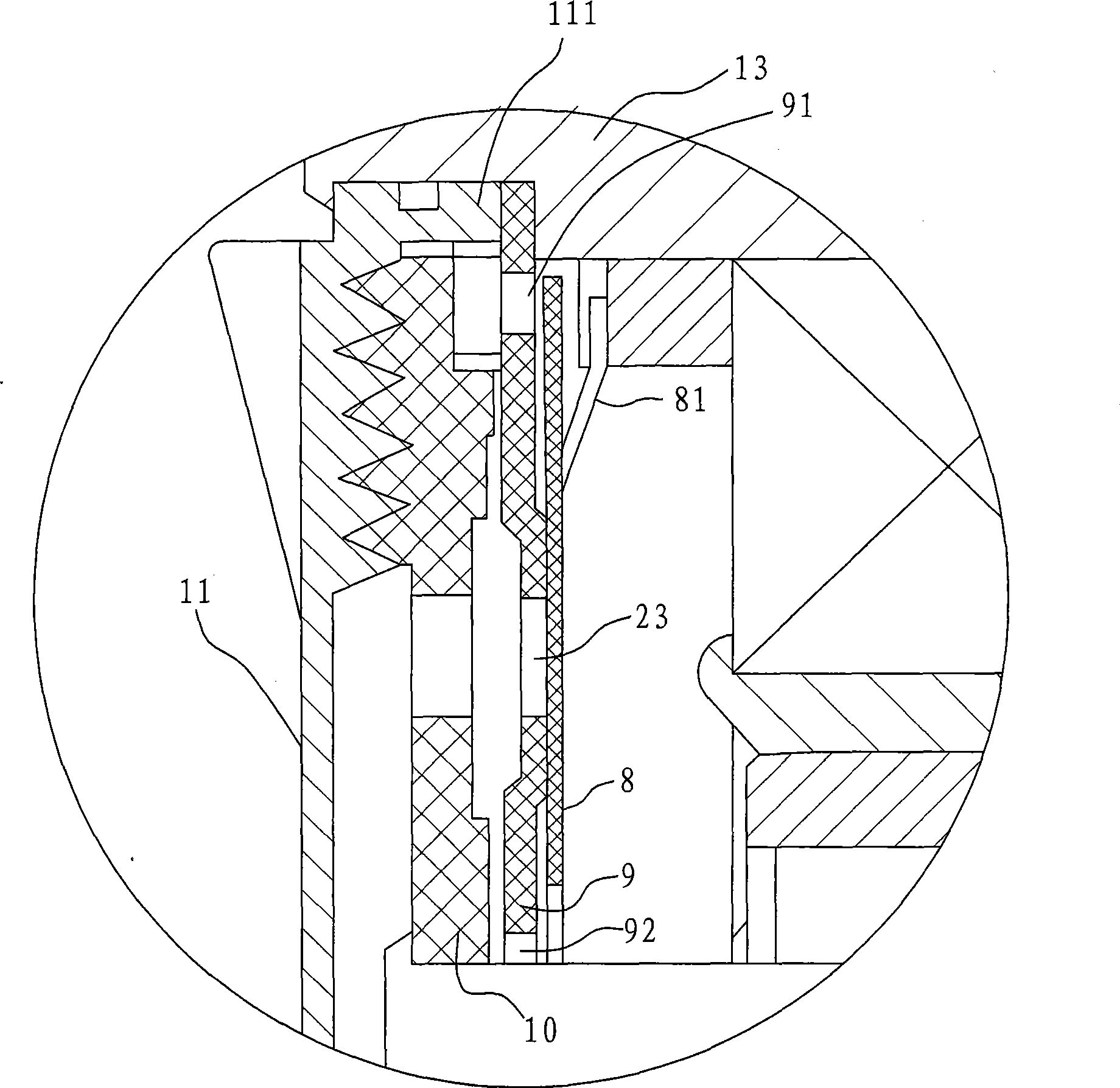

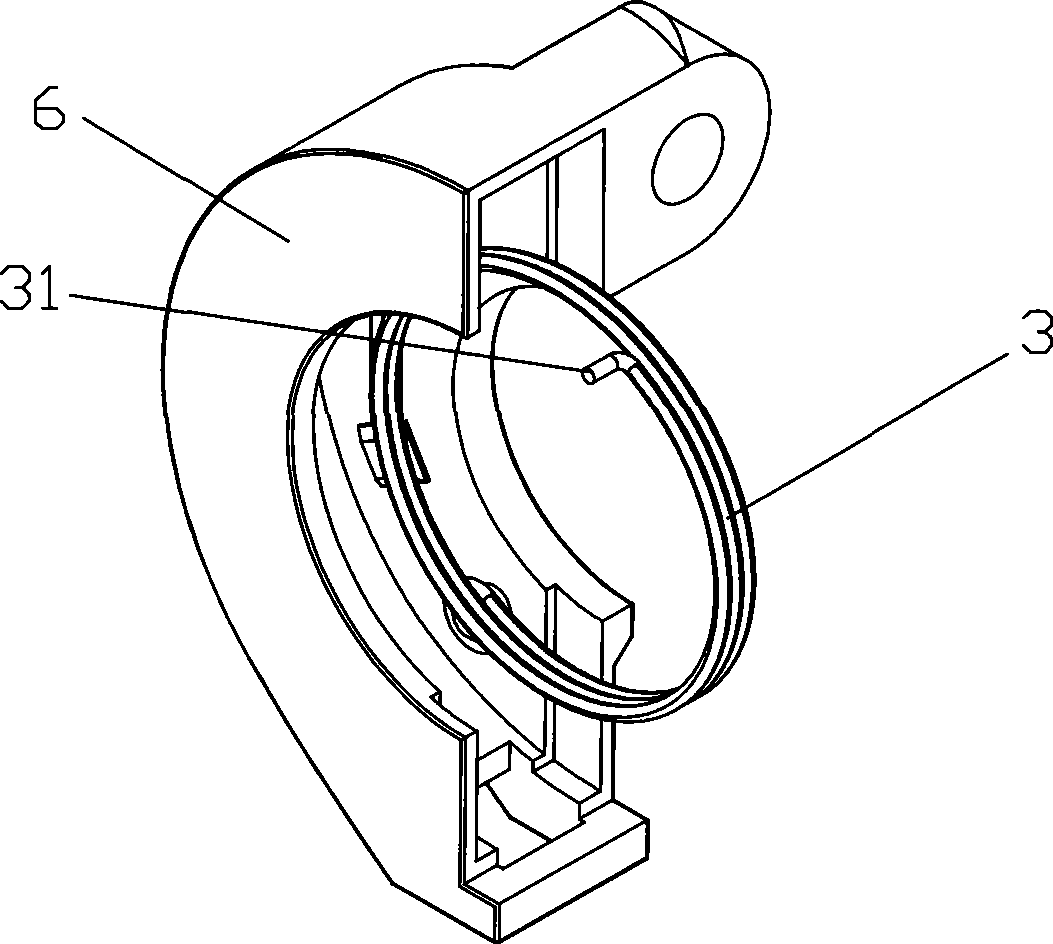

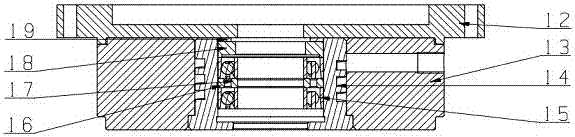

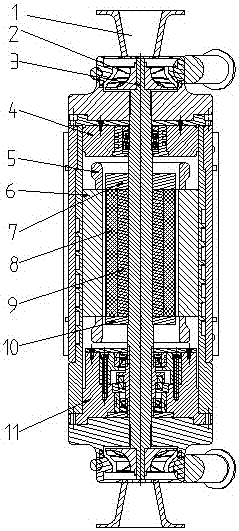

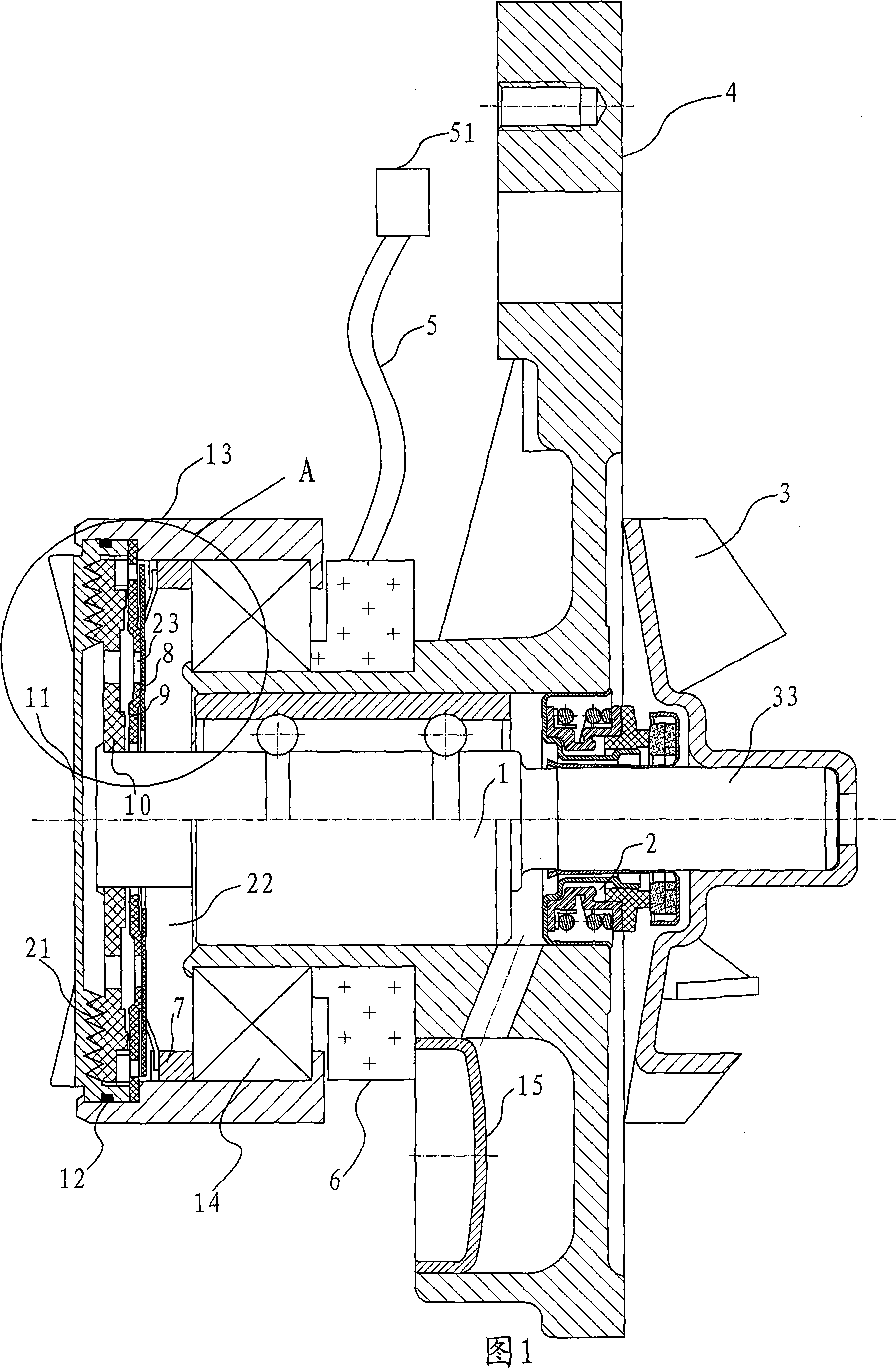

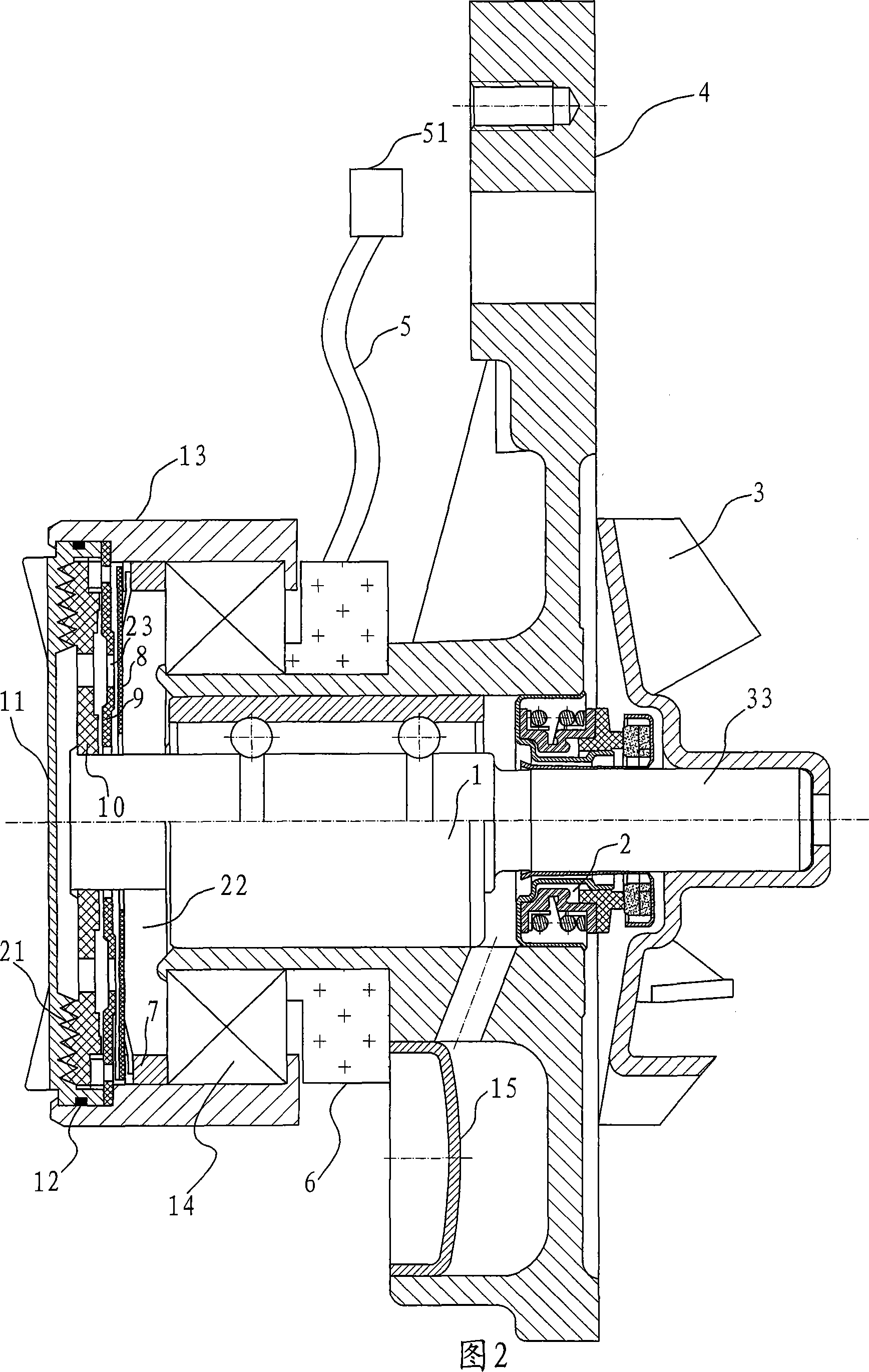

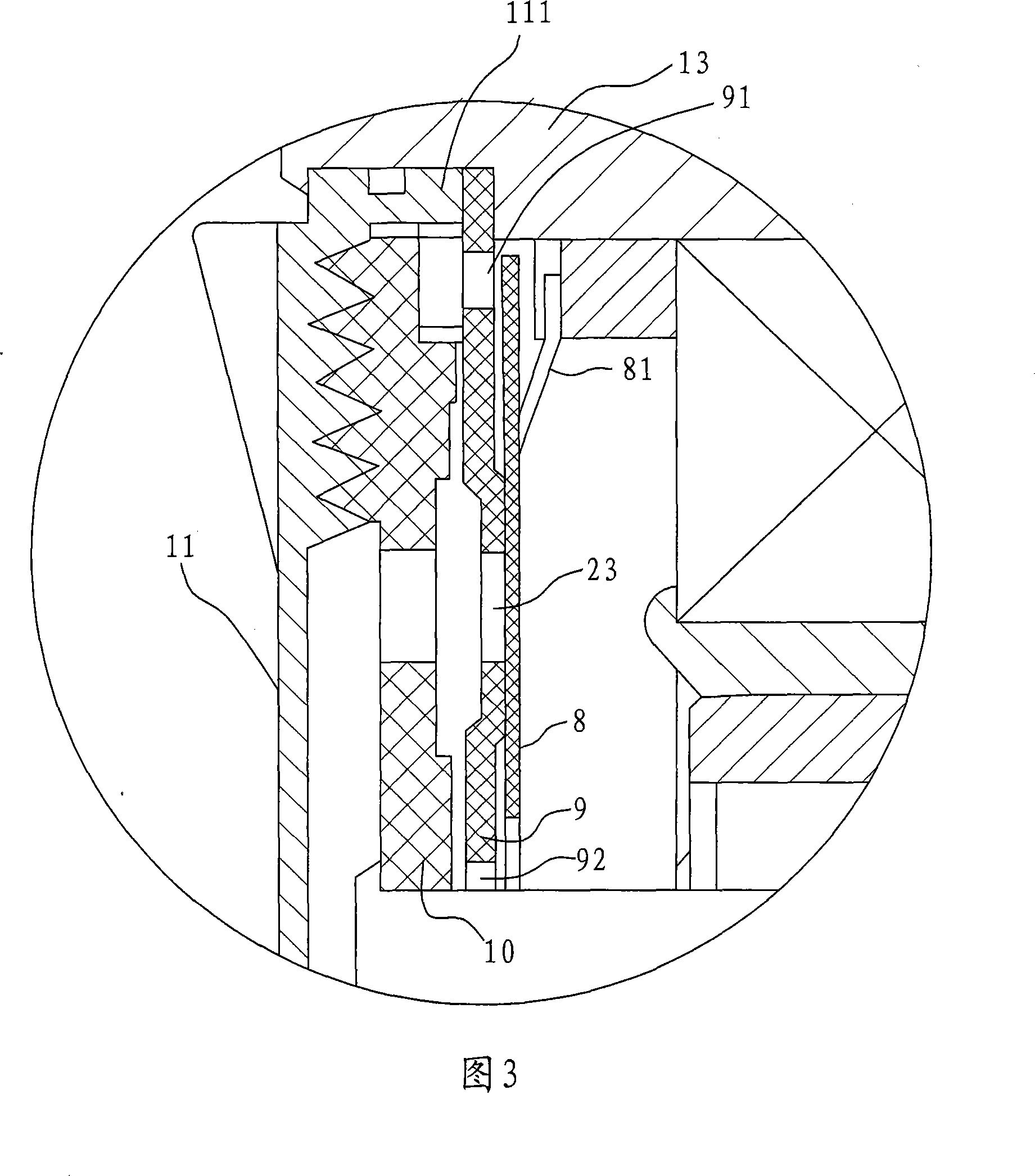

Electric silicon oil clutch water pump

ActiveCN101435362AHigh driving torqueDrive torque savingCoolant flow controlMachines/enginesElectricityInterior space

An electronic silicone oil clutch water pump comprises a water pump body, a front cover, an oil storage cover, a shaft coupling bearing and an impeller. The front cover is hermetically connected with the front end part of the water pump body so as to form an inner space which has an oil storage cavity and an engagement cavity for a circulation passage. In addition, a valve plate controlling the circulation of silicone oil between the oil storage cavity and the engagement cavity is arranged between the oil storage cavity and the engagement cavity. Correspondingly, the oil storage cover is provided with an oil regulating hole. The shaft coupling bearing is inserted into the water pump body. The electronic silicone oil clutch water pump is characterized in that the clutch water pump also comprises an electromagnet which can attract the valve plate after being electrified and further control the opening of the oil regulating hole, and a wire bundle which is connected with an electronic control unit. The electromagnet at least comprises an iron core and a coil. The valve plate is elastic and closes the oil regulating hole from the oil storage cavity to the engagement cavity due to the self elasticity in an unstressed status. Compared with the prior art, the electronic silicone oil clutch water pump has the advantages of electronic control on the impeller speed, quick response and accurate control.

Owner:WARNER SHENGLONG NINGBO CO LTD

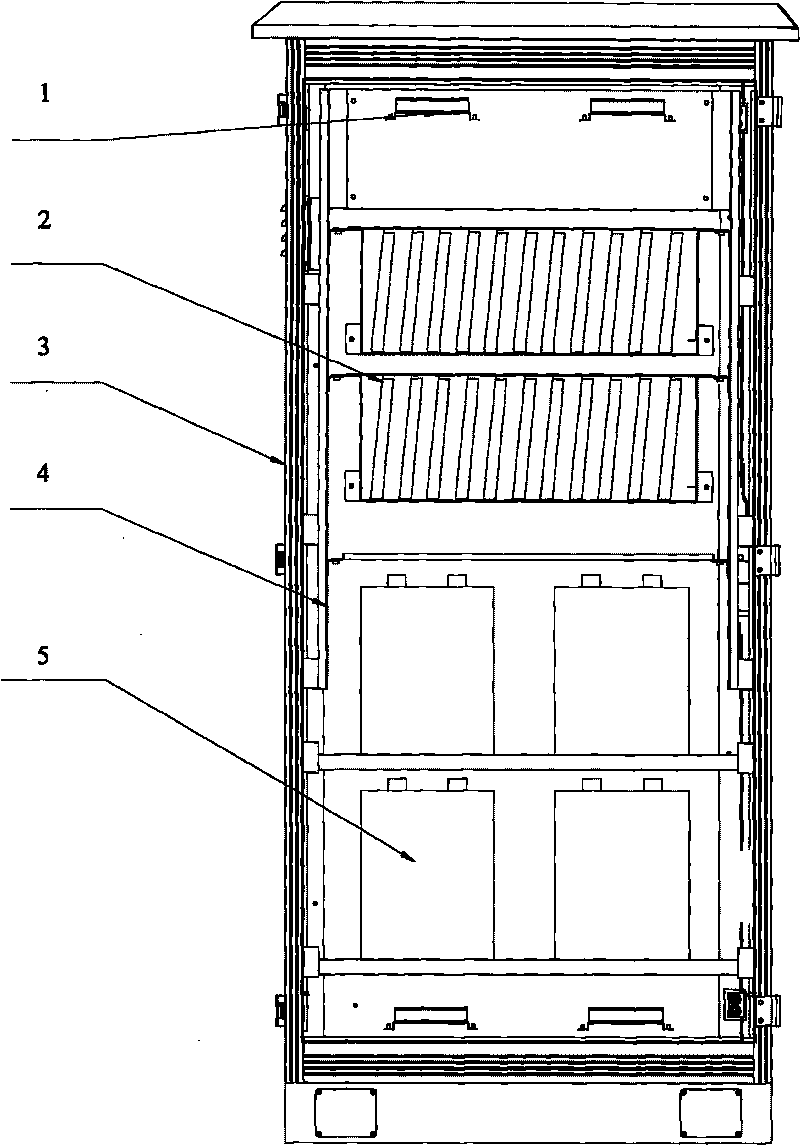

Method for balancing temperature of outdoor cabinet and structure of outdoor cabinet

InactiveCN101737881AImprove thermal performanceExtended service lifeLighting and heating apparatusAir conditioning systemsEngineeringEquilibrium control

The invention discloses a method for balancing temperature of an outdoor cabinet and a structure of the outdoor cabinet. The method for balancing the temperature of outdoor cabinet comprises the following steps: assembling the phase-change materials in an outdoor cabinet, and selecting the phase-change materials suitable for the temperature required to run an electronic device in the outdoor cabinet. When the temperature of the environment is lower, the phase-change materials and the electronic device release heat to the environment; when the temperature of the environment is higher, the phase-change materials absorb the heat released by the electronic device to inhibit the temperature in the outdoor cabinet. The outdoor cabinet also adopts the ventilation way of entering from the upper and exiting from the lower to ventilate and dissipate heat externally. The method for balancing temperature of outdoor cabinet and the structure have the advantages of realizing the balance control of the outdoor cabinet temperature by using phase-change materials and passive refrigeration mode, and matching with the ventilation way of entering from the upper and exiting from the lower, thereby protecting the environment and saving the energy; and moreover, the outdoor cabinet has good thermal performance, so that the service life of the electronic device in the outdoor cabinet can be prolonged and the running reliability of the electronic device can be enhanced.

Owner:上海凌御电气有限公司

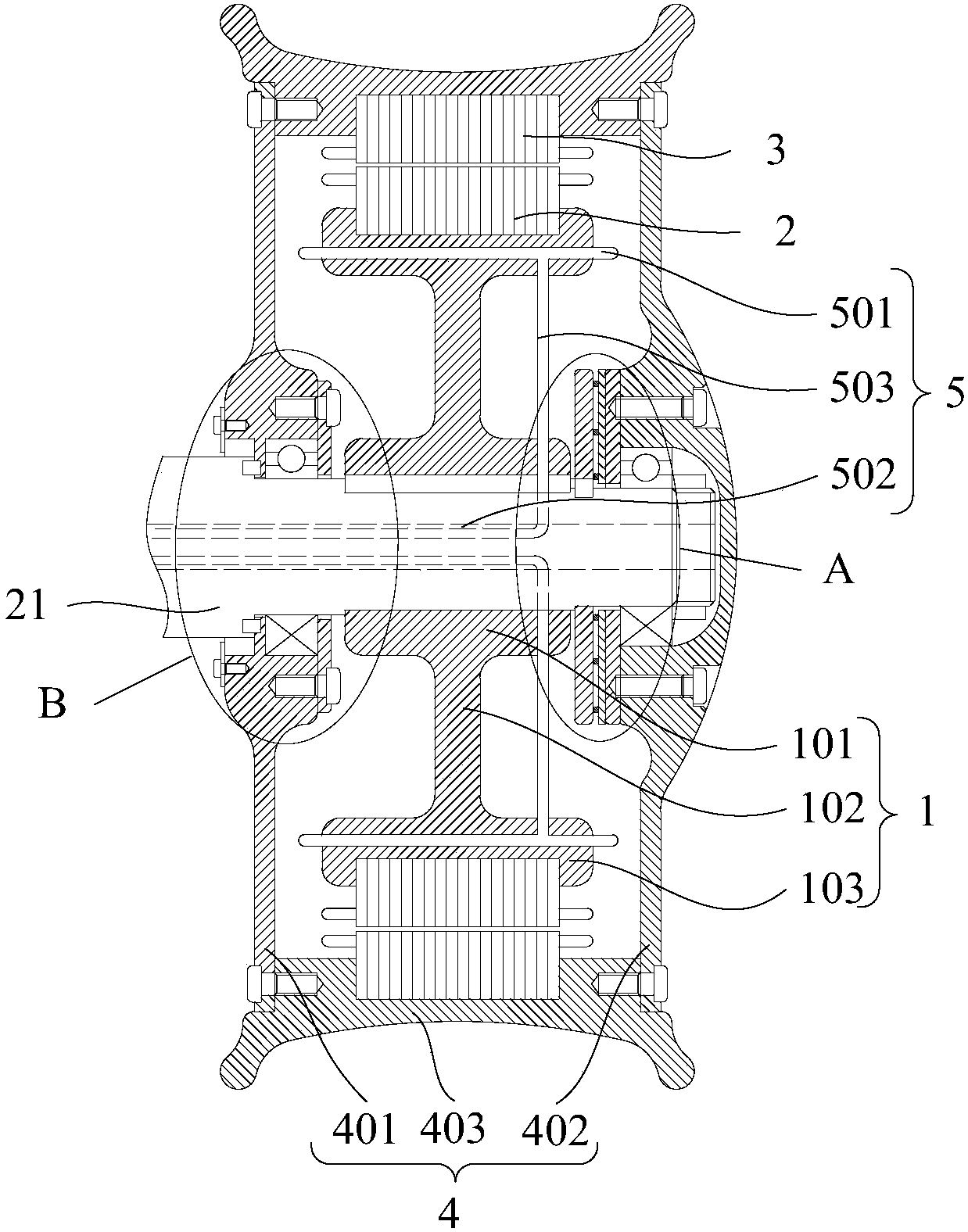

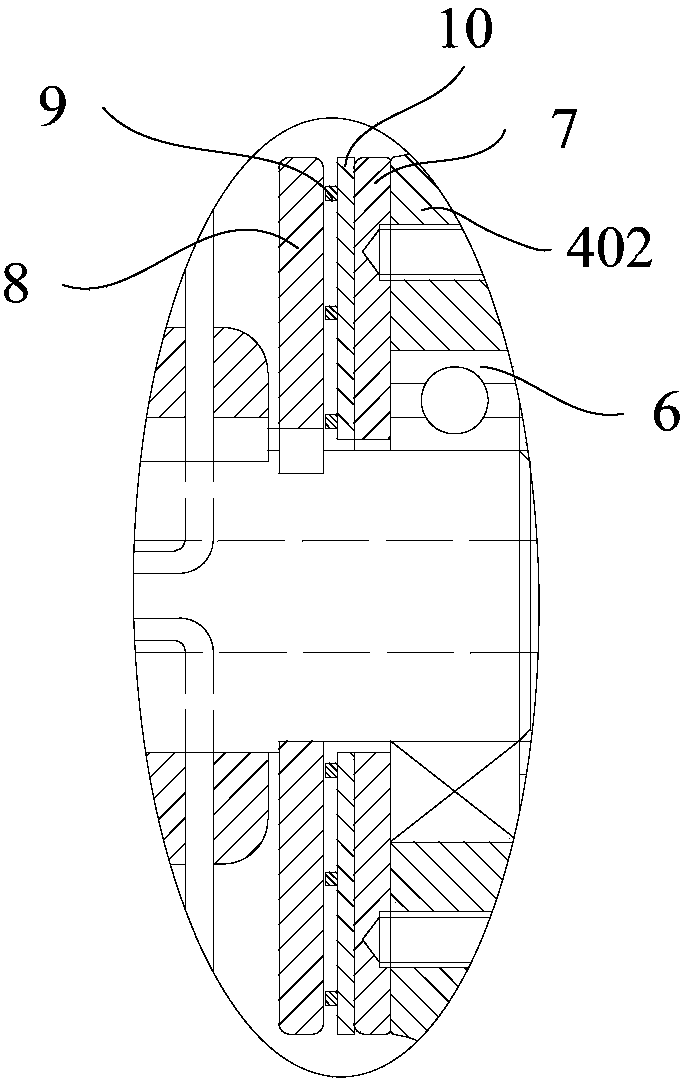

Electric drive and power-generating integrated outer-rotor hub device and electric vehicle

PendingCN108482105AHigh strengthImprove battery lifeHubsElectrodynamic brake systemsElectric driveBattery electric vehicle

The invention relates to the technical field of electric vehicles, in particular to an electric drive and power-generating integrated outer-rotor hub device and an electric vehicle. The electric driveand power-generating integrated outer-rotor hub device comprises a spindle, a support, a stator, a rotor and a hub enclosure component, wherein the support sleeves the spindle, the hub enclosure component encloses the support and is rotationally connected with the spindle, the stator is arranged at the end of the support far away from the spindle, the rotor is arranged on the hub enclosure component, the rotor can rotate relative to the stator, the stator and the rotor are connected with a battery of the electric vehicle, and the battery is used for outputting or storing electric energy. Theelectric drive and power-generating integrated outer-rotor hub device can convert the electric energy of the battery into kinetic energy of a vehicle such that the vehicle is driven to travel; no energy is wasted when the electric vehicle travels with no load; braking kinetic energy can as also be converted into electric energy that is stored in the battery, such that driving range of the electricvehicle is widened.

Owner:刘昱含

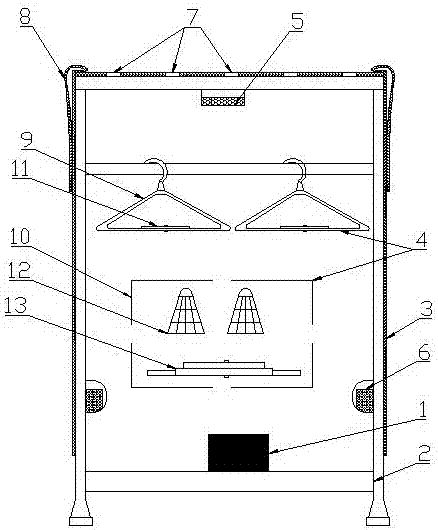

Novel laundry dryer

InactiveCN106894214AIncrease flow rateImprove the effectTextiles and paperLaundry driersLaundryClothes hanger

The invention relates to a novel laundry dryer. The novel laundry dryer comprises a warm air blower, a stand and an outer cover and further comprises novel clothes hangers, an adsorption package and smell removal packages; a plurality of openings are formed in the top of the outer cover, a fabric covering is sewed to the outer side of the top of the outer cover, and the size of the outer cover can cover all the openings; absorbent materials are contained inside the adsorption package, and the adsorption package is arranged below the top of the stand; perfume is contained inside the smell removal packages, and the smell removal packages are arranged on the two sides below the middle in the outer cover; the novel clothes hangers comprise clothes hanger bodies and accessories thereof; a rotating pole is arranged at the midpoint of the support cross rod of each clothes hanger body; the accessories comprise plastic bodies which are put in leg openings or clothes cuffs and have a pierced round head circular cone structure, the accessories further comprise a telescopic pole which is arranged on the bottom edges of clothes, wherein the rotating pole is arranged at the midpoint of the telescopic pole. The novel laundry dryer can be more energy-saving, and the drying of clothes is achieved more efficiently; the novel laundry dryer has the advantages that the structure is simple, manufacturing is easy, and the cost is low.

Owner:黄科钧

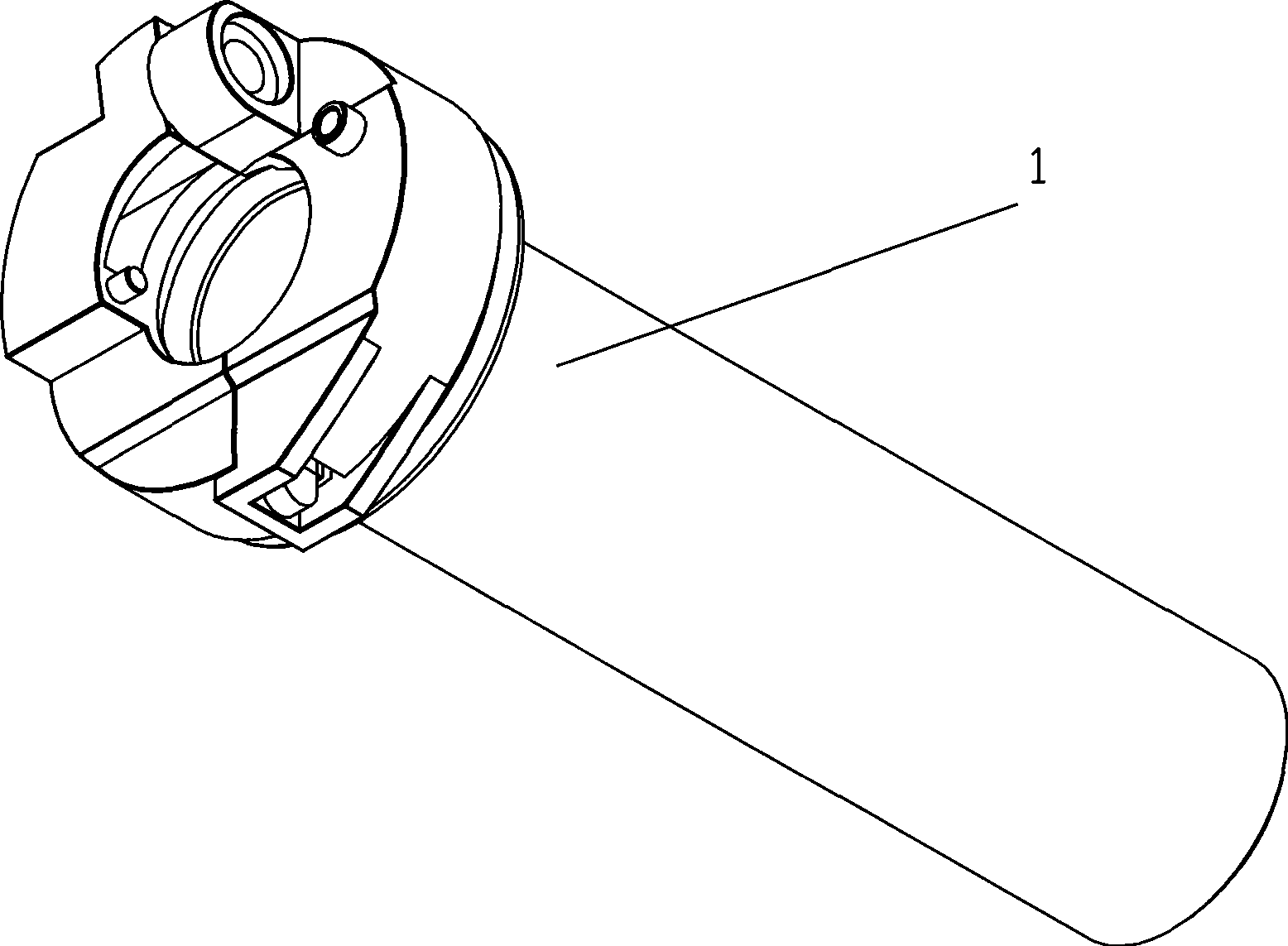

Engine for hybrid power motorcycle and electric motor integrated controlling speed regulating handle

InactiveCN101362495ASimple structural designEasy to operateCycle control systemsElectric machineryDriving mode

The invention discloses an engine used for a hybrid motorcycle and a speed adjustment handle jointly controlled by a motor, comprising a turning handle and a casing body. A spool is arranged at the front end of the turning handle, a cable accelerator is winded on the spool, a magnetic steel is also arranged on the spool, a hall element is arranged on the casing body, the hall element is opposite to the magnetic steel on the spool, and a return spring is also arranged between the casing body and the turning handle; a raised arc connecting surface is arranged on the circumference of the spool. Compared with the technology of the prior art, the speed adjustment handle jointly controlled by the motor realizes the application of the carburetor type engine on the hybrid motorcycle, which ensures the controlling of the carburetor type engine to be flexible and the performance to be reliable; the speed adjustment handle jointly controlled by the motor is matched with the motorcycle performance, the steady switching of the driving mode and the smooth regulation of the speed exert the environment-protective and energy-saving effect of the hybrid motorcycle better. The device has the advantages of small volume, simple and compact structure, low manufacturing cost, and convenient assembly and disassembly on vehicles.

Owner:SOUTHEAST UNIV

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307BImprove phase change energy storage technologyWith the ability of automatic temperature adjustmentHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooledto room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Agricultural irrigation equipment convenient to move

ActiveCN110012823AEasy to guideAvoid cloggingWatering devicesCultivating equipmentsAgricultural irrigationEngineering

The invention provides agricultural irrigation equipment convenient to move. The agricultural irrigation equipment comprises pull rings, telescopic insertion rods, fixed sleeves, buried cones, square-head bolts, telescopic screws, inner-thread tubes, an inverted-U-shaped base, an angle-rotatable and angle-adjustable sprinkling irrigation type cleaning pipe structure, a connecting sleeve, a rack whose gradient can be adjusted at any time, a connecting seat, a height-adjustable detaching rod structure and a moving silt trap preventing type remotely-controllable wheel structure. The agriculturalirrigation equipment has the advantages that by a connecting pipe head, a water guide bar and a cleaning cap, the connecting pipe head can be favorably connected with an external tap water pipeline toguide tap water, the water guide bar is filled with water in real time, the irrigation can be performed smoothly, the interior of the water guide bar can be cleaned through an external cleaning brushby taking down the cleaning cap from the right-end thread of the water guide bar, water guide bar interior blocking caused by accumulated impurities is avoided, and smooth irrigation can be guaranteed.

Owner:衡水丽华润康生态科技股份有限公司

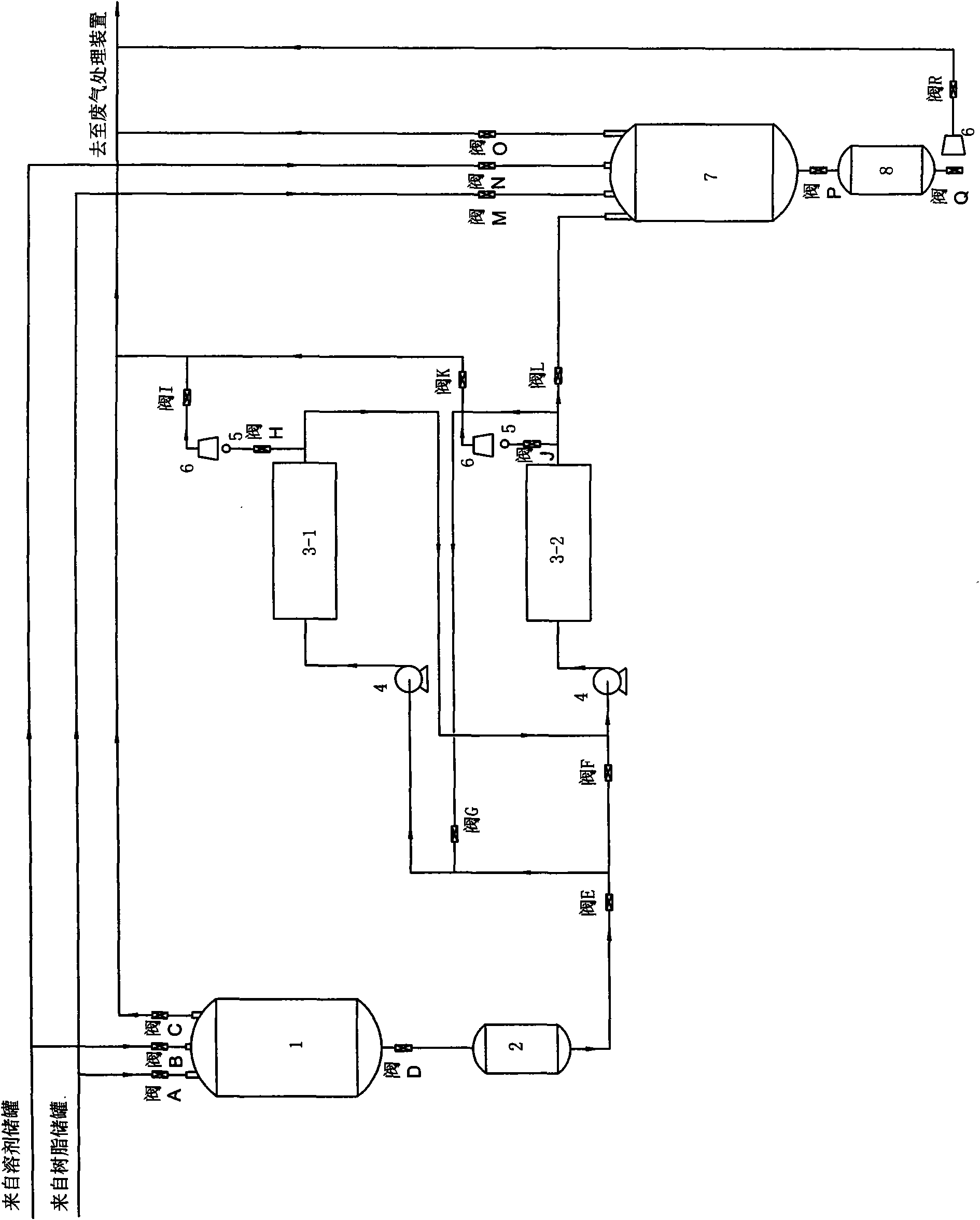

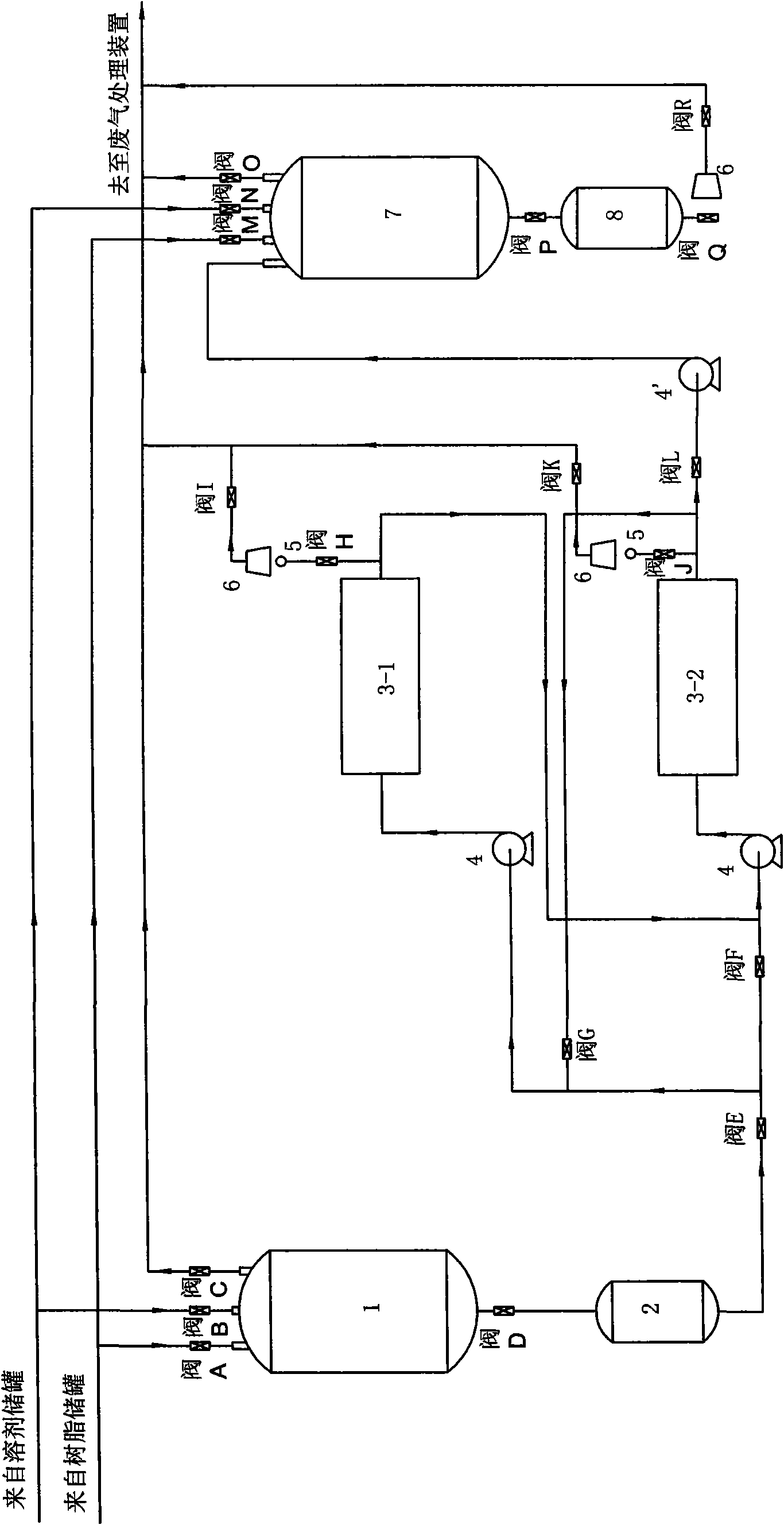

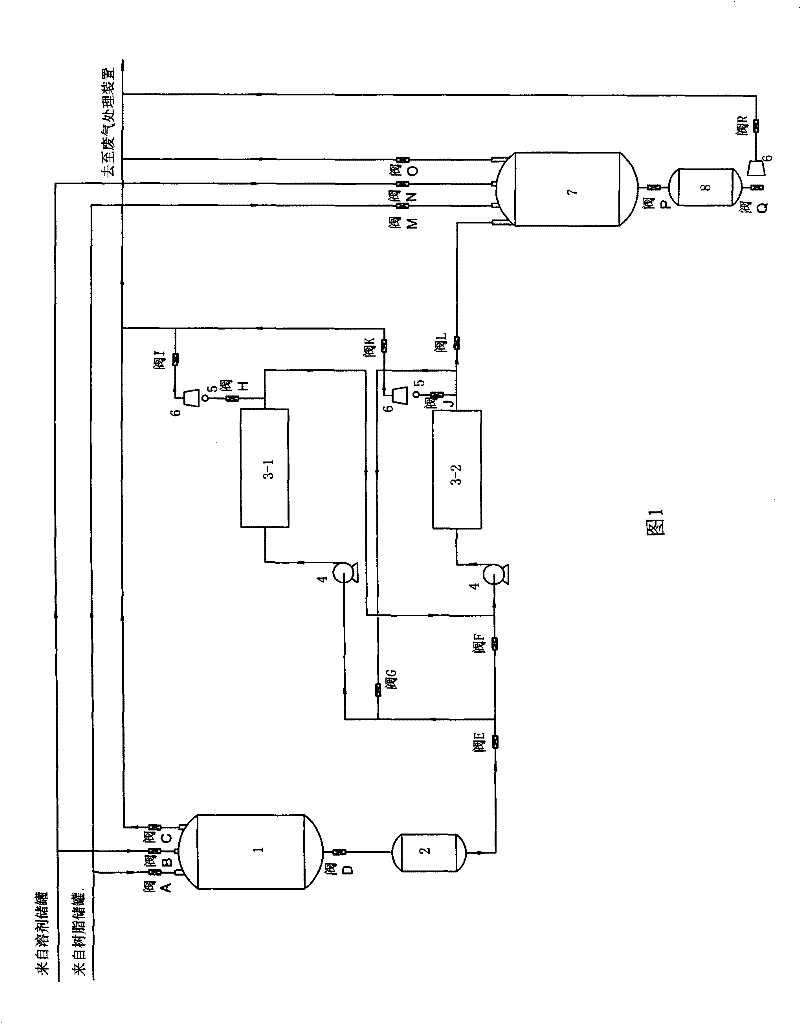

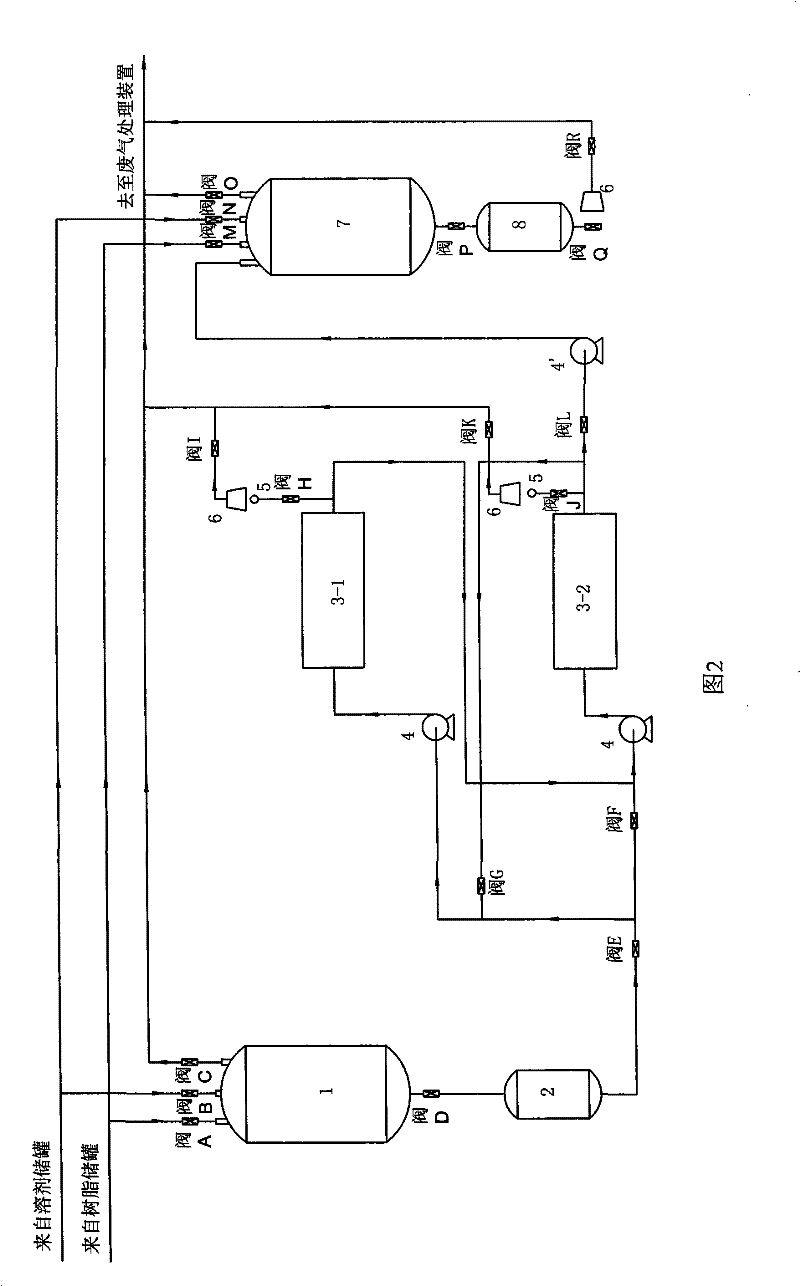

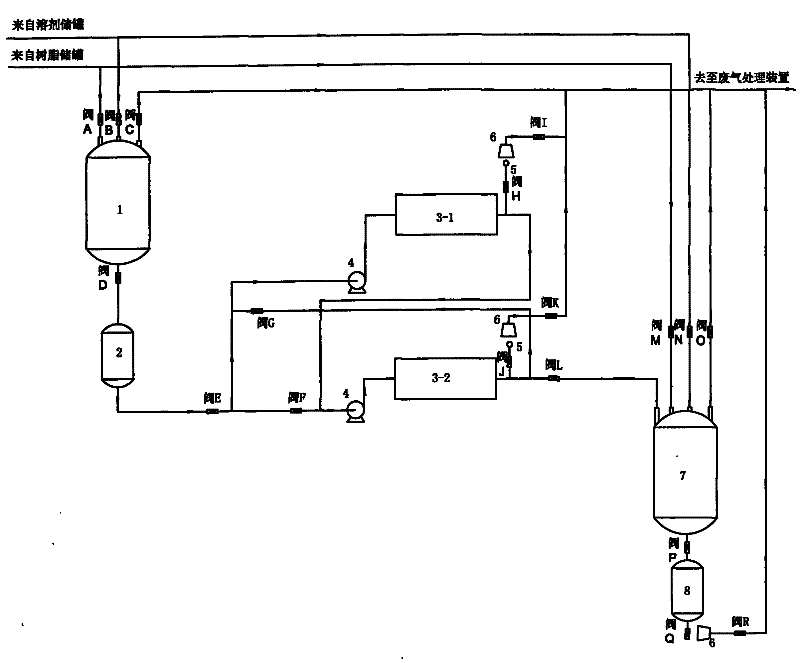

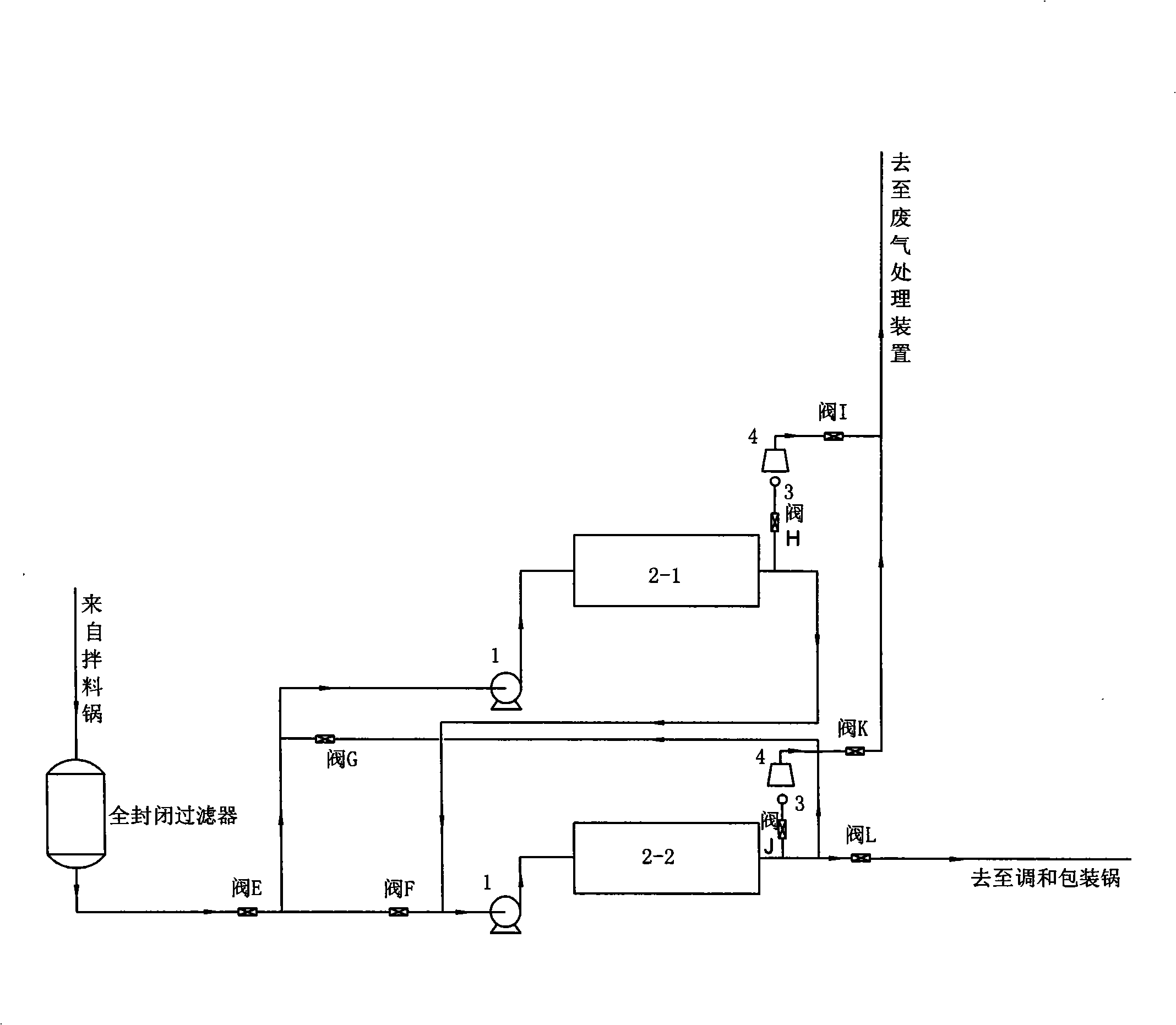

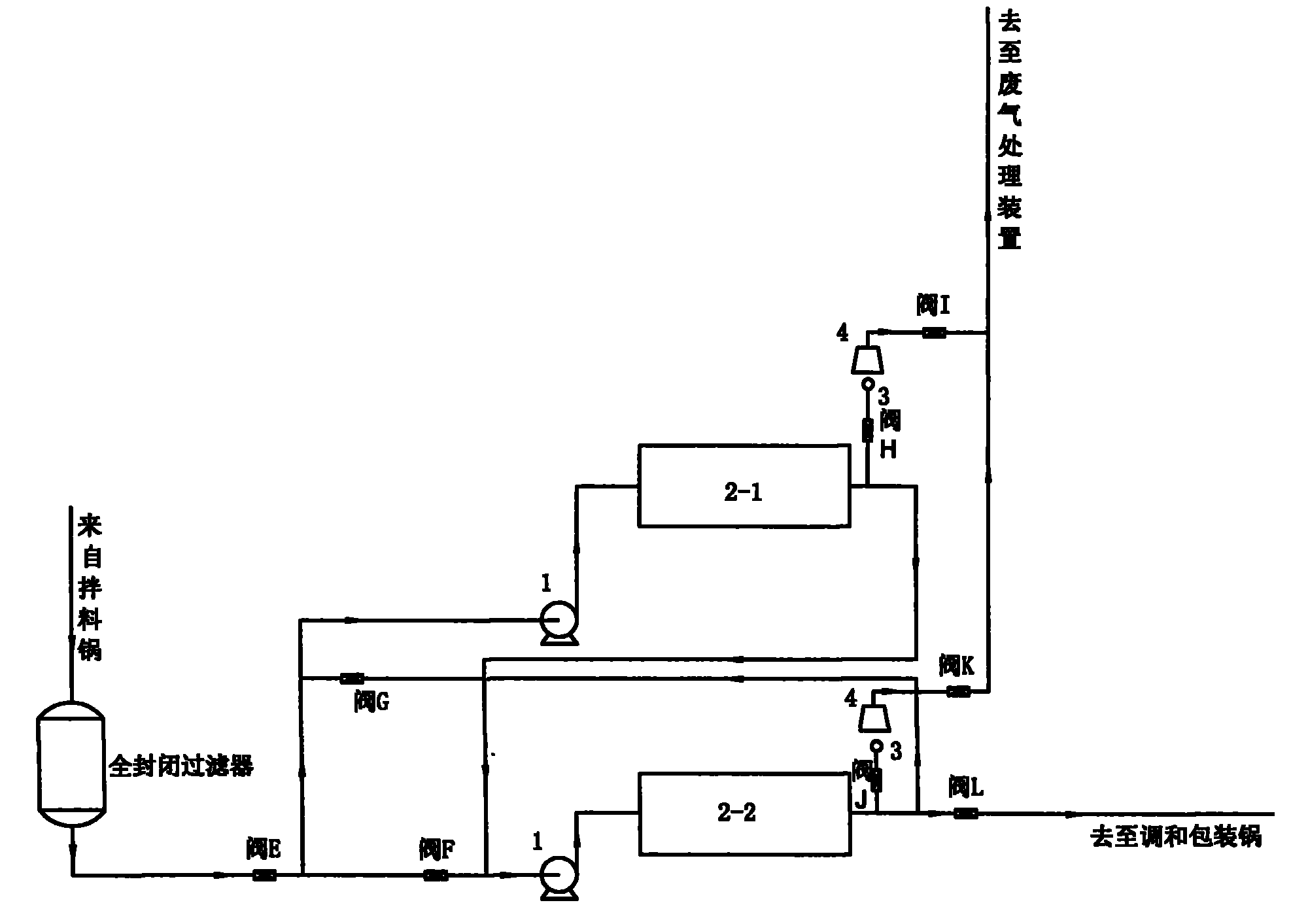

Totally closed production technology of paints

InactiveCN101538426ASolve the problems caused by emissionsFully enclosedChemical industryCoatingsOrganic solventTransmitted power

A totally closed production technology of paints selects a gravity and pneumatic-driving membrane pump to transmit power, different paint fineness requires the serial arrangement of different numbers of horizontal grinders for grinding, the paint fineness is qualified by the one-time grinding of the horizontal grinders, paint viscosity is qualified by detection, the paint flows into a fully closed filtering packaging machine at a first layer under the action of gravity, and the discharged material is weighed and packaged after filtering. A waste gas collecting hood is not only arranged at a fineness monitoring port, but also at a material-mixing position, a blending packaging pot and the fully closed filtering packaging machine, thus collecting waste gases generated in the whole procedure for centralized processing, greatly improving working environment and labor intensity, canceling all opening parts such as an opening intermediate paint cylinder, a flow conducting and adding port of a centrifugal pump and the like between the horizontal grinder and the blending packaging pot in the traditional production technology of the paint which is considered to be irreplaceable by persons in the same field, realizing full closing, fundamentally solving the problem of disorganized discharging in production of organic solvents, having the functions of protecting the environment and saving energy by adopting a clean-power pneumatic-driving membrane pump, and being the newly updated production technology in the paint industry.

Owner:袁泉利

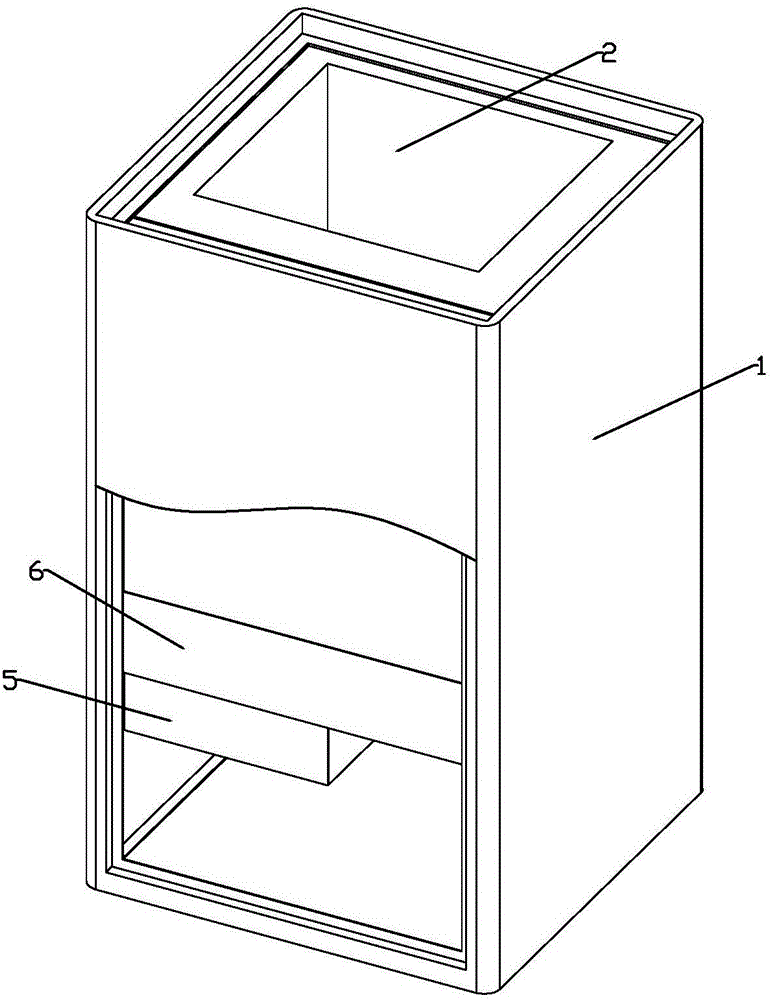

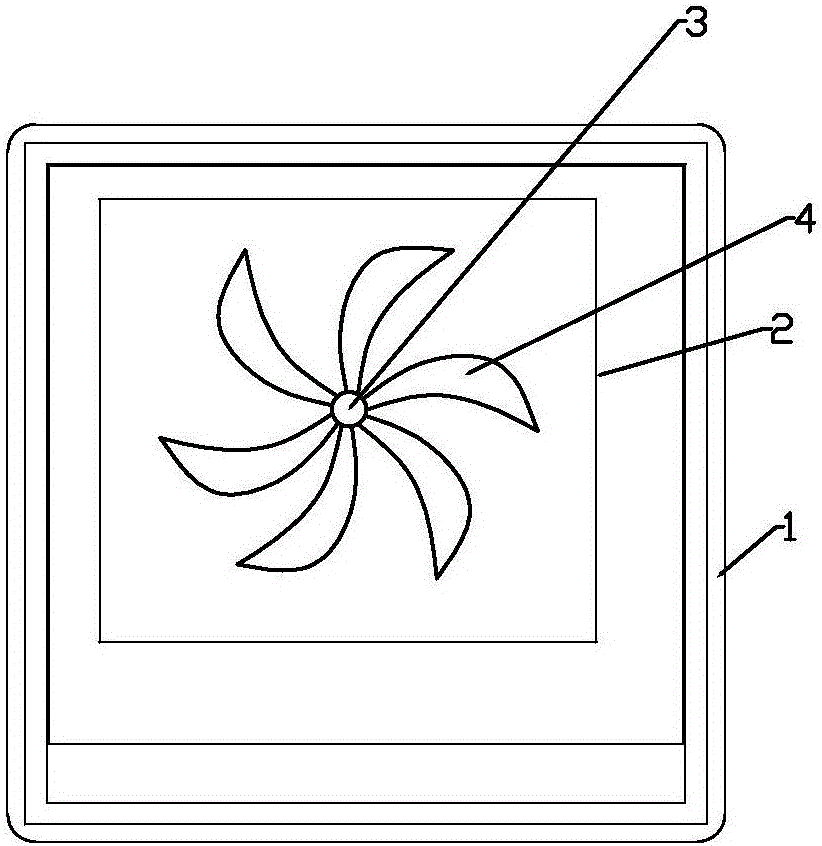

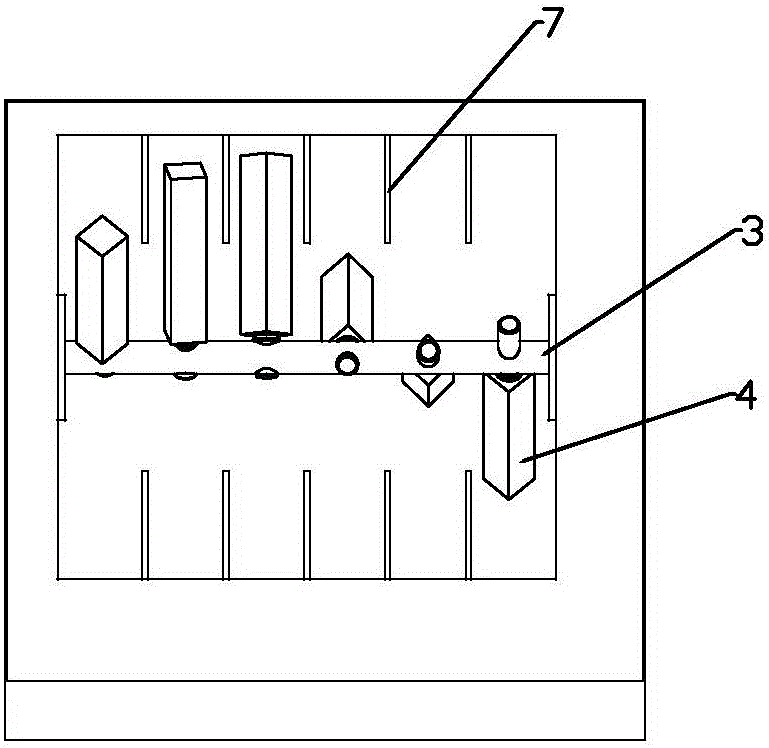

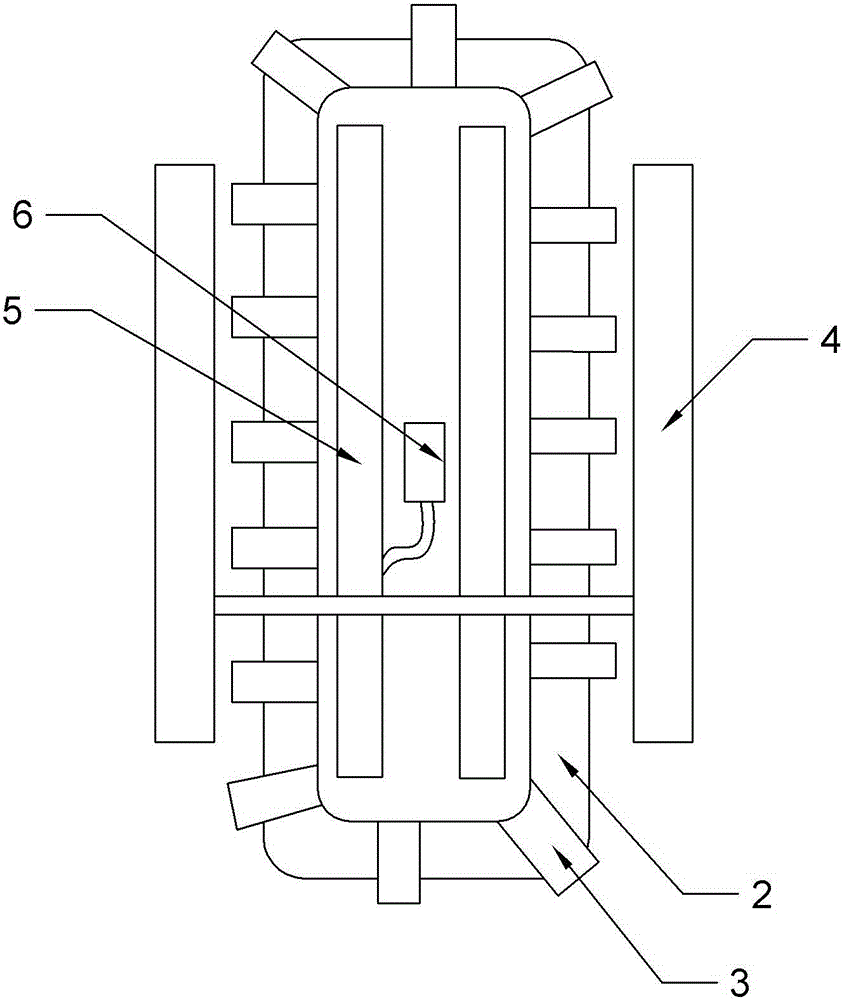

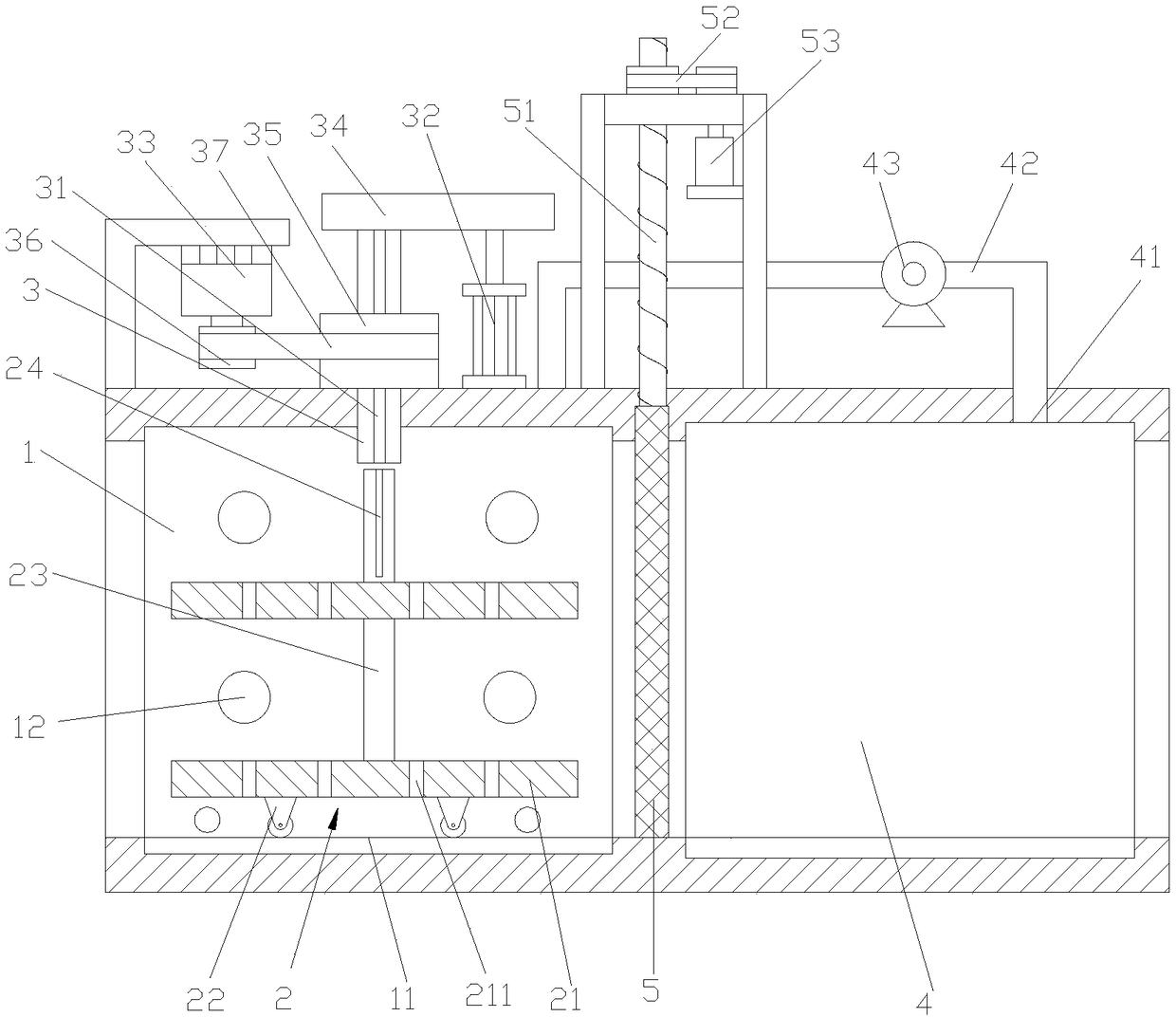

Kitchen waste smashing, stirring and fermenting device

InactiveCN105948833ASimple structureReduce volumeClimate change adaptationChemical industryLitterBiochemical engineering

The invention provides a kitchen waste smashing, stirring and fermenting device which comprises a shell, a stirring bin, a stirring linkage shaft, a smashing cutter, a motor and a heating device. One end of the shell is closed, one end of the shell is open, the stirring bin is arranged in the shell, and the smashing cutter is disposed on the stirring linkage shaft. At least one end of the stirring linkage shaft is fixedly installed on the inner wall of the stirring bin and connected with an output shaft of the motor, the heating device is arranged on the outer wall of the stirring bin, and the motor is arranged between the shell and the stirring bin. The device integrates the smashing function, the stirring function and the fermenting function, is simple in structure, small in size, convenient to use, capable of being placed in a home to ferment kitchen waste and good in smashing and fermenting effect, fermentation broth can serve as fertilizer, and the environment-protecting and energy-saving functions are achieved.

Owner:姜红成 +1

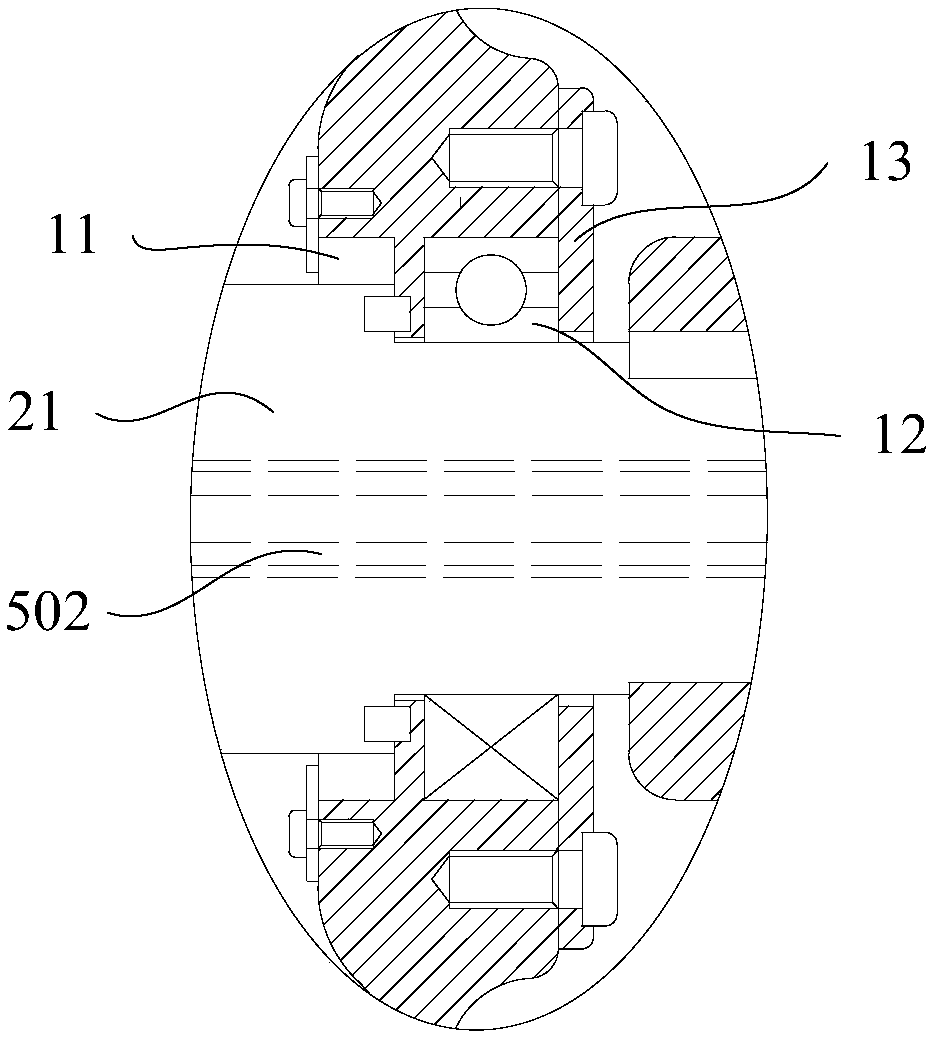

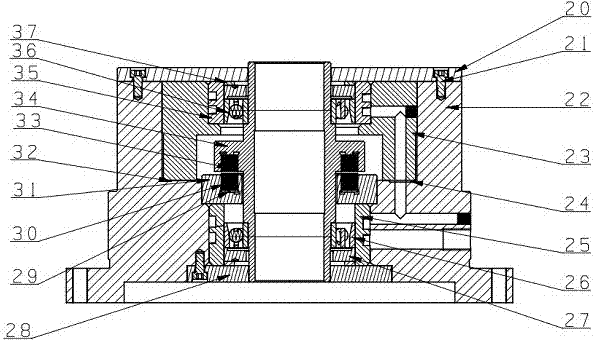

Vertical permanent-magnet suspension waste-heat power generator

InactiveCN107023328AProminent realityTake advantage ofMagnetic circuit rotating partsMachines/enginesImpellerEngineering

The invention relates to a vertical permanent-magnet suspension waste-heat power generator which comprises a power generator outer shell, an expander volute, a power generator impeller, a power generator rotating shaft, a stator system, a rotor system, an upper bearing part and a lower bearing part, wherein the expander volute is mounted on the power generator outer shell; the power generator impeller is connected with a power generator rotating shaft; the power generator rotating shaft is connected with a power generator rotor arranged in the rotor system, and supported by the upper bearing part and the lower bearing part; the upper bearing part and the lower bearing part are fixed on the power generator outer shell; a power generator stator arranged in the stator system is fixed on the power generator outer shell; an air gap is formed between the power generator stator and the power generator rotor; and high-temperature steam of waste-heat resources is absorbed by the expander volute, the power generator impeller is pushed to rotate, and then the vertical permanent-magnet suspension waste-heat power generator is driven to generate power. The vertical permanent-magnet suspension waste-heat power generator provided by the invention is reasonable in design, compact in structure and reliable in running; by utilization of the permanent-magnet suspension bearings which are free from oil lubrication, little in abrasion, long in life, and capable of running at high rotating speed, the supporting function is achieved; the vertical permanent-magnet suspension waste-heat power generator is cooled by adopting a cooling water injection mode; the waste-heat resources in a factory can be sufficiently utilized; the environmentally-friendly and energy-saving effects are achieved; and the market application prospect is broad.

Owner:SHANGHAI UNIV

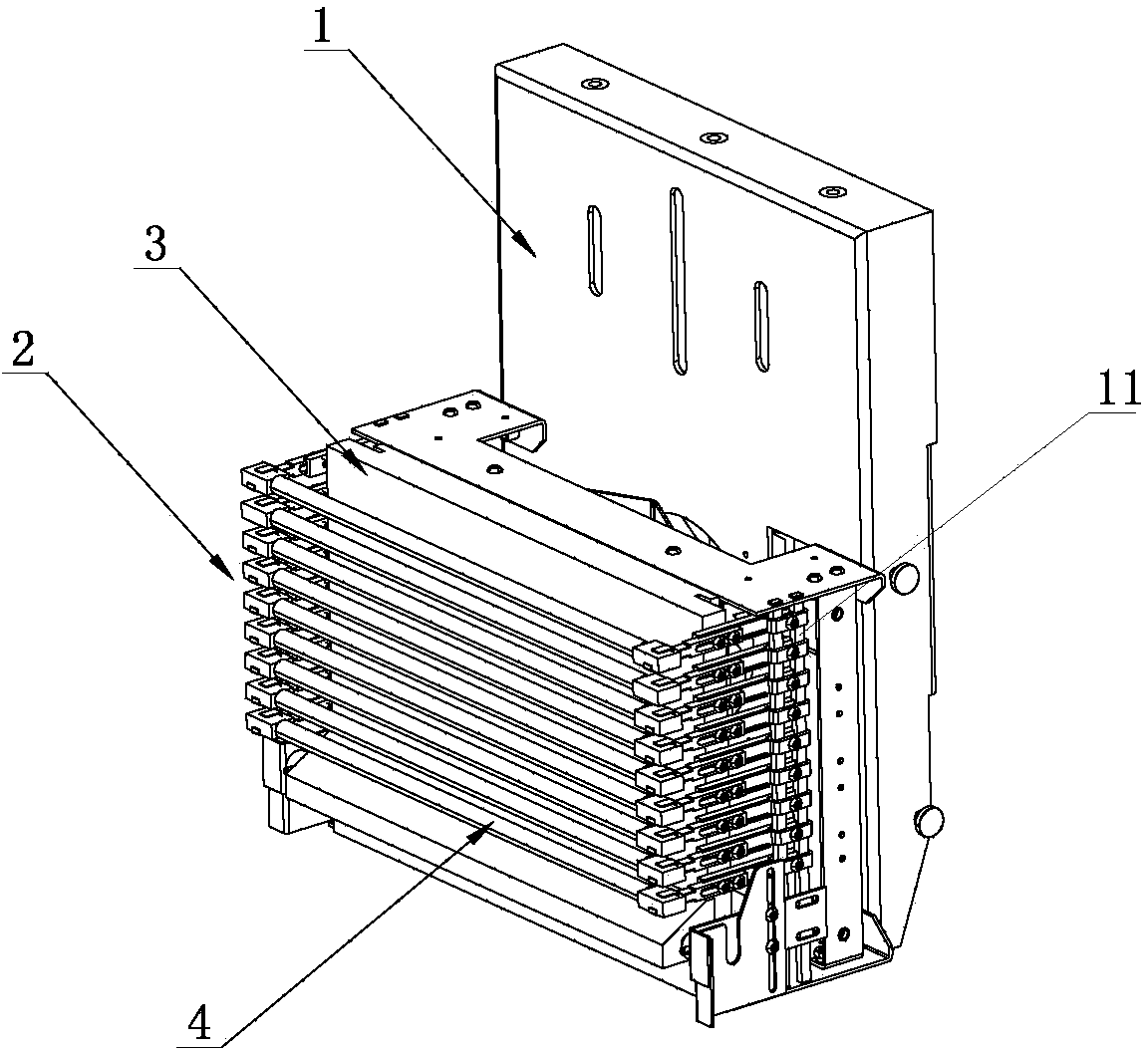

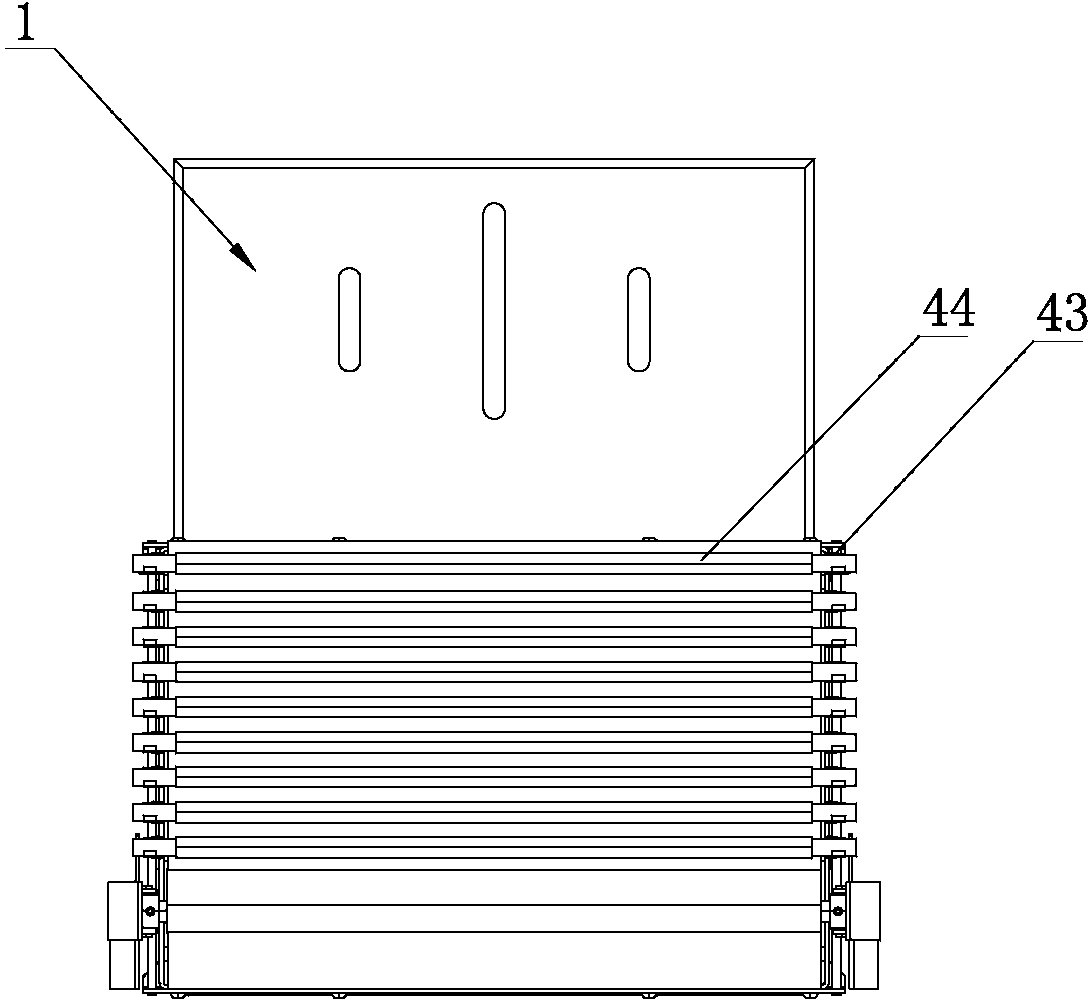

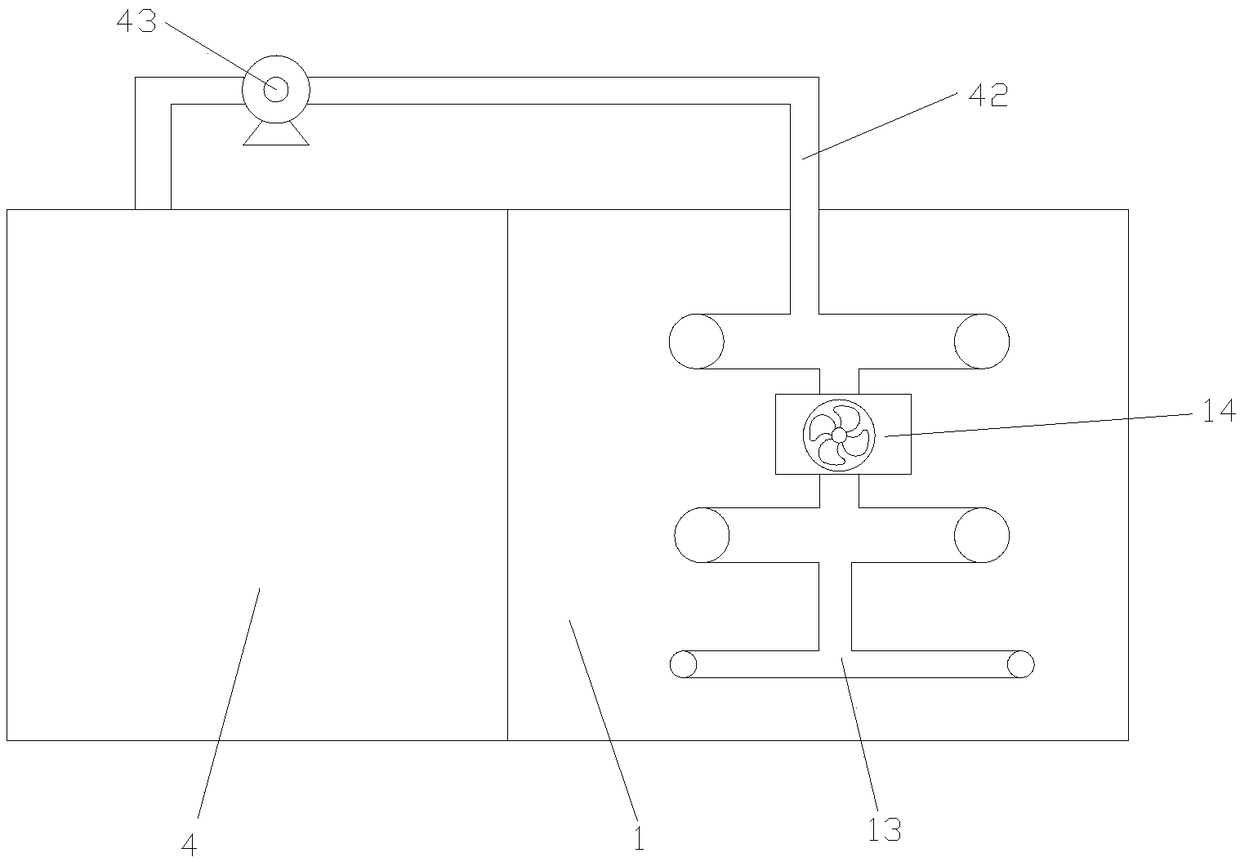

Bottle blank heater

The invention relates to the field of blow molding heating, in particular to a bottle blank heater. The bottle blank heater comprises a case. An operating console is arranged in the horizontal direction of the case and provided with a bottle blank supporting seat. Transmission of the bottle blank supporting seat is achieved through a transmission chain and the transmission chain is of an annular structure. Heating devices are arranged in the case and located on the two sides of the bottle blank supporting seat. A reflection board is arranged in the annular transmission chain. A temperature sensor is connected to the end of the reflection board. An automatic controller and a draught fan are arranged on the case. The temperature sensor, the automatic controller and the draught fan are electrically connected. Due to the arrangement of the temperature sensor and the draught fan, the temperature inside the case is distributed evenly and the bottle blank heating quality is improved.

Owner:CHONGQING DEWEN HONEYSUCKLE PLANTATIONS

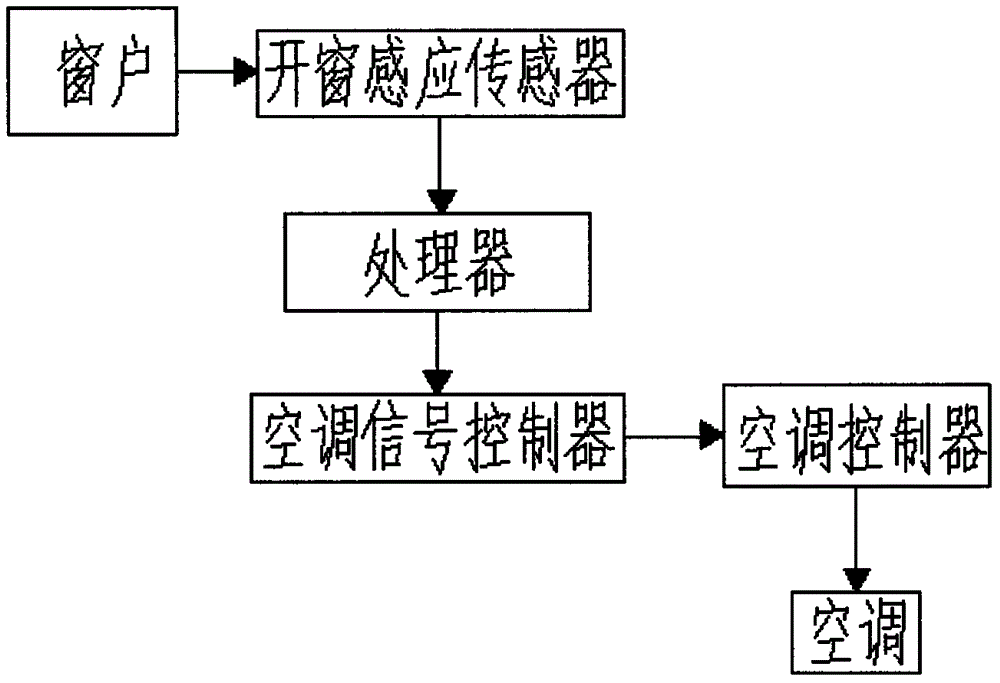

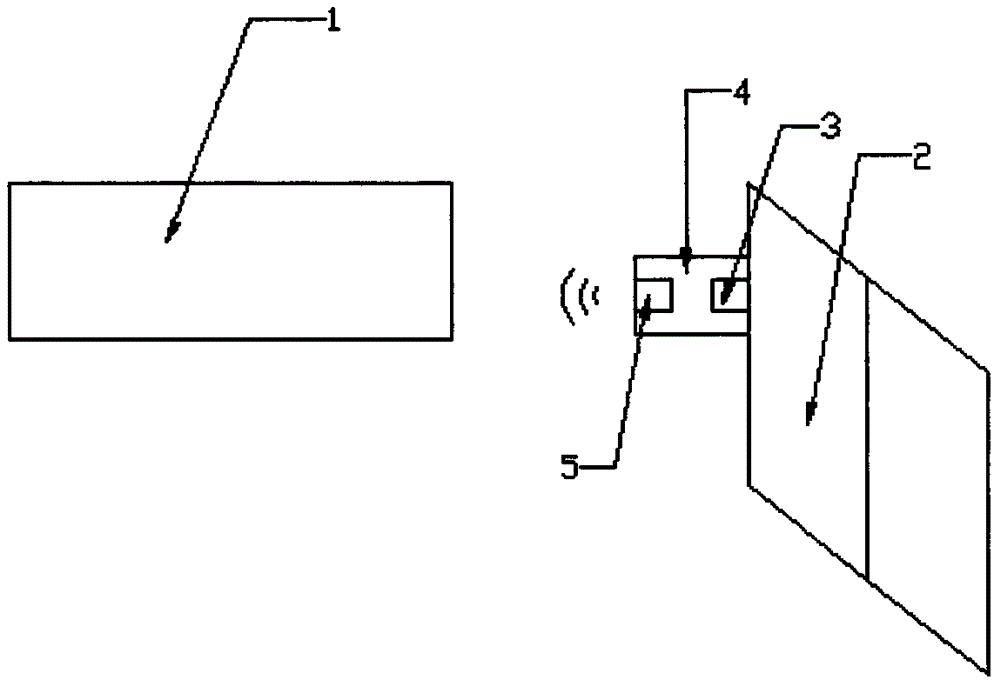

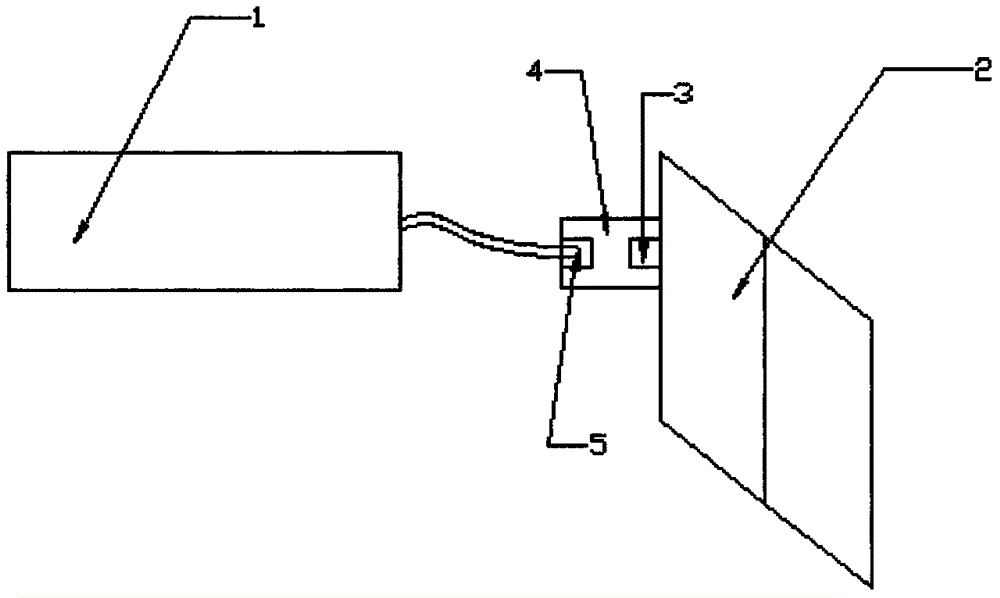

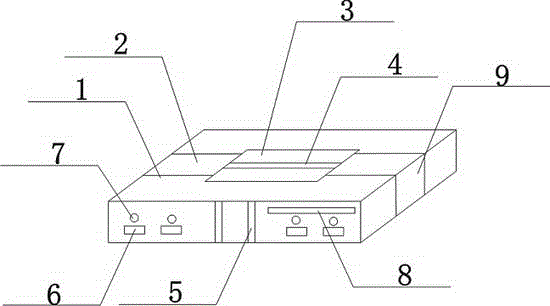

Window opening induction air conditioner control switch

InactiveCN106288252AThere are various ways to realizeRealize automatic sensingMechanical apparatusSpace heating and ventilation safety systemsElectricityWindow opening

The invention discloses a window opening induction air conditioner control switch. According to the technical scheme, a window, an air conditioner and an air conditioner controller which is installed on the air conditioner and used for controlling the air conditioner to be started or stopped are included. The window opening induction air conditioner control switch is characterized in that the control switch is connected to the window and comprises a window opening induction sensor, a processor and an air conditioner signal controller, wherein the window opening induction sensor is used for inducting the position of the window; the processor is electrically connected to the window opening induction sensor and processes and judges the opening-closing state of the window by receiving an induction signal of the window opening induction sensor; and the air conditioner signal controller is electrically connected to the processor, and according to the judgment result, the processor controls the air conditioner signal controller to send a starting or stopping order to the air conditioner controller so that the air conditioner can be controlled to be started or stopped. The window opening induction air conditioner control switch is suitable for the interiors of hospital wards and other occasions and sites; and when the air conditioner operates and the window is opened, the air conditioner can be stopped through the control switch, and unnecessary waste is avoided.

Owner:宁波市安基尔电子科技有限公司

Solar charging device

InactiveCN104821616AReduce sizeEasy to carryBatteries circuit arrangementsPhotovoltaicsElectricitySolar cell

The invention discloses a solar charging device which comprises a charger housing. The charger housing has a waterproof structure. Portions which are next to two side surfaces on the surface of the charger housing are respectively provided with a USB input interface and a USB output interface. The port at one end of the USB input interface and the port at one end of the USB output interface are electrically connected with a solar cell panel. The solar cell panel is arranged between the USB input interface and the USB output interface. The charger housing is provided with a recessed trough which matches the solar cell panel. The solar cell panel is arranged in the recessed trough. The surface of the solar cell panel is provided with a snapping device which has a reversed U-shaped structure. Two ends of the snapping device are arranged at two side surfaces of the solar cell panel. Furthermore the open end of the snapping device is snapped in the charger housing. The solar charging device can repeatedly charge infinitely and has the advantages of small size, convenient carrying and good compatibility. The solar charging device is suitable for charging different kinds of mobile phone or digital products. Furthermore the solar charging device can perform environment-friendly and energy-saving functions and has high waterproof performance.

Owner:CHENGDU LYUDI TECH

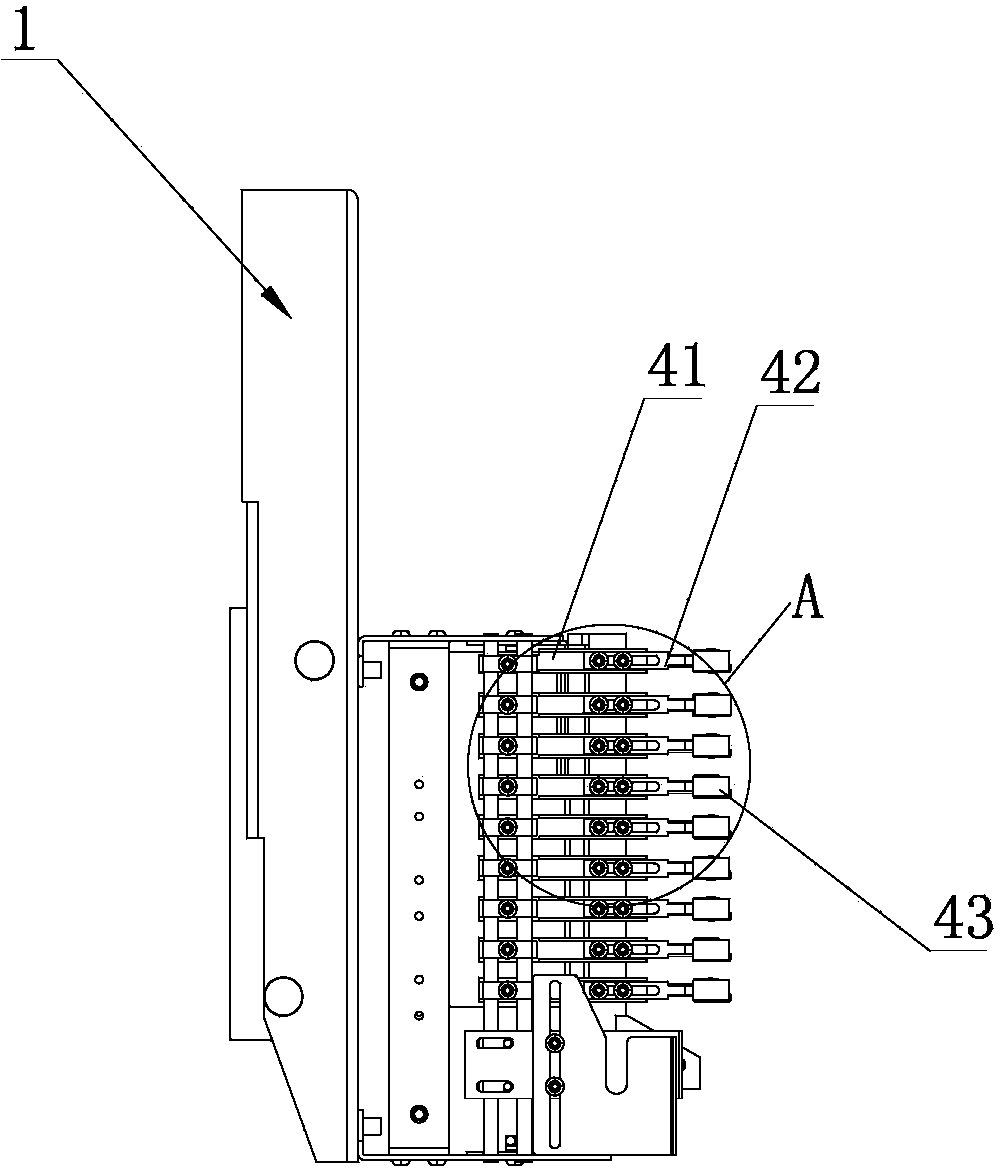

Improved heating lamp box for blow molding machine

The invention relates to the technical field of a heating device for a blow molding machine, and in particular relates to an improved heating lamp box for a blow molding machine. The improved heating lamp box comprises a lamp box frame; a heating device is arranged at the front end of the lamp box frame; a heat insulation plate is arranged between the heating device and the lamp box frame; the heating device consists of a plurality of heating components; each heating component comprises a longitudinal adjusting terminal, a transverse adjusting terminal and a heating lamp tube; the longitudinal adjusting terminals are connected with the front end of the lamp box frame in a longitudinal sliding way; the transverse adjusting terminals are connected with the front ends of the longitudinal adjusting terminals in a transverse sliding way; the front ends of the transverse adjusting terminals are connected with lamp tube clamps; the heating lamp tubes are arranged in the lamp tube clamps. Longitudinal distance adjustment and transverse distance adjustment are realized by the longitudinal adjusting terminals and the transverse adjusting terminals respectively, so that the distances between the heating lamp tubes and plastic bottle blanks can be adjusted, and the distances among the heating lamp tubes also can be adjusted; therefore, the heating quality of the plastic bottle blanks can be improved, the plastic bottle blanks are evenly heated, and the blow molding quality of the plastic bottle blanks can be improved.

Owner:李伟宏

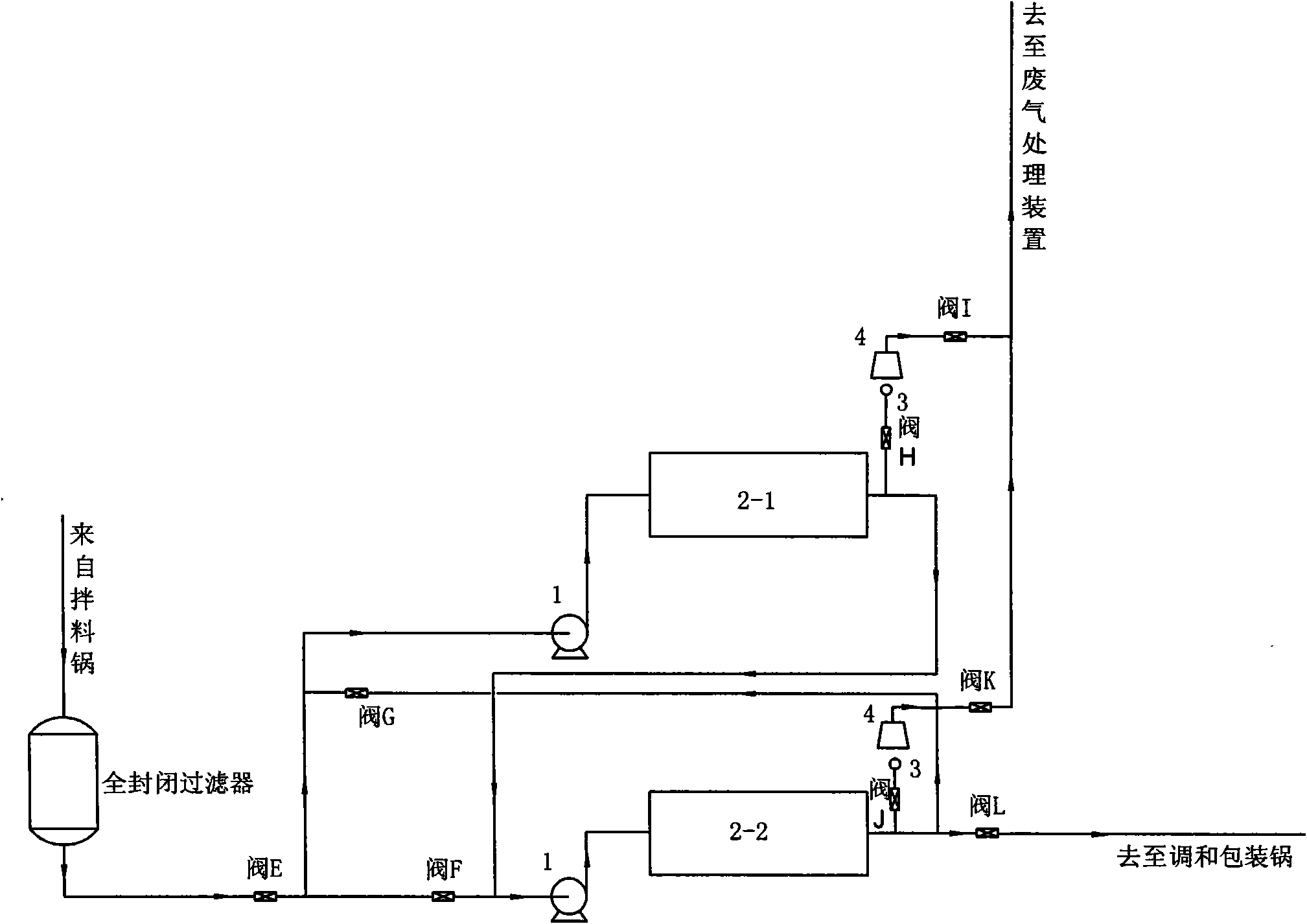

Totally-closed sand grinding technology for coating production

InactiveCN101554608ASolving problems arising from fugitive emissionsFully enclosedDirt cleaningGrain treatmentsEnvironmental resistanceDiaphragm pump

The invention discloses a totally-closed sand grinding technology for coating production, which comprises the steps: pigment paste which is primarily filtered by a totally-closed filter is conveyed to a horizontal sand grinding unit for sand grinding by the power provided by a pneumatic diaphragm pump on a sand grinding machine; after the fineness is detected by a fineness monitoring port to be qualified, the pigment paste directly flows into a blending and packaging pot under the gravity action through a transporting pipe; the fineness monitoring port is provided with a waste gas collecting cover; the waste gas collecting cover is opened when the fineness monitoring port is opened; and the waste gas generated in the production process is all collected for centralized processing. The technology greatly improves the working atmosphere and the work intensity, and cancels the unsealed middle paint cylinder which is arranged between the horizontal sand grinding machine and the blending and packaging pot and considered to be irreplaceable by the industry peer in the coating production; all the unsealed parts such as flow guiding and adding port of the centrifugal pump realize totally closing, thus solving the problem of inorganized emission of organic solvent from the root; and the clean power of the pneumatic diaphragm pump is adopted to play the roles of environmental protection and energy saving, therefore, the technology is a new production technology for the upgrading of the coating industry.

Owner:NINGBO FEILUN PAINT MFG

Electric silicon oil clutch water pump

ActiveCN101435362BHigh driving torqueDrive torque savingCoolant flow controlMachines/enginesElectricityInterior space

Owner:WARNER SHENGLONG NINGBO CO LTD

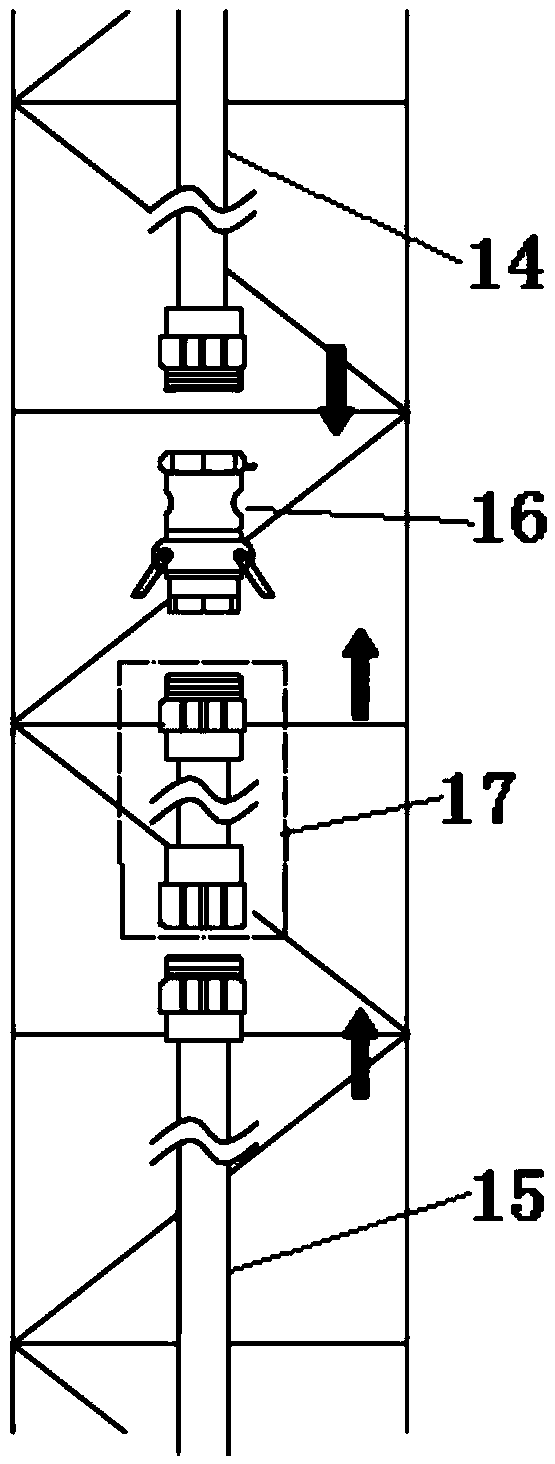

A tower crane spraying device with automatic control function

ActiveCN104179144BEasy to installEasy to useUsing liquid separation agentRoad cleaningAutomatic controlEngineering

The invention provides a tower crane spraying device having an automatic control function. The tower crane spraying device comprises, at least, a base, a tower crane frame, a balancing arm and a hoisting arm, wherein the balancing arm and the hoisting arm are horizontally connected onto the tower crane frame, a vertical pipe is arranged on the tower crane frame, a horizontal water supply pipe is arranged on the hoisting arm, and spraying heads are evenly distributed on the horizontal water supply pipe. The horizontal water supply pipe and the vertical pipe are connected through a rotating connector. A control box and a water pump are arranged on the vertical pipe, the control box is located on the base, a flow meter, a water pressure gauge and a controller are arranged in the control box, and a flow control knob, a time control knob and a water pressure control knob are arranged on the controller. The shortcomings in the prior art are overcome, and the tower crane spraying device is simple in structure, convenient to install and use and capable of automatically controlling the spraying time and water volume.

Owner:WUHAN CUIYU ENVIRONMENTAL TECH

Rapid drying device for wooden plates

InactiveCN109357504AAchieve spin dryingSave time at workDrying gas arrangementsDrying chambers/containersCooling chamberPulp and paper industry

The invention discloses a rapid drying device for wooden plates, and relates to a rapid drying device for wooden plates. The rapid drying device for wooden plates comprises a drying chamber and a cooling chamber, wherein a conveying belt are arranged in the drying chamber and the cooling chamber in a communicated mode, a drying rack is arranged on the conveying belt, the drying rack comprises at least two layers of drying plates, at least two universal wheels are arranged on the bottom surface of the drying plates of the bottom layer, and the adjacent drying plates are connected through a stand column; a hot air inlet is formed in the upper side and the lower side of the drying chamber in the drying chamber, a hot air pipe is connected to the hot air inlet, and a hot air blower is arrangedon the hot air pipe; and a hot air outlet is formed in the cooling chamber, an air suction pipe is connected to the hot air outlet, an air suction fan is arranged on the air suction pipe, and the other end of the air suction pipe is in communication with the hot air pipe. The rapid drying device has the advantages that the working efficiency is improved, the drying effect is enhanced, the environment is protected and the energy is saved.

Owner:湖州南浔登越家居有限公司

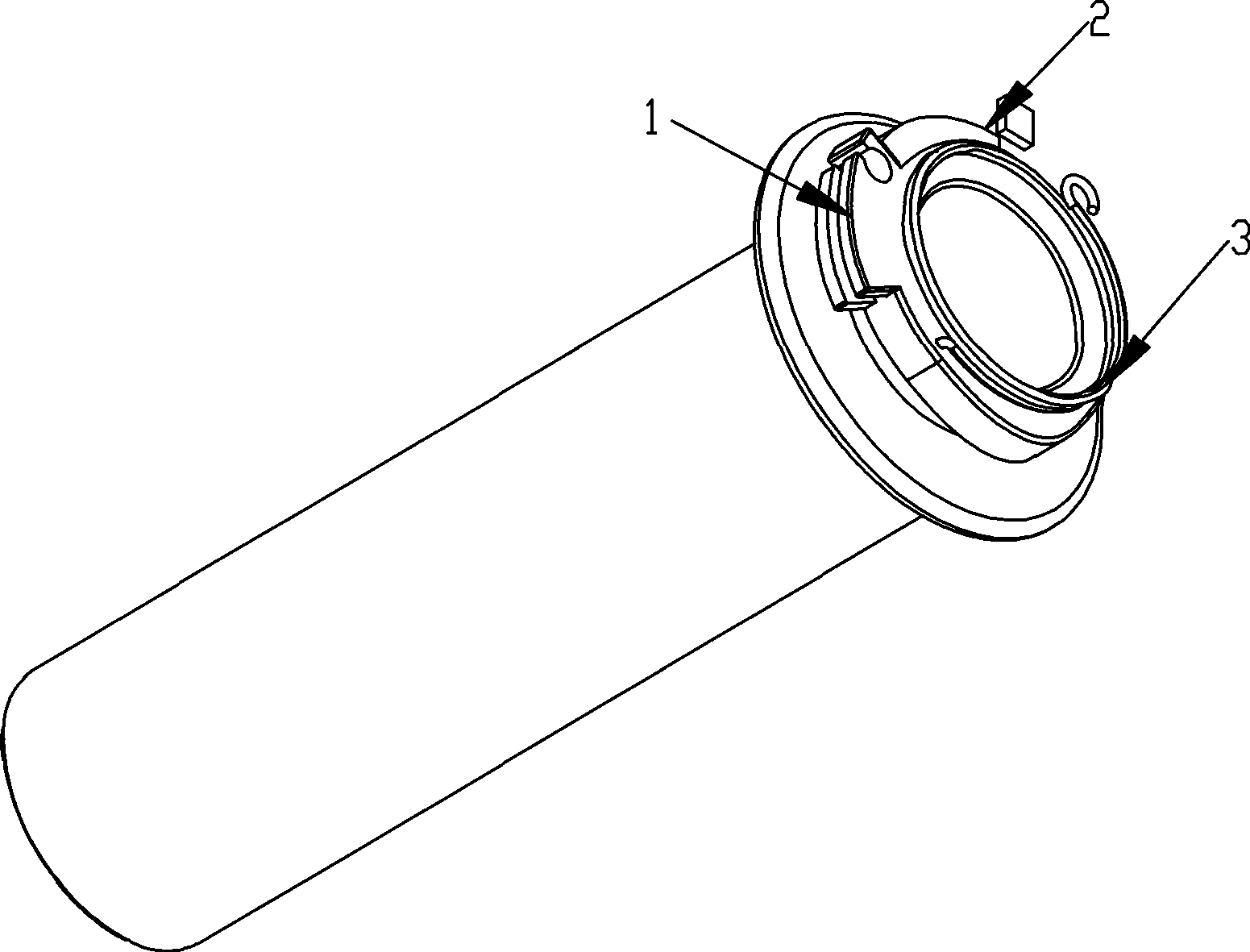

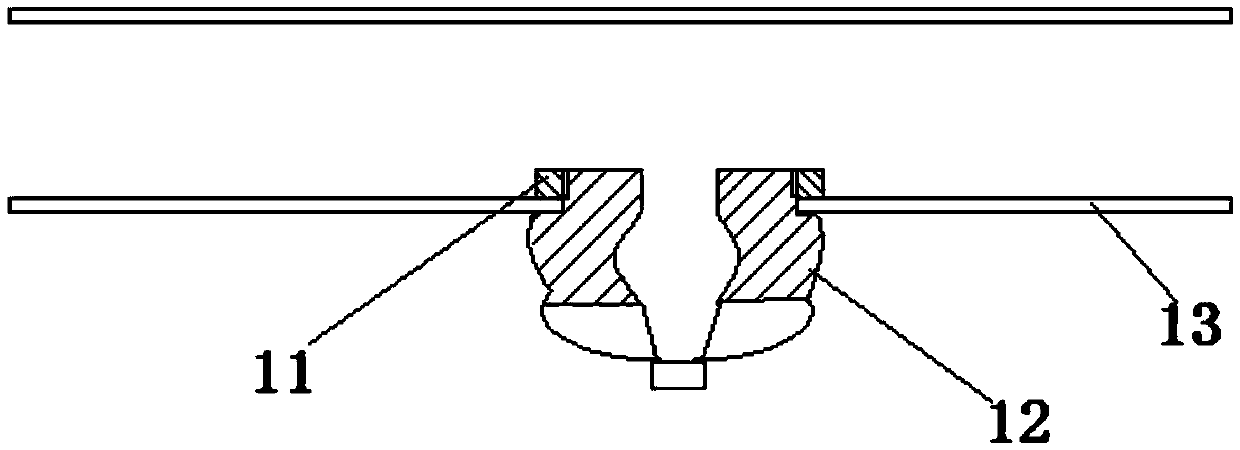

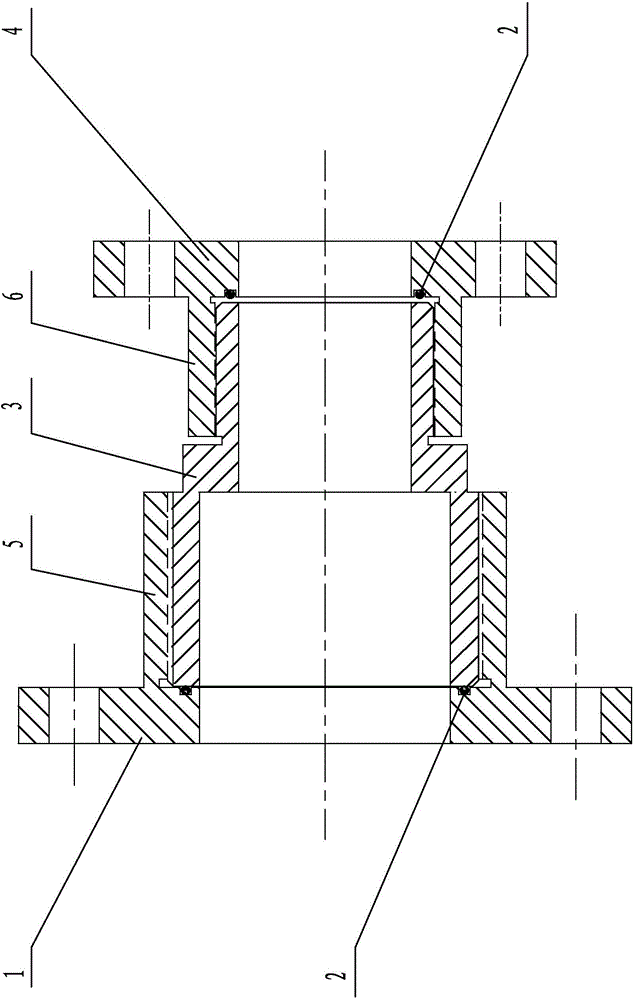

Changeable flange joint

InactiveCN103953808AEasy to install on siteMeet reliable connectionFlanged jointsThreaded pipeFlange

The invention discloses a changeable flange joint. The changeable flange joint comprises a large flange plate and a small flange plate with different diameters and a dual-head threaded pipe joint connected with the large flange plate and the small flange plate; the diameters of threads at two ends of the dual-head threaded pipe joint are different; a large diameter threaded pipe capable of being screwed with the large diameter threaded end of the dual-head threaded pipe joint is coaxially arranged at the bottom end of the large flange plate; a small diameter threaded pipe capable of being screwed with the small diameter threaded end of the dual-head threaded pipe joint is coaxially arranged at the bottom end of the small flange plate; sealing slots are formed between two ends of the dual-head threaded pipe joint and the bottom ends of the large flange plate and the small flange plate; seal rings are arranged in the sealing slots. Two pipelines of different standards can be connected, and the connection need of the pipelines of multiple different specifications can be met by replacing different flange plates.

Owner:NO 6 CONSTR CO OF CHINA PETROLEUM & NATURAL GAS CORP

Totally closed production technology of paints

InactiveCN101538426BSolve the problems caused by emissionsFully enclosedChemical industryCoatingsEnvironmental resistanceOrganic solvent

A totally closed production technology of paints selects a gravity and pneumatic-driving membrane pump to transmit power, different paint fineness requires the serial arrangement of different numbers of horizontal grinders for grinding, the paint fineness is qualified by the one-time grinding of the horizontal grinders, paint viscosity is qualified by detection, the paint flows into a fully closed filtering packaging machine at a first layer under the action of gravity, and the discharged material is weighed and packaged after filtering. A waste gas collecting hood is not only arranged at a fineness monitoring port, but also at a material-mixing position, a blending packaging pot and the fully closed filtering packaging machine, thus collecting waste gases generated in the whole procedurefor centralized processing, greatly improving working environment and labor intensity, canceling all opening parts such as an opening intermediate paint cylinder, a flow conducting and adding port ofa centrifugal pump and the like between the horizontal grinder and the blending packaging pot in the traditional production technology of the paint which is considered to be irreplaceable by persons in the same field, realizing full closing, fundamentally solving the problem of disorganized discharging in production of organic solvents, having the functions of protecting the environment and saving energy by adopting a clean-power pneumatic-driving membrane pump, and being the newly updated production technology in the paint industry.

Owner:袁泉利

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240BImprove qualityIncrease bulkCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramSulfate

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

Vanadium-titanium nodular cast iron smelting method

The invention discloses a vanadium-titanium nodular cast iron smelting method which comprises the steps of weighing furnace burden, smelting, spheroidizing and inoculating, wherein the smelting step comprises the sub-steps: adding oxide scale of which the addition amount is 0.5-1.5 percent of the weight of the furnace burden, and adding the oxide scale at the bottom of the furnace burden during smelting and charging; in the smelting step, after the furnace burden is molten down, adding silicon iron into molten iron for regulating the components, so as to achieve the deoxidation effect. The method has the beneficial effects that the low-price oxide scale is added into the bottom of the furnace burden during charging, and the element Ti is oxidized preferentially, so that the titanium content is reduced, the inverse spheroidizing effect of titanium is weakened, nodularizing in vanadium-titanium ductile iron is guaranteed, and a good dephosphorization effect is achieved when the oxide scale is added during smelting; the oxide scale is wide in source and low in price, the oxide scale is reasonably utilized, the production cost can be reduced, and the environment-friendly energy-saving effects are achieved. According to the method, the process is simple, the operation is convenient and the cost is low, and the comprehensive performance of the vanadium-titanium nodular cast iron is guaranteed.

Owner:XIHUA UNIV

Energy-saving work table under the mine

ActiveCN109469307BReduce the burden onEasy to foldBuilding scaffoldsStructural engineeringIndustrial engineering

Owner:嘉兴华维新能源有限公司

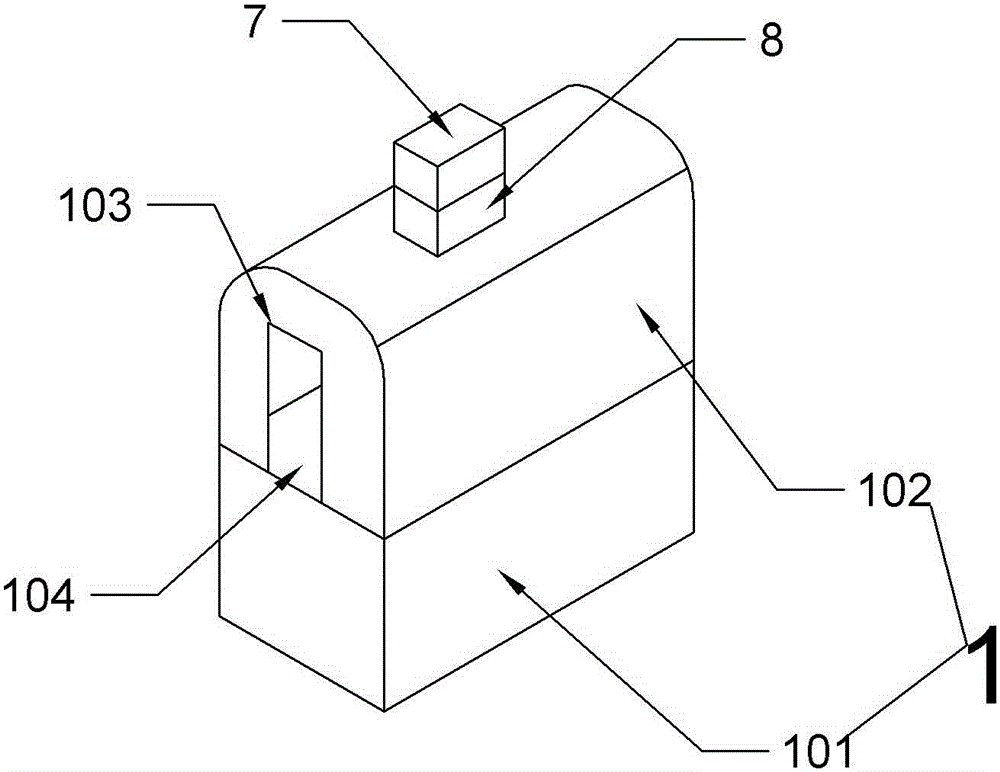

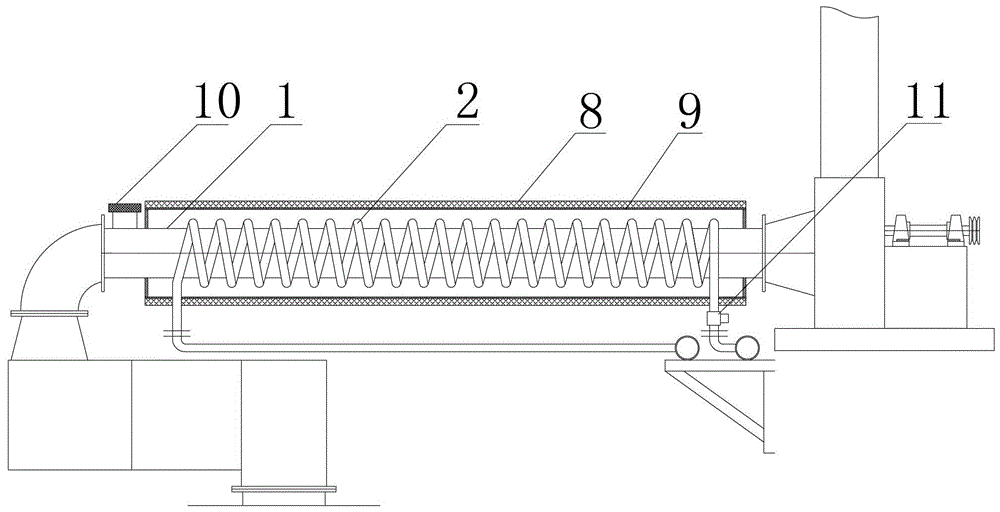

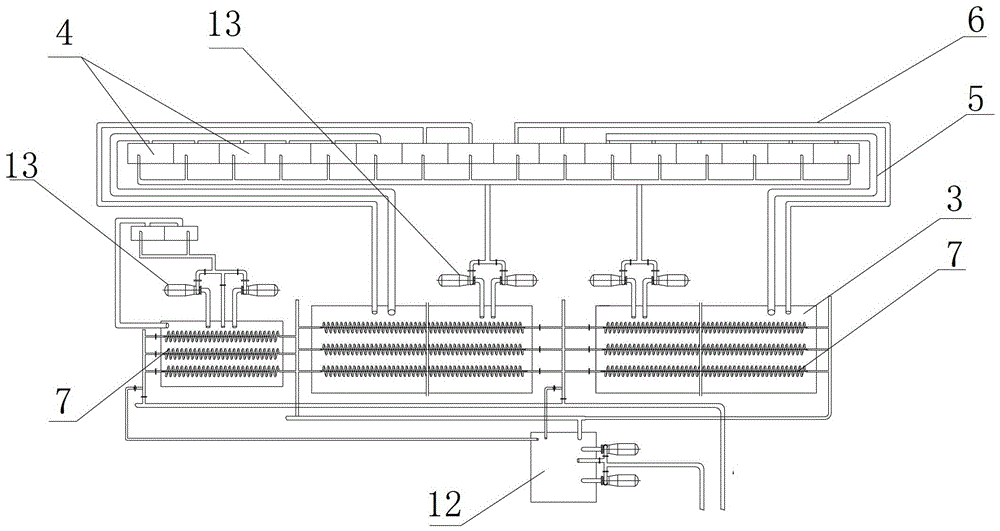

An automatic temperature control device for waste heat recovery and centralized heating of bath liquid

InactiveCN104062988BPlay the role of environmental protection and energy savingTemperature control without auxillary powerTemperature controlTemperature difference

Disclosed is an automatic temperature control device for waste heat recycle and bath solution concentrated heating. The automatic temperature control device includes a waste heat acquisition device and an automatic temperature controlling device connected with the waste heat acquisition device. The waste heat acquisition device includes a hot wind channel and a spring coil pipe which winds the periphery surface of the hot wind channel. The automatic temperature controlling device includes a plurality mutually communicated heat exchanging water tanks and coating baths. The coating baths are in loop connection with the heat exchanging water tanks through bath solution inlet pipes and bath solution outlet pipes. A plurality of heat exchanging coil pipes which are in mutual communication are arranged in the heat exchanging water tanks. The heat exchanging coil pipes are in communication with the spring coil pipe of the waste heat acquisition device. The automatic temperature control device recycles waste heat generated by exhaust gases discharged by other devices (waste heat which is not recycled is discharged externally through gas ducts) so that an environment protection role is played; and water is used as a conduction medium and a temperature difference not larger than 60 DEG C is used to heat the bath solution so that harmful effects because of overly high local temperature of the bath solution are not caused.

Owner:金华市大田线材有限公司

Natural environment-friendly cleaning suite for kitchen ware cleaning and application method thereof

InactiveCN111842247AEasy to distribute and carryEasy to plan and controlCleaning using toolsCleaning using liquidsSea saltSodium bicarbonate

The invention discloses a natural environment-friendly cleaning suite for kitchen ware cleaning and an application method thereof. The natural environment-friendly cleaning suite for kitchen ware cleaning comprises a suite A, a suite B and a suite C, and is characterized in that the suite A comprises natural towel gourd ladle cleaning cloth, lemon powder cleaning capsules and sodium bicarbonate cleaning capsules; the suite B comprises natural towel gourd ladle cleaning cloth, bamboo salt cleaning capsules and sodium bicarbonate cleaning capsules; and the suite C comprises natural towel gourd ladle cleaning cloth, sea salt cleaning capsules and sodium bicarbonate cleaning capsules. According to the natural environment-friendly cleaning suite, the towel gourd ladle cleaning cloth is cut to serve as a packaging material; the cleaning capsules are placed in cuts of the towel gourd ladle cleaning cloth, the packaging material is saved, and the environmental protection and energy conservation effects are achieved; the packaging material belongs to a 100% pure natural renewable raw material which is safe and environment-friendly; and meanwhile, the natural environment-friendly cleaning suite has the effects of being convenient to distribute and carry, is quite suitable for single persons and families with fewer family members, and can also be used as a lunch box and used on occasionssuch as canteens.

Owner:苏州惠炫清洁科技有限公司

Totally-closed sand grinding technology for coating production

InactiveCN101554608BSolving problems arising from fugitive emissionsFully enclosedDirt cleaningGrain treatmentsDiaphragm pumpOrganic solvent

The invention discloses a totally-closed sand grinding technology for coating production, which comprises the steps: pigment paste which is primarily filtered by a totally-closed filter is conveyed toa horizontal sand grinding unit for sand grinding by the power provided by a pneumatic diaphragm pump on a sand grinding machine; after the fineness is detected by a fineness monitoring port to be qualified, the pigment paste directly flows into a blending and packaging pot under the gravity action through a transporting pipe; the fineness monitoring port is provided with a waste gas collecting cover; the waste gas collecting cover is opened when the fineness monitoring port is opened; and the waste gas generated in the production process is all collected for centralized processing. The technology greatly improves the working atmosphere and the work intensity, and cancels the unsealed middle paint cylinder which is arranged between the horizontal sand grinding machine and the blending andpackaging pot and considered to be irreplaceable by the industry peer in the coating production; all the unsealed parts such as flow guiding and adding port of the centrifugal pump realize totally closing, thus solving the problem of inorganized emission of organic solvent from the root; and the clean power of the pneumatic diaphragm pump is adopted to play the roles of environmental protection and energy saving, therefore, the technology is a new production technology for the upgrading of the coating industry.

Owner:NINGBO FEILUN PAINT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com