Kitchen waste smashing, stirring and fermenting device

A technology for stirring fermentation and kitchen waste, which is applied in the fields of organic fertilizer, sustainable manufacturing/processing, climate change adaptation, etc. It can solve the problems of waste collection, transportation and treatment, blockage of oily sewage drainage pipes, and difficult treatment, and achieve crushing And good fermentation effect, simple structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

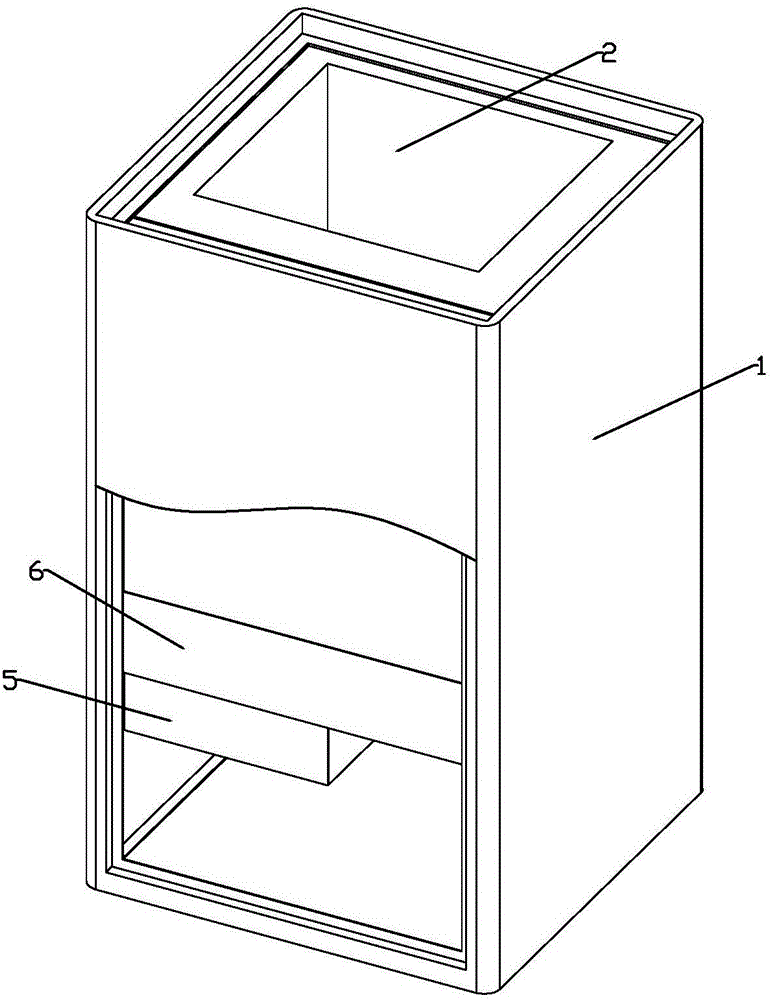

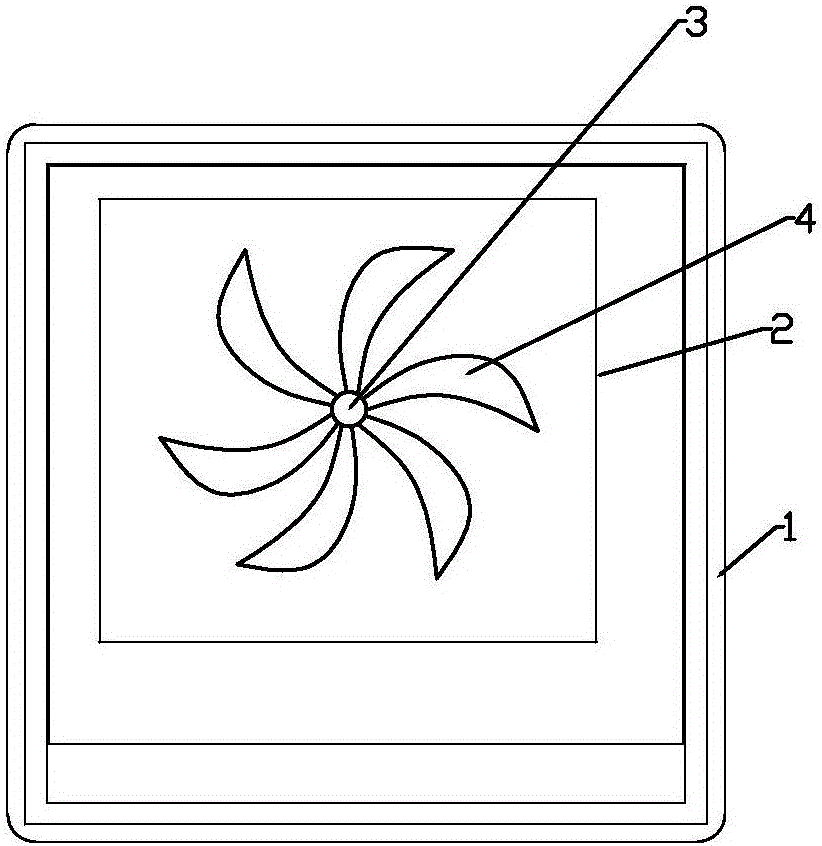

[0021] A kitchen waste crushing and stirring fermentation device, such as figure 1 and figure 2 As shown, it includes a shell 1 with one end closed and one end open, a stirring bin 2 located in the shell 1, a stirring linkage shaft 3, a crushing cutter 4 arranged on the stirring linkage shaft 3, a motor 5 and a heating device 6, the stirring linkage shaft At least one end of 3 is fixedly installed on the inner wall of the stirring bin 2, which is connected with the output shaft of the motor 5, the heating device 6 is arranged on the outer wall of the stirring bin 2, and the motor 5 is arranged on the outer wall of the stirring bin 2. Between the shell 1 and the mixing chamber 2.

[0022] Pour the kitchen waste into the mixing bin 2, start the food waste crushing and stirring fermentation device, the motor 5 drives the stirring linkage shaft 3, and the crushing knife 4 on the stirring linkage shaft 3 crushes the kitchen waste into fine particles, and at the same time puts in ...

Embodiment 2

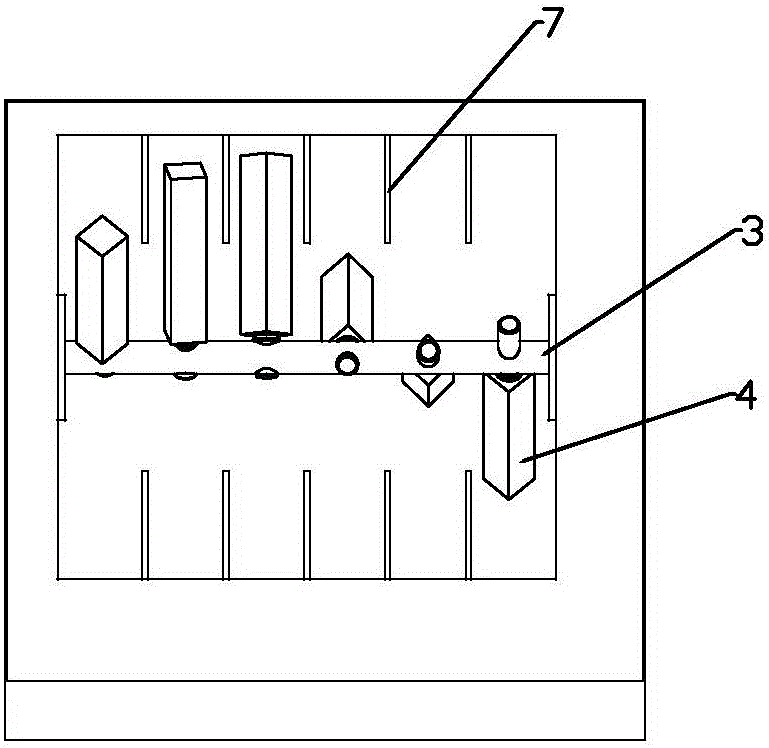

[0024] A kitchen waste crushing and stirring fermentation device, such as image 3 As shown, the difference from Example 1 is that: the two ends of the stirring linkage shaft 3 are respectively fixedly installed on the opposite inner walls of the stirring chamber 2, and the pulverizing cutters 4 are several pieces that are spirally installed on the stirring linkage shaft 3. A cuboid metal block with the same size and shape, the surface of the cuboid metal block is provided with several protrusions consistent with the axial direction of the stirring linkage shaft 3, which are fixed on the stirring linkage shaft 3 by screws, and the stirring linkage Auxiliary knives 7 are respectively installed on the inner walls of the mixing chamber 2 corresponding to both sides of the shaft 3. The auxiliary knives 7 are respectively composed of a number of metal plates with the same size and shape, which are arranged in parallel and evenly. The edges of the metal plates are serrated. The thic...

Embodiment 3

[0028] A kitchen waste crushing and stirring fermentation device, such as Figure 4 As shown, the difference from Example 2 is that an upper cover 8 is installed on the open end of the housing 1, the heating device 6 is a far-infrared heater, and the device also includes a deodorizing device 9, and the deodorizing device 9 9 Installed between the shell 1 and the mixing chamber 2, it is composed of a fan, an activated carbon filter layer, a honeycomb ceramic layer with a catalyst inside, an air inlet and an air outlet, and the air inlet is set on the inner wall of the mixing chamber 2 The air outlet is arranged on the outer wall of the housing 1 .

[0029] Installing the upper cover 8 at the top opening of the housing 1 is not only beneficial to the fermentation of the kitchen waste particles, but also prevents the indoor environment from being polluted by the kitchen waste and the gas generated by the fermentation of the kitchen waste. Harmful and odorous gases produced durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com