Patents

Literature

42results about How to "Reduce temperature drop rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

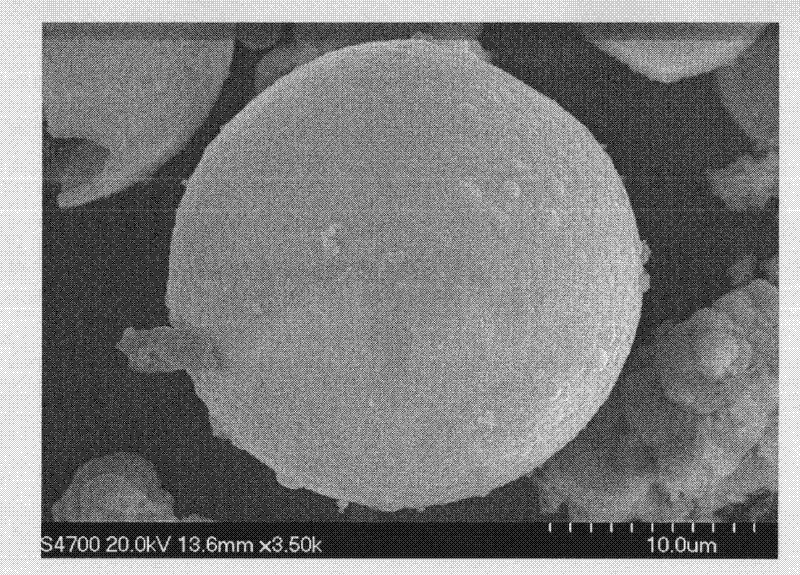

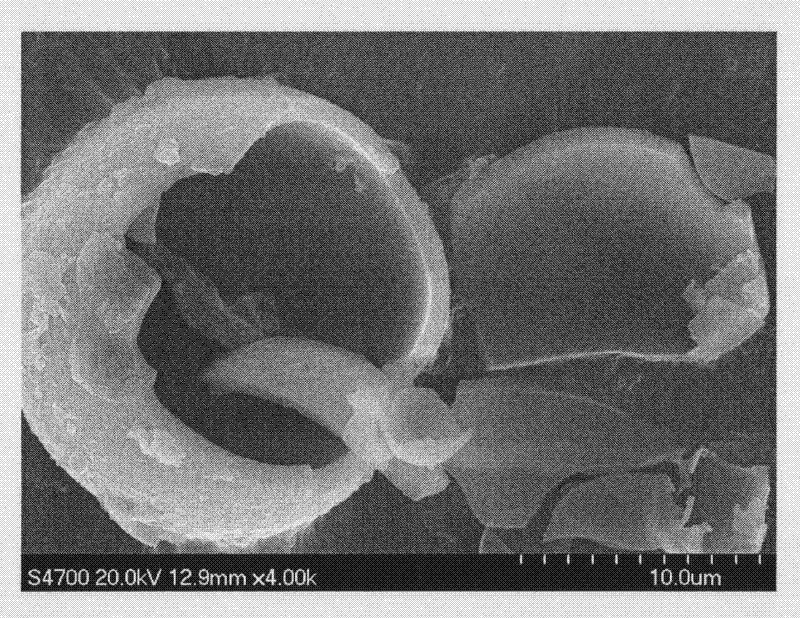

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

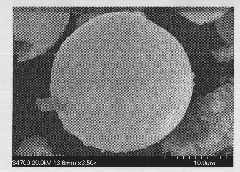

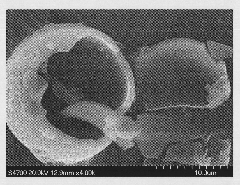

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Concrete

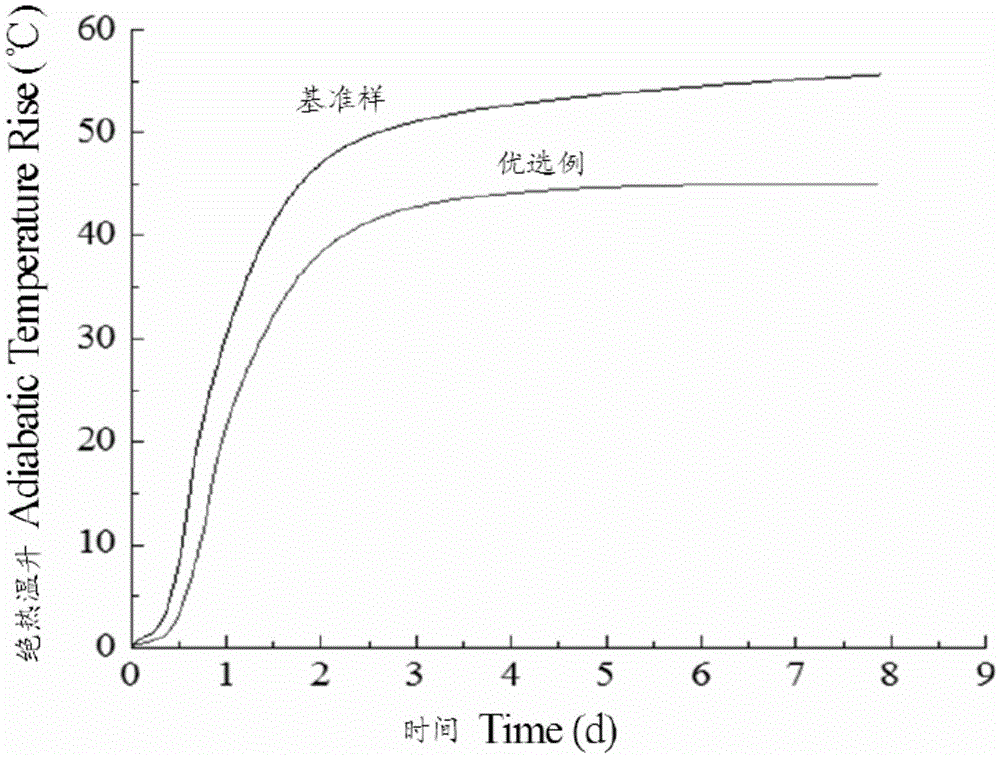

InactiveCN105645866AReduced risk of crackingReduce heat of hydrationCrack resistanceFineness modulus

The invention discloses concrete. The concrete is prepared from the following components of ordinary Portland cement, a mineral admixture, a water reducing agent, medium sand, broken stones, an anti-cracking silicone waterproof agent (FQY) and water, wherein the mineral admixture is prepared from pulverized fuel ash and granulated blast-furnace slag; the fineness modulus of the medium sand is 2.3 to 2.9, and the broken stones are continuous graded broken stone particles of which the particle size is 5 to 25 mm. The novel concrete disclosed by the invention has higher performance index on aspects of crack resistance, leakage prevention, working performance and durability.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

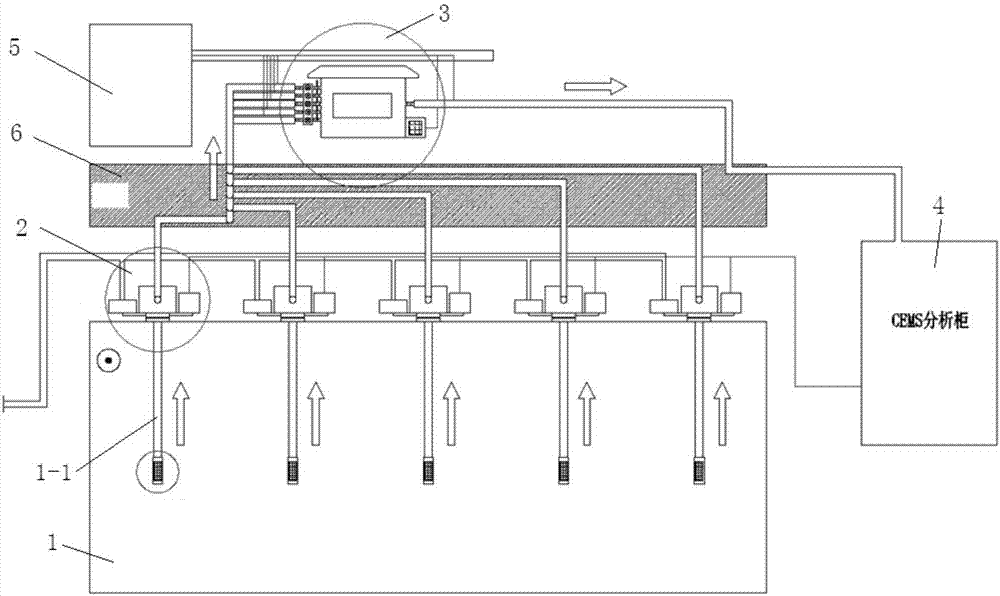

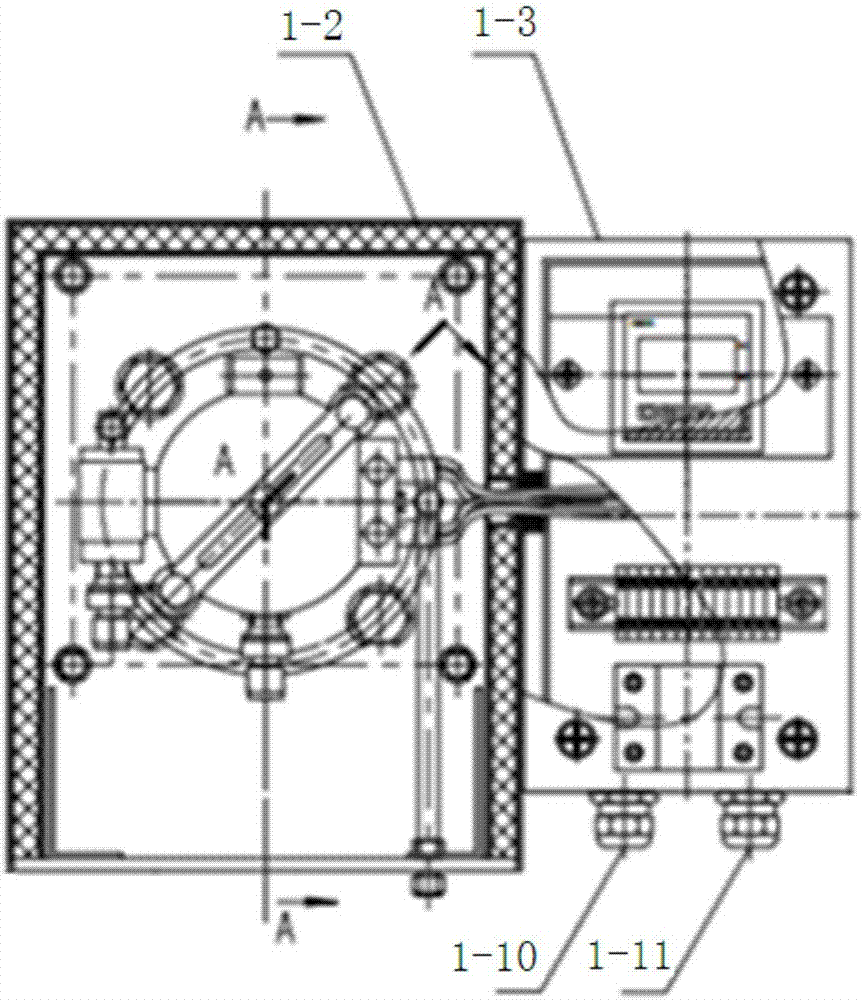

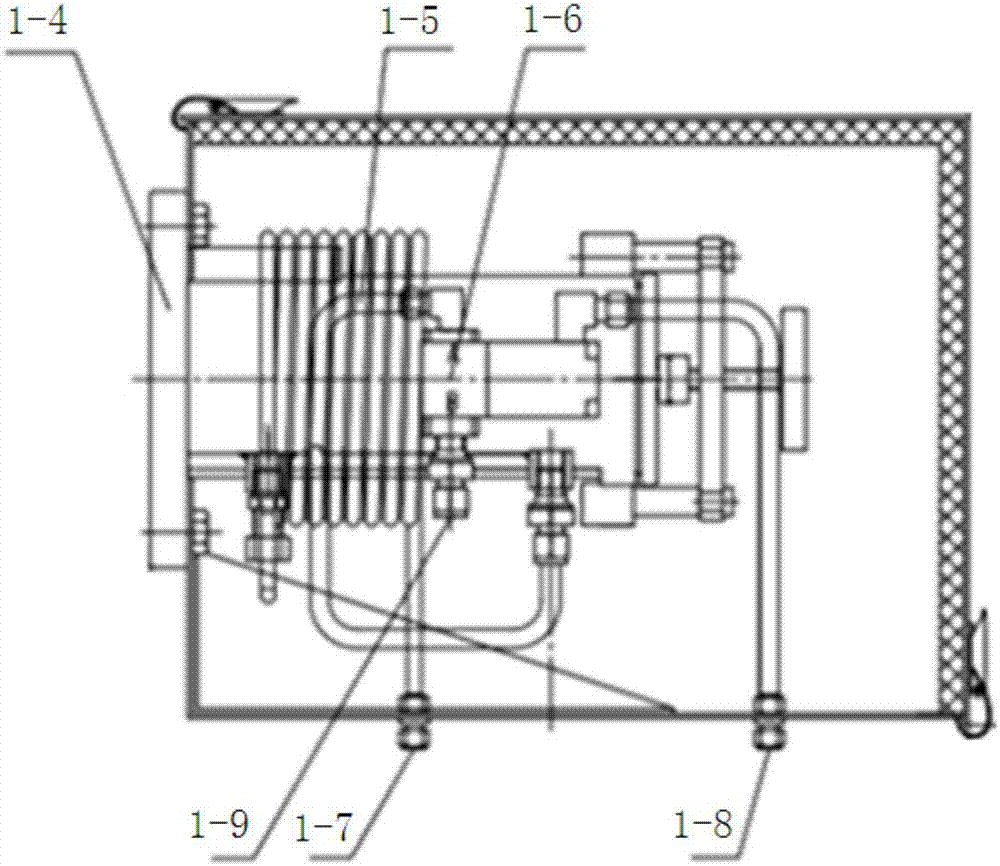

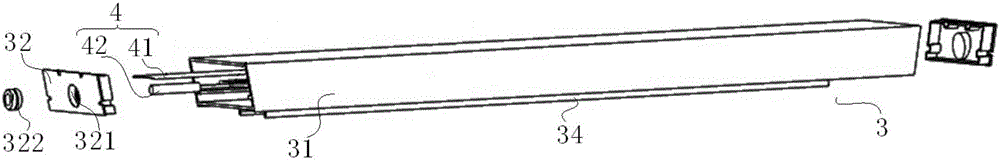

Gaseous pollutant multi-point matrix mixed sampling device, sampling method thereof and reverse blowing maintenance method

ActiveCN107421790ASolve the problem of unrepresentative samplingMixed average concentration is reasonableWithdrawing sample devicesAir quality improvementFlue gasFiltration

The invention discloses a gaseous pollutant multi-point matrix mixed sampling device, a sampling method thereof and a reverse blowing maintenance method. The device comprises a flue gas duct, a plurality of high-temperature sampling probes are uniformly arranged on the outer side of the pipe wall of the flue gas duct along the same section of a pipe, gaseous pollutants are conveyed into a rear-end mixing box by a 180-DEG C high-temperature heat tracing pipe, mixed and then conveyed into an analysis cabinet. The sampling device solves the problems that single-point flue gas sampling is non-representative, a sampling section of an existing sampling device is blocked by dust, and sampling of a sampling end does not meet standards. According to the whole multi-point matrix mixed sampling device, each probe is individually filtered, two-stage filtration is performed, namely, a front feeler lever is provided with a sintered metal filtering screen, middle high-temperature sampling probes are provided with sintered ceramic filter elements, and dust in flue gas is further prevented from entering the pipe.

Owner:NANJING YOUZHI TECH CO LTD

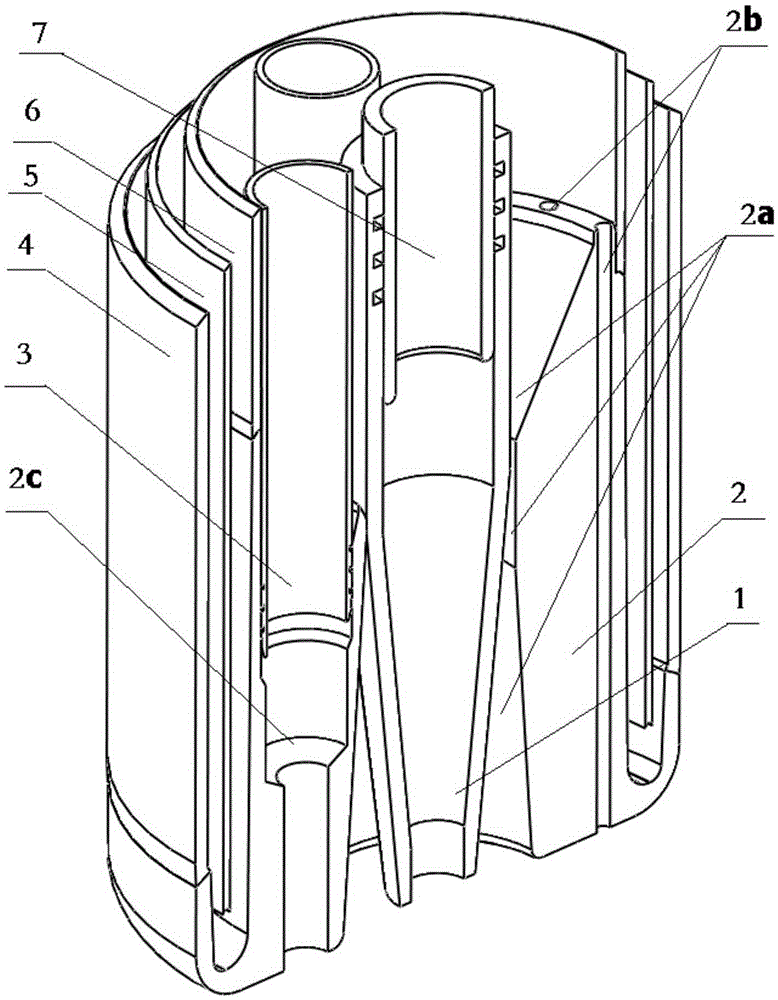

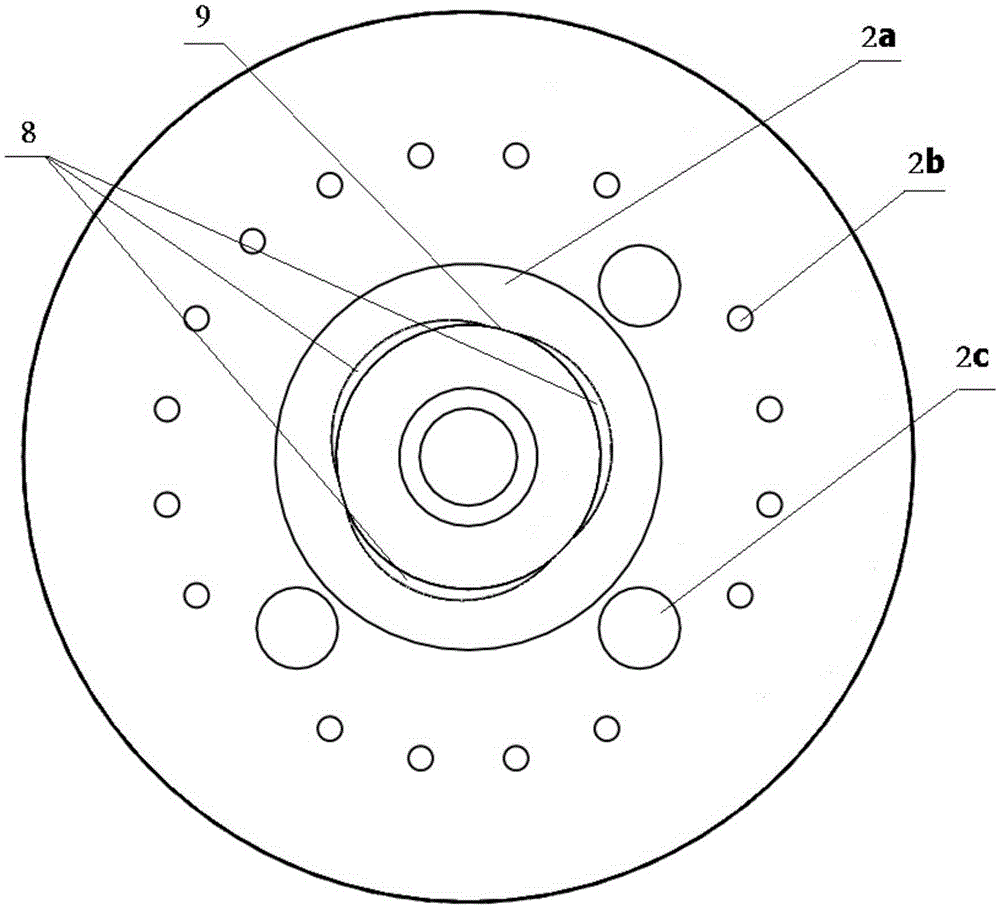

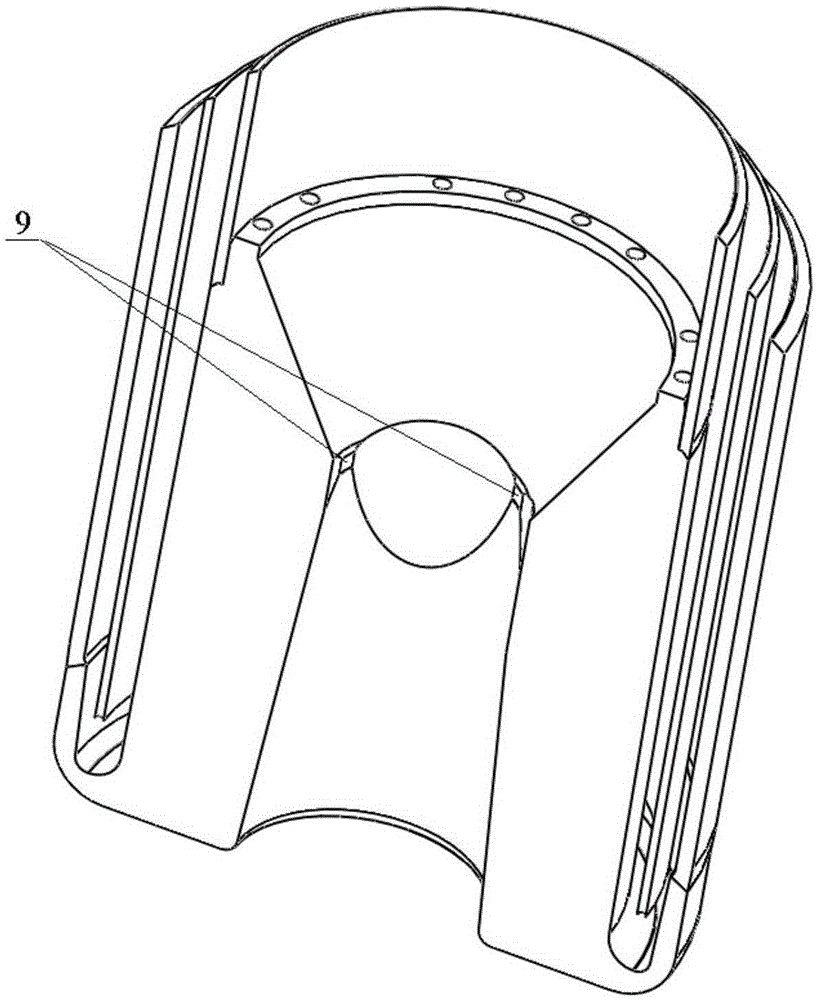

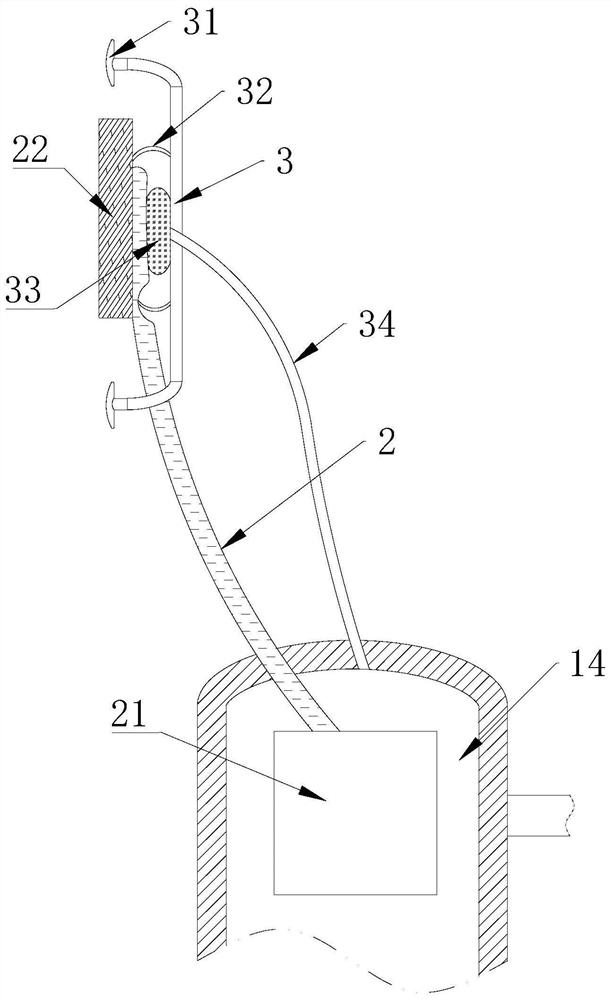

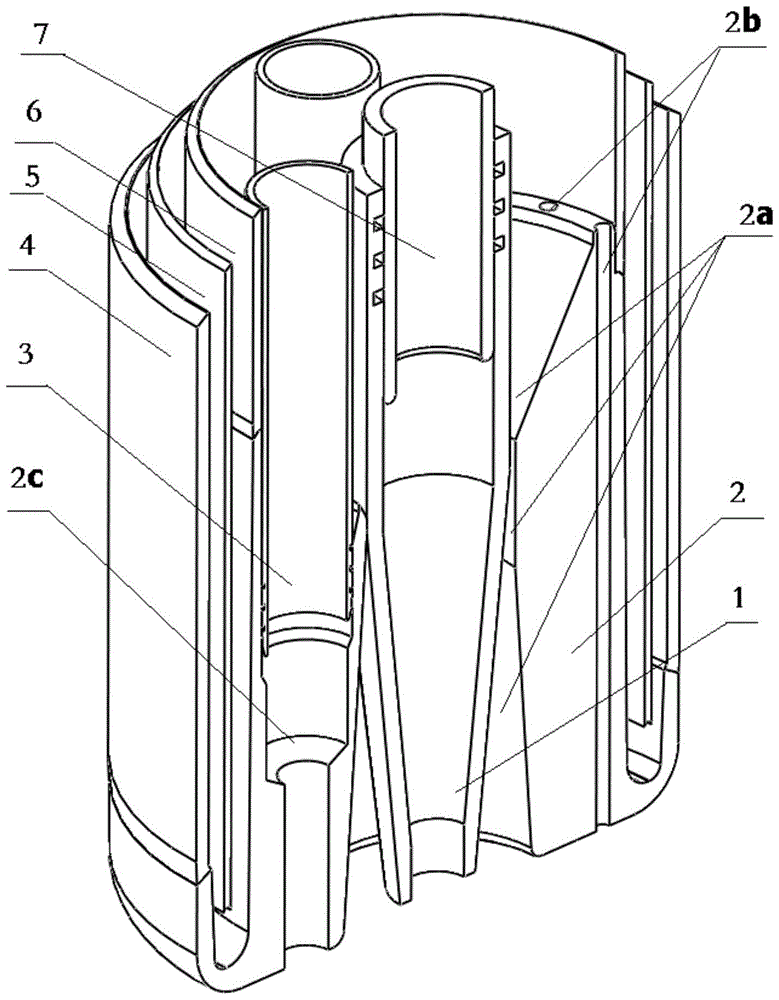

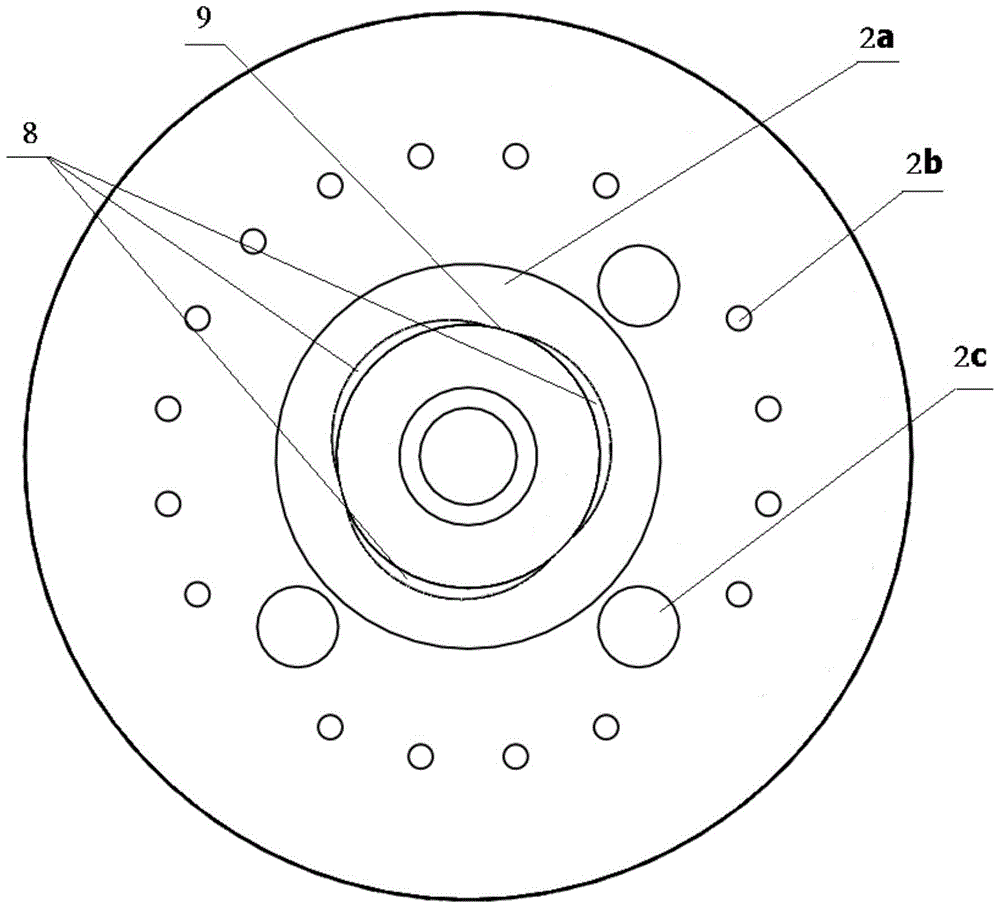

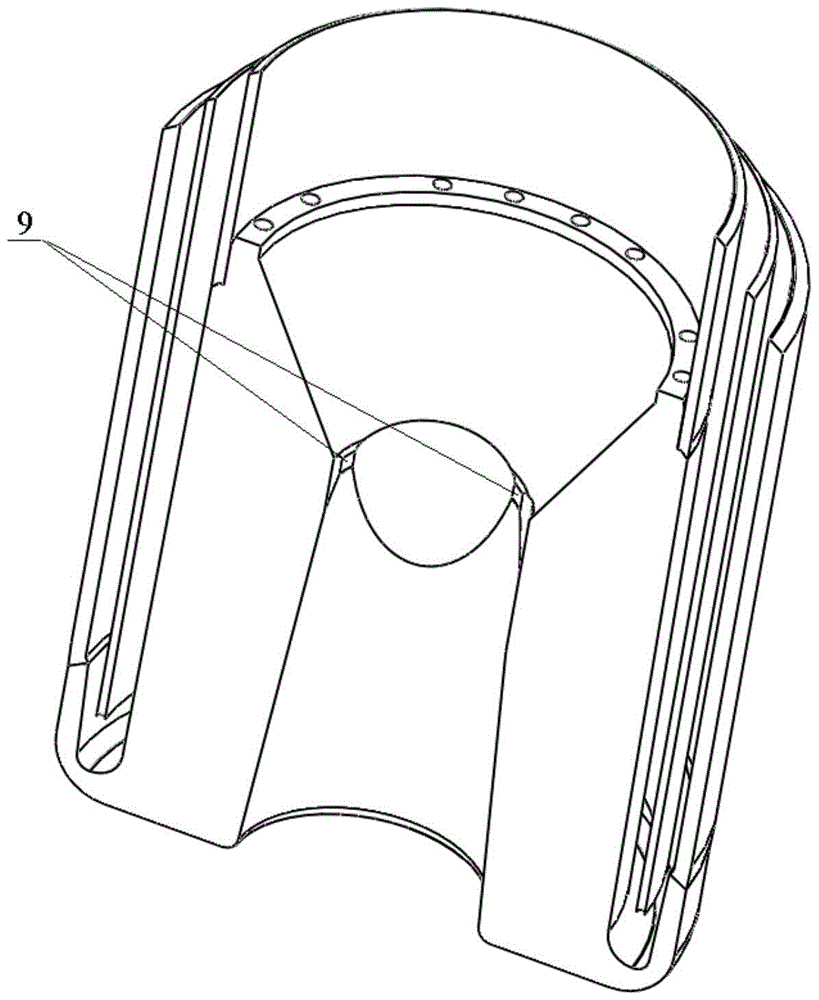

High-lance-position vacuum refining method based on coherent jet top lance

The invention provides a high-lance-position vacuum refining method based on a coherent jet top lance. The coherent jet top lance is provided with a powder passage located at the center, a main oxygen passage located on the periphery of the powder passage and an auxiliary oxygen passage located on the periphery of the main oxygen passage; and during RH vacuum refining, oxygen enters from the main oxygen passage and the auxiliary oxygen passage to form a main oxygen flow and an auxiliary oxygen flow respectively, powder is injected into molten steel together with the main oxygen flow under the sweeping and protection of the main oxygen flow, the main oxygen flow impacts the molten steel and reacts with carbon in the molten steel to generate carbon monoxide, and carbon monoxide escaping from the molten steel is subjected to secondary combustion with the coherent surrounding accompanying auxiliary oxygen flow to heat a vacuum tank so as to reduce temperature drop of the molten steel. According to the invention, the auxiliary oxygen flow forms the surrounding accompanying flow outside the central supersonic jet flow, so that the expansion and attenuation of the central supersonic jet flow are smaller, the supersonic jet flow is longer, the penetration depth and stirring strength of the oxygen jet flow to a molten bath are increased, a lance position is raised to reduce splashing of the molten steel and slag sticking to a lance head, and the service life is prolonged.

Owner:CISDI ENG CO LTD +1

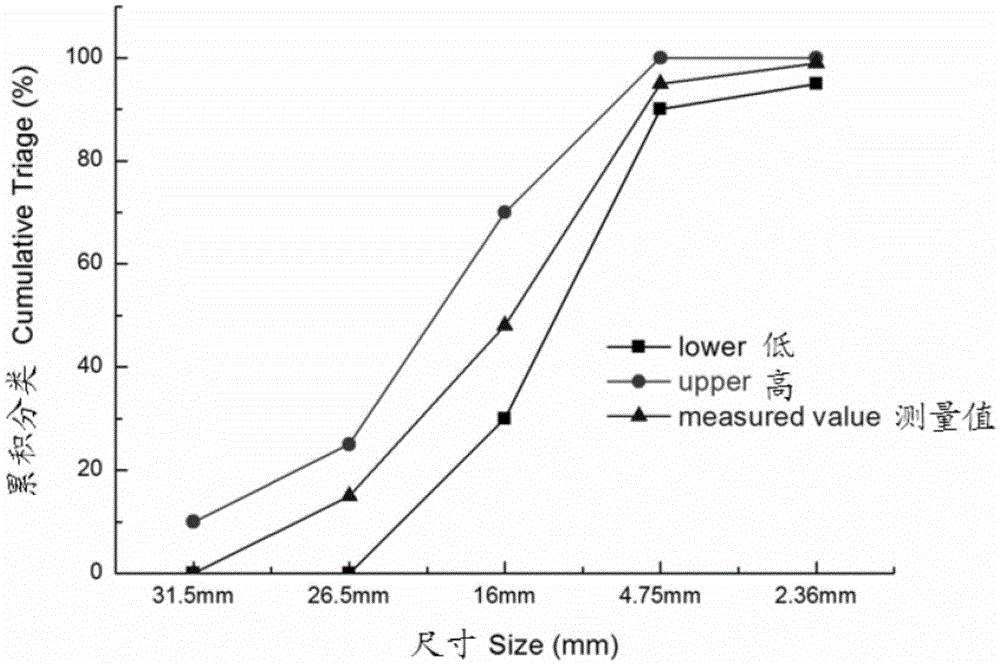

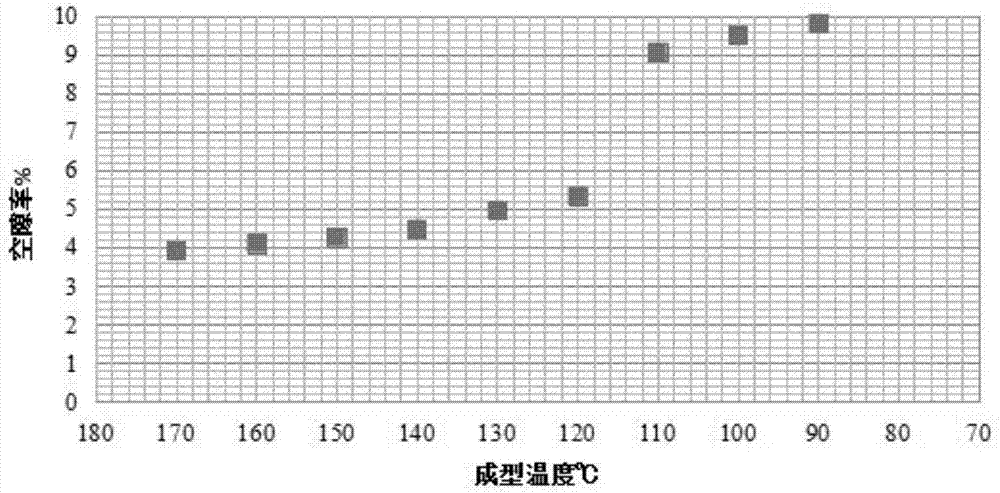

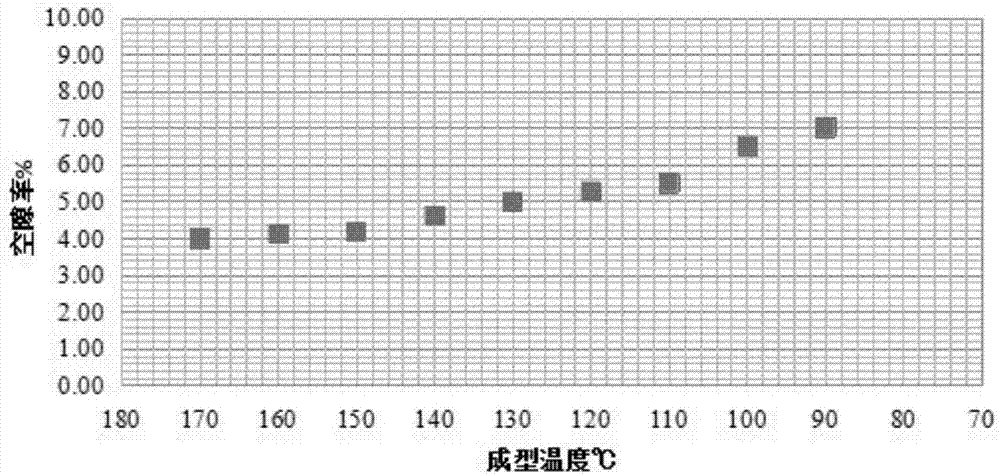

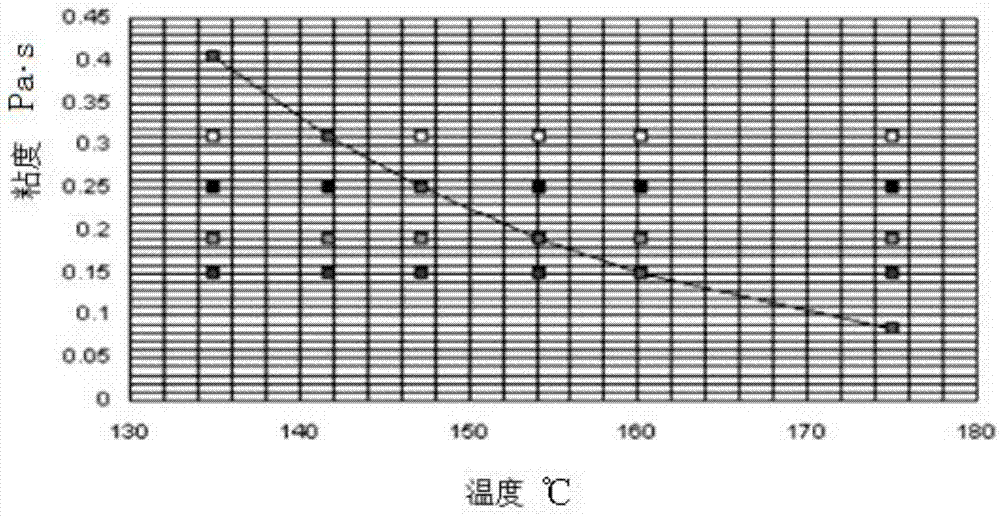

Rolling compaction process based on asphalt mixed material compaction characteristic

InactiveCN107386037AGuaranteed compactionImprove the compaction effectIn situ pavingsClimate change adaptationExperimental methodsMixed materials

The invention relates to a rolling compaction process based on asphalt mixed material compaction characteristic. The rolling compaction process comprises the following steps: 1) determining the inserting pressing temperature of the asphalt mixed material; 2) determining the final pressing temperature of the asphalt mixed material by a compaction characteristic experimental method; 3) determining the effective rolling compaction time; 4) determining the rolling compaction mode; and 5) determining rolling compaction parameters. The invention provides the rolling compaction process capable of guaranteeing complete compaction of the asphalt mixed material by considering the compaction characteristic of the asphalt mixed material and the temperature field change rule and by reasonably determining the final pressing temperature of the asphalt mixed material and the effective compaction time so as to guarantee that the compaction degree meets the requirements.

Owner:天津市国腾公路咨询监理有限公司 +2

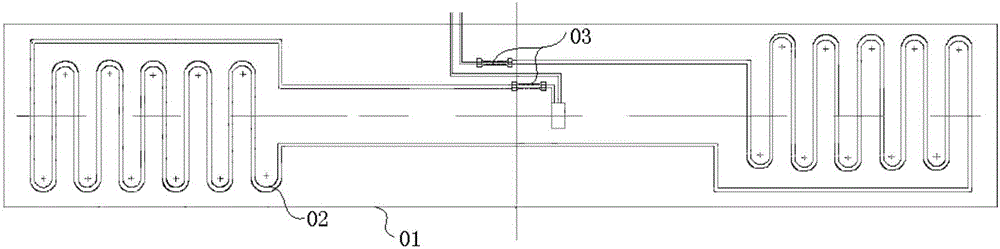

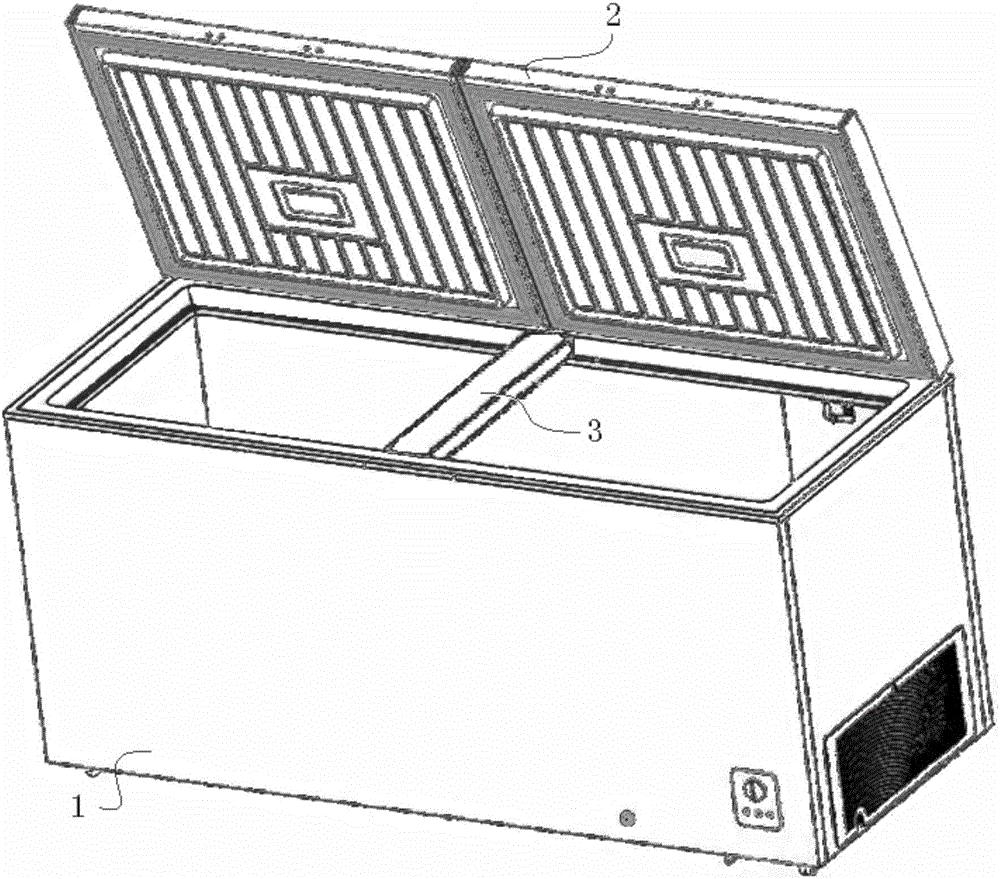

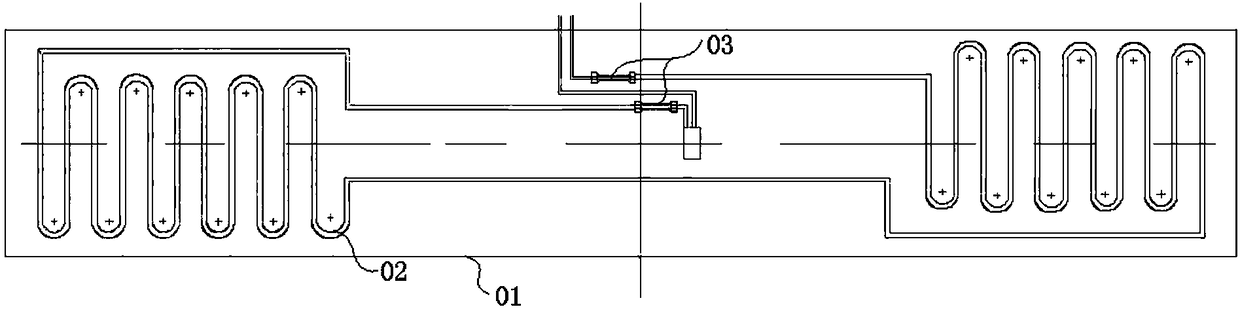

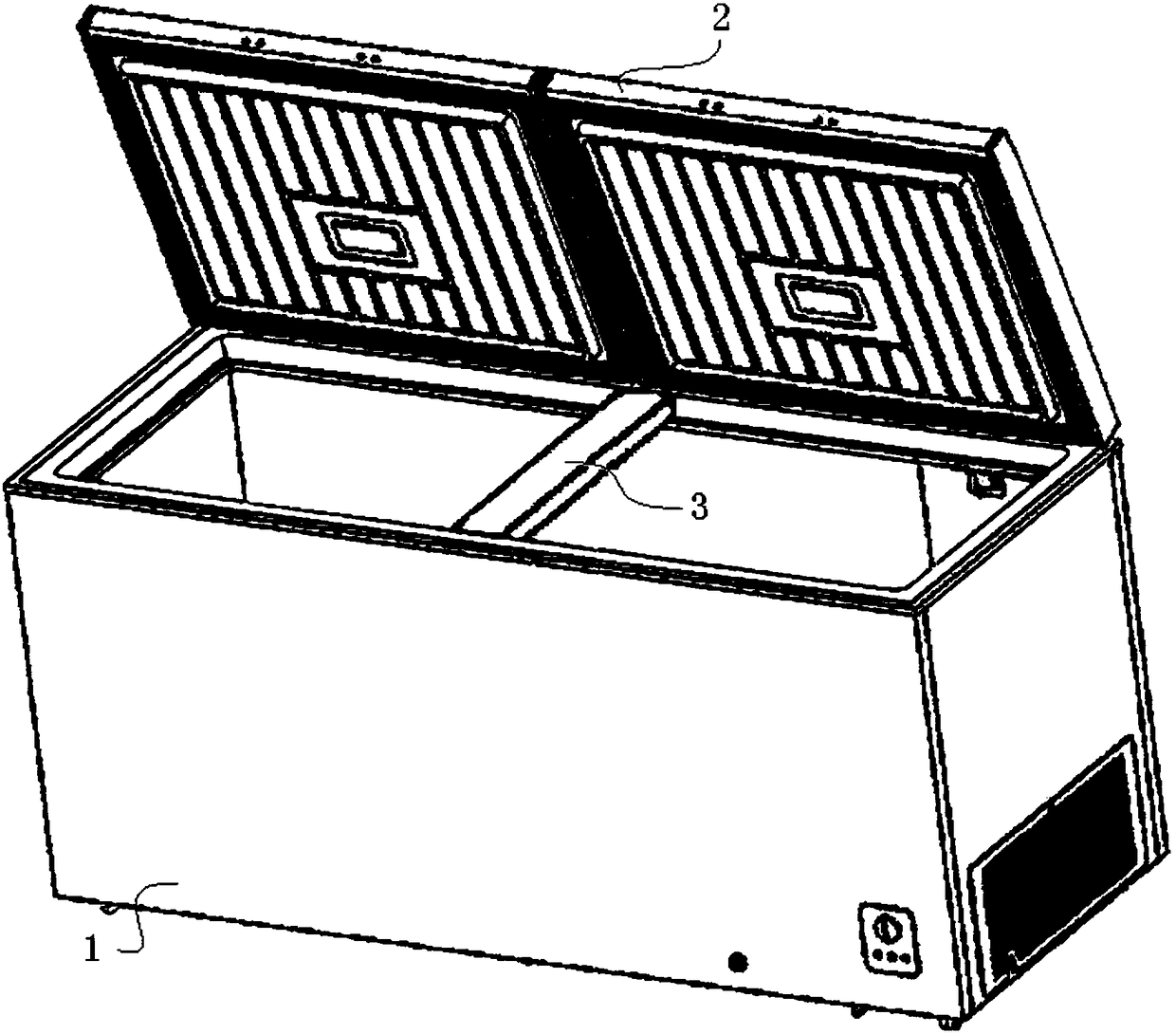

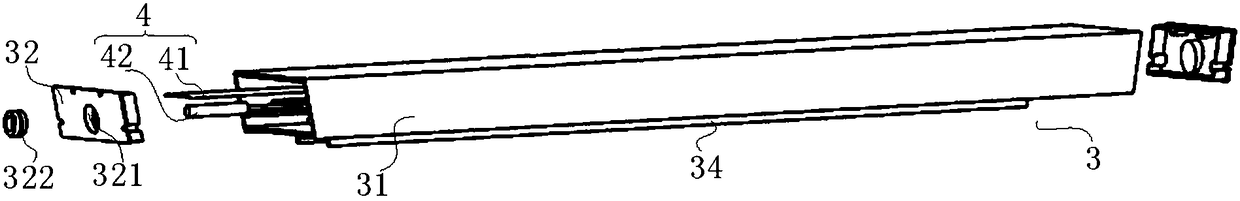

Refrigerator capable of preventing upper surface of middle beam from being frozen

ActiveCN106016893AReduce temperature drop ratePrevent standing water from freezingLighting and heating apparatusDomestic refrigeratorsRefrigerator carElectricity

The embodiment of the invention provides a refrigerator capable of preventing the upper surface of a middle beam from being frozen, and relates to the technical field of refrigeration equipment. The refrigerator is provided for solving the problem that a lead of a heating device of a middle beam of an existing refrigerator is likely to be affected with cold and damp so as to be aged. The refrigerator capable of preventing the upper surface of the middle beam from being frozen comprises a box body and door bodies used for sealing the box body. The middle beam is arranged at the position of an opening of the box body. The middle beam is of a hollow structure, a heating device is arranged inside the middle beam, and the middle beam is filled with heat insulation materials. The end of the middle beam is in sealed connection with the inner wall of the box body. A lead of the heating device is electrically connected with a control circuit of the refrigerator after penetrating out of the end of the middle beam and the inner wall of the box body. The refrigerator capable of preventing the upper surface of the middle beam from being frozen is used for storing goods at a low temperature.

Owner:HISENSE RONSHEN GUANGDONG FREEZER

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307BImprove phase change energy storage technologyWith the ability of automatic temperature adjustmentHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooledto room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

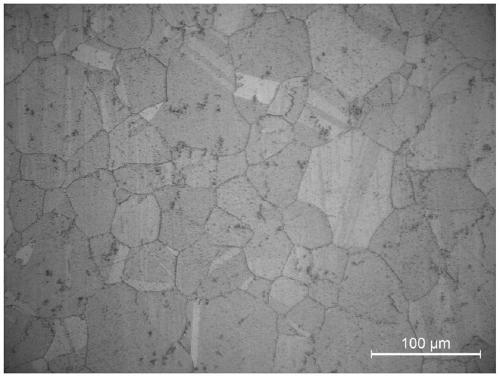

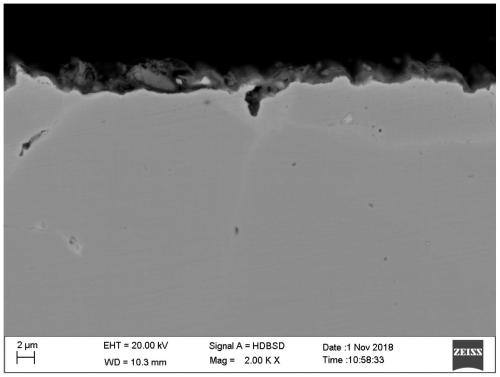

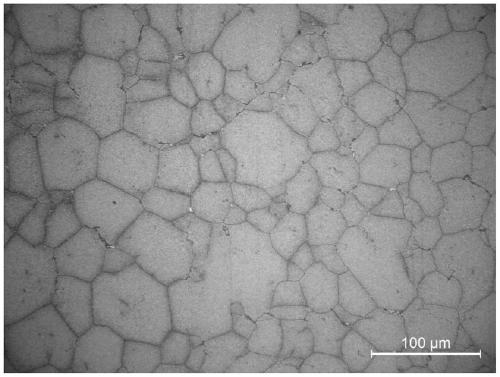

High-strength corrosion-resistant nickel-based polycrystalline high-temperature alloy and preparation method thereof

InactiveCN111394619AImprove stabilityImproved corrosion/oxidation resistanceSuperalloyUltimate tensile strength

The invention relates to a high-strength corrosion-resistant nickel-based polycrystalline high-temperature alloy and a preparation method thereof. The alloy comprises the following components of, in percentage by mass, 13%-17% of Cr, 15%-20% of Co, 0.1%-0.5% of Ti, 5.0%-5.5% of Al, 3.0%-7.0% of W, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 1.5%-2.0% of Nb, 0.04%-0.07% of Cand the balance Ni. Homogenizing treatment is conducted after smelting is conducted, hot rolling is conducted and finally heat treatment is conducted. The alloy has excellent strength and corrosion resistance, and the tensile yield strength of the alloy at a room temperature and 850 DEG C is higher than 900 MPa and 680 MPa respectively, and the alloy has excellent processing performance and structure stability at the same time.

Owner:HUANENG POWER INTERNATIONAL +1

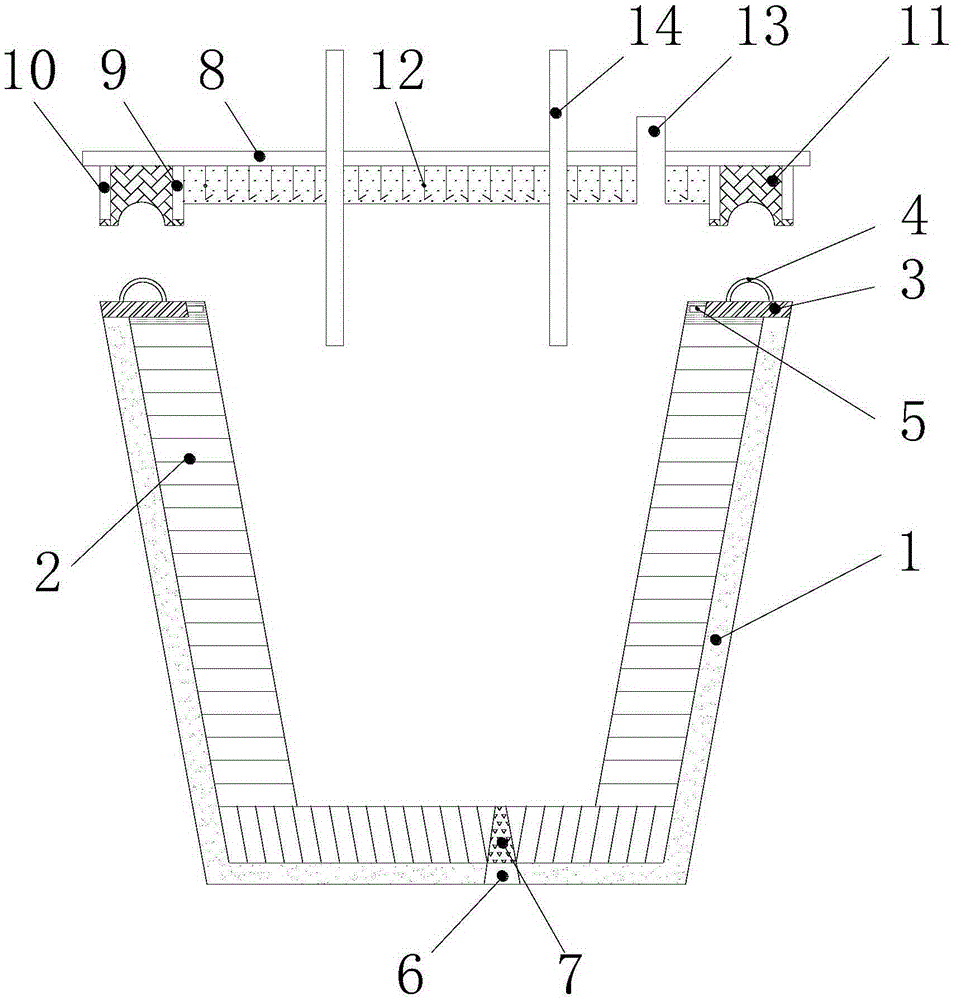

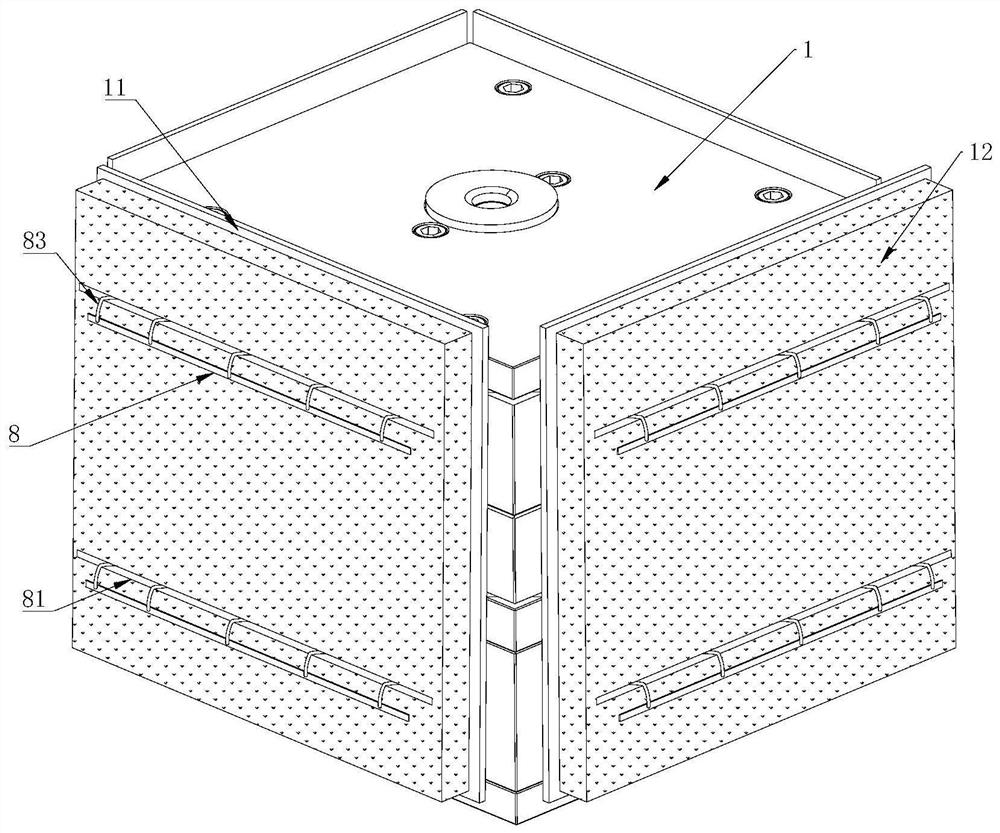

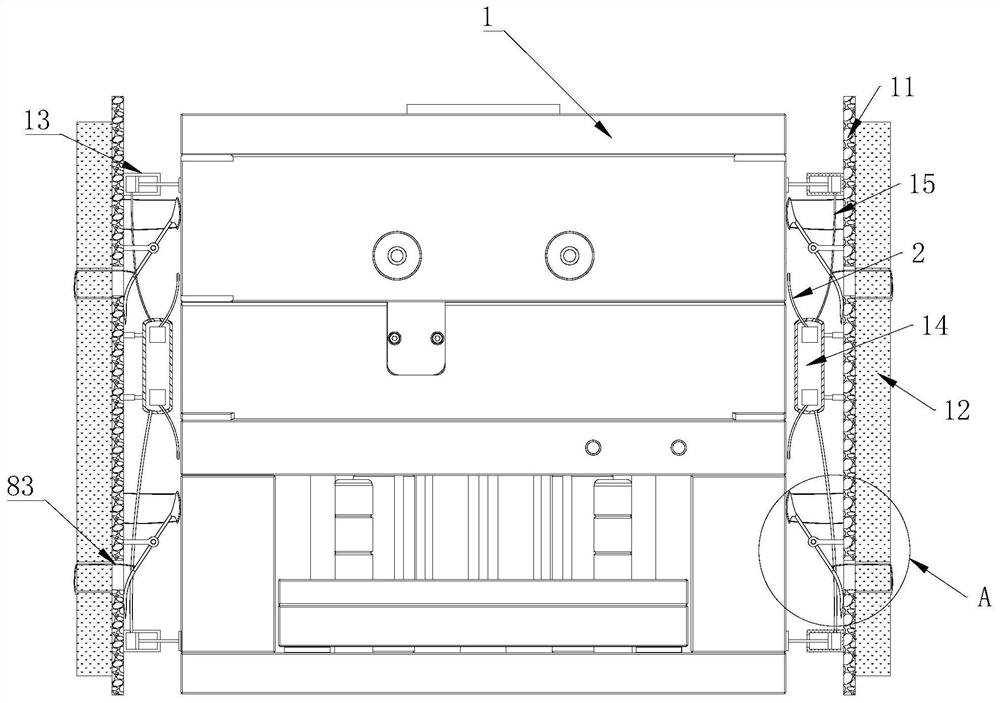

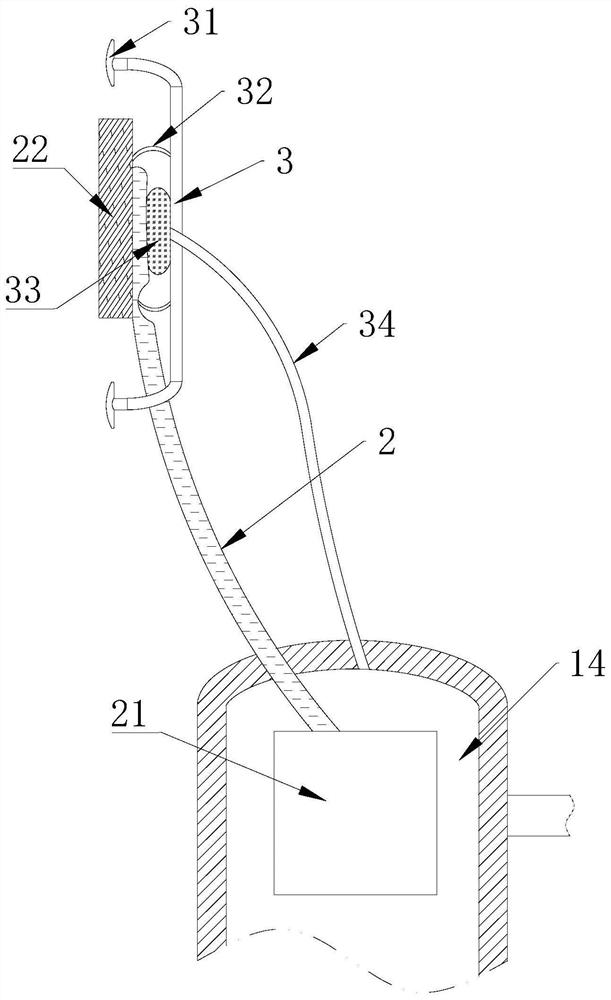

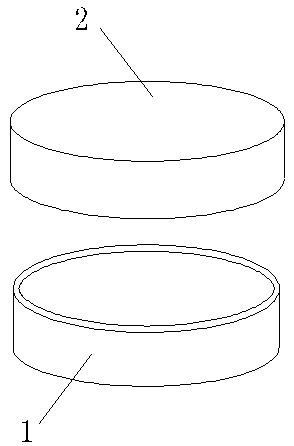

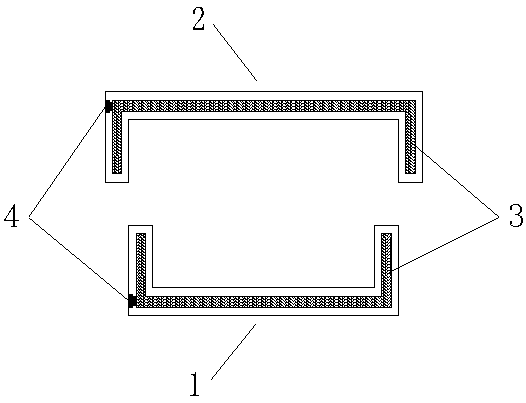

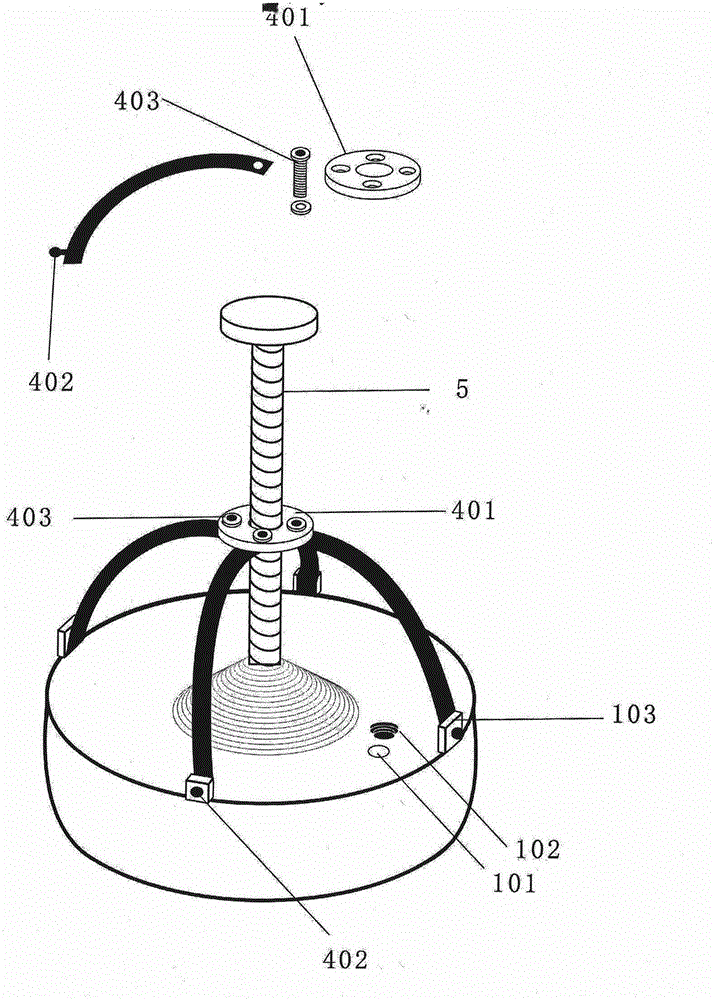

Ladle furnace (LF) refining steel ladle sealing device and use method thereof

The invention discloses a ladle furnace (LF) refining steel ladle sealing device and a use method thereof. The LF refining steel ladle sealing device comprises a ladle body and a ladle cover. The bottom edge of the ladle cover and the top edge of the ladle body are sealed and buckled. The ladle cover is provided with one or more wire feeding pipes. When the ladle cover and the ladle body are buckled, the bottoms of the wire feeding pipes are located above molten steel inside the ladle body. When the LF refining steel ladle sealing device is used, the ladle cover is sealed on the ladle body through hoisting equipment, alloy core wires penetrate through the wire feeding pipes, and the wire feeding depth is controlled to be 100-200 mm below the interface of the molten steel. The ladle body is sealed through the ladle cover, so that contact burning of strong deoxidizer and oxygen in air on the steel slag interface is avoided, and loss of the strong deoxidizer is reduced. Contact burning of the alloy core wires and the oxygen is reduced, and the situation that calcium compounds in the molten steel cannot be drained and pollutes the molten steel is avoided. Secondary oxidization of the molten steel in the wire feeding process is avoided, dust emission is reduced, and the environment is protected.

Owner:高志勇 +1

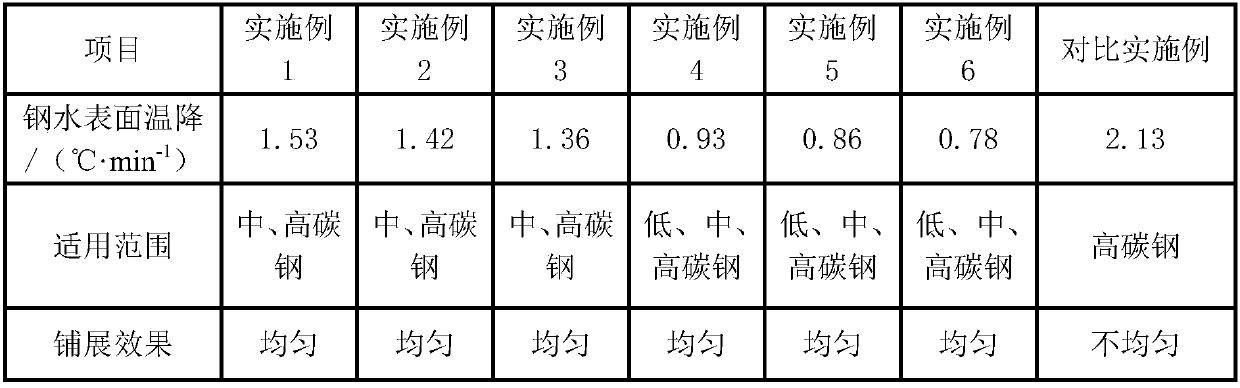

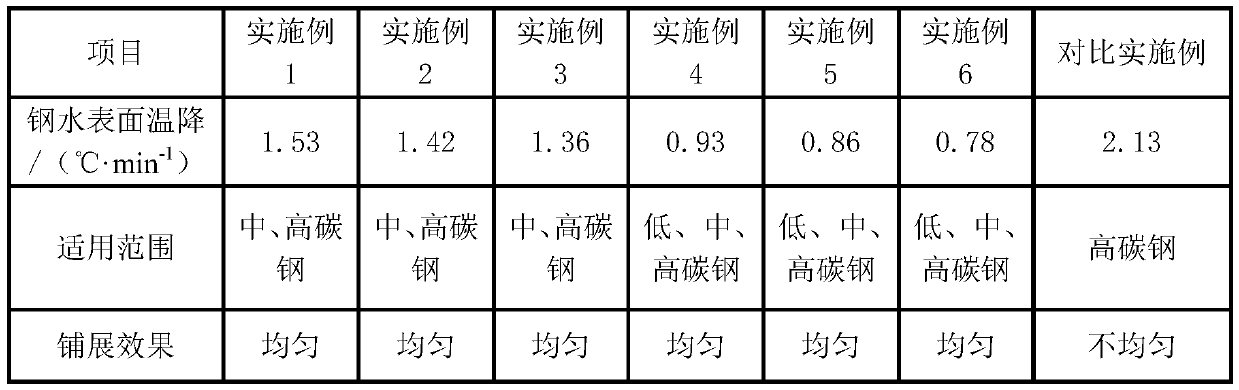

Molten steel thermal insulating agent and thermal insulating agent layer thereof

The invention discloses a molten steel thermal insulating agent and belongs to the field of thermal insulating agents. The molten steel thermal insulating agent comprises the following components of,by mass, 70-100 parts of carbonized rice husk ash, 1-10 parts of carbon source and 1-30 parts of silicon source, and the carbonized rice hull ash comprises the following elements of, by mass, 2%-17% of C, 40%-60% of Si, and the balance H, O, S, Ca, Fe and P. Water of the carbonized rice husk ash is less than 3% of the total mass of the thermal insulating agent. The bulk density of the molten steelthermal insulating agent is 0.18-0.35 g / cm<3>. Compared with carbonized rice hulls of a honeycomb structure, the molten steel thermal insulating agent provided by the invention can make the surface temperature of molten steel be lowered to 0.78 DEG C.min<-1> from 1.56 DEG C.min<-1> maximally. The molten steel thermal insulating agent provided by the invention is low in heat conductivity coefficient, good in thermal insulating effect, excellent in spreadability, free of caking, and low in production cost.

Owner:赣州鼎洋贸易有限公司

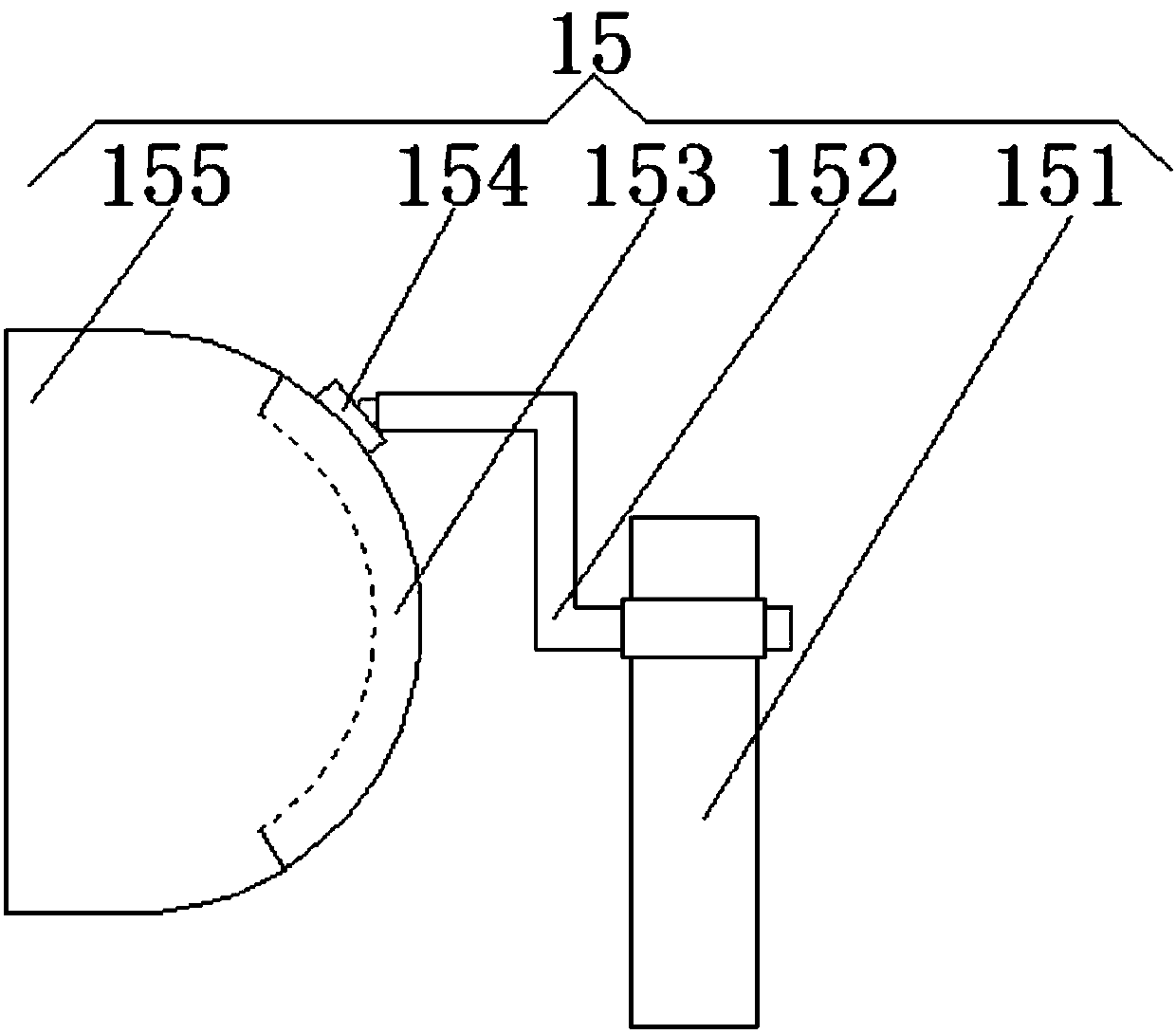

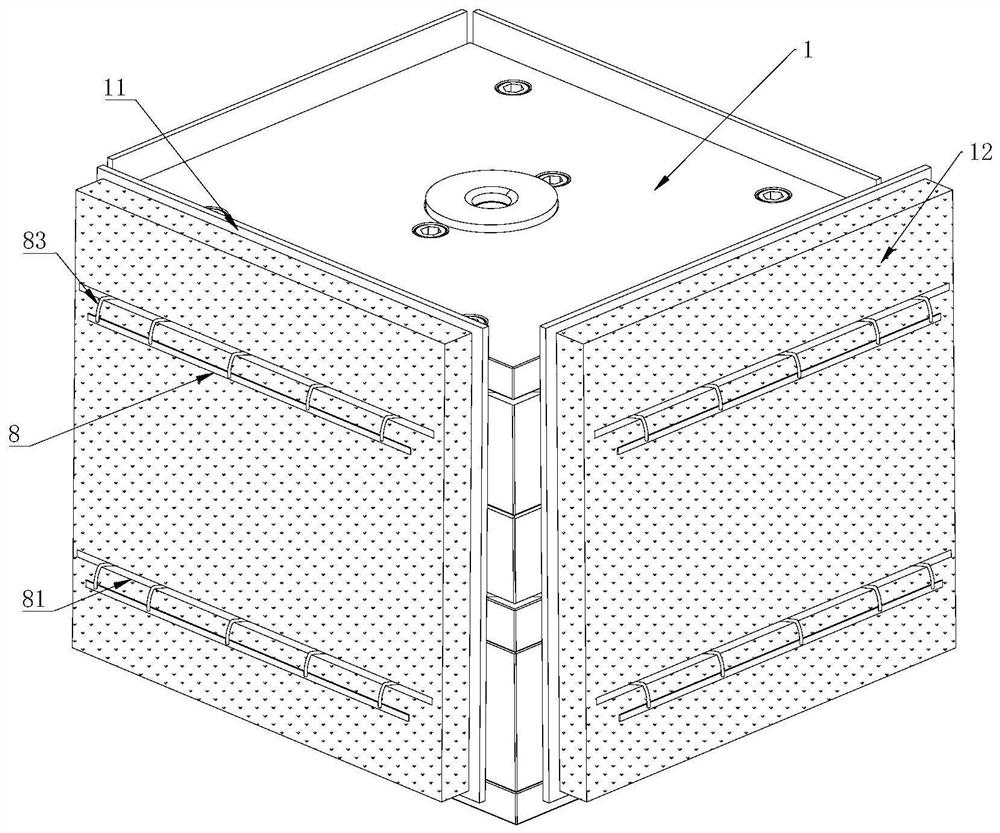

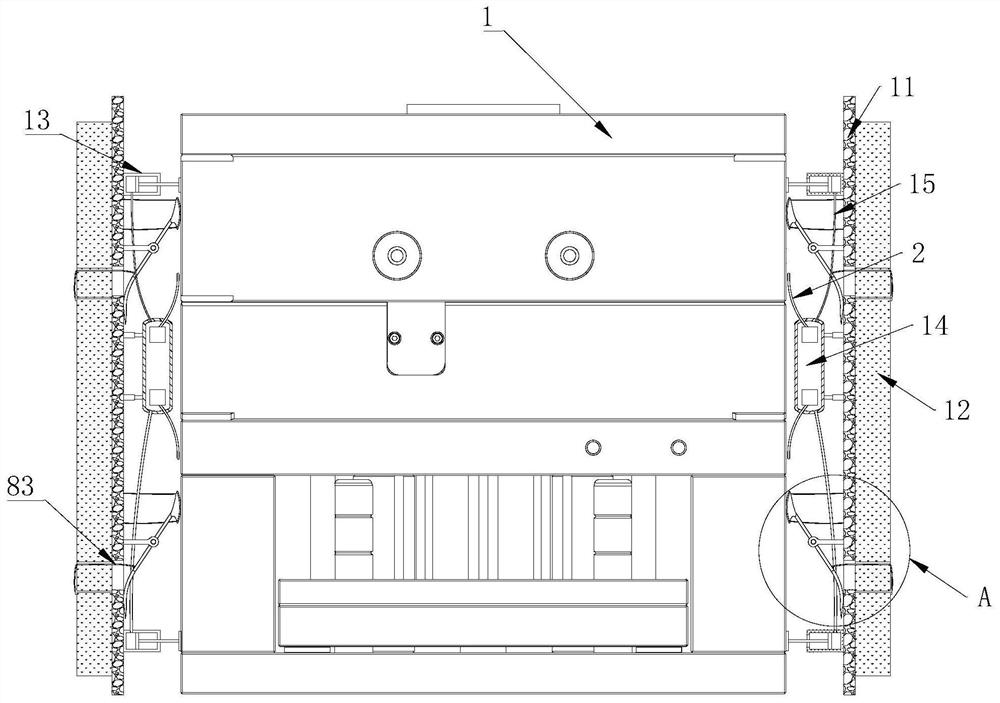

An intelligent constant temperature injection mold

The invention belongs to the technical field of moulds, and is specifically an intelligent constant-temperature injection mold, which includes a main body; multiple sets of isolation plates are arranged on the side wall of the main body; a thermal insulation resistance is fixedly connected to the side of the isolation plate away from the main body. Combustible material; the side close to the main body of the isolation plate is fixed with a cylinder; the gas inside the gas storage tank will cause the effect of heat expansion and contraction, and is introduced into the rodless cavity of the cylinder by the first air guide tube, and then the cylinder is It will push the isolation plate away from the main body, increase the space between the isolation plate and the main body, and accelerate the cooling speed of the main body. When the temperature of the main body is low, the gas inside the gas storage tank will shrink, and the cylinder will be inactive. The gas inside the rod cavity is drawn out, so that the insulation board and the heat preservation and flame retardant material are close to the body, so that the temperature drop speed of the body is slowed down, and the insulation effect of the insulation board and the heat preservation flame retardant material on the body is increased.

Owner:广州市天霸美容美发用品有限公司

Quenched-tempered heat treatment method for bearing sleeve machining

InactiveCN107385187AReduce temperature drop rateReduce temperature differenceFurnace typesHeat treatment furnacesQuenchingMachining process

The invention aims to provide a quenched-tempered heat treatment method for bearing sleeve machining. The heat treatment method comprises the steps that (1) pre-heating treatment is carried out, specifically, a bearing sleeve used in the machining process is made from 20CrMnTi steel, the rough-machined bearing sleeve is preheated to 350 DEG C, and heat preservation is carried out for 30 minutes at a constant temperature; (2) normalizing heating is carried out on the bearing sleeve, specifically, the bearing sleeve which is pre-heated in the step 1 is further subjected to secondary heating to reach 800 DEG C; (3) quenching and cooling treatment is carried out, specifically, cold water is firstly sprayed on the surface of the high-temperature bearing sleeve to carry out cold water cooling, when the temperature of the bearing sleeve is decreased to 530 DEG C, water spraying is stopped, and then the bearing sleeve is immersed into oil for secondary cooling and then is placed in air to be air-cooled to 120 DEG C; and (4) high-temperature tempering treatment is carried out. The method has the advantages that the temperature reduction speed in the quenching process can be decreased, the temperature difference between inside and outside of the bearing sleeve can be reduced, the surface fracture in the quenching process can be avoided, the quenching quality can be improved, and the hardness and the surface wear resistance of the bearing sleeve can be improved.

Owner:ANHUI BUERYUE BEARING

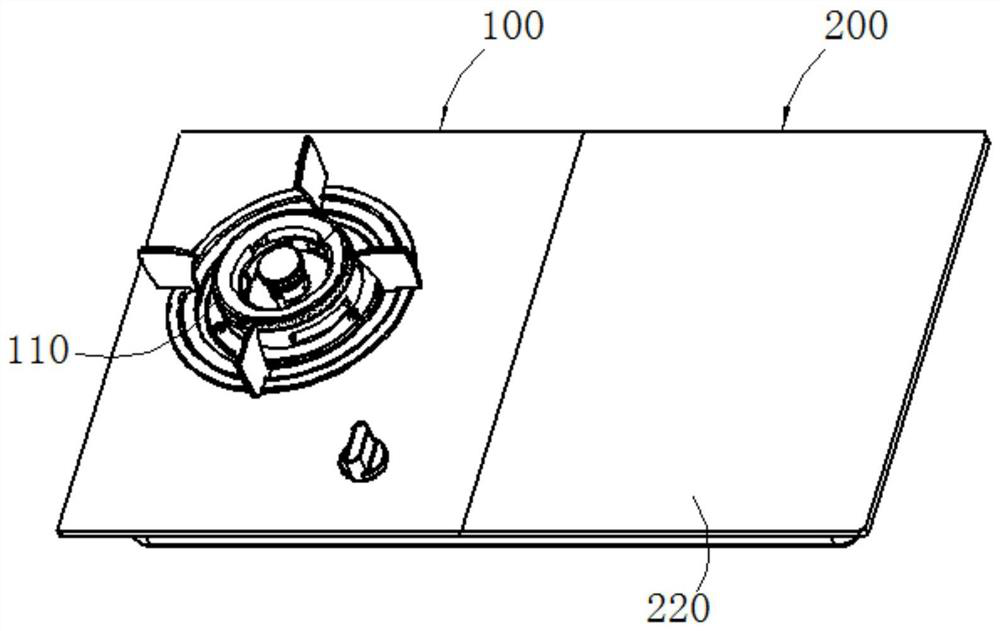

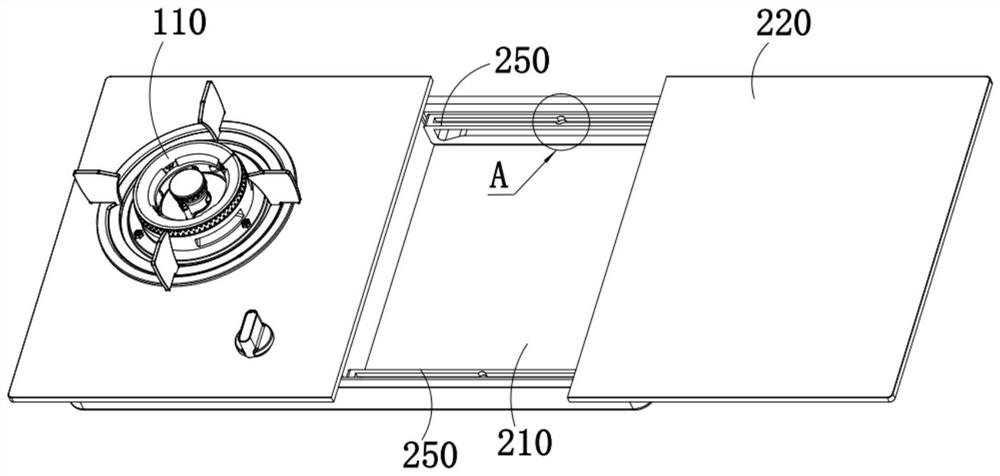

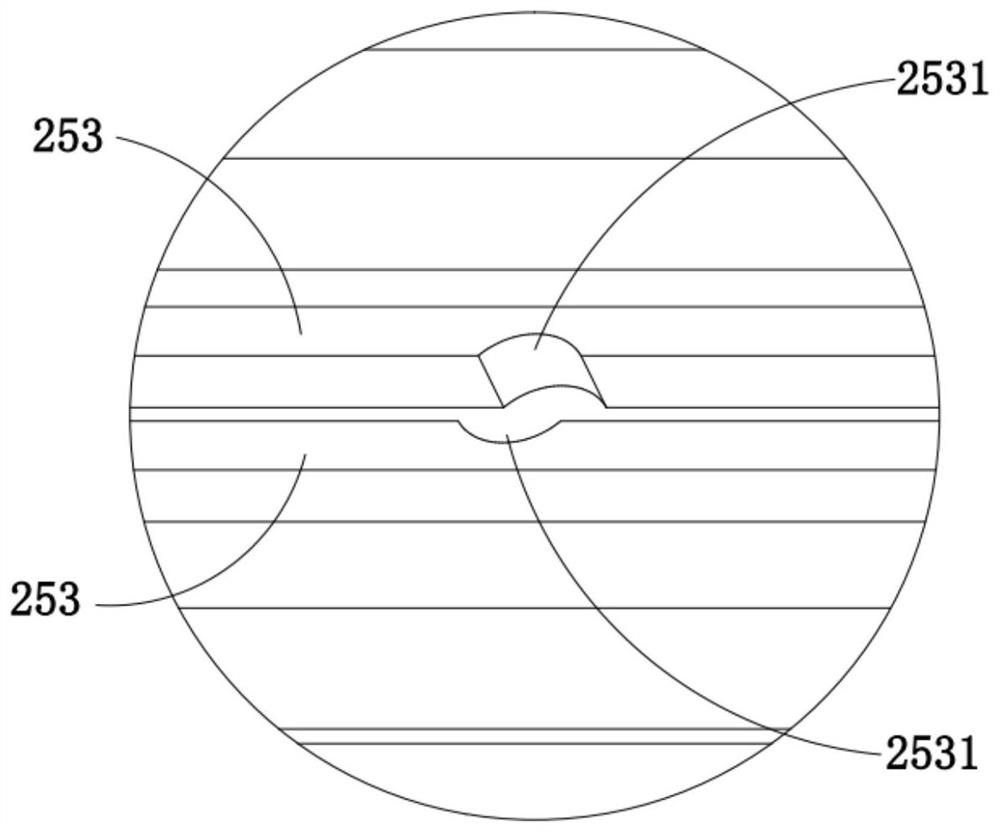

Stove with heat preservation function

PendingCN111795412AReduce temperature drop rateGuaranteed tasteDomestic stoves or rangesLighting and heating apparatusThermodynamicsEngineering

The invention relates to a stove with a heat preservation function, and relates to the technical field of stoves. The stove with the heat preservation function comprises a first working position and asecond working position which are adjacently arranged, wherein the first working position is provided with a cooking stove used for cooking food, the second working position is provided with a heat preservation assembly, the heat preservation assembly comprises a heat preservation box body and a cover body, a containing cavity with an opening in one side is formed in the heat preservation box body, and the cover body is movably installed on the heat preservation box body and used for opening or closing the opening. The stove relieves the technical problem that by means of a stove in the priorart, the temperature of the cooked food cannot be effectively kept after cooking of the food is completed.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

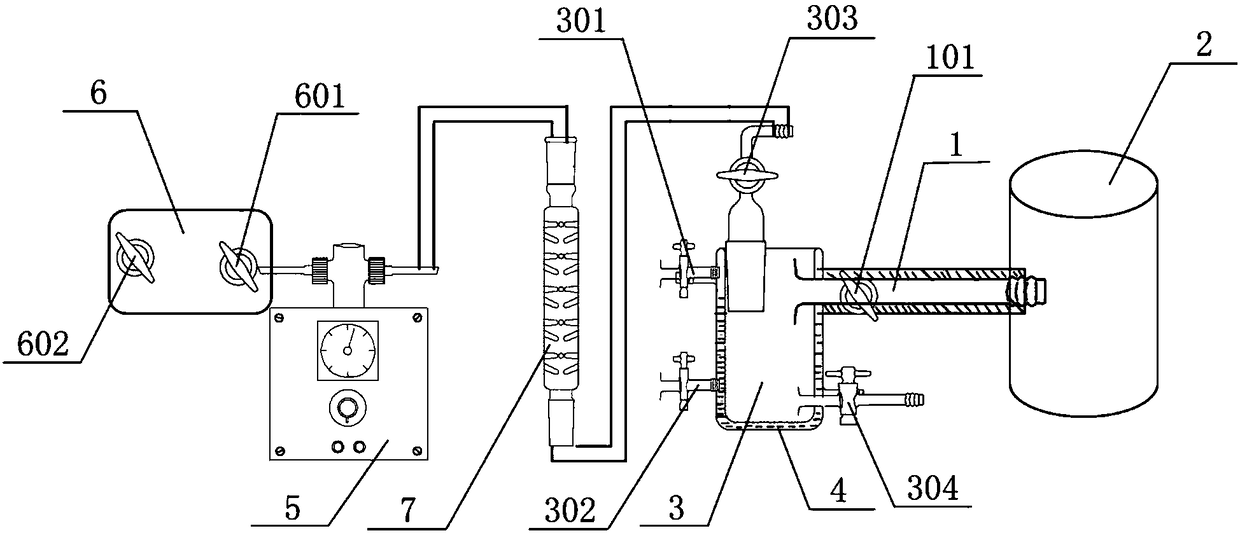

Natural gas sampling device and method thereof

InactiveCN109115564AQuality improvementFacilitate post-analysisWithdrawing sample devicesInlet valveEngineering

The invention discloses a natural gas sampling device and a method thereof, which belong to the field of gas sampling. The device comprises a tubular sampling probe, wherein a sampling port is inserted into a natural gas pipe at one end, and a safety bottle is connected with the other end; a heating assembly for heating the tubular sampling probe and the safety bottle; a sampling pump connected tothe safety bottle through a first pipeline; and a sampling air bag, wherein the sampling air bag is detachably connected to the sampling pump through a second pipeline, and the sampling air bag is provided with an intake valve and an outlet valve. The natural gas sampling device provided by the invention can avoid the clogging of the sampling port, and the obtained sample has the advantages of good quality and convenient usage, and is suitable for large-scale popularization and application.

Owner:PETROCHINA CO LTD

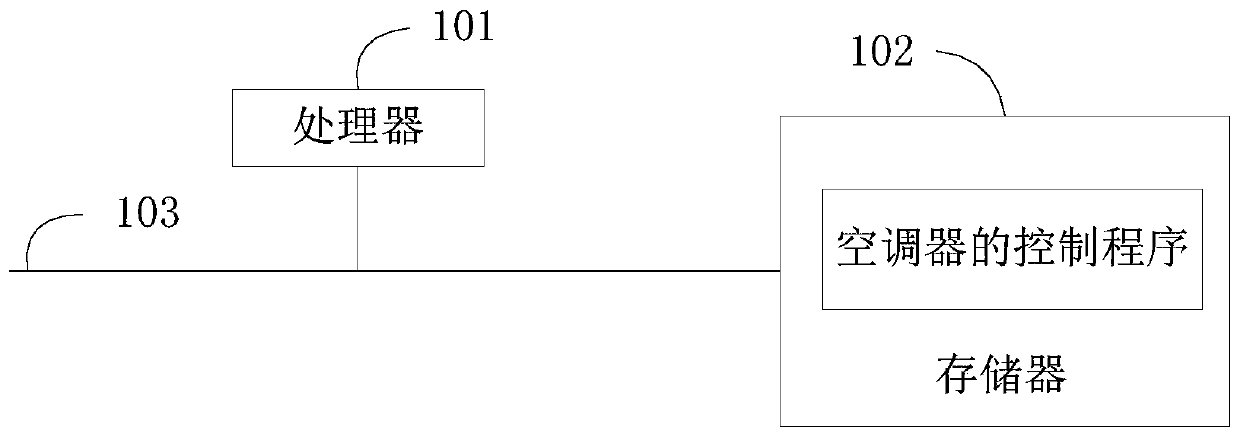

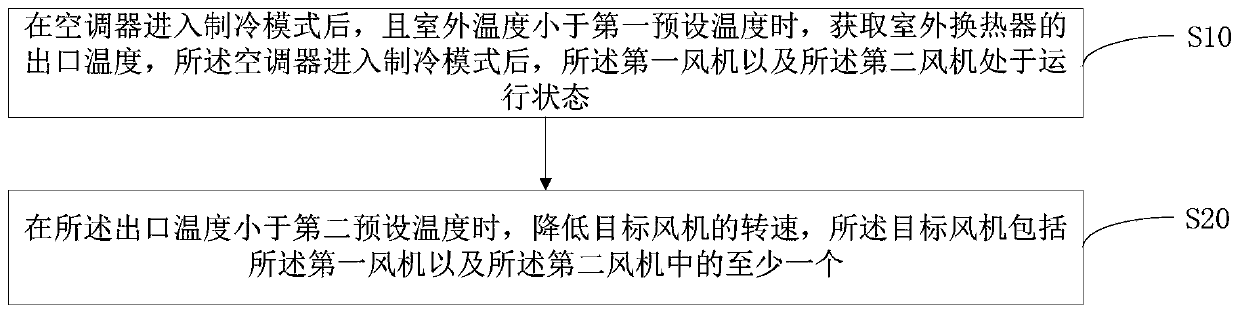

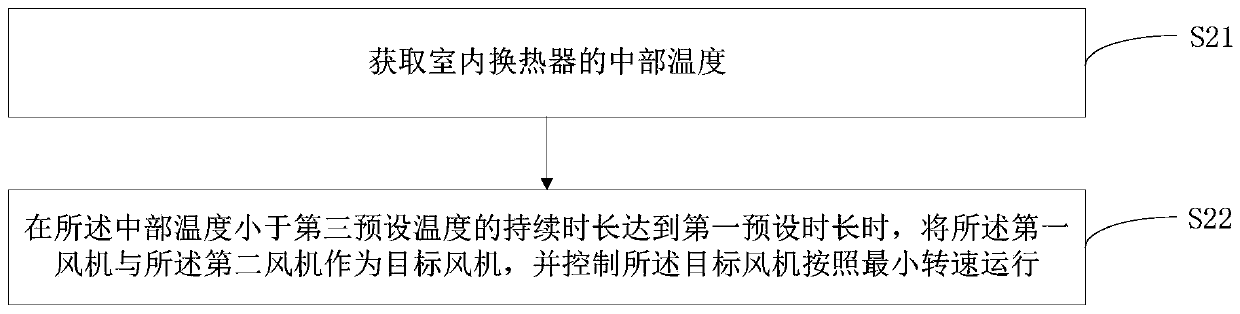

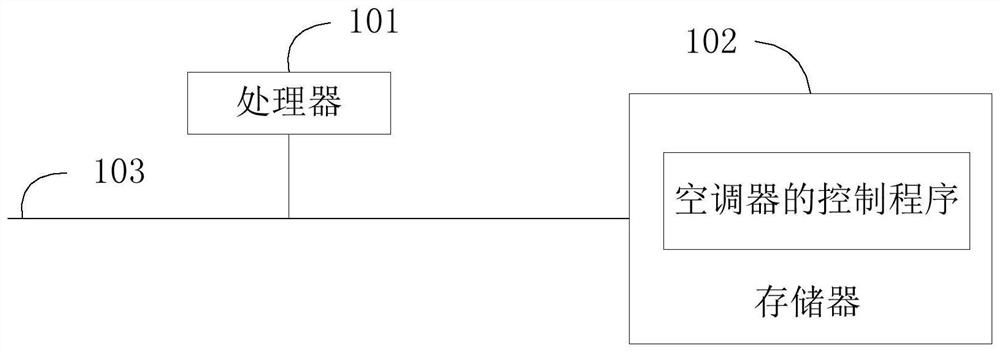

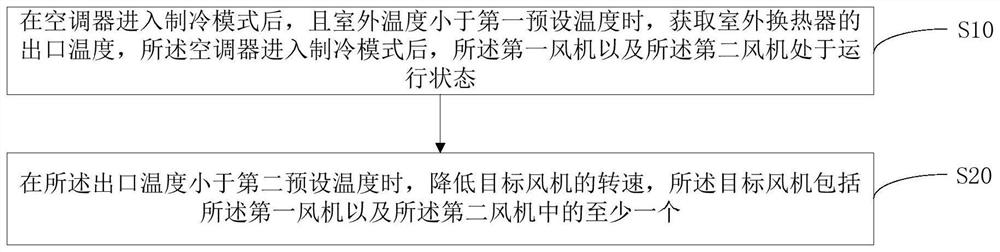

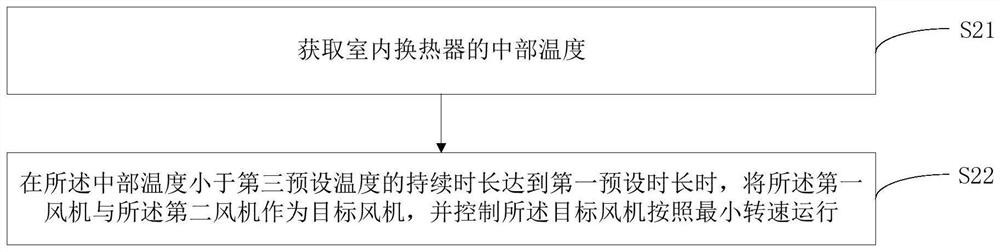

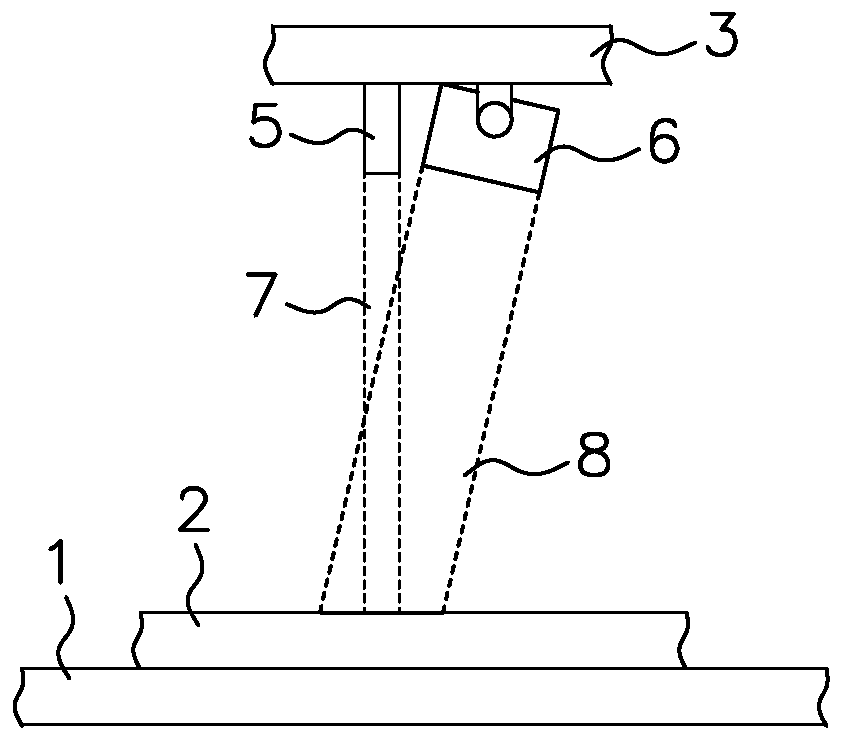

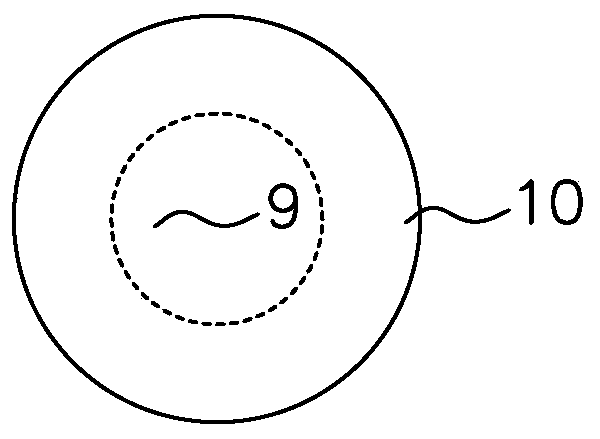

Air conditioner, control method of air conditioner and computer storage medium

ActiveCN110848888AAvoid frostReduce cooling capacityMechanical apparatusSpace heating and ventilation safety systemsOutdoor temperatureEngineering

The invention discloses a control method of an air conditioner, the air conditioner and a computer readable storage medium. An outdoor unit of the air conditioner comprises an outdoor heat exchanger,a first fan and a second fan, wherein an air outlet surface of the first fan is opposite to the upper part of an indoor heat exchanger, and an air outlet surface of the second fan is opposite to the lower part of the outdoor heat exchanger. The control method of the air conditioner comprises the steps that after the air conditioner enters a refrigeration mode and the outdoor temperature is less than a first preset temperature, the outlet temperature of the outdoor heat exchanger is obtained, and after the air conditioner enters the refrigeration mode, the first fan and the second fan are in anoperation state; and when the outlet temperature is less than a second preset temperature, the rotating speed of the target fan is reduced, wherein the target fan comprises at least one of the firstfan and the second fan. According to the control method and the air conditioner, the frequency of starting and stopping a compressor is low.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

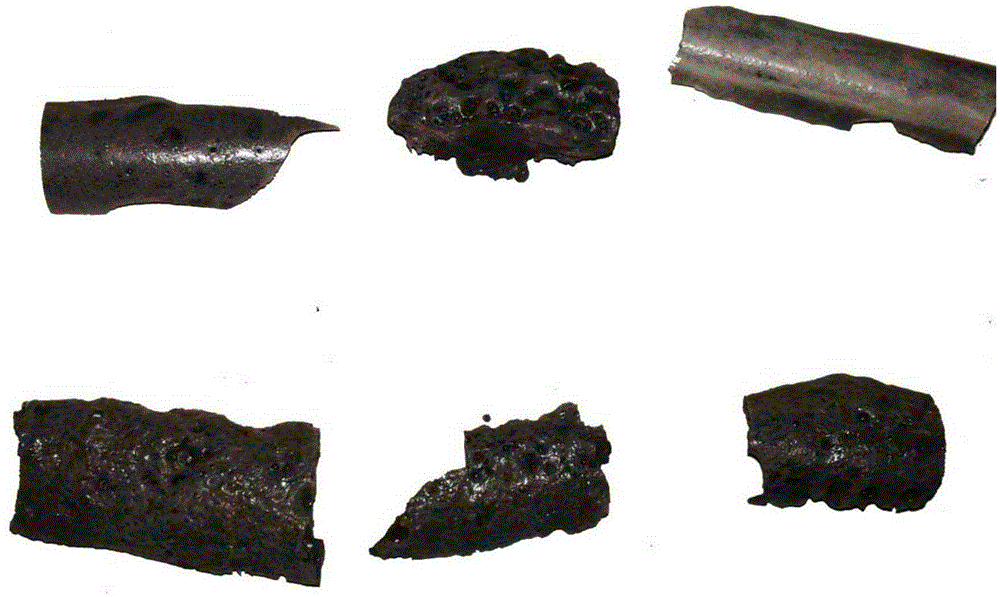

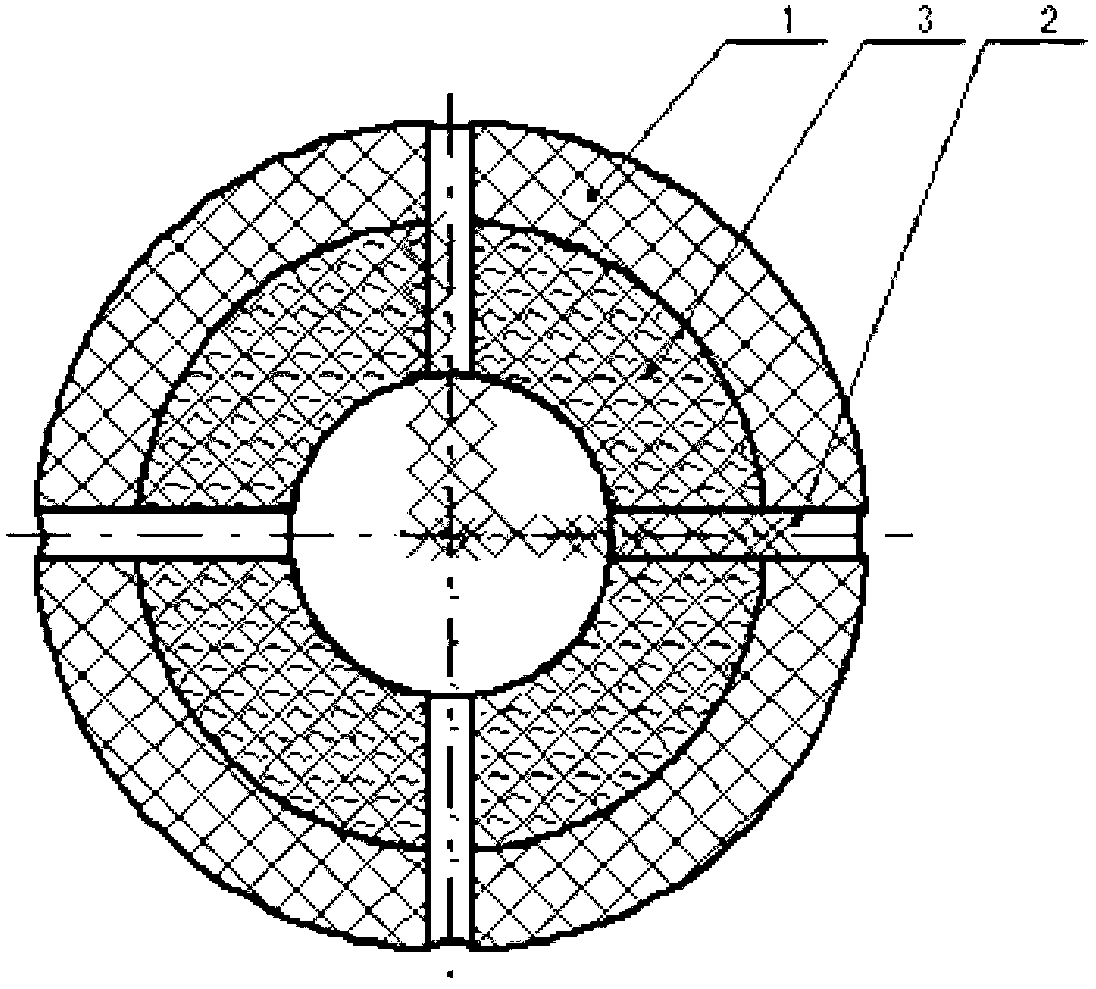

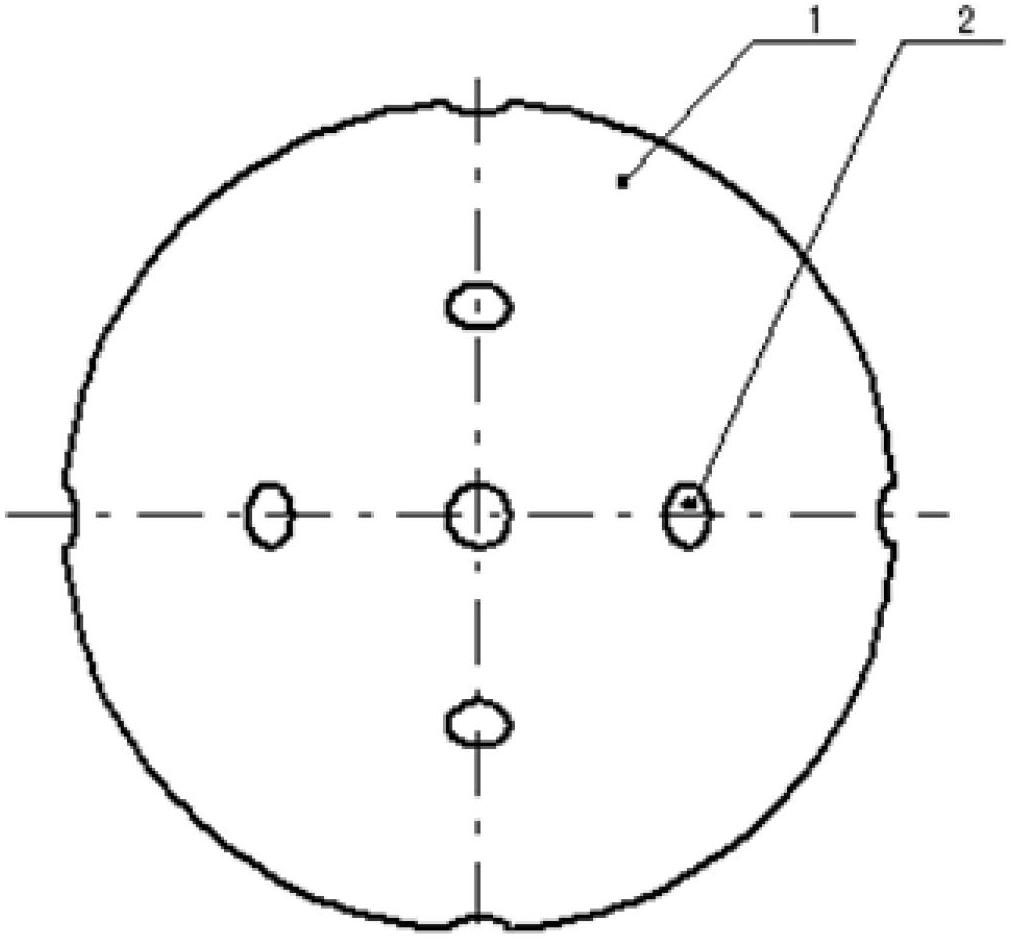

Combustion-heated heating ball

InactiveCN102705814AReduce consumptionMeet the needs of the production processCombustion chambersThermal insulationSlag

The invention relates to a combustion-heated heating ball, which is a hollow ball body compounded by a fireproof material layer and a combustible material layer, and a centripetal through hole is manufactured on the ball body. By adding the heating ball to the melt liquid metal surface of the high-temperature conveying equipment during the metallurgical production, the combustible material of the ball body is contacted with the oxygen above the melt liquid metal surface to carry out combustion reaction to emit heat under the radiation and heating action of the high-temperature liquid metal, so as to heat the liquid metal and the equipment; at the same time, the fireproof ball housing not only can serve as the carrier of solid fuel, but also can be used for thermal insulation, so as to reflect and block the combusting heat and the heat emitted by the liquid metal, as a result, the heating effect of the heating ball is improved, the thermal insulation function is achieved, the temperature drop speed of the liquid metal is reduced, and the purpose of energy saving is achieved. Due to the heat emitted by the heating ball, the temperature surrounding the openings of the liquid iron ladle and the steel ladle for containing the melt liquid metal in the steel industry is kept very high, as a result, the slag bonding problem on the brims of the liquid iron ladle and the steel ladle is greatly reduced.

Owner:TIANJIN NANJI STAR INSULATING MATERIAL

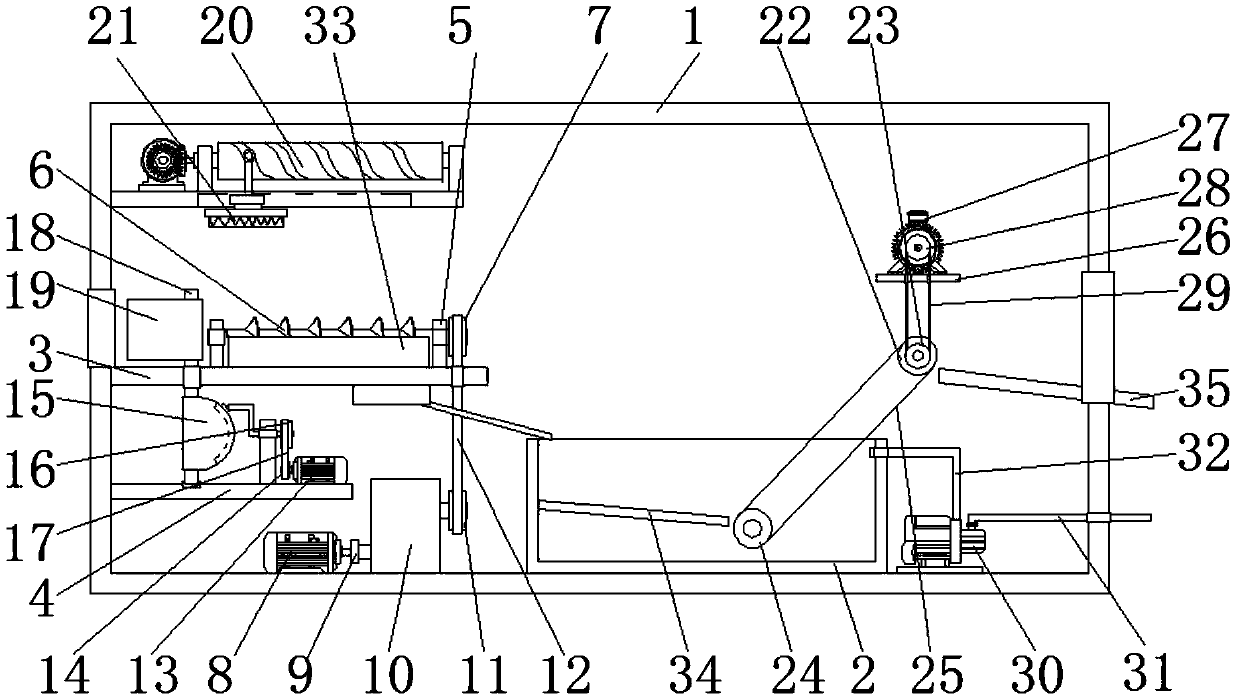

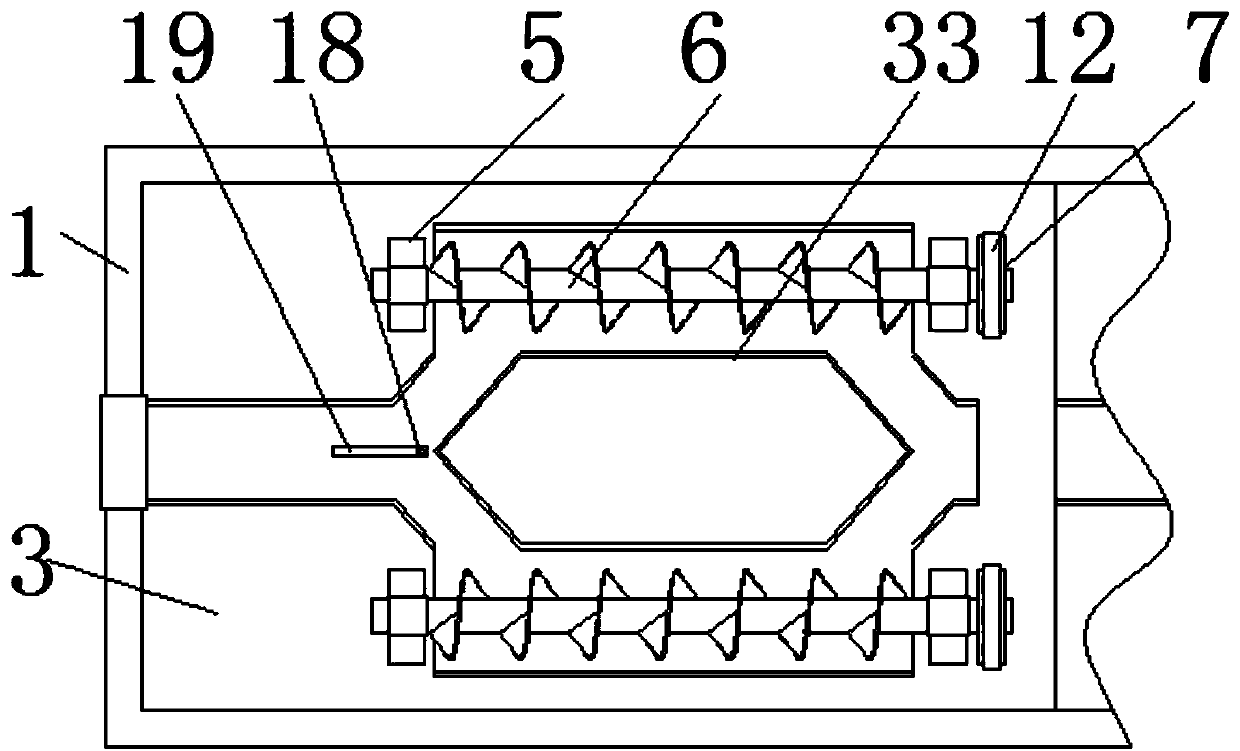

A quenching device for steel balls after hot rolling

InactiveCN107794353BSufficient holding timeIncrease temperatureFurnace typesHeat treatment furnacesCouplingReducer

The invention discloses a quenching device after hot rolling forming of steel balls. The quenching device after hot rolling forming of the steel balls comprises a box body; the bottom of the inner wall of the box body is fixedly connected with a quenching box; a first fixing plate and a second fixing plate are sequentially and fixedly connected to one side between the opposite two sides of the inner wall of the box body from top to bottom; the top of the first fixing plate is rotationally connected with a spiral feeding roller through a pair of rotating bases; one side of the bottom of the inner wall of the box body is fixedly connected with a first motor; the output shaft end of the first motor is fixedly connected with a speed reducer through a coupler; a rotating device is fixedly connected with the top of the second fixing plate; one side of the rotating device is fixedly connected with a rotating plate through a rotating shaft; a moving device is fixedly connected with the top ofthe inner wall of the box body; and a heating pipe is fixedly connected with the bottom of the moving device. The invention relates to the technical field of steel ball machining. The quenching deviceafter hot rolling forming of the steel balls solves the problem that the steel balls are affected by temperature in the transferring process, meanwhile solves the problem of manual flow distributing,reduces the labor amount and improves the production efficiency.

Owner:西马克艾洛特姆感应设备技术(上海)有限公司

Intelligent constant-temperature injection mold

The invention belongs to the technical field of molds, and particularly relates to an intelligent constant-temperature injection mold which comprises a body. A plurality of groups of isolation plates are arranged on the side wall of the body. The side, away from the body, of each isolation plate is fixedly connected with a heat preservation flame-retardant material. An air cylinder is fixedly connected to the side, close to the body, of each isolation plate. Gas in gas storage tanks can cause the effect of heat expansion and cold shrinkage and is guided into rodless cavities of the ai cylinders through first gas guide pipes, then the air cylinders push the isolation plates away from the body, the space between the isolation plates and the body is increased, the cooling speed of the body can be increased, and when the temperature of the body is low, the gas in the gas storage tanks is shrunk, the gas in the rodless cavities of the air cylinders is pumped out, so that the isolation plates and the heat-preservation flame-retardant material are close to the body, the temperature reduction speed of the body is reduced, and the heat-preservation effect of the isolation plates and the heat-preservation flame-retardant material on the body is improved.

Owner:广州市天霸美容美发用品有限公司

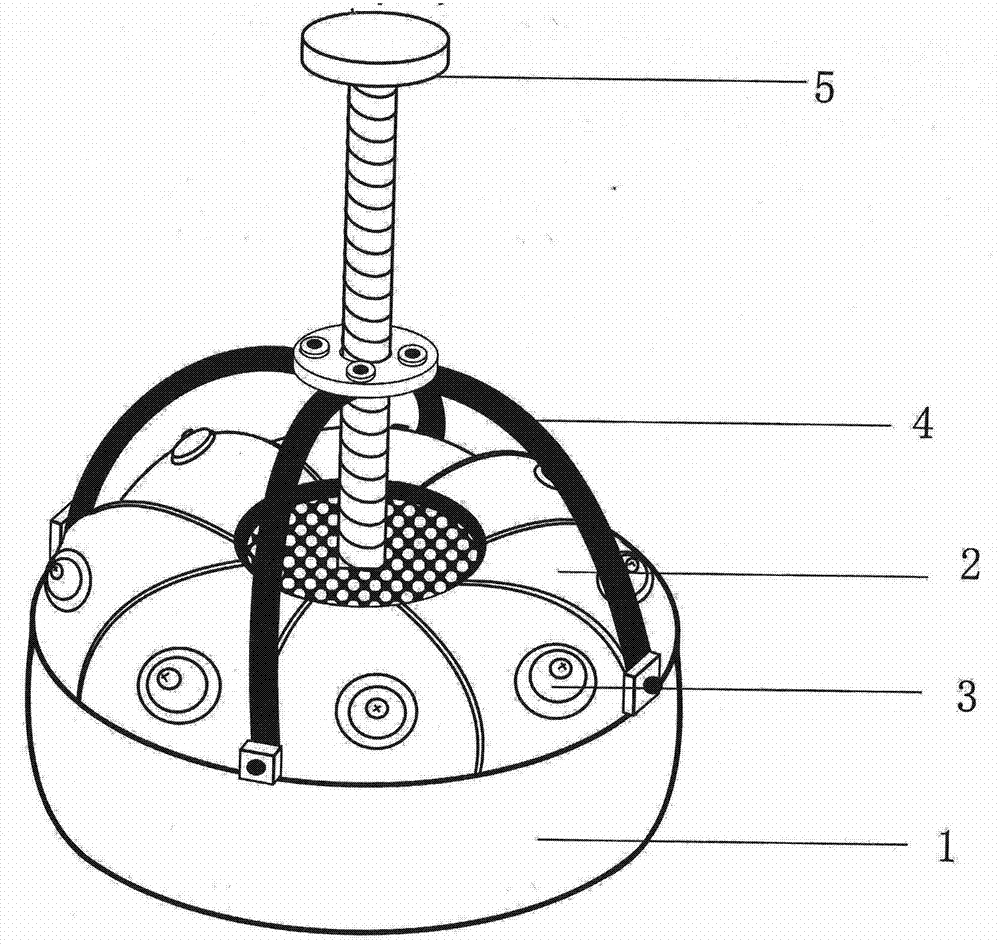

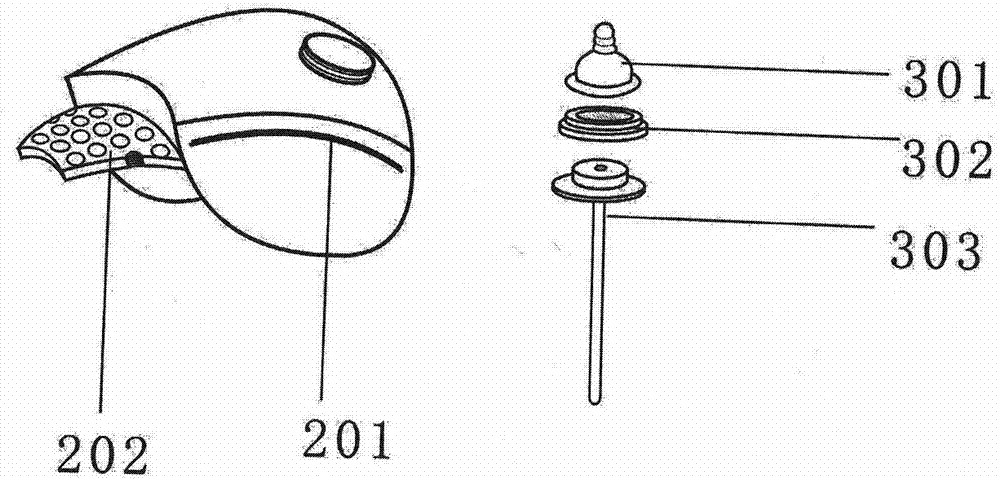

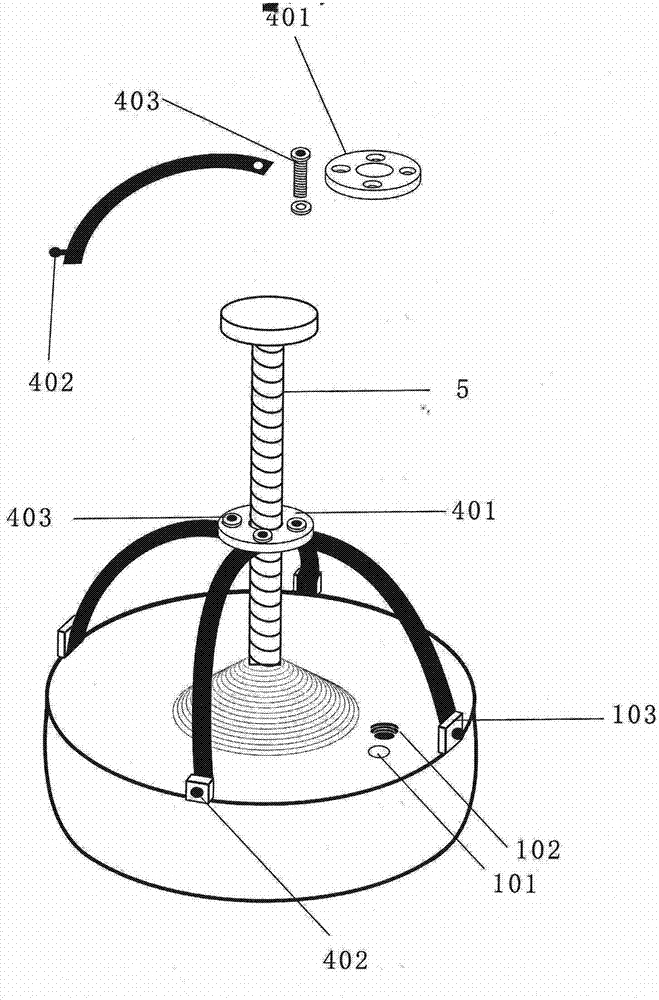

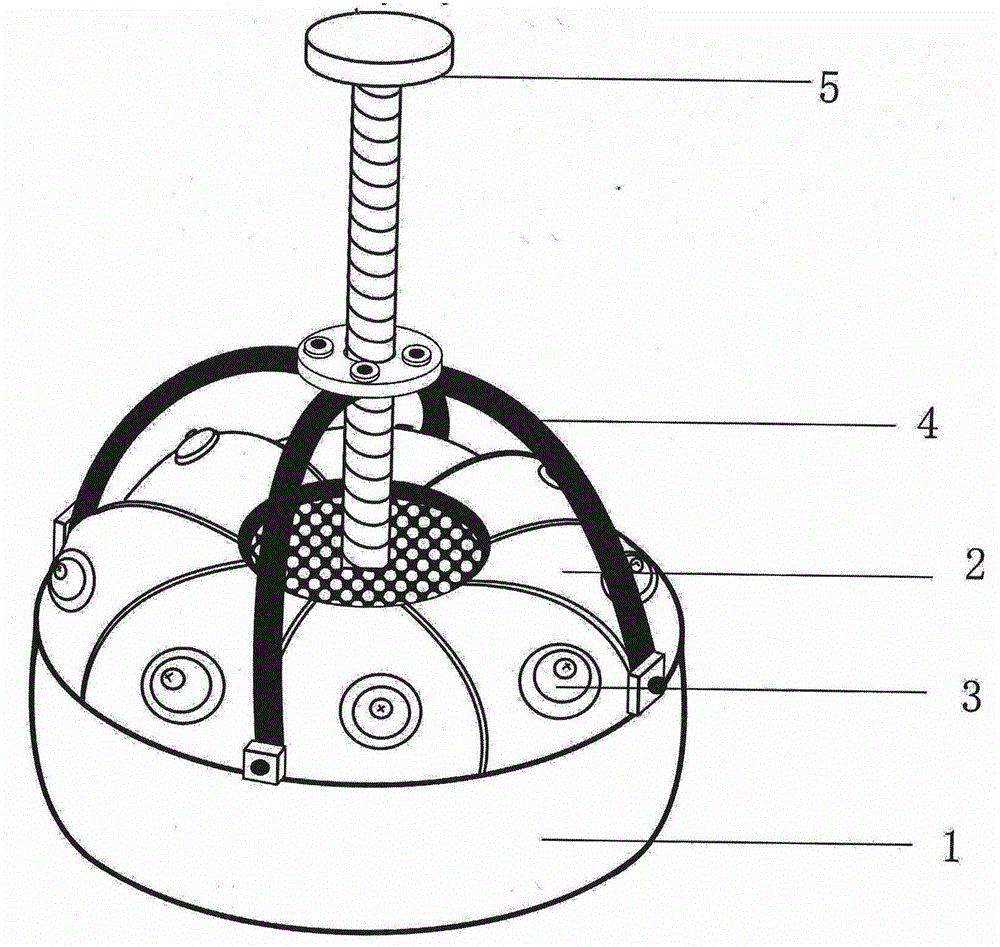

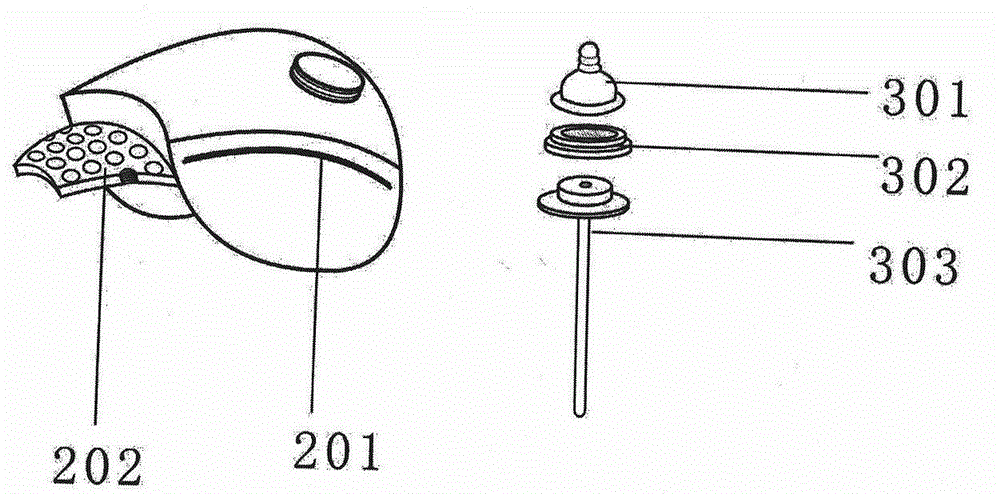

Milking pig feeding device

ActiveCN104521796BReduce temperature drop rateReduce self-temperature lossAnimal feeding devicesPig farmsEconomic benefits

The invention relates to a milk supplementing device for suckling pigs. The milk supplementing device comprises a trough, a trough cover box, nipples, separation rods and a lifting frame. The milk supplementing device is simple in structure, reasonable in design and detachable. When the trough cover box and the nipples are not assembled, the milk supplementing device can be used as a crib of granular fodder and dry powdered fodder. Accordingly, the milk supplementing device is multifunctional and suitable for pig farms of different sizes and pigs of different days, and the utilization of the device is improved. Under the condition that new-born suckling pigs are short of milk or sows can not provide enough milk, the milk supplementing device can supplement milk for several suckling pigs, therefore, the survival rate and the growing speed of the suckling pigs can be improved, labor intensity of workers is lowered, and economic benefits of the pig farms are improved.

Owner:湘西芙蓉资源农业科技有限公司

Air conditioner, control method thereof, and computer storage medium

ActiveCN110848888BReduce cooling capacityIncrease temperatureMechanical apparatusSpace heating and ventilation safety systemsEngineeringOutdoor temperature

The invention discloses a control method of an air conditioner. The outdoor unit of the air conditioner includes an outdoor heat exchanger, a first fan and a second fan. The air outlet surface of the first fan is opposite to the indoor heat exchanger. The air outlet surface of the second fan is arranged on the lower part of the outdoor heat exchanger. The control method of the air conditioner includes the following steps: after the air conditioner enters the cooling mode, and the outdoor temperature is lower than the first preset temperature, the outlet temperature of the outdoor heat exchanger is obtained. After the air conditioner enters the cooling mode, the first fan and the second fan are in the running state; when the outlet temperature is lower than the second preset temperature, lower The rotational speed of a target fan, where the target fan includes at least one of the first fan and the second fan. The invention also discloses an air conditioner and a computer-readable storage medium. The frequency of starting and stopping of the compressor of the present invention is relatively low.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD

Laser etching method and device, substrate electrode and electroluminescent device

ActiveCN106271046BAvoid depositionIncrease temperatureMetal working apparatusLaser beam welding apparatusLaser etchingLaser beams

Owner:NANJING TECH CORP LTD

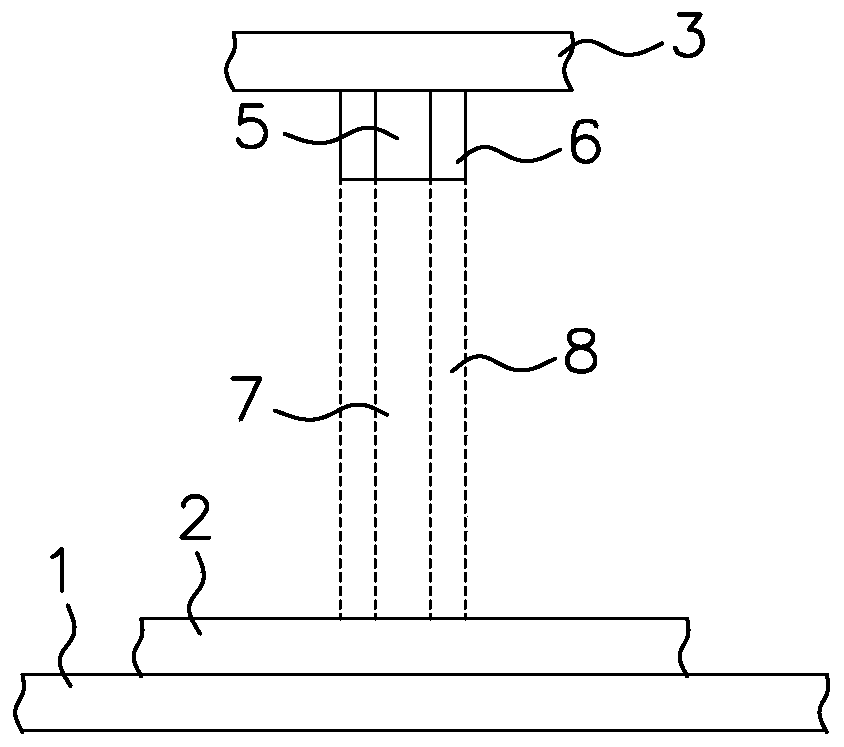

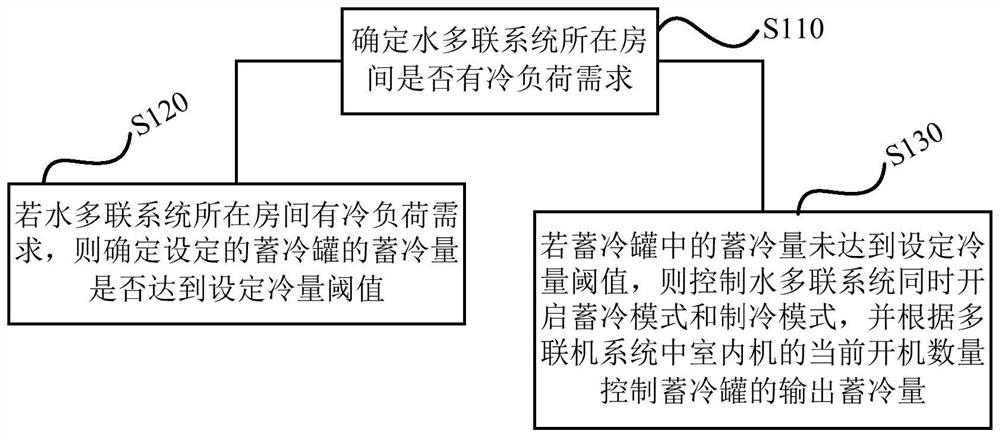

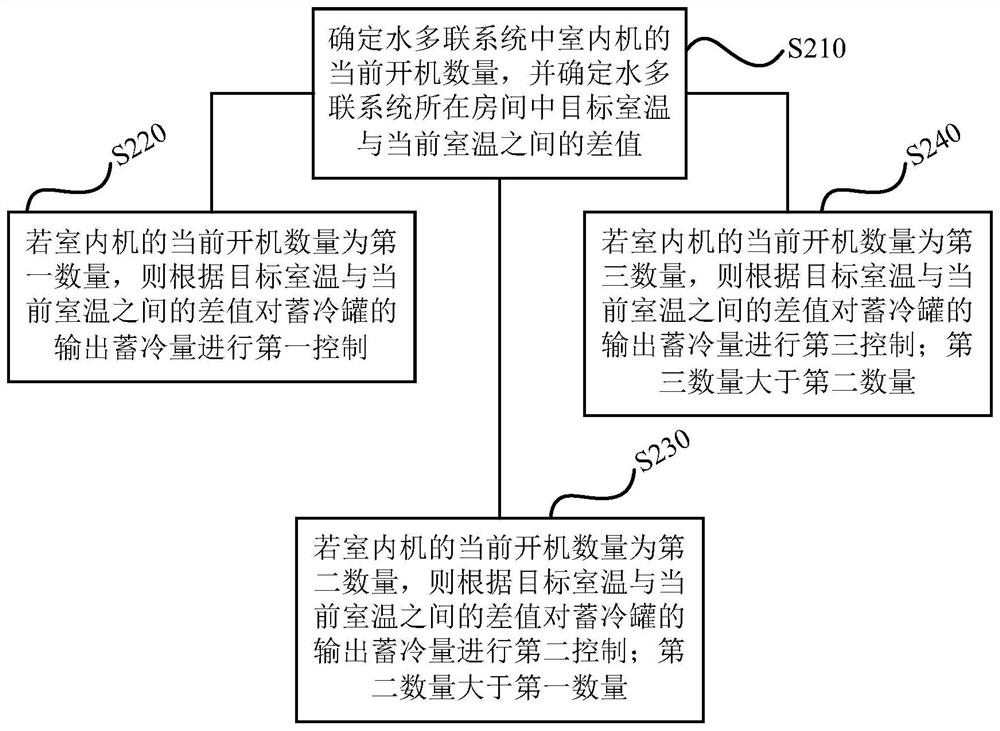

Water multi-system control method, device, storage medium and water multi-system

ActiveCN110895013BReduce temperature drop rateImprove experienceMechanical apparatusSpace heating and ventilation safety systemsRoombaUnit system

The invention discloses a water multi-unit system control method, device, a computer readable storage medium and a water multi-unit system. The method comprises steps: whether a room where the water multi-unit system is located has a cooling load requirement or not is determined; if the room where the water multi-unit system is located has the cooling load requirement, whether the set cold accumulation capacity of a cold accumulation tank reaches a set cold capacity threshold value or not is determined; and if the cold accumulation capacity in the cold accumulation tank does not reach the setcold capacity threshold value, the water multi-unit system is controlled to start a cold accumulation mode and a refrigeration mode at the same time, and the output cold accumulation capacity of the cold accumulation tank is controlled according to the current starting number of indoor units in the multi-unit system. According to the scheme, the problem that the comfort of a user is poor due to the fact that the indoor unit and the outdoor unit of the water multi-unit machine cannot be linked can be solved, and the effect of improving the comfort of the user is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of molten steel thermal insulation agent and thermal insulation agent layer thereof

The invention discloses a molten steel thermal insulating agent and belongs to the field of thermal insulating agents. The molten steel thermal insulating agent comprises the following components of,by mass, 70-100 parts of carbonized rice husk ash, 1-10 parts of carbon source and 1-30 parts of silicon source, and the carbonized rice hull ash comprises the following elements of, by mass, 2%-17% of C, 40%-60% of Si, and the balance H, O, S, Ca, Fe and P. Water of the carbonized rice husk ash is less than 3% of the total mass of the thermal insulating agent. The bulk density of the molten steelthermal insulating agent is 0.18-0.35 g / cm<3>. Compared with carbonized rice hulls of a honeycomb structure, the molten steel thermal insulating agent provided by the invention can make the surface temperature of molten steel be lowered to 0.78 DEG C.min<-1> from 1.56 DEG C.min<-1> maximally. The molten steel thermal insulating agent provided by the invention is low in heat conductivity coefficient, good in thermal insulating effect, excellent in spreadability, free of caking, and low in production cost.

Owner:赣州鼎洋贸易有限公司

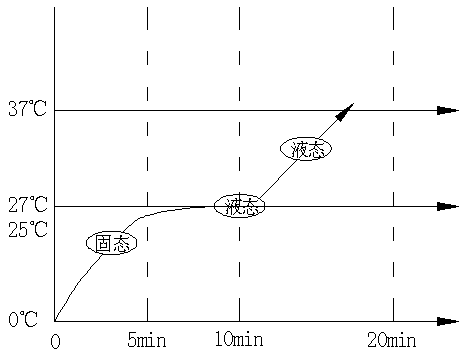

Nano phase-change constant-temperature culture dish and manufacturing method thereof

PendingCN111500421AReduce temperature drop rateStable temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsPetri dishProcess engineering

The invention provides a nano phase-change constant-temperature culture dish which is characterized in that a single-layer structure of a traditional culture dish is improved, a double-layer culture dish in a hollow sandwich structure form is manufactured, a nano phase-change constant-temperature capsule material is injected into the middle of a sandwich layer, and the nano phase-change constant-temperature culture dish is manufactured after the sandwich layer is sealed. According to the culture dish, when the environment temperature rises, the nano phase-change capsule material can absorb andstore external heat, and when the environment temperature is lower than the phase-change temperature, the nano phase-change capsule material can release heat outwards, so that the temperature in theculture dish is kept relatively stable within a certain time range. The invention also provides a manufacturing method of the nano phase-change constant-temperature culture dish.

Owner:浙江吉诺赛百尔生物科技有限公司

A freezer capable of preventing the upper surface of the center beam from freezing

ActiveCN106016893BReduce temperature drop ratePrevent standing water from freezingLighting and heating apparatusDomestic refrigeratorsElectricityEngineering

The embodiment of the invention provides a refrigerator capable of preventing the upper surface of a middle beam from being frozen, and relates to the technical field of refrigeration equipment. The refrigerator is provided for solving the problem that a lead of a heating device of a middle beam of an existing refrigerator is likely to be affected with cold and damp so as to be aged. The refrigerator capable of preventing the upper surface of the middle beam from being frozen comprises a box body and door bodies used for sealing the box body. The middle beam is arranged at the position of an opening of the box body. The middle beam is of a hollow structure, a heating device is arranged inside the middle beam, and the middle beam is filled with heat insulation materials. The end of the middle beam is in sealed connection with the inner wall of the box body. A lead of the heating device is electrically connected with a control circuit of the refrigerator after penetrating out of the end of the middle beam and the inner wall of the box body. The refrigerator capable of preventing the upper surface of the middle beam from being frozen is used for storing goods at a low temperature.

Owner:HISENSE RONSHEN GUANGDONG FREEZER

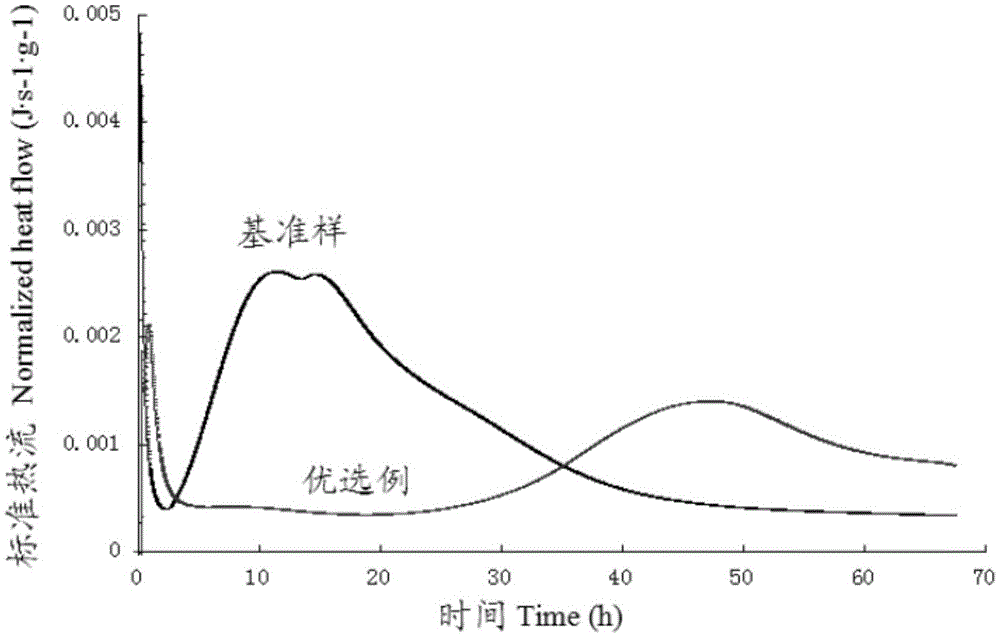

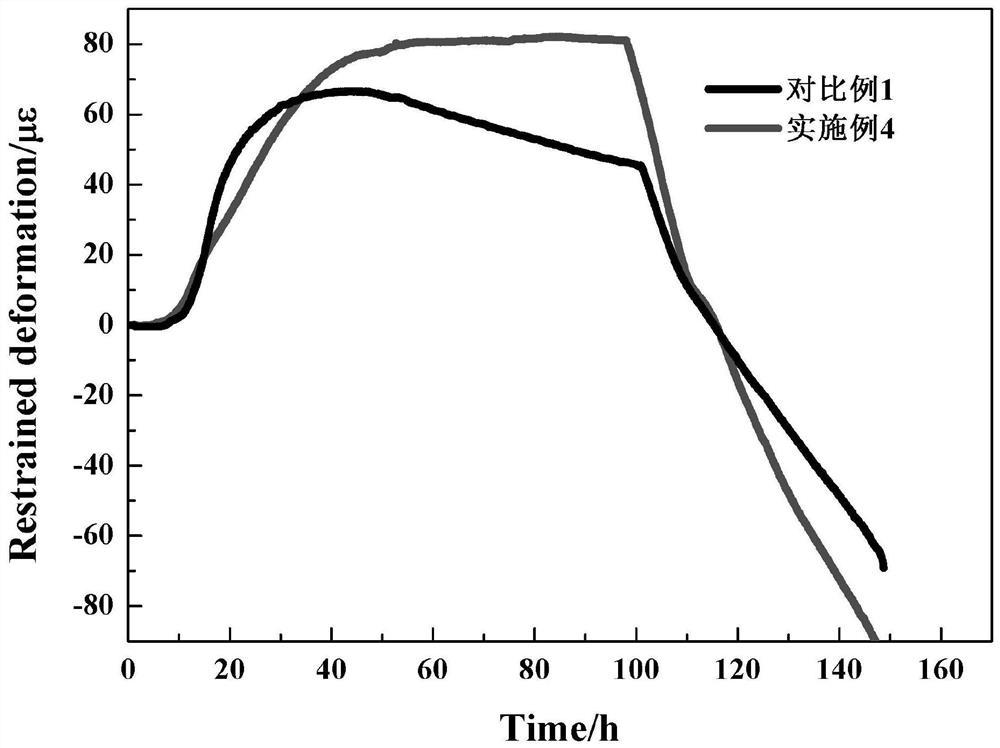

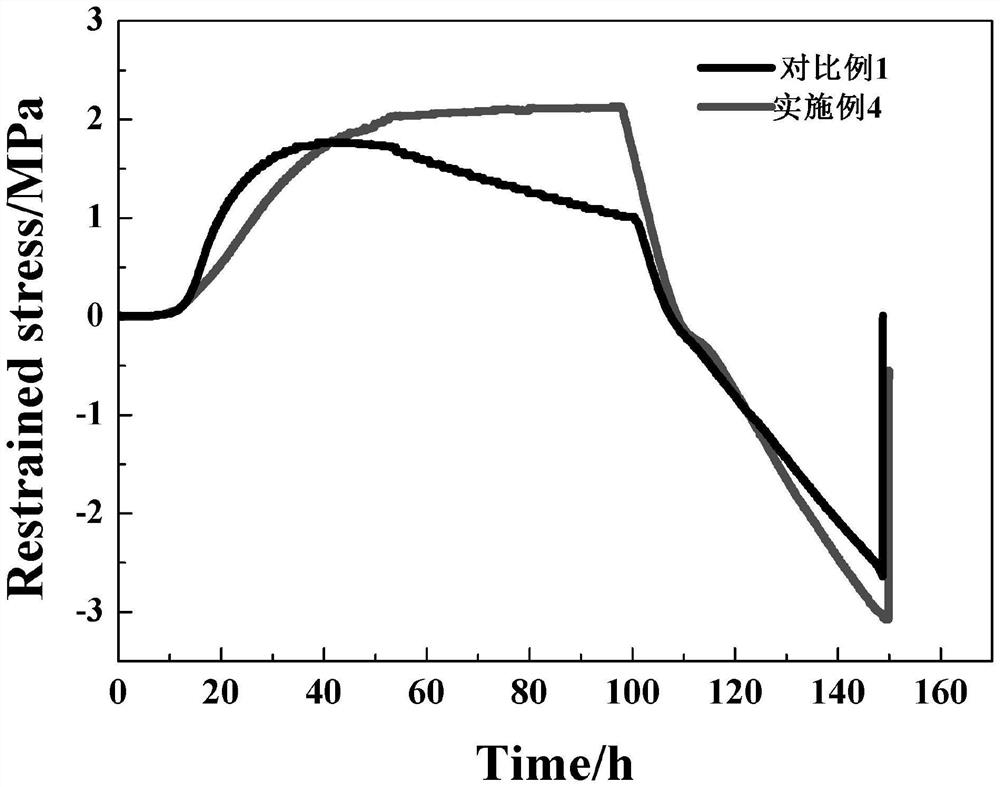

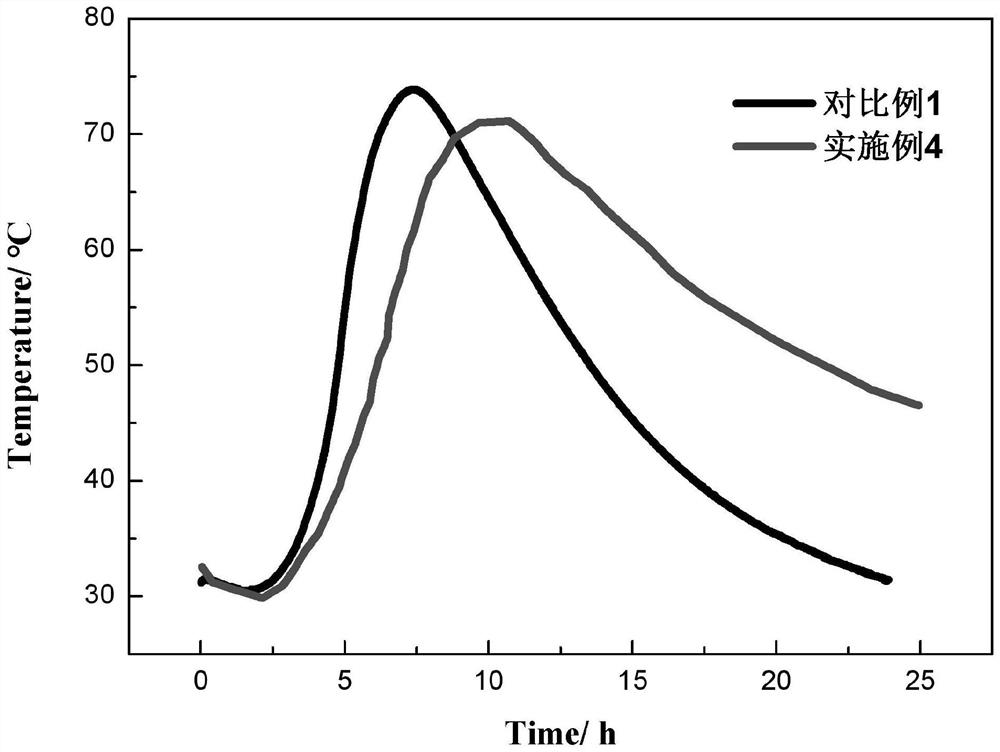

Phase change expansion anti-cracking agent for concrete and preparation method of phase change expansion anti-cracking agent

ActiveCN114538817AReduce expansion energy lossPromote expansionSolid waste managementMolten statePolyethylene glycol

The invention relates to a phase-change expansion anti-cracking agent for concrete and a preparation method thereof, and the preparation method comprises the following steps: heating polyethylene glycol to a molten state, adding a mixed expansion agent into the molten state, uniformly mixing, adding graphite-phase carbon nitride, uniformly mixing, putting the mixed material into a vacuum drying oven, and carrying out vacuum adsorption, so as to obtain the phase-change expansion anti-cracking agent for concrete. The polyethylene glycol and the mixed expanding agent are adsorbed in the porous structure of the graphite phase carbon nitride, so that the phase change expansion anti-cracking agent for the concrete is prepared. Wherein the mass percentage ratio of the polyethylene glycol to the mixed expanding agent to the graphite phase carbon nitride is (35-49.5%): (49.5-60%): (1-5%). Different active expanding agents are compounded to form the mixed expanding agent, the calcium expanding agent is high in activity and hydration rate and mainly compensates for early-stage shrinkage of the concrete, meanwhile, M-type and S-type MgO expanding agents with different activities are added, shrinkage of the concrete in the middle and later stages is compensated, and therefore compensation shrinkage of the concrete in all stages is guaranteed, and the concrete quality is improved. And the cracking risk of the concrete is reduced.

Owner:武汉三源特种建材有限责任公司

Milk supplementing device for suckling pigs

ActiveCN104521796AReduce temperature drop rateReduce self-temperature lossAnimal feeding devicesPig farmsEconomic benefits

The invention relates to a milk supplementing device for suckling pigs. The milk supplementing device comprises a trough, a trough cover box, nipples, separation rods and a lifting frame. The milk supplementing device is simple in structure, reasonable in design and detachable. When the trough cover box and the nipples are not assembled, the milk supplementing device can be used as a crib of granular fodder and dry powdered fodder. Accordingly, the milk supplementing device is multifunctional and suitable for pig farms of different sizes and pigs of different days, and the utilization of the device is improved. Under the condition that new-born suckling pigs are short of milk or sows can not provide enough milk, the milk supplementing device can supplement milk for several suckling pigs, therefore, the survival rate and the growing speed of the suckling pigs can be improved, labor intensity of workers is lowered, and economic benefits of the pig farms are improved.

Owner:湘西芙蓉资源农业科技有限公司

Novel method for composting fermentation of kitchen garbage

PendingCN113307668APromote reproductionEasy to useBio-organic fraction processingClimate change adaptationCarbon particleOrganic fertilizer

The invention discloses a novel method for composting fermentation of kitchen garbage. The method comprises the following steps: in the composting fermentation process of the kitchen garbage, mixing iron-carbon particles into a pile body, and continuously fermenting until the pile body is thoroughly decomposed. By utilizing the method disclosed by the invention, the fermentation period can be remarkably shortened, the quality of the obtained bio-organic fertilizer is improved, and meanwhile, the number of beneficial viable bacteria in the bio-organic fertilizer is increased.

Owner:安徽国祯环卫科技有限公司

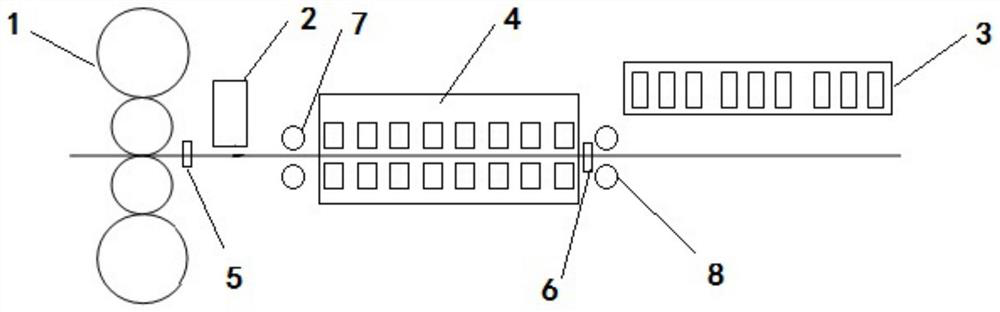

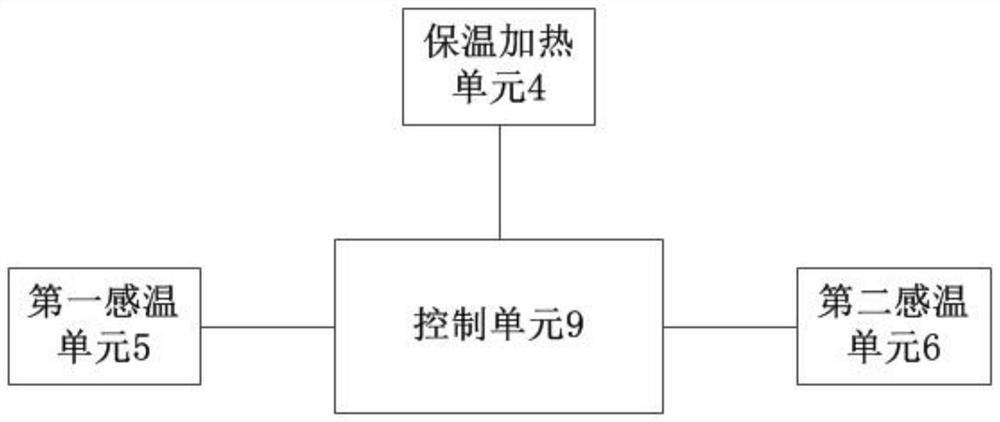

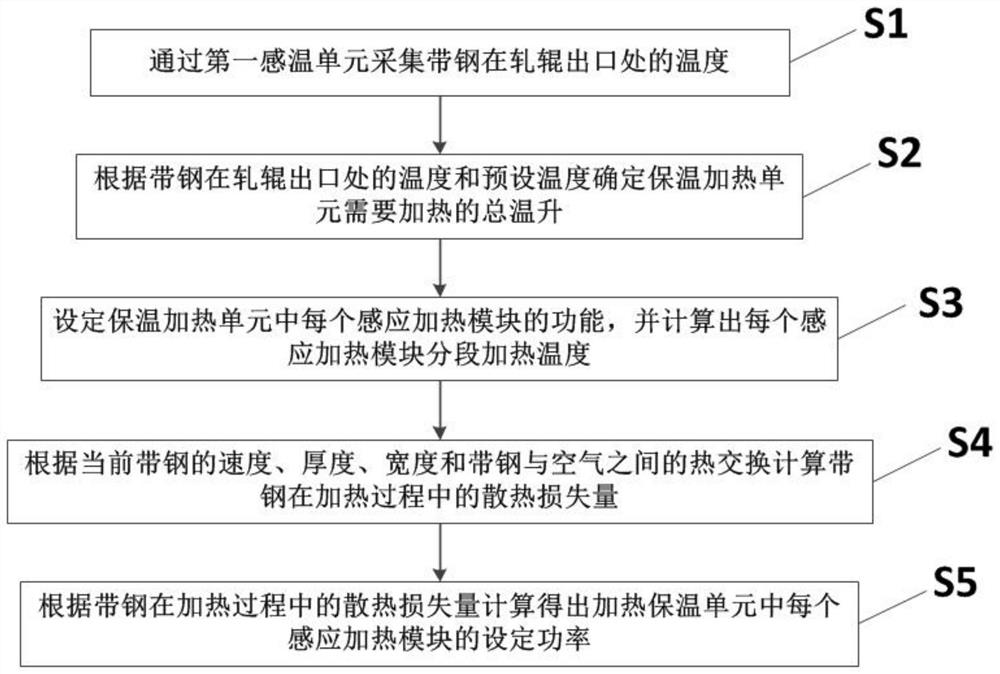

Temperature control system and method for hot-rolled thin strip steel production

PendingCN113275388AReduce temperature drop rateImprove tissue performanceTemperature control deviceMeasuring devicesTemperature controlLaminar cooling

The invention provides a temperature control system and method for hot-rolled thin strip steel production. The temperature control system comprises a hot-rolled thin strip steel production line, and rollers, a width and thickness gauge and a stream cooling device are sequentially arranged in the hot-rolled thin strip steel production line in the rolling direction of strip steel; the temperature control system further comprises a heat preservation heating unit, a first temperature sensing unit, a second temperature sensing unit and a control unit; the first temperature sensing unit is arranged at the outlet ends of the rollers, the heat preservation heating unit is arranged between the first temperature sensing unit and the stream cooling device, and the second temperature sensing unit is arranged at the outlet end of the heat preservation heating unit; and the control unit is connected with the heat preservation heating unit, the first temperature sensing unit and the second temperature sensing unit. According to the temperature control system and method for hot-rolled thin strip steel production, the temperature during low-temperature strip steel production can be effectively increased, and the requirement of customers for the strip steel forming quality is further met.

Owner:RIZHAO STEEL HLDG GROUP

A high lance position vacuum refining method based on cluster top lances

The invention provides a high gun position vacuum refining method based on cluster top lances. The cluster top guns have a powder channel located in the center, a main oxygen channel located on the periphery of the powder channel, and an oxygen supply channel located on the periphery of the main oxygen channel; Oxygen enters from the main oxygen channel and the auxiliary oxygen channel to form the main oxygen flow and the auxiliary oxygen flow respectively. Under the protection of the main oxygen flow, the powder is injected into the molten steel together with the main oxygen flow. The carbon in the liquid reacts to generate carbon monoxide, and the carbon monoxide overflowing the molten steel and the oxygen flow that surrounds and accompanies them undergo secondary combustion to heat the vacuum tank to reduce the temperature drop of the molten steel. The oxygen-supporting flow of the present invention forms a surrounding accompanying flow outside the central supersonic jet, which makes the expansion and attenuation of the central supersonic jet smaller, the supersonic jet is longer, and the penetration depth and stirring intensity of the oxygen jet to the molten pool are improved. Improve the reduction of molten steel splash and sticky slag at the tip of the gun, and prolong the service life.

Owner:CISDI ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com