Gaseous pollutant multi-point matrix mixed sampling device, sampling method thereof and reverse blowing maintenance method

A technology of mixed sampling and pollutants, applied in sampling device, measuring device, sampling and other directions, can solve the problem of non-representation, and achieve the effect of increasing the heat tracing path, reducing the temperature drop, and reducing the energy consumption of the probe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the multi-point matrix mixed sampling device for gaseous pollutants of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

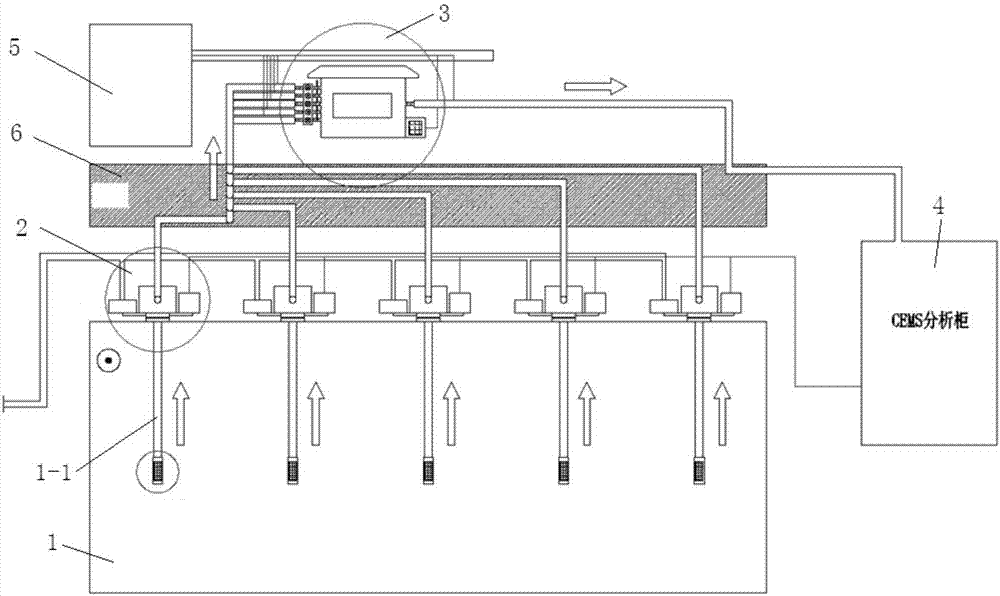

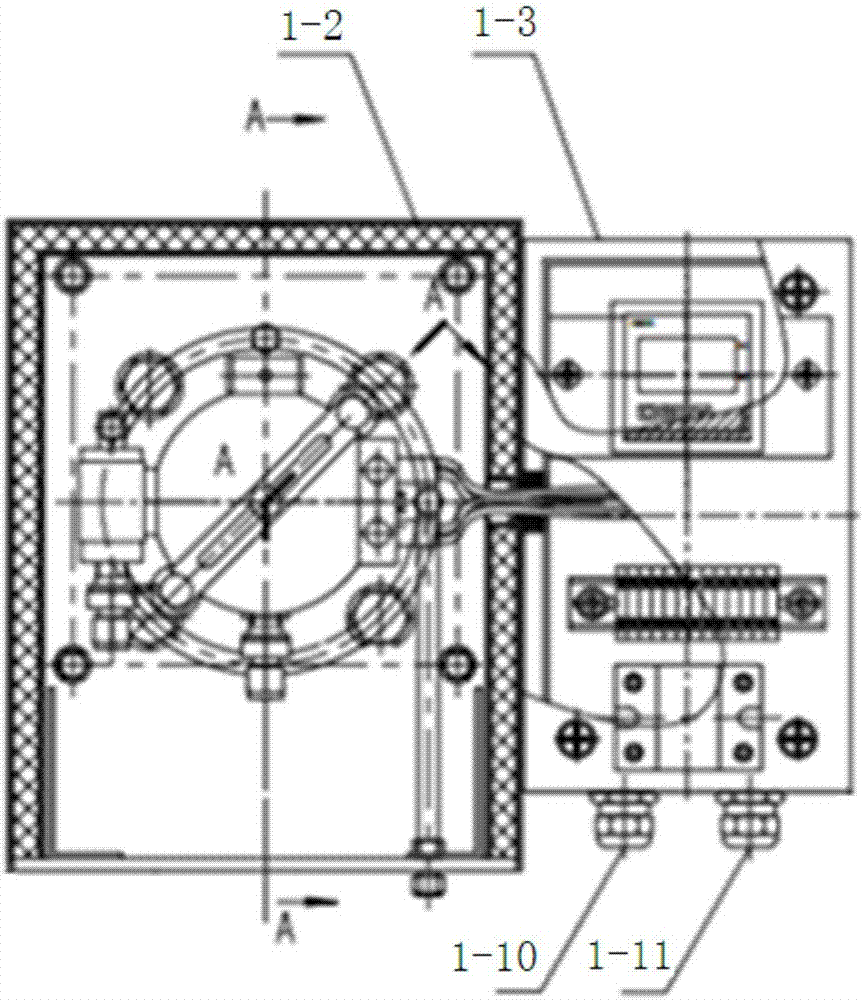

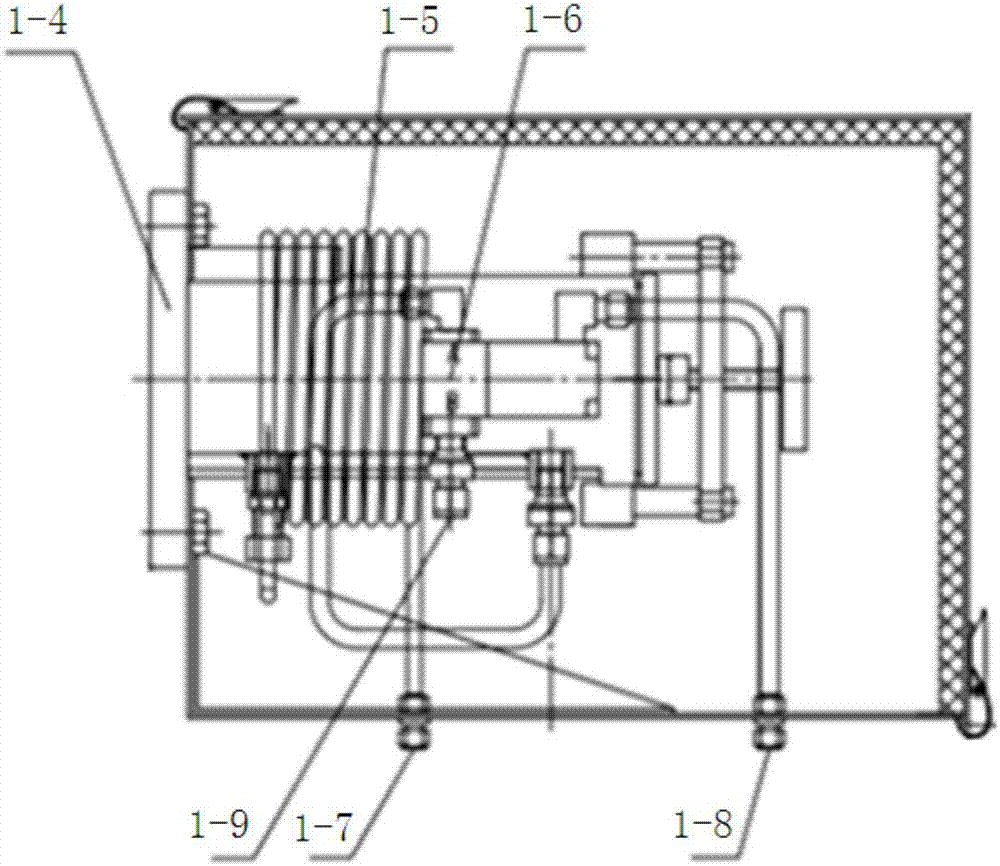

[0055] Such as figure 1 As shown, a multi-point matrix mixed sampling device for gaseous pollutants includes a flue gas flue, and multiple sets of high-temperature sampling probes are evenly arranged along the same section of the pipe outside the pipe wall of the flue gas flue. The pipeline is sent to the back-end mixing box for mixing, and then sent to the analysis cabinet; each set of high-temperature sampling probes includes:

[0056] A probe rod, the probe rod extends into the flue gas flue to send the collected high-temperature flue gas into the high-temperature sampling probe, the front end of the probe rod is provided with a first filter element, and the sampling port is set on the windward side;

[0057] A casing, the casing is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com