Patents

Literature

32results about How to "Save quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

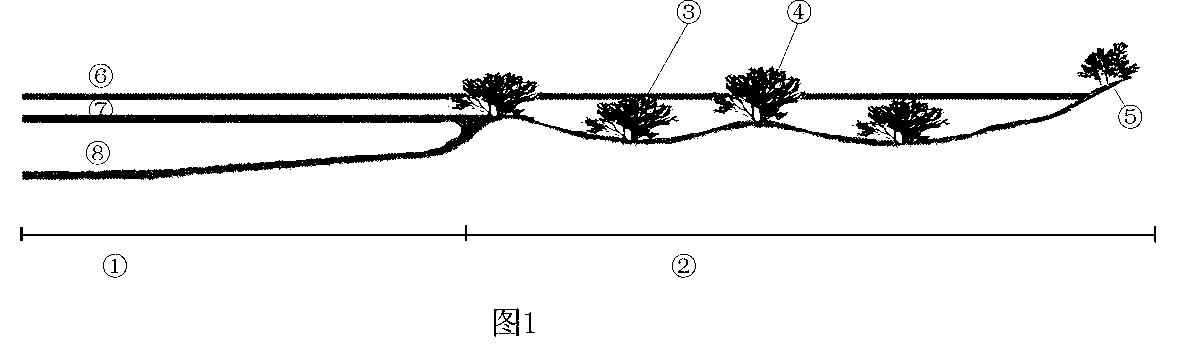

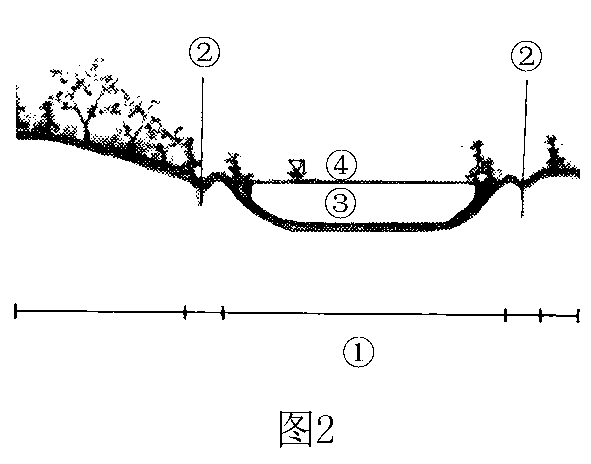

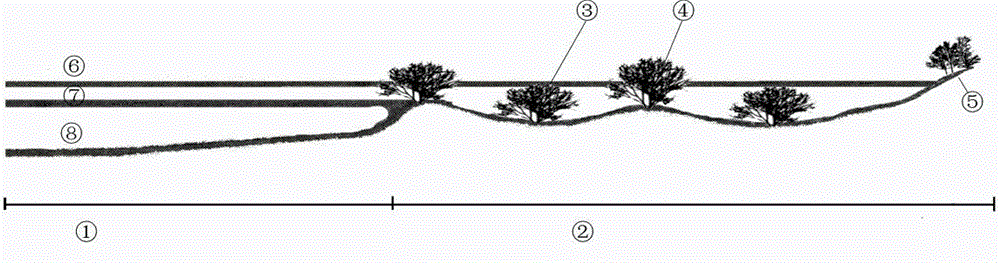

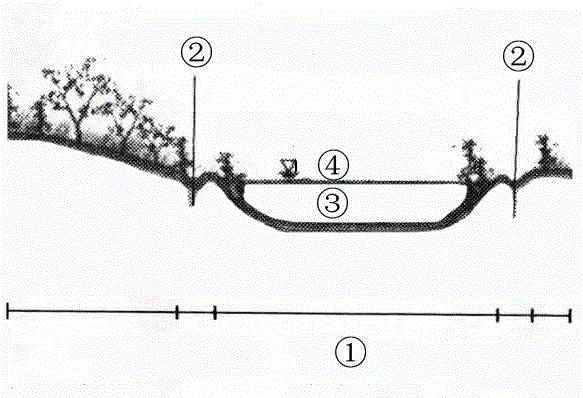

Micro-reformation and vegetation restoration method for degraded plateau and lake wetlands

ActiveCN103314763AAccelerate the speed of recovery successionImprove water qualityClimate change adaptationHorticultureRevegetationRestoration method

The invention belongs to the technical field of environmental protection and ecological engineering, relates to topological micro-reformation and vegetation restoration, and discloses a vegetation restoration method applicable to degraded plateau and lake wetlands. The vegetation restoration method is low in personnel and capital investment and mainly includes stages of background evaluation, selective enclosure and livestock reduction, topological micro-reformation for the wetlands and construction of screened plant communities or plant zones. The vegetation restoration method has the advantages that plateau wetland vegetation restoration is accelerated, wetland vegetation ecosystems are constructed, and the environmental quality of the degraded wetlands is improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

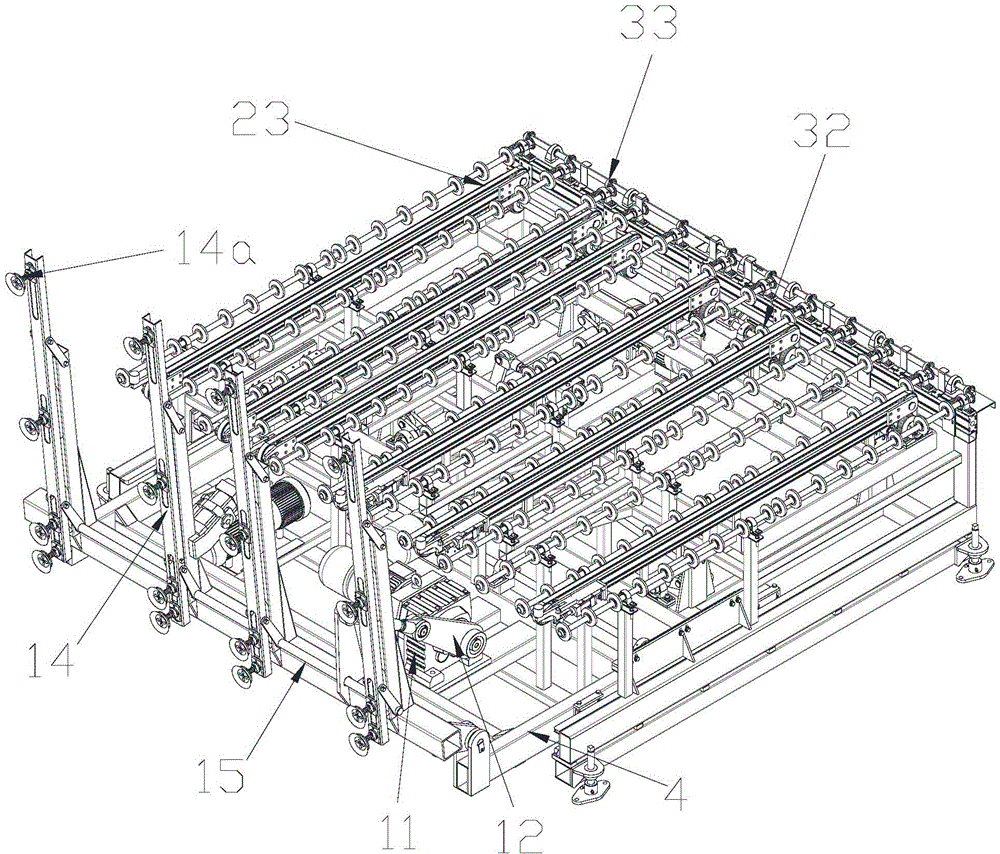

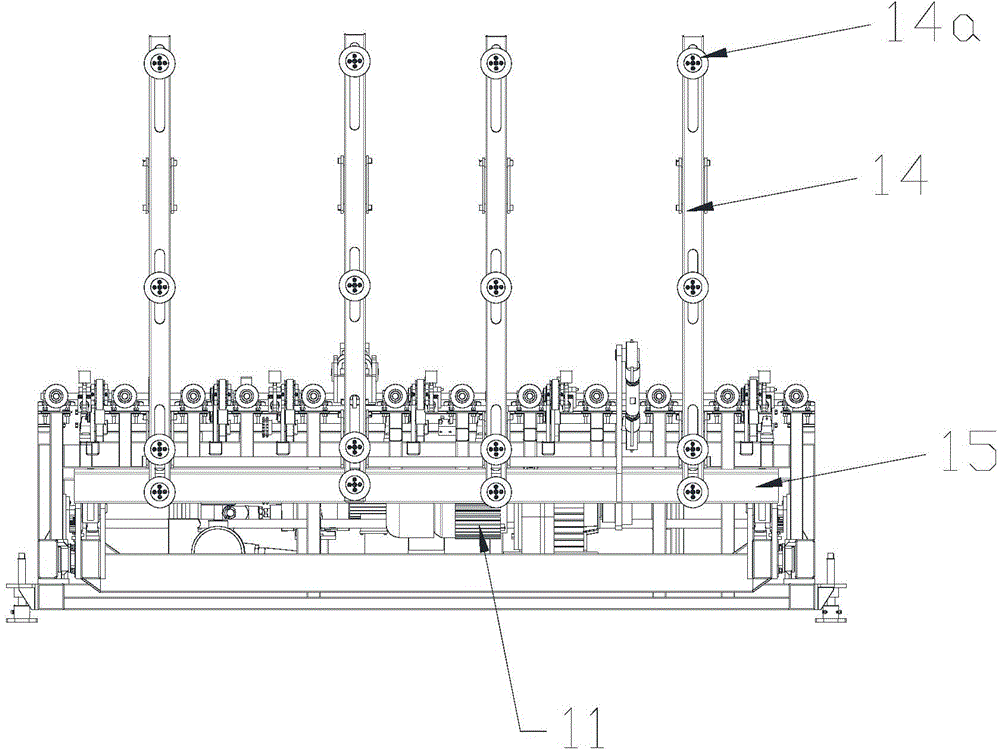

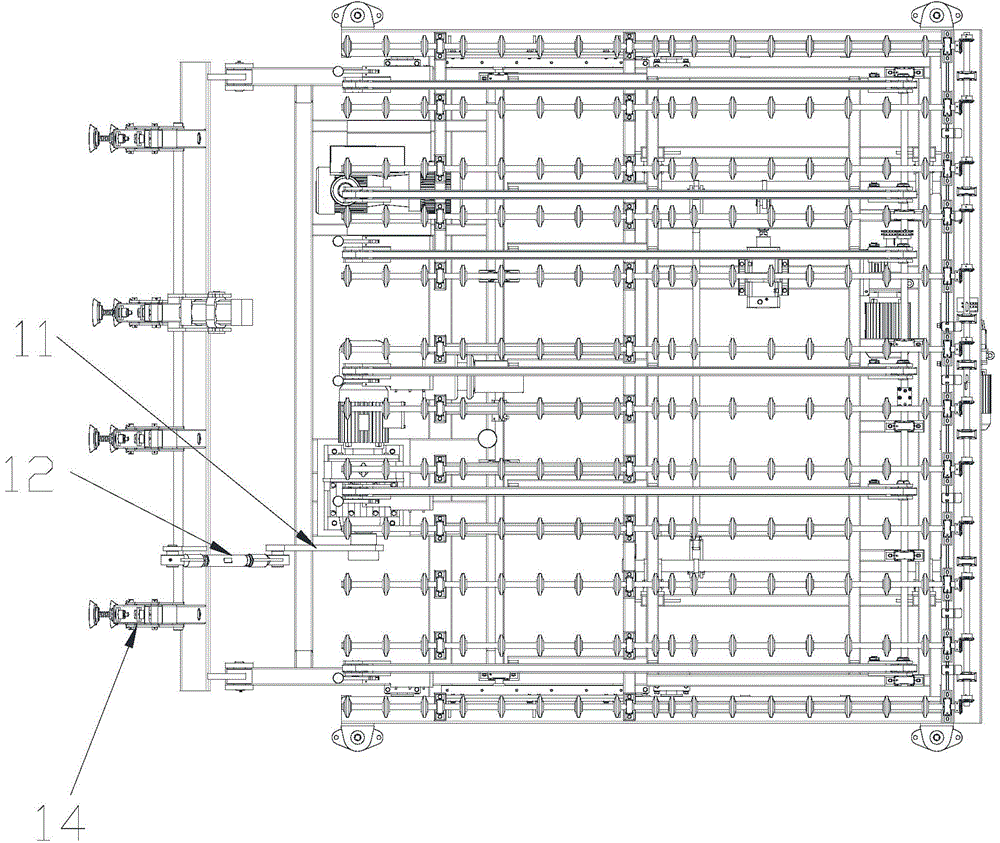

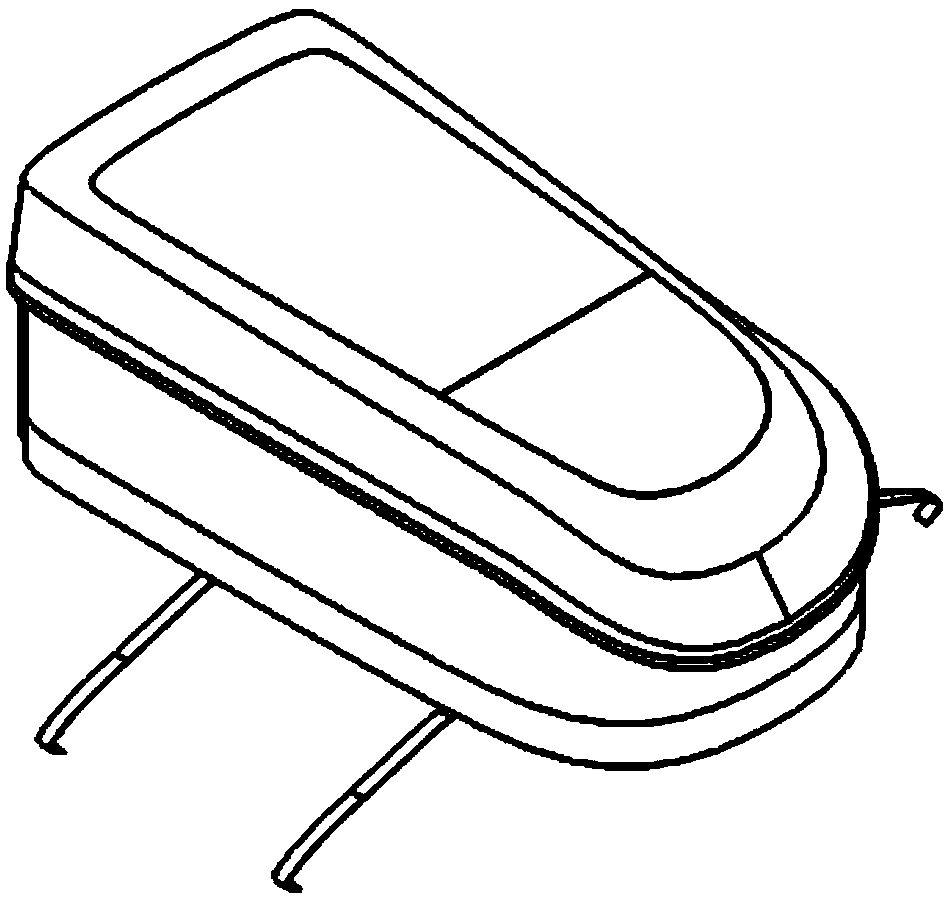

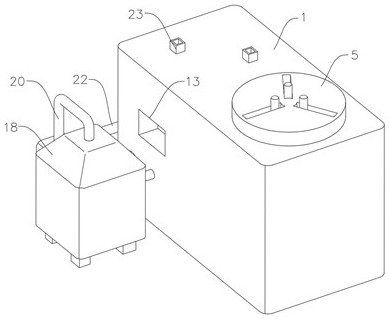

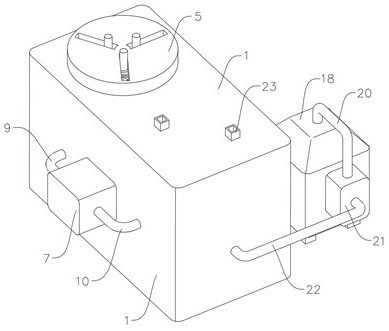

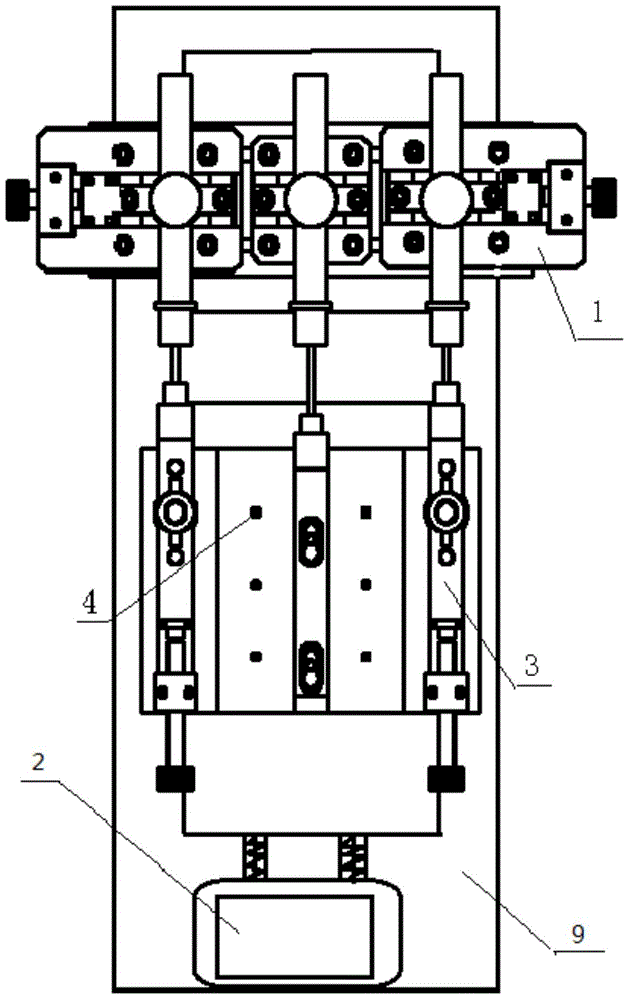

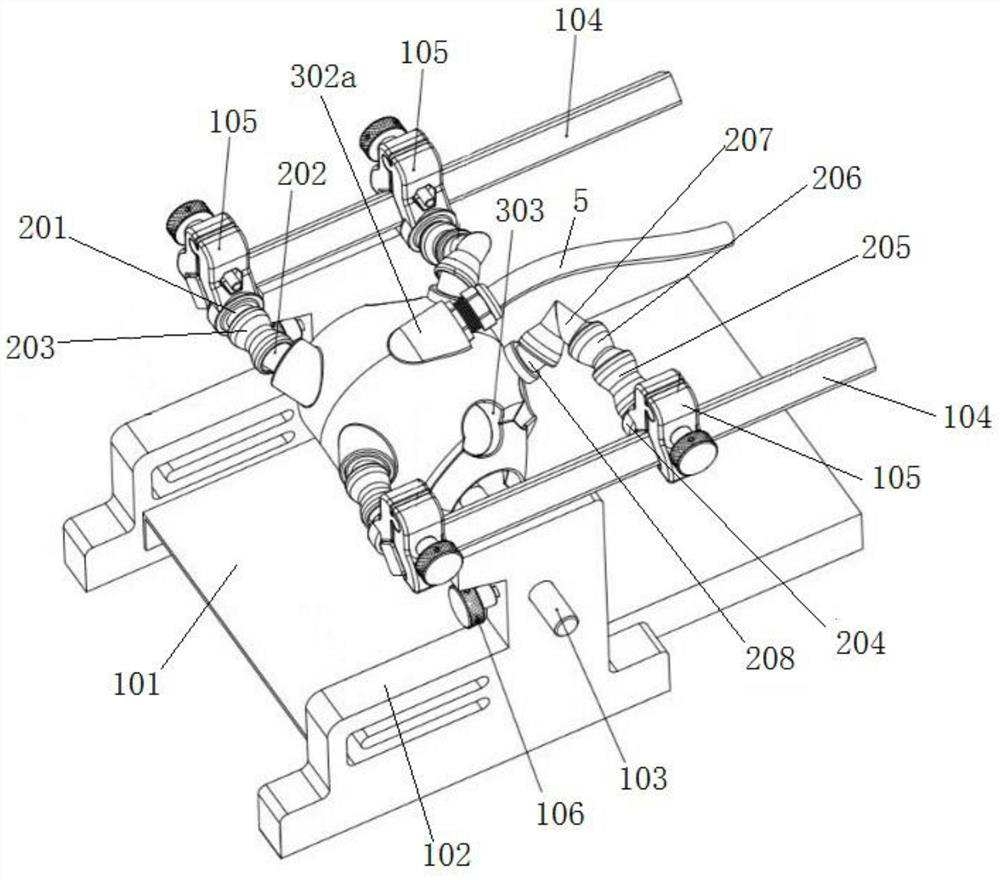

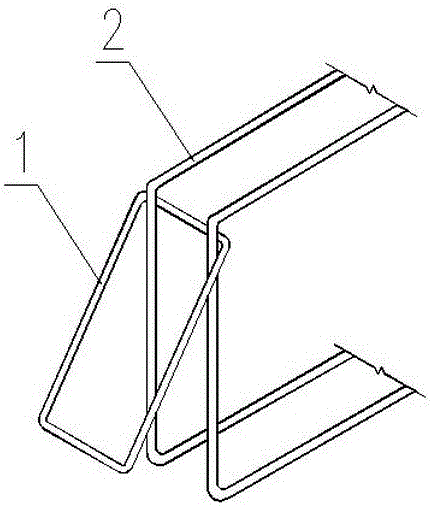

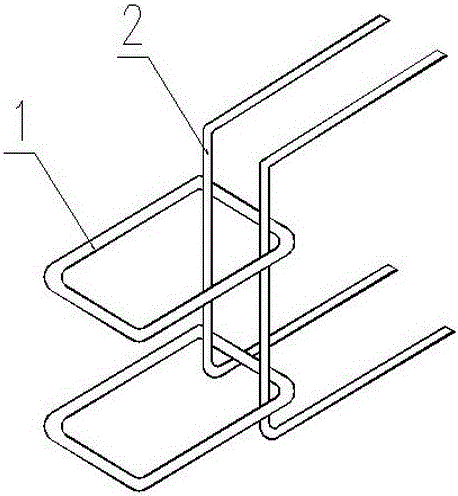

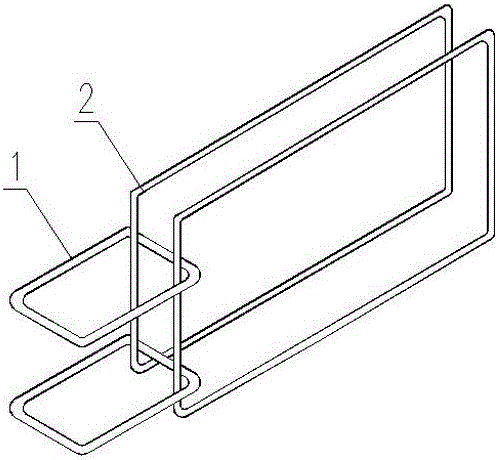

Sheet mounting, dismounting and positioning all-in-one machine

ActiveCN104803194ASave quantityCut costsCharge manipulationConveyor partsFixed positionInvestment cost

The invention discloses a sheet mounting, dismounting and positioning all-in-one machine, which comprises a bottom frame, a turning mechanism, a positioning mechanism and an ascending and descending mechanism, wherein the turning mechanism, the positioning mechanism and the ascending and descending mechanism are arranged on the bottom frame, glass is turned to the horizontal direction from the vertical state by the turning mechanism and is arranged on the positioning mechanism, the positioning mechanism conveys the glass to a fixing position through a Y-axis conveying belt, and the ascending and descending mechanism can do ascending and descending movement, so that the glass on the positioning mechanism is assembled and conveyed to a next station. The sheet mounting, dismounting and positioning all-in-one machine has the advantages that various functions such as turning, Y-axis moving, positioning and glass conveying can be realized on one piece of equipment, the space occupied by sheet mounting, positioning and sheet dismounting is minimized, and the equipment investment quantity and the equipment investment cost are reduced.

Owner:HUMAN INTELLIGENT MACHINE

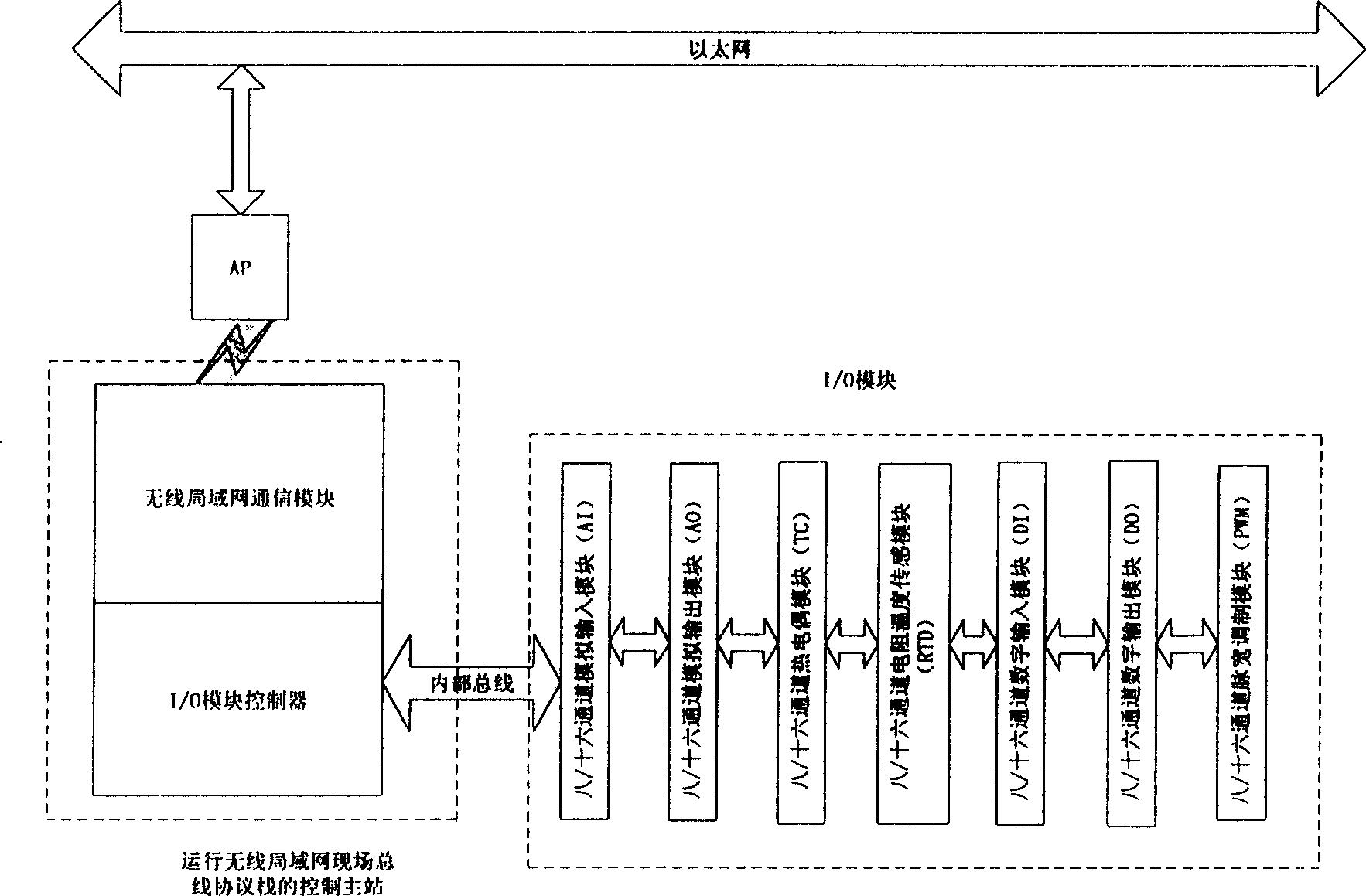

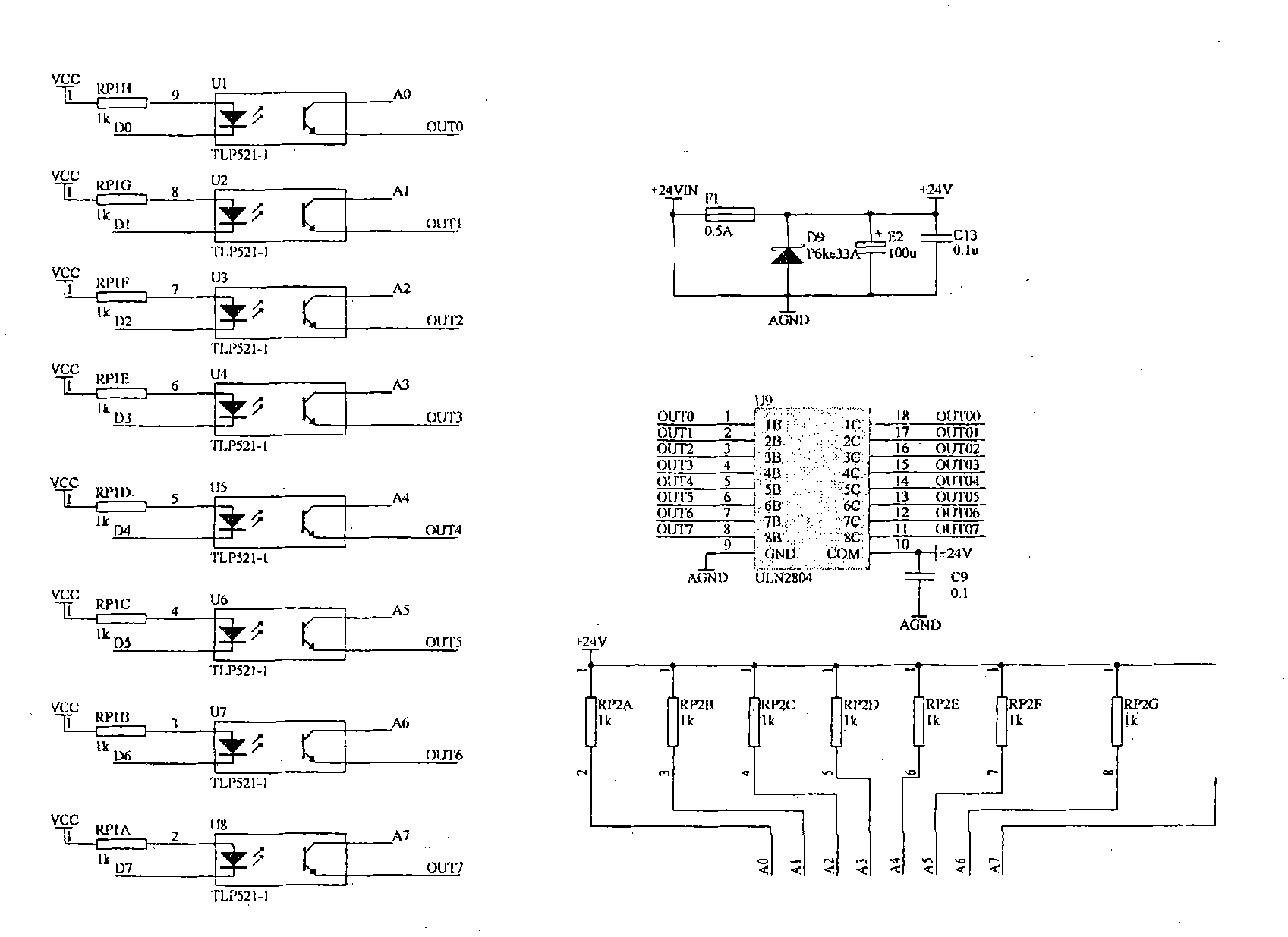

Wireless local area network on-site bus network control station

InactiveCN1567114ASupport hot swapSupport plug and play technologyTotal factory controlElectric digital data processingAutomatic controlDistributed structure

This invention relates to auto-control field, which in detail is used to a wireless LAN on-site bus net control station. It comprises main control station and I / O module, wherein, its main control station runs the wireless LAN on-site bus agreements and accomplishes the distribution I / O control through I / O module controller and receives and transmits data to Ethernet through wireless LAN transmission module. The I / O module is to accomplish the collection and conversion of the on-site signals. It is based on intelligence control device of the wireless Ethernet and turns the DCS total distributed system structure into new type of total distribution structure to completely distribute the control into the on site by network control station. This invention especially applies to old industry control system reconstruction to make it possible for old enterprises to enter the new time of on-site bus.

Owner:无锡中科泛在信息技术研发中心有限公司

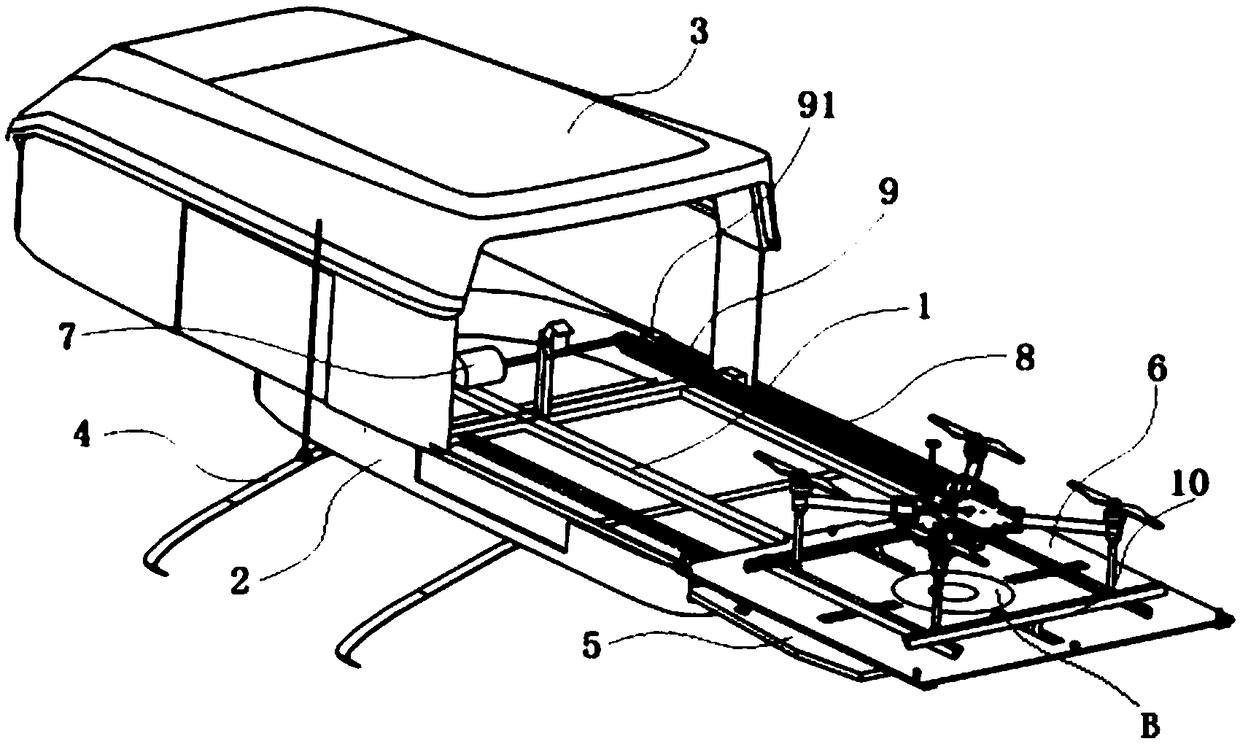

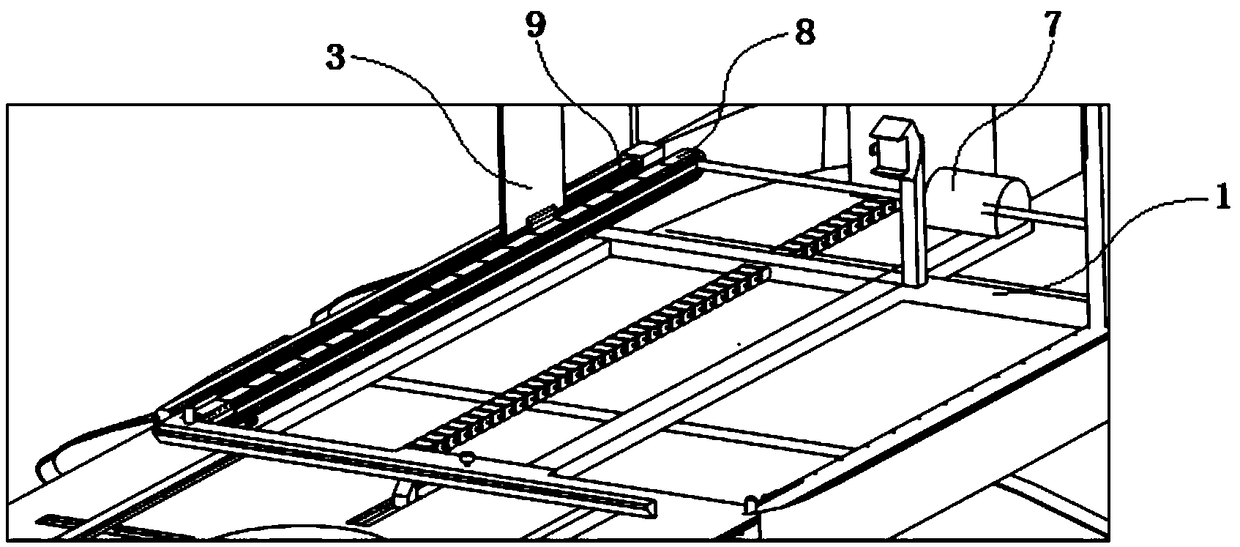

Vehicle-mounted unmanned aerial vehicle nest and a use method thereof

ActiveCN109018413ARealize storageAchieve releaseAnchoring installationsVehicular energy storageMarine engineeringIn vehicle

The utility model relates to a vehicle-mounted unmanned aerial vehicle nest and a use method thereof. The nest comprises a main frame, a lower shell, a sliding cover, a sliding cover driving mechanism, a tail door, a parking apron, a parking apron driving mechanism and a nest controller. Wherein the main frame is connected with a luggage rack provided with the vehicle, and the lower shell is connected with the main frame; The sliding cover is installed on the main frame, and under the action of the sliding cover driving mechanism, the sliding cover can slide relative to the main frame according to the front and rear directions of the vehicle body, the tail door is connected with the main frame, and the relative main frame can be opened or closed; The apron is installed on the main frame, and under the action of the apron driving mechanism, the apron slides relative to the main frame, which is opposite to the moving direction of the sliding cover; A lan target is arranged on that pad; The nest controller controls the sliding cover driving mechanism and the apron driving mechanism in the nest according to the received signal. The nest allows enough space for takeoff and landing to avoid damage during takeoff and landing.

Owner:张欣

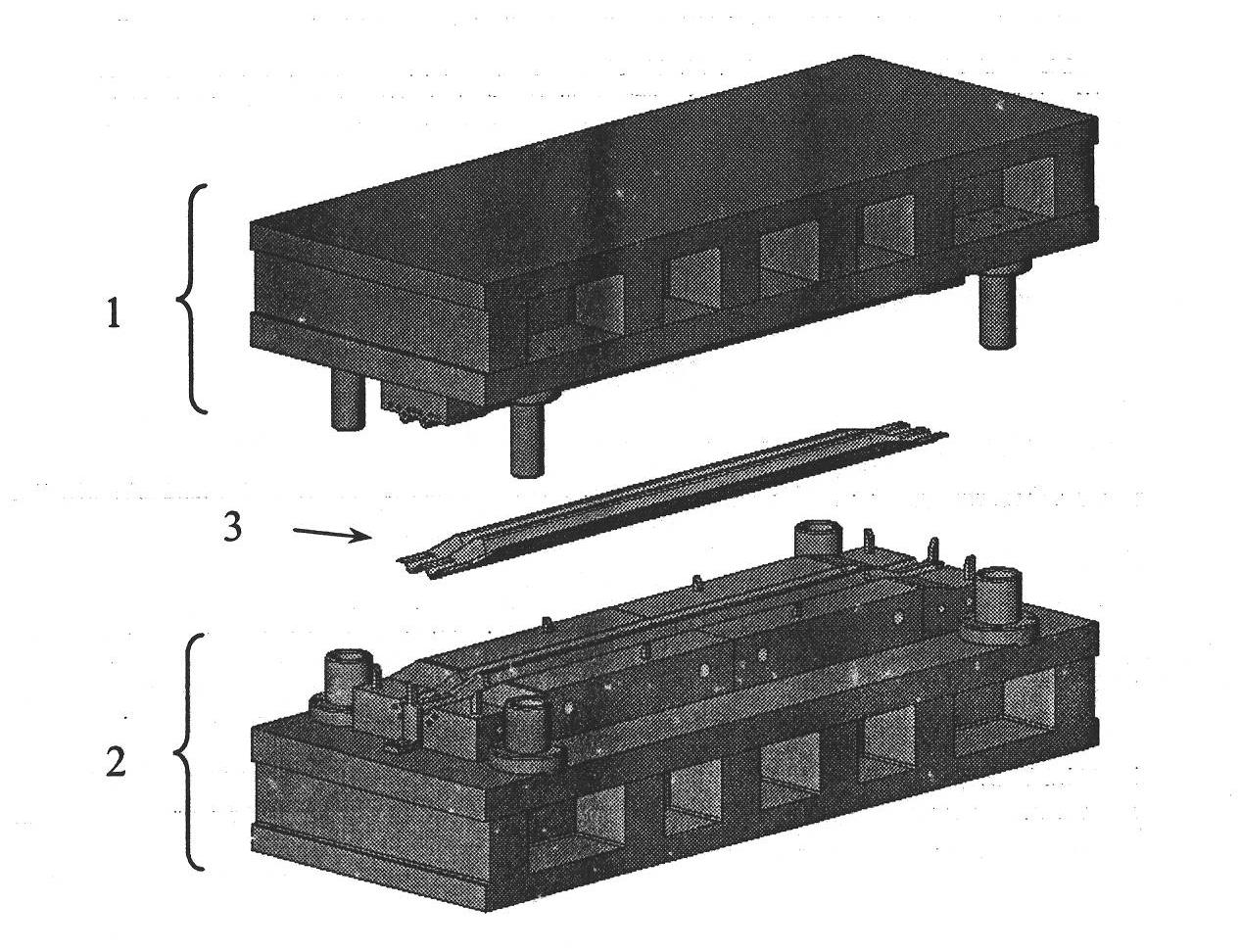

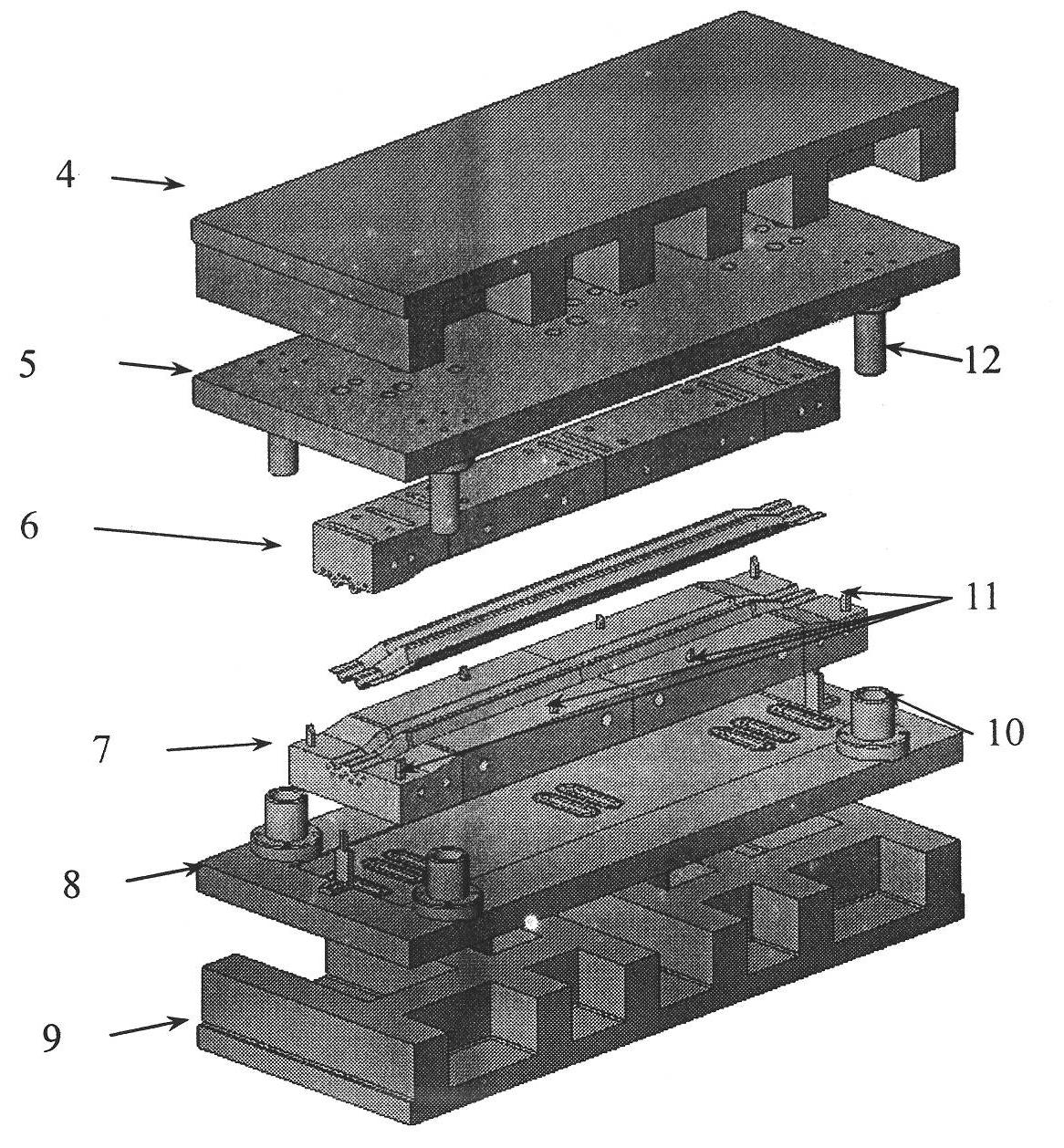

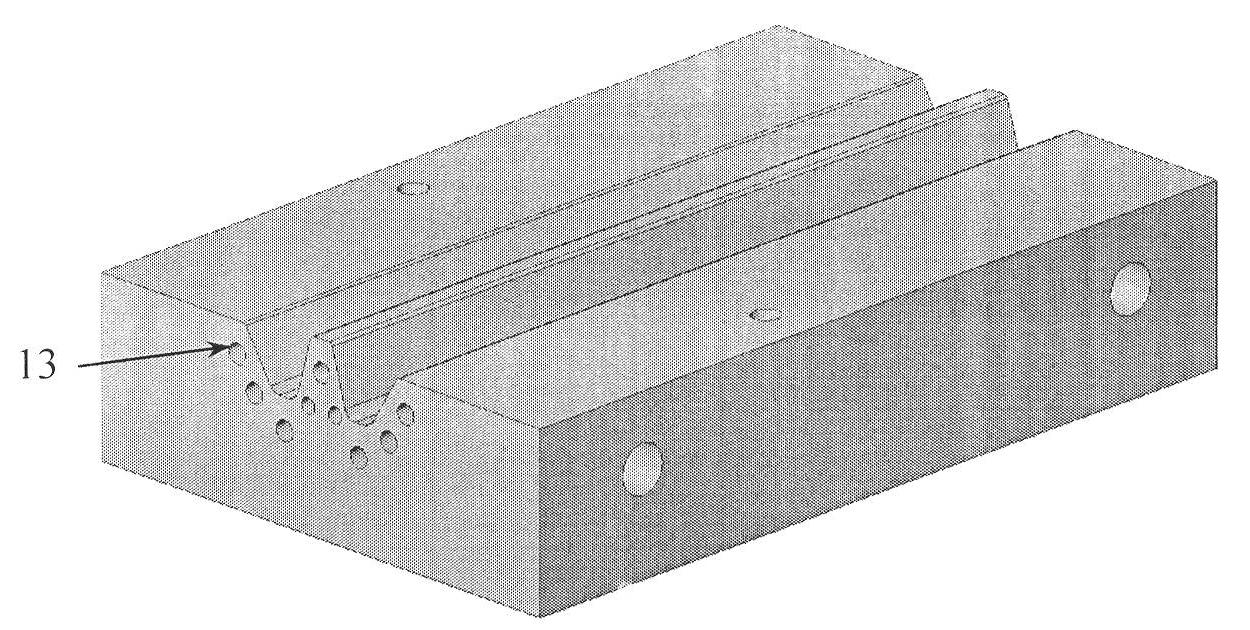

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

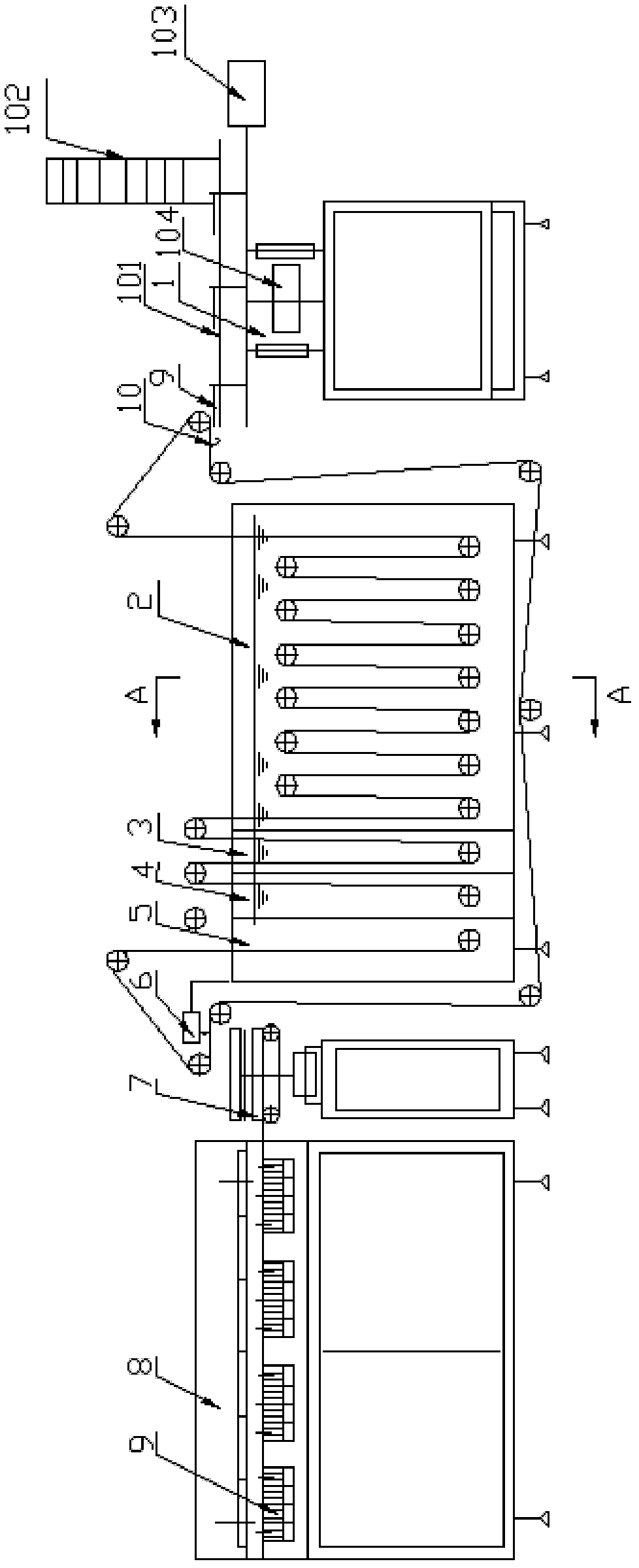

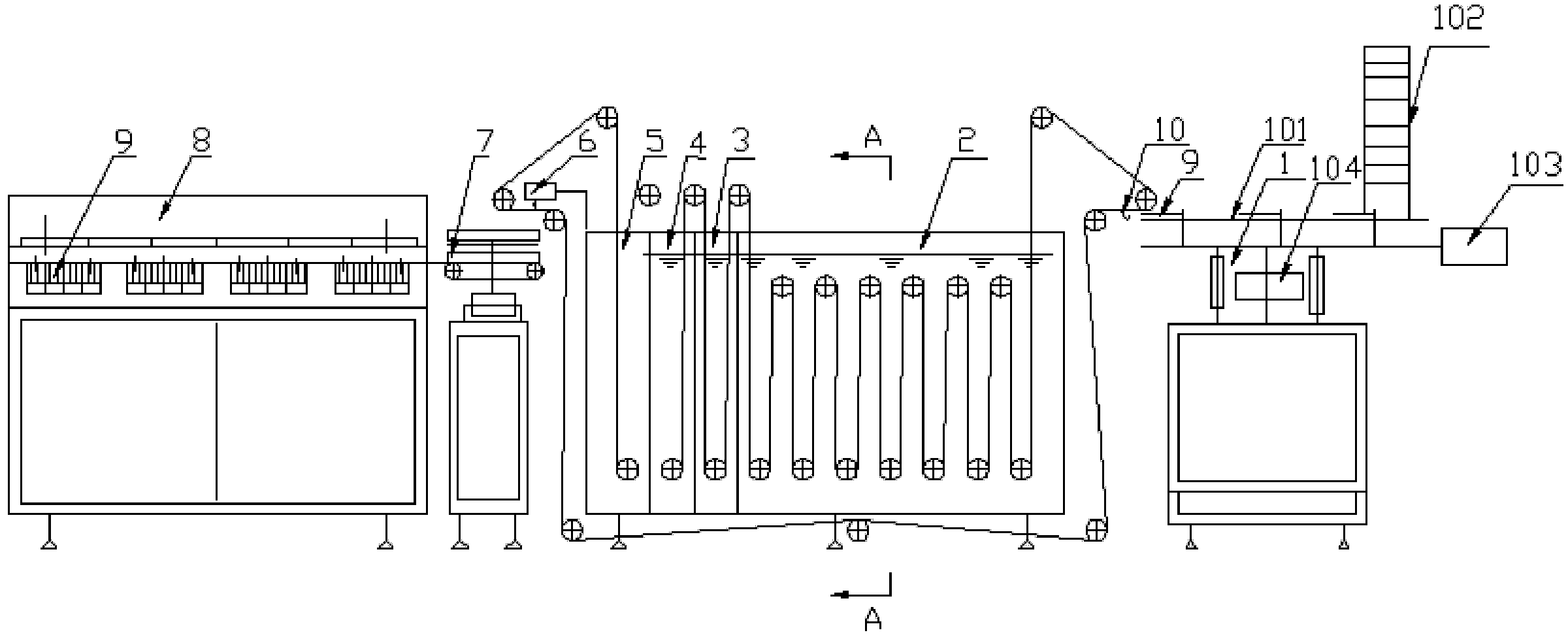

Excessive glue full automatic production line of semiconductor lead frame

The invention discloses an excessive glue full automatic production line of a semiconductor lead frame. The production line comprises the following steps of continuous and automatic loading, chemical treatment solution soaking, air exhaustion, electrolytic excessive glue removal, water washing, soaking and automatic unloading, reversing and high pressure water knife spraying. An automatic loading and unloading mechanism is mainly driven pneumatically; a transmission mechanism is a chain transmission mechanism; and a discharged material strip after being soaked directly enters the high pressure water knife system. The excessive glue full automatic production line of the semiconductor lead frame, disclosed by the invention, has the advantages of compact equipment, small space usage, stability in operation, convenience for maintenance, reliable process, good quality of the treated product, high efficiency, large treatment quantity, medicine liquor conservation, water and electricity conservation, environment friendliness, substantially no damage to human body from hot air and medicine liquor smell; and the field operation environment is largely improved. Glue removing liquors with different performances and operation temperatures can be adopted by using multiple parallel soaking grooves; and electrolytic excessive glue removal can be also combined to realize optimal excessive glue removing effect. By using a reversing turntable, the high pressure water knife can be arranged in parallel with the soaking system so that space usage is saved and convenience in operation is obtained.

Owner:SHENZHEN ALLMERIT TECH

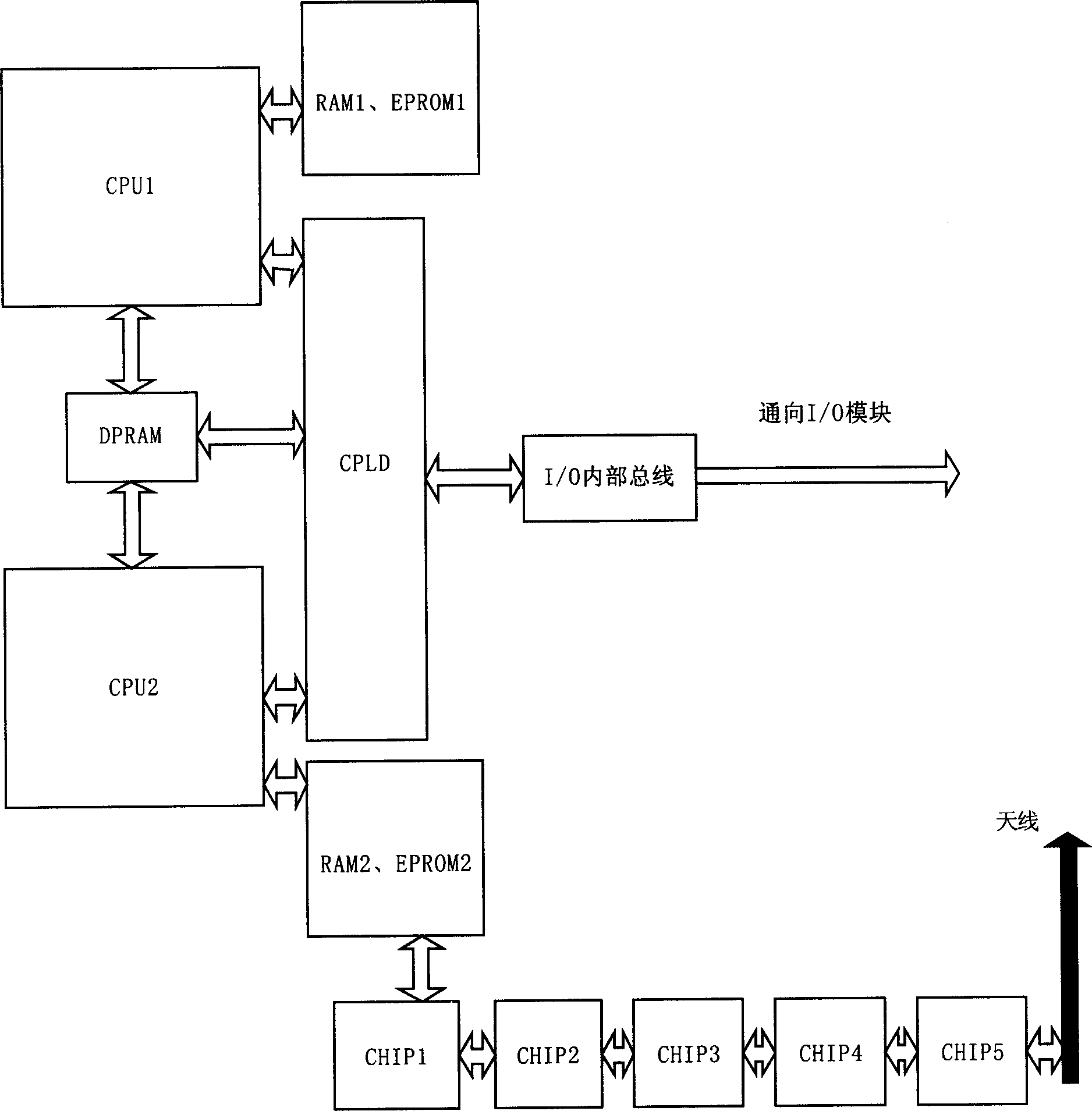

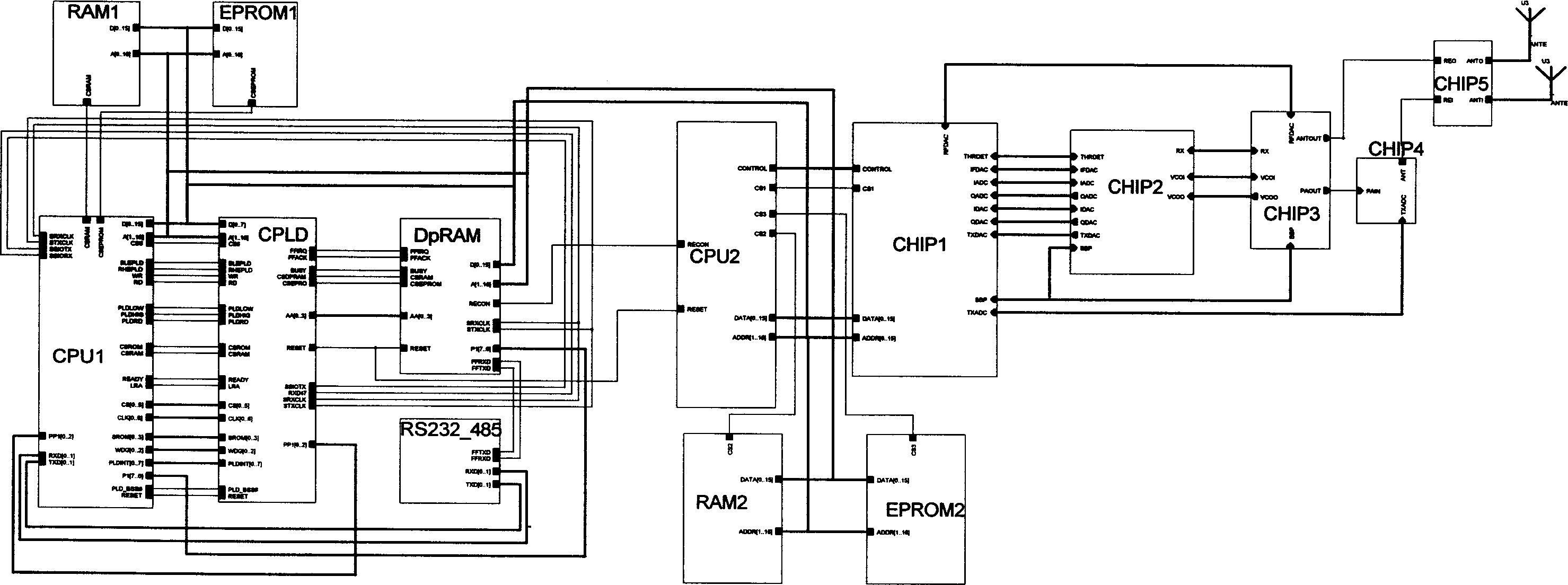

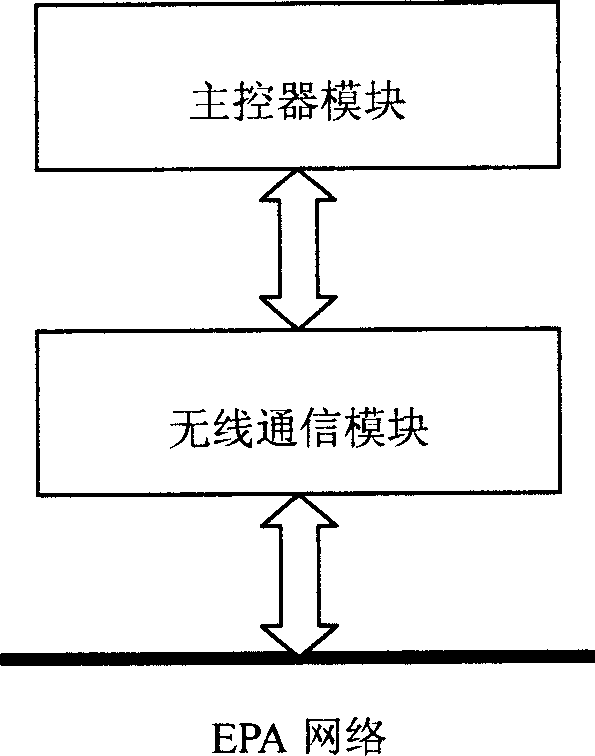

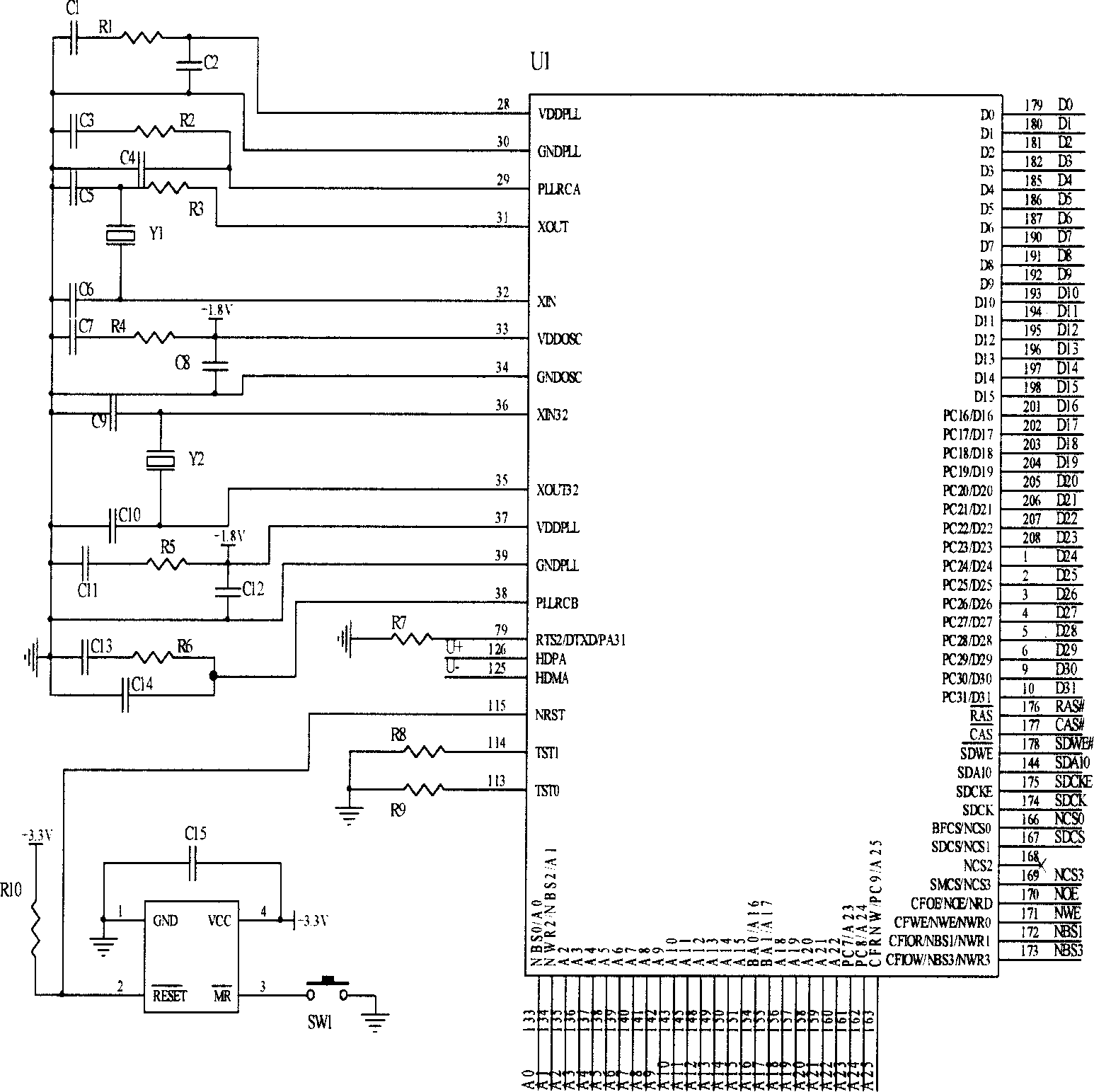

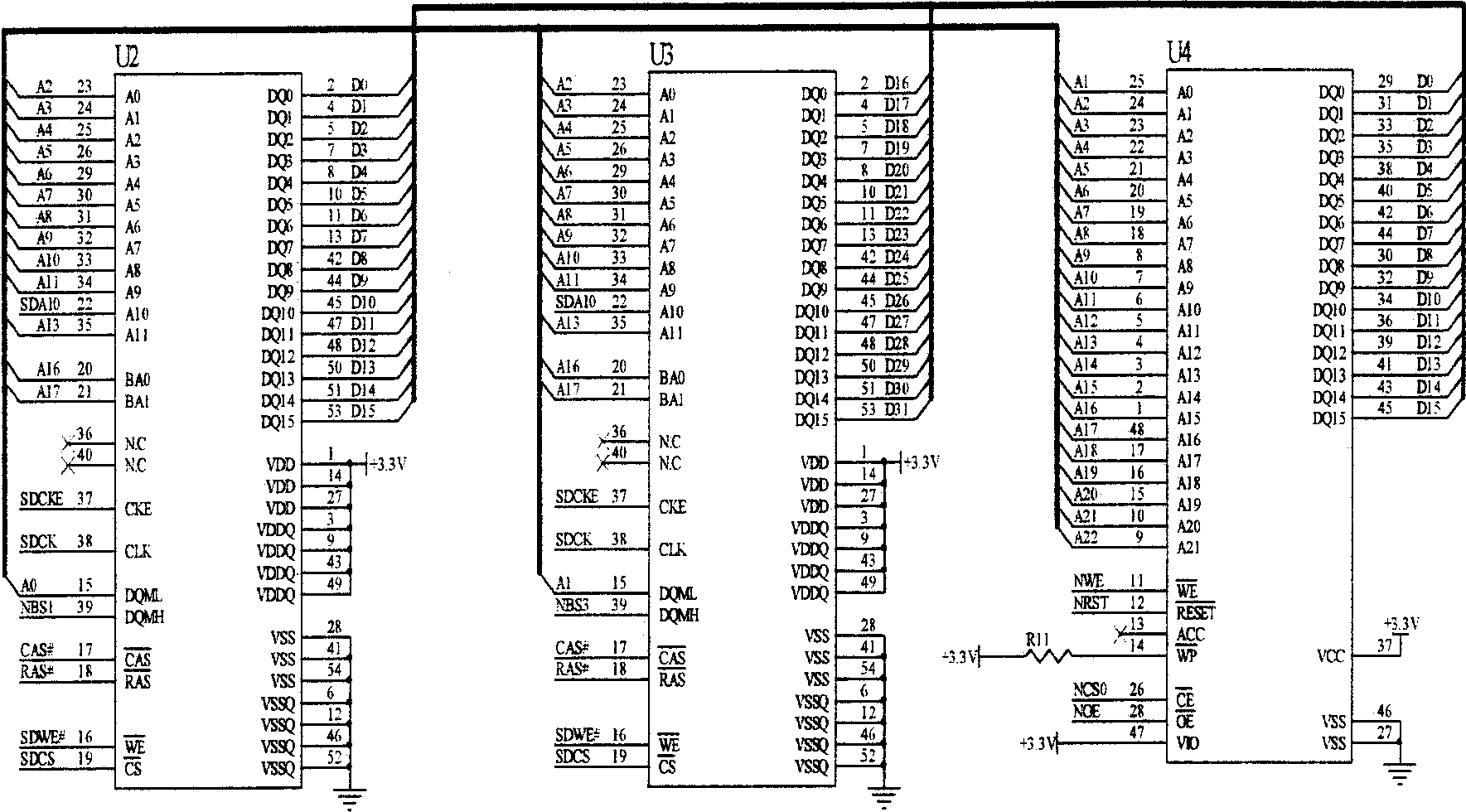

Wireless built-in controller based on automatic industrial Ethernet field bus

InactiveCN1897557AWith fully distributed controlIncrease opennessNetworks interconnectionNetwork connectionsAutomatic controlUSB

The invention comprises a main control module and a radio communication module. Wherein the main control module runs the EPA industrial Ethernet field bus communication protocol stack, and the radio communication module takes charge of the communication to the other radio field devices, provides seamless connection to Ethernet and through USB interface circuit connects to the main control module to commonly build the EPA control network.

Owner:无锡中科泛在信息技术研发中心有限公司

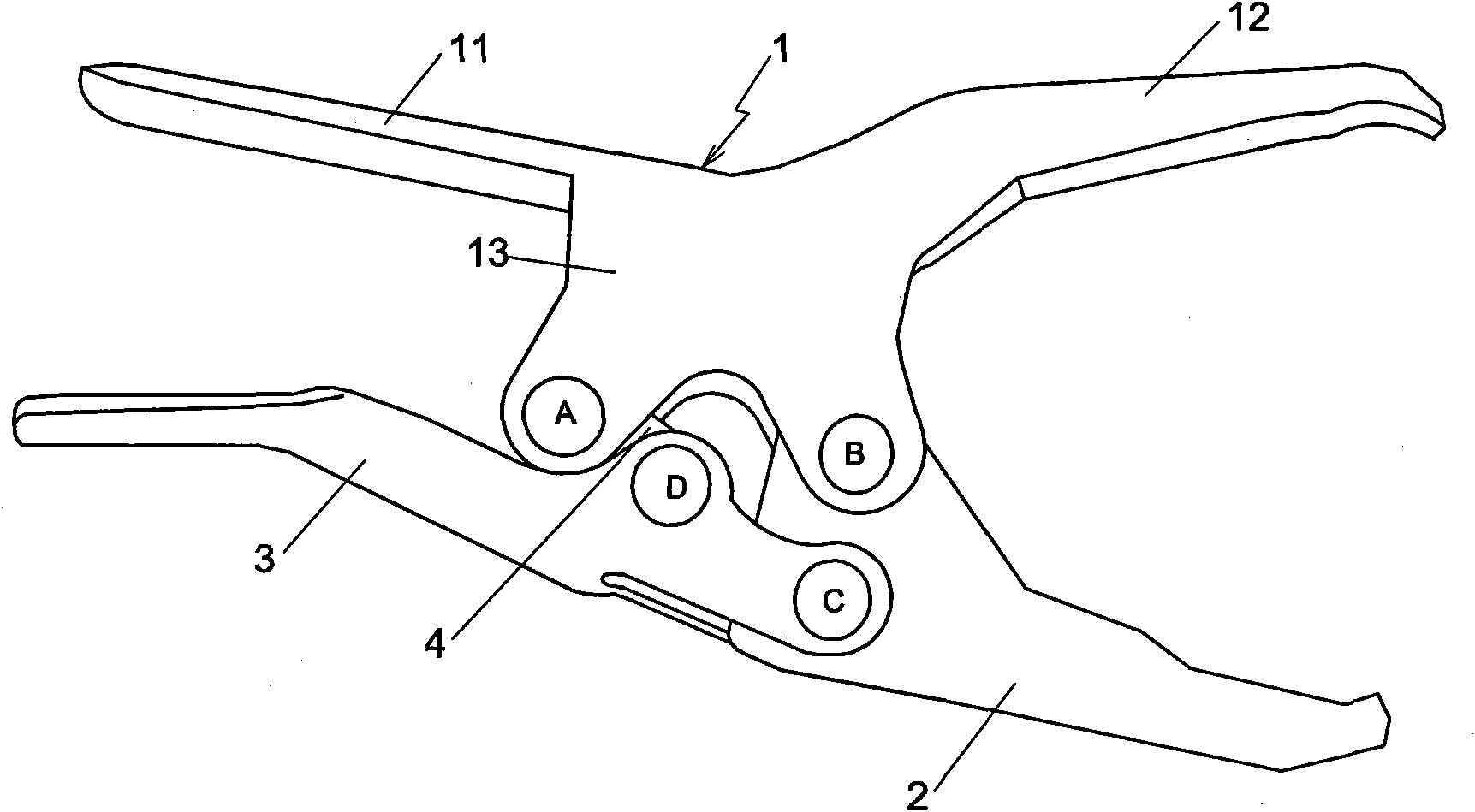

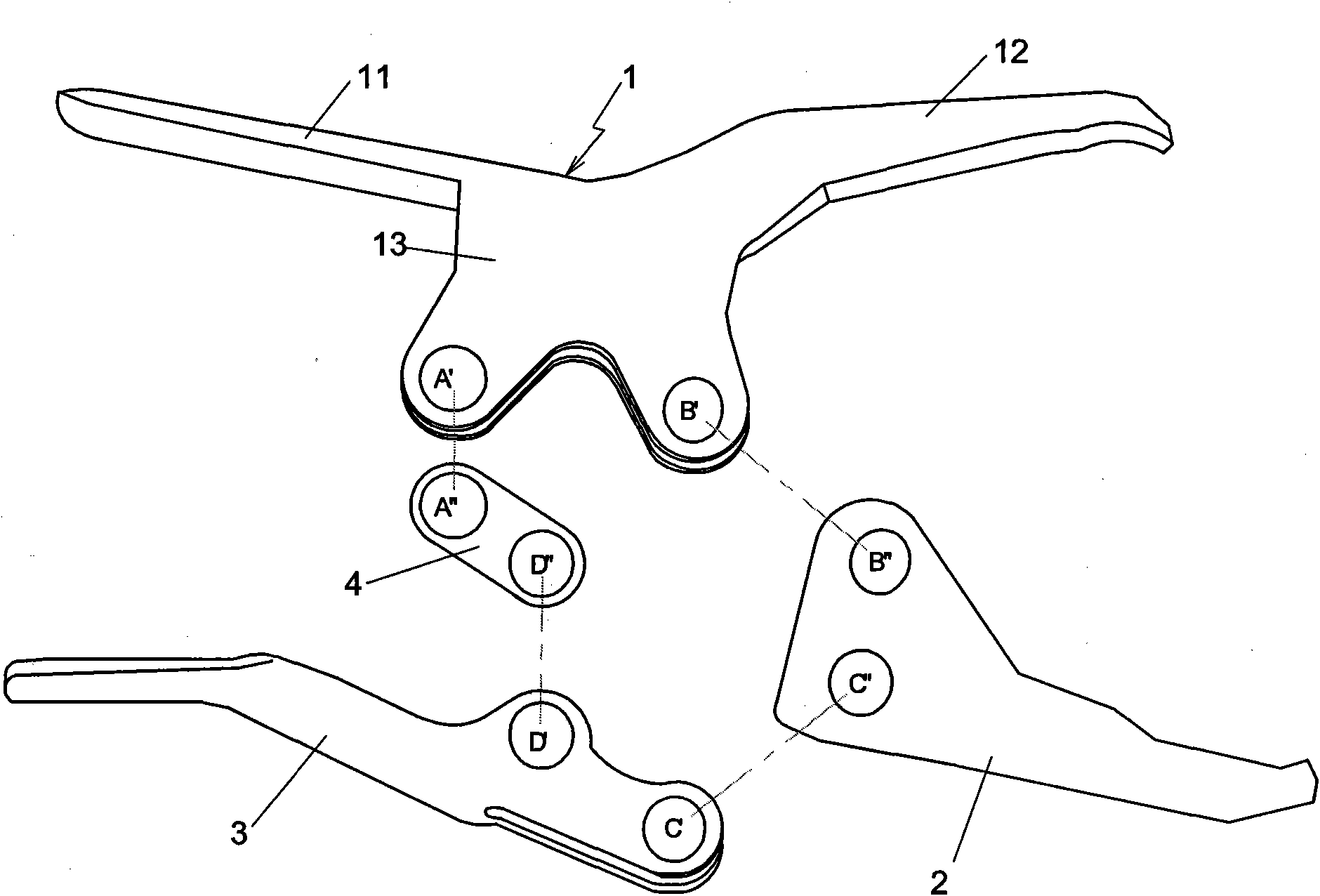

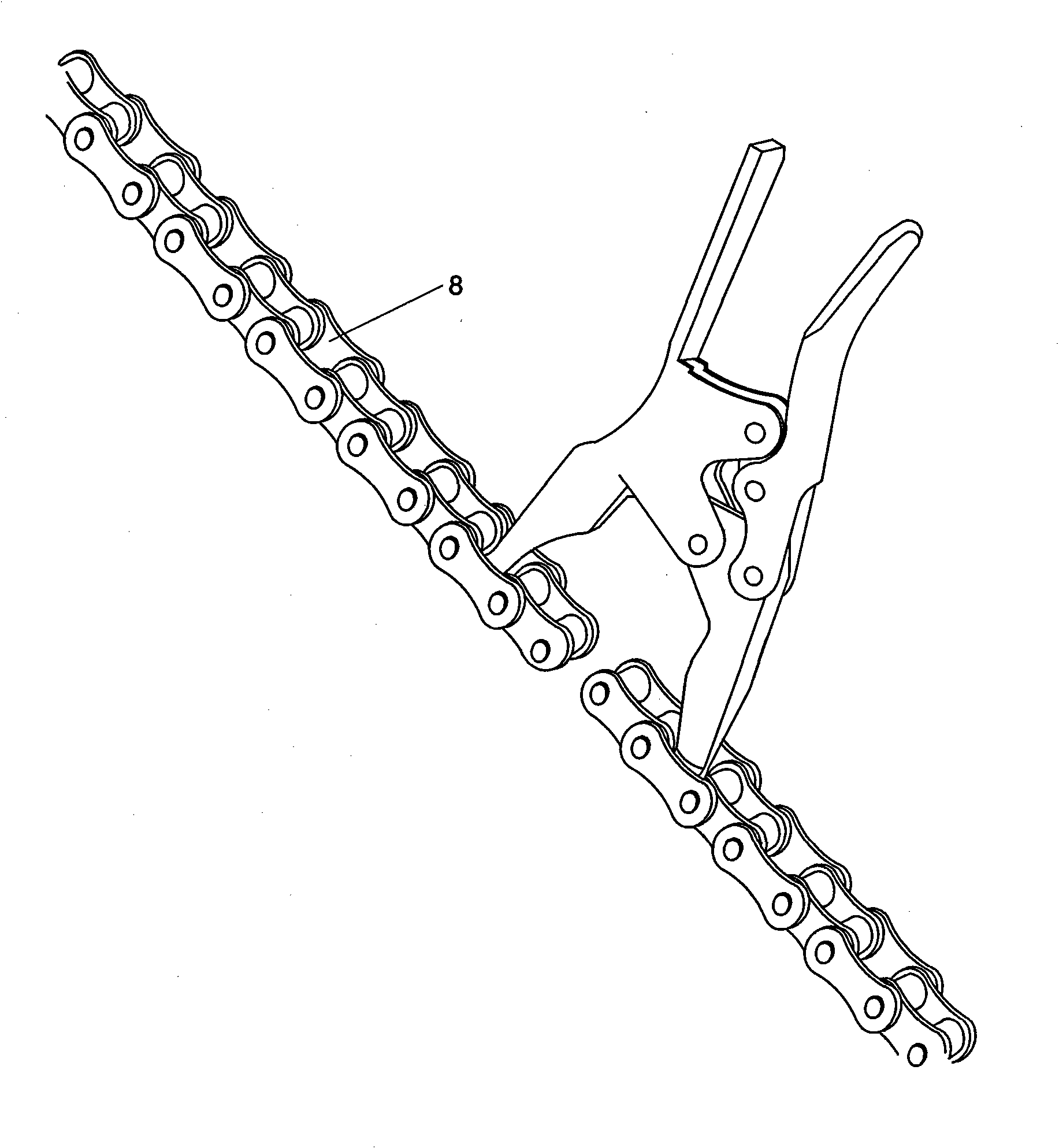

Roller chain tensioning pliers

InactiveCN101920487ASave quantitySave workloadMetal-working hand toolsMetal chainsProduction lineLeft half

The invention relates to roller chain tensioning pliers, which comprise a fixed left half part, a movable right half part and a double-hole connecting block, wherein the left half part comprises a claw at the front end, a handle at the back end and a convex fork-shaped articulated part in the middle; and the movable right half part comprises a reversed L-shaped movable claw at the front end and a movable handle at the back side. The fixed left half part, the movable right half part and the double-hole connecting block form the tensioning pliers with a four-rod principle, can quickly tension a chain, and is suitable for installation and replacement of a heavy long chain and a flow production line with pressed requirement for maintenance time, thereby effectively reducing the maintenance time, improving the equipment operation rate, improving the comprehensive production efficiency, having the advantages of simple structure, reasonable design and good use effect, and being very favorable for popularization and implementation.

Owner:李解放

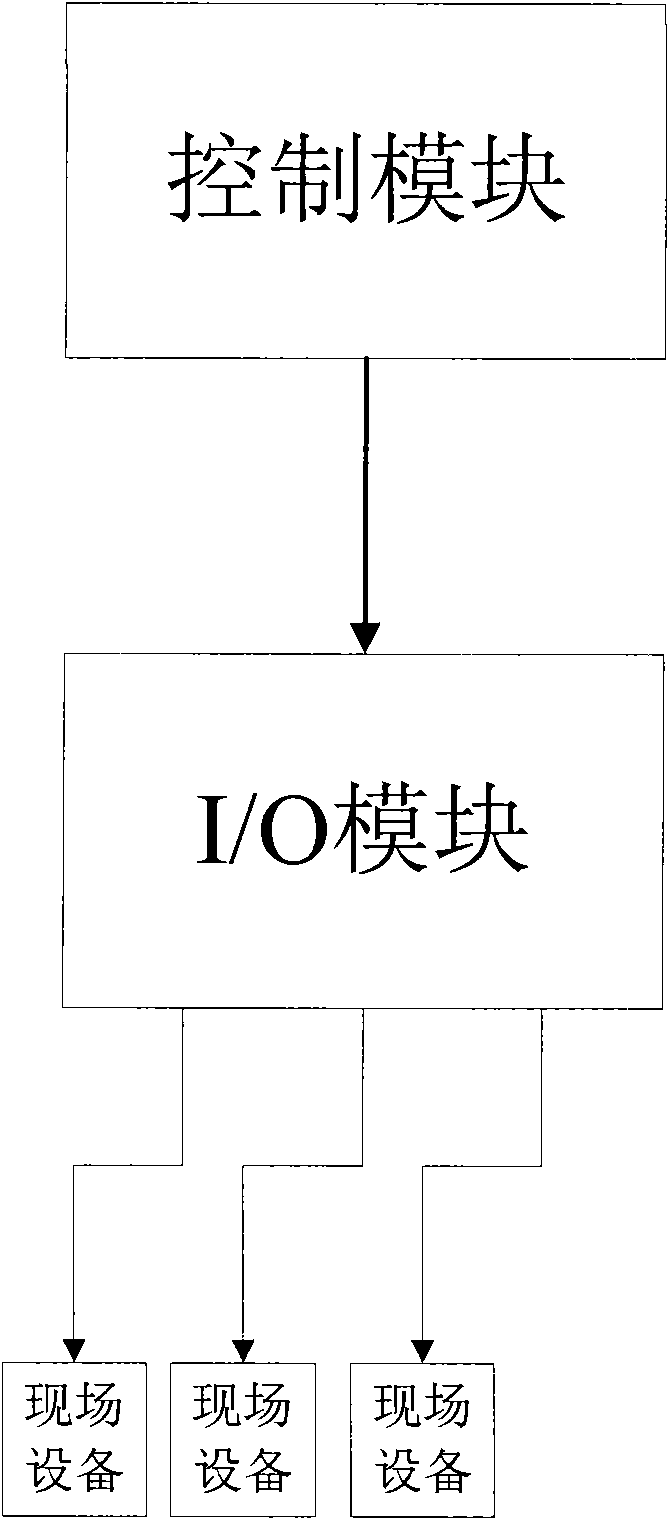

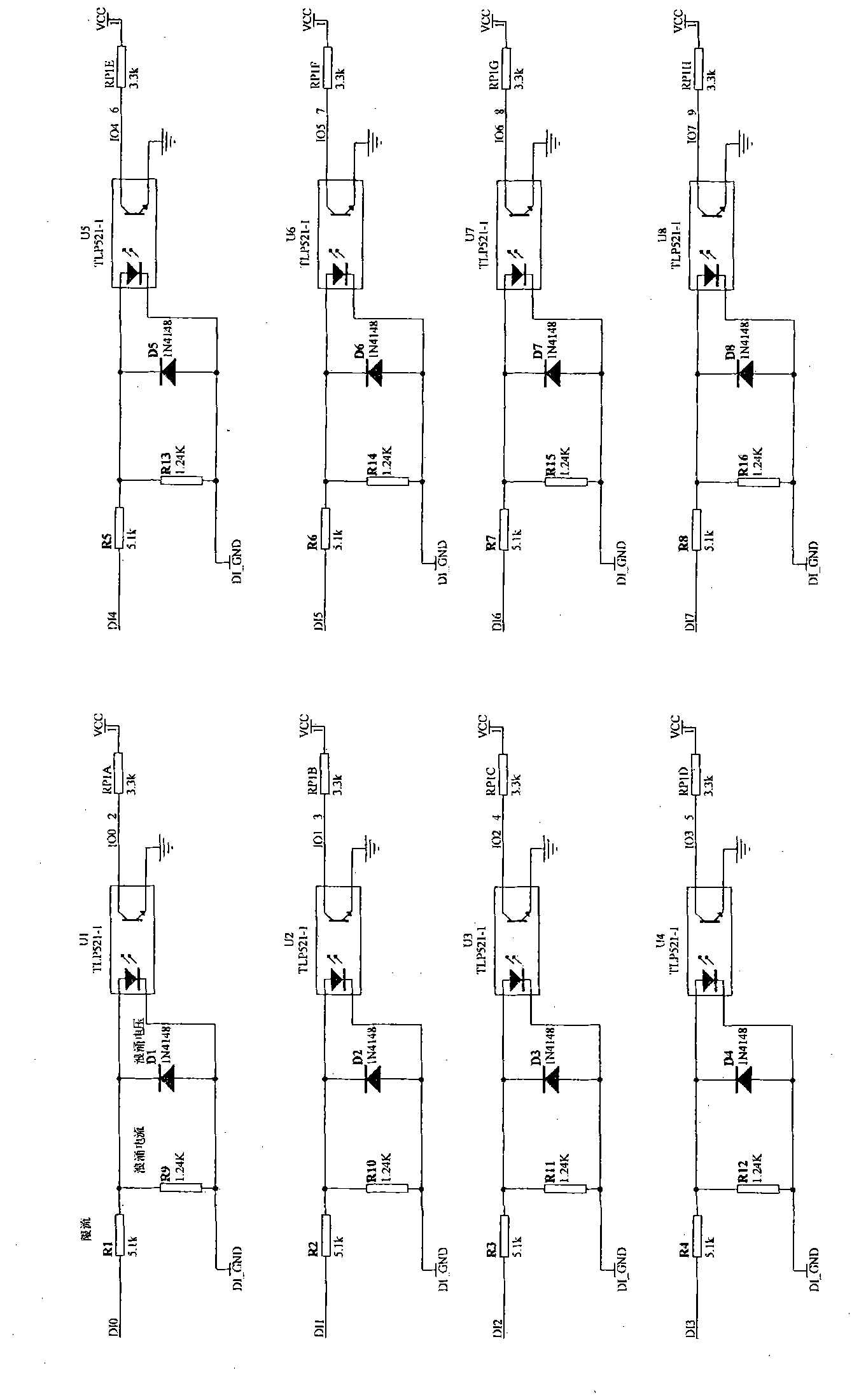

Low-cost field bus remote input-output system

InactiveCN102314161AIntelligentFunctionalTotal factory controlProgramme total factory controlModbusMaster station

The invention discloses a low-cost field bus remote input-output system comprising a control module and an I / O (Input / Output) module; a control program is stored in the control module; the control module is used for managing the I / O module through an internal bus; the acquisition and the conversion of field signals are finished by the I / O module; and field equipment is controlled by the control module through the I / O module. An MODBUS communication protocol is stored in the control module which operates an MODBUS-RTU protocol stack; the MODBUS communication protocol comprises an MODBUS slave station protocol and an MODBUS master station protocol; and the MODBUS master station protocol realizes data acquisition and remote monitoring of the field equipment through the MODBUS slave station protocol. The low-cost field bus remote input-output system is simple in structure and convenient to install. Due to the adoption of RS-485 bus, the workload for design and installation is reduced, and the investment is saved. The low-cost field bus remote input-output system can realize real-time monitoring and controlling functions and has rather high real-time property and reliability.

Owner:MICROCYBER CORP +1

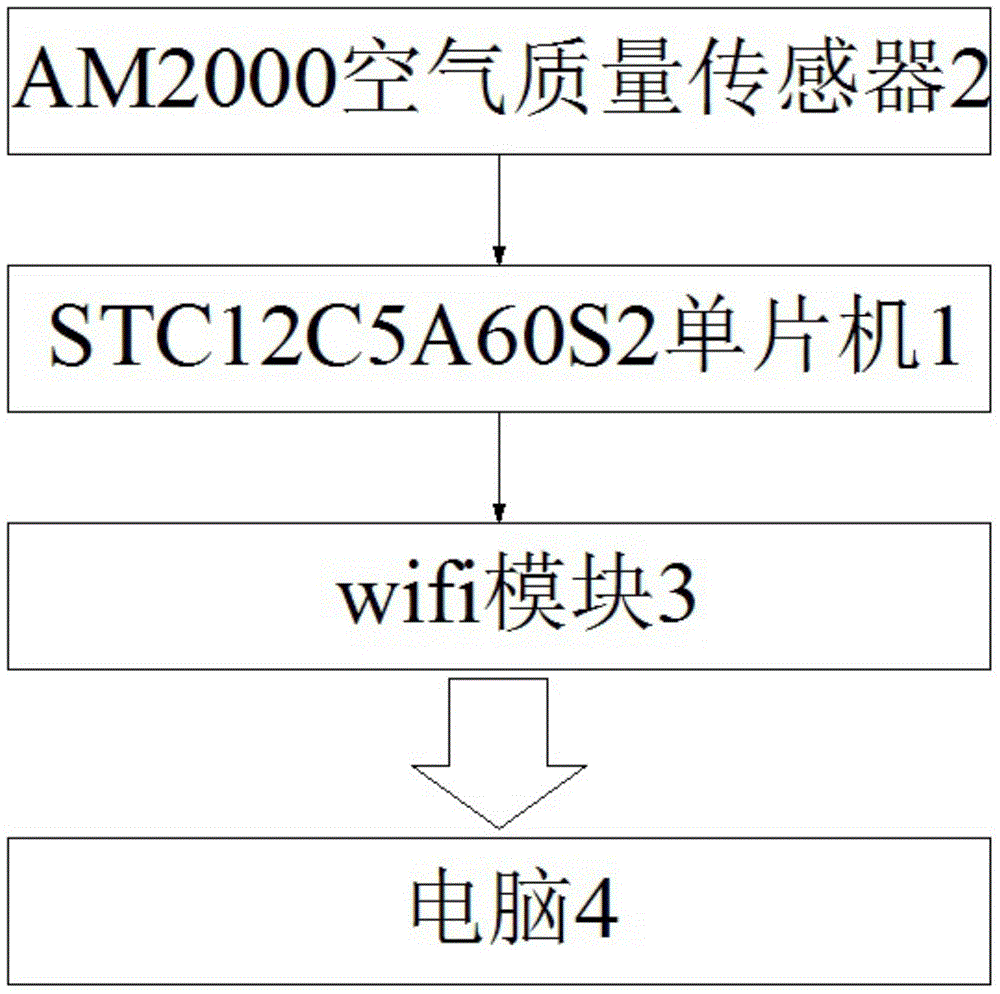

Remote air quality detection system and detection method thereof

InactiveCN104614490AEasy to assembleReduce power consumptionTransmission systemsMaterial analysisMicrocomputerMicrocontroller

The invention discloses a remote air quality detection system and a detection method thereof. The remote air quality detection system comprises a data acquisition end and a data reception end, wherein the data acquisition end comprises an STC12C5A60S2 single chip microcomputer, an AM2000 air quality sensor and a wifi module; the data reception end adopts a computer; the AM2000 air quality sensor and the wifi module are connected with a first serial port and a second serial port of the STC12C5A60S2 single chip microcomputer respectively; the STC12C5A60S2 single chip microcomputer is communicated with the computer through the wifi module. The STC12C5A60S2 single chip microcomputer is a new generation single chip microcomputer with high speed, low power consumption and super-high interference resistance; the single chip microcomputer has double serial ports which can be connected with the AM2000 air quality sensor and the wifi module, so that the data acquisition end is very convenient to assemble.

Owner:海柯蓝(上海)环保科技有限公司

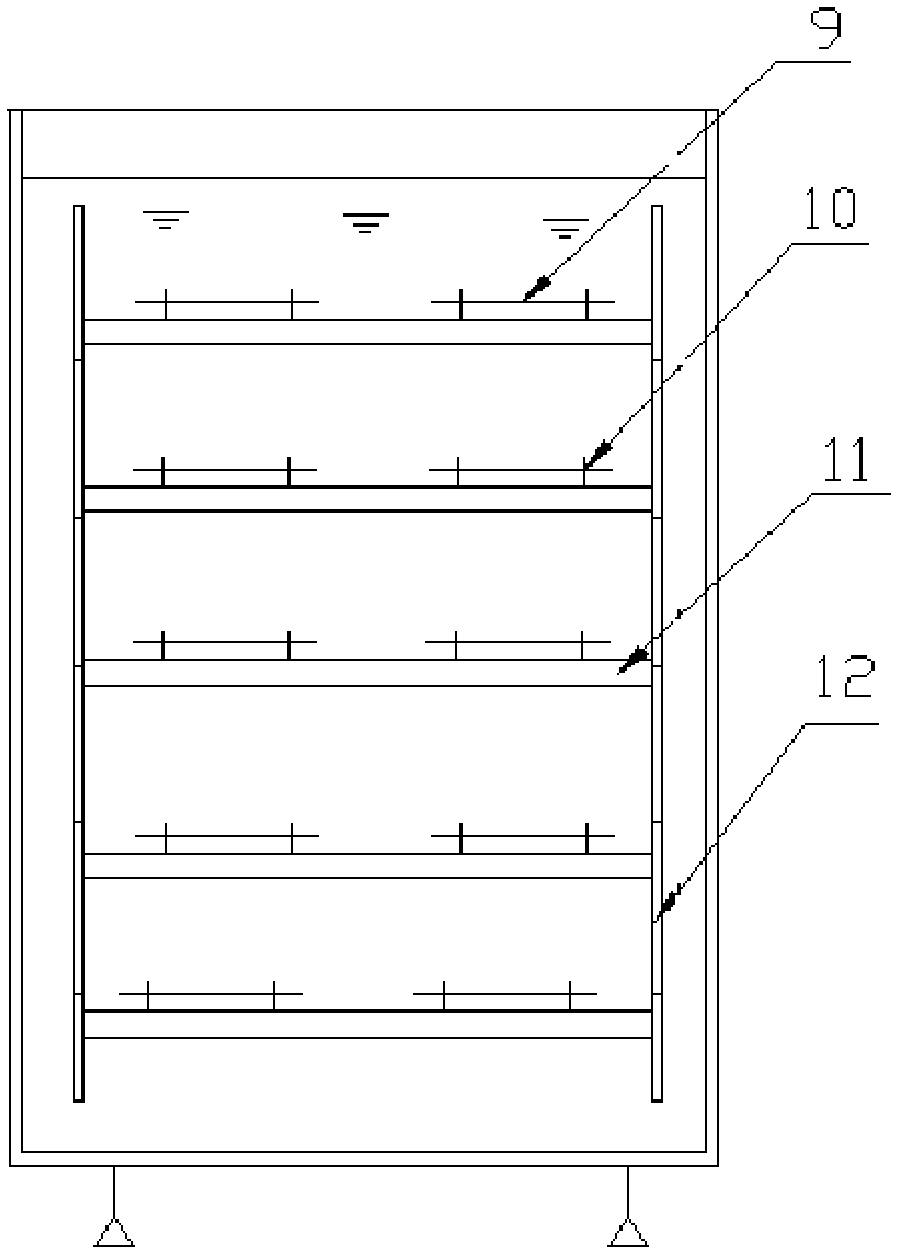

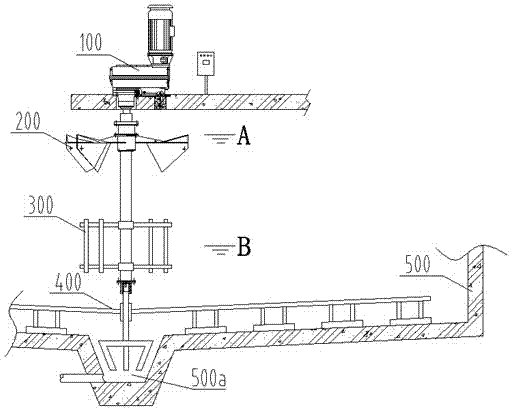

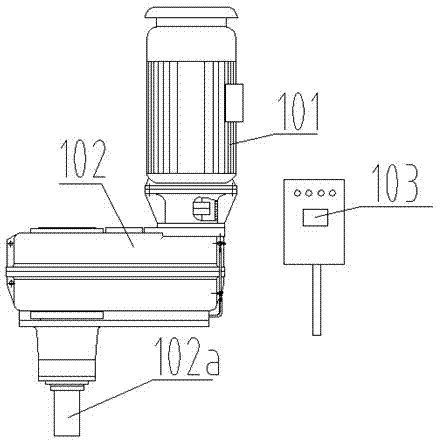

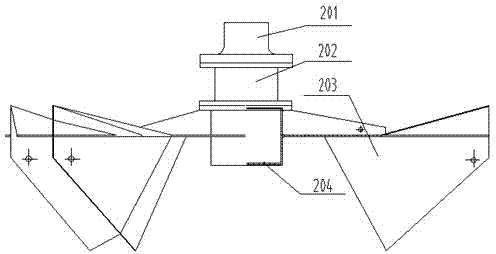

Small town sewage treatment multifunctional integrated equipment

InactiveCN104773905ASave quantitySave floor spaceMultistage water/sewage treatmentNitrogen removalFrequency conversion

The invention relates to small town sewage treatment multifunctional integrated equipment, which includes a reaction tank, a host above the reaction tank, a main shaft connected to the host output end, and an aeration component, a stirring component and a mud scraping component that are disposed on the main shaft from top to bottom in order. The main shaft consists of the rotation shafts of the aeration component, the stirring component and the mud scraping component together. The host comprises a double speed motor, a speed reducer connected to the output shaft of the double speed motor, and a frequency conversion control cabinet for controlling the double speed motor. Specifically, the aeration component is used for realizing the aeration function so as to complete organic matter degradation and ammonia nitrogen nitrification of the reaction tank water body; the stirring component is used for realizing the mixing function so as to complete nitrogen removal by denitrification of the organic carbon source in the reaction tank water body; and the mud scraping component is used for realizing the mud scraping function so as to complete discharge of mud sinking at the reaction tank bottom. The equipment provided by the invention can serve several purposes, and finishes multiple sewage treatment processes in the same reaction tank, thus having very high promotional value for small town sewage treatment.

Owner:中节能国祯环保科技股份有限公司

Corner treatment equipment for plastic product processing

ActiveCN113492344ARich varietySatisfy processingEdge grinding machinesGrinding/polishing safety devicesPolishingElectric machinery

The invention discloses corner treatment equipment for plastic product processing. A machining table and a smelting furnace are included, a driving cavity and a cleaning cavity are formed in the machining table, a motor is fixed to the inner bottom of the driving cavity, a rotary table is fixed to an output shaft of the motor, a polishing table is fixed to the upper end of the rotary table, and a transfer cavity is formed in the polishing table; and a corner adapting mechanism is arranged in the transfer cavity, a fan is fixed to the outer wall of the machining table, and an air suction pipe and an air inflation pipe are fixed to an air inlet and an air outlet of the fan correspondingly. The corner treatment equipment has the advantages that a polishing rod can be tightly attached to the surface of a workpiece under the action of elastic force, no matter whether the corner shape of the workpiece is regular or not, effective attachment can be achieved, the corner and the end portion of the workpiece are comprehensively and effectively treated,the corner treatment equipment can adapt to any irregular-shaped workpiece and complete effective treatment, the equipment is high in adaptability, various types of workpieces can be processed, and the requirement for machining of most workpieces can be met.

Owner:南通海峰家居用品有限公司

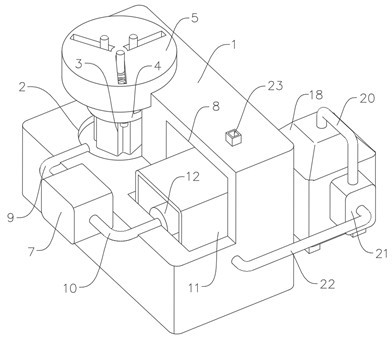

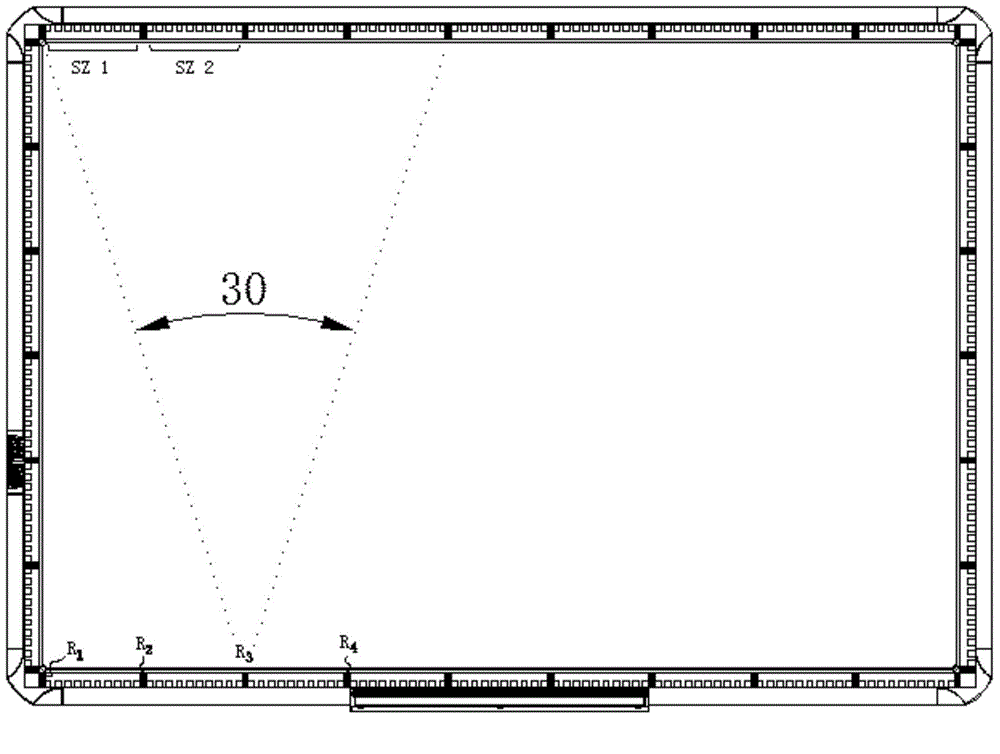

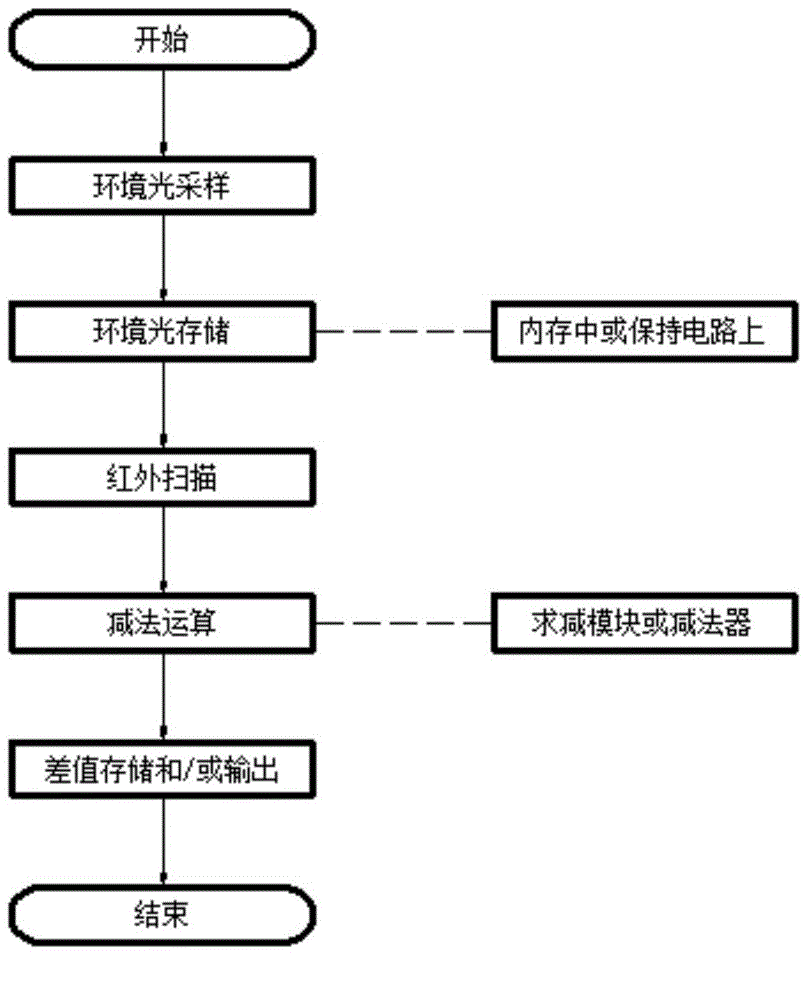

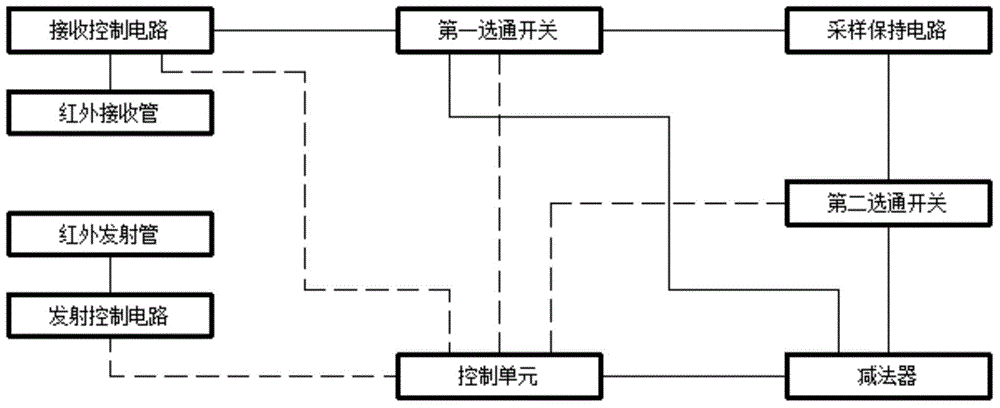

Ambient light self-adaption method and apparatus for infrared touch screen

InactiveCN105808018ASave quantitySave the environmentInput/output processes for data processingTouchscreenDiode

The invention discloses an ambient light self-adaption method applied to an infrared touch screen with a touch screen and an infrared bezel. The touch screen is used for receiving a touch input; the infrared bezel is used for detecting coordinates of touch points and is arranged at the periphery of the touch screen; infrared emission diodes and infrared receiving diodes are arranged on any edge of the infrared bezel; the infrared emission diodes are densely distributed; the infrared receiving diodes are sparsely distributed; an infrared emission region is formed between the two infrared receiving diodes on any edge of the infrared bezel; and the emission diodes in each emission region are covered with an effective receiving angle of at least two receiving diodes on the opposite bezel. The method is characterized by comprising a step of acquiring ambient light when each infrared emission region is subjected to infrared scanning, a step of storing the ambient light, a step of performing infrared scanning, a step of calculating a difference value and a step of storing and / or outputting an effective signal. Therefore, the circuit size is reduced and the situation of unrepresentative ambient light sampling is avoided.

Owner:HITEVISION CO LTD

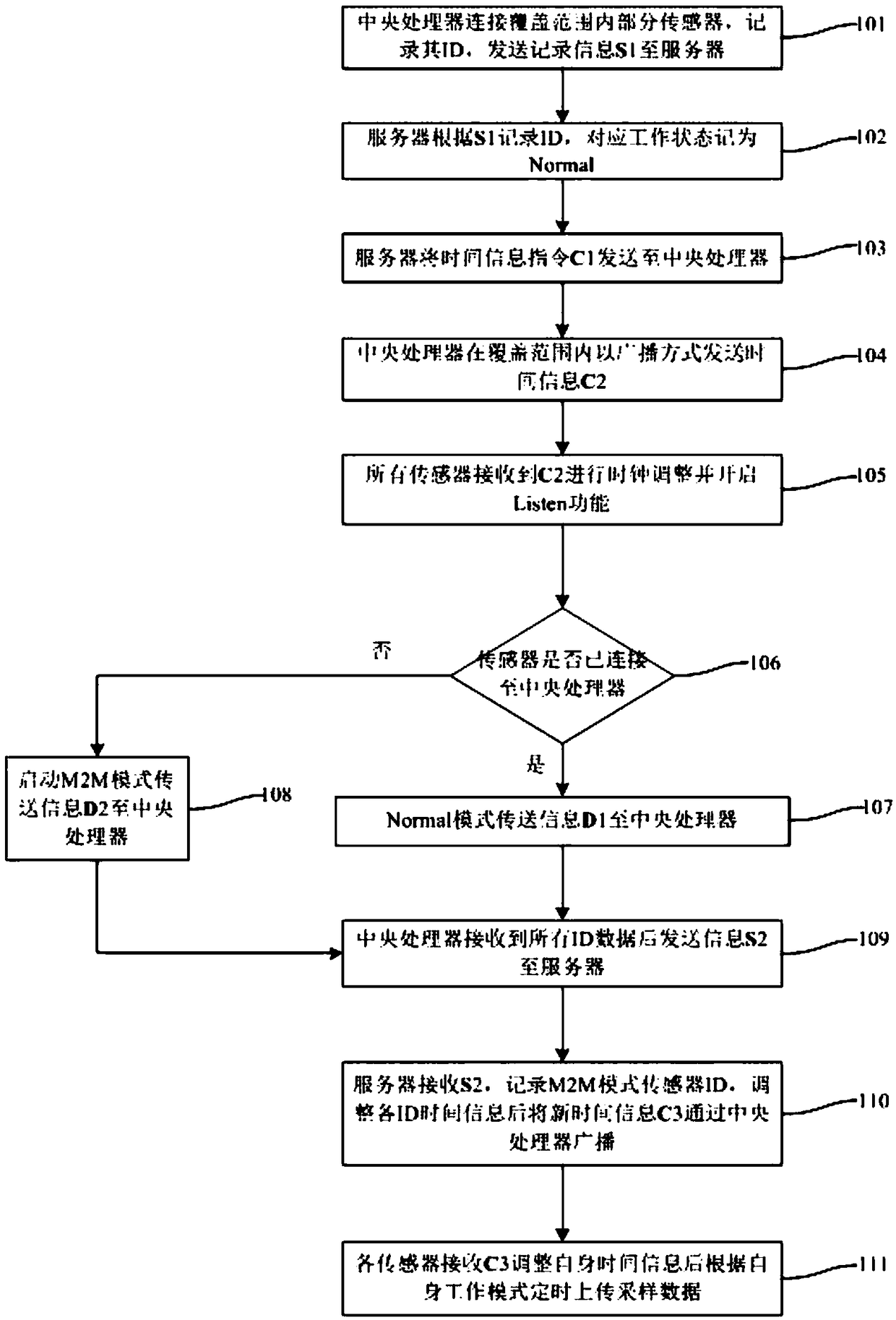

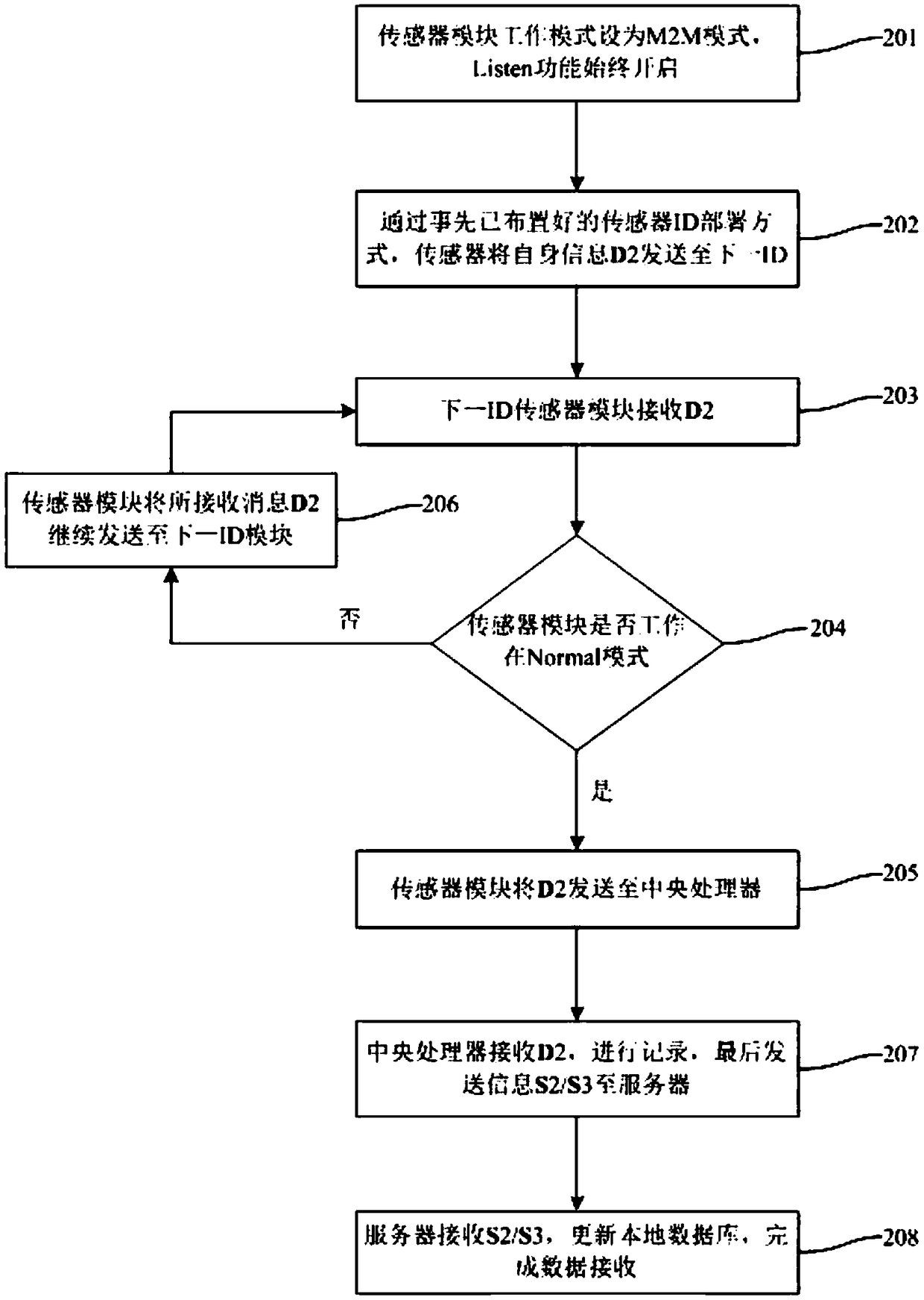

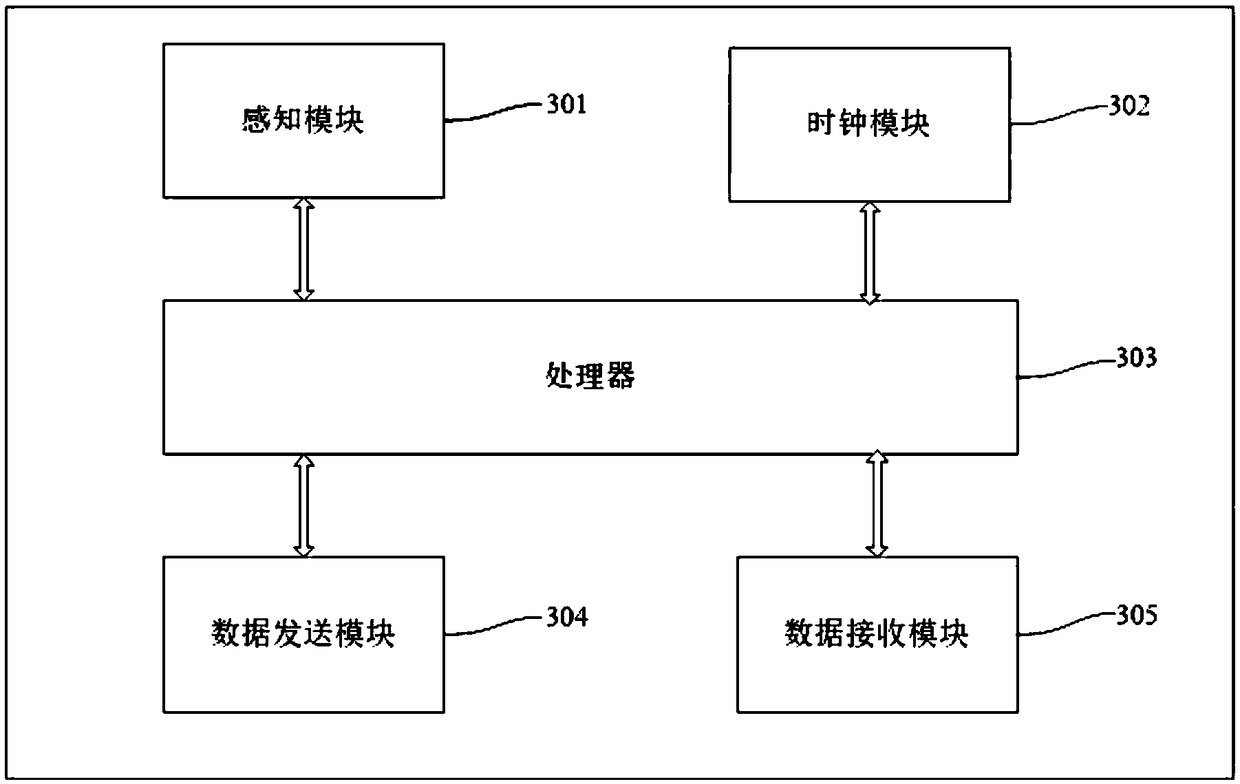

Sensing system for large-scale wireless sensor and M2M communication method thereof

ActiveCN108738163AReduce the number of loadsSave quantityTransmission systemsNetwork topologiesLine sensorData port

The invention discloses a sensing system for a large-scale wireless sensor and an M2M communication method thereof. A part of the sensor modules are connected within the coverage of the central sensor. The direct connected sensor modules work in the Normal mode, which lays a precondition for the subsequent M2M communication mode, then the classification of direct communication and M2M communication is completed through the communication of the server, the network transmission module and the central processing unit with each sensor module, and finally each module performs data collection and upload according to the determined working mode. The system and method thereof combine the M2M communication mode with the direct connection communication mode, which greatly reduces the direct connection load of the central processing unit, saves the data ports, and greatly increases the number of sensor modules that may be connected originally.

Owner:JILIN UNIV

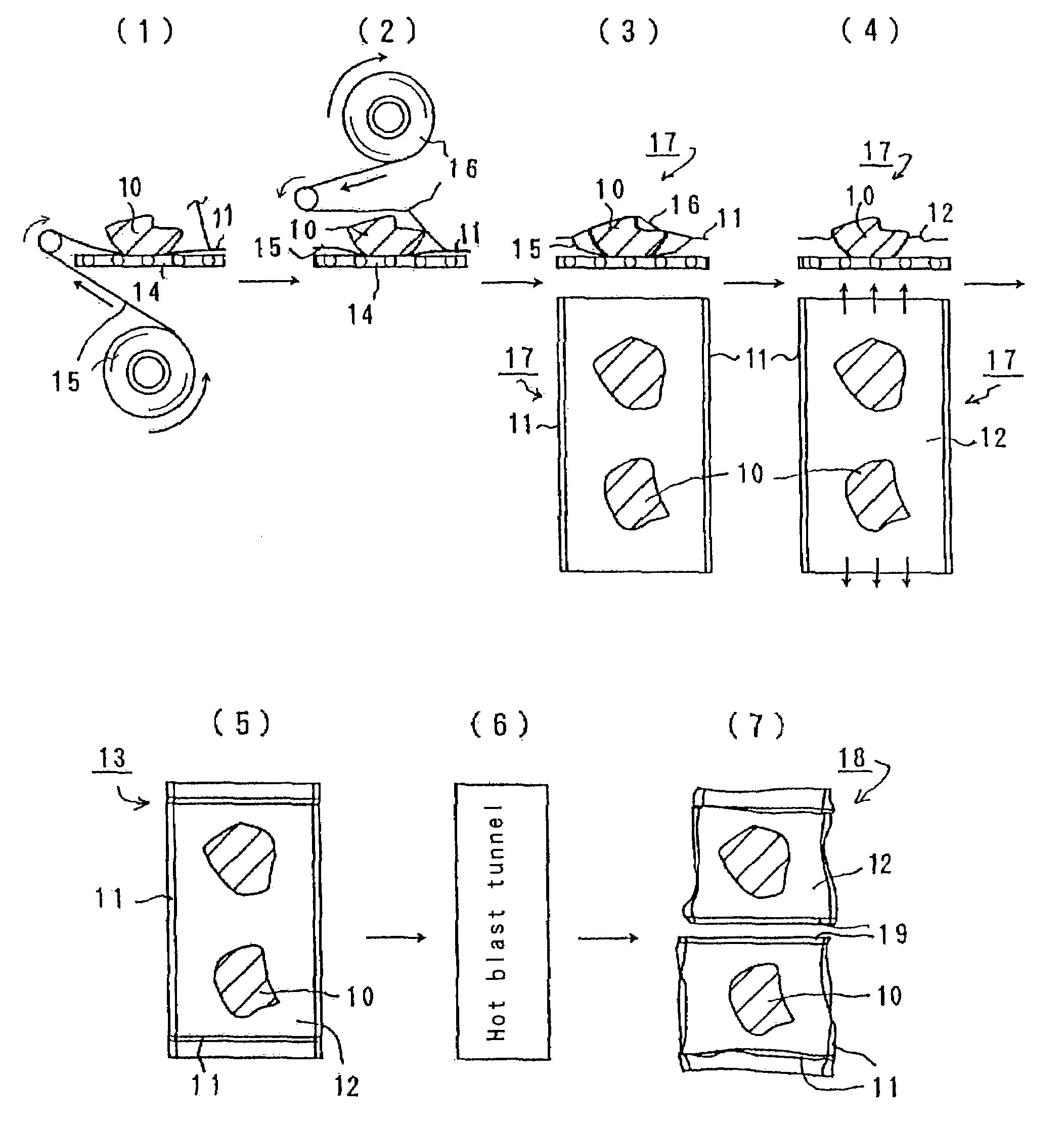

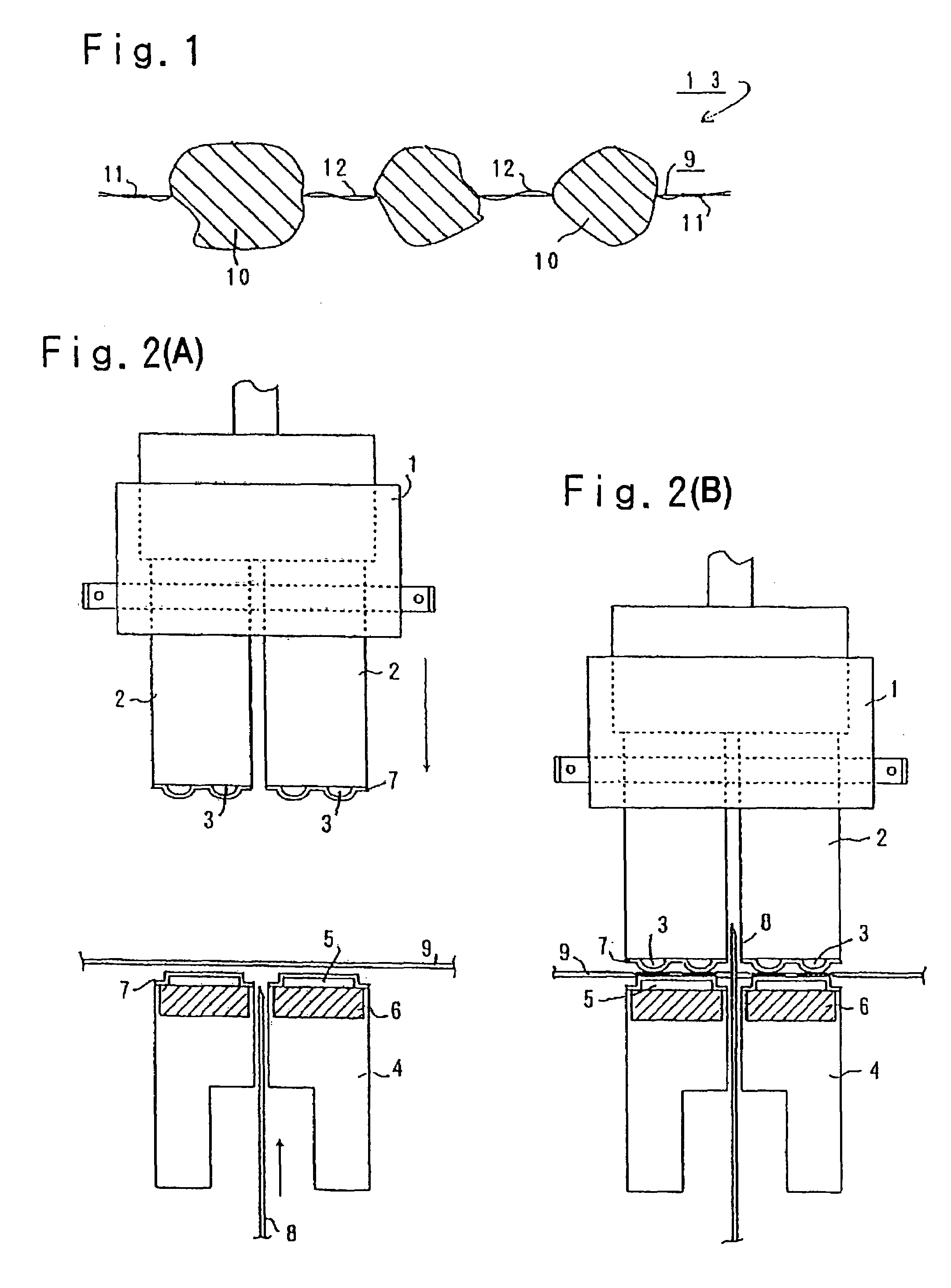

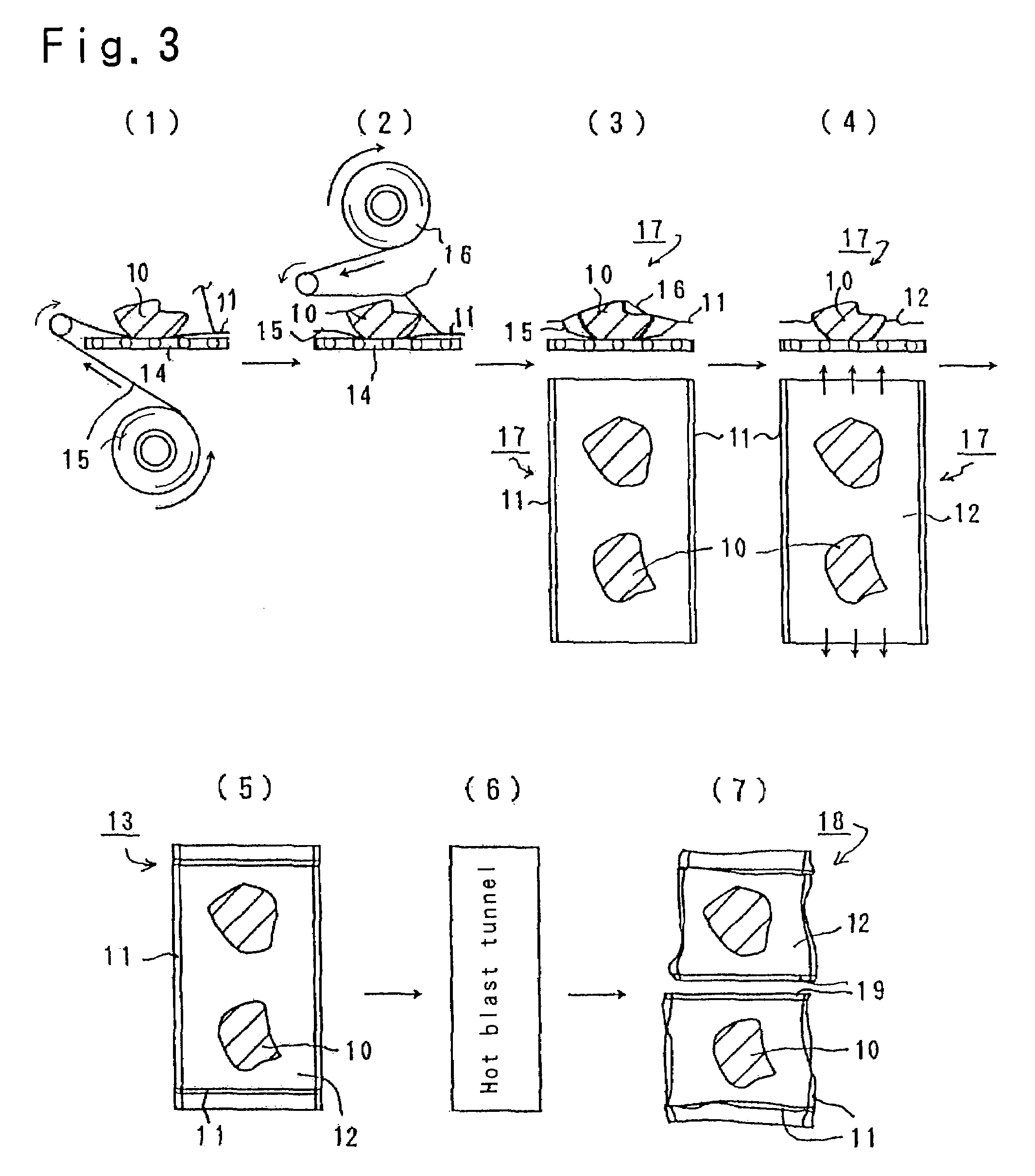

Method for high-speed vacuum unitary packaging of portion-cut meats

ActiveUS7246476B2Reduce the temperatureEliminate needWrappers shrinkagePackaging meatBond propertiesEngineering

Disclosed is a method for high-speed vacuum unitary packaging of portion-cut meats, wherein a vacuum four-side sealed object containing a plurality of portion-cut meats obtained by dividing a livestock meat, such as beef, pork, chicken, or the like, or a large-size fish into many portions, is divided into four-side sealed objects with vacuum being maintained at high speed using an impulse sealer for vacuum unitary packaging. At least two portion-cut meats are loaded on a conveyor with a prescribed spacing being given between portion-cut meats; a vacuum four-side sealed object is formed by using upper and lower wrapping films having gas-barrier properties and inner surface thermal fusion bonding properties to integrally vacuum package the portion-cut meats; a flat part between portion-cut meats in the vacuum four-side sealed object is fusion bonded by using a heat impulse sealer for heating film layers from both above and below to form at least two seal lines; and the films between the at least two seal lines are secondary cut, with a second energization of lower heater wires and secondary cutting being simultaneously performed after a first energization of upper heater wires has been completed, or with a second energization of upper heater wires and secondary cutting being simultaneously performed after a first energization of lower heater wires has been completed.

Owner:BEST PACK

Debugging method of heat-engine plant field bus

InactiveCN107918372AAccurate connectionFlexible integration initiativeTotal factory controlProgramme total factory controlAutomatic controlBiology

The invention belongs to the technical field of automatic control of heat-engine plant set, and specifically relates to a debugging method of a heat-engine plant field bus. The debugging method of a heat-engine plant field bus includes type selection and application range of the field bus, the key points and important matters needing attention during the construction process of the field bus, andthe technical points of configuration and debugging of the field bus. The debugging method of a heat-engine plant field bus preferably applies the bus technology to automatic control of the heat-engine plant, is simple, reliable, economical and practical, can fully improve the intelligent control and automation level of the whole heat-engine plant, can save the energy and is environmentally friendly at the same time, and can save the mounting cost and the maintenance cost, thus being economical and practical. Besides, the debugging method of a heat-engine plant field bus can guarantee reliableand stable operation of equipment or system, and at the same time the bus technology can realize bidirectional serial multinode digital communication, can provide more flexible system integration initiative, can also improve the adaptability of the system to the field environment, thus providing a new direction for automatic control of the heat-engine plant.

Owner:LIAONING DONGKE ELECTRIC POWER

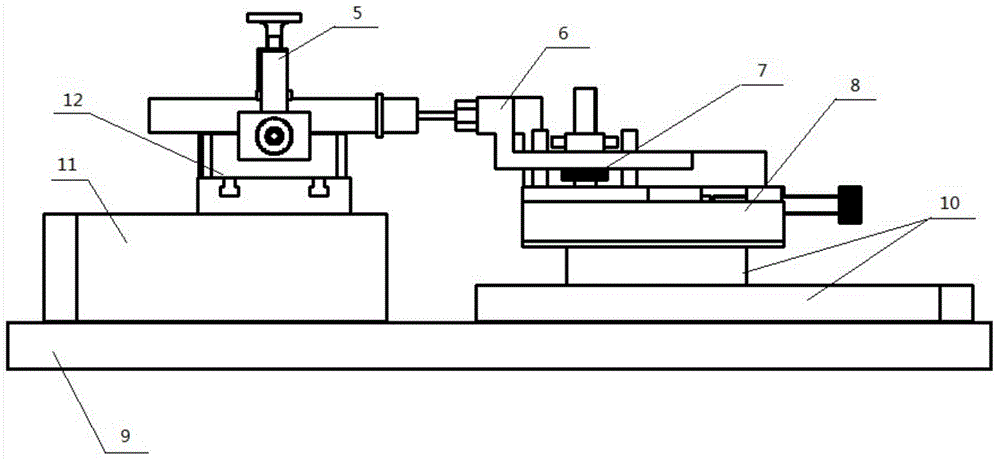

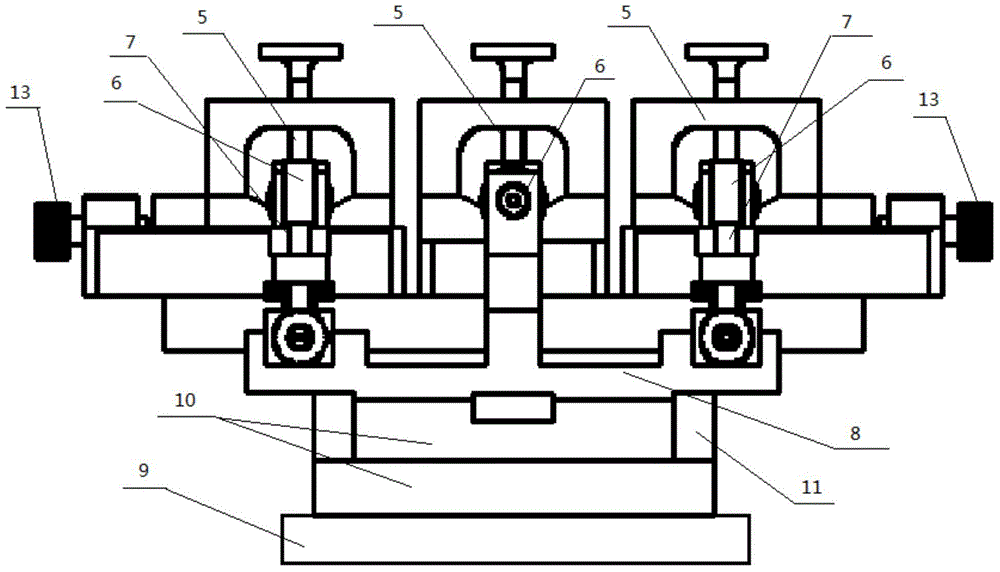

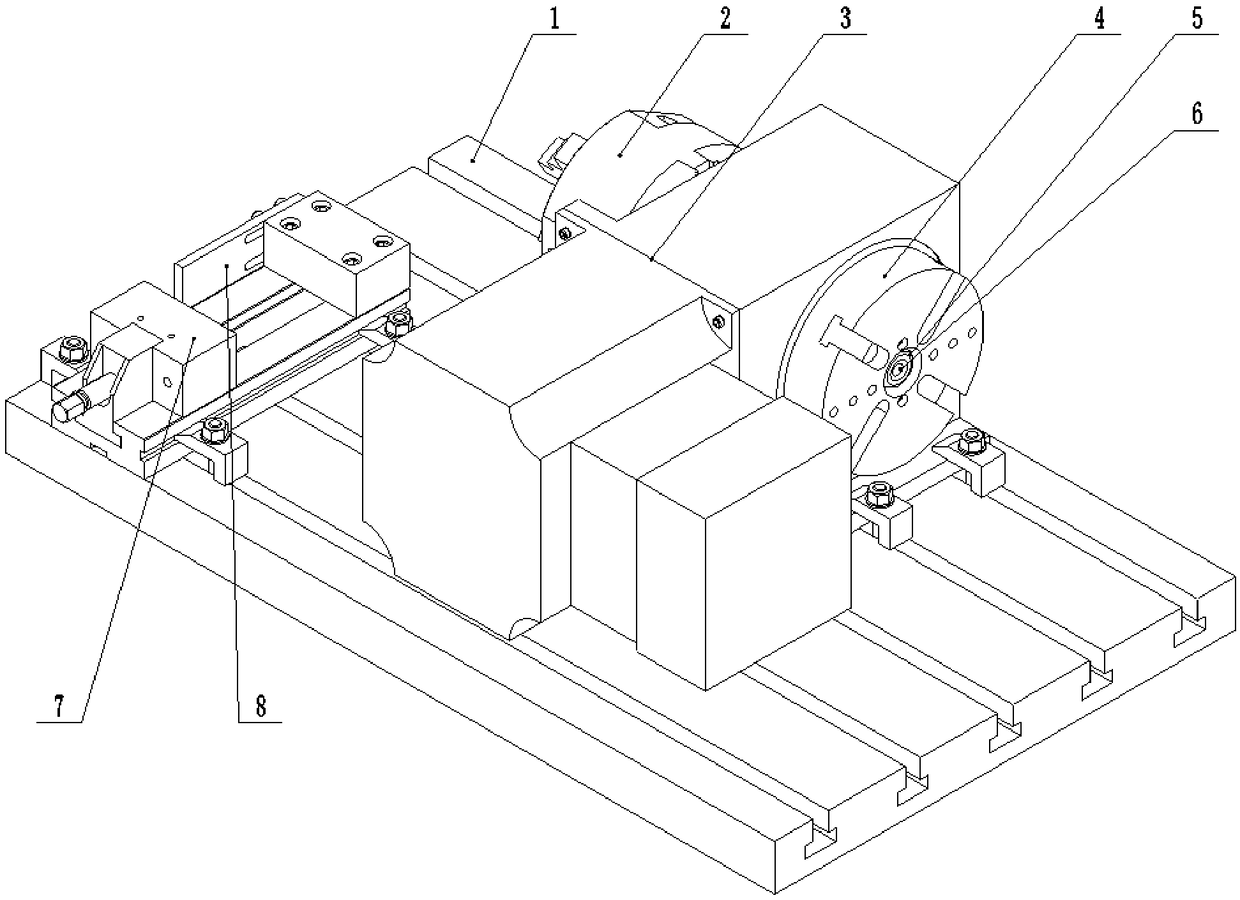

Multi-station micro-positioning line displacement measuring device

ActiveCN104596406AReduced measurement timeImprove work efficiencyUsing electrical meansMeasurement deviceBall screw

The invention belongs to a linear displacement measuring device, and specifically discloses a multi-station multi-degree-of-freedom high-precision micro-positioning linear displacement measuring device. The device comprises a reference carrier, a measuring clamping structure which is fixed on the reference carrier, a measuring driving structure fixed on the reference carrier, and a multi-degree-of-freedom which is positioned on the reference carrier and can be driven by the measuring driving structure to move relative to the reference carrier; the measuring clamping structure, the multi-degree-of-freedom adjusting device and the measuring driving structure are in the same straight line; the multi-degree-of-freedom adjusting device moves in the straight line direction. With the adoption of the device, the measurement time is reduced, the working efficiency is increased, and the quantity of bought devices and economic cost are saved; the multi-degree-of-freedom adjusting device is convenient to operate, flexible to perform, small in size and high in stability; a high-precision ball screw is used as a connecting device and can effectively reduce the fitting error of the system as well as improving the measurement precision.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

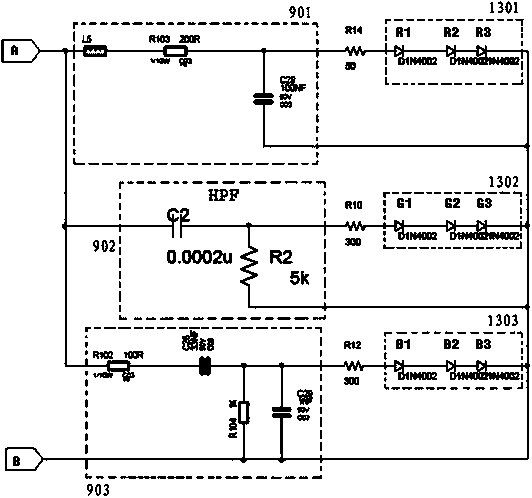

Device and method for realizing multi-color backlight by means of two-line transmission diving method

ActiveCN103514838AReduce in quantitySave quantityStatic indicating devicesDriving currentEngineering

The invention provides a multi-color backlight realizing device which comprises a positive pole transmission line used for transmitting driving currents of one kind of frequency, first to nth light emitting units used for displaying first to nth colors of light respectively, first to nth passive filters used for outputting driving currents of first to nth frequencies respectively to switch on one of the first to nth light emitting units correspondingly, and a negative pole transmission line connected with second ends of the first to nth light emitting units, wherein each light emitting unit is provided with a first end and a second end, n is a natural number which is larger than 1, and each passive filter comprises an input end connected to the positive pole transmission line, an output end connected to the first end of one of the first to nth light emitting units correspondingly, and a grounding end connected with the negative pole transmission line. Compared with a prior multi-color backlight driving method, the multi-color backlight realizing method has the advantages that the number of transmission lines is reduced, the number and cost of electronic elements are reduced, the complexity of an electronic circuit is reduced, and the reliability of a backlight circuit is improved.

Owner:SCHNEIDER ELECTRIC IND SAS

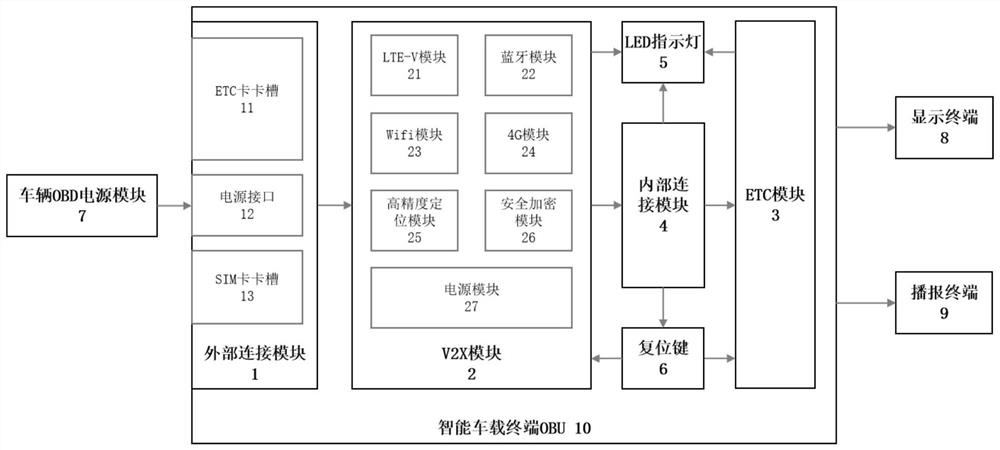

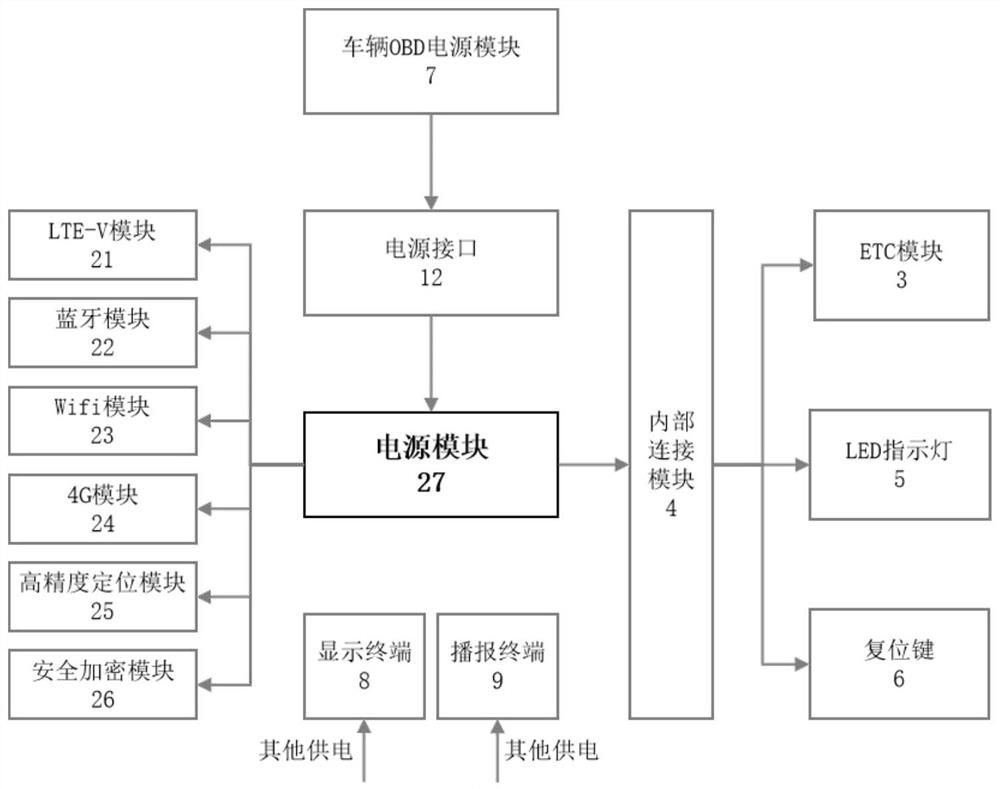

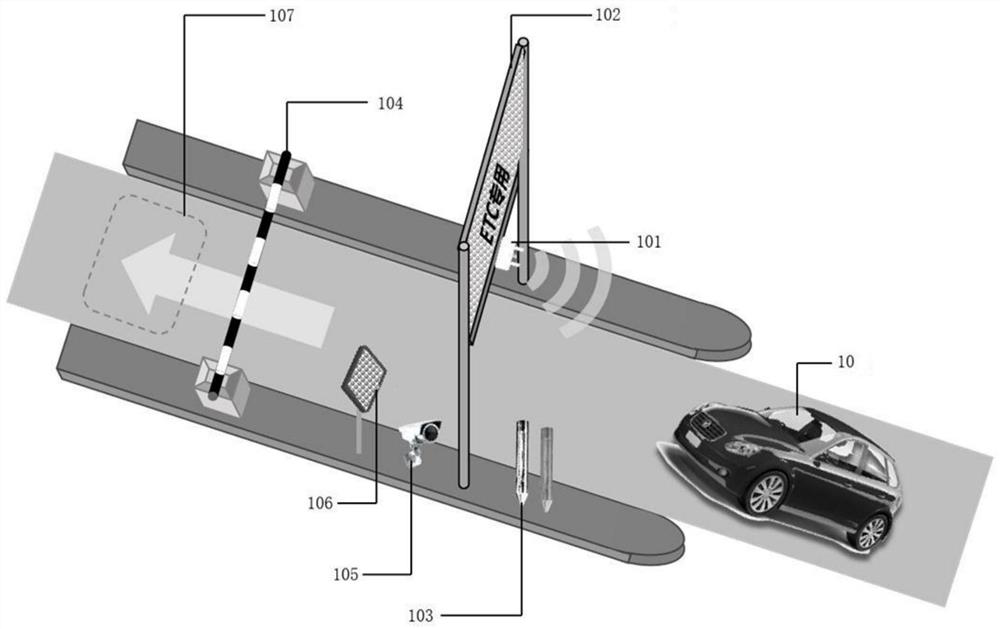

Intelligent vehicle-mounted terminal OBU integrating ETC and V2X functions and application

PendingCN114120460ASave quantityCut costsTicket-issuing apparatusParticular environment based servicesComputer hardwareEmbedded system

An intelligent vehicle-mounted terminal OBU integrating ETC and V2X functions is installed on a front windshield of a vehicle and comprises a shell and two main boards, the two main boards are arranged in the shell and integrated with an ETC module and a V2X module respectively, the ETC module and the V2X module are connected through an internal connection module, and the ETC module and the V2X module are independent of each other and do not perform data interaction; an external connection module, an LED indicating lamp and a reset key are arranged on the shell. According to the invention, the number and cost of in-vehicle equipment installation are saved, the communication modes are diversified, and the application range is wide; the antenna is built in and is not connected to a CAN bus, so that the equipment is light and miniaturized; according to the actual environment condition, the ETC service requirement can be met, the method can also be used for C-V2X vehicle-road cooperation scene application, the information service level of a vehicle end user is greatly improved, and the road traffic safety and the passing efficiency are improved.

Owner:浙江海康智联科技有限公司

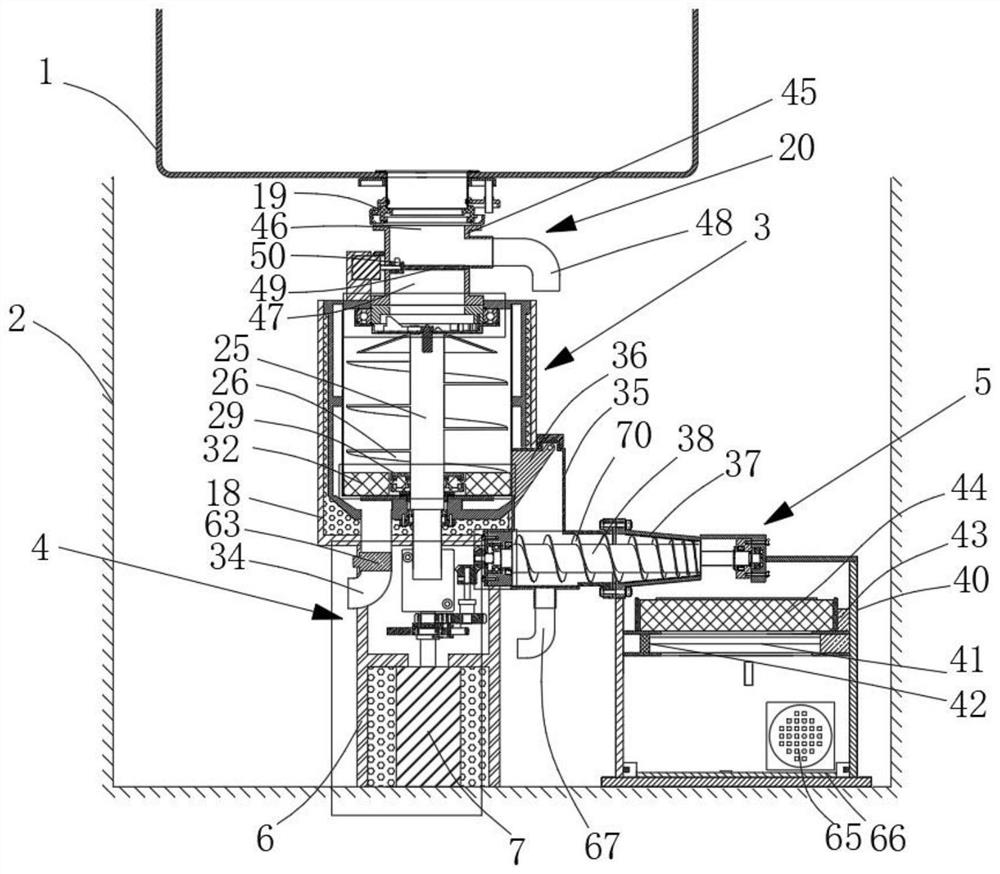

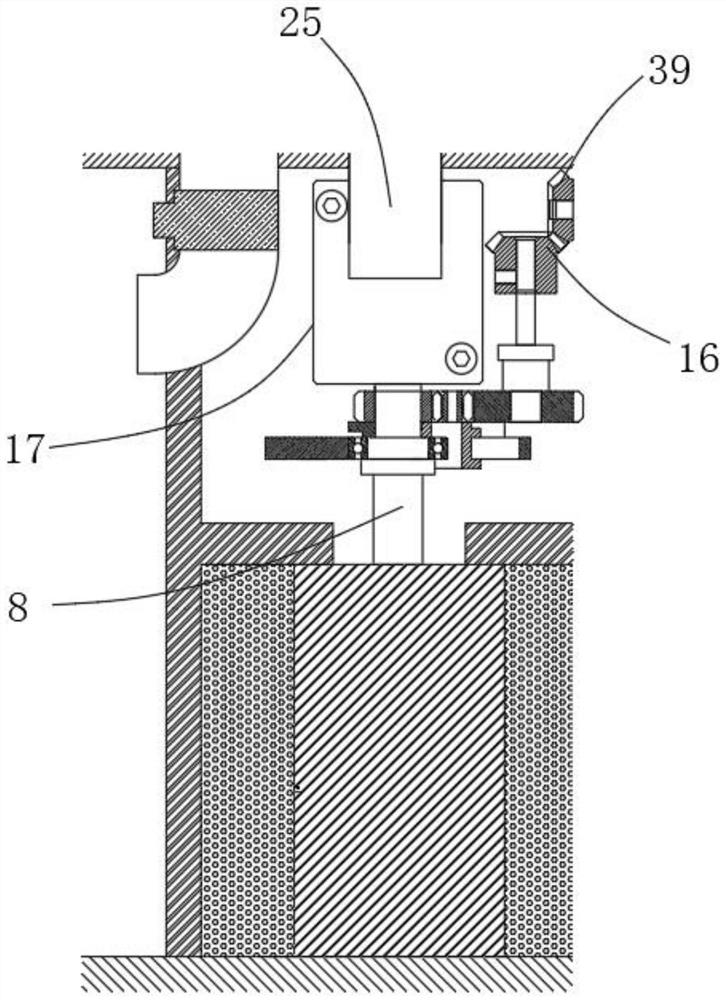

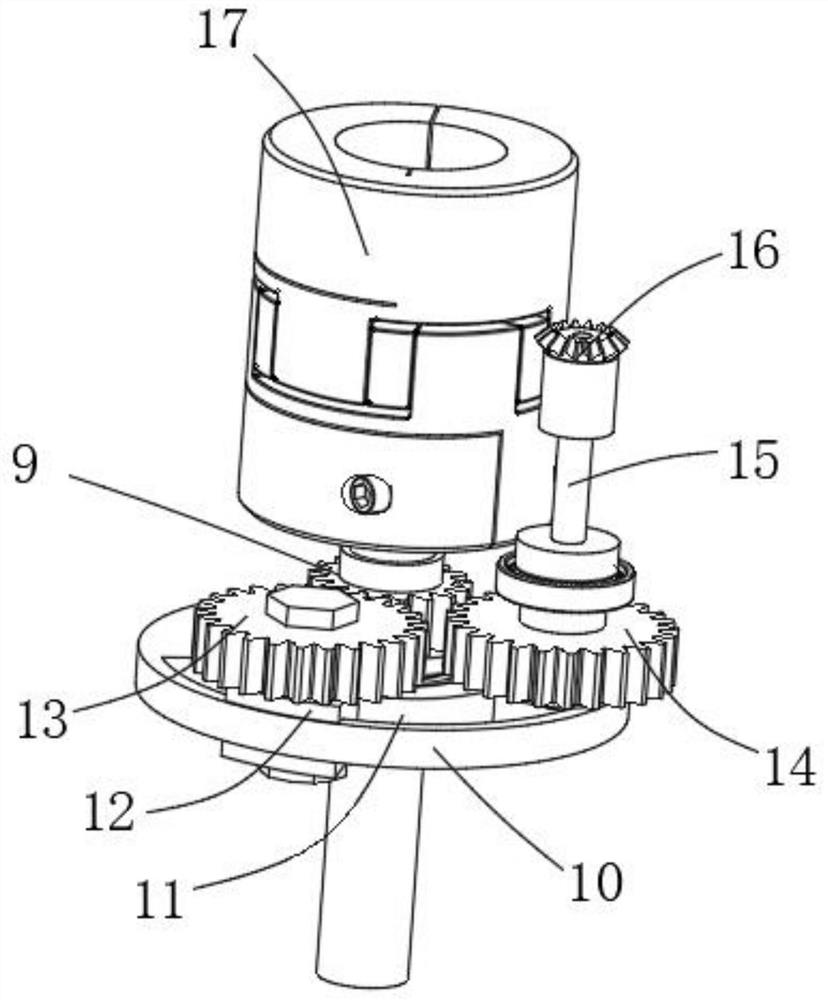

Integrated kitchen garbage treatment equipment based on lower cabinet of household kitchen sink

ActiveCN113898041AImprove ease of useImprove processing efficiencyDomestic plumbingRefuse receptaclesElectric machineryDrive motor

The invention discloses integrated kitchen garbage treatment equipment based on a lower cabinet of a household kitchen sink. The integrated kitchen garbage treatment equipment comprises a sink (1) and a sink lower cabinet (2), a centrifugal chopping device (3) is arranged below the sink (1), a transmission device (4) is arranged below the centrifugal chopping device (3), the side part of the transmission device (4) is provided with a compression device (5) in communication with the centrifugal chopping device (3), and the compression device (5) and the centrifugal chopping device (3) are connected with the transmission device (4); and the transmission device (4) comprises a transmission shell (6) located at the bottom of the sink lower cabinet (2), a driving motor (7) is arranged in the transmission shell (6), a driving shaft (8) is arranged at the output end of the driving motor (7), and a driving gear (9) is arranged on the driving shaft (8). The integrated kitchen garbage treatment equipment can cut, dehydrate and compress kitchen garbage, realizes pretreatment before recycling of the kitchen garbage, and has the characteristics of convenience in use and high treatment efficiency.

Owner:WENZHOU UNIVERSITY

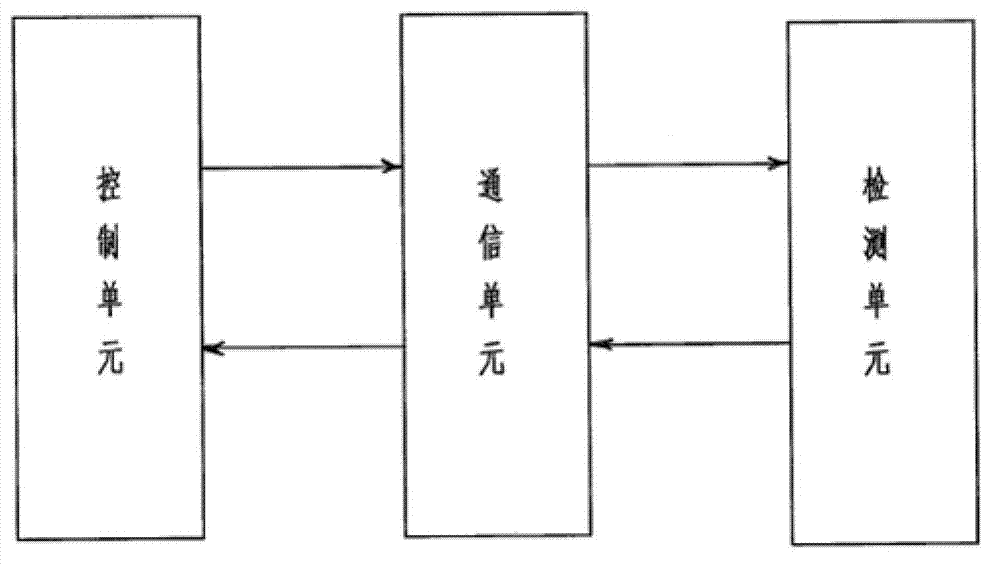

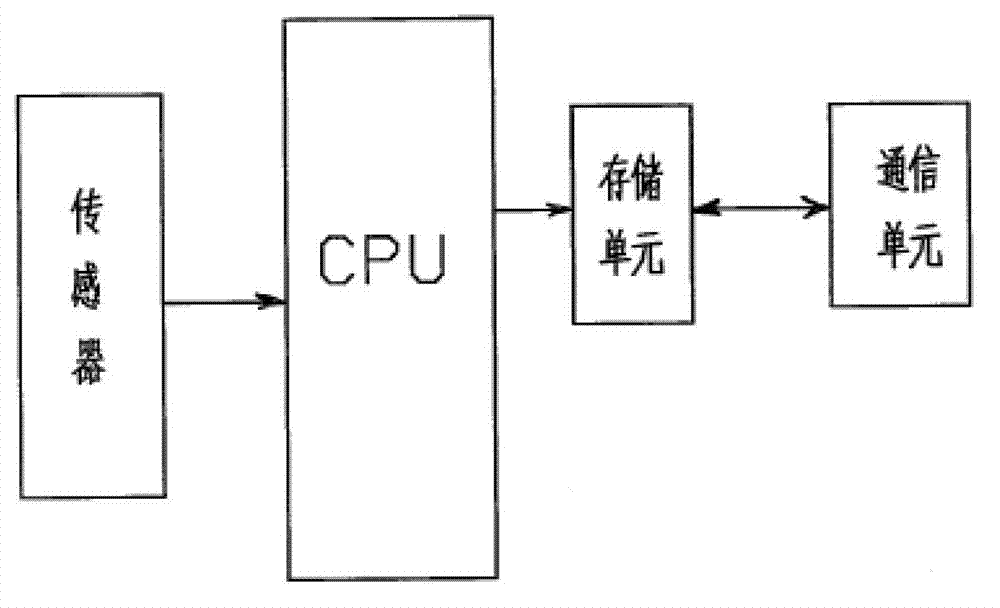

Intelligent monitoring system for node temperature of switching room

InactiveCN102853915ASave quantitySave installation timeRadiation pyrometryIntelligent lightingCommunication unit

The invention relates to an intelligent monitoring system for node temperature of a switching room. The intelligent monitoring system for node temperature of the switching room comprises a control unit, a detection unit and a communication unit connected with the detection unit. The detection unit comprises a detection module and a sensor, wherein the sensor providing the detection module with monitoring data is disposed in a distribution box. A topographic map of all to-be-monitored circuits in the distribution box to be monitored is disposed in a CPU (central processing unit) in the detection module. An information storage unit is used for storing monitoring results in the detection module in the topographic map manner, the CPU transmits the topographic map data stored in the information storage unit to a console through the communication unit, and the results are displayed on a display screen of the console.

Owner:NINGBO DWOO ELECTRIC

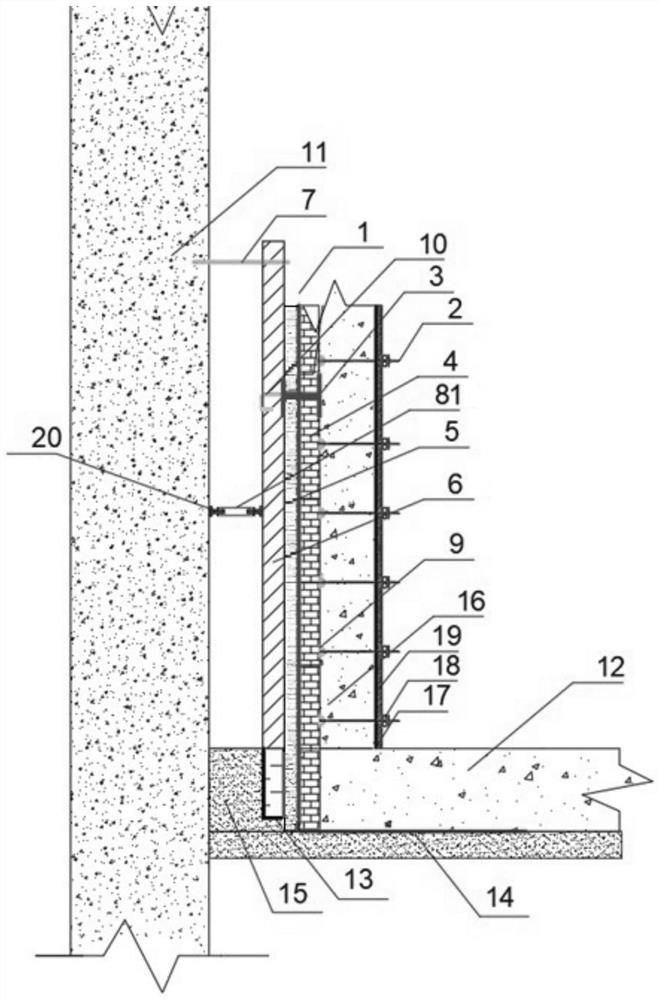

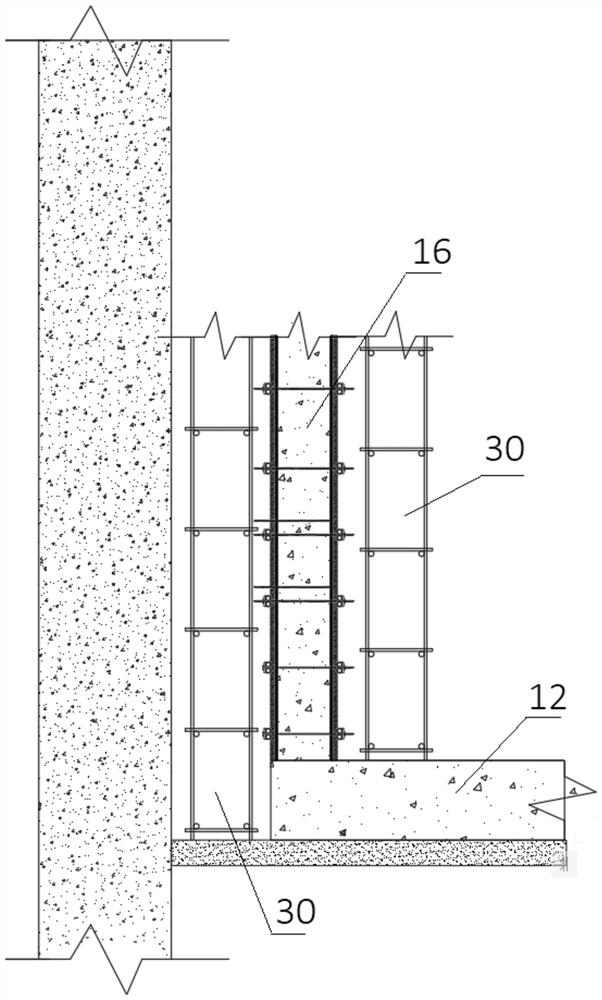

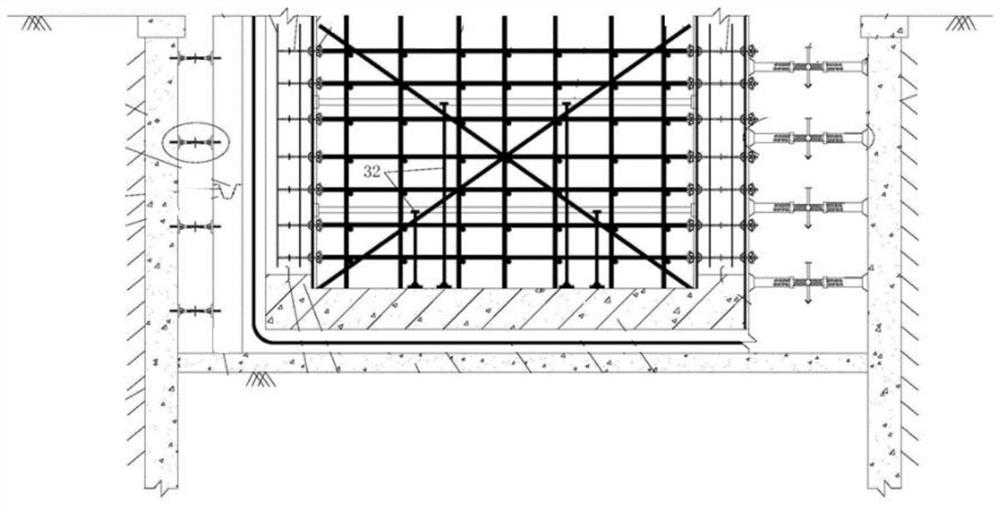

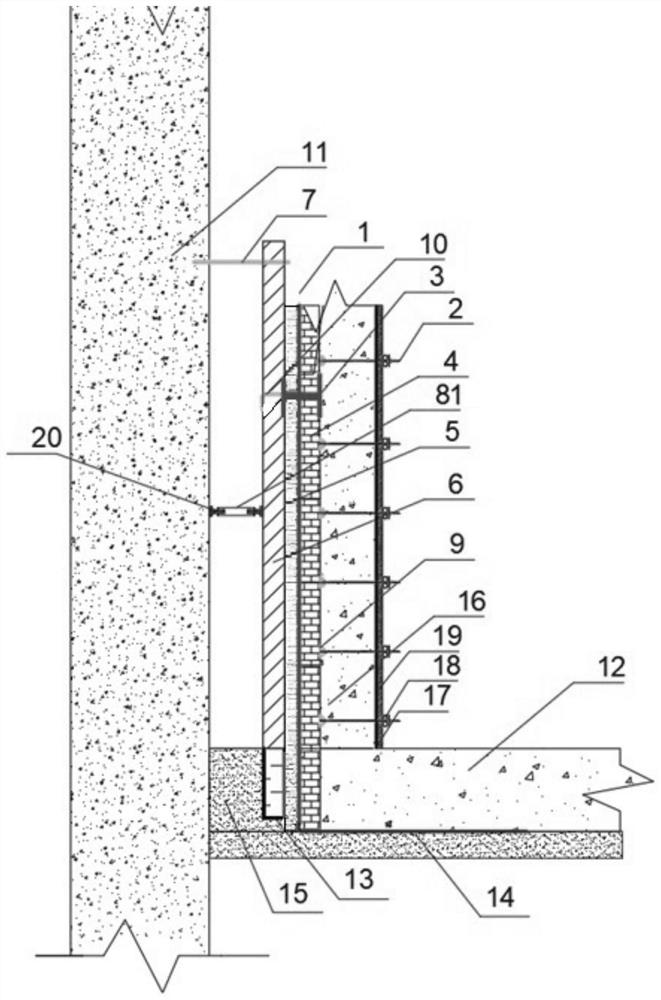

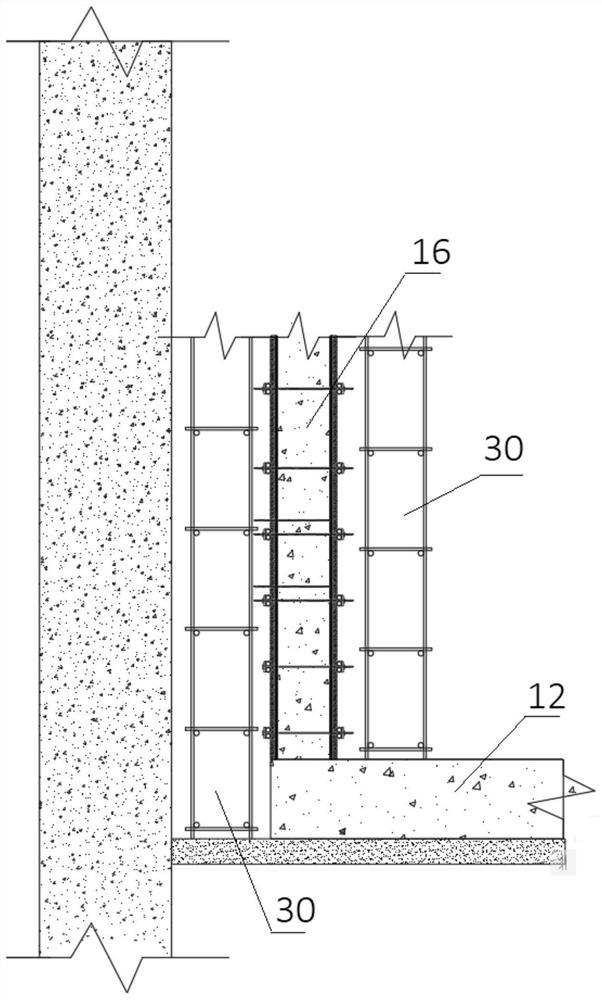

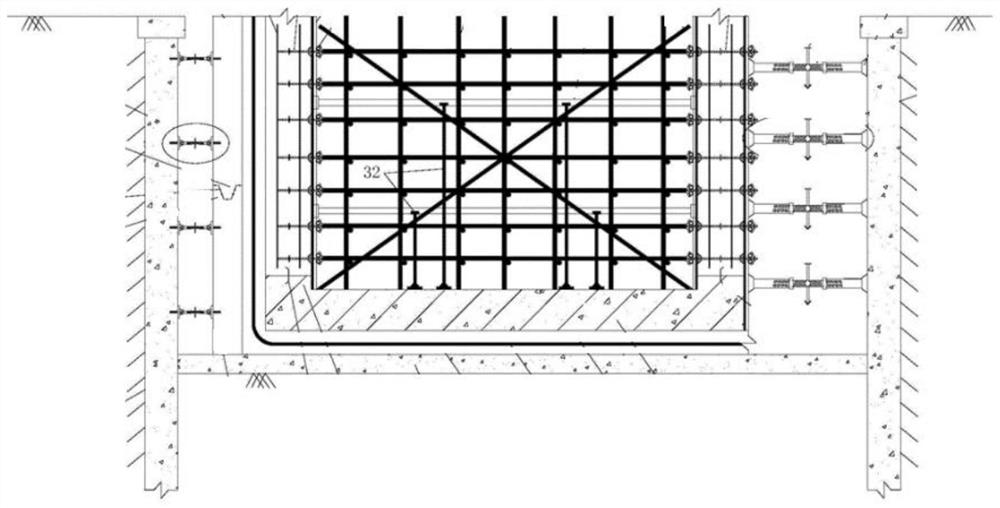

Deep foundation pit outer wall integrated structure and construction method

ActiveCN113802721ACircumference smallReduce in quantityWallsBuilding material handlingBrickArchitectural engineering

The invention discloses a construction method for a deep foundation pit outer wall integrated structure. The construction method comprises the following steps that retaining wall constructional columns are replaced with socket type steel columns, a retaining wall is built on the outer side of a basement outer wall by using two layers of prefabricated brick tire membranes, a waterproof roll is paved between the two layers of prefabricated brick tire membrane retaining walls, opposite-pulling connecting pieces can be pre-embedded in the inner-layer prefabricated brick blank film retaining wall to fix the formwork, an enclosing wall for pouring the outer wall is formed, and therefore the space for pouring the outer wall is formed. According to the construction method, firstly, the situation that the construction amount is increased due to the fact that inclined struts are arranged before outer wall pouring can be avoided, the stability, pressure resistance and perpendicularity of the prefabricated brick forming die wall are enhanced through the steel columns, meanwhile, the number of the socket type steel columns is small, the distance between the supporting structure and the socket type steel columns is not limited by the small construction space any more when the distance is adjusted, and the distance between the supporting structure and the socket type steel columns can be adjusted to be less than 0.8 m; secondly, constructional columns such as the steel columns are flexible to assemble and disassemble, and the construction amount is greatly reduced; and thirdly, the construction method greatly reduces the dependence on the outer side space of the outer wall, so that the construction amount is greatly reduced. According to the construction method, the construction period can be greatly shortened, and the foundation pit design can be more flexible and more economical.

Owner:WUHAN CONSTR ENG

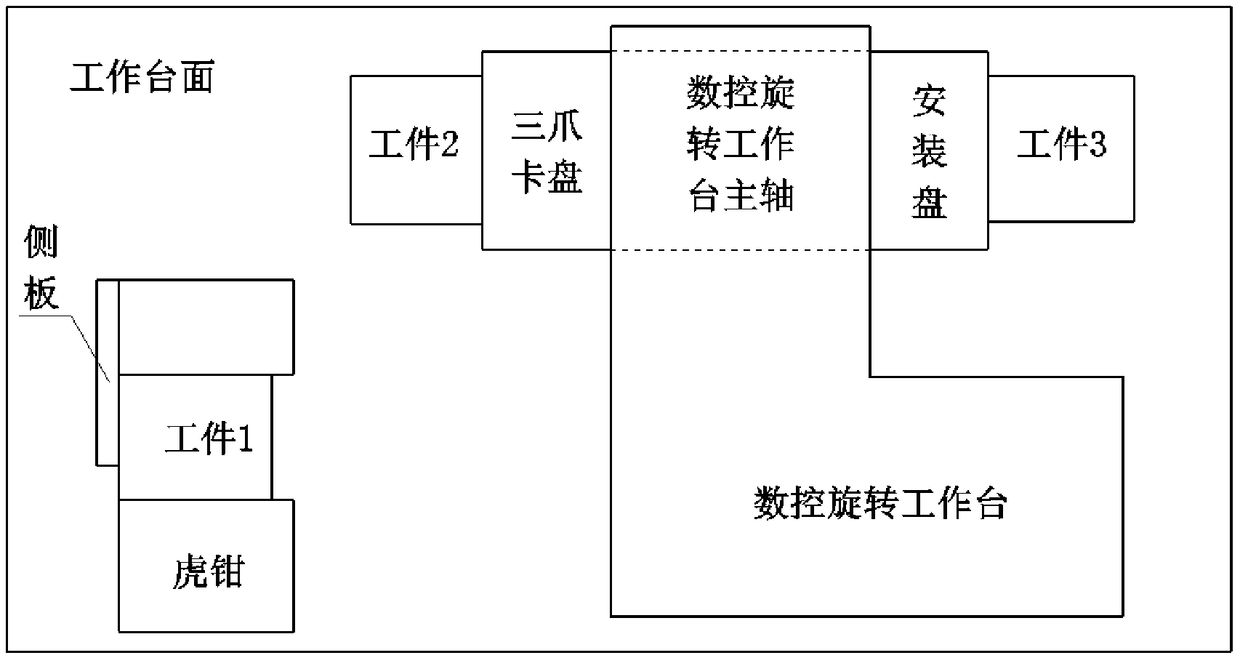

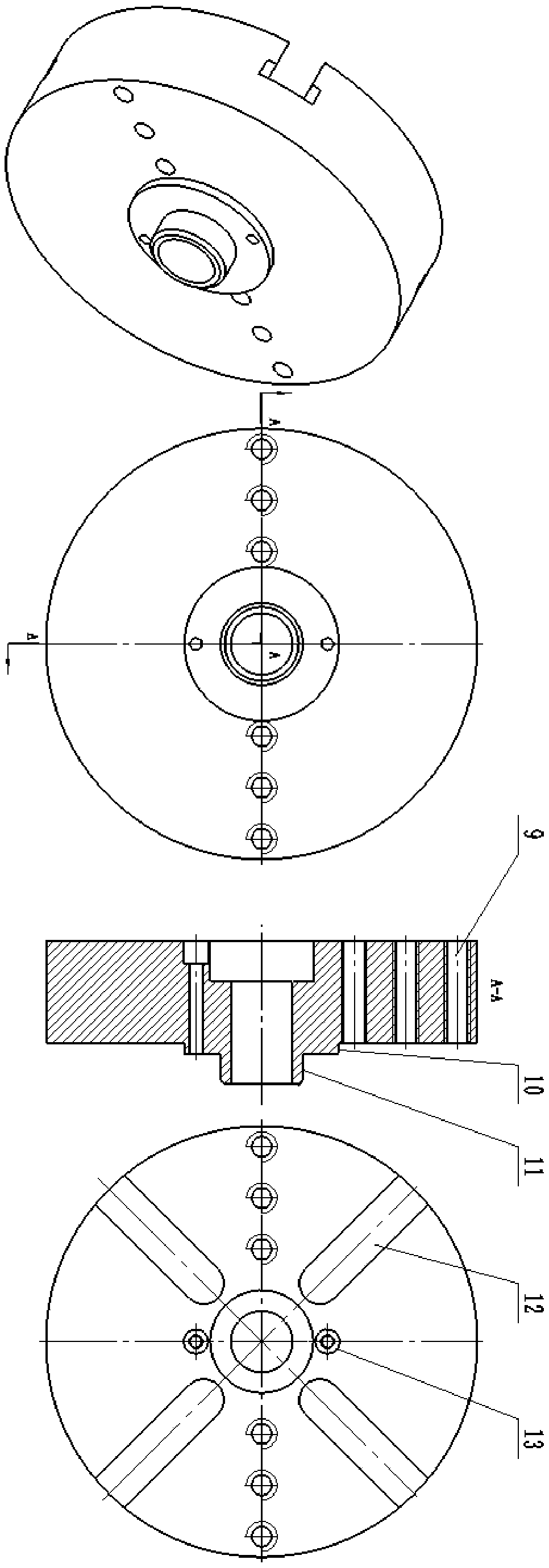

Numerical control machine tool and method for machining workpiece through numerical control machine tool

InactiveCN109500419AImprove the clamping methodAvoid harmPositioning apparatusMetal-working holdersNumerical controlMachine tool

The invention discloses a numerical control machine tool and a method for machining a workpiece through the numerical control machine tool. The numerical control machine tool is characterized by comprising a work table board, a three-jaw chuck, a numerical control rotating workbench, an installing disk and a jaw vice; the end side position of the work table board is provided with the jaw vice; thenumerical control rotating workbench is installed at the middle position of the work table board, and comprises a numerical control rotating workbench rotating shaft; the three-jaw chuck is installedon the first side face of the numerical control rotating workbench through the workbench rotating shaft; the installing disk is installed on the second side face of the numerical control rotating workbench through the workbench rotating shaft; and the installing disk is provided with one or more positioning parts used for installing a to-be-machined workpiece and / or a clamp. Due to the numericalcontrol machine tool and the method for machining the workpiece through the numerical control machine tool, the utilizing rate of a numerical control vertical type machining center can be increased, the machining efficiency is improved, and the numerical control machine tool and the method for machining the workpiece through the numerical control machine tool adapt to a modern production machiningmanner of a factory.

Owner:BEIJING ZHONG CHUANG HU LIAN TECH CO LTD

Micro-reformation and vegetation restoration method for degraded plateau and lake wetlands

ActiveCN103314763BAccelerate the speed of recovery successionImprove water qualityClimate change adaptationHorticultureRevegetationRestoration method

The invention belongs to the technical field of environmental protection and ecological engineering, relates to topological micro-reformation and vegetation restoration, and discloses a vegetation restoration method applicable to degraded plateau and lake wetlands. The vegetation restoration method is low in personnel and capital investment and mainly includes stages of background evaluation, selective enclosure and livestock reduction, topological micro-reformation for the wetlands and construction of screened plant communities or plant zones. The vegetation restoration method has the advantages that plateau wetland vegetation restoration is accelerated, wetland vegetation ecosystems are constructed, and the environmental quality of the degraded wetlands is improved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

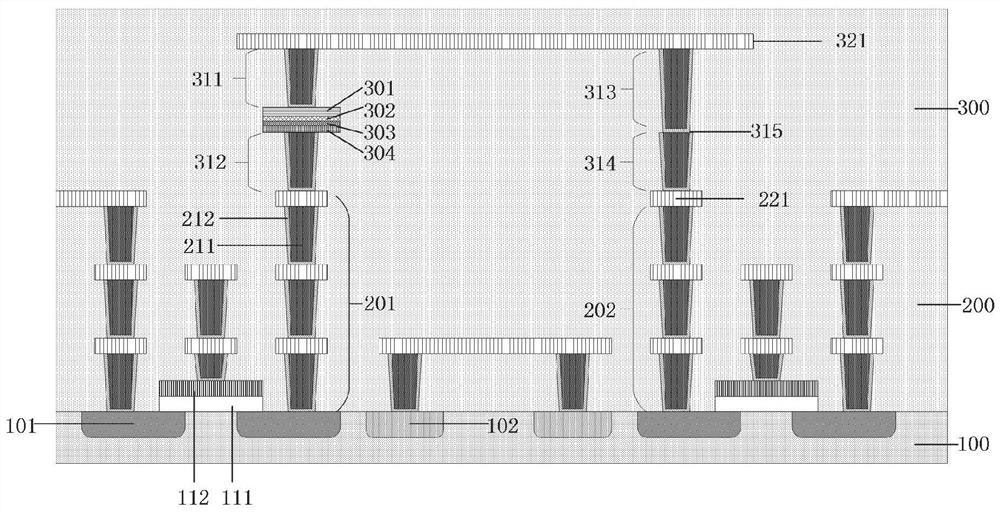

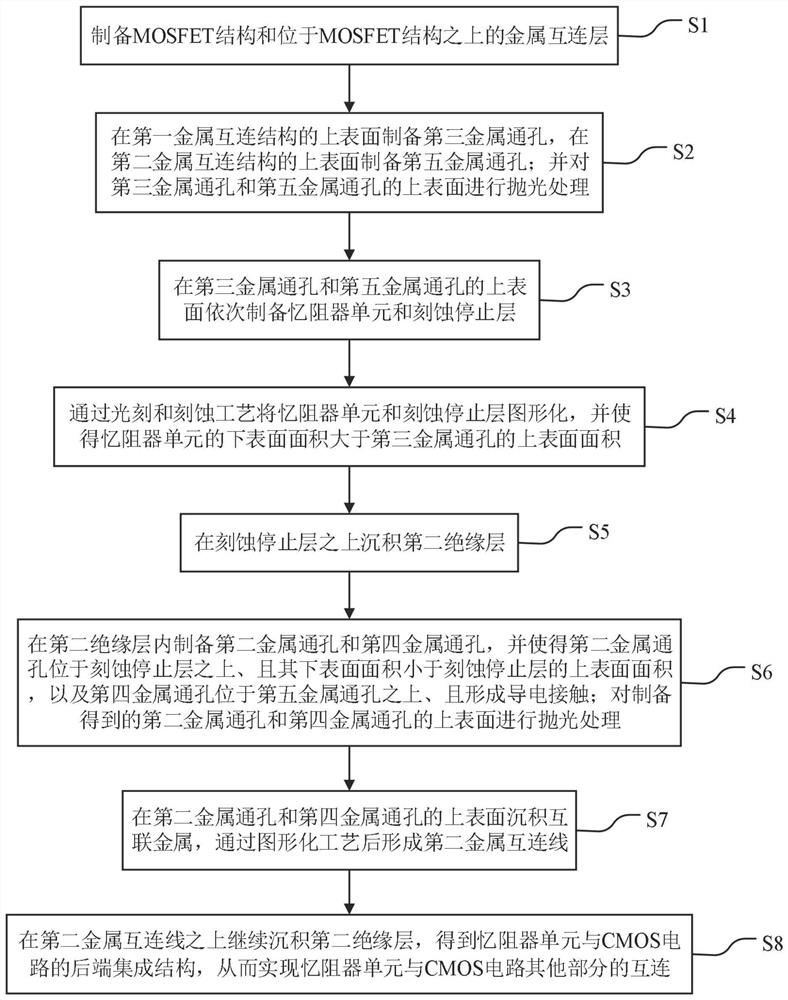

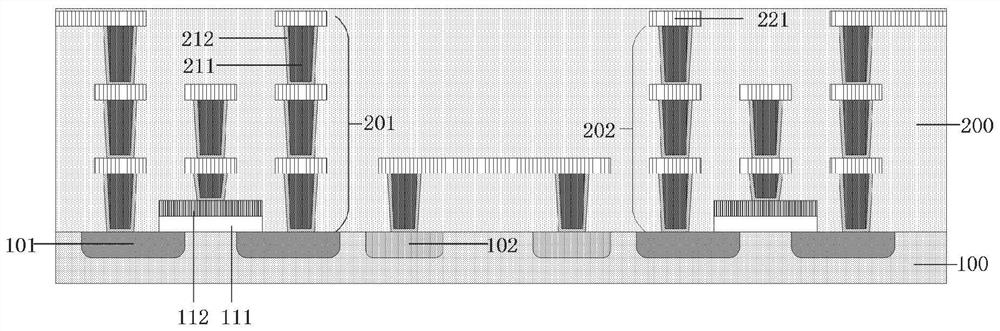

Rear-end integrated structure of memristor unit and CMOS (complementary metal oxide semiconductor) circuit and preparation method of rear-end integrated structure

PendingCN114203756ATo achieve electrical connectionEffective protectionSemiconductor/solid-state device detailsSolid-state devicesCMOSMetal interconnect

The invention discloses a rear-end integrated structure of a memristor unit and a CMOS (complementary metal oxide semiconductor) circuit and a preparation method of the rear-end integrated structure, the memristor unit is arranged between two layers of metal interconnection lines and is communicated with upper and lower metal interconnection lines through metal through holes, and an etching stop layer is arranged on the memristor unit; the memristor structure can be effectively protected when the upper through hole of the memristor unit is etched, so that the memristor structure is not damaged while good butt joint of the metal through hole butt joint structure part can be achieved, and electrical connection between the memristor unit and a CMOS circuit can be achieved under the condition that the performance of the memristor is guaranteed. On the basis of a standard CMOS (Complementary Metal-Oxide-Semiconductor Transistor) process, a rear-end process integration method is adopted, so that hybrid integration of the memristor and a CMOS circuit is realized. According to the method provided by the invention, the memristor with high performance can be prepared on the metal interconnection layer on the basis of adding a small number of steps of processes and two layers of layouts, the interconnection between the memristor and a CMOS (Complementary Metal Oxide Semiconductor) circuit is realized, and the performance of the CMOS device is not influenced.

Owner:HUAZHONG UNIV OF SCI & TECH

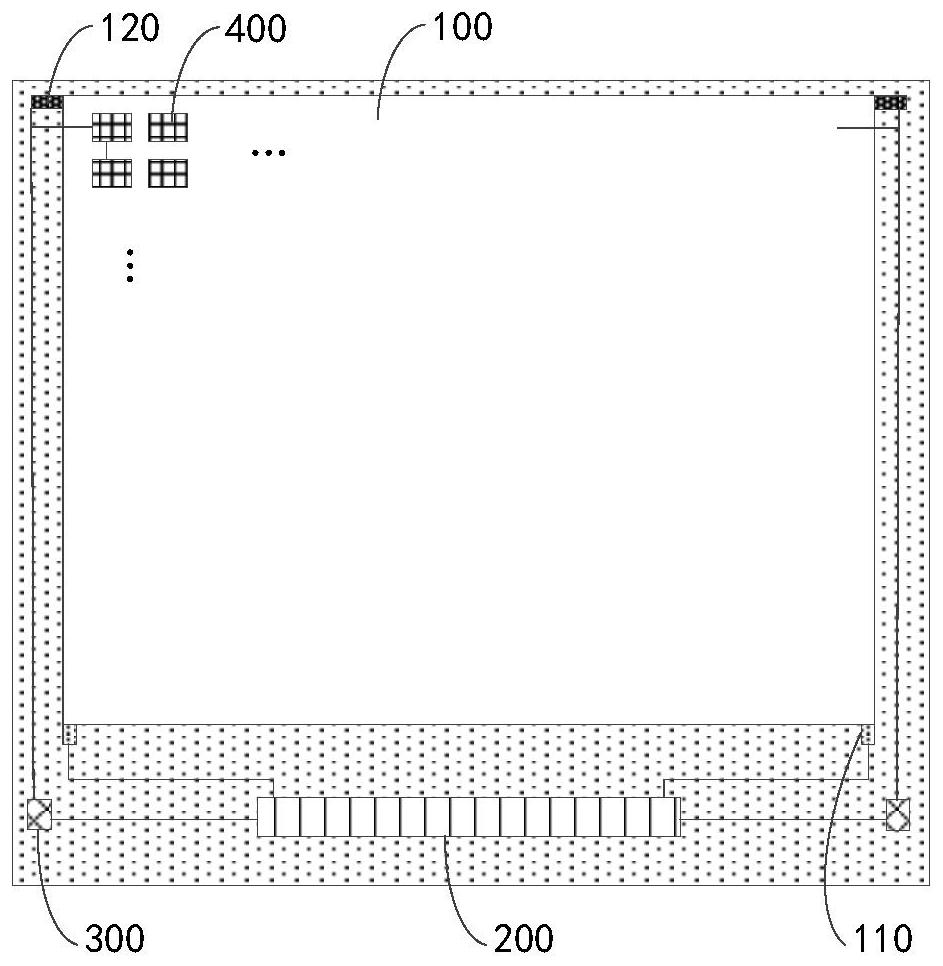

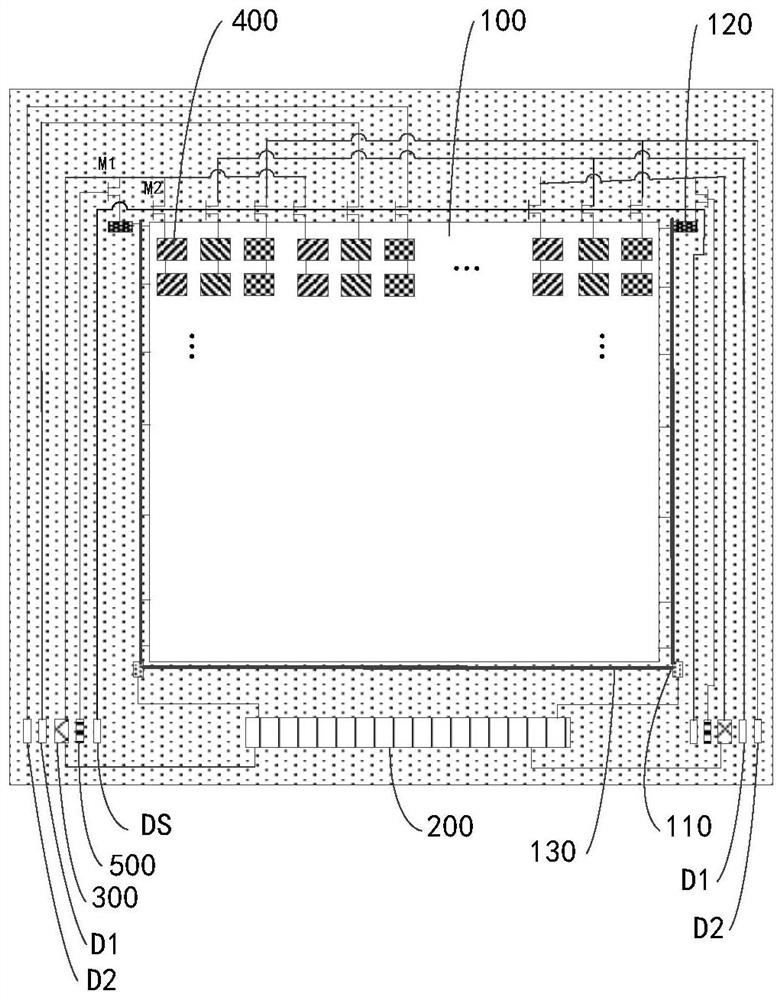

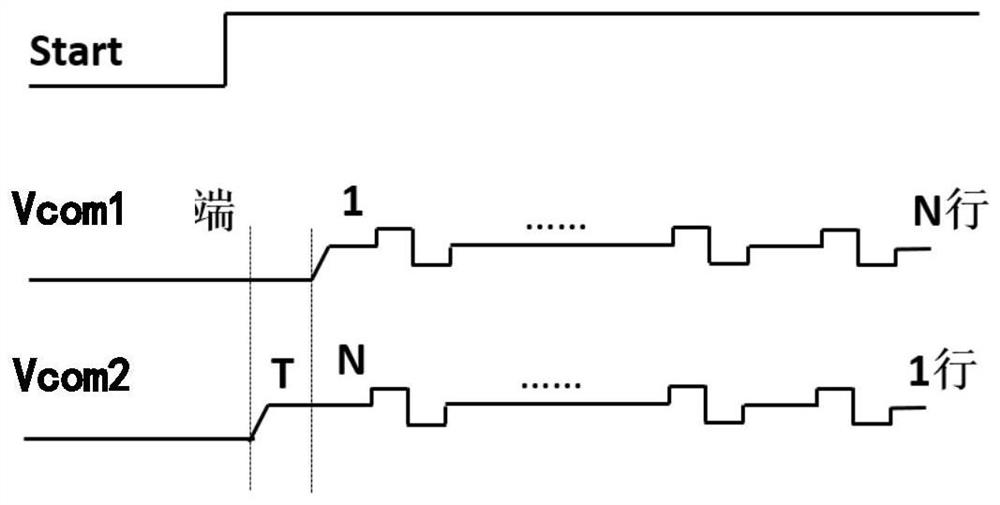

Display panel, driving method and related equipment

ActiveCN114664251AEliminate Bad StreaksReduce defective rateStatic indicating devicesDisplay deviceElectrical connection

The invention discloses a display panel, a driving method and related equipment, relates to the technical field of display, and can improve poor stripe display. The display panel comprises a common electrode, the end, close to a driving chip, of the common electrode is electrically connected with at least one near-end pin, and the end, away from the driving chip, of the common electrode is electrically connected with at least one far-end pin; the electrical test pin is used for transmitting an electrical test signal to a display device of the display panel, and the electrical test pin is electrically connected with the far-end pin; wherein the driving chip is used for transmitting a common voltage signal to the common electrode through the near-end pin, and transmitting the common voltage signal to the common electrode through the electrical property test pin and the far-end pin.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

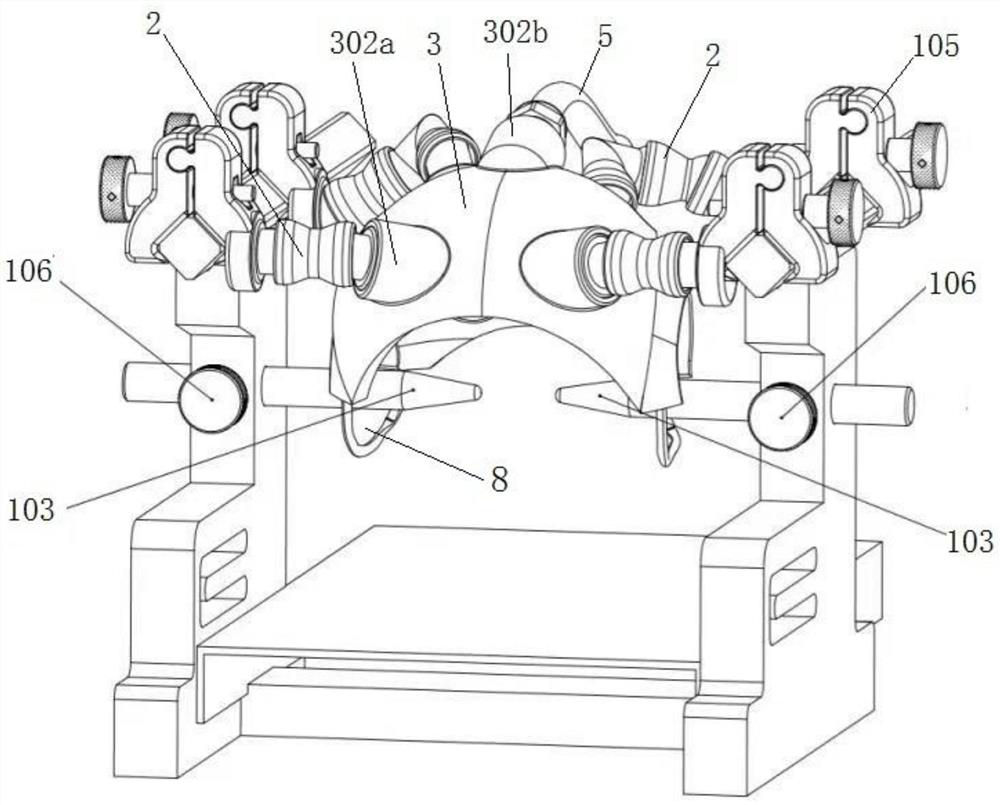

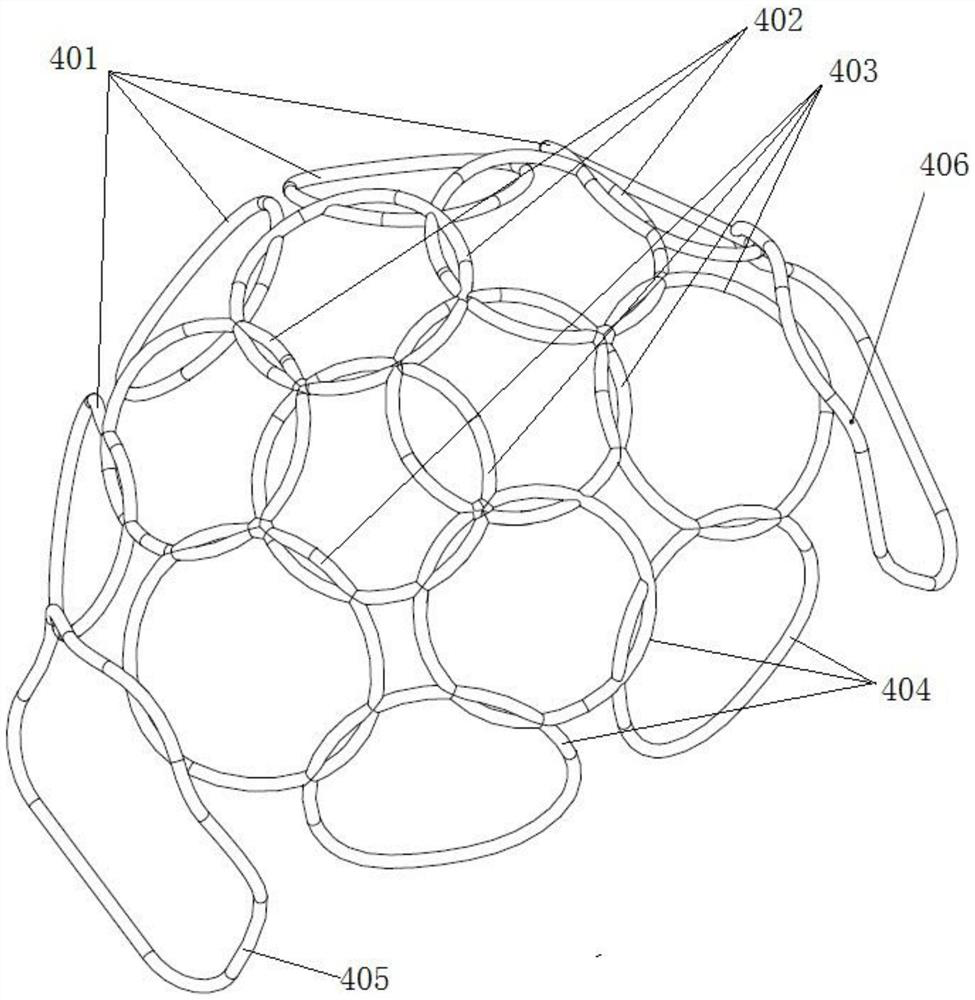

High-fitting helmet-type radio frequency coil device for magnetic resonance experiments of primates

PendingCN113050003AImprove signal-to-noise ratioImprove image qualityDiagnostic recording/measuringSensorsNoise (radio)Primate

The invention discloses a high-fitting helmet-type radio frequency coil device for an magnetic resonance experiment of primates. The high-fitting helmet-type radio frequency coil device comprises an animal fixing base used for fixing a tested animal, a helmet-type coil supporting shell connected with the animal fixing base through a universal connecting rod and capable of being worn on the head of the tested animal, a radio frequency receiving coil arranged in the coil supporting shell, and a signal lead wire which is in circuit connection with the radio frequency receiving coil and extends out of the coil supporting shell. No matter at what angle the head of the tested animal is fixed, the radio frequency receiving coil in the device can be arranged close to the scalp of the tested animal, so that the signal-to-noise ratio and the magnetic resonance imaging quality of signal induction receiving are improved.

Owner:ZHEJIANG UNIV

Construction method of recoverable deep foundation pit outer wall integrated structure

ActiveCN113802722ACircumference smallReduce in quantityWallsBuilding material handlingBrickArchitectural engineering

The invention discloses a construction method of a recoverable deep foundation pit outer wall integrated structure. The construction method comprises the steps that retaining wall constructional columns are replaced by socket type steel columns, a retaining wall is built on the outer side of a basement outer wall by using two layers of prefabricated brick tire membranes, a waterproof coiled material is laid between the two layers of prefabricated brick tire membrane retaining walls, opposite-pulling connecting pieces can be pre-embedded in the inner-layer prefabricated brick blank film retaining wall to fix the formwork, an enclosing wall for pouring the outer wall is formed, and therefore the space for pouring the outer wall is formed. According to the construction method, firstly, the situation that the construction amount is increased due to the fact that inclined struts are arranged before outer wall pouring can be avoided, the stability, pressure resistance and perpendicularity of the prefabricated brick forming die wall are enhanced through the steel columns, meanwhile, the number of the socket type steel columns is small, the distance between the supporting structure and the socket type steel columns is not limited by the small construction space any more when the distance is adjusted, and the distance between the supporting structure and the socket type steel columns can be adjusted to be less than 0.8 m; secondly, constructional columns such as the steel columns are flexible to assemble and disassemble, and the construction amount is greatly reduced; and thirdly, the construction method greatly reduces the dependence on the outer side space of the outer wall, so that the construction amount is greatly reduced. According to the construction method, the construction period can be greatly shortened, and the foundation pit design can be more flexible and more economical.

Owner:WUHAN CONSTR ENG

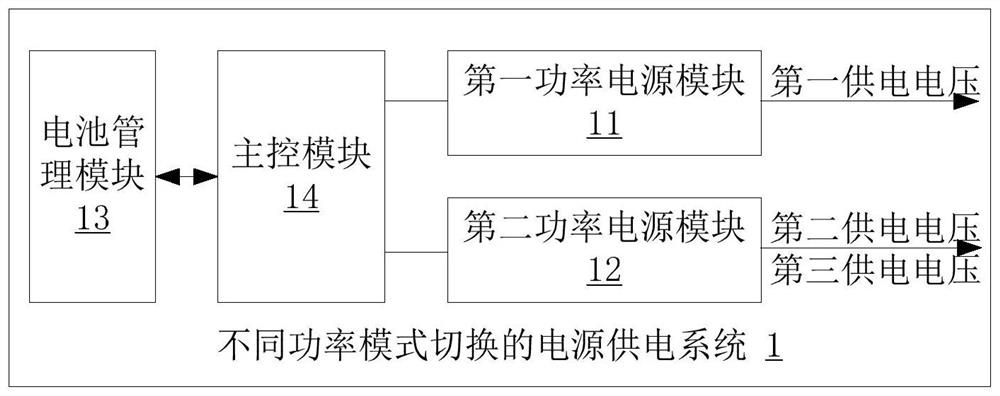

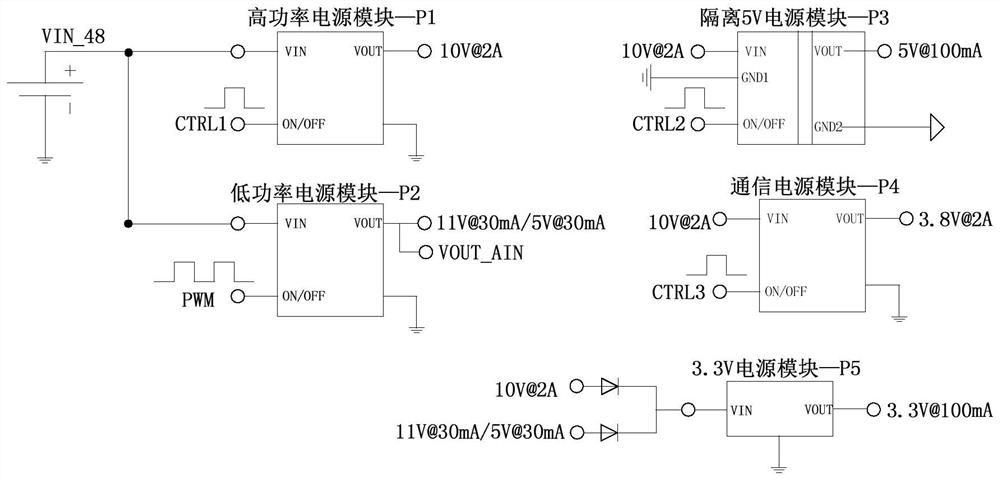

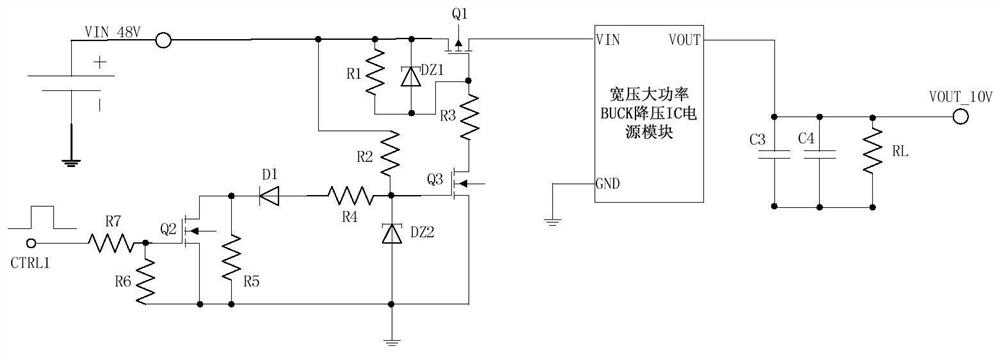

Power supply system capable of switching different power modes

ActiveCN114498905AReduce real power consumptionReduce power consumptionEfficient power electronics conversionPower network operation systems integrationPower modeElectrical battery

The invention provides a power supply system capable of switching different power modes, and the system comprises a first power supply module which is used for outputting a first power supply voltage; the second power supply module is used for outputting a second power supply voltage; a battery management module; the main control module is used for starting according to the first power supply voltage after the system power supply end is powered on, establishing communication with the battery management module and entering a normal power operation mode; and in an abnormal power operation mode, the main control module controls the second power supply module to output the second power supply voltage, and after normal output of the second power supply voltage is detected, the first power supply voltage output by the first power supply module is closed, and the second power supply module is controlled to output a third power supply voltage. According to the invention, two power supplies with different powers and corresponding control circuits are combined to supply power to a BMS digital part circuit.

Owner:SHANGHAI MAKESENS ENERGY STORAGE TECH CO LTD

Producing method of precast reinforced concrete member with connecting reinforcement

InactiveCN106626050AEasy to manufacturePrevent overflowCeramic shaping apparatusBuilding constructionsFiberReinforced concrete

The invention relates to a producing method of precast reinforced concrete member with connecting reinforcement, in particular to the technical field of precast reinforced concrete structural member. A connecting reinforcement is hung on the side of the precast reinforced concrete member. One end of the connecting reinforcement is hung on the reinforcement cage of the precast reinforced concrete member. The other end of the connecting reinforcement is connected with nothing. The producing method of precast reinforced concrete member with connecting reinforcement includes the following steps. (1) The reinforcement cage of the precast reinforced concrete member is colligated and the connecting reinforcement is hung on the reinforcement cage. (2) The connecting reinforcement is wrapped by a piece of fiber cloth or a piece of kraft paper. (3) The mould of the precast reinforced concrete member is installed and the connecting reinforcement should closely adhere to the mould, which is on the side of the precast reinforced concrete member. (4) Concrete is placed. (5) The mould can be removed, when the concrete is finally set or achieves the predetermined strength. (6) The free end of the connecting reinforcement is pulled out and turned. The fiber cloth and the kraft paper are divested. Then, the precast reinforced concrete member with connecting reinforcement is formed. The method of producing precast reinforced concrete member with connecting reinforcement will improve industrialization level of building structure.

Owner:初明进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com