Corner treatment equipment for plastic product processing

A technology of plastic products and processing equipment, which is applied in the field of plastic product processing, can solve the problems of poor corner processing effect, achieve the effect of easy storage and utilization, saving quantity and processing cost, and satisfying the effect of continuous processing for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

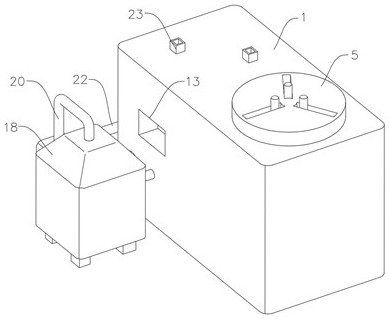

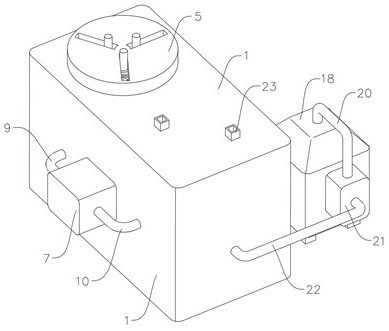

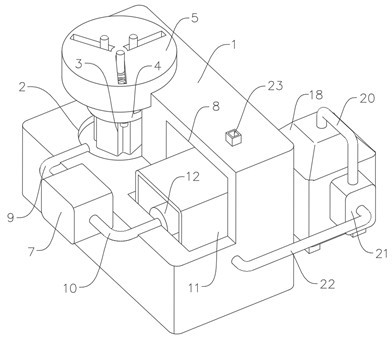

[0019] refer to figure 1 , figure 2 , image 3 and Figure 7 , a kind of corner processing equipment for processing plastic products, including a processing table 1 and a melting furnace 18, a driving chamber 2 and a cleaning chamber 8 are provided in the processing table 1, a motor 3 is fixed on the inner bottom of the driving chamber 2, and an output shaft of the motor 3 A turntable 4 is fixed, and the upper end of the turntable 4 is fixed with a grinding table 5. The motor 3 has sufficient driving force to drive the grinding table 5 to complete effective grinding. There is a corner adaptation mechanism, the grinding table 5 protrudes from the upper surface of the processing table 1, so as to facilitate the observation of the workpiece, the outer wall of the processing table 1 is fixed with a fan 7, and the air inlet and outlet of the fan 7 are respectively fixed with a suction pipe 9 and an air filling pipe 10. The exhaust pipe 9 and the inflation pipe 10 communicate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com