Deep foundation pit outer wall integrated structure and construction method

A construction method and an integrated technology, applied to building structures, walls, building components, etc., can solve the problems of collapse of prefabricated protective walls, astonishing construction volume, and low work efficiency, so as to save quantity and earthwork construction volume and reduce construction costs , The effect of flexible foundation pit design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

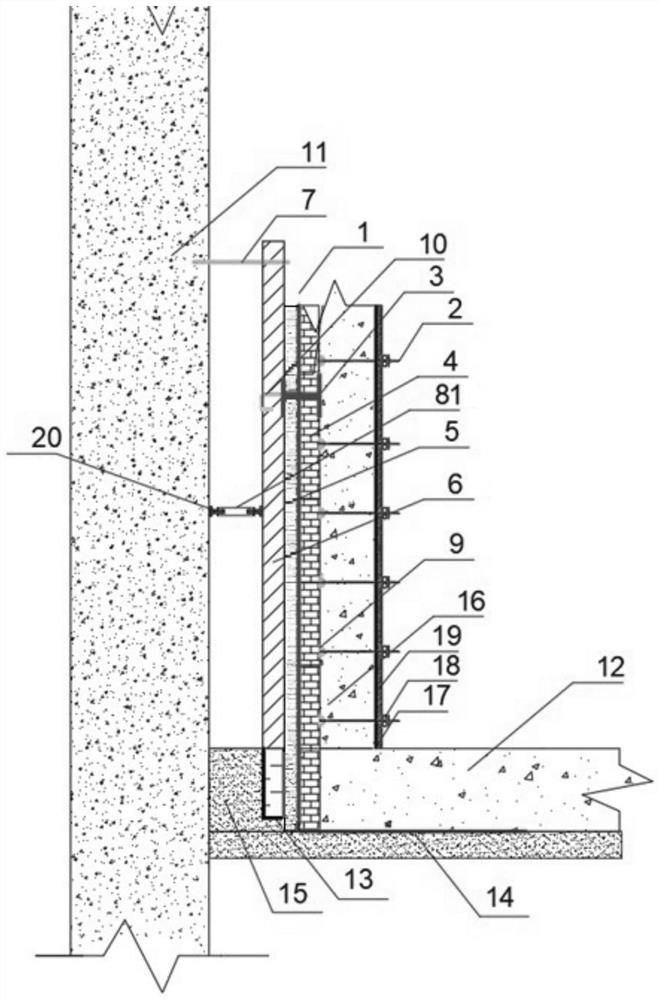

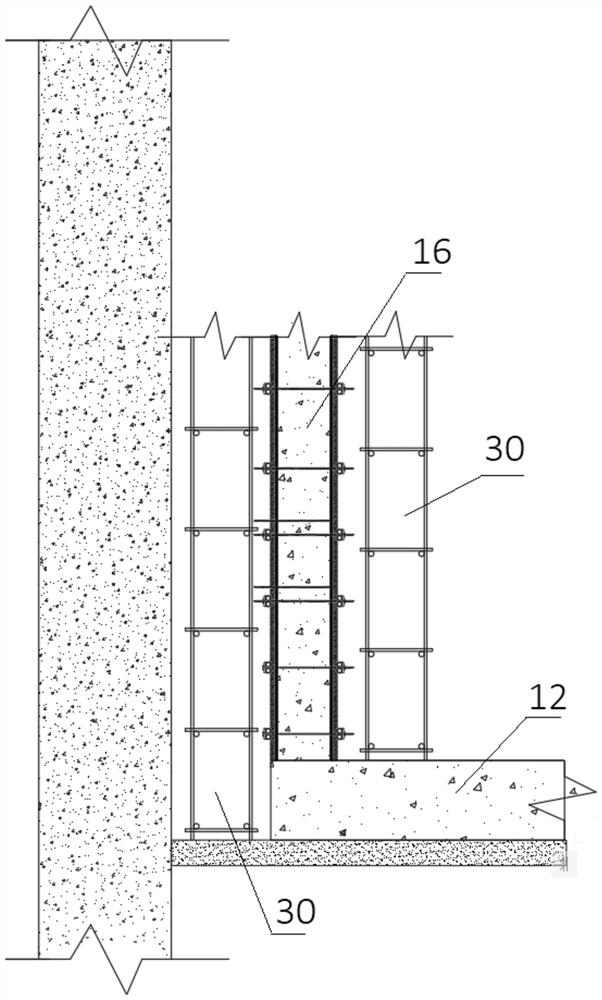

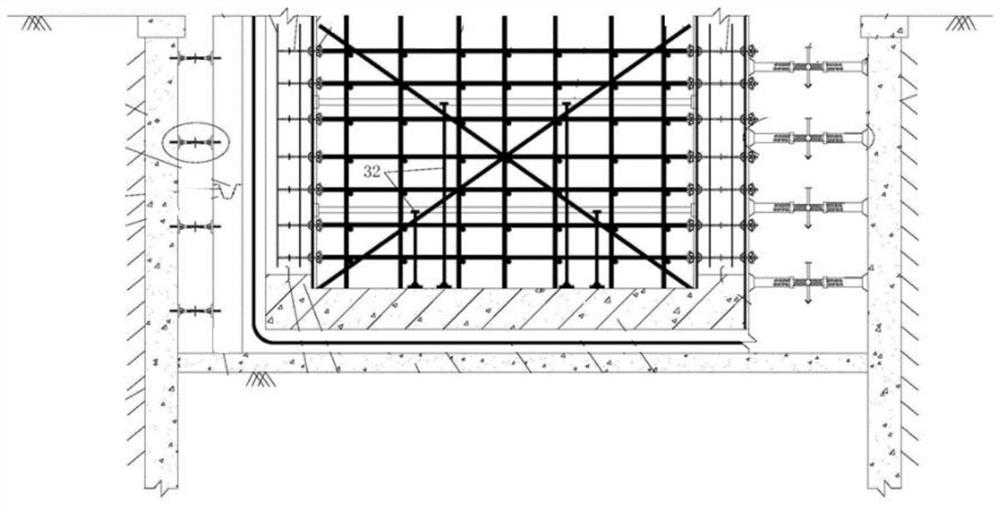

[0033] An integrated structure for the outer wall of a deep foundation pit, including steel columns 6, inner membrane retaining wall 4, outer membrane retaining wall 5, waterproof coiled material 1, ring beam 3, outer wall 16, cushion 14, and structural floor 12 , formwork 17, annular cap 15.

[0034]Wherein, the cushion layer 14 is flatly laid on the ground of the foundation pit, and the annular cap 15 is poured around the upper surface of the cushion layer 14 along the supporting side wall 11 of the foundation pit, and the steel column 6 is inserted into the ring cap 15 formed in the In the socket holes 13, all the socket holes 13 are evenly arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com