Multi-station micro-positioning line displacement measuring device

A measuring device and micro-positioning technology, applied in the direction of measuring devices, electric devices, instruments, etc., can solve the problems of low work efficiency, failure to meet the requirements of productivity, high production costs, etc., to achieve convenient operation, improve work efficiency, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

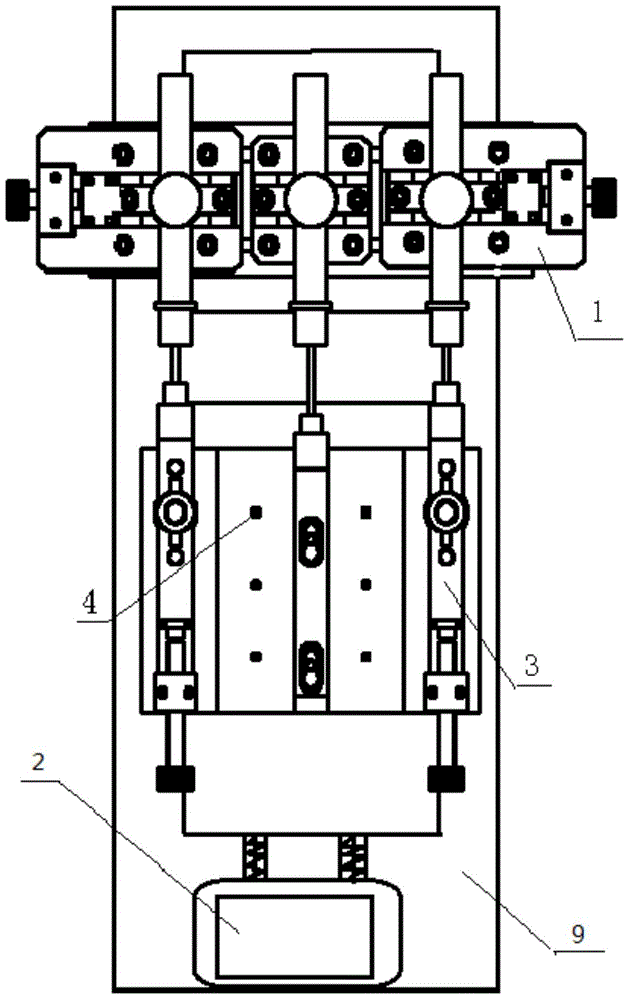

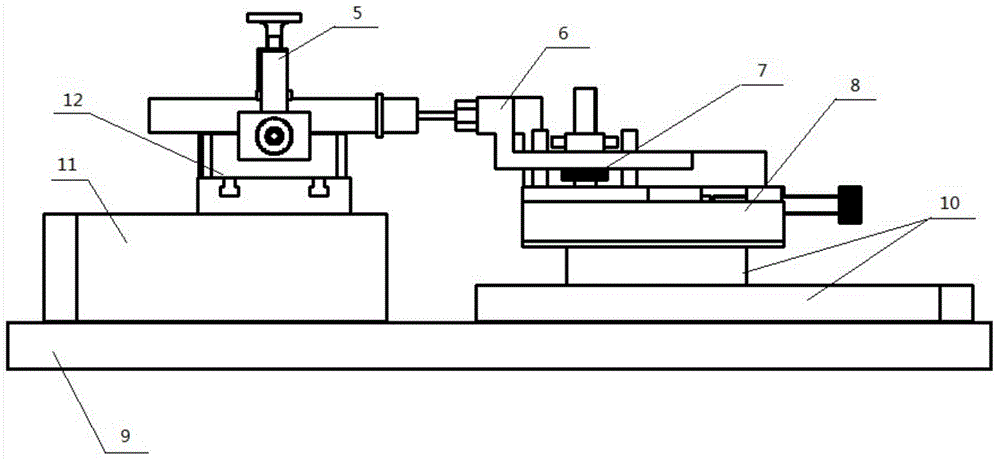

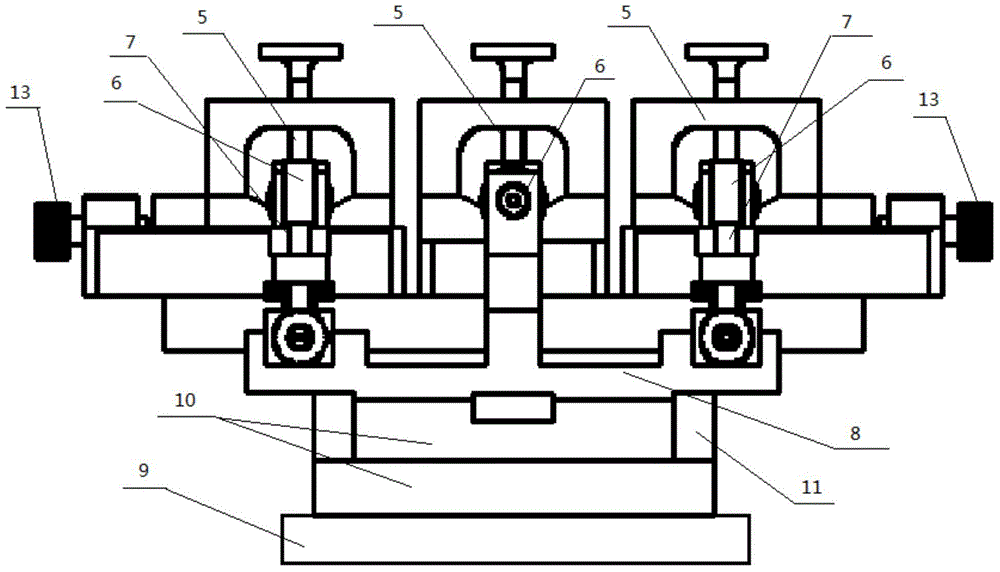

[0021] Figures 1 to 3 Shown is a schematic diagram of the overall structure of the multi-station micro-positioning measurement device system. The present invention includes a measurement clamping structure 1 , a measurement driving structure 2 , a multi-degree-of-freedom adjustment device 3 , a reference carrier 9 , and a base block 10 . Among them, there are two slideways on the upper cuboid of the reference carrier 9, the slideways are the working position of the roller screw rod of the measurement drive structure 2, and the reference carrier 9 needs to be placed strictly horizontally; the measurement clamping structure 1 is fixed on the In the slideway of the reference carrier 9, there are three measuring fixtures 5 on the measurement clamping structure 1, which are the clamping parts of the sensor; the base block 10 is located on the refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com