Patents

Literature

47results about How to "Save workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

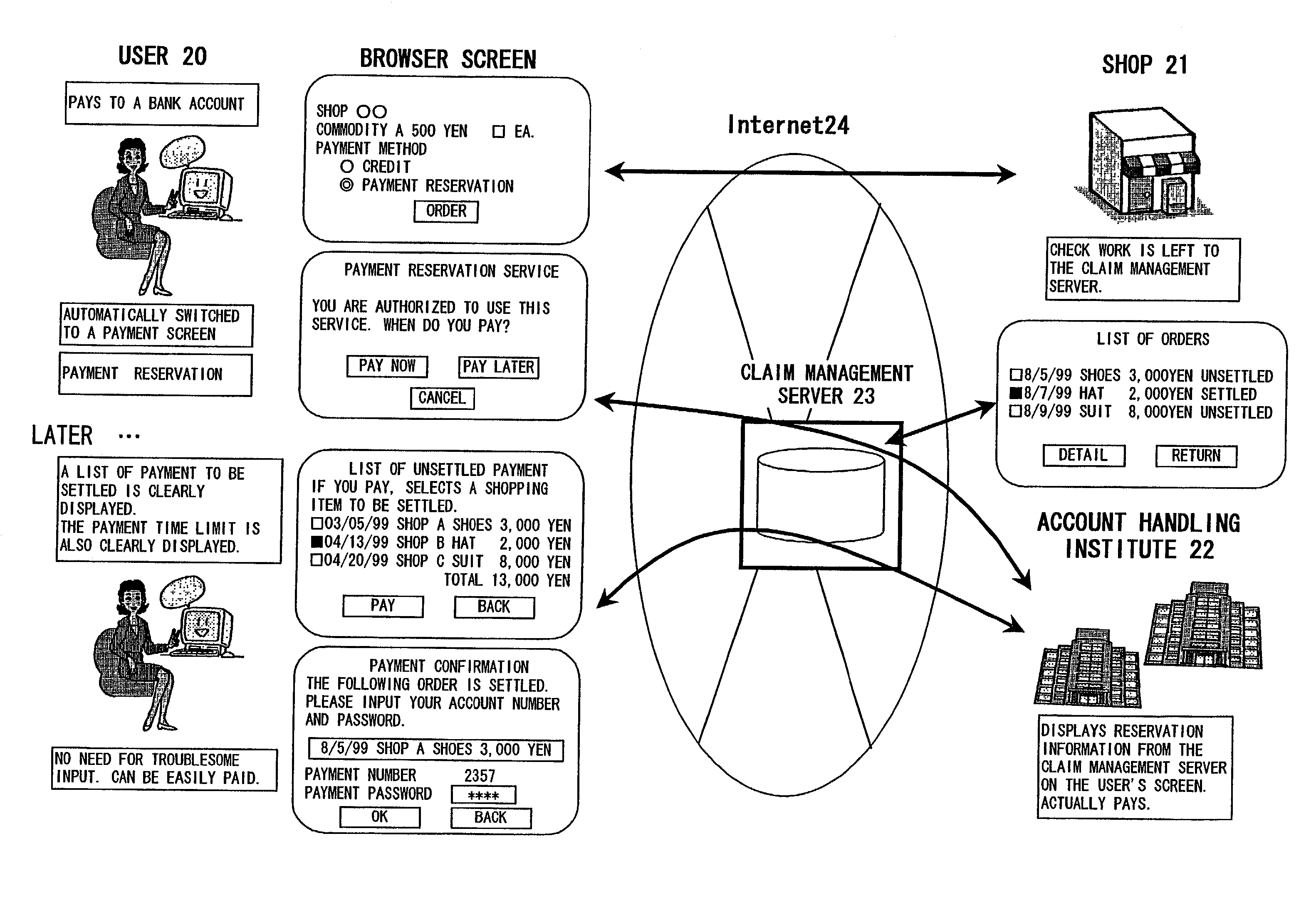

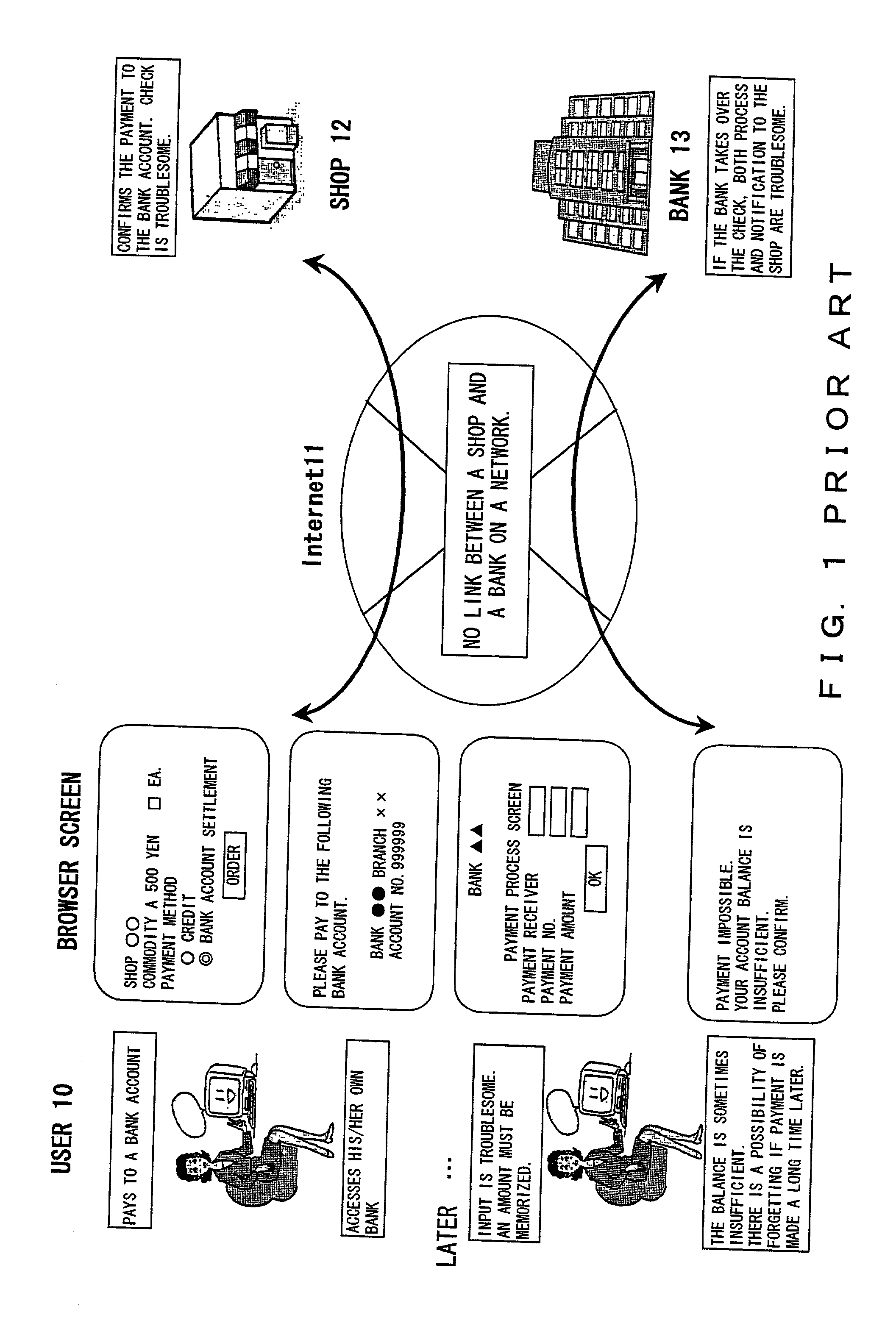

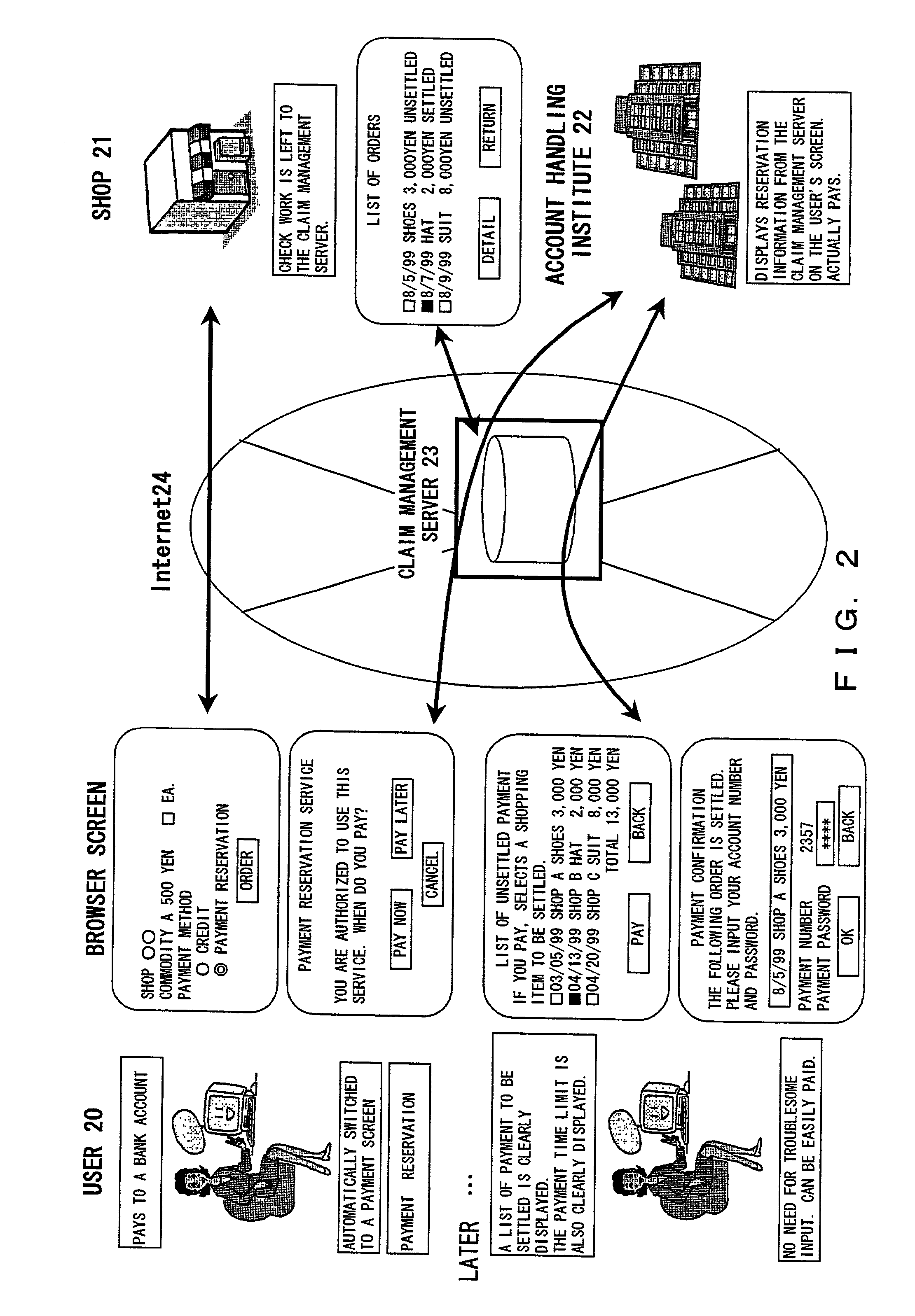

Online settlement system, method thereof and storage medium

When a user does shopping on a commodity purchase screen provided by a shop via the Internet, the user uses a payment reservation service provided by a claim management server. Then, the claim management server stores the shopping content of the user as a database and simultaneously stores both a payment amount and a settled / unsettled payment status in the shopping contents. The user views the list of unsettled payment of the shopping content provided by the claim management server, selects a shopping item, the price payment of which the user is going to settle, designates an account handling institute to use and settles payment online. The claim management server automatically does the check work of the shopping content, the price payment of which is settled.

Owner:FUJITSU LTD

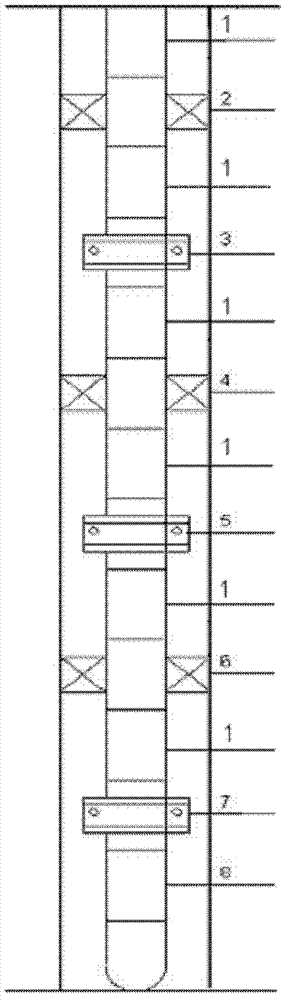

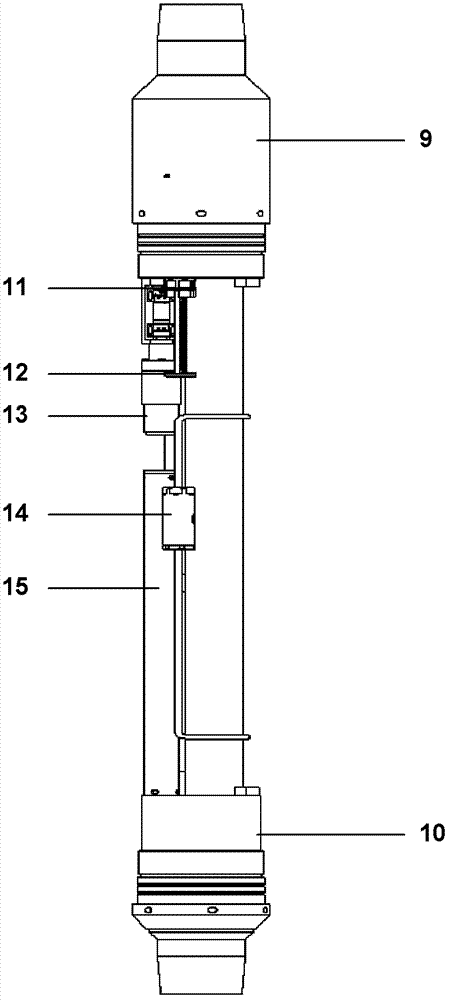

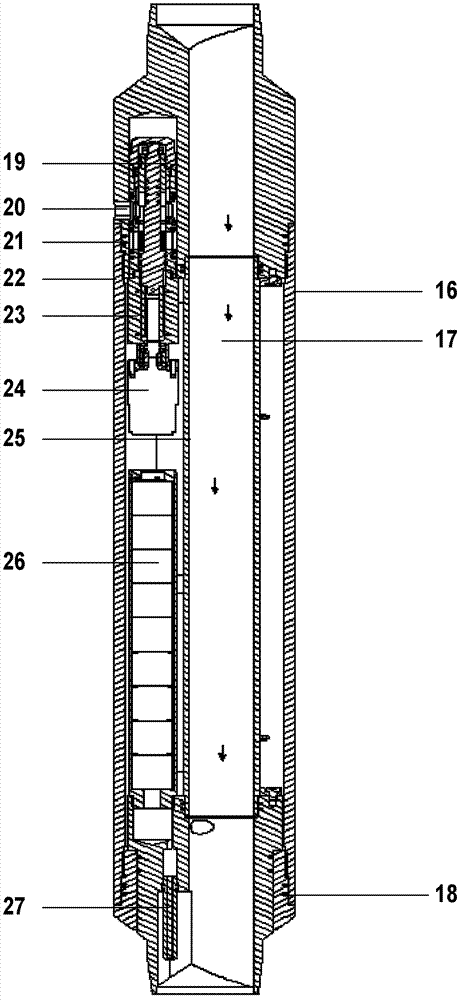

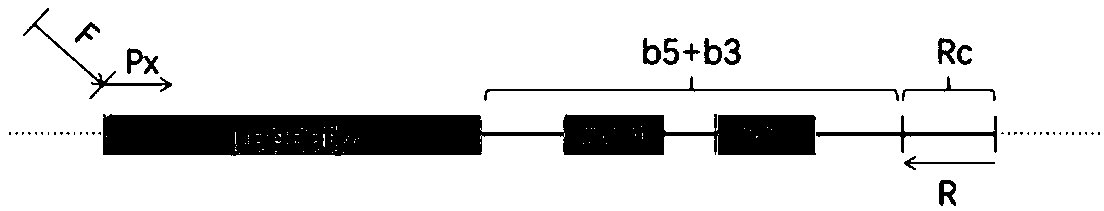

Digital underground layering water injection testing and adjusting process pipe column and operation method thereof

The invention discloses a digital underground layering water injection testing and adjusting process pipe column and an operation method thereof. According to the purpose, the instantaneous flow rate and the accumulative total injection rate of a single reservoir stratum can be monitored and recorded in real time underground, pressure of the reservoir stratum is monitored in real time, underground well shut-in layering pressure drop is tested, and bi-directional transmission of data and orders between a down-hole and the ground is carried out in a wireless mode. The process pipe column is formed by connecting a multistage digital water distributor and an Y344 water injection packer through an oil pipe, and eliminates steps of testing and allocating steel wires of the flow rate compared with an existing water distributor and a packer used for layering water injection. Meanwhile, the instantaneous flow rate and the accumulative total injection rate of the single reservoir stratum can be monitored and recorded in real time underground, the pressure of the reservoir stratum is monitored in real time, and the underground well shut-in layering pressure drop is tested. The pipe column can greatly reduce workloads of matching tests and pressure-drop tests of an oil field layering water injection well, provides the true and reliable accumulative total injection rate of the single stratum, and provides reliable evidence for policy adjustment of the oil field development technology.

Owner:PETROCHINA CO LTD

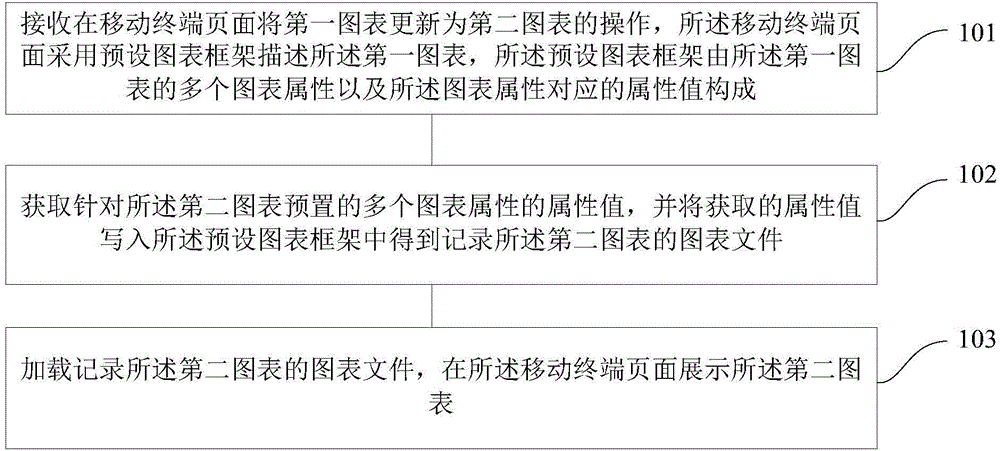

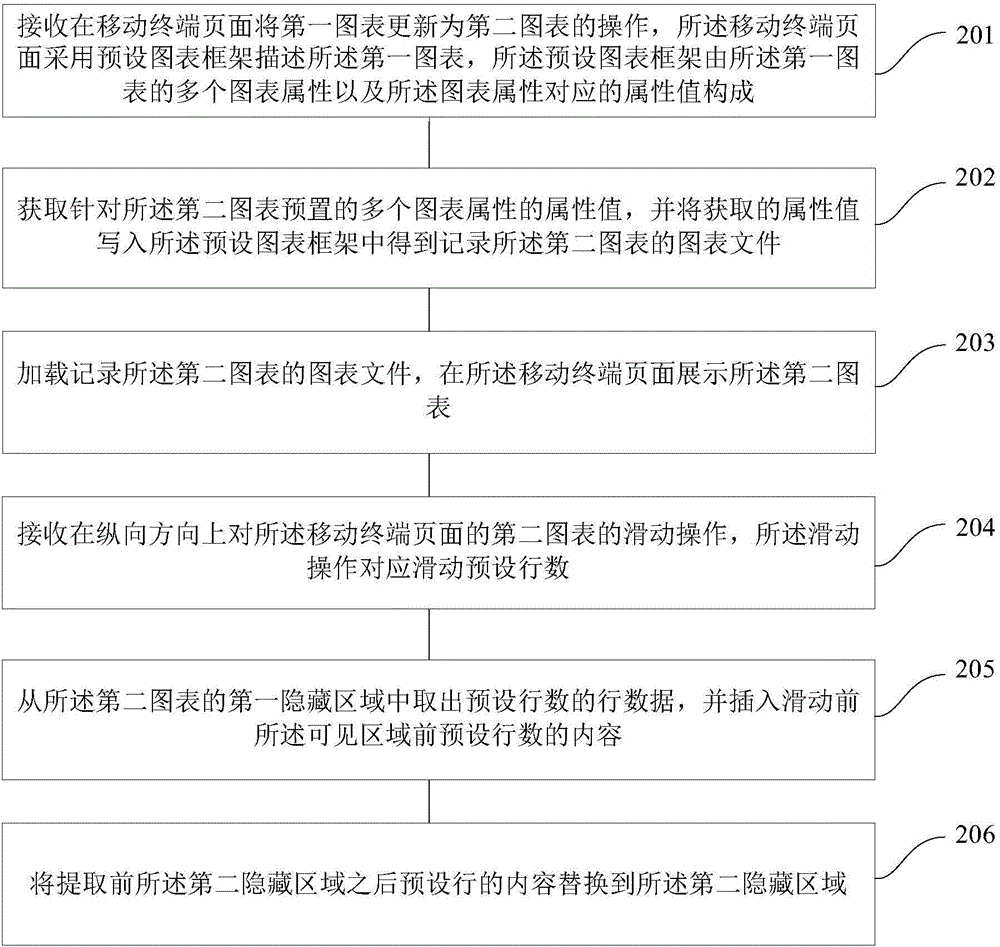

Updating method and device of mobile terminal page diagram

InactiveCN104572098ASave workloadShorten the timeProgram loading/initiatingComputer terminalComputer engineering

The invention discloses an updating method and device of mobile terminal page diagram. The method comprises the following steps: receiving the operation of updating the first diagram into the second diagram on the mobile terminal page, the mobile terminal page adopts the preset diagram framework for describing the first diagram, the preset diagram framework is composed of a plurality of diagram attributes of the first diagram and the attribute value corresponding to the diagram attribute; obtaining the attribute value of the preset diagram attributes of the second diagram and writing the obtained attribute value in the preset diagram framework to obtain the diagram file recording the second diagram; loading the diagram file recording the second diagram, displaying the second diagram on the mobile terminal page. The occupation of the storage space is greatly reduced, the server resource and the mobile terminal resource offering the page are reduced, frequent operation for creating all kinds of repeat style can be avoided while rendering the diagram, the system memory consumption is greatly reduced and the system performance is raised.

Owner:BEIJING QIHOO TECH CO LTD +1

Special liquid pesticide fertilizer for insect prevention, residue reduction and harmlessness of garden trees, and preparation method thereof

ActiveCN103848692APromote photosynthesisReduce pollutionFertilizer mixturesPesticide residueBULK ACTIVE INGREDIENT

The invention belongs to the field of fertilizer for trees and particularly relates to a special liquid pesticide fertilizer for insect prevention of garden trees, and a preparation method thereof. The pesticide fertilizer comprises the following active ingredients: microbial flora, humic acid, nitrogen fertilizer, phosphatic fertilizer, potassic fertilizer, boric acid, insecticide, water-soluble isolating agent, plant growth regulator, water and the like. The liquid pesticide fertilizer is directly sprayed on leave surfaces of the trees, nutrient substances are evenly distributed, high in utilization rate, and easily absorbed by the leaf surfaces of the plants, the preparation and applications are simple and easy, and the special liquid pesticide fertilizer can degrade pesticide residue, and truly prevent insect disease and promote the growth of the trees.

Owner:上海波咖西生物科技有限公司

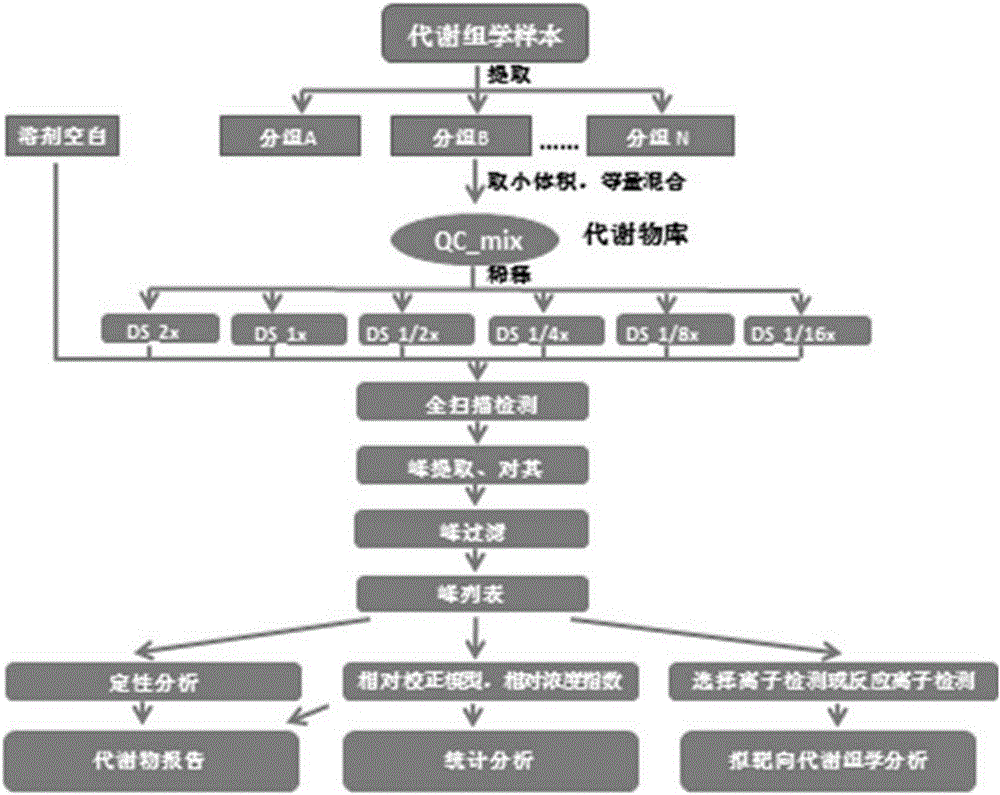

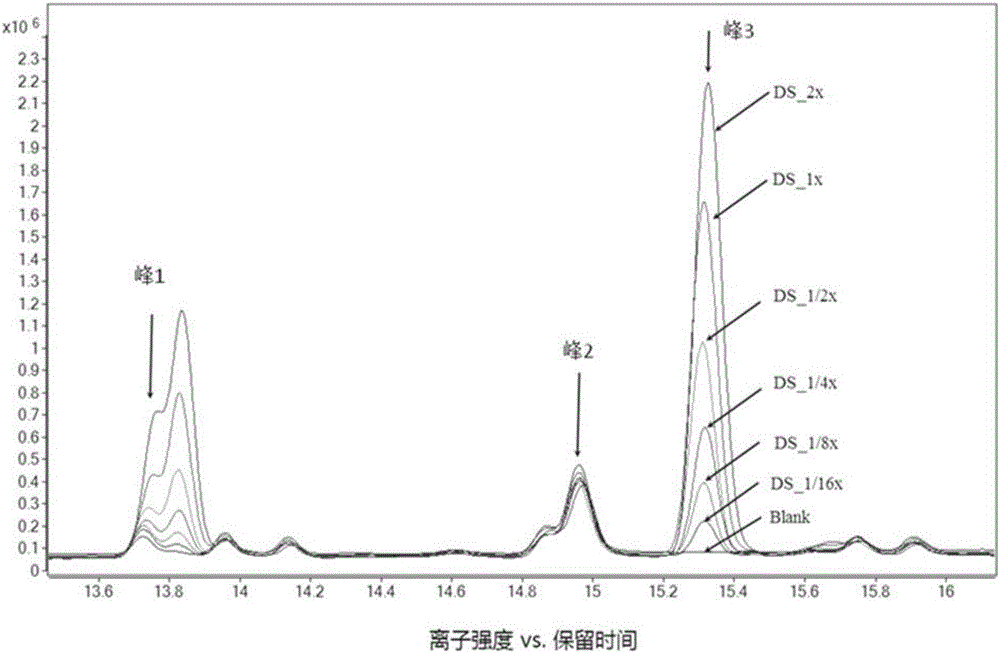

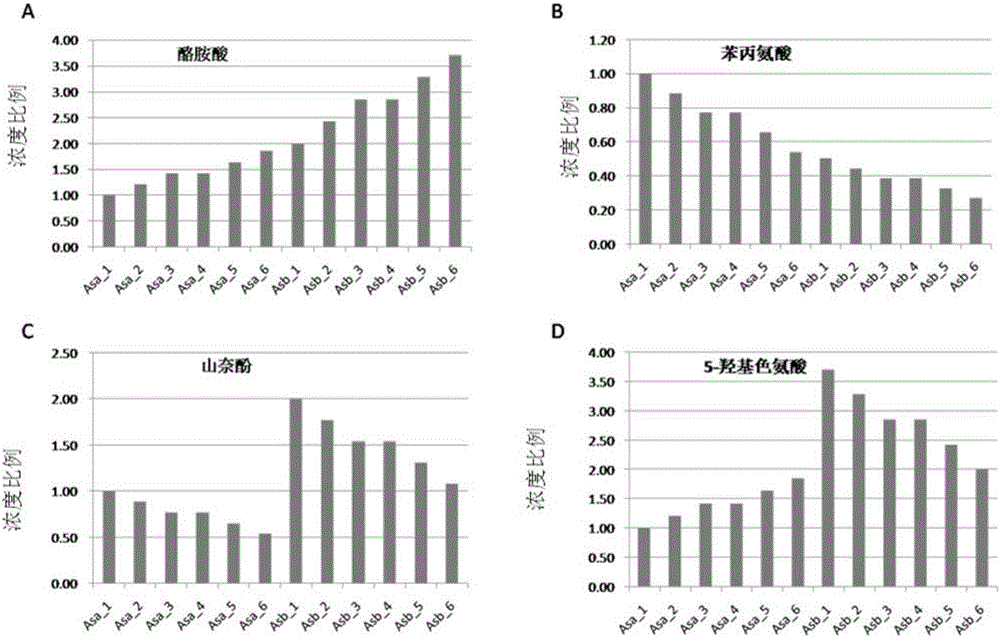

Metabolism group method for distinguishing false positive mass spectra peak signals and quantificationally correcting mass spectra peak area

ActiveCN106018600AEasy to filterSimple Metabolomics StudyComponent separationGroup studySample dilution

The invention discloses a metabolism group method for distinguishing false positive mass spectra peak signals and quantificationally correcting mass spectra peak area. The invention provides a metabolism group study method; by the method, the biological source and non-biological source mass spectra peak signals can be effectively distinguished; the mass spectra peak signals are quantificationally evaluated; the mass spectra peaks with poor quantification performance are excluded; through QC sample dilution, a relative content correction model is built; the mass spectra peak area is corrected. The method has the maximum characteristics that the false positive mass spectra signals can be effectively eliminated, so that the metabolism group data becomes reliable; the real biomarkers can be favorably screened. The method can aim at plant, animal and microbe samples; the method can also be suitable for the mass-spectra-platform-based metabolism group analysis of GC-MS, LC-MS and CE-MS.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

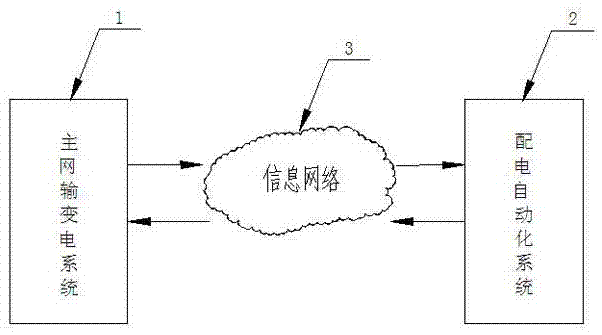

Real time data run-through method for intelligent power grid deployment automatic system

ActiveCN105449855AReduce the burden onPromote construction resultsCircuit arrangementsInformation technology support systemTransformerSmart grid

The invention discloses a real time data run-through method for an intelligent power grid deployment automatic system, comprising steps of main network model synchronization, matching system functions, flexibly configuring a forwarding mode, adopting various forwarding data mechanisms according to the main grid power transmission and transformation system having various functions, adopting an event mechanism to realize the real time data importing of the main grid power transmission and transformation system for the main grid power transmission and transformation system supporting the event service mechanism, and adopting the information mechanism to realize the real-time data importing of the main grid power transmission and transformation for the power grid transmission and transformation system which does not support event service mechanism. The real time data run-through method for the power grid deployment automation system can realize the transformer station data deployment measurement information collection, which not only alleviates the burden of the prepositive servers of the main grid power transmission system and the power distribution automatic system, eliminates the substantial working load of the manual maintenance, and solves the time delay brought by the traditional data forwarding method.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +2

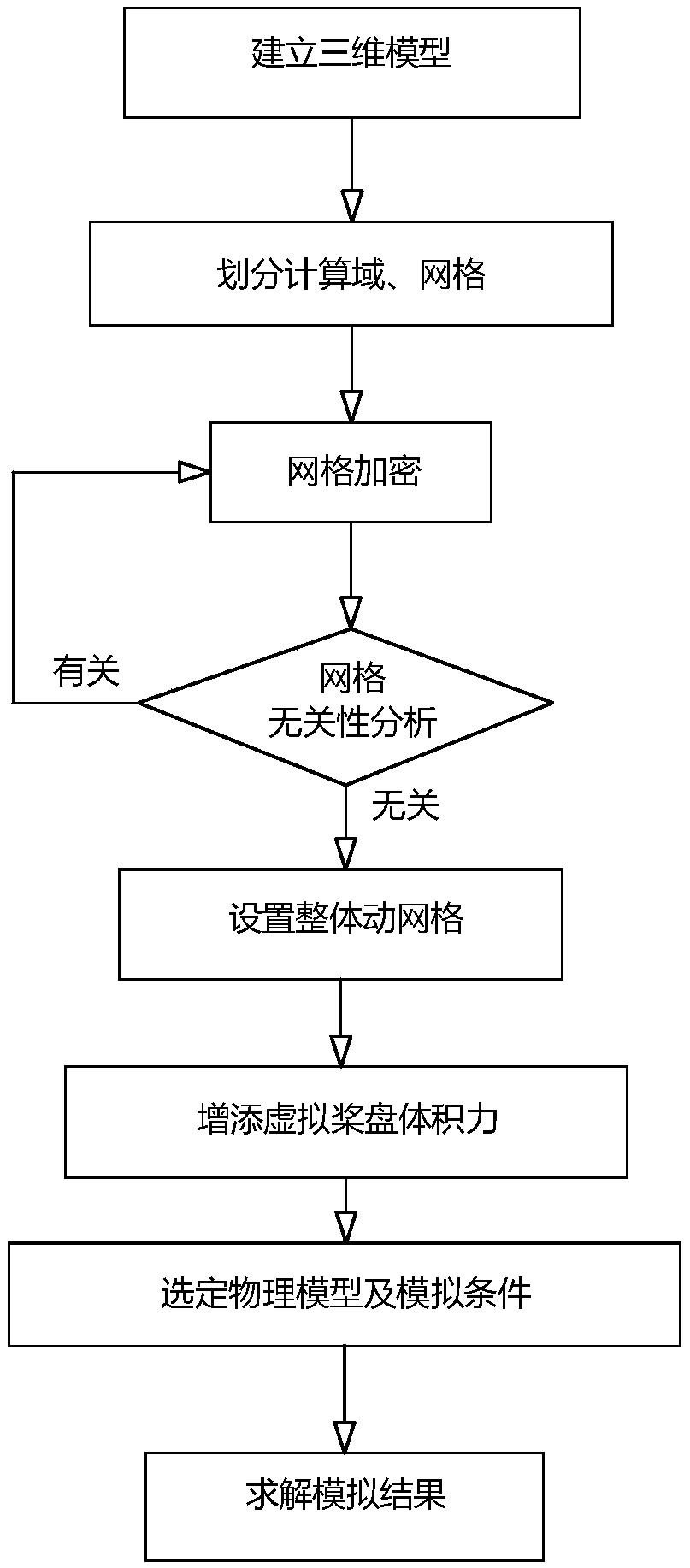

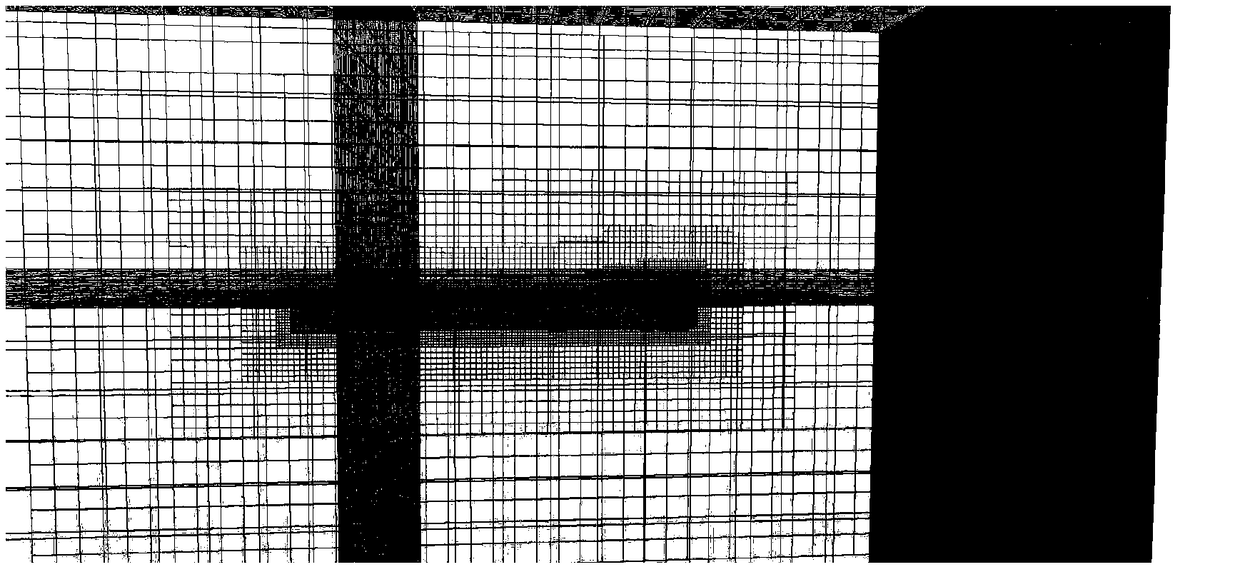

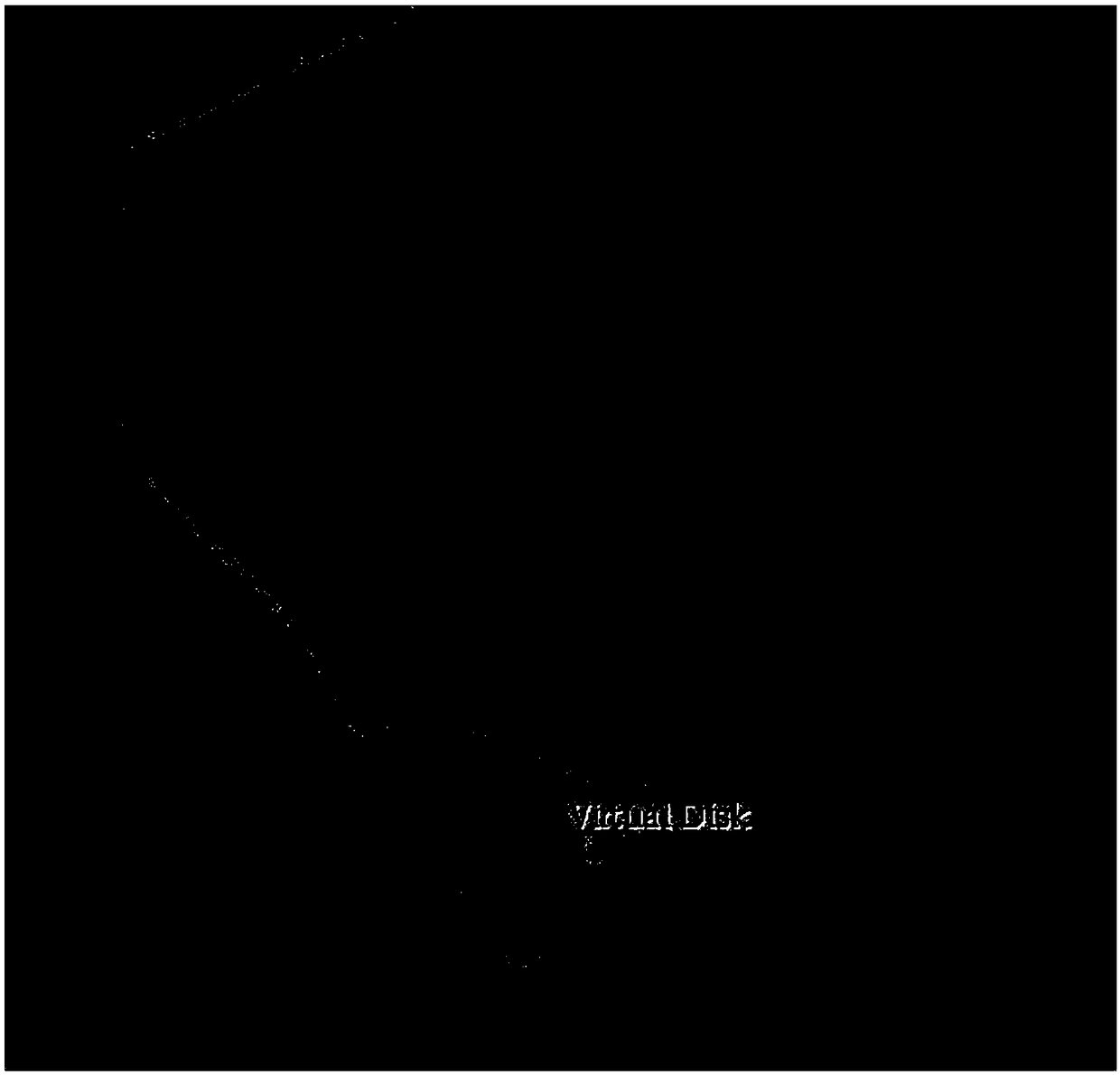

Ship turning motion simulation method

ActiveCN109325303ASave workloadSave the amount of calculationSustainable transportationDesign optimisation/simulationGyrationPropeller

The invention belongs to the technical field of ship motion measurement, in particular to a ship turning motion simulation method. The method does not model a propeller, but simulates propeller thrustwith virtual paddle volume force, and simulates ship or submarine rotating motion in water with integral dynamic mesh, so that the simulation precision is improved and the modeling difficulty is simplified, and accordingly designers and testers can quickly and accurately predict the hydrodynamic performance of the ship 's gyration.

Owner:NAVAL UNIV OF ENG PLA

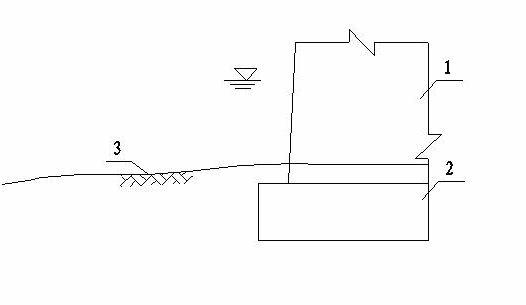

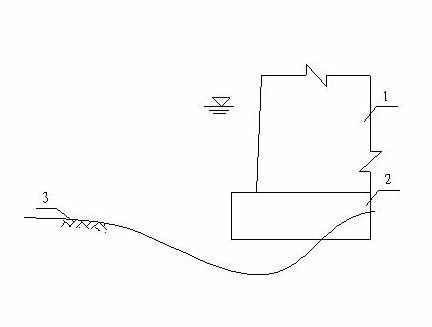

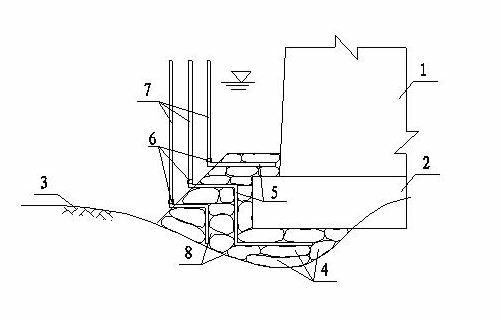

Method for reinforcement and protection of underwater foundation by pressing and pouring grout and matching with bagged dry mix

InactiveCN102134863AAvoid scourExcellent strengthFoundation repairArchitectural engineeringCement grout

The invention relates to a method for reinforcement and protection of an underwater foundation by pressing and pouring grout and matching with bagged dry mix, which comprises the following steps: dry-mixing the mix comprising cement, sand and gravel, bagging according to different weights, stacking the bagged dry mix at the part which is hollow due to flushing and the periphery of the bottom surface of the foundation, simultaneously pre-embedding grout pressing pipes among the well stacked bagged mix, connecting the grout pressing pipes with a grout pouring pipe through two-way joints, performing the operation of pressing and pouring the grout on a working platform on water so as to fill gaps among the bagged dry mix after self-solidification, and finally enabling the bagged mix after the self-solidification and the pressed and poured grout to commonly form integral concrete which is completely jointed with a river bed and the bottom surface of the foundation. The method has the advantages of low cost, good effects and convenience and quickness in construction.

Owner:江西中煤建设集团有限公司

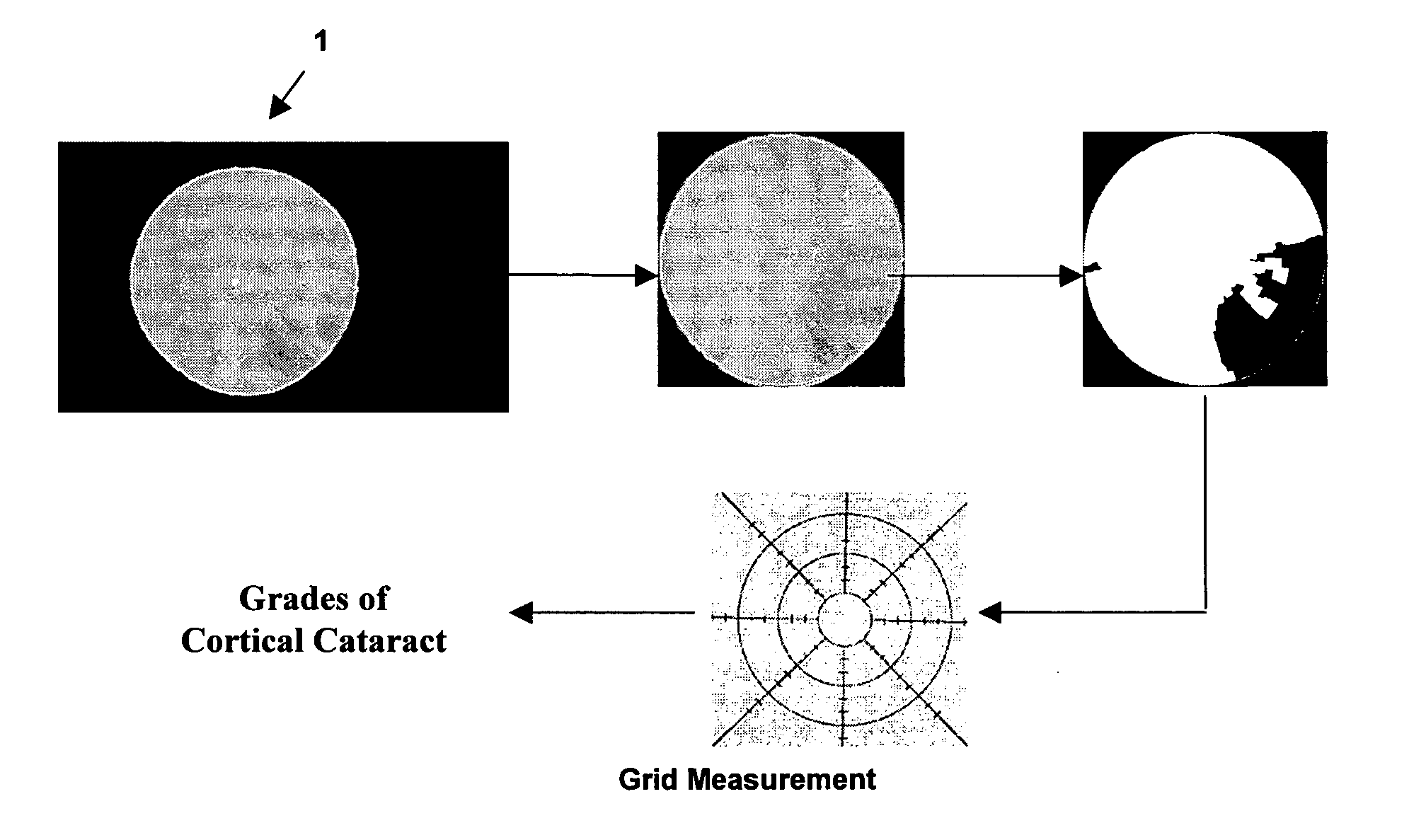

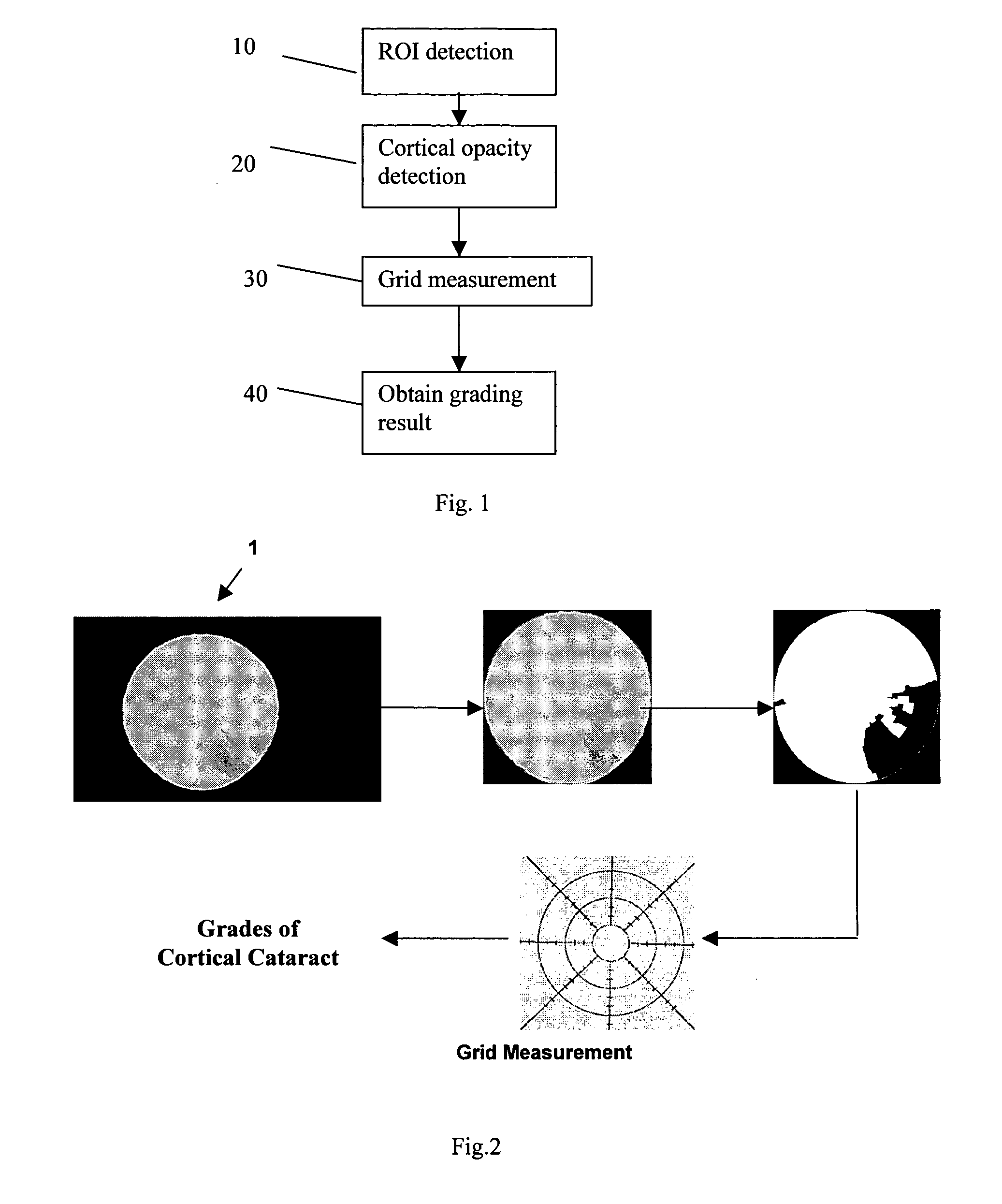

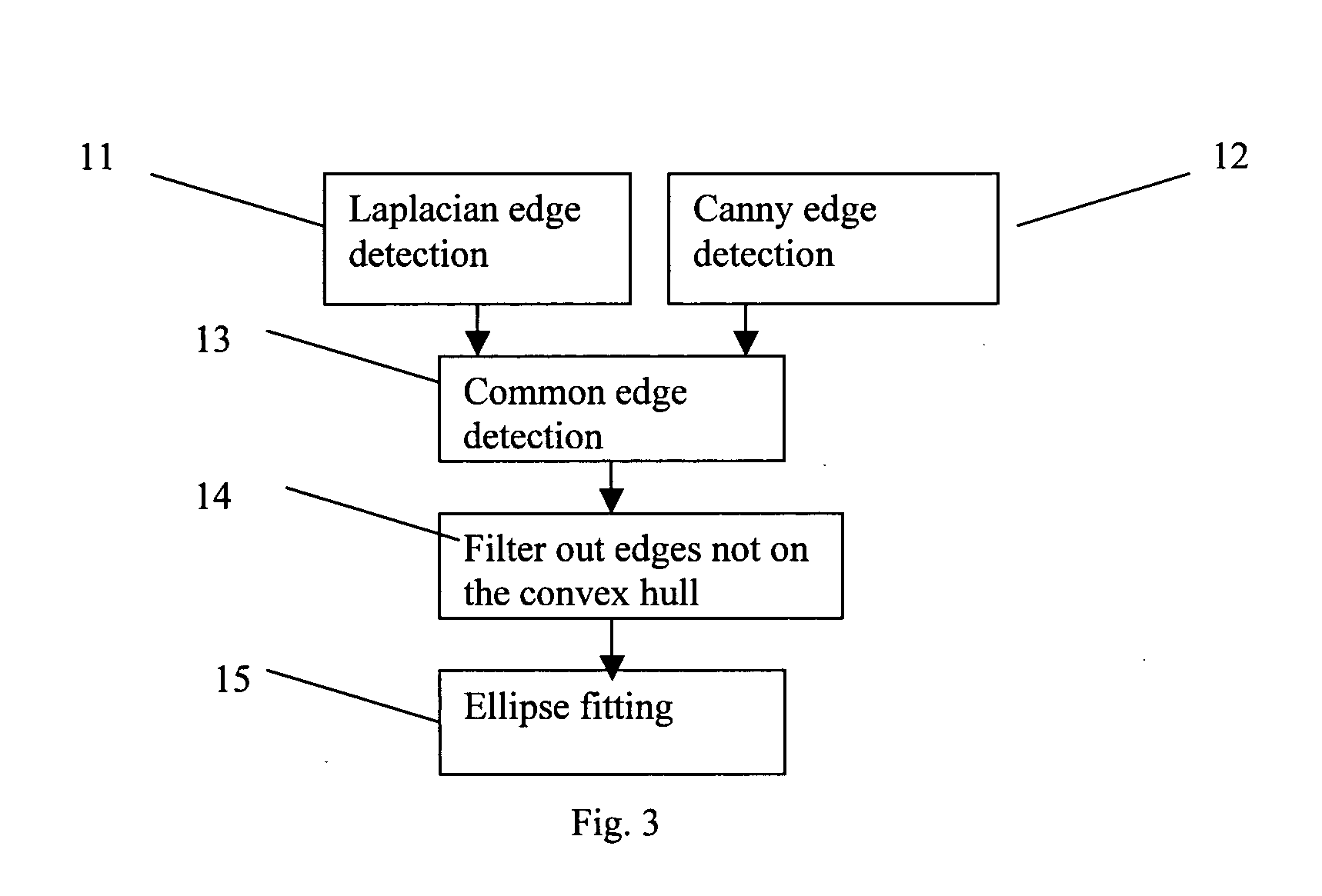

Automatic opacity detection system for cortical cataract diagnosis

InactiveUS20110091084A1Reduce estimated effect of edgeReduce opacityImage enhancementImage analysisCapsular cataractRegion of interest

A method performed by a computer system for detecting opacity in an image of the lens of an eye. The method includes detecting a region of interest in a picture of the lens, and processing the region of interest to produce a modified image using an algorithm which emphasizes opacity associated with a cortical cataract relative to opacity caused by other types of opacity, such as opacity caused by posterior sub-capsular cataracts (PSC). The modified image may be used for grading the level of cortical opacity, by measuring, in the modified image, the proportion of opacity in at least one area of the region of interest.

Owner:AGENCY FOR SCI TECH & RES +2

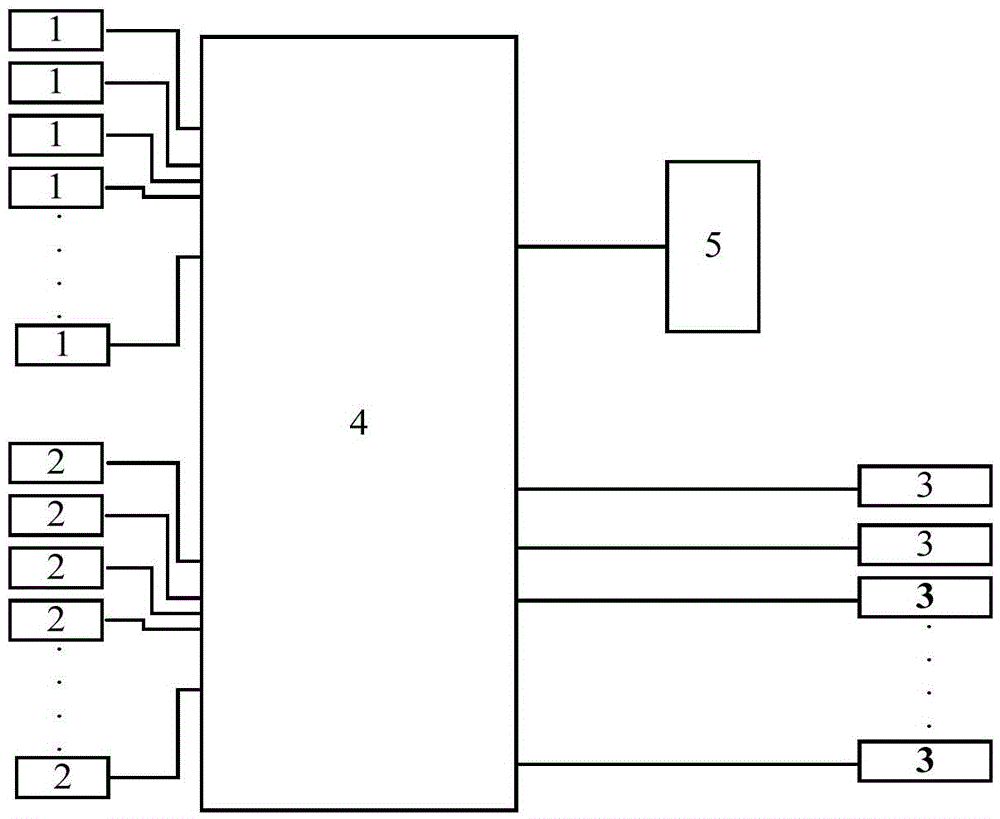

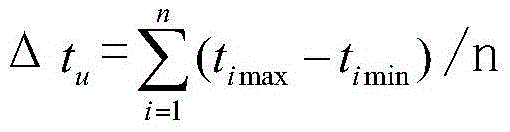

Thermostat field calibration device and method based on cloud server

InactiveCN105675171ARealize automatic calibrationAchieve calibrationThermometer testing/calibrationTransmissionCalibration resultComputer terminal

The invention relates to a device and method for on-site calibration of a constant temperature box, in particular to a device and method for calibrating multiple constant temperature boxes based on a cloud server. The controller scans the electronic label to read and write the basic information of the incubator and the performance test standard of the incubator; the controller communicates with the incubator through the temperature measurement module; the controller communicates with the remote terminal network cloud server through the wireless module. The controller processes the collected temperature data in real time, obtains the calibration result, and uploads the calibration result to the remote terminal network cloud server for storage through the wireless module, and controls the alarm to alarm according to the calibration result. The invention can automatically calibrate a plurality of constant temperature boxes at the same time, which greatly saves the verification time; and the method of scanning electronic labels reduces the workload and mistakes of the verification personnel.

Owner:CHINA JILIANG UNIV

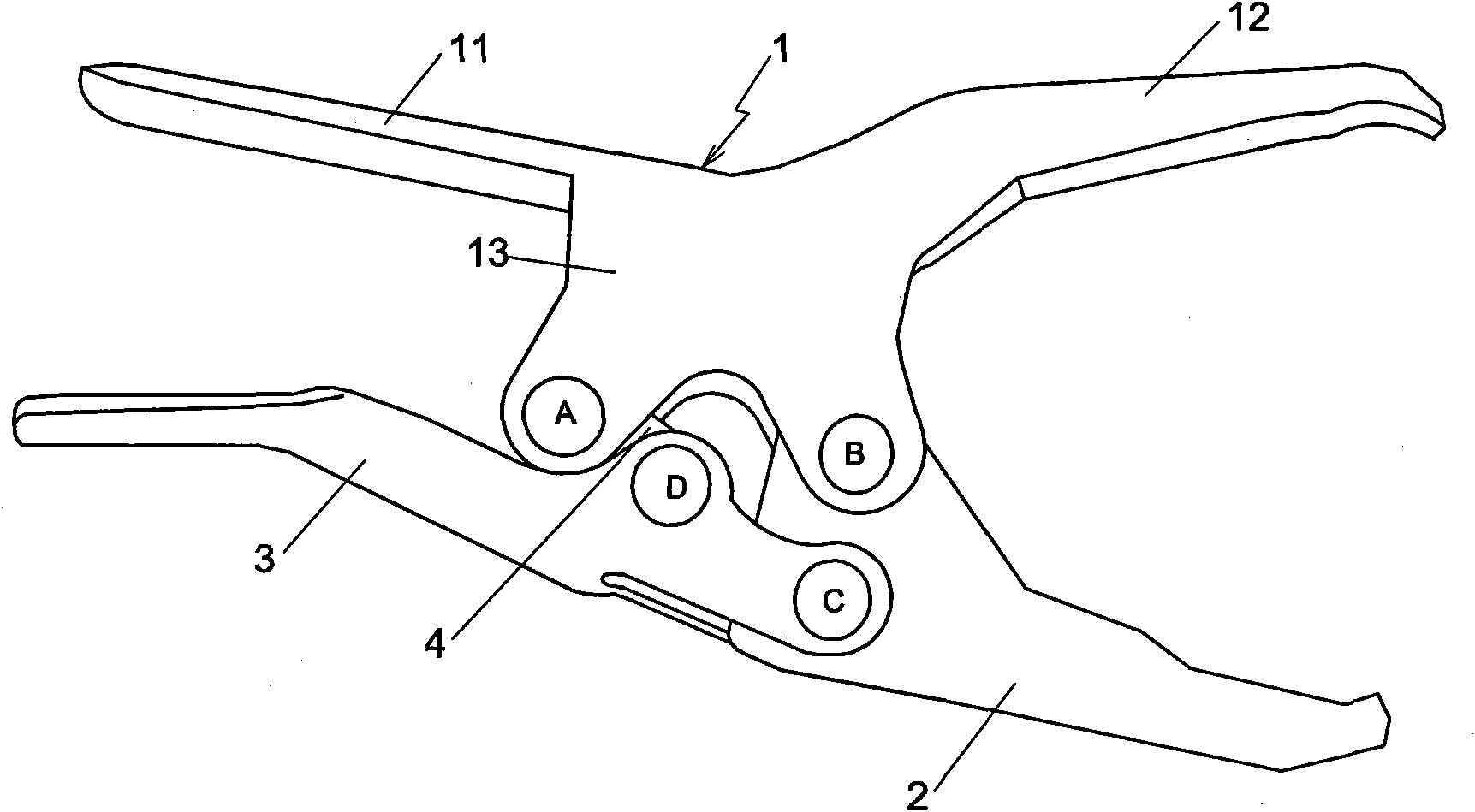

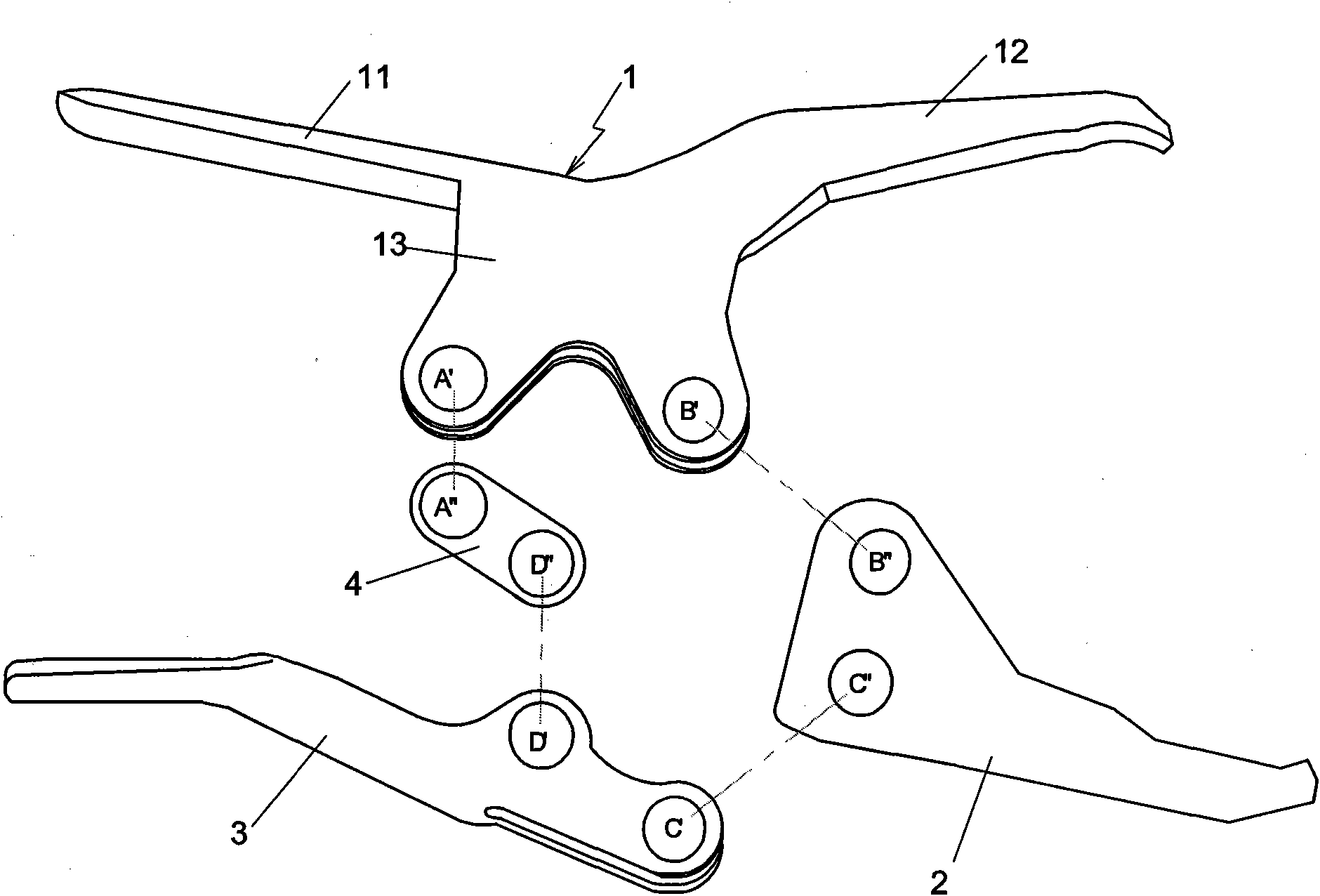

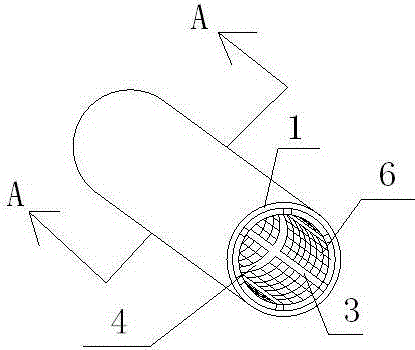

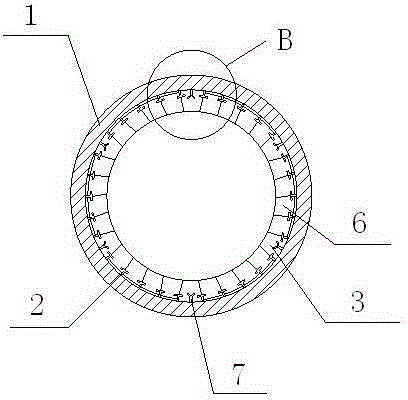

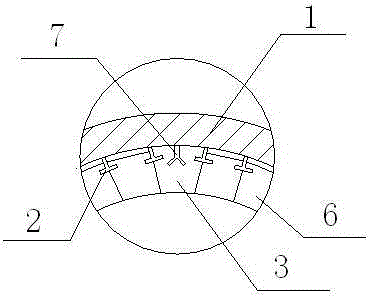

Roller chain tensioning pliers

InactiveCN101920487ASave quantitySave workloadMetal-working hand toolsMetal chainsProduction lineLeft half

The invention relates to roller chain tensioning pliers, which comprise a fixed left half part, a movable right half part and a double-hole connecting block, wherein the left half part comprises a claw at the front end, a handle at the back end and a convex fork-shaped articulated part in the middle; and the movable right half part comprises a reversed L-shaped movable claw at the front end and a movable handle at the back side. The fixed left half part, the movable right half part and the double-hole connecting block form the tensioning pliers with a four-rod principle, can quickly tension a chain, and is suitable for installation and replacement of a heavy long chain and a flow production line with pressed requirement for maintenance time, thereby effectively reducing the maintenance time, improving the equipment operation rate, improving the comprehensive production efficiency, having the advantages of simple structure, reasonable design and good use effect, and being very favorable for popularization and implementation.

Owner:李解放

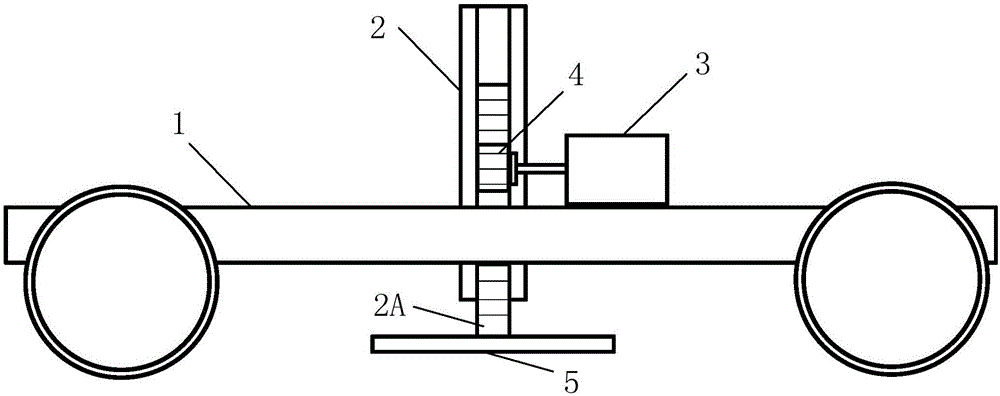

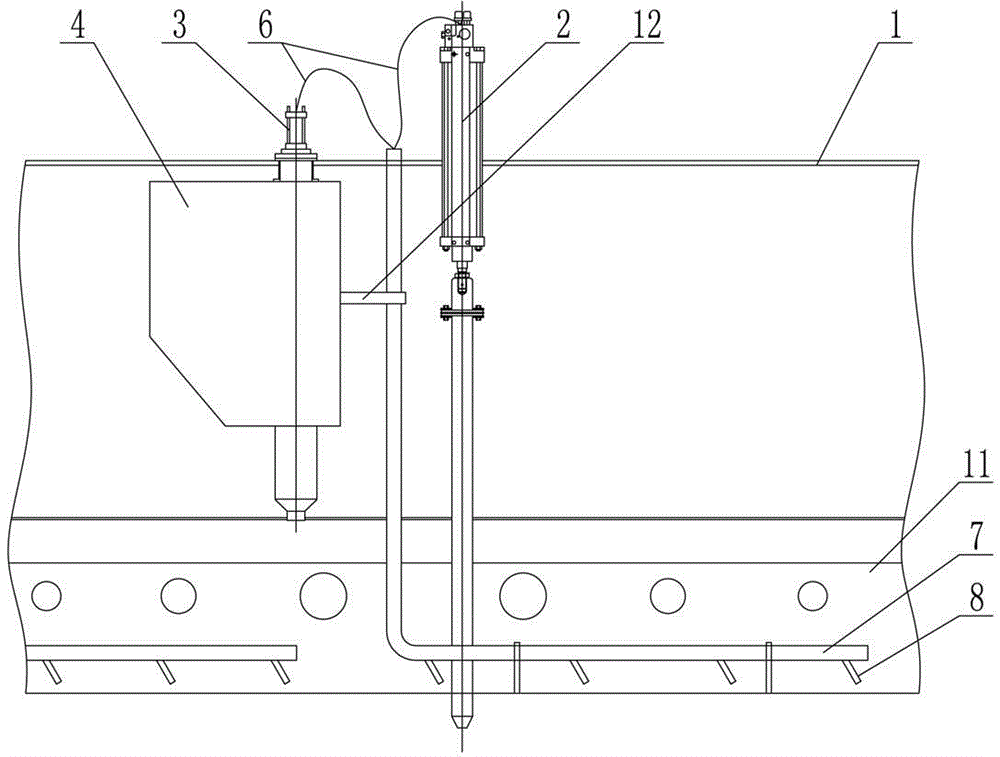

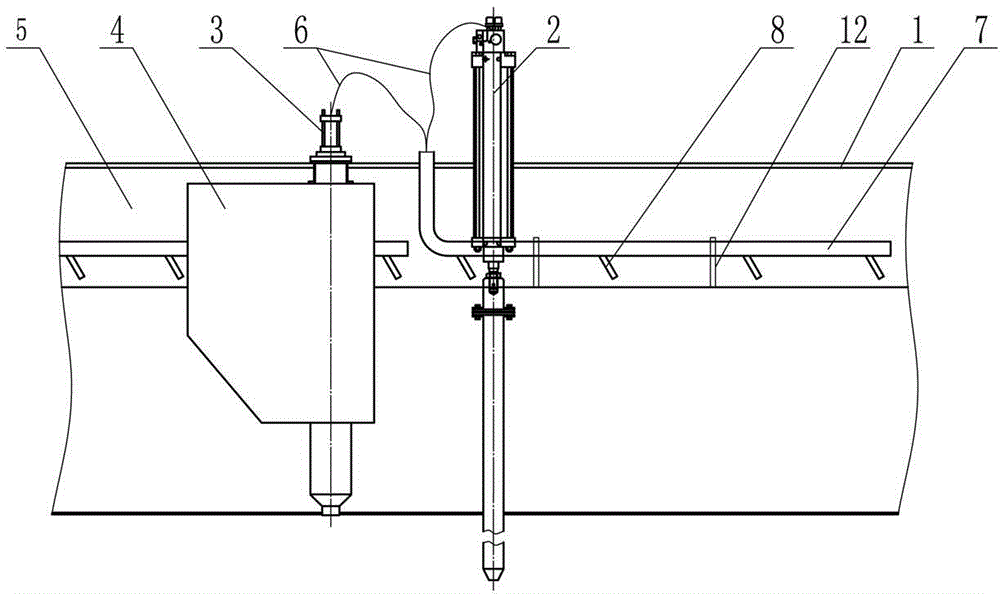

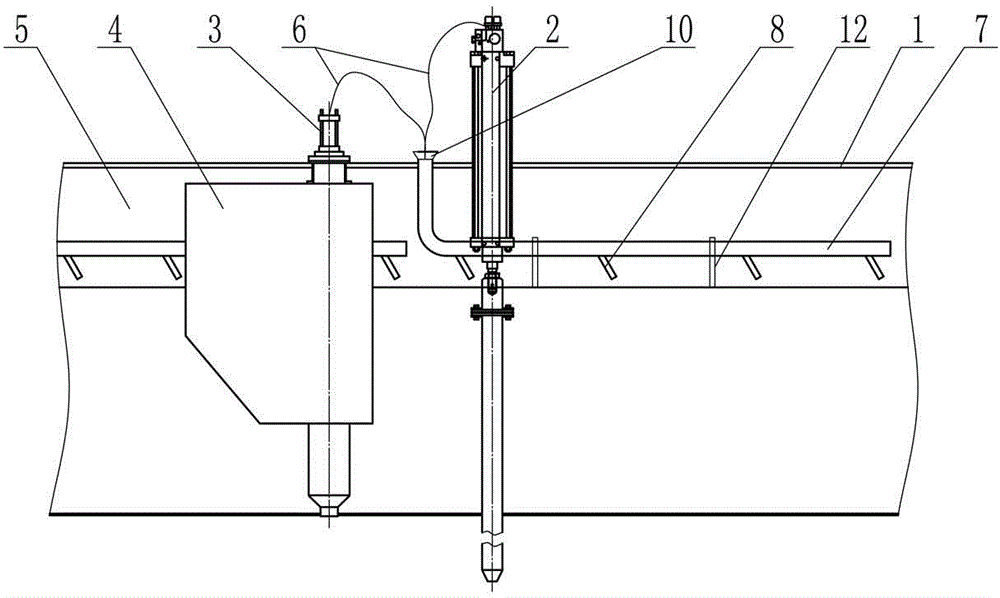

Metal foreign matter removal device of track traffic wireless power supply system

InactiveCN106256962AWorking current can be adjustedAdjustable ground clearanceRailway cleaningForeign matterElectricity

The invention discloses a metal foreign matter removal device of a track traffic wireless power supply system. According to the metal foreign matter removal device, a vertical sliding rail (2) is arranged on a car body (1) of a small rail car, and the lower end of a sliding block (2A) of the sliding rail (2) penetrates through the car body (1) to be connected with an electromagnet (5); a motor (3) is arranged on the car body (1), and a gear (4) on an output shaft of the motor (3) is engaged with a gear groove of the sliding block (2A); the electromagnet (5) and the motor (3) are both electrically connected with a control system of the small rail car. The device is simple in structure and convenient to operate, iron, cobalt, nickel and other magnetic metal foreign matter in a rail or a primary coil area can be effectively removed, and therefore stable, efficient and safe operating of the track traffic wireless power supply system is ensured.

Owner:SOUTHWEST JIAOTONG UNIV

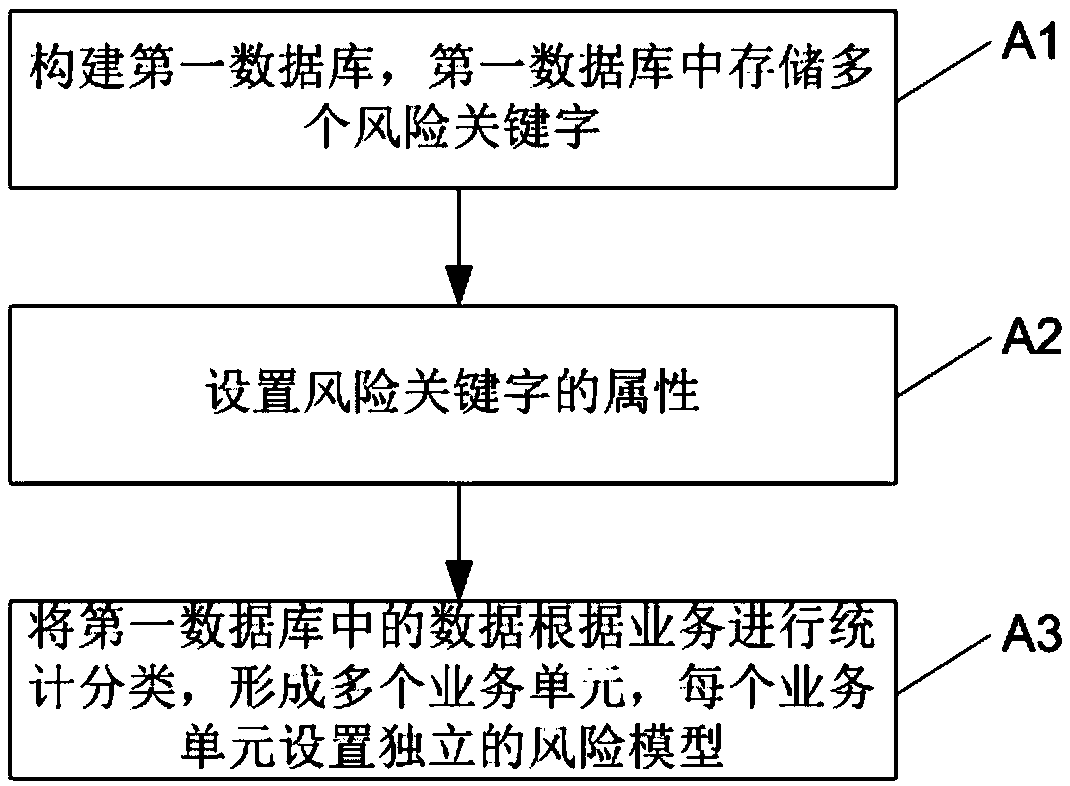

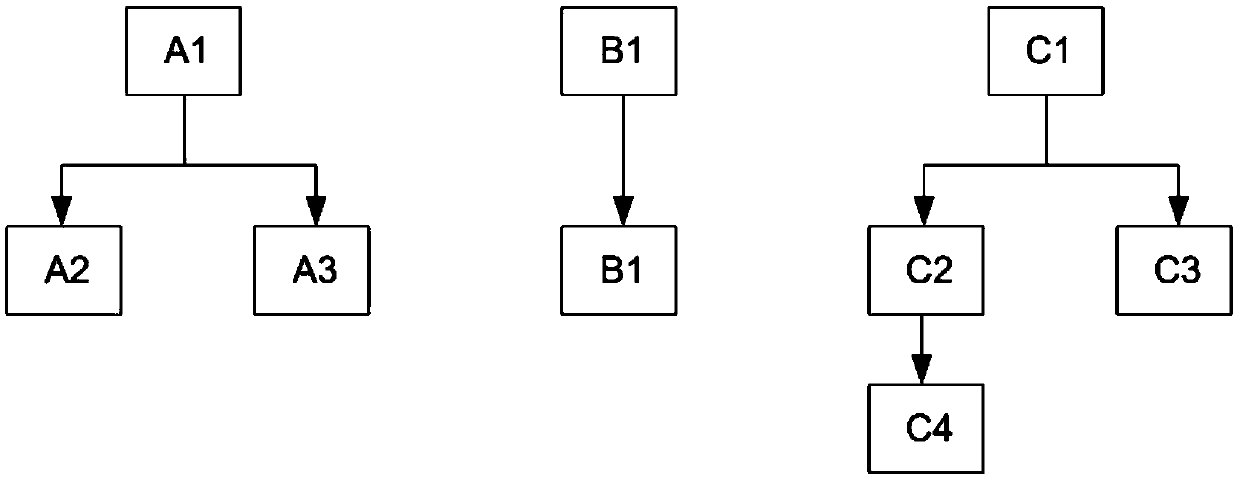

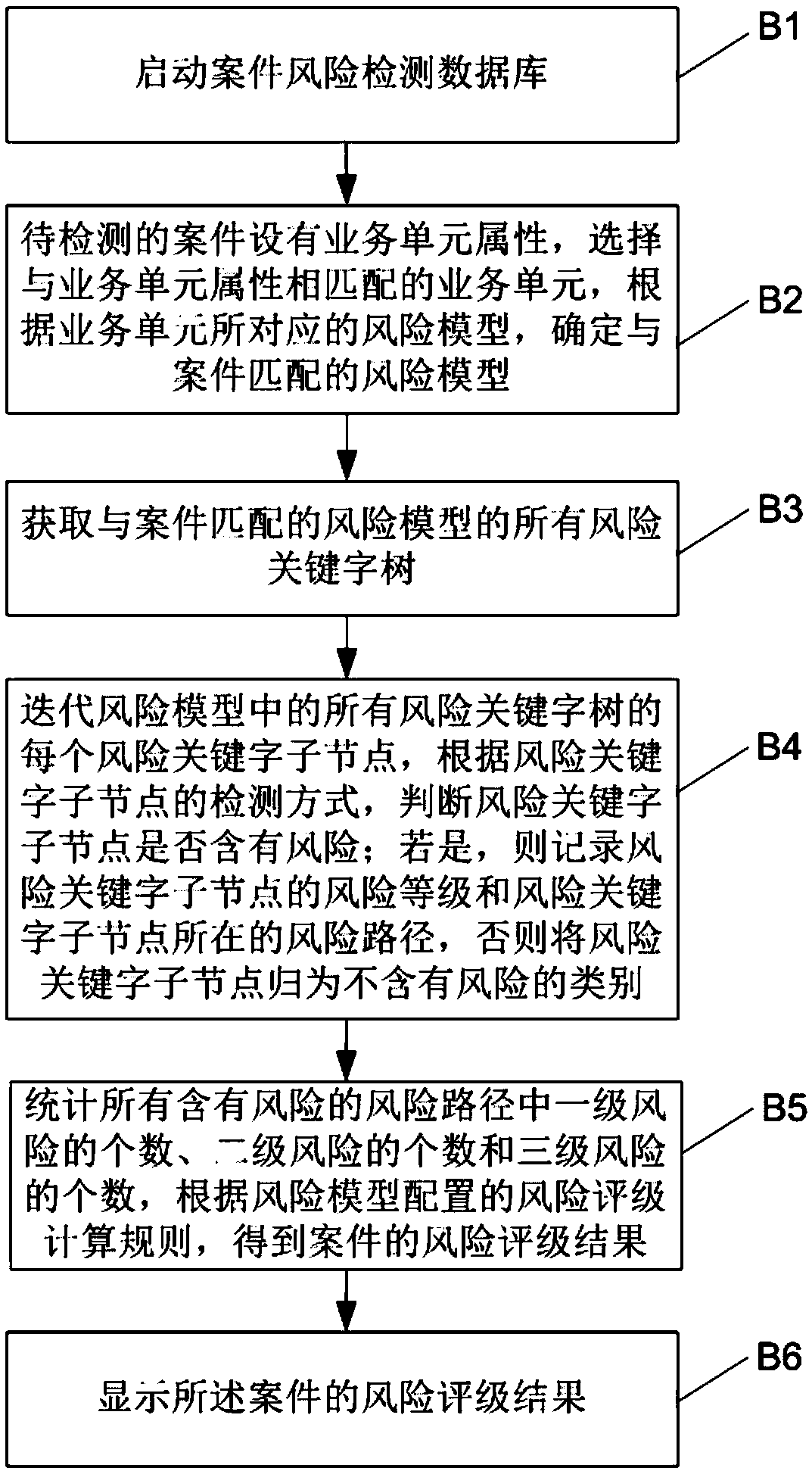

Case risk detection method and system

ActiveCN109656904ARealize accurate calculationAvoid errorsData processing applicationsDatabase design/maintainanceRisk levelRisk rating

The invention discloses a case risk detection method and system. The method comprises the steps of starting a case risk detection database; Selecting a service unit matched with the to-be-detected case, and finding out a risk model matched with the case from the service unit; Obtaining all risk keyword trees of the risk model, iterating each risk keyword sub-node of all risk keyword trees, judgingwhether the risk keyword sub-nodes contain risks or not according to a detection mode of the risk keyword sub-nodes, and outputting a risk path where the risk keyword sub-nodes with the risks are located and the risk level of each risk keyword sub-node; And counting the number of risk levels in all risk paths containing risks, and obtaining a risk rating result of the case according to a risk rating calculation rule configured by the risk model. Accurate calculation of risk detection in legal cases is achieved, large errors caused by subjective judgment of risk values are avoided, and case risk detection efficiency is improved.

Owner:SHANGHAI BESTONE INFORMATION TECH CO LTD

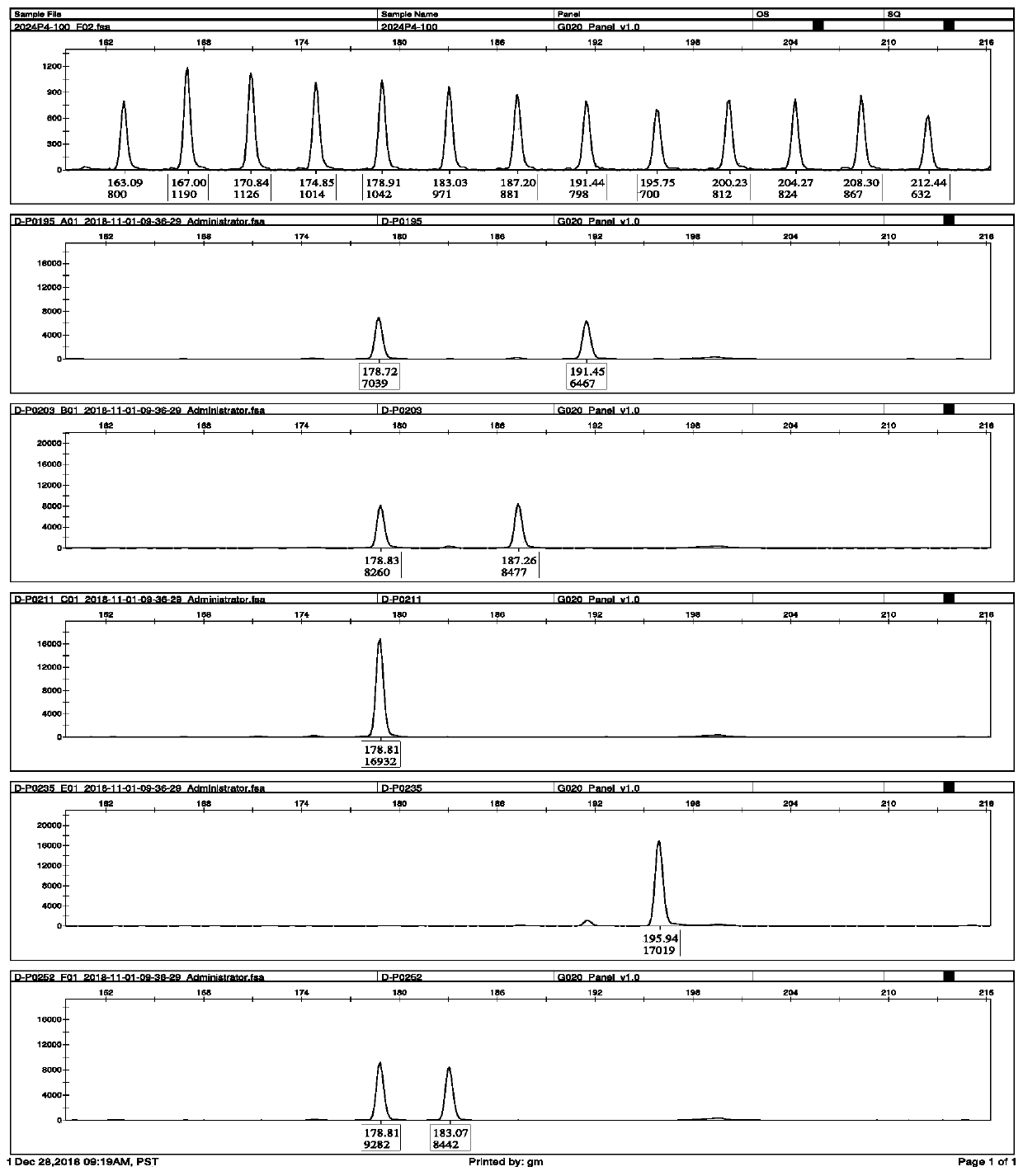

Preparation method of universal short tandem repeat (STR) allele ladder

ActiveCN110229871ASave cycleSave costsMicrobiological testing/measurementAgainst vector-borne diseasesAlleleTandem repeat

The invention provides a preparation method of a universal short tandem repeat (STR) allele ladder. The preparation method comprises the following steps of (1) designing and synthesizing a primer anda plasmid according to an STR locus; (2) using the primer to perform a PCR amplification reaction by using the plasmid as an amplification formwork; and (3) performing purification on PCR amplification products, and performing appropriate dilution so as to obtain the STR allele ladder. According to the preparation method disclosed by the invention, only one plasmid needs to be synthesized, the PCRreaction needs to be performed only once, and after the PCR products are subjected to purification and dilution, the allele ladder of the corresponding STR locus can be obtained, so that the preparation technological process of the allele ladder of the STR locus is greatly simplified, and labor cost,, time cost and economic cost for preparation are saved.

Owner:上海晶准生物医药有限公司

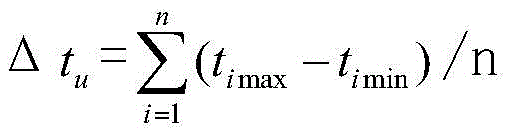

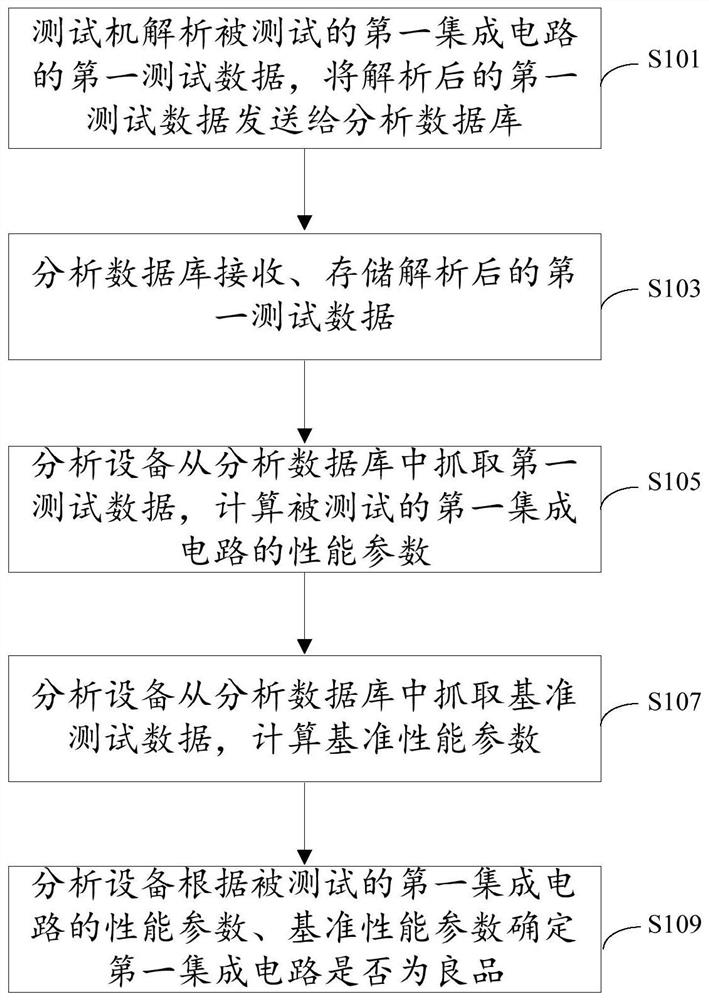

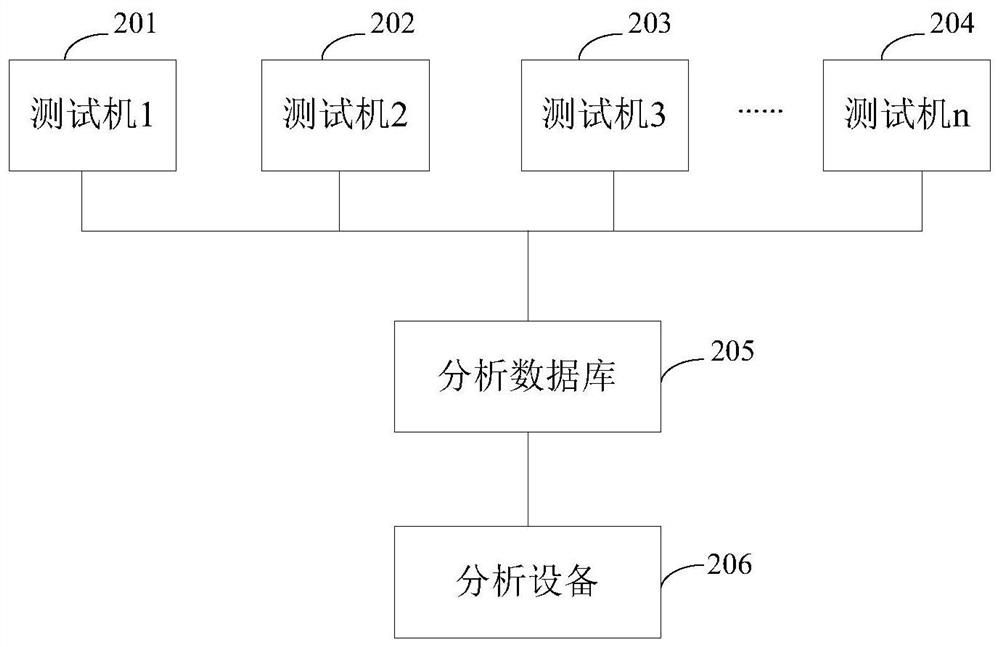

Integrated circuit test data analysis method and system

PendingCN112346920AImprove accuracyImprove efficiencyFaulty hardware testing methodsAnalysis dataData profiling

The invention provides an integrated circuit test data analysis method and system, and the method comprises the steps that a test machine analyzes the first test data of a tested first integrated circuit, and transmits the first test data to an analysis database; an analysis database receives and stores the first test data; an analysis device captures the first test data from the analysis databaseand calculates performance parameters of the first integrated circuit; the analysis device captures benchmark test data from the analysis database and calculates benchmark performance parameters, wherein the benchmark test data is m batches of test data before the first test data, the m batches of test data are adjacent in sequence, one batch of test data in the m batches of test data is adjacentto the first test data, and m is a positive integer; and the analysis device determines whether the first integrated circuit is a good product or not according to the performance parameters of the tested first integrated circuit and the benchmark performance parameters. According to the method, dynamic analysis of key indexes (yield, BIN class and the like) is realized, and the accuracy and efficiency of chip testing are improved.

Owner:ITEST SEMICON TECH JIANGSU CO LTD

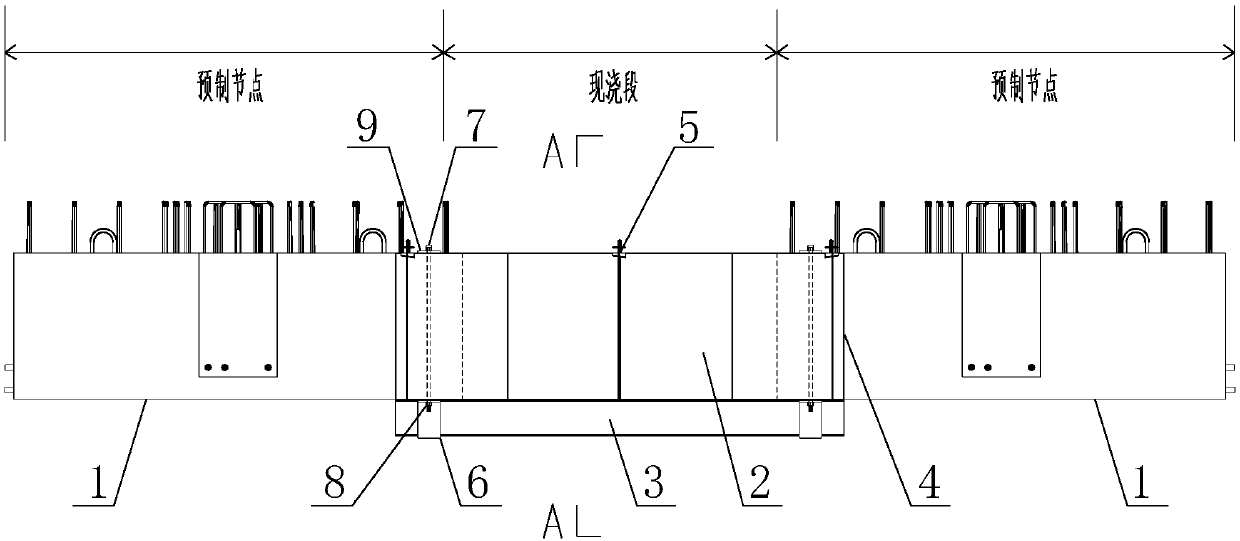

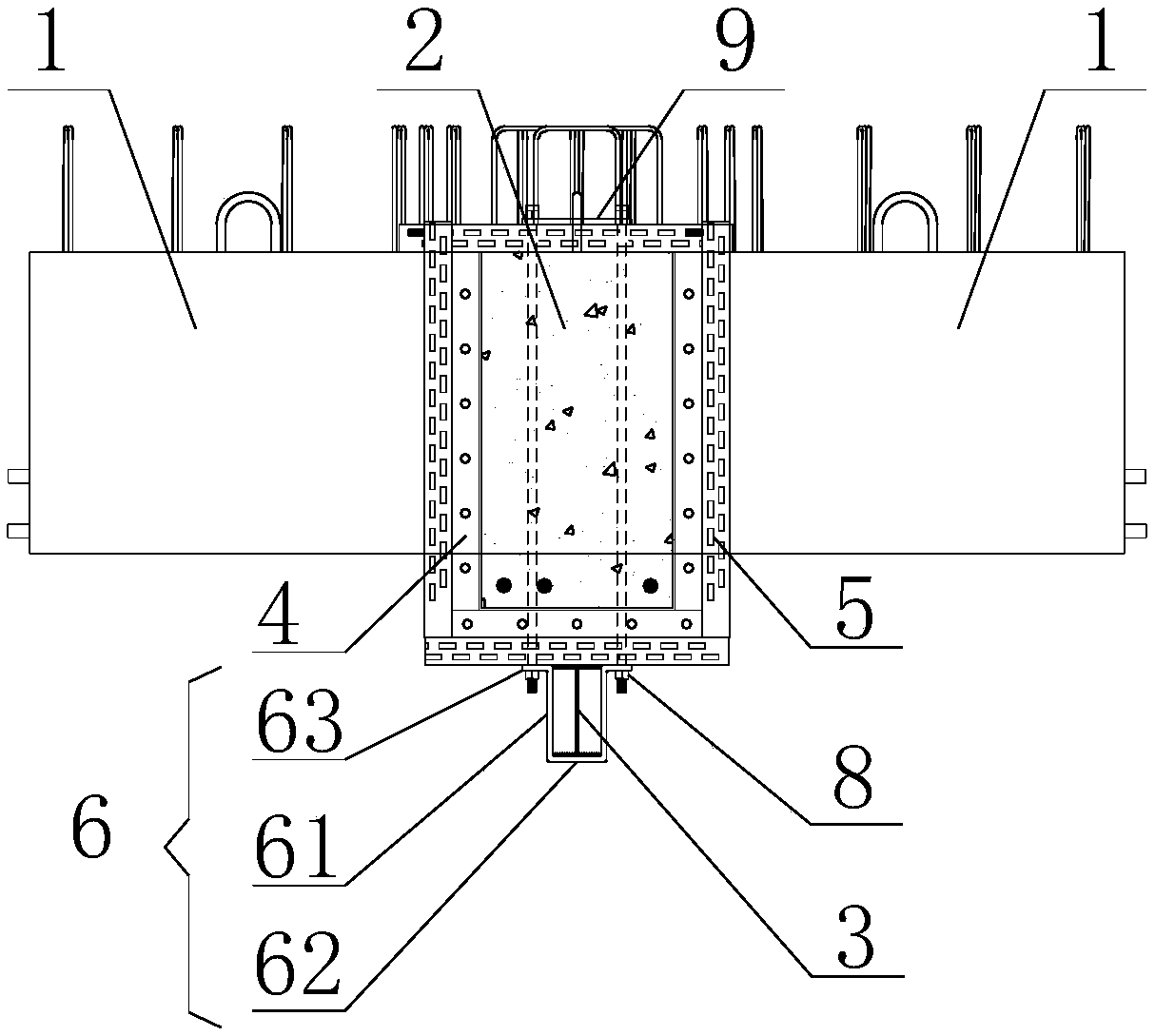

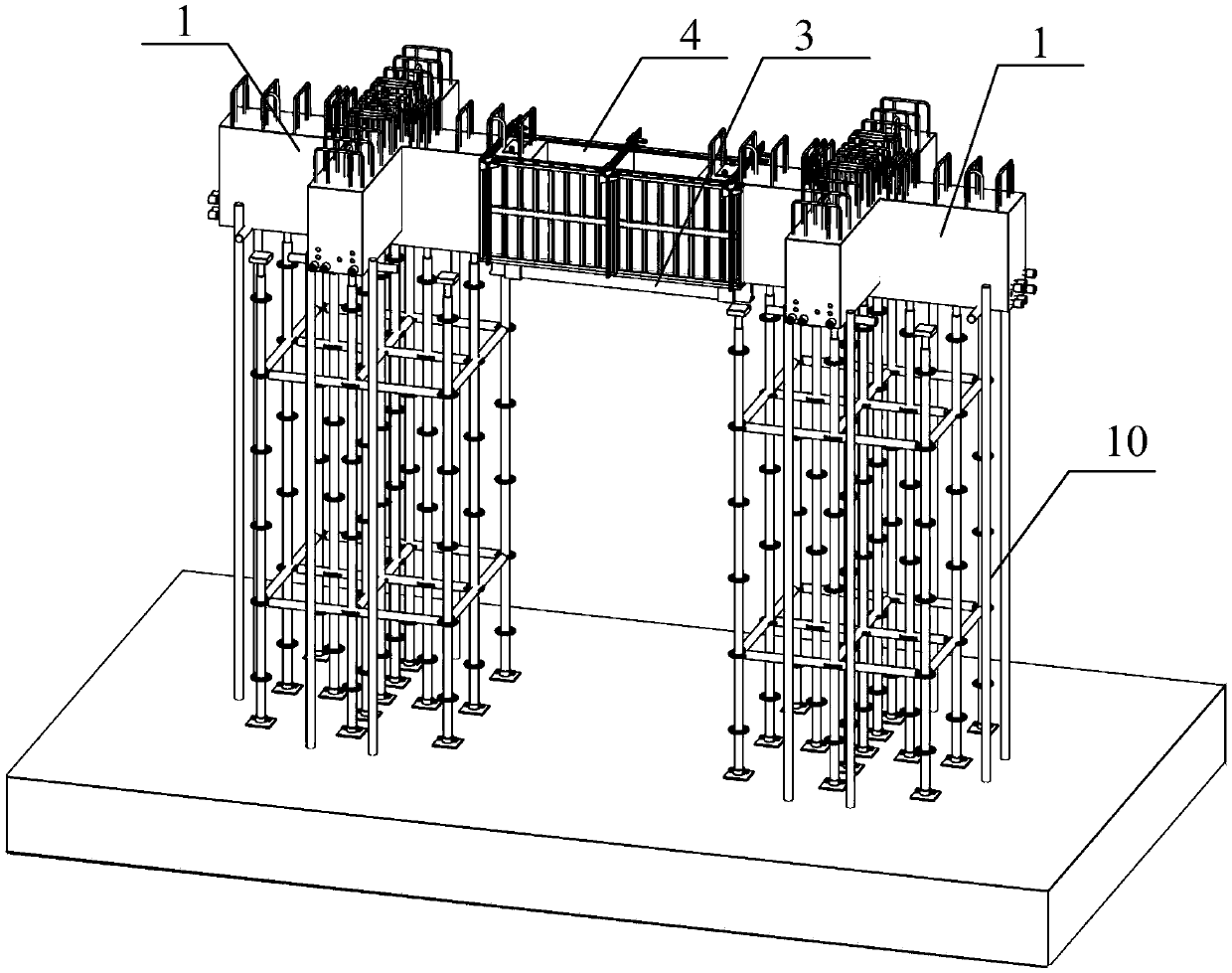

Support-free toolized formwork system applied to fabricated cast-in-place section and use method thereof

ActiveCN109518950AShorten the timeSave workloadForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksConcrete beamsButt joint

The invention discloses a support-free toolized formwork system applied to a fabricated cast-in-place section and a use method thereof and aims to solve the problem that in the prior art, a supportingframed bent needs to be erected under a cast-in-place section and accordingly a construction period is long, manpower and material input is large and the supporting framed bent occupies excessive construction space. By arranging lower hanging mechanisms on two fabrication nodes for butt joint of cast-in-place concrete beam sections to hang two ends of I-steel, the weights of clamps, formworks andthe cast-in-place concrete beam sections are borne by the I-steel and transferred by the I-steel to the two prefabrication nodes through the lower hanging mechanisms at both ends. The support-free toolized formwork system has the advantages of convenient construction and high efficiency and is good in stability and high in bearing capacity, the lower portion of the I-steel is not provided with asupporting framed bent, namely no supporting framed bent is arranged below the cast-in-place concrete beam sections, the construction operation space and the time and work amount of erection and dismantling of the supporting framed bent are effectively saved, the manpower and material input in the existing construction process is greatly decreased, and the environment-friendly construction requirements are met.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Rotary kiln masonry method

ActiveCN103615884BSave workloadIntegrity guaranteedLining supportsLinings repairEngineeringStructural engineering

The invention discloses a masonry method for rotary kilns. The masonry method includes steps of (1), dividing areas; (2), welding anchoring parts; (3), mounting precast bricks; (4), pouring mortar. The masonry method has the advantages that integral precast brick layers are divided into a plurality of areas, when the precast bricks in a certain area fall off, the integrity of the other areas can be guaranteed, accordingly, the cost can be saved, and workload on workers can be reduced; mortar joints are reserved among the various adjacent precast bricks, so that the integrity of the rotary kilns can be corrected, and accidents caused by the fact that only refractory mortar in joints is squeezed when existing precast bricks are heated and expanded, and the existing precast bricks are squeezed by one another, are broken and fall off can be prevented; the precast bricks are fixed to kiln bodies by the aid of the anchoring parts, so that joints among the precast bricks and the inner walls of the kiln bodies can be set and prevent the precast bricks from squeezing the inner walls of the kiln bodies when the precast bricks are radially expanded, and accidents caused by the fact that the inner walls of existing kiln bodies are squeezed by the existing precast bricks and anchoring parts are broken can be prevented.

Owner:CHINA MCC5 GROUP CORP

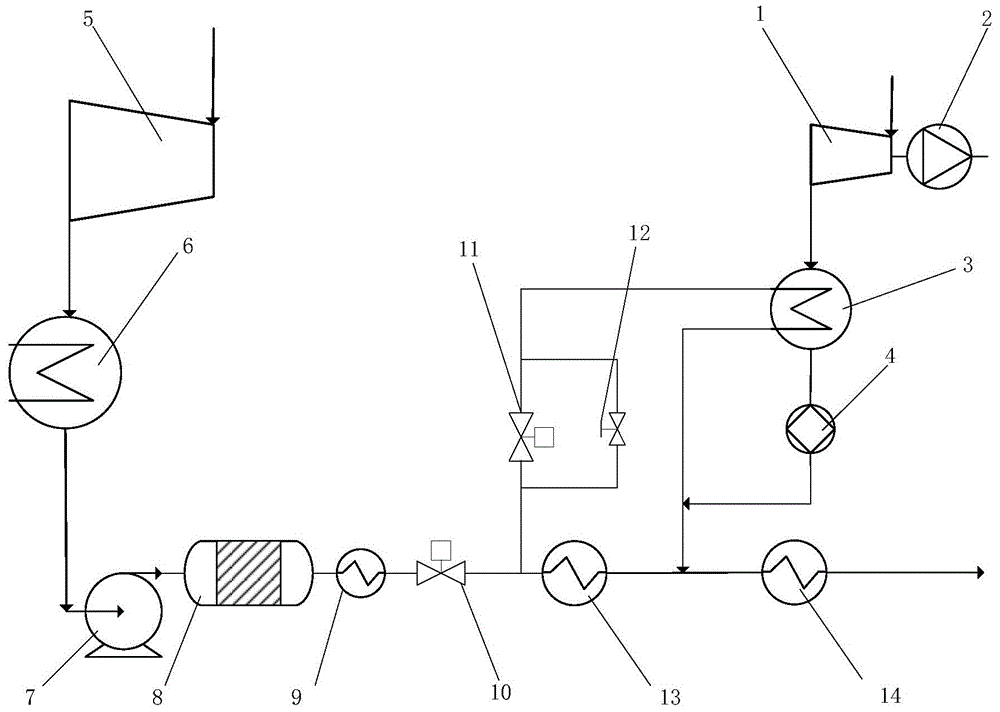

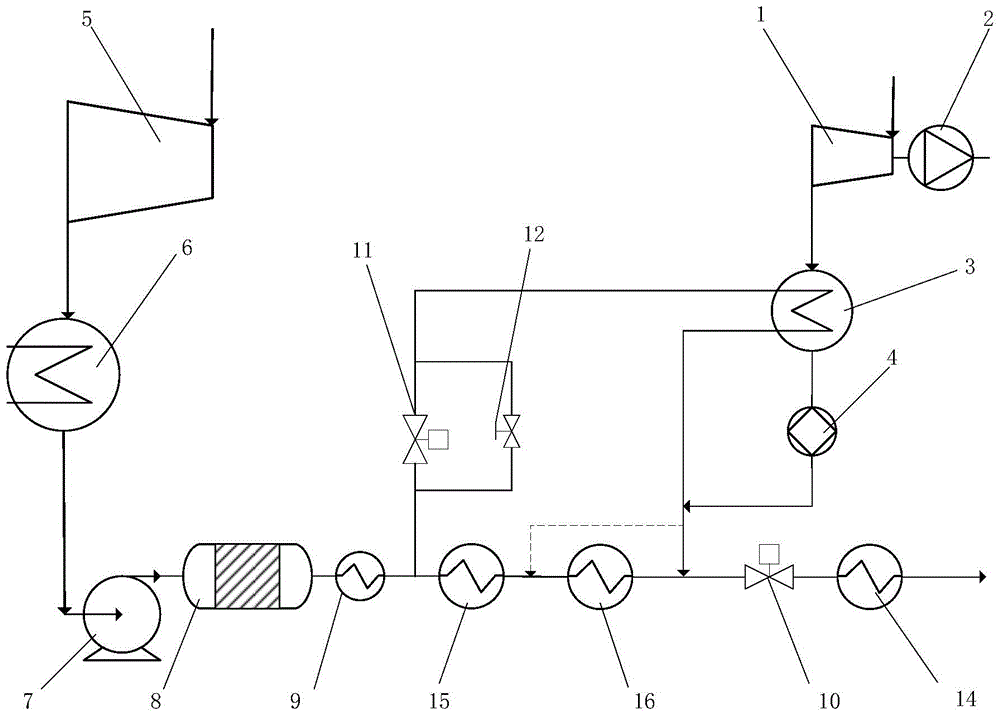

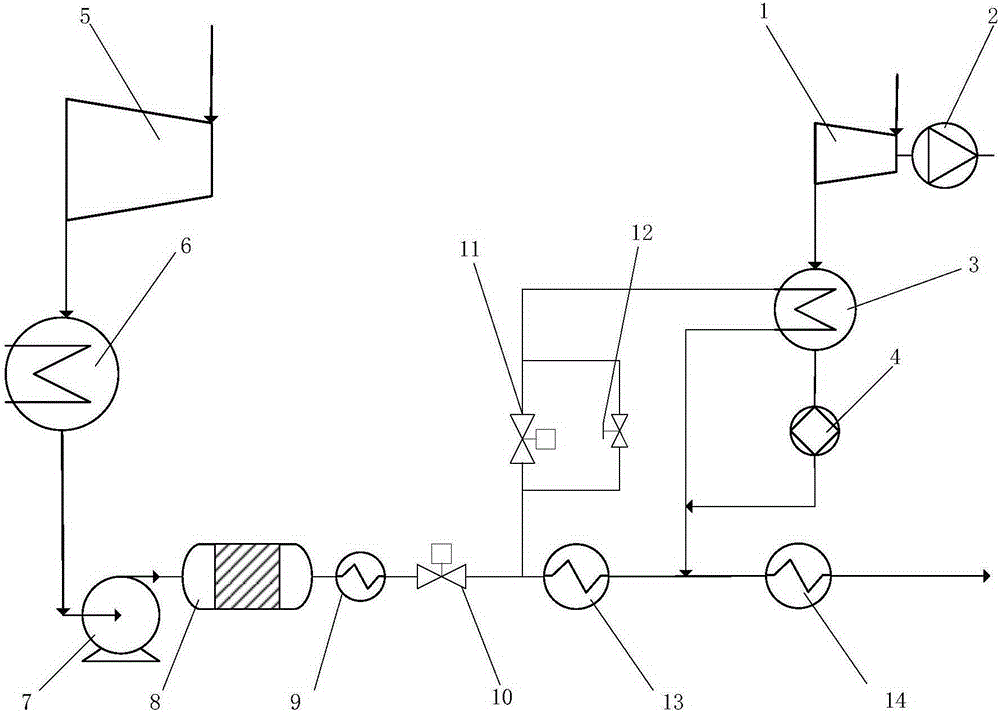

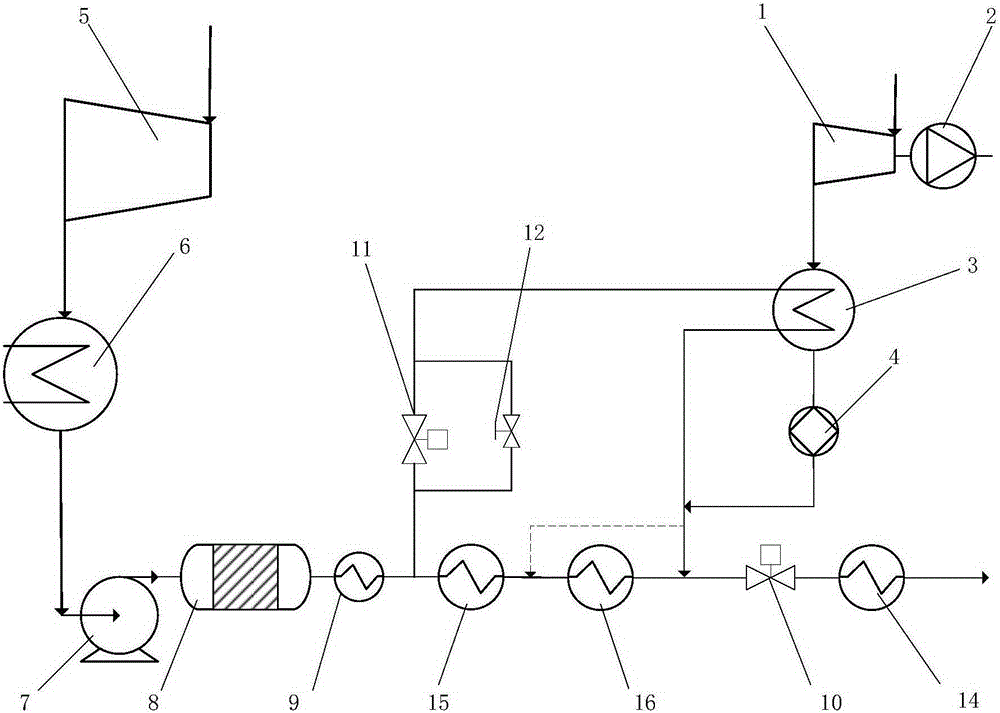

Steam discharge waste heat utilization system of condensing type small turbine for driving induced draft fan

A steam discharge waste heat utilization system of a condensing type small turbine for driving an induced draft fan comprises a main turbine and the condensing small turbine connected with the induced draft fan. The steam outlet of the small turbine is connected with the condenser of the small turbine. The steam outlet of the main turbine is sequentially communicated with a mainframe condenser, a condensing water pump, a condensate polishing device, a shaft-sealing condenser and a low-pressure regenerative system. The outlet of the shaft-sealing condenser and the condensate outlet pipeline of the condenser of the small turbine converge at a condensate return pipeline. The outlet of the condensate return pipeline is connected with the low-pressure regenerative system. The steam discharge and waste heat utilization system has the advantages that mainframe condensate is used as the cooling water source of the condenser of the small turbine, steam discharge waste heat of the small turbine can be fully recycled, total system cold source loss is reduced, and the system is relatively simple, small in operation and maintenance workload, and universal for water cooling units and air cooling units.

Owner:XIAN THERMAL POWER RES INST CO LTD

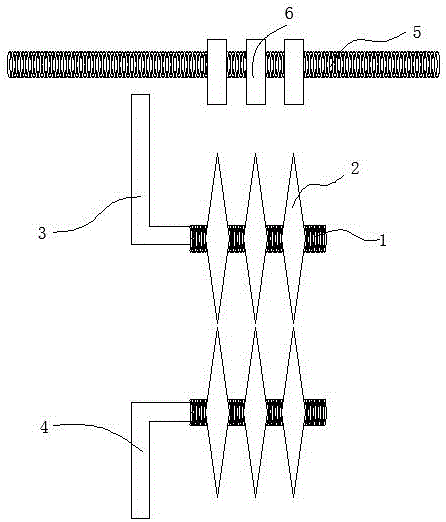

Edge cutting device

InactiveCN105835099ASave workloadSave time at workMetal working apparatusArticle deliveryLaser KnivesMechanical engineering

The invention discloses an edge trimming device, comprising an upper cutting knife set and a lower cutting knife set, both of the upper cutting knife set and the lower cutting knife set include a hollow screw (1), the hollow screw (1) There are at least two cutting knives (2) on the top, and the knives (2) in the upper cutting knife group and the lower cutting knife group correspond one-to-one, and the hollow screw (1) in the upper cutting knife group is set on the upper On the lifting bracket (3), the hollow screw rod (1) in the lower cutting knife group is set on the lower lifting bracket (4); a cross bar (5) is also arranged above the upper cutting knife group, and the cross bar (5) A number of laser tool setting mechanisms (6) are arranged on the top, and the laser tool setting mechanism (6) can move on the cross bar (5), and the laser is arranged on two hollow screw rods (1). In the present invention, since a plurality of cutting knives are provided, both sides of the film can be cut into strips while trimming the film, which greatly saves the workload and working time.

Owner:JIANGYIN LICHNEG MACHINERY CO LTD

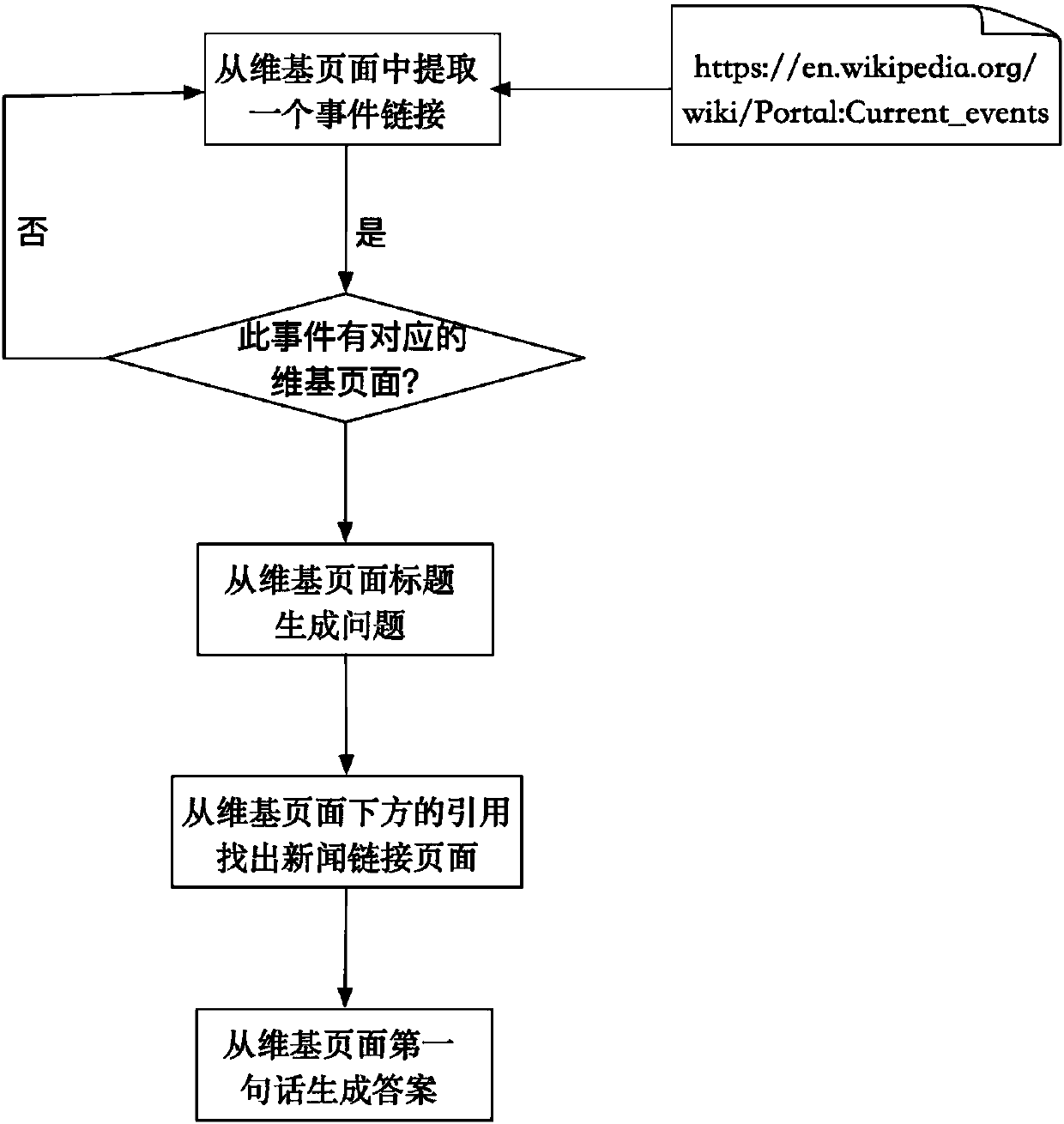

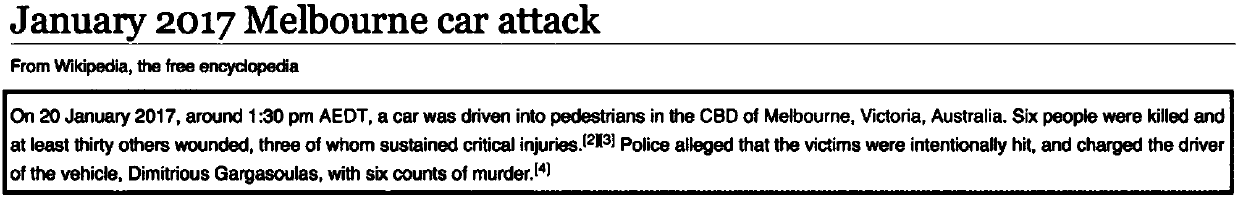

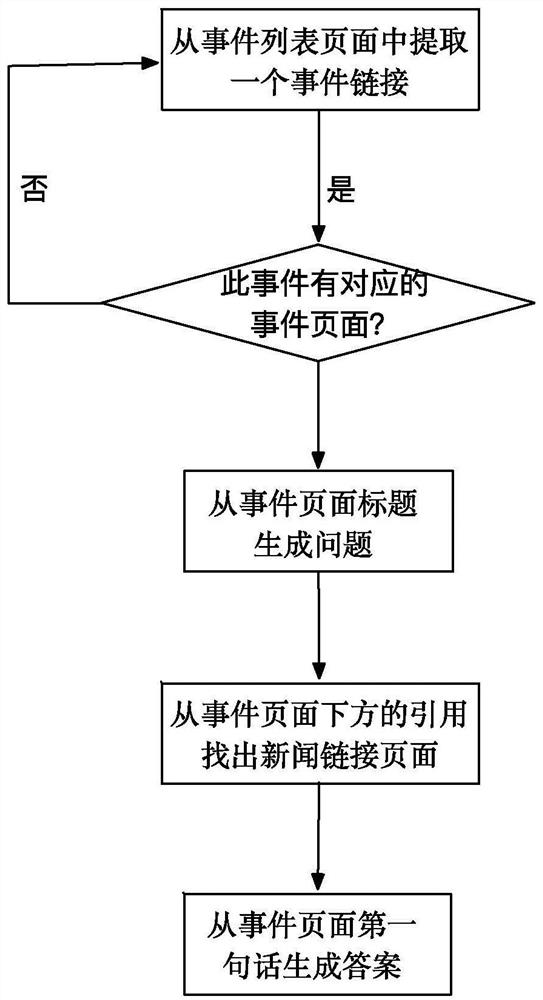

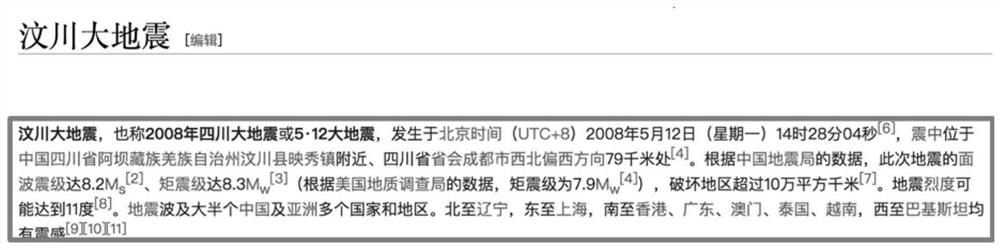

Method for generating news event generation type question and answer data sets

ActiveCN110110050ASave the trouble of manual labelingGuaranteed accuracyDigital data information retrievalSpecial data processing applicationsData setManual annotation

The invention discloses a method for generating news event generation type question and answer data sets. The method is used for constructing event-oriented news scene generation type question and answer data sets and can realize event generation type intelligent automatic question and answer. The method comprises the following steps: extracting to obtain all events with corresponding link pages;splicing the generated problem template and the core information of the generated problem to generate an event problem; extracting news link pages in all reference documents below the event page, andputting news texts in the news link pages in the reference documents as corpora into a corpus set; and taking the first segment of the text part of the event page as a reference answer of the questionof the generated event. The method is automatically generated, manual annotation is not needed, and the accuracy and effectiveness of generated news scene data are high.

Owner:PEKING UNIV

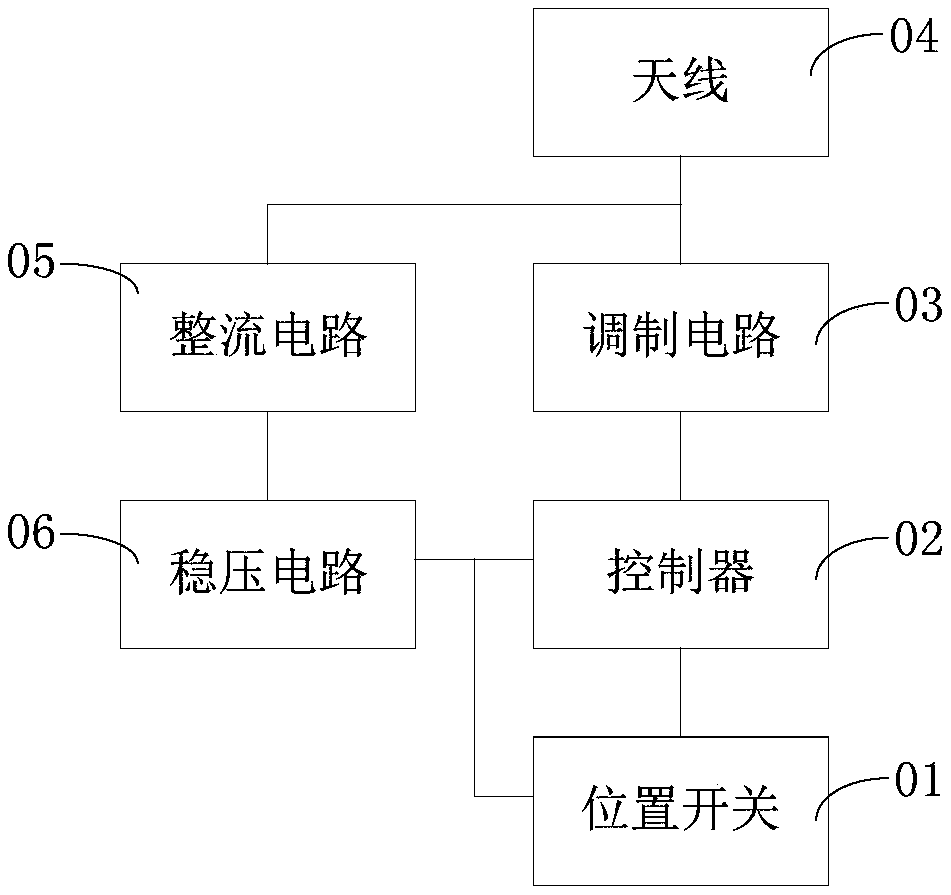

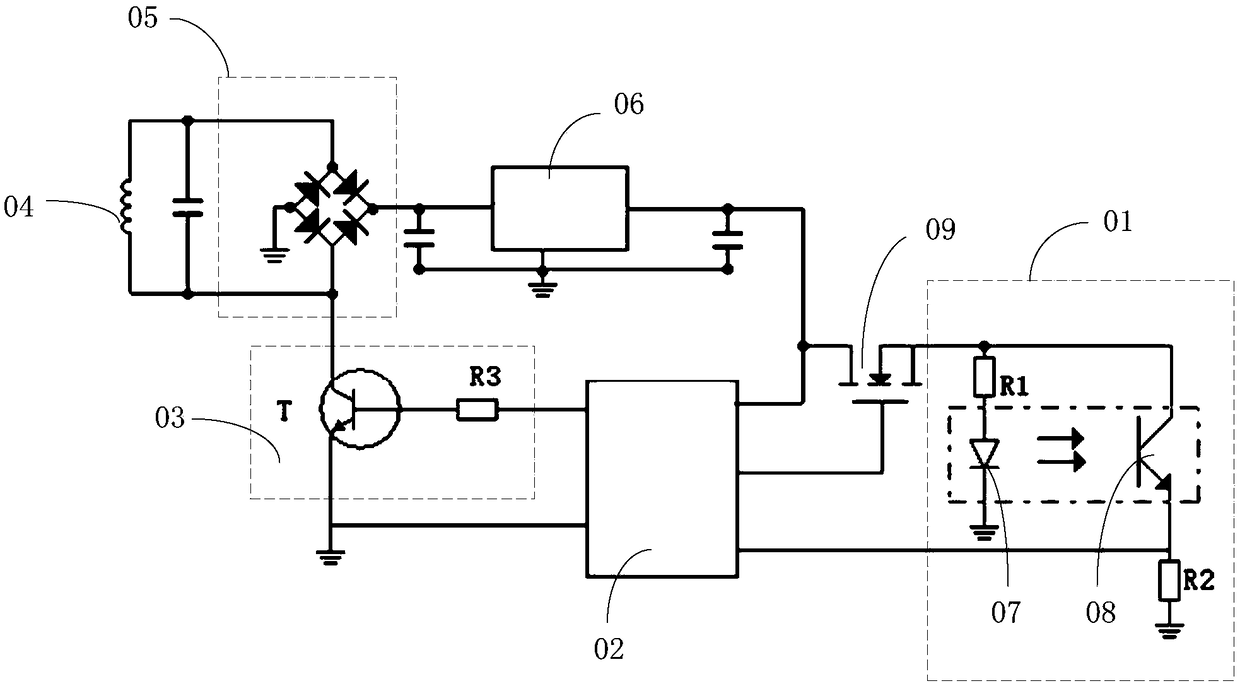

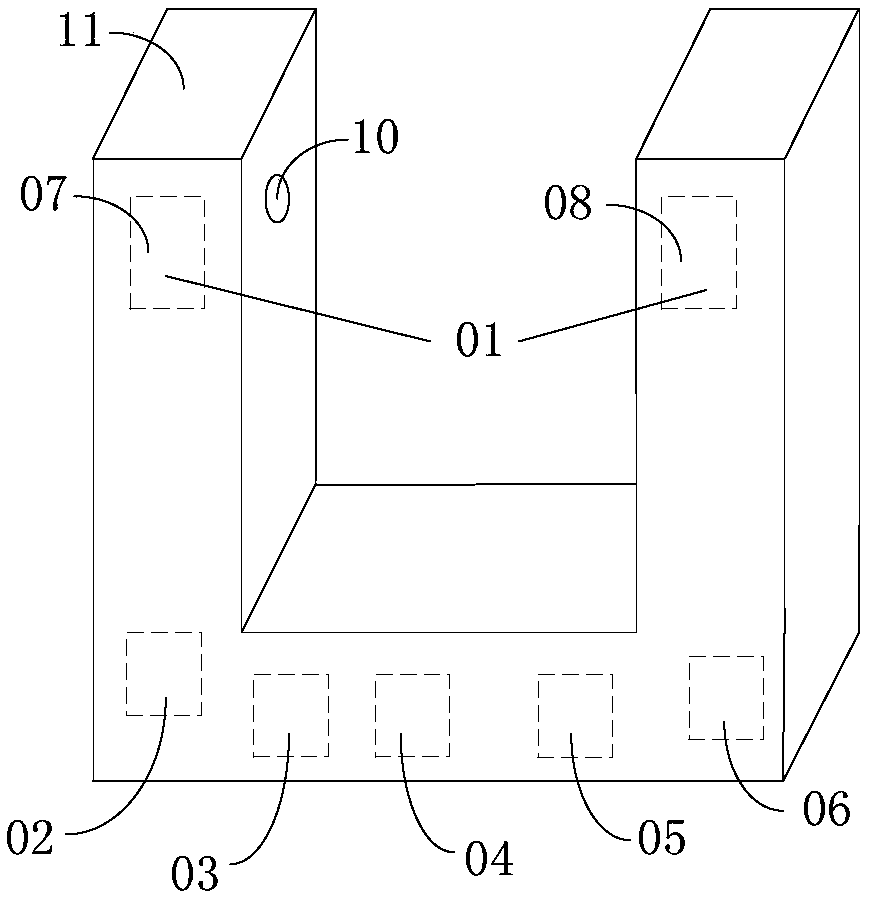

Passive position detecting device

The invention provides a passive position detecting device. The device comprises a position switch, a controller, a modulation circuit, an antenna, a rectifying circuit and a voltage stabilizing circuit. The antenna is connected to the voltage stabilizing circuit through the rectifying circuit. The voltage stabilizing circuit is used to output a direct voltage as the work power supply of the controller and the position switch. The position switch is connected to the controller and is used for detecting whether a detected object is in place and generating position information. The controller isconnected to the antenna through the modulation circuit and is used for acquiring the position information, generating positioning information according to the position information, sending the information to the modulation circuit to carry out modulation, and then sending to a reader through the antenna. By using the passive position detecting device, the power supply can be provided for the position switch through wireless power taking and the wireless transmission of data can be realized so that the workload and the cost of the laying of a power line and a data line are avoided.

Owner:SHIJIAZHUANG TIEDAO UNIV

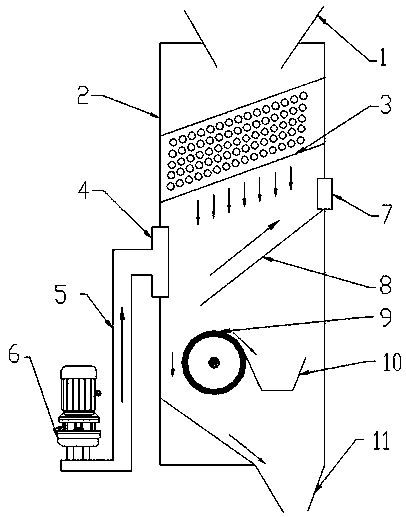

Automatic ash removal device for flue of aluminum electrolysis cell

The invention relates to an automatic ash removal device for a flue, in particular to an automatic ash removal device for a flue of an aluminum electrolysis cell. By the adoption of the ash removal device, ash removal for the gas collection flue can be achieved by means of tail gas of a crust-breaking and feeding system used for the aluminum electrolysis cell. The automatic ash removal device for the flue of the aluminum electrolysis cell comprises a crust-breaking cylinder and a constant-volume feeder. An exhaust vent of the crust-breaking cylinder and an exhaust vent of the constant-volume feeder are connected with an ash removal pipe arranged in the flue through hoses correspondingly. By the adoption of the automatic ash removal device for the flue of the aluminum electrolysis cell, automatic ash removal for the gas collection flue can be achieved by effectively utilizing the tail gas of the crust-breaking and feeding system, the energy utilization rate is increased, the gas collection effect of the flue and the sealing efficiency of the aluminum electrolysis cell are effectively guaranteed, the work of manual removal of accumulated ash in the flue is completely eliminated, and flying loss of aluminum oxide raw materials in the manual ash removal process is avoided.

Owner:沈阳铝镁科技有限公司

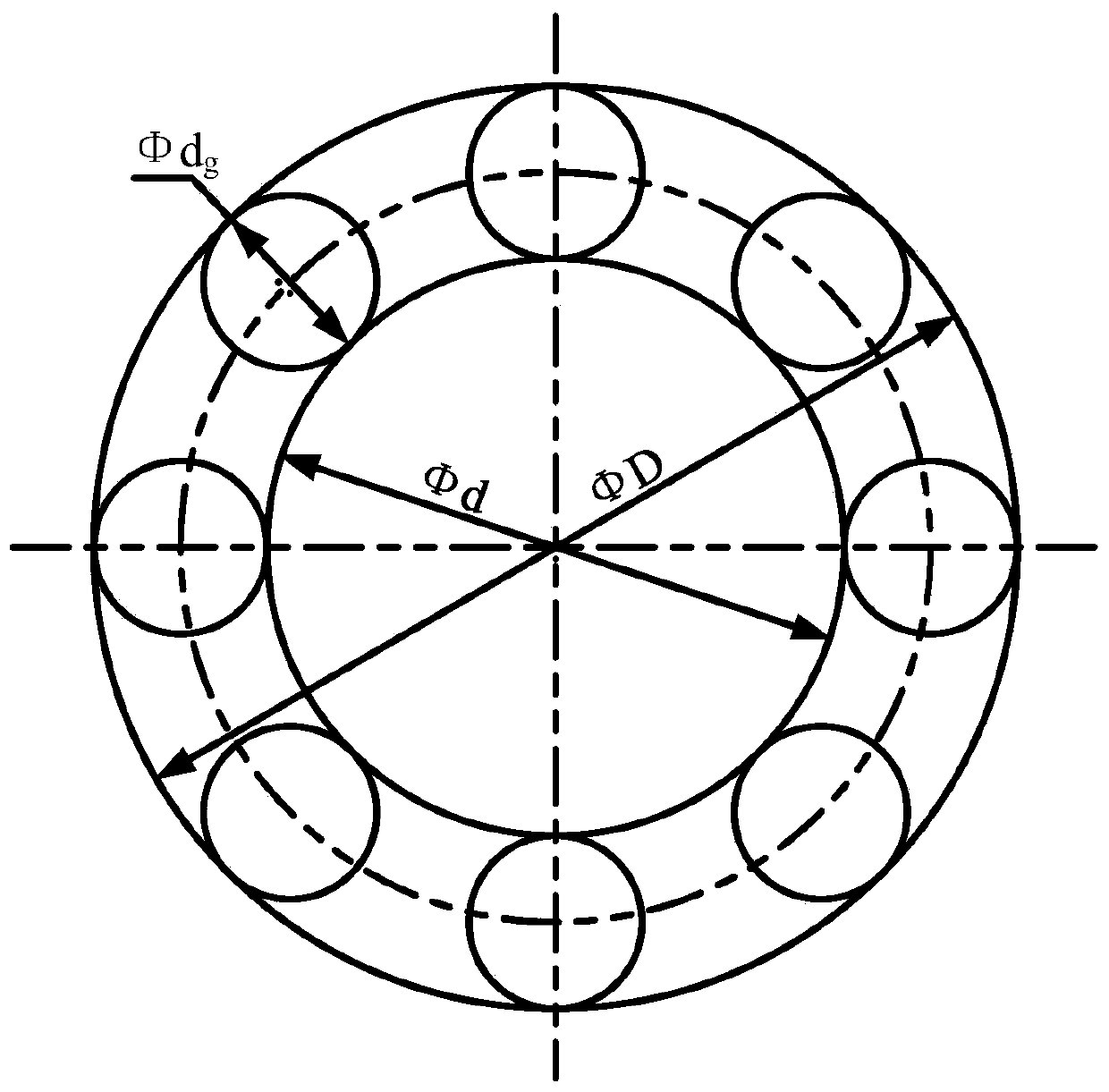

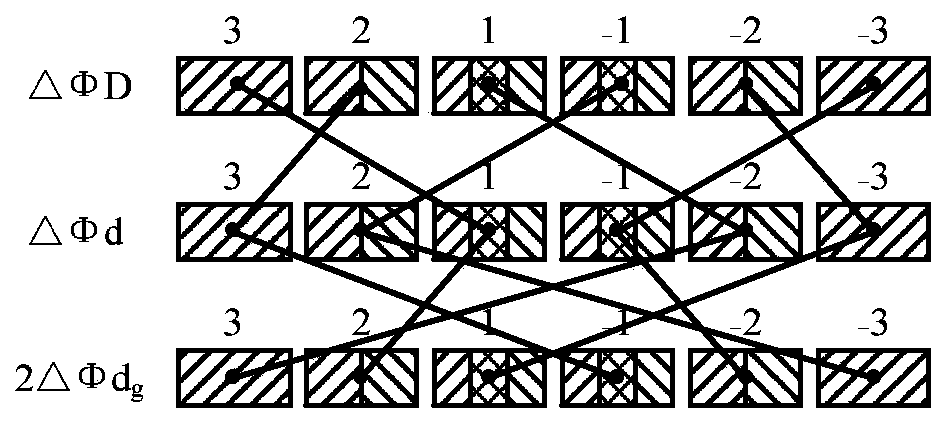

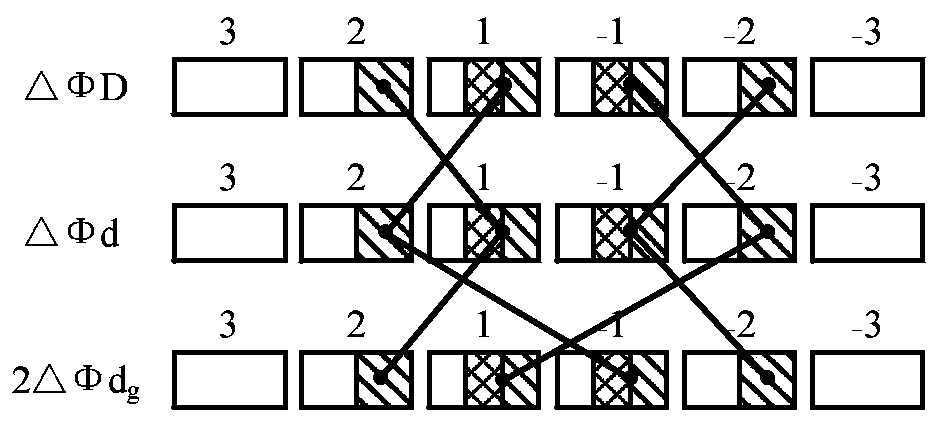

Assembly process for controlling bearing clearance

ActiveCN110185709AReduce manufacturing costSave workloadBearing componentsManufacturing cost reductionEngineering

The invention discloses an assembly process for controlling bearing clearance. When inner ring grooves and outer ring grooves are assembled with balls, the clearance is inconsistent, the precision islow, or even out of tolerance due to the fact that the size errors of the inner ring grooves and the outer ring grooves of bearings and the balls in the machining process are different. The process comprises the following steps: firstly, taking and grading the outer rings, inner rings and balls of one batch; secondly, subdividing the outer rings, the inner rings and the balls of each grade into two stages; thirdly, performing superior precision assembly; fourthly, carrying out secondary precision assembly for the first time; and fifthly, carrying out secondary precision assembly for the secondtime; and sixthly, finishing the bearing assembling. With the process, the inner rings, the outer rings and the balls are divided into six grades according to the measurement error, wherein the grades are respectively +3 grade, +2 grade, +1 grade, -1 grade, -2 grade and -3 grade, and a combination scheme of workpieces of each grade is established according to the characteristic that the number ratio of the workpieces of the six grades approaches to 1:2:3:3:2:1; and therefore, the residual quantity waste of the inner rings, the outer rings and the balls in one batch is reduced, and the manufacturing cost is reduced.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

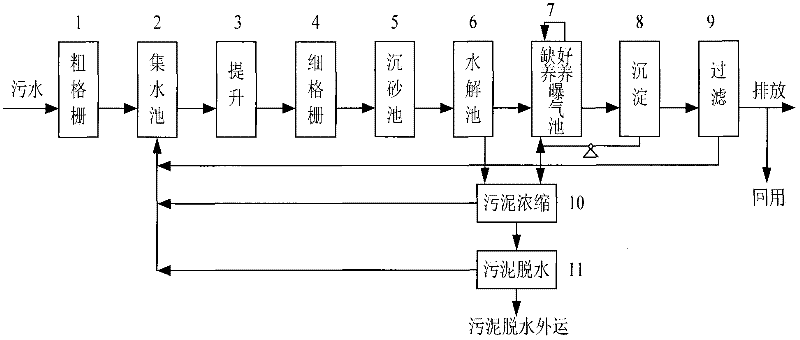

Novel sewage treatment technology

InactiveCN102476891ASave processing powerSave workloadSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentElectricitySludge

The invention relates to a novel sewage treatment technology, which comprises the procedures of: passing a thick grid, entering a collecting basin, conducting lifting, passing a fine grid, entering a grit chamber, entering a hydrolysis basin, entering an anoxic and aerobic aeration basin, entering a sedimentation basin, and entering a filter basin. The technology of the invention has the advantages of reasonable design, low energy consumption, and low capital construction cost. About 0.2-0.35KWH of electricity is needed for treating 1M<3> of sewage, the amount of sludge needing dehydration is only half of that of a routine technology, and the total cost for treating every M<3> of sewage is 0.2-0.4 RMB yuan (excluding equipment depreciation). For a treatment plant with a treatment scale of 20,000M<3> / day, an investment cost of about 500-600 RMB yuan is needed for treating 1M<3> / day of sewage. The sewage treated by the technology of the invention can reach or even exceed the intermediate water quality standard of Beijing municipality.

Owner:天津市庆安环境检测有限公司

A waste heat utilization system of exhaust steam from a condensing steam turbine driving an induced draft fan

ActiveCN104100314BImprove water qualityFull recovery of waste heat from exhaust steamSteam useWater sourceEngineering

A steam discharge waste heat utilization system of a condensing type small turbine for driving an induced draft fan comprises a main turbine and the condensing small turbine connected with the induced draft fan. The steam outlet of the small turbine is connected with the condenser of the small turbine. The steam outlet of the main turbine is sequentially communicated with a mainframe condenser, a condensing water pump, a condensate polishing device, a shaft-sealing condenser and a low-pressure regenerative system. The outlet of the shaft-sealing condenser and the condensate outlet pipeline of the condenser of the small turbine converge at a condensate return pipeline. The outlet of the condensate return pipeline is connected with the low-pressure regenerative system. The steam discharge and waste heat utilization system has the advantages that mainframe condensate is used as the cooling water source of the condenser of the small turbine, steam discharge waste heat of the small turbine can be fully recycled, total system cold source loss is reduced, and the system is relatively simple, small in operation and maintenance workload, and universal for water cooling units and air cooling units.

Owner:XIAN THERMAL POWER RES INST CO LTD

A Generative Q&A Dataset Generation Method for News Events

ActiveCN110110050BSave workloadSave the trouble of manual labelingDigital data information retrievalSpecial data processing applicationsData setQuestions and answers

Owner:PEKING UNIV

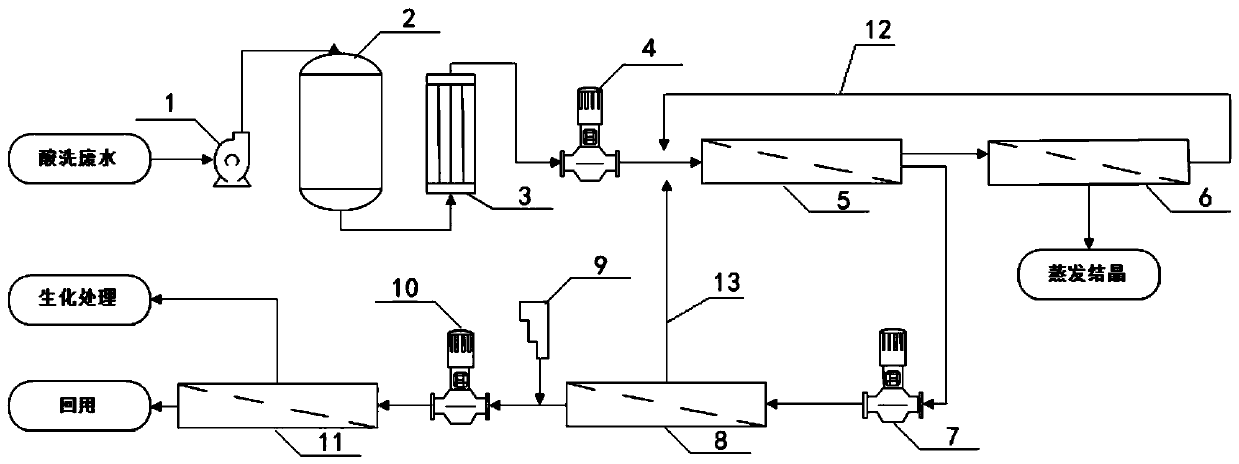

Ferrous sulfate concentration treatment system

PendingCN111392948ANo secondary water source requiredSecondary water source does not generateWater treatment parameter controlTreatment involving filtrationFiltrationFerrous sulfate iron

The invention discloses a ferrous sulfate concentration treatment system. The system comprises a booster pump, a multi-medium filter, a precision filter, a nanofiltration device set and a reverse osmosis device which are connected in sequence, the precision filter and the nanofiltration device set are connected by a first high-pressure pump, a second high-pressure pump is arranged between the nanofiltration device set and the reverse osmosis device, and a PH adjusting device is further arranged between the second high-pressure pump and the nanofiltration device set; the nanofiltration device set comprises a first nanofiltration device, a second nanofiltration device and a third nanofiltration device, and a third high-pressure pump is arranged between the third nanofiltration device and thefirst nanofiltration device. The technical scheme has the beneficial effects that: impurities in raw water are removed by adopting a multi-stage filtration and concentration mode, the filtered waterreaching the standard is recycled, and the obtained concentrated water is subjected to biochemical treatment, so that the work amount of biochemical treatment is reduced, and water resources are alsosaved.

Owner:德兰梅勒(北京)分离技术有限公司

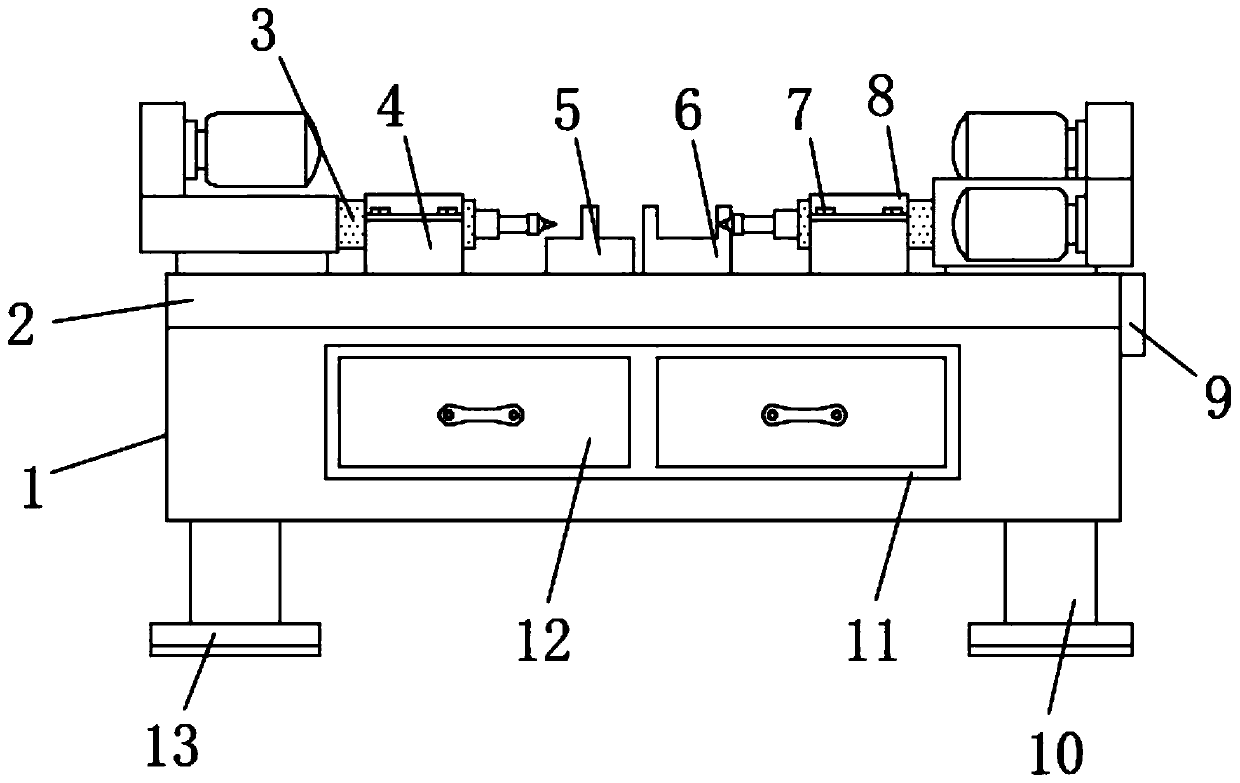

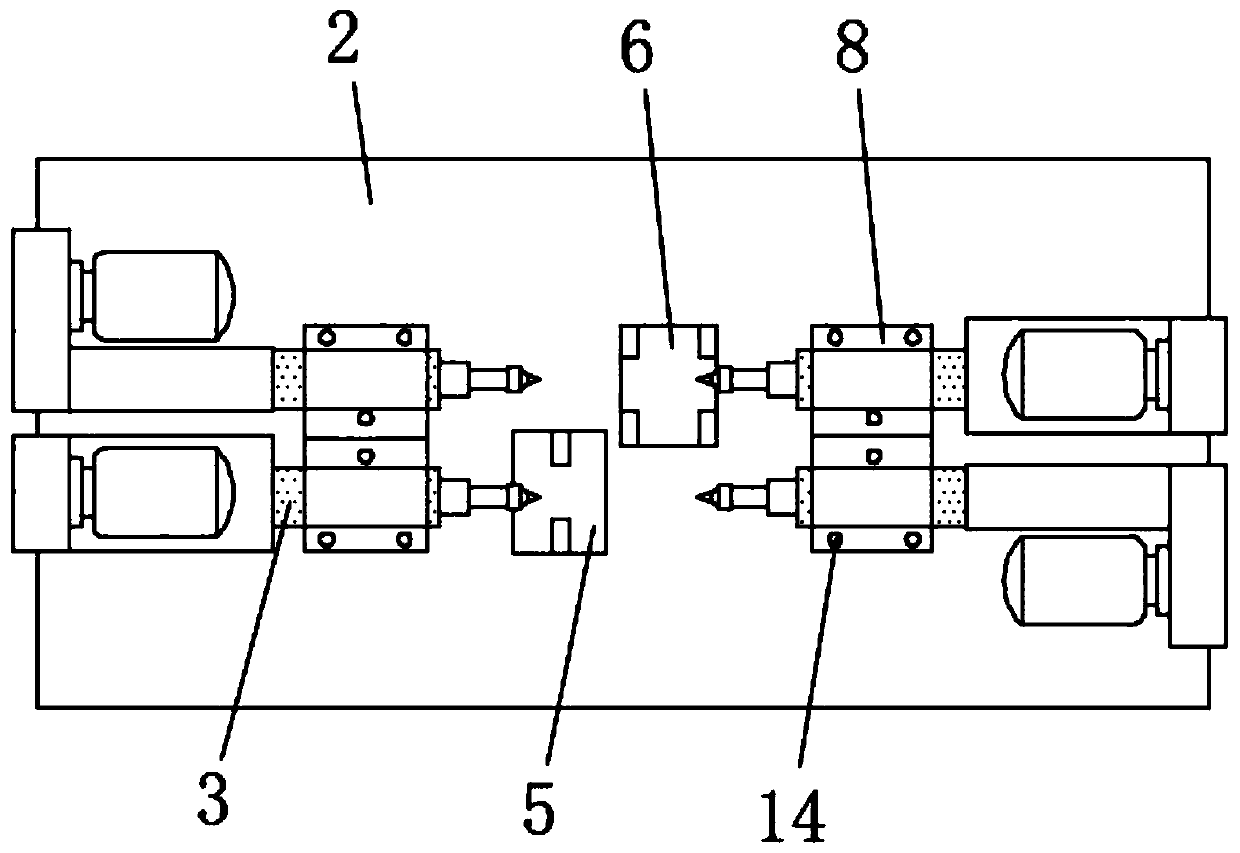

Multi-axis center hole puncher

PendingCN110976941ASave workloadGuaranteed machining accuracyWork clamping meansPositioning apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of machining equipment, and discloses a multi-axis center hole puncher. The multi-axis center hole puncher comprises a frame body, wherein a mounting plateis fixed on the upper surface wall of the frame body; a controller is mounted at the side wall of the mounting plate; power head fixing seats are symmetrically fixed at two ends of the upper surfacewall of the mounting plate; the upper surface wall of each of the power head fixing seats is symmetrically provided with first clamping grooves; power heads are mounted inside the first clamping grooves; the upper surface walls of the power head fixing seats are equipped with fastening cover plates; and the lower surface walls of the fastening cover plates curve inwards to form second clamping grooves. The multi-axis center hole puncher adopts the relatively mature drilling power heads on the market and combines self-centering clamps, thereby realizing the operation of center hole punching byclamping four center holes at a time, realizing multi-hole machining at a time, greatly improving the machining efficiency while effectively ensuring the machining precision, avoiding the workload ofrepeatedly carrying and clamping products by workers, and reducing the labor intensity.

Owner:日照德信机械制造有限公司

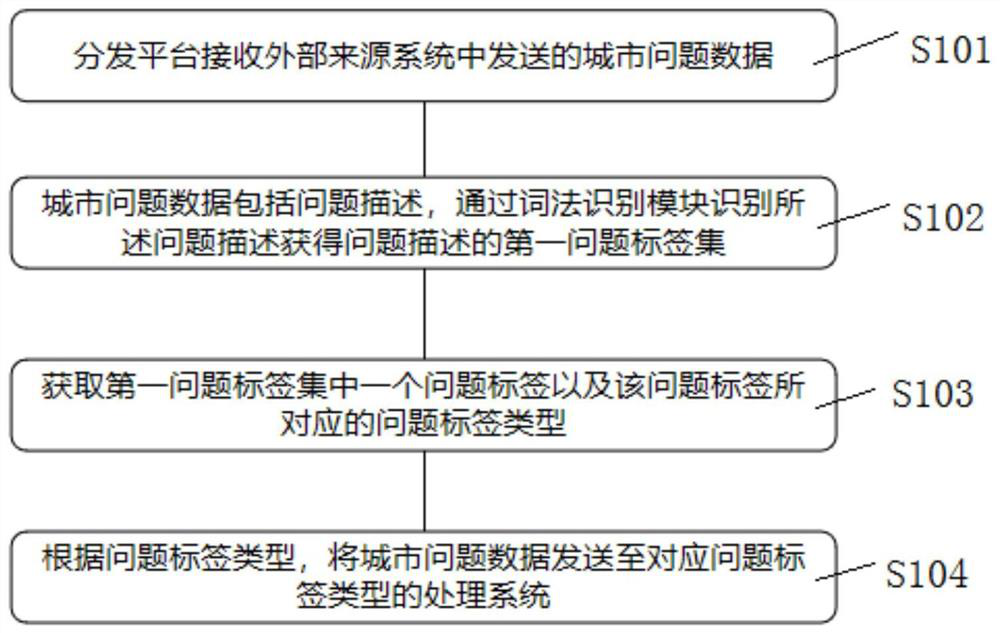

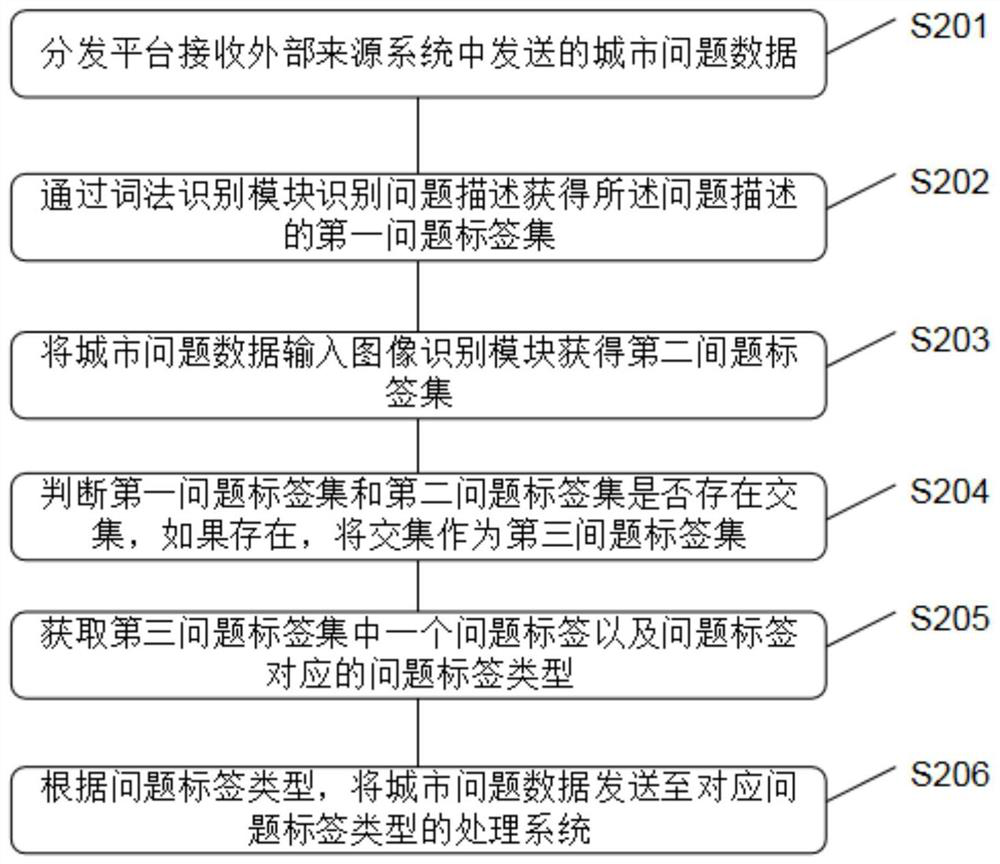

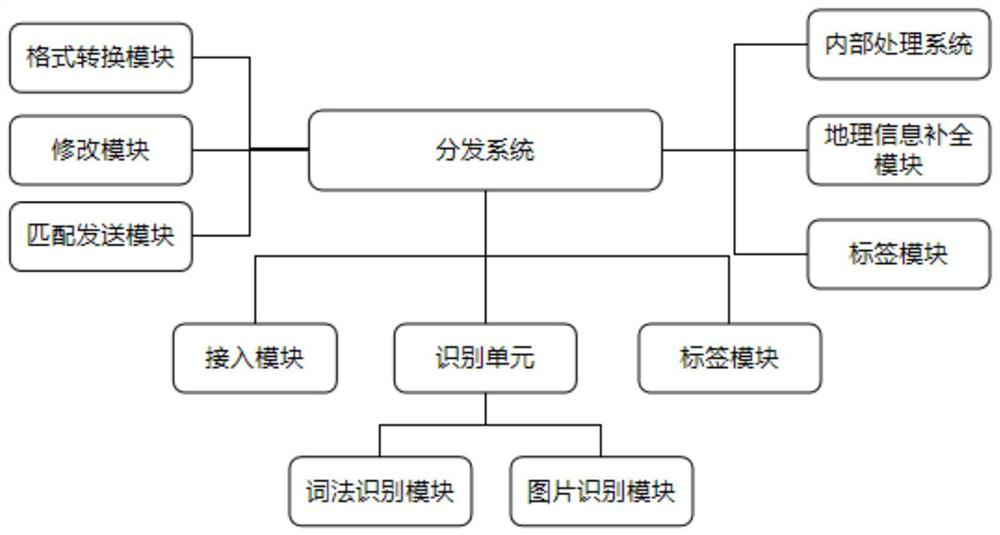

Information distribution method, system and system equipment for city management and storage medium

InactiveCN112214628ARealize the function of automatic distribution and circulationImprove access efficiencyData processing applicationsNatural language data processingDistribution methodData mining

The invention discloses an information distribution method, system and system equipment for city management, and a storage medium, and relates to the technical field of data management. The method comprises the following steps: a distribution platform receives formatted urban problem data, generates a first problem label set and a second problem label set through identification of a lexical identification module and an image identification module, and judges whether the first problem label set and the second problem label set have an intersection or not, if the intersection exists, the intersection is taken as a third problem label set; the method also includes obtaining a problem label in the third problem label set and a problem label type corresponding to the problem label; and sendingthe city problem data to a processing system corresponding to the problem label type according to the problem label type. According to the invention, the providing requirements of the problem data arelimited, and the information is subjected to label marking processing, so that the information can be efficiently distributed to the corresponding processing platform, and the problem publishing efficiency is improved.

Owner:CITY CLOUD TECH HANGZHOU CO LTD

Feed filtering device with permanent magnet roller

The invention discloses a feed filtering device with a permanent magnet roller. The feed filtering device is composed of a feeding port, a shell, a leakage net, a nozzle, an air pipe, a fan, an air outlet, a slope sliding plate, the permanent magnet roller, a temporary storage groove and a discharging port, and is characterized in that the feeding port is formed in the upper part of the shell, thedischarging port is formed at the lower part of the shell, the leakage net is fixedly connected with the shell, the slope sliding plate is located below the leakage net and is obliquely fixed on theshell, the upper part of the slope sliding plate is fixedly connected with the air outlet, the air outlet is fixedly connected to the shell, the permanent magnet roller is connected with the shell through bearings, the surface of the permanent magnet roller is in contact connection with the temporary storage groove, the temporary storage groove is fixed on the shell, the fan is fixedly connected with the air pipe, the air pipe is fixedly connected with the nozzle, and the nozzle is fixedly connected with the shell and is positioned below the slope sliding plate. The feed filtering device has the beneficial effects that impurities in a raw material of feed can be directly filtered by one-time filling, compared with a traditional production method, the time and workload are saved, and the working efficiency is also improved.

Owner:高丽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com