Automatic ash removal device for flue of aluminum electrolysis cell

A technology of automatic ash removal and aluminum electrolytic cell, which is applied in the field of automatic ash removal device for flue, can solve the problems of heavy cleaning workload of flue ash accumulation, effective utilization of tail gas in shelling and feeding system, etc., and achieves improved energy utilization rate, Avoid flying loss and enhance the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

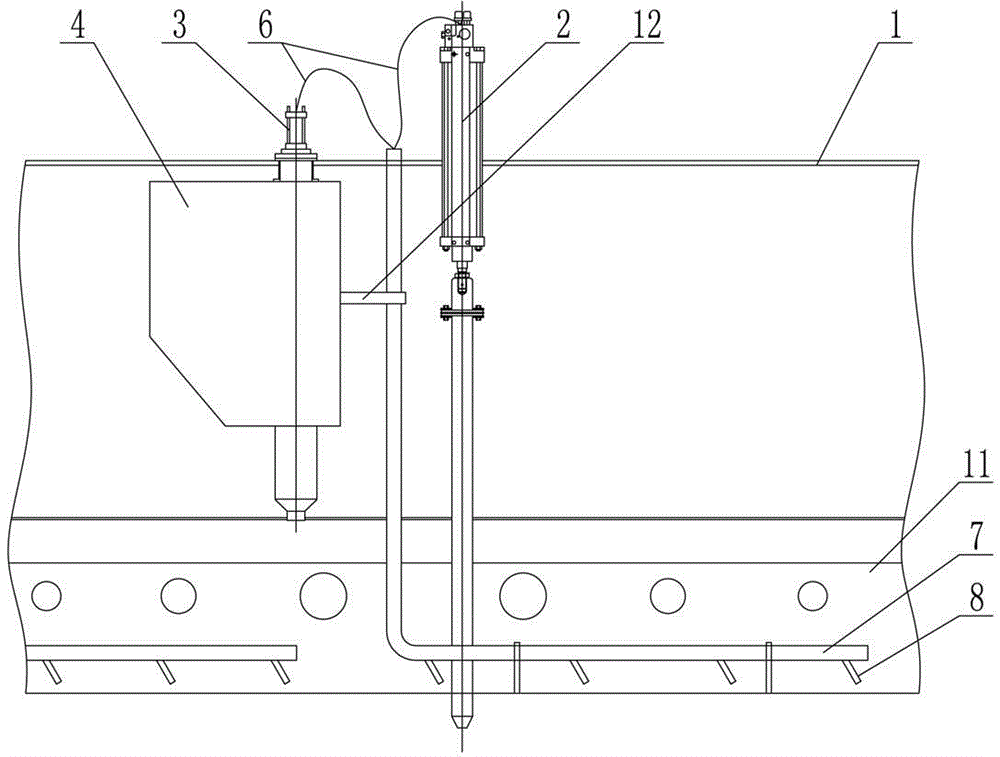

[0028] Such as figure 1 As shown, the automatic dust removal device for the flue of an aluminum electrolytic cell includes a shelling cylinder 2 and a constant volume feeder 3. The cleaning pipe 7 in the road is connected. The cleaning pipe 7 is provided with a blowing pipe 8 . The flue includes an upper flue 5 and a lower flue 11. In the present embodiment, the dust removal pipe 7 is arranged in the lower flue 11 . The number of blowing pipes 8 welded on each cleaning pipe 7 is 2 to 20. The diameter of the blowing pipe is 10-100 mm, and the diameter of the blowing pipe in this embodiment is 30 mm. The diameter range of the dust removal pipe is 20-200 mm, and the diameter of the dust removal pipe 7 in this embodiment is 40 mm. The ash removal pipe 7 is fixed on the material box 4 and the lower flue 11 by a bracket 12 .

Embodiment 2

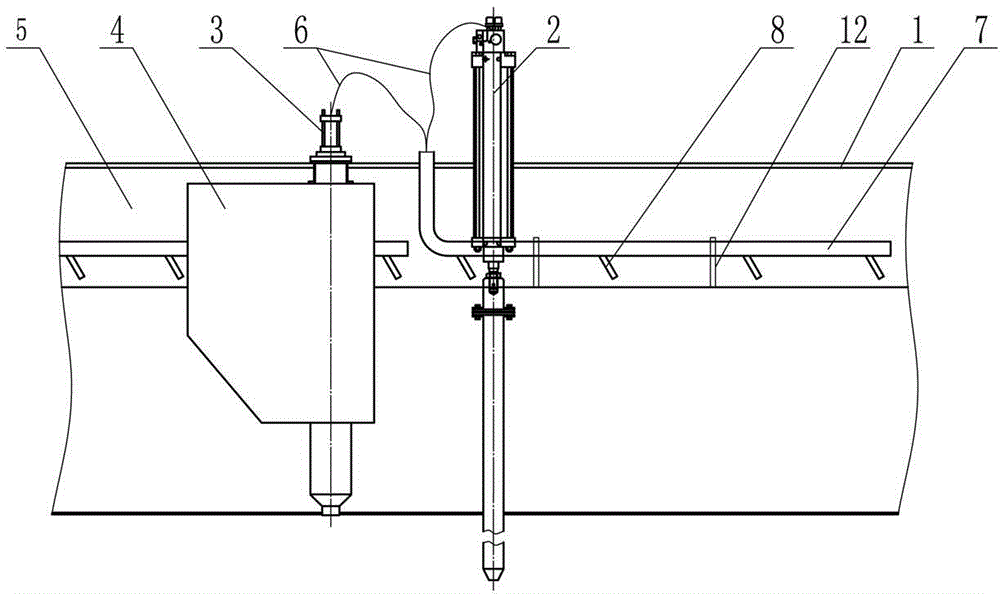

[0030] Such as figure 2 As shown, the dust removal pipe 7 in Embodiment 1 is arranged in the upper flue 5 , and the dust removal pipe 7 is fixed on the upper flue 5 through the bracket 12 . Others are with embodiment 1.

Embodiment 3

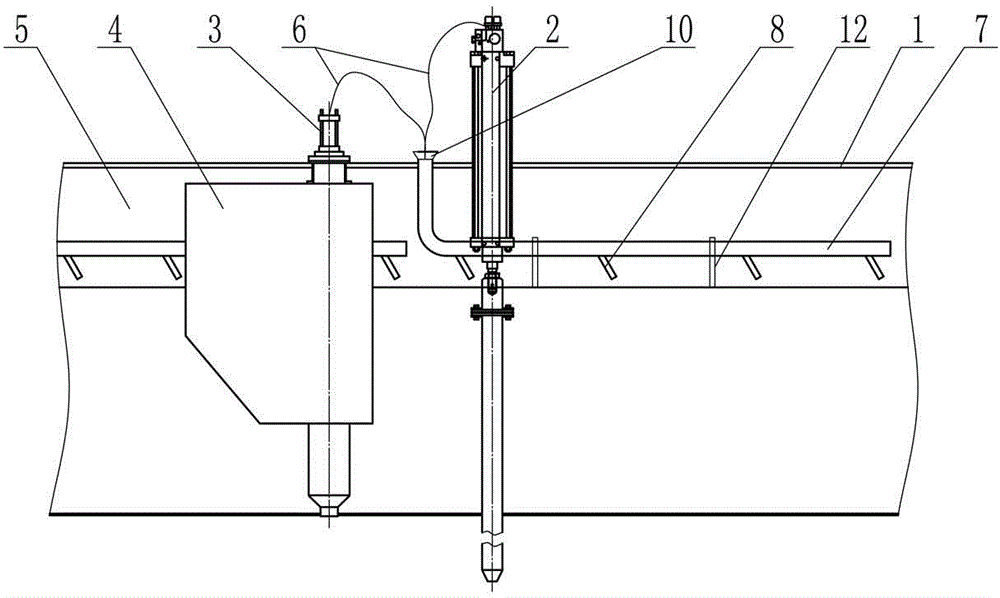

[0032] Such as image 3 As shown, the end of the ash inlet end of the ash removal pipe 7 in Embodiment 2 is provided with a trumpet-shaped drainage horn pipe 10 . Flexible pipe 6 is inserted in the drainage bell pipe 10. The diameter of the spray pipe in this embodiment is 50mm. The diameter range of the dust removal pipe is 20-200 mm, and the diameter of the dust removal pipe 7 in this embodiment is 80 mm. The pipe diameter ranges of the upper and lower mouths of the drainage trumpet pipe 10 are 40-300 mm and 20-200 mm respectively, and the height ranges are 30-300 mm. Drainage trumpet pipe 10 is welded or bolted to soot cleaning pipe 7. In this embodiment, the ash removal pipe 7 is arranged in the upper flue 5 . Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com