Panel material positioning and dust-removing device

A material positioning and dust removal device technology, applied in rotary printing presses, printing, printing presses, etc., can solve problems such as low positioning efficiency, large labor costs, and inability to meet industrial needs, so as to improve the yield rate, reduce the difficulty of debugging, and reduce The effect of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

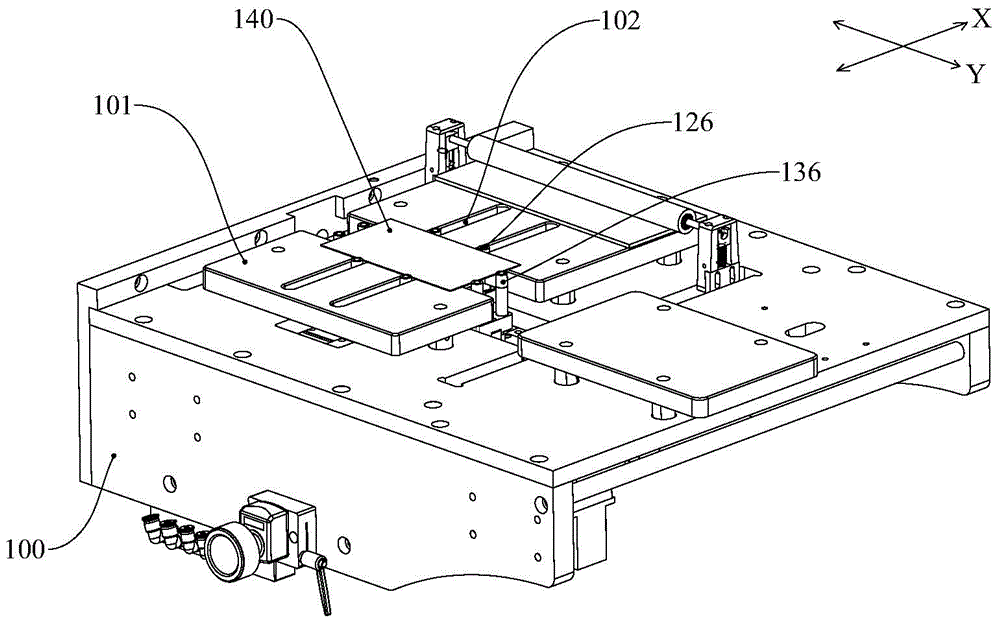

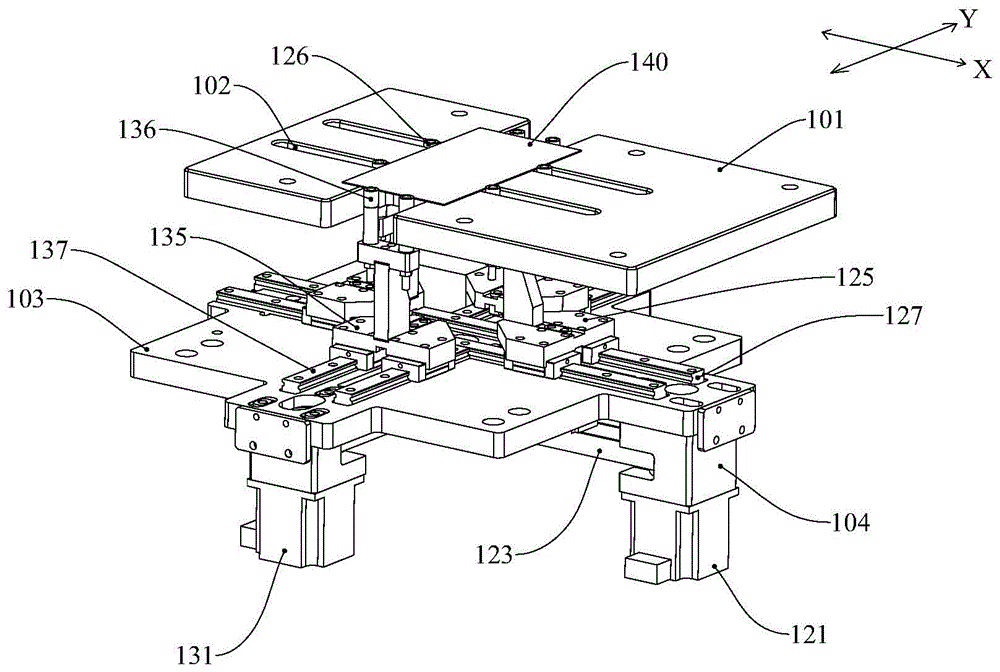

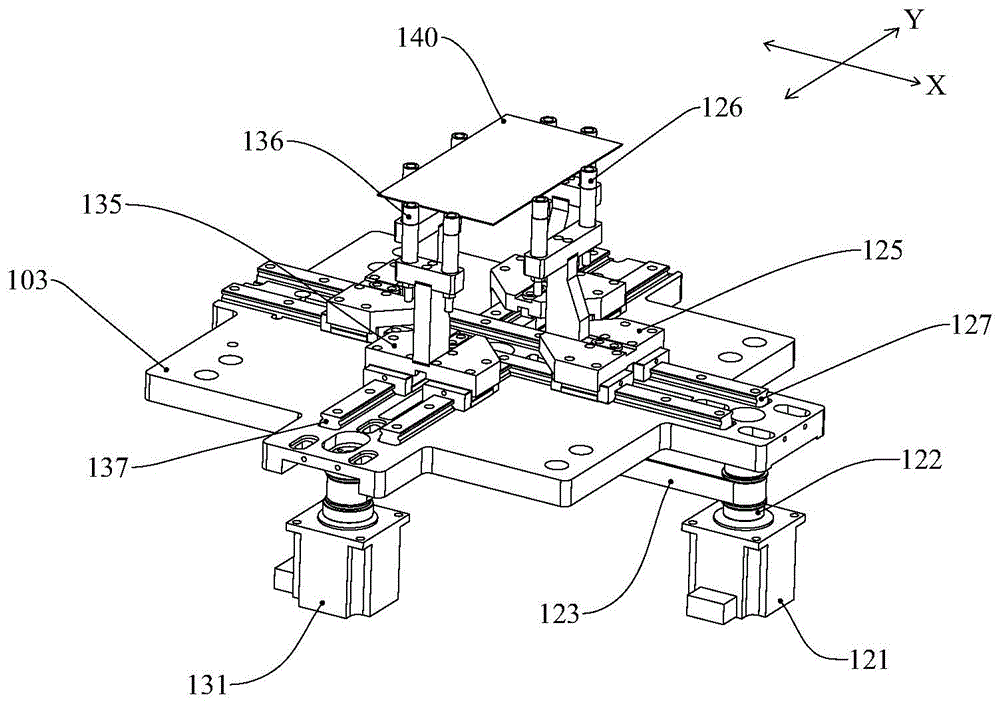

[0042] The specific structure of the first embodiment is as Figure 1 to Figure 5 shown.

[0043] like Figure 1 to Figure 5 As shown, the panel material automatic positioning device in this embodiment includes a base 100 , a loading platform 101 on the base 100 for placing the panel 140 , a mounting plate 103 fixed on the base 100 and an automatic positioning mechanism. The automatic positioning mechanism includes a first positioning component and a second positioning component. Both the first positioning component and the second positioning component are arranged on the base 100 , and the first positioning component and the second positioning component work independently of each other.

[0044] like Figure 1 to Figure 5 As shown, the first positioning component positions the panel from a first direction X on the main plane of the panel 140, and the second positioning component positions the panel 140 from a second direction Y on the main plane of the panel 140, and the f...

no. 2 example

[0055] The specific structure of the second embodiment is as Figure 6 to Figure 10 shown.

[0056] The panel material positioning dust removal device of the second embodiment adds an automatic dust removal mechanism on the basis of the first embodiment, and the automatic dust removal mechanism includes a sticky dust assembly 220 for removing dust from the panel 240 and a driving force for the sticky dust assembly 220 drive components.

[0057] like Figure 6 and Figure 7 As shown, the sticky dust assembly 220 includes a roller 221 that takes away the dust on the panel 240 through surface adhesion, and a sticky paper 222 that takes away the dust on the roller 221 through surface adhesion. The sticky paper 222 is disposed on the loading platform 211 , and the driving assembly drives the roller 221 to roll between the sticky paper 222 and the panel 240 .

[0058] like Figure 7 and Figure 8 As shown, the loading platform 211 is provided with a ventilation hole 212 and a ...

no. 3 example

[0064] The specific structure of the third embodiment is as Figure 11 to Figure 18 shown.

[0065] The panel material positioning and dust removal device of the third embodiment adds an adjustment mechanism for adjusting the mounting plate 320 on the basis of the second embodiment.

[0066] like Figure 11 to Figure 15 As shown, the adjustment mechanism is fixedly installed on the base 300 . The adjustment mechanism includes a guide rod 334 fixed on the base 300 , a support block 335 for connecting the mounting plate 320 and the guide rod 334 , and a lead screw 331 for adjusting the axial position of the mounting plate 320 on the guide rod 334 . The lead screw 331 is fixed on the base 300 , the nut of the lead screw 331 is fixedly connected with the mounting plate 320 , and the axial direction of the lead screw 331 is parallel to the axial direction of the guide rod 334 . The adjusting direction V of the lead screw 331 of the adjusting mechanism is perpendicular to the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com