Method for reinforcement and protection of underwater foundation by pressing and pouring grout and matching with bagged dry mix

An underwater foundation and mixing technology, which is applied in basic structure engineering, basic structure repair, construction, etc., can solve problems such as difficulty, long construction time, and stones washed away, so as to reduce project cost and prevent water flow from continuing. The effect of scouring the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

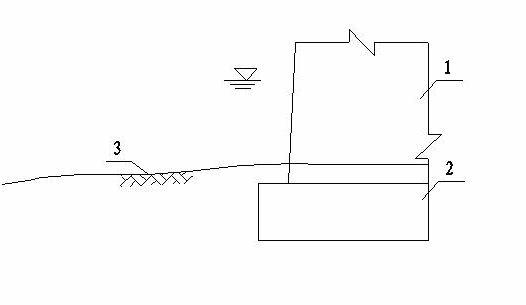

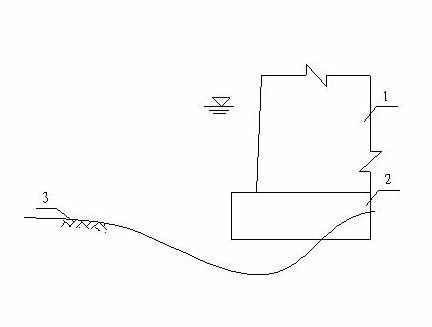

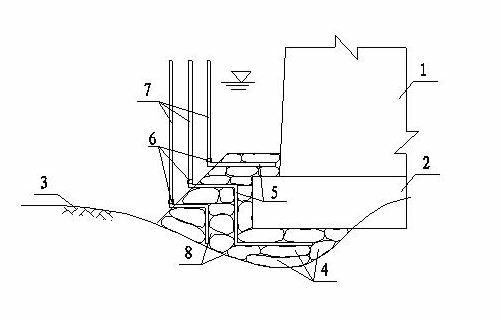

[0014] An underwater foundation reinforcement and protection method of injection cement slurry combined with bagged dry-mixed mixture, which is to dry-mix cement, sand and gravel mixture on the shore according to the requirements of the designed concrete mix ratio, and mix them according to the total weight of 15kg, 20kg , 25kg in bags of different specifications, with the assistance of divers, the bagged dry mix 4 is stacked at a slope of 1:1 on the part of the bottom of the foundation 2 that has been severely scoured or even partially emptied and the surrounding area, and meets the requirements of the foundation. According to the requirements of the burial depth, the grouting pipe 5 is pre-embedded between the stacked bagged mixture 4. There is a through hole 9 on the grouting pipe 5, and the grouting pipe 5 is connected to the grouting pipe 7 through a two-way joint 6. , after the bagged dry mixture 4 meets water and naturally coagulates, press the grout through the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com