Multi-axis center hole puncher

A punching machine and shaft centering technology, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problem of low efficiency of multi-directional center drilling, complicated fixing of power head, labor intensity Major problems, to achieve the effect of reducing labor intensity, ensuring long-term normal use, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] Embodiment 2: Different from Embodiment 1, the front surface wall of the frame body 1 is concave to form a groove 11, and the interior of the groove 11 is symmetrically installed with a storage drawer 12, which is installed in the middle of the outer wall of the storage drawer 12. There are handles, and the outer wall of the storage drawer 12 is sleeved with rubber pads. The tools and accessories of the equipment do not need to be placed on the mounting plate 2, but can be placed in the storage drawer 12 inside the groove 11, which can effectively avoid loss, and It is convenient to quickly find when needed, wherein the storage drawer 12 is conveniently opened and closed through the handle, which is convenient and labor-saving.

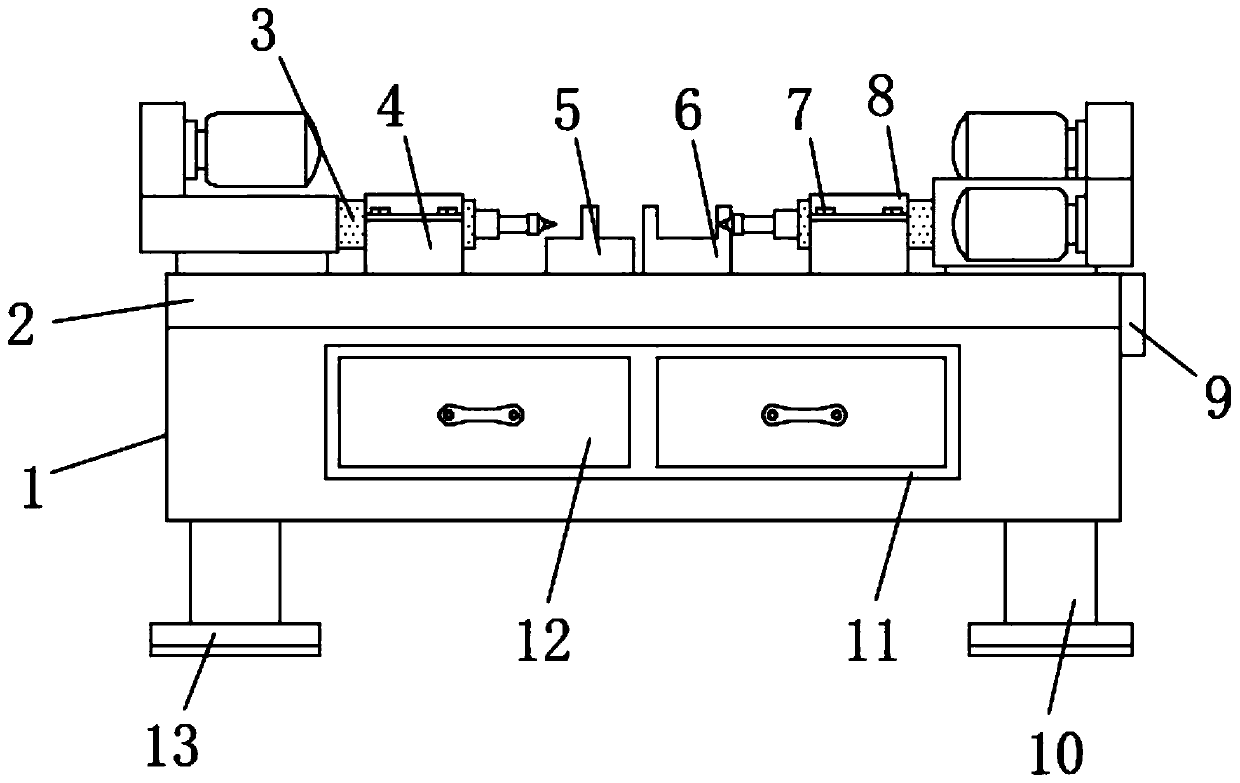

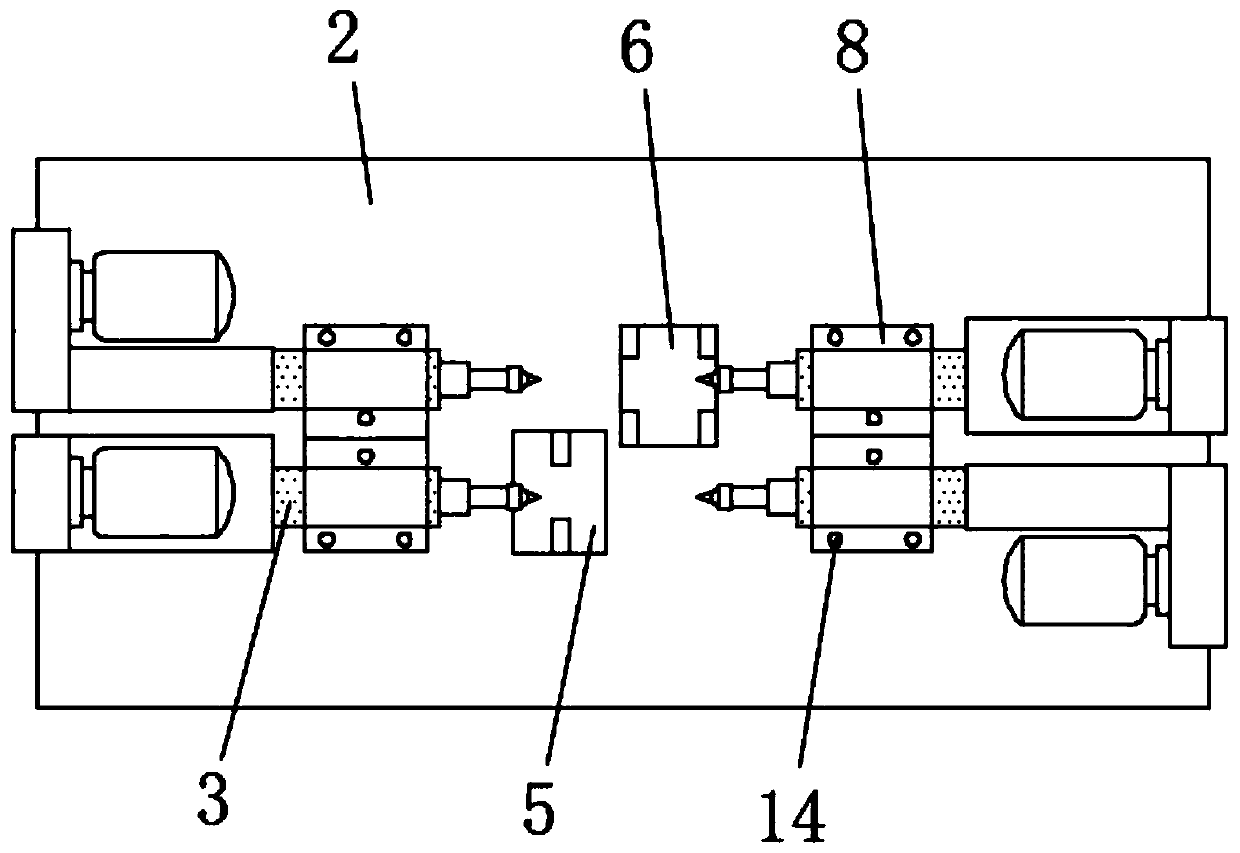

[0032] The working principle and use process of the present invention: when the present invention is used, the workpiece to be processed is first placed on the mounting plate 2 at the top of the frame body 1, and then the first pneumatic clamp 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com