Digital underground layering water injection testing and adjusting process pipe column and operation method thereof

A technique of pipe string and layered water injection, which is applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., can solve the problems that the separate injection technology cannot meet the requirements, and achieve the reduction of operation risk, reduction of unsealing force, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

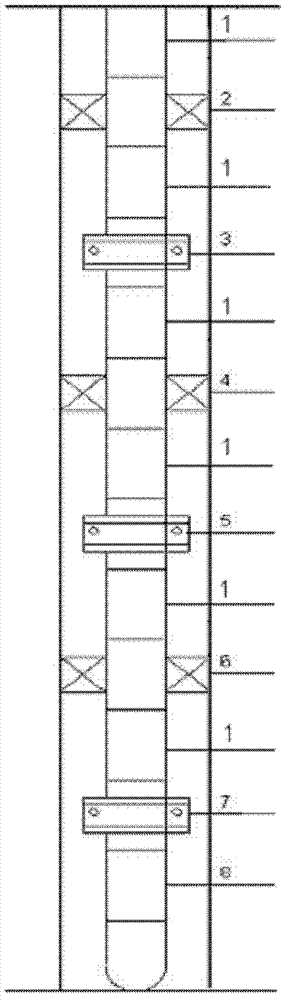

[0028] refer to figure 1 Embodiments of the present invention are further described:

[0029] The present invention uses a digital water distributor and a Y 344 water injection packer as the main process string, which is composed of the following components connected from top to bottom in sequence:

[0030] Tubing 1+ primary water injection packer 2+ tubing 1+ primary digital water distributor 3+ tubing 1+ secondary water injection packer 4+ tubing 1+ secondary digital water distributor 5+ tubing 1+ tertiary water injection Packer 6+ oil pipe 1+ three-stage digital water distributor 7+ anti-overflow check valve and eye pipe assembly 8.

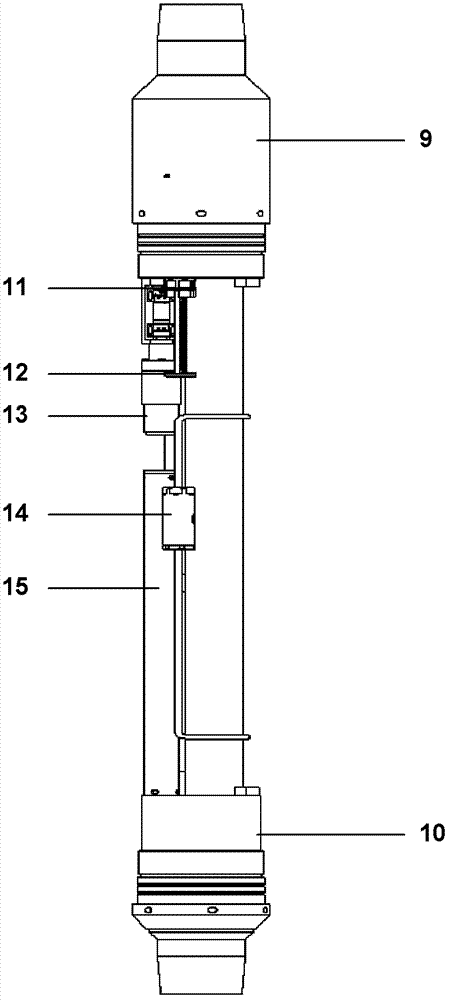

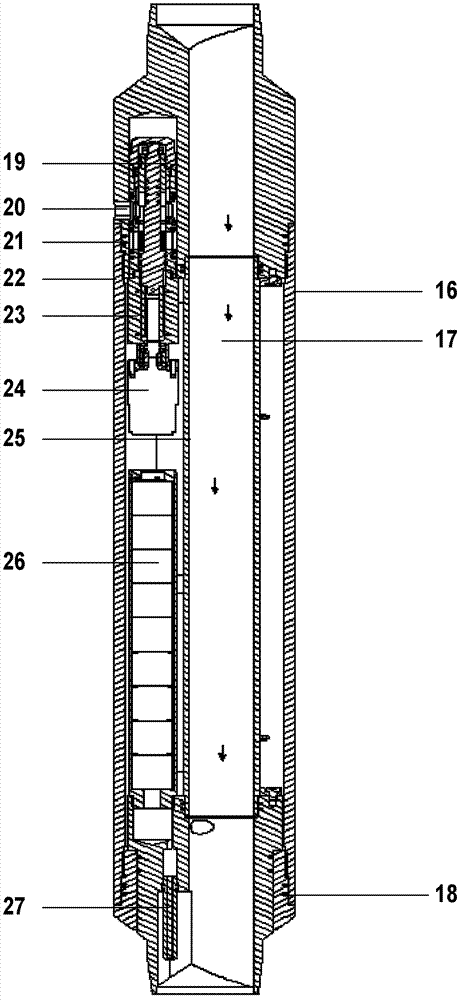

[0031] The central inner tube 25 is connected between the upper joint 9 and the lower joint 10 of the digital water distributor, and the outer cylinder 16 is connected by a sealing joint 18. The central inner tube 25 communicates with the central hole of the upper joint 9 and the lower joint 10 to form a liquid flow channel 17;

[0032] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com