Excessive glue full automatic production line of semiconductor lead frame

A lead frame, semiconductor technology, applied in the coating and other directions, can solve the problems of increasing the loss of chemical liquid and waste water, the efficiency is not improved, the washing time is short, etc., and the washing method is simple and reasonable, good consistency, saving quantity and physical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

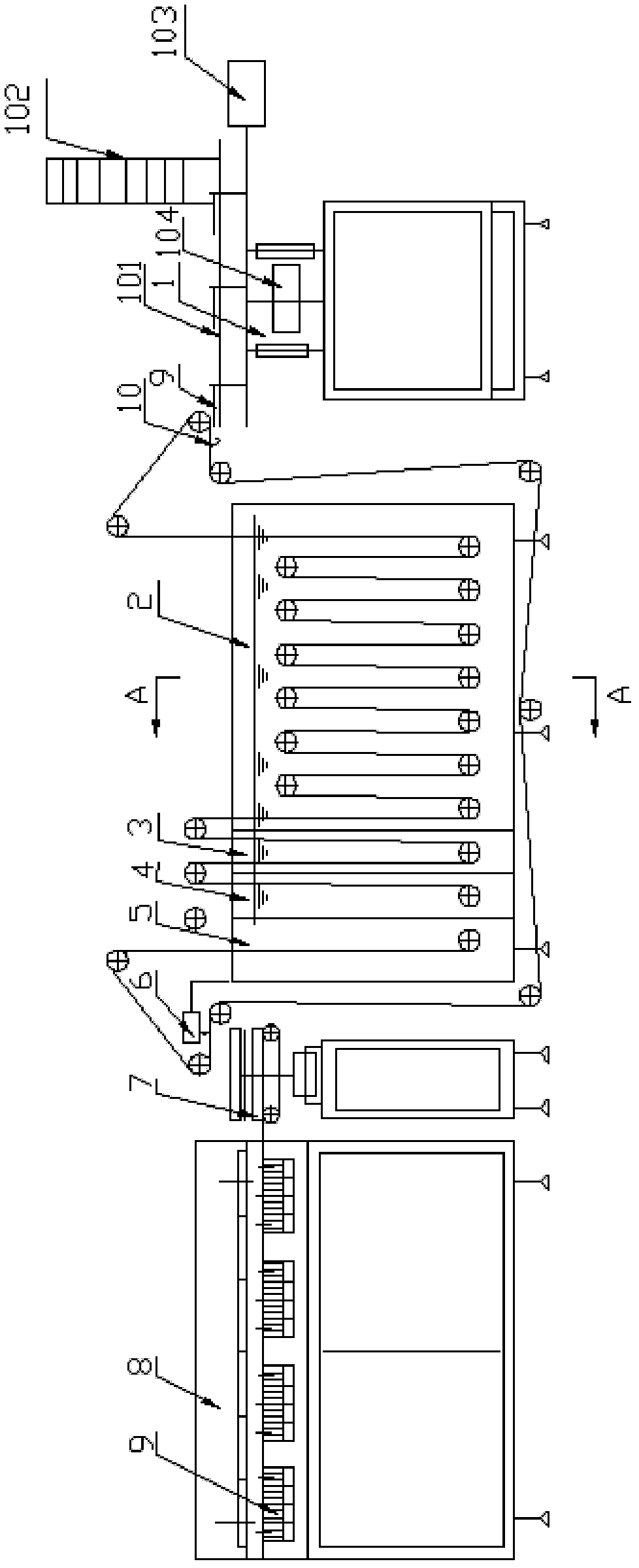

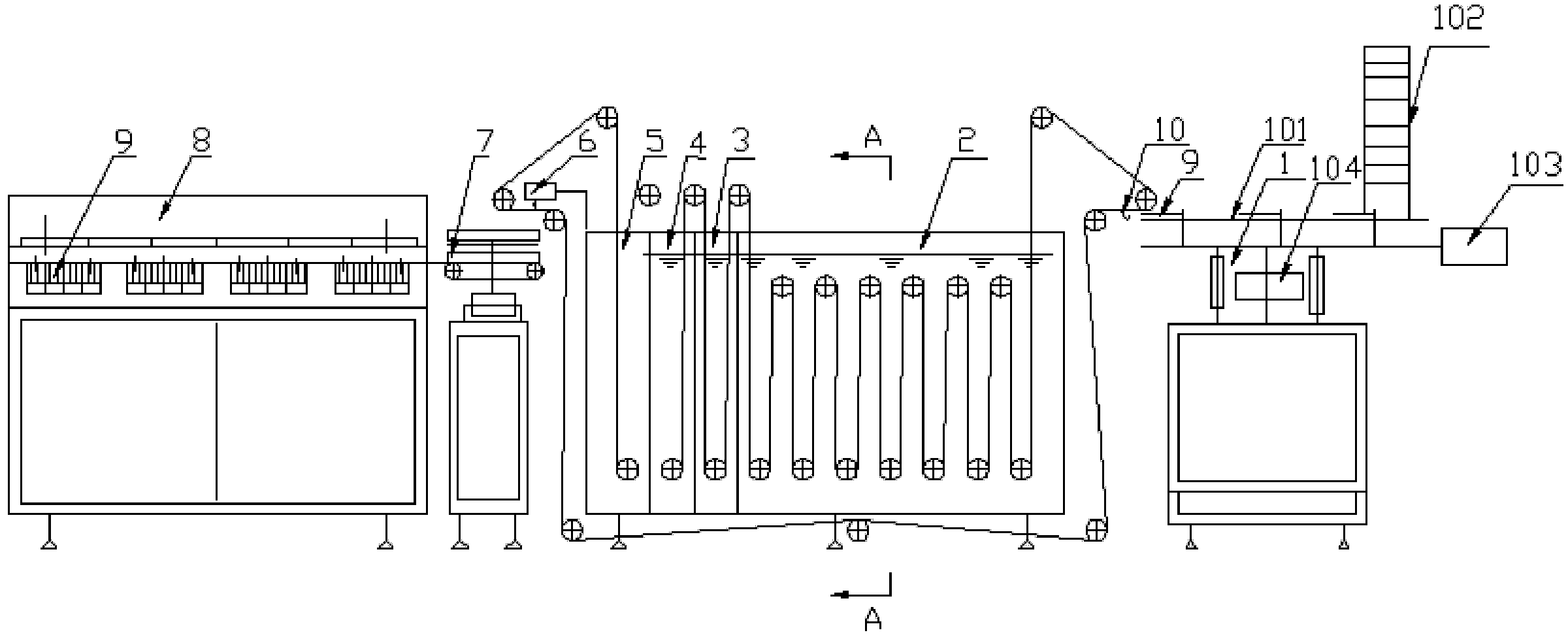

[0037] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-Figure 2 Shown:

[0038] The treatment tanks are organically connected together by two stainless steel chains 12 to realize their respective functions and complete the conveying and carrying cycle.

[0039] The automatic feeding device is composed of a feeding platform 101 , a material storage box 102 , a pneumatic pushing device 103 and an ascending cylinder 104 . The material pushing device 103 constantly pulls out the material bar from the bottom of the material storage box 102 and pushes it forward to feed the material.

[0040]After the soaking system is completed, the automatic unloading is changed by the reversing turntable by 90°, and then enters the automatic feeding of the high-pressure water jet 8, and the high-pressure water jet spraying is further completed inside it to complete the whole process of glue removal.

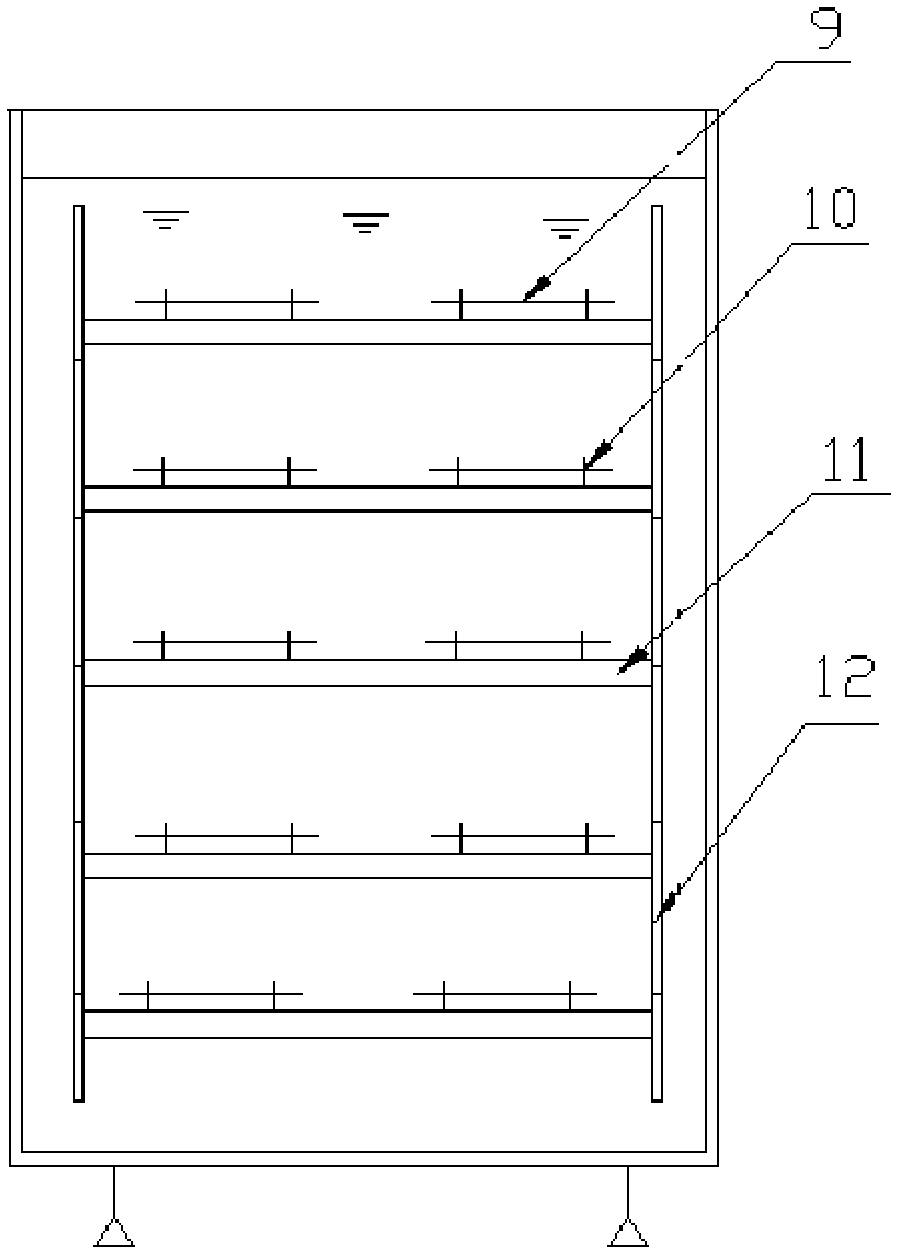

[0041] like figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com