Sheet mounting, dismounting and positioning all-in-one machine

An all-in-one machine and positioning mechanism technology, applied in the direction of conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of large space occupation, high cost, long occupied space, etc., and achieve a wide range, saving quantity and cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail through specific implementation examples below.

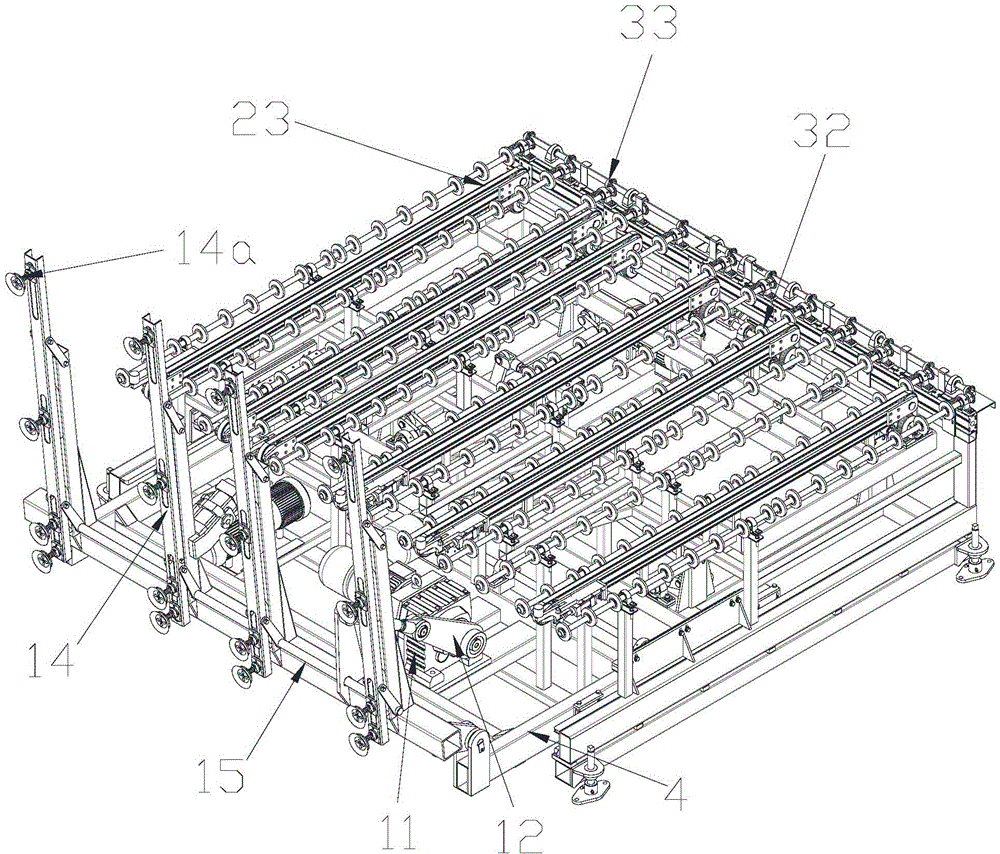

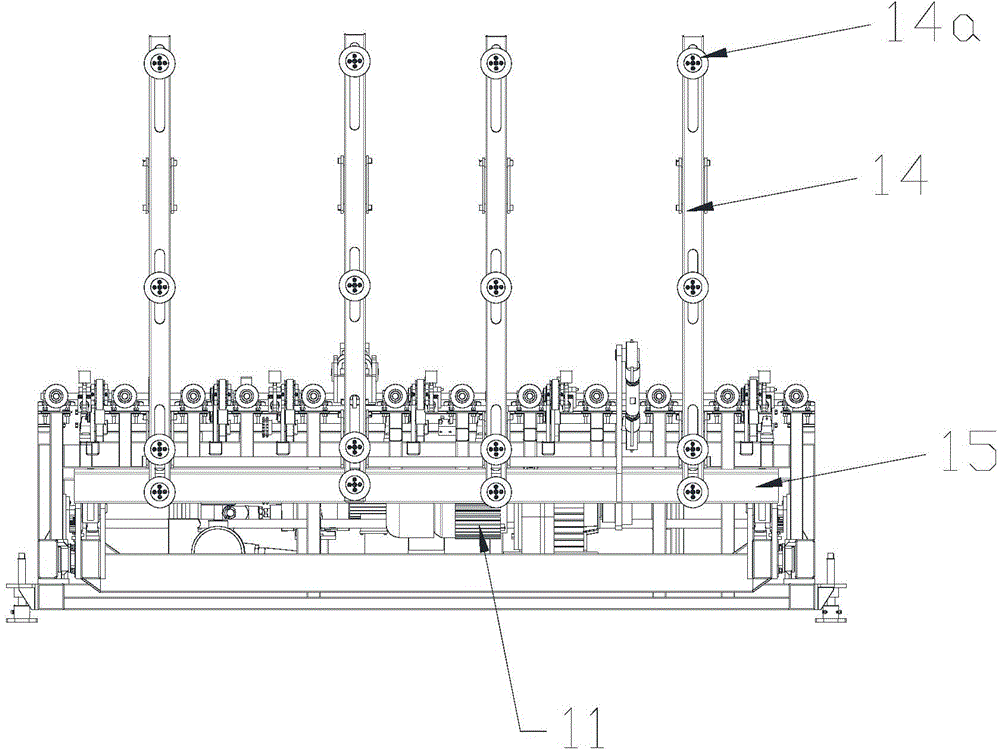

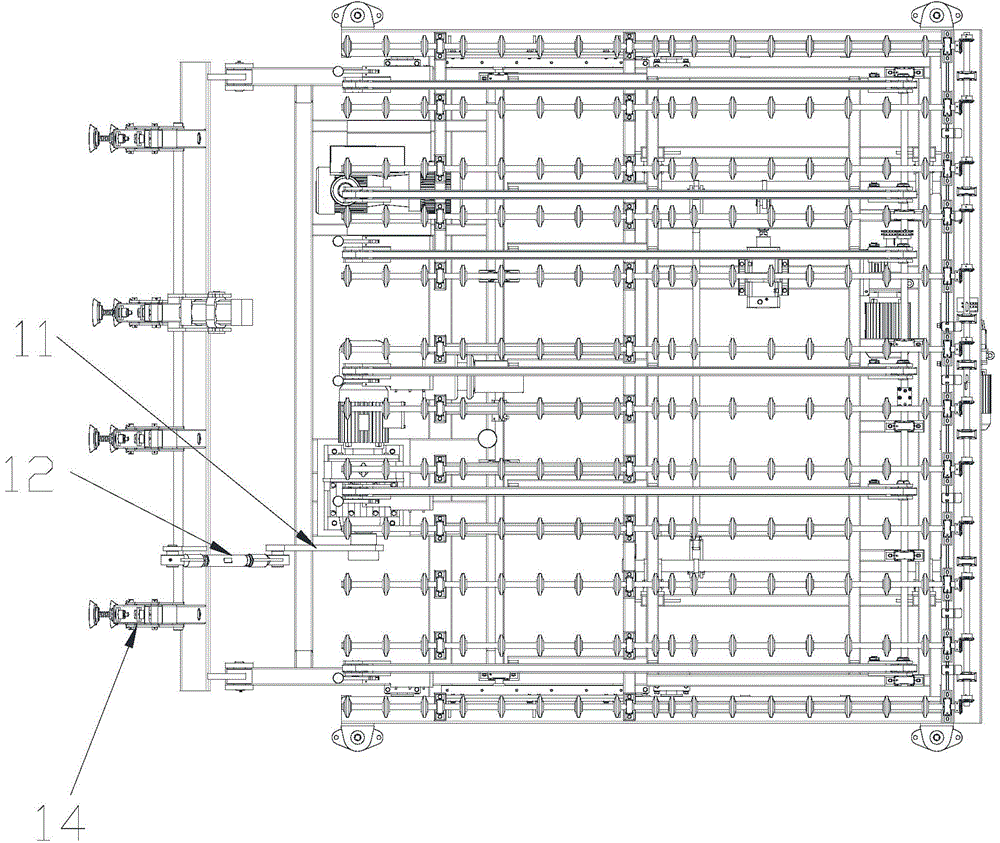

[0030] An all-in-one positioning machine for loading and unloading sheets, comprising a bottom frame (4), a turning mechanism, a positioning mechanism and a lifting mechanism installed on the bottom frame (4).

[0031] Described overturn mechanism comprises first motor 11, and the output end of described first motor is connected with first crank 12, and described first crank 12 is connected with overturn arm 14 by connecting rod 13, on the free end of described overturn arm 14 A suction cup 14a is provided. The working principle of the turning mechanism is: when the suction cup 14a vacuumizes, it absorbs the glass sheet placed on the glass shelf, the first motor 11 drives the crank 12 to rotate, and the crank 12 drives the turning arm 14 to move from upright to horizontal through the connecting rod 13 .

[0032] The positioning mechanism includes a second motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com