Natural gas sampling device and method thereof

A sampling device, natural gas technology, applied in the direction of sampling device, sampling, measuring device, etc., can solve the problems of easy cooling and solidification of sulfur element, time-consuming and laborious sampling process, blockage of sampling port, etc., to achieve easy analysis and processing, smooth sampling process, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

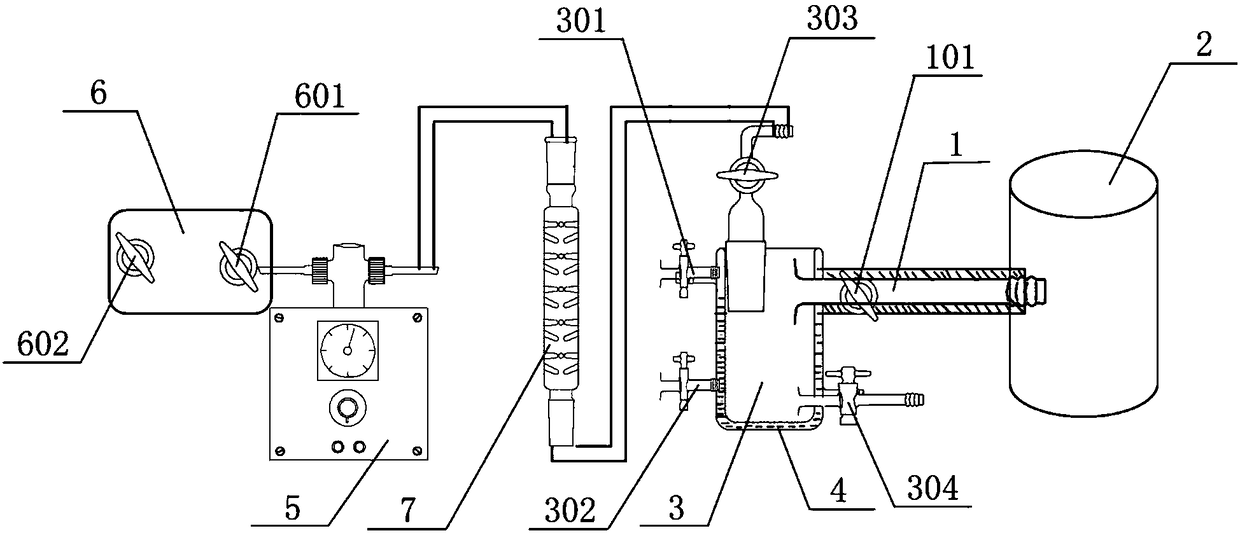

[0075] This embodiment provides a natural gas sampling device, which includes:

[0076] The tubular sampling probe 1 has one end sealed into the sampling port on the natural gas pipeline 2 through an open-hole rubber plug, and the other end is connected to the safety bottle 3. A first valve 101 is provided on the tubular sampling probe 1.

[0077] The upper part of the safety bottle 3 is provided with a second valve 303, and the lower part is provided with a drain valve 304.

[0078] The walls of the tubular sampling probe 1 and the safety bottle 3 are both hollow structures and communicate with each other to form a heat preservation cavity. The heat preservation cavity is filled with thermal oil to form a heating assembly 4. An oil inlet valve 301 and an oil outlet valve 302 are provided on the wall of the safety bottle 3.

[0079] The sampling pump 5, namely the atmospheric sampler, is connected to the safety bottle 3 through the first pipeline.

[0080] The sampling gas bag 6 is co...

Embodiment 2

[0083] This embodiment provides a method for obtaining a natural gas sample by using the device provided in Embodiment 1. The method includes:

[0084] Open the oil inlet valve 301 on the safety bottle 3, close the oil outlet valve 302, pour 160-200℃ heat conduction oil into the insulation cavity, and use the heating assembly 4 to keep the temperature of the safety bottle 3 and the tubular sampling probe 1 at 130-160 ℃, keep the sulfur element in natural gas liquid. Open the first valve 101, the second valve 303, the inlet valve 601, and the outlet valve 602, and extract the natural gas from the natural gas pipeline 2 through the sampling pump 5, so that the natural gas enters the sampling probe 1, the safety bottle 3, and the sampling pump 5. The air bag 6 is then discharged from the air outlet valve 602, so that the natural gas can displace the air in the natural gas sampling device to complete the emptying process of the natural gas sampling device.

[0085] The gas outlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com