Patents

Literature

56results about How to "Facilitate post-analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recording method of Android logs and mobile terminal

ActiveCN105204979AReduce space consumptionFacilitate post-analysisHardware monitoringEvent typeComputer terminal

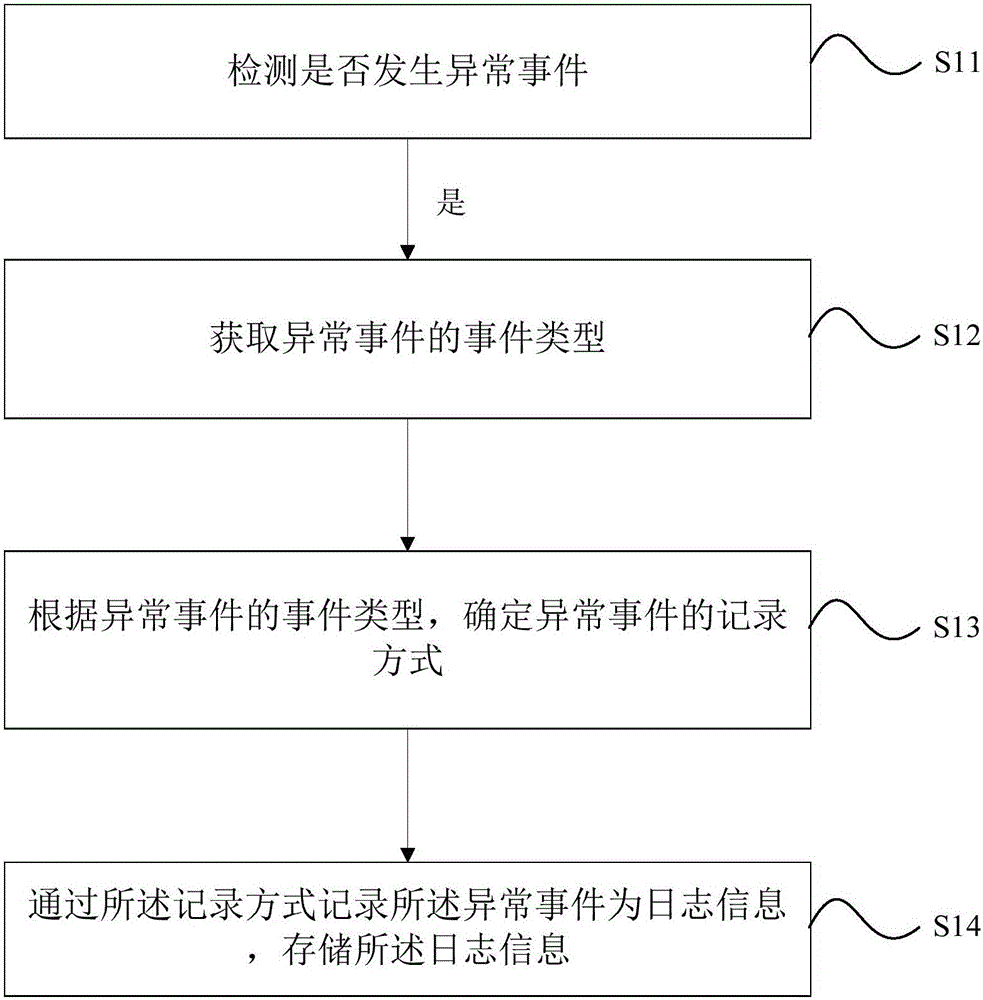

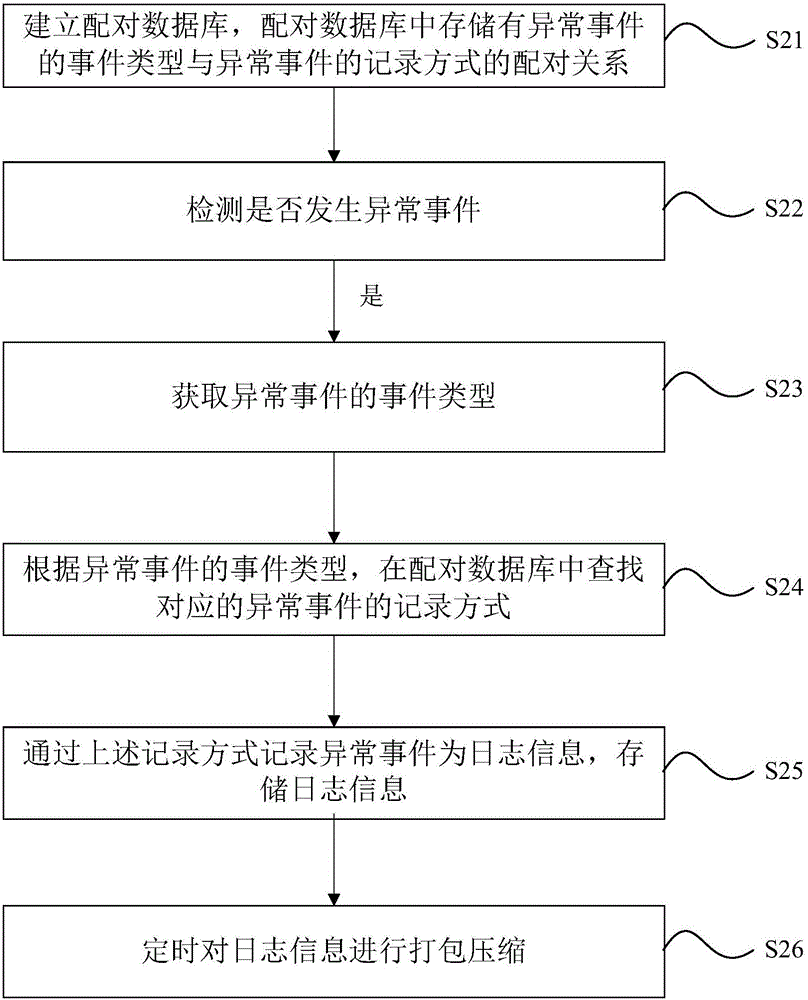

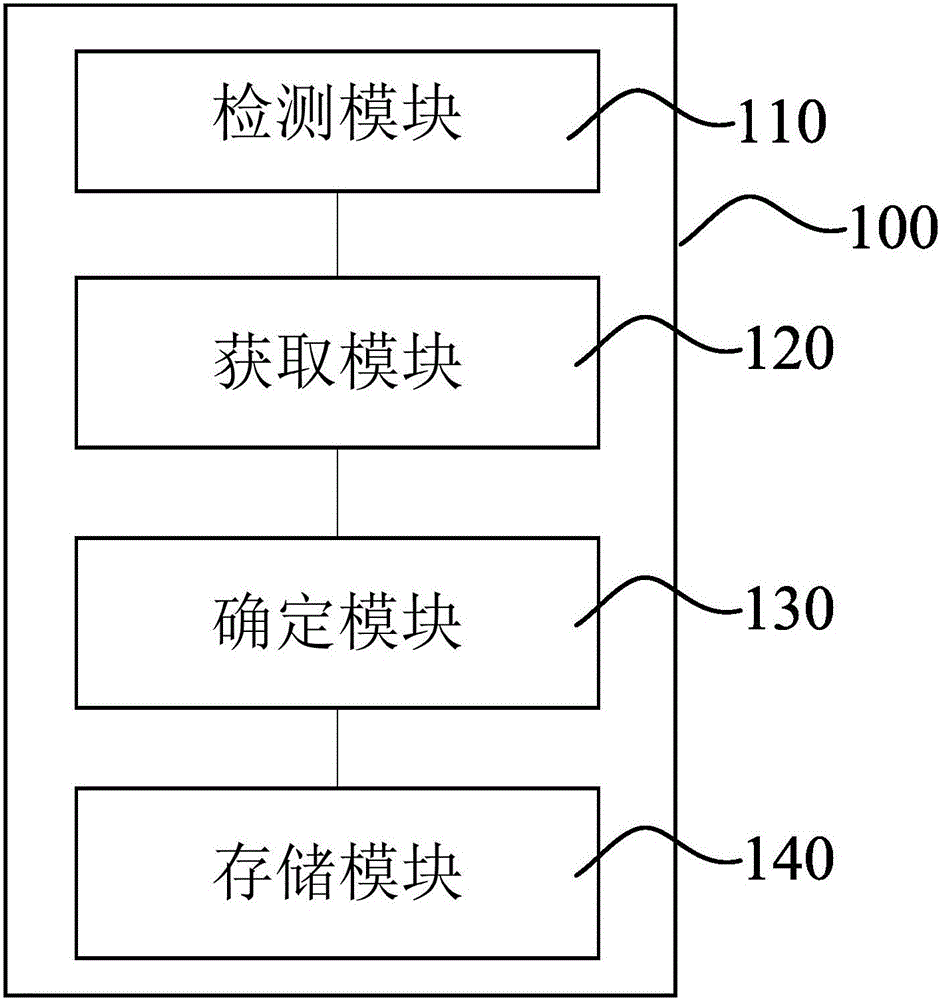

The invention relates to the technical field of mobile communication and discloses a recording method of Android logs. The recording method comprises the following steps: detecting whether an abnormal event occurs or not; if so, acquiring an event type of the abnormal event; determining a recording manner of the abnormal event according to the event type of the abnormal event; and recording the abnormal event as log information according to a recording manner, and storing the log information. The invention further discloses a mobile terminal which is controlled according to the method; the space occupation of the log information can be effectively reduced and the analysis work of the log information can be conveniently carried out by technology developers.

Owner:VIVO MOBILE COMM HANGZHOU CO LTD

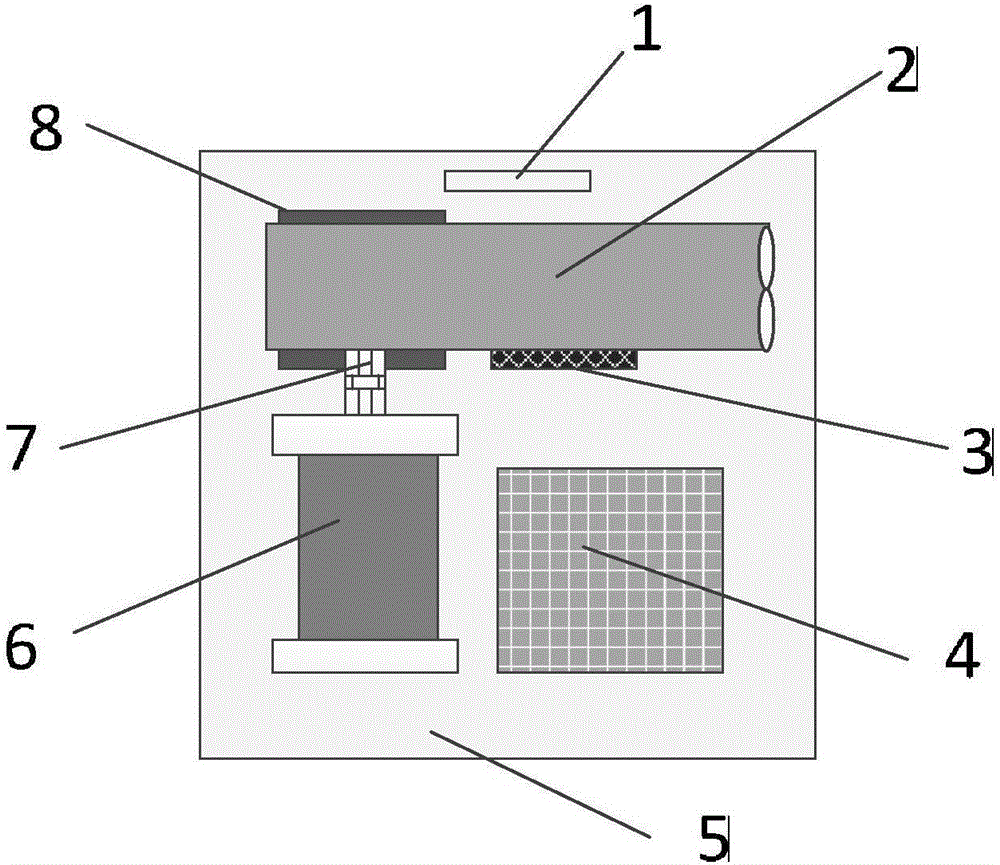

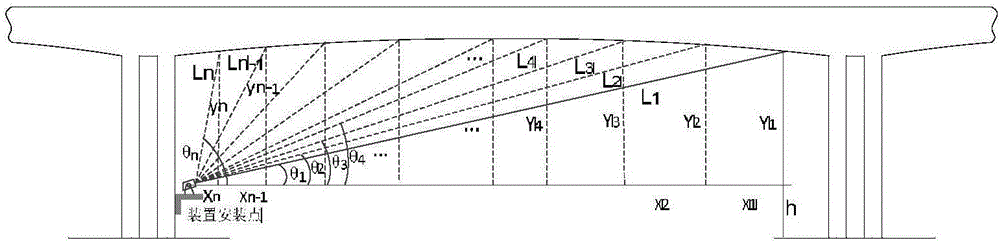

A Bridge Continuous Deformation Detection Device and Bridge Deflection Measurement Method

InactiveCN106353053AFacilitate post-analysisEasy to operateUsing optical meansElasticity measurementContinuous measurementCommunication interface

This invention discloses a bridge continuous deformation detection device and bridge deflection measurement method. The bridge continuous deformation detection device comprises a level module, distance measuring module, a dip-angle measurement module, a main control board, a mounting bracket, a stepper motor, a coupling and a rotating base. The distance measuring module and the rotating base constitute a rotating mechanism through the rotating axis, and is connected with the stepper motor through the coupling. The base is fixed on the upper surface of the mounting bracket. The dip-angle measuring module is mounted on the shell of the distance measuring module, which can rotate with it simultaneously. The base of the stepper motor, the main control board, and the level module are mounted on the upper surface of the mounting bracket. The main control board provides power supple and communication interface for the stepper motor, dip-angle measuring module and distancing measuring module. The bridge continuous deformation detection device, easy to operate, precise in detection and reliable in results, is suitable for long-term and continuous measurement of bridge deformation, and can further provide a prospect for on-line monitoring of deflection.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

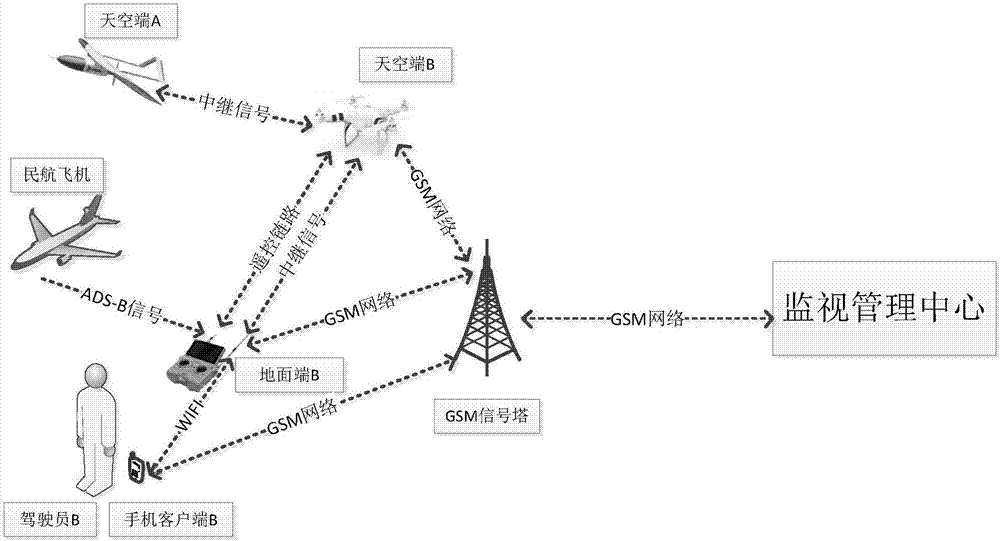

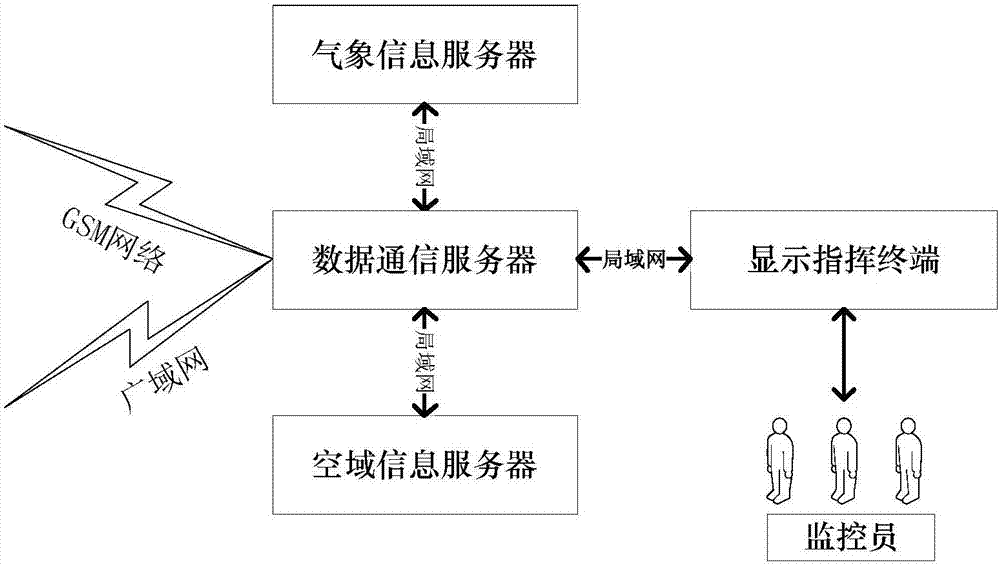

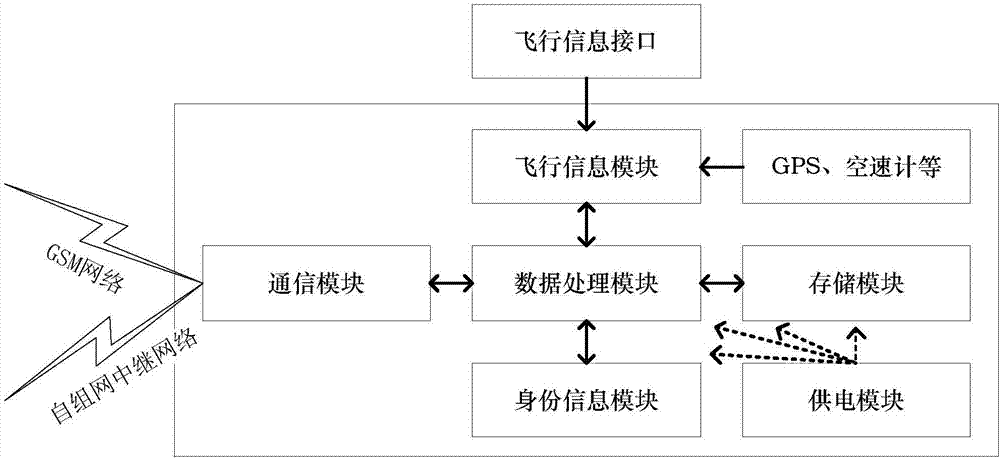

Unmanned aerial vehicle monitoring system based on ad hoc network relay and GSM communication

ActiveCN107274724ARealize real-time monitoringImprove abilitiesTransmission systemsSubstation equipmentSkyMonitoring system

The invention discloses an unmanned aerial vehicle (UAV) monitoring system based on ad hoc network relay and GSM communication. The system includes a monitoring management center, a UAV monitoring sky terminal, a UAV monitoring ground terminal, and a UAV monitoring sky mobile phone client. By combining an ad hoc network and GSM network communication, the scope of UAV real-time monitoring is expanded greatly. The UAV monitoring system of the invention receives civil aviation ADS-B information, and guides the driver to avoid relevant airspace to ensure the safety of aviation operation. The UAV monitoring system receives airspace restriction information and weather information to ensure the safety of UAV operation. The UAV monitoring system can authenticate a UAV and the driver thereof to ensure that the driver matches the UAV. The UAV monitoring system can record the flight track which is used as a data black box for later analysis. The monitoring management center of the UAV monitoring system can curb dangerous behaviors of UAV drivers.

Owner:中国航空器拥有者及驾驶员协会

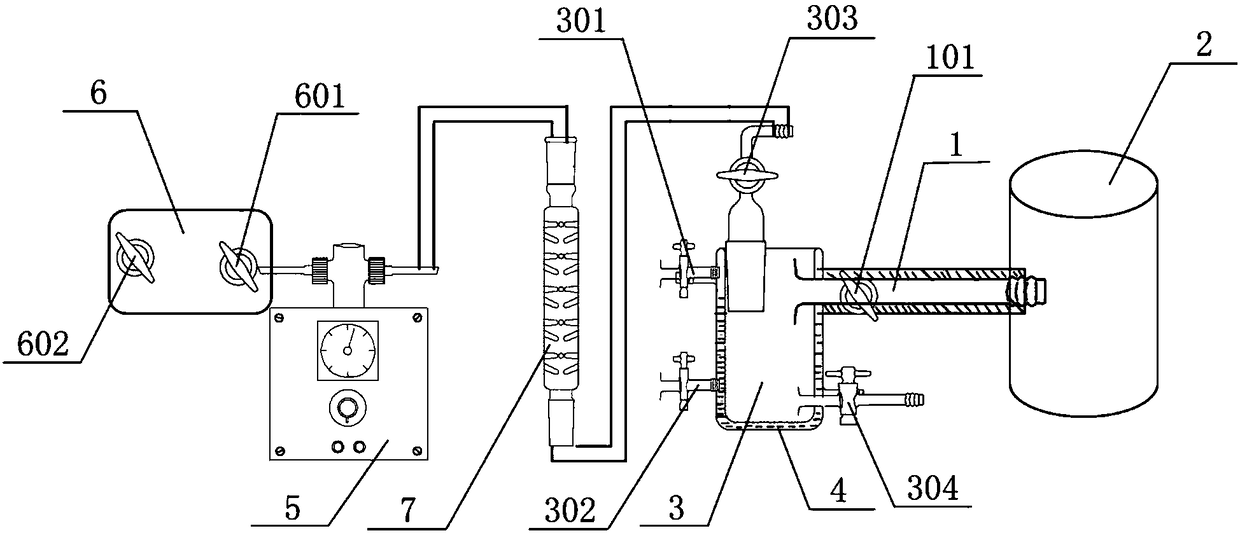

Method and device for washing and seal detecting of railway vehicle braking lines

ActiveCN102401725ASimple equipmentEasy to transportMeasurement of fluid loss/gain rateHollow article cleaningTesting equipmentEngineering

The invention relates to a method and a device for washing and seal detecting of railway vehicle braking lines. Air inlet lines and air outlet lines are communicated with each other at the inlet end and the outlet end of each braking line, an air inlet solenoid valve is arranged on each air inlet line, a plugging solenoid valve is connected with each air outlet line correspondingly, a pressure sensor used for detecting the air pressure in the line is arranged on each of the air outlet lines, and the air inlet solenoid valves, the plugging solenoid valves and the pressure sensors are respectively connected with a microcomputer. The microcomputer controls the opening and closing of the air inlet solenoid valves and air outlet solenoid valves according to the detected air pressure in the lines so as to complete the air inflation, exhausting and pressure maintaining process of the braking lines and merge line washing equipment and seal detecting equipment into a whole to complete the line washing and the seal detecting at one time; and the operation is simple, few equipment is required, and the cost is low; and the equipment operation is controlled by the microcomputer automatically, so that the labor intensity of workers is lowered, and the line washing and the quality as well as the precision of the sealing property detection can be ensured.

Owner:CRRC QINGDAO SIFANG CO LTD

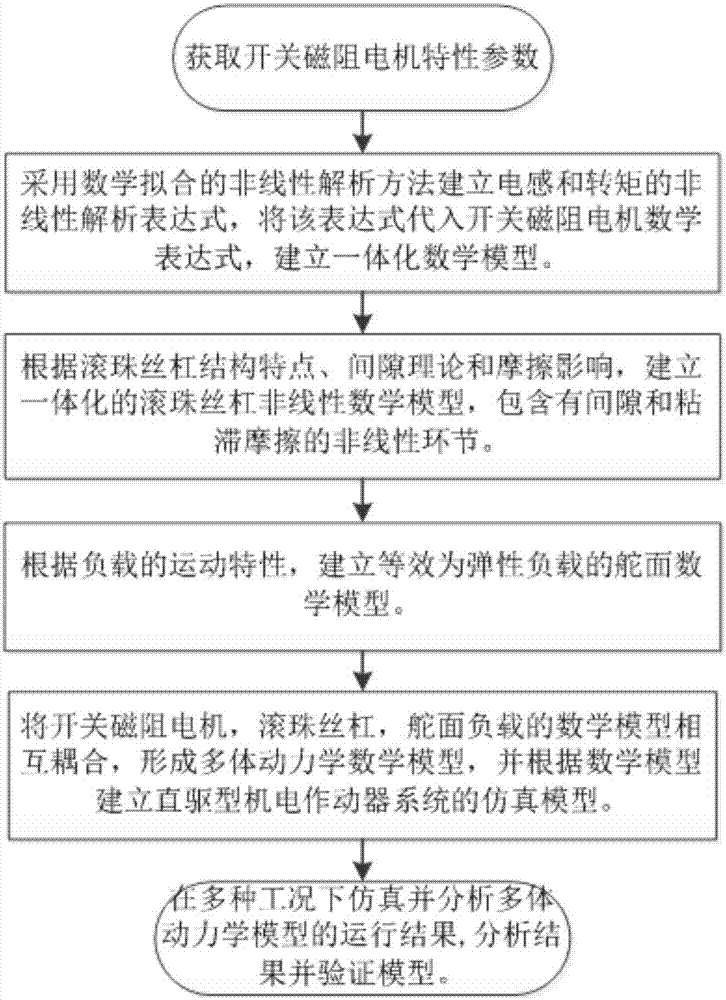

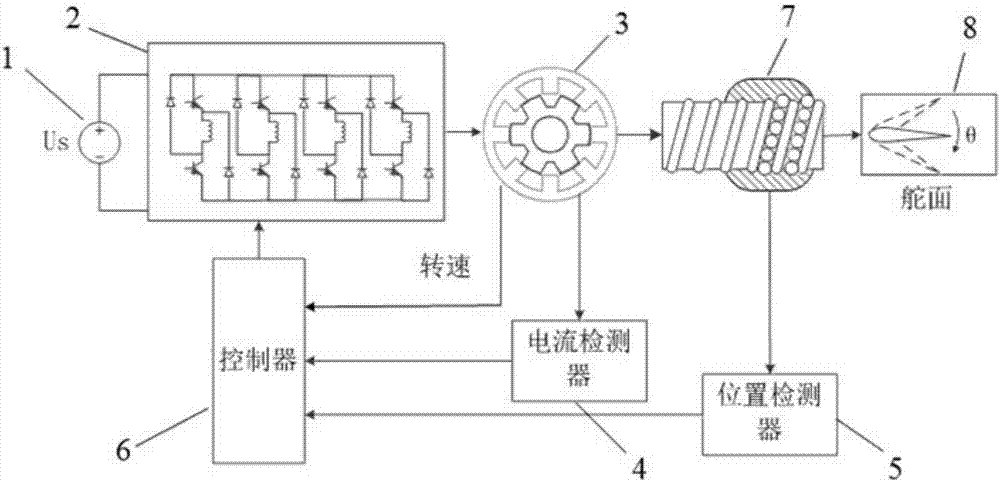

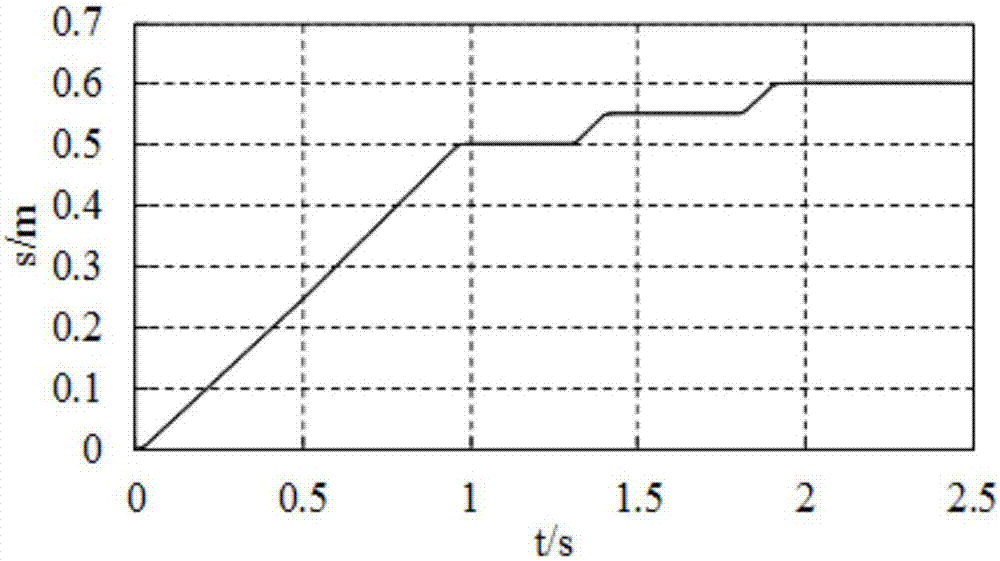

Many-body dynamics simulation analysis method for airborne direct-drive electromechanical actuator system

InactiveCN107168107AImprove work efficiencyImprove stabilitySimulator controlMathematical modelAnalysis method

The invention discloses a many-body dynamics simulation analysis method for an airborne direct-drive electromechanical actuator system, and the method gives consideration to nonlinear characteristics of a system. Moreover, the method is high in work efficiency, is good in stability, is simple and visual in operation, and facilitates the subsequent analysis. The employed technical scheme of the invention is that the method comprises the steps: 1), obtaining the characteristic parameters of a switch reluctance machine; 2), building an inductance and torque nonlinear analysis expression through a mathematic fitting nonlinear analysis method, substituting the expression into a mathematic expression of the switch reluctance machine, and building an integrated mathematic model; 3), building an integrated ball screw nonlinear mathematic model; 4), building a control surface mathematic model equivalent to an elastic load; 5), enabling the mathematic models of the switch reluctance machine, a ball screw and a control surface load to be coupled mutually, forming a many-body dynamics mathematic model, and building a simulation model for the direct-drive electromechanical actuator system according to the mathematic model; 6), simulating and analyzing an operation result of the many-body dynamics mathematic model under various work conditions.

Owner:XI AN JIAOTONG UNIV

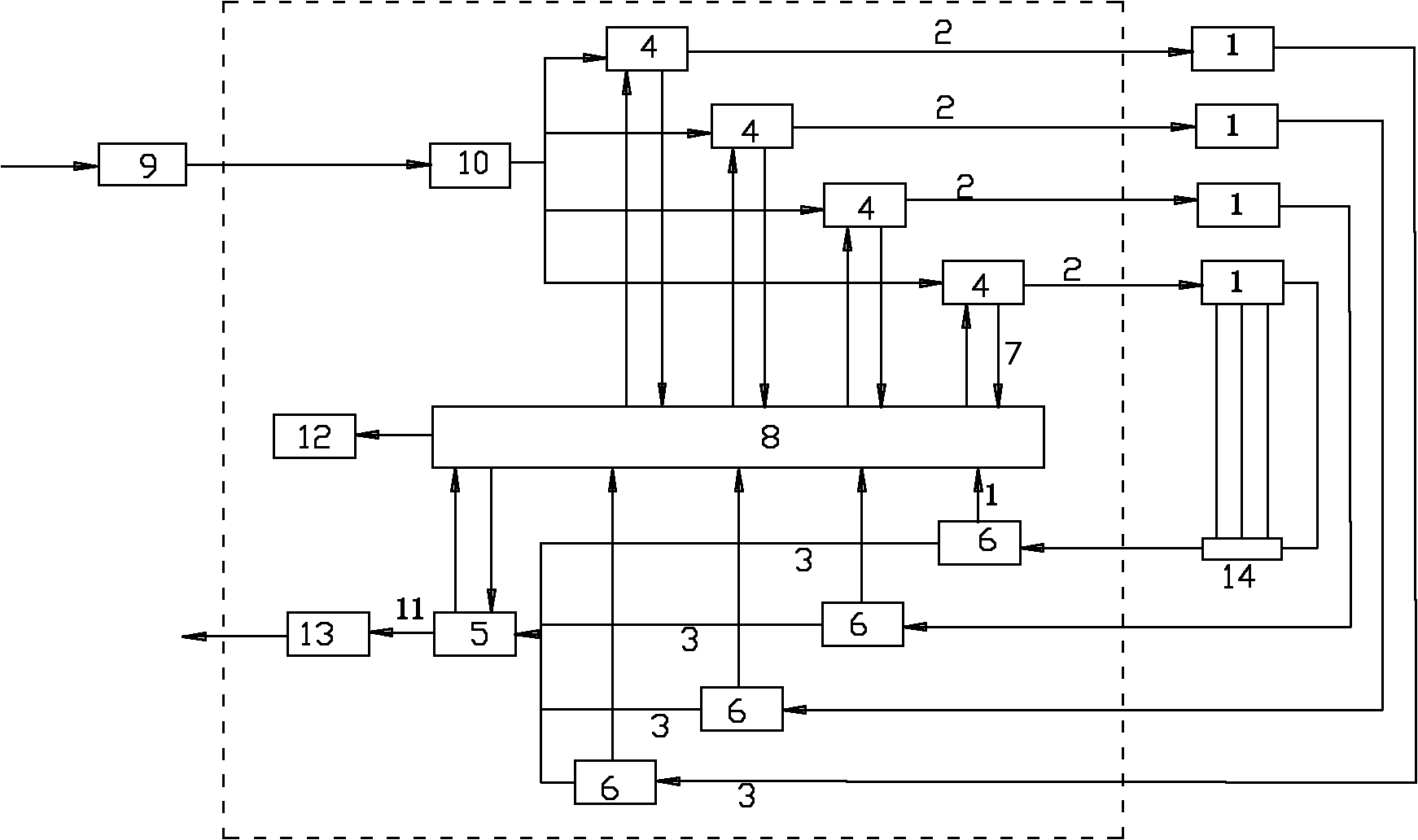

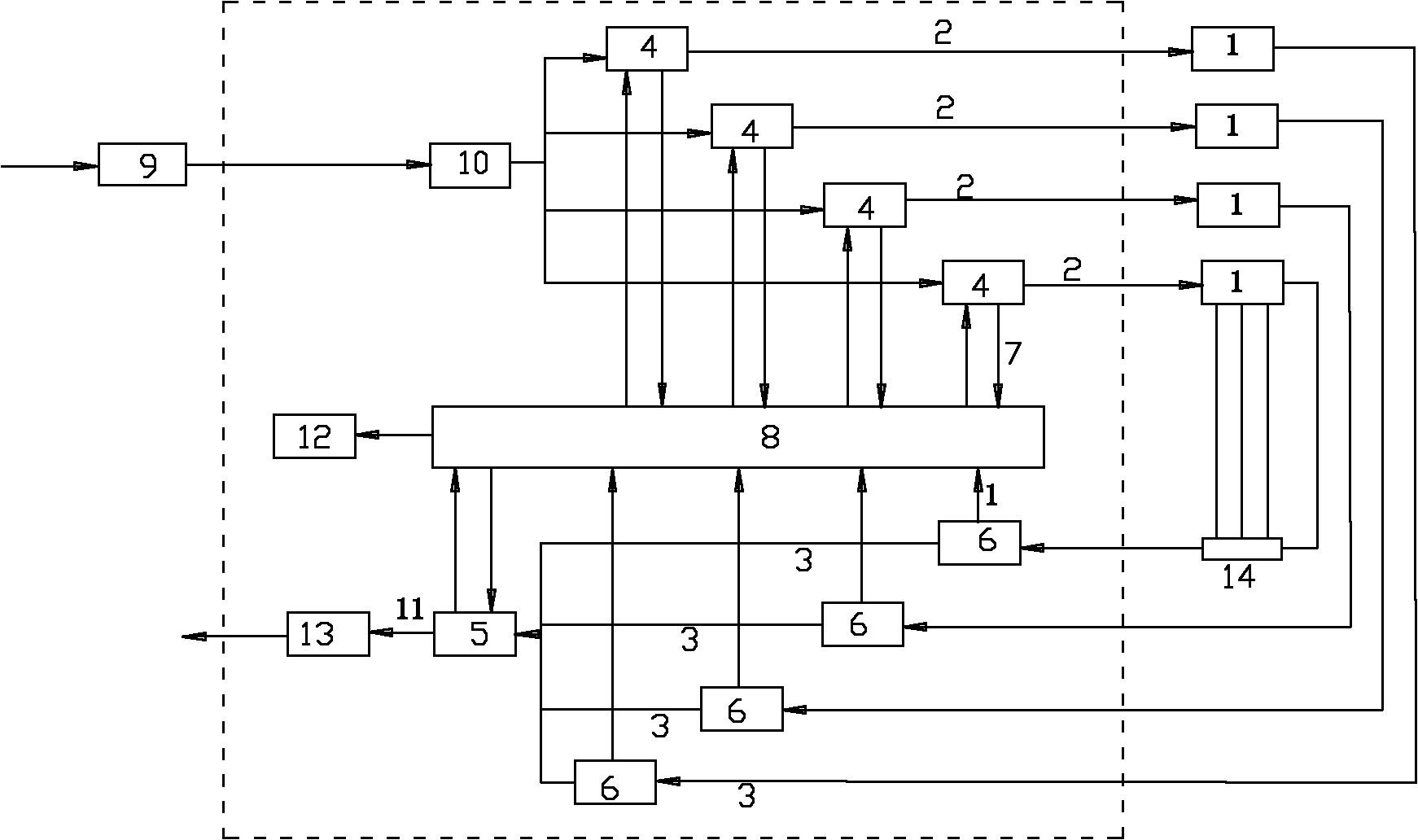

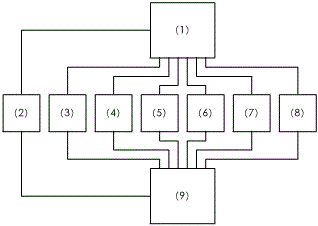

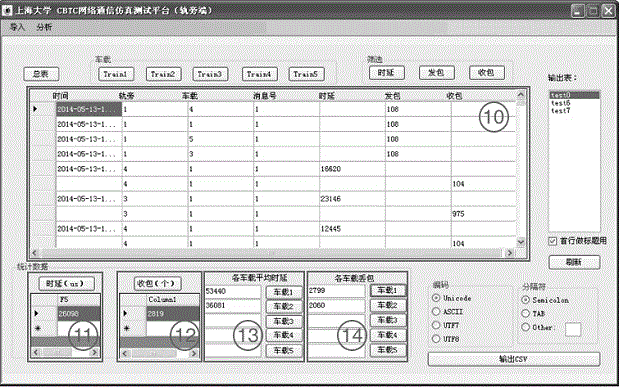

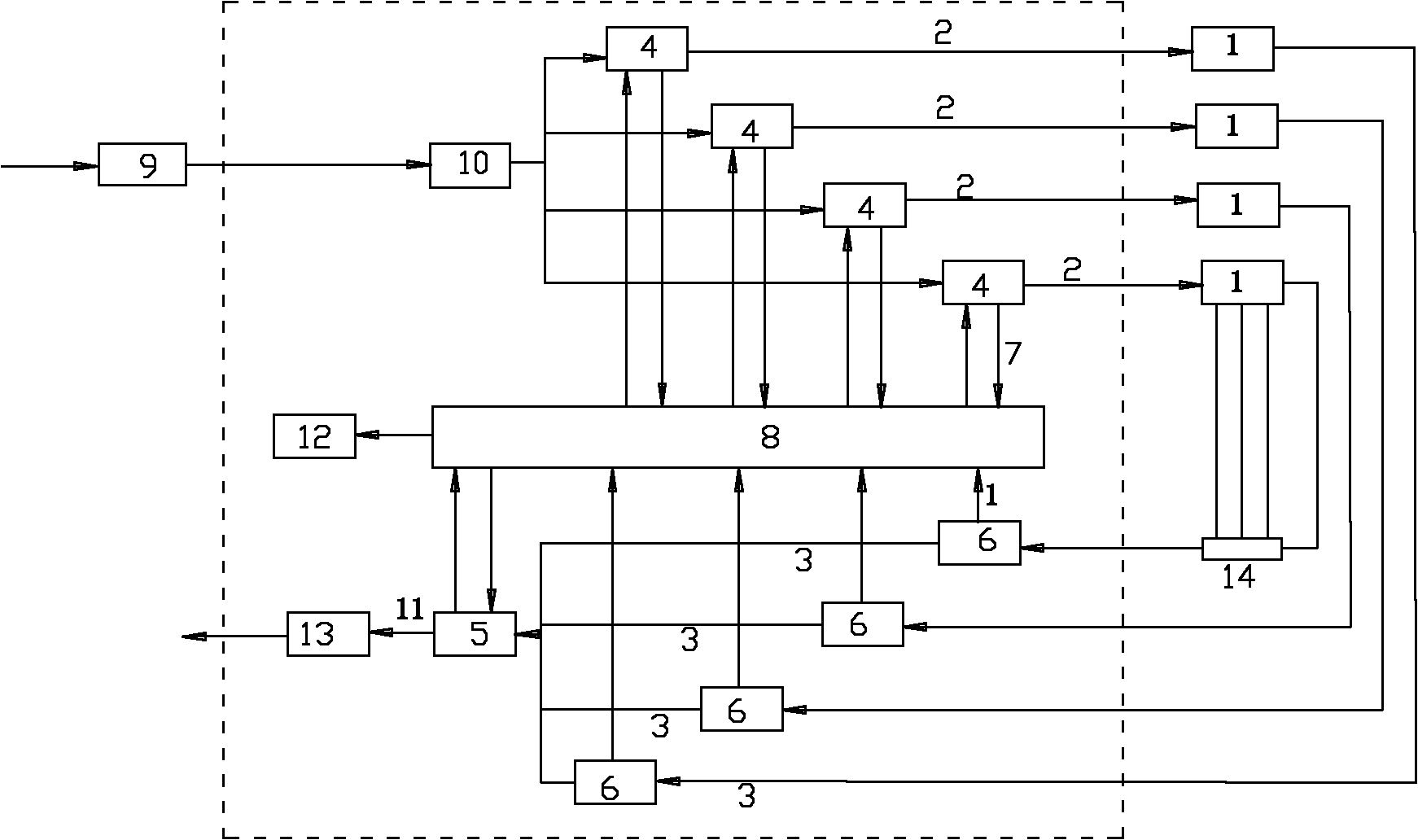

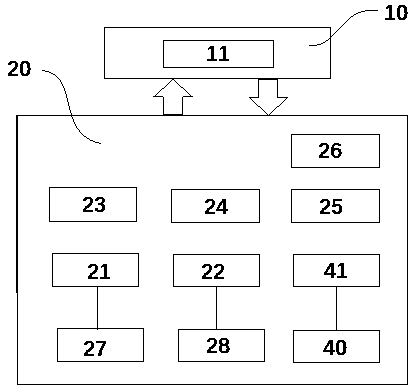

Dual-network-based rail transit train-ground communication detection platform

InactiveCN105791050AMeet the test requirementsFacilitate post-analysisSynchronisation arrangementRailway traffic control systemsData packData retrieval

The invention provides a dual-network-based rail transit train-ground communication detection platform comprising a to-be-detected communication based train control (CBTC) system, a trackside PC, n vehicle-mounted PCs, and a switch. The n is the number of to-be-detected zone trains. The trackside PC and the vehicle-mounted PCs are configured with dual-network cards; and one network card is connected to the to-be-detected CBTC system by a cable to form a train-ground communication network to transmit train-ground communication data and the other network card is connected to the switch by a cable to form a time synchronization network to realize time synchronization of the vehicle-mounted PCs and the trackside PC. With the platform, a CBTC system train-ground communication situation can be simulated indoors; and the communication performance of the CBTC system can be tested. A testing data statistic management system of the trackside PC can gather testing results of all vehicle-mounted PCs to the local unit; and an intelligent testing data retrieval system can carry out retrieving rapidly to obtain loss data packet information. Therefore, the CBTC system testing work efficiency can be improved; and a reference can be provided for testing researches and development of the CBTC system.

Owner:SHANGHAI UNIV

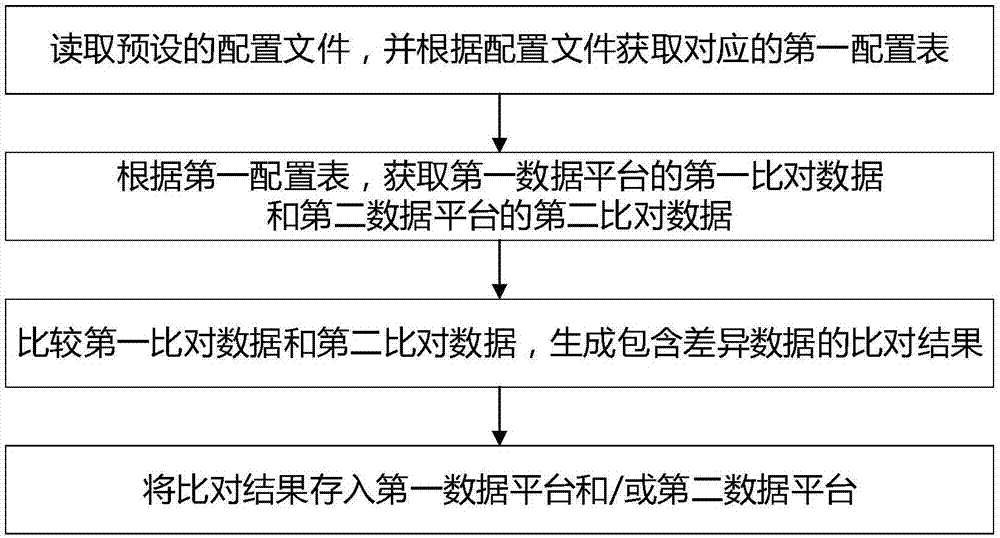

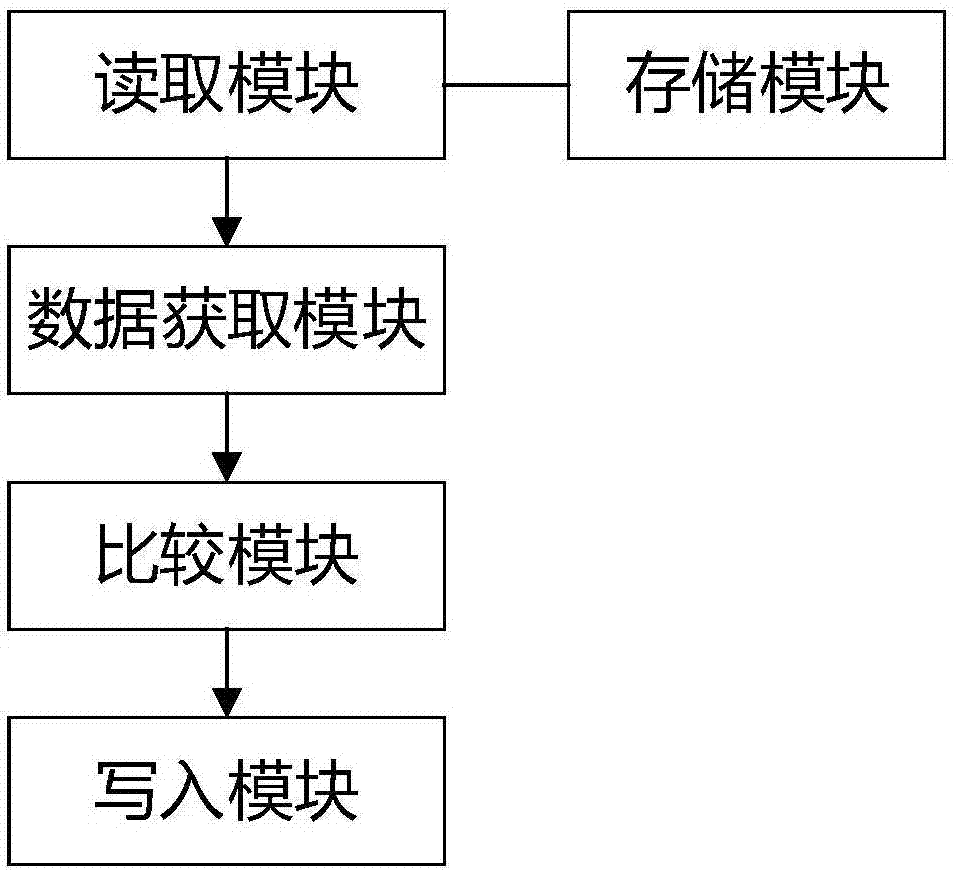

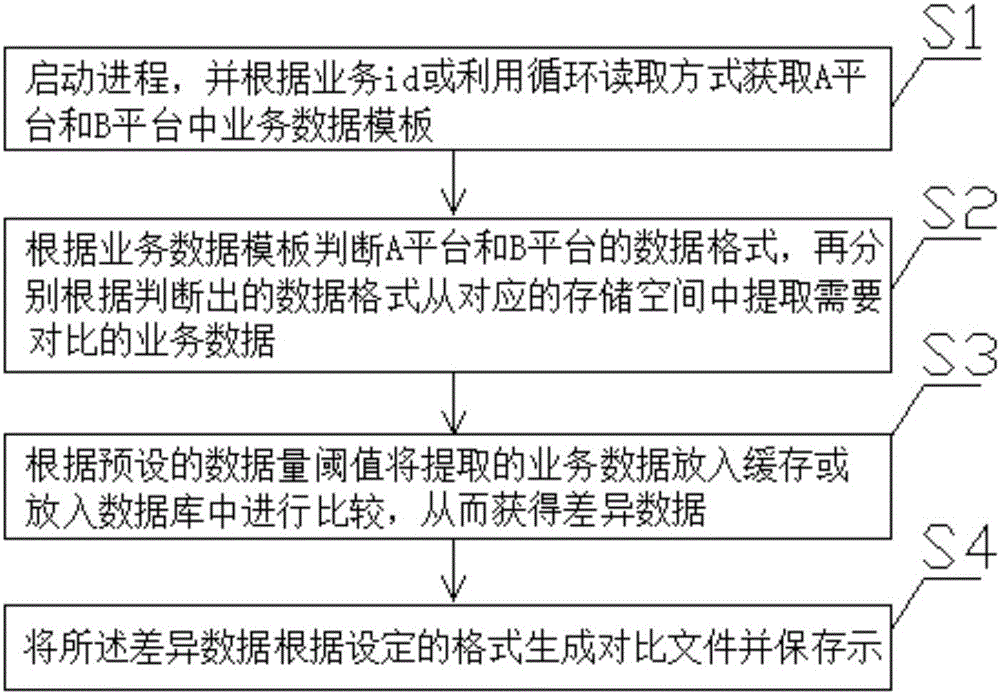

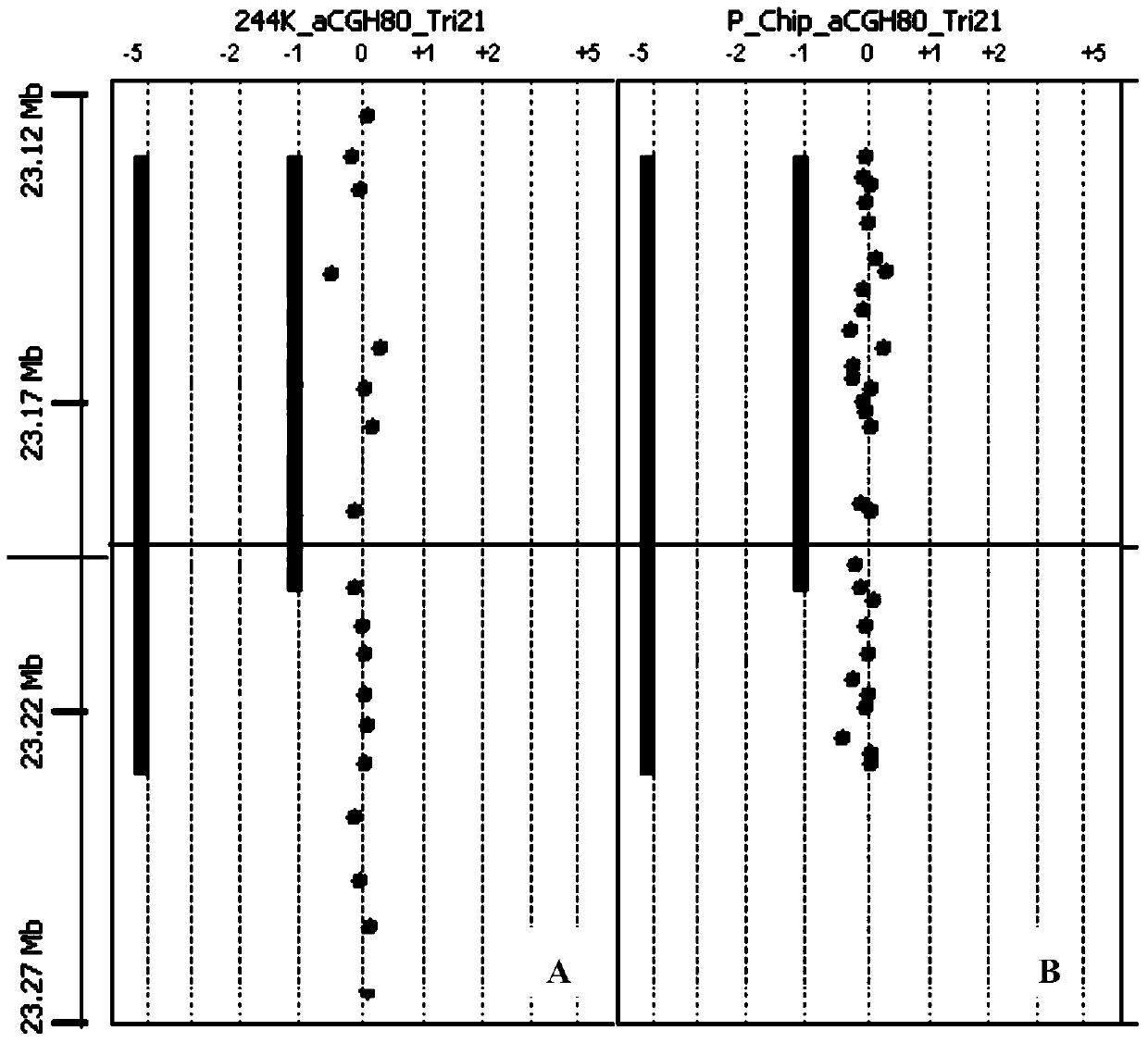

Data comparison method and system

InactiveCN107291827AThe comparison process is clearSteps to Simplify the ComparisonSpecial data processing applicationsData platformBusiness data

The invention particularly relates to a data comparison method and system. The method comprises the following steps of reading a preset configuration file and obtaining a corresponding first configuration table according to the configuration file; according to the first configuration table, obtaining first comparison data of a first data platform and second comparison data of a second data platform; comparing the first comparison data and the second comparison data to generate a comparison result containing differential data; and storing the comparison result in the first data platform and / or the second data platform. The data comparison process is separated from business logic and does not need to concern specific business data, so that a user does not need to rewrite a program; and the generated differential data can be stored or generates a file in a defined format, so that later analysis and processing are facilitated. Compared with an operation process in the prior art, the data comparison step is greatly simplified, the operation and maintenance costs are reduced, and the work of repeated code development is reduced.

Owner:北京思特奇信息技术股份有限公司

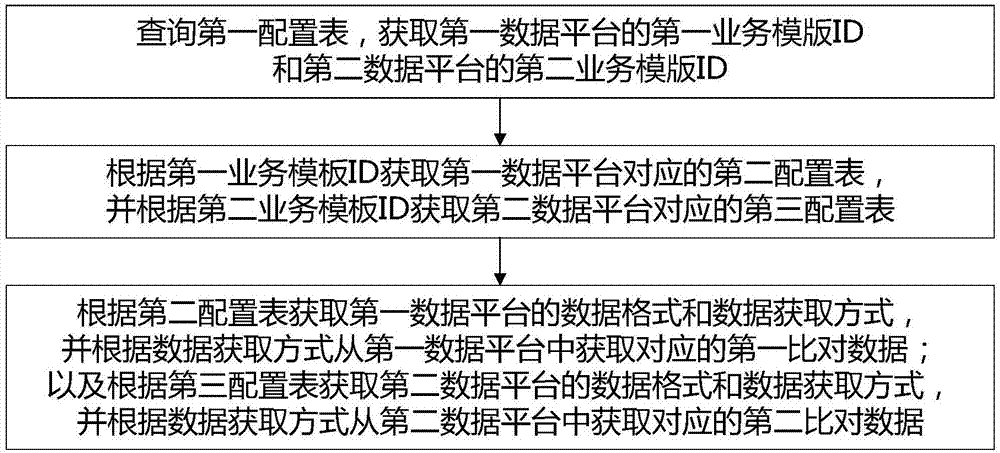

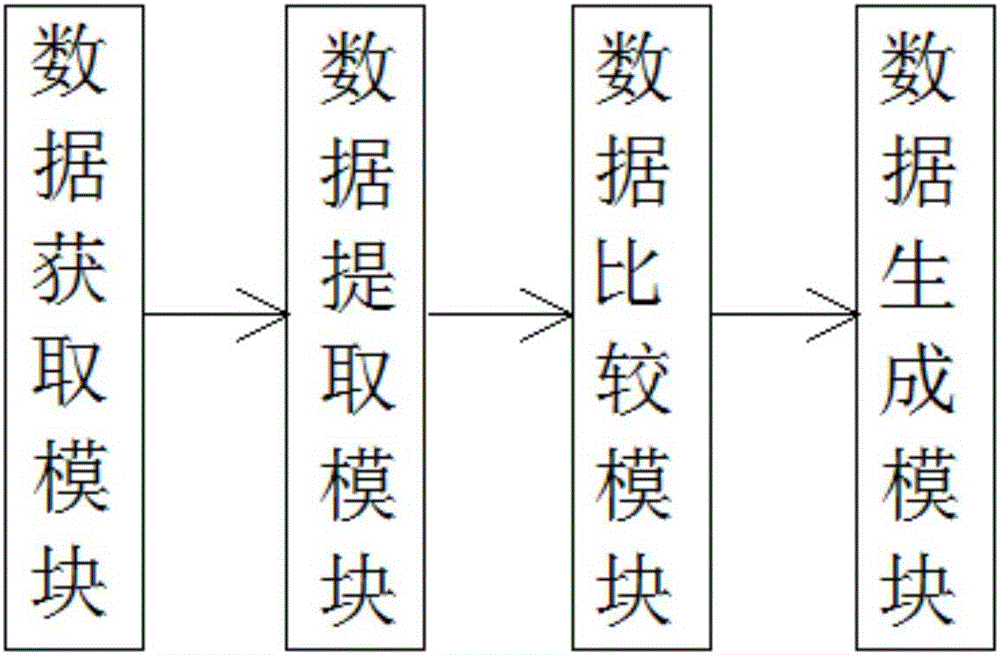

Comparing system and method for data having different file formats

ActiveCN106021301AFacilitate post-analysisEasy to handleDatabase distribution/replicationSpecial data processing applicationsData acquisition moduleDatabase

The invention provides a comparing system and method for data having different file formats. The comparing system includes: a data acquisition module for acquiring service data templates of an A platform and a B platform; a data extraction module for extracting service data to be compared from a corresponding storage space; a data comparing module for putting the extracted service data in a cache or a database to be compared; and a data generation module for allowing different data to generate a comparing file according to a preset format. The data comparing system does not have to concern service data, data comparing and a service body cannot be separated, various service responsible person needs performing configuration according to the corresponding format of a file, and then data processing can be performed; the different data is stored in the database or generates the file according to the preset format after data processing, and later analysis and processing is facilitated; and the step of data processing is simplified to the greatest extent, the operation and maintenance cost is reduced, and the working efficiency is improved.

Owner:北京思特奇信息技术股份有限公司

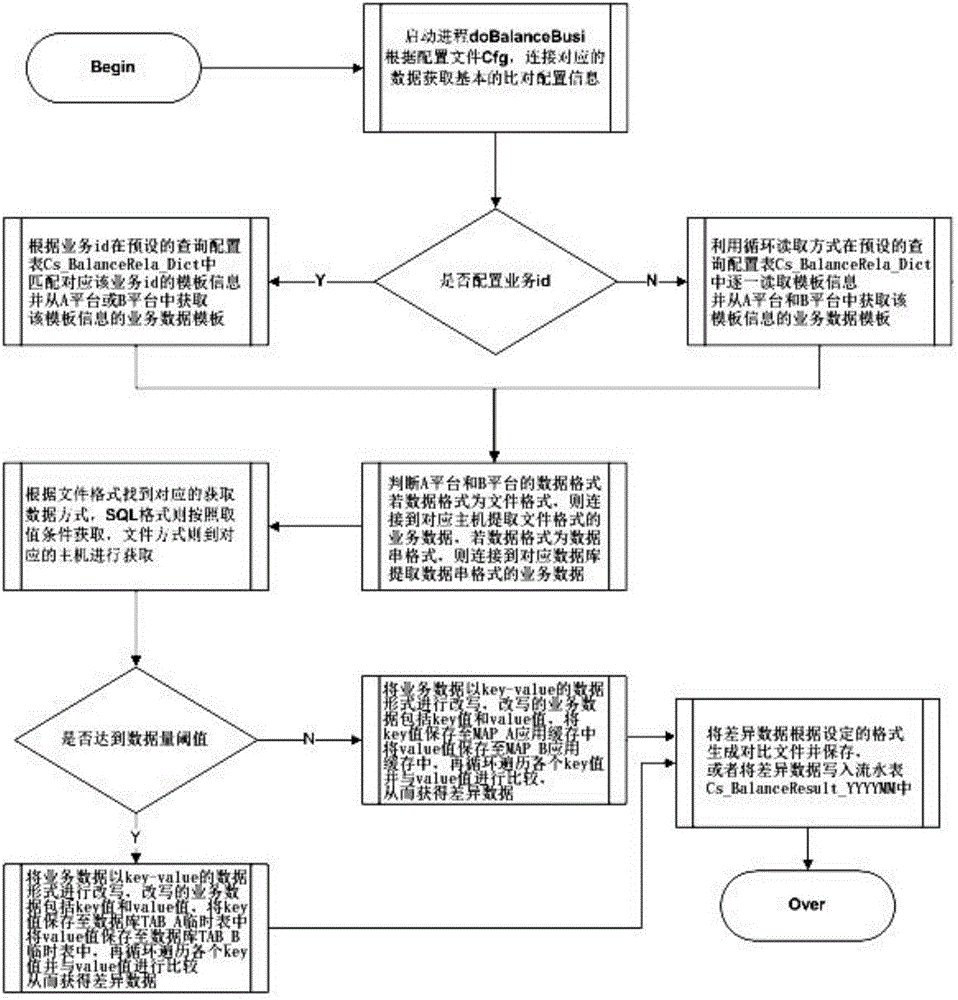

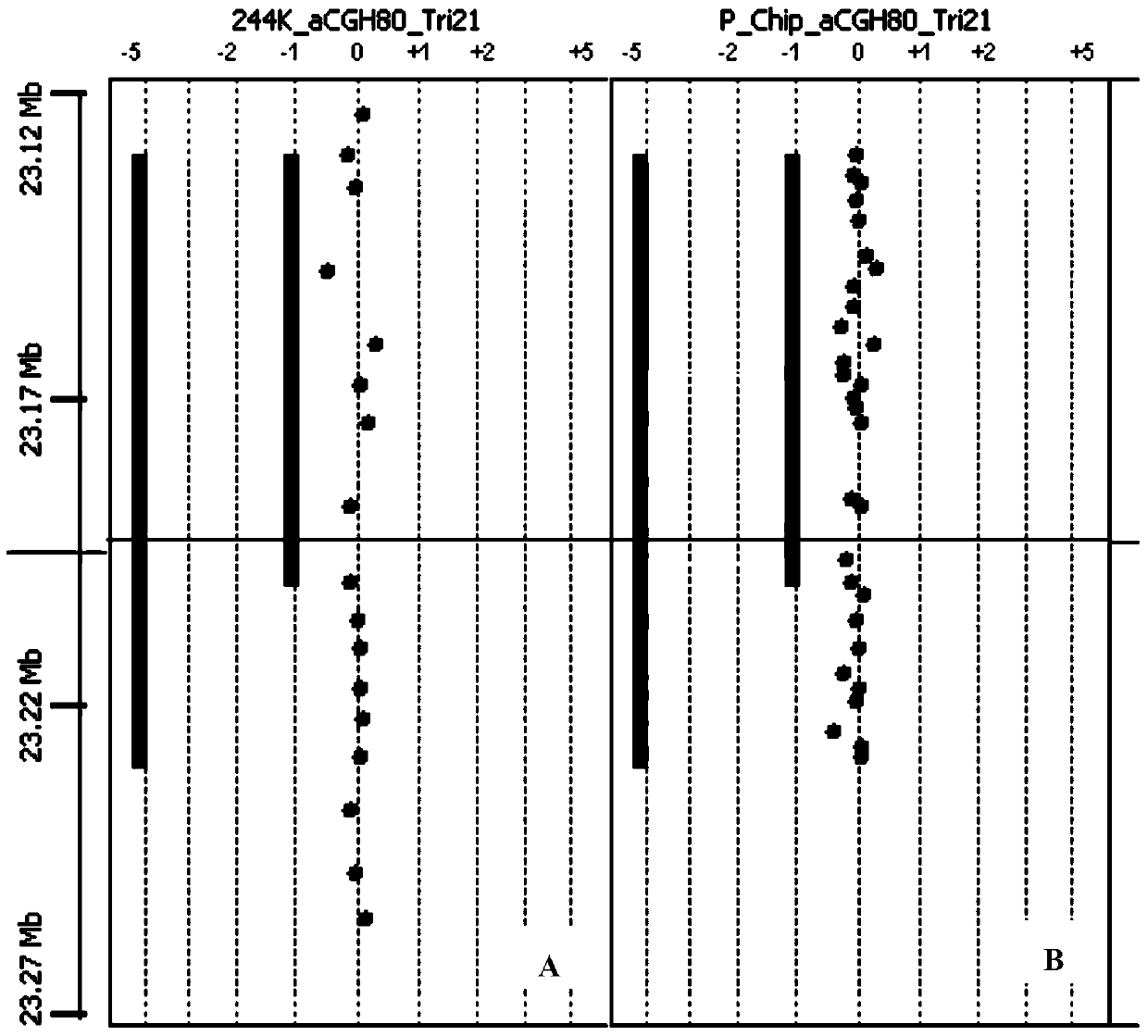

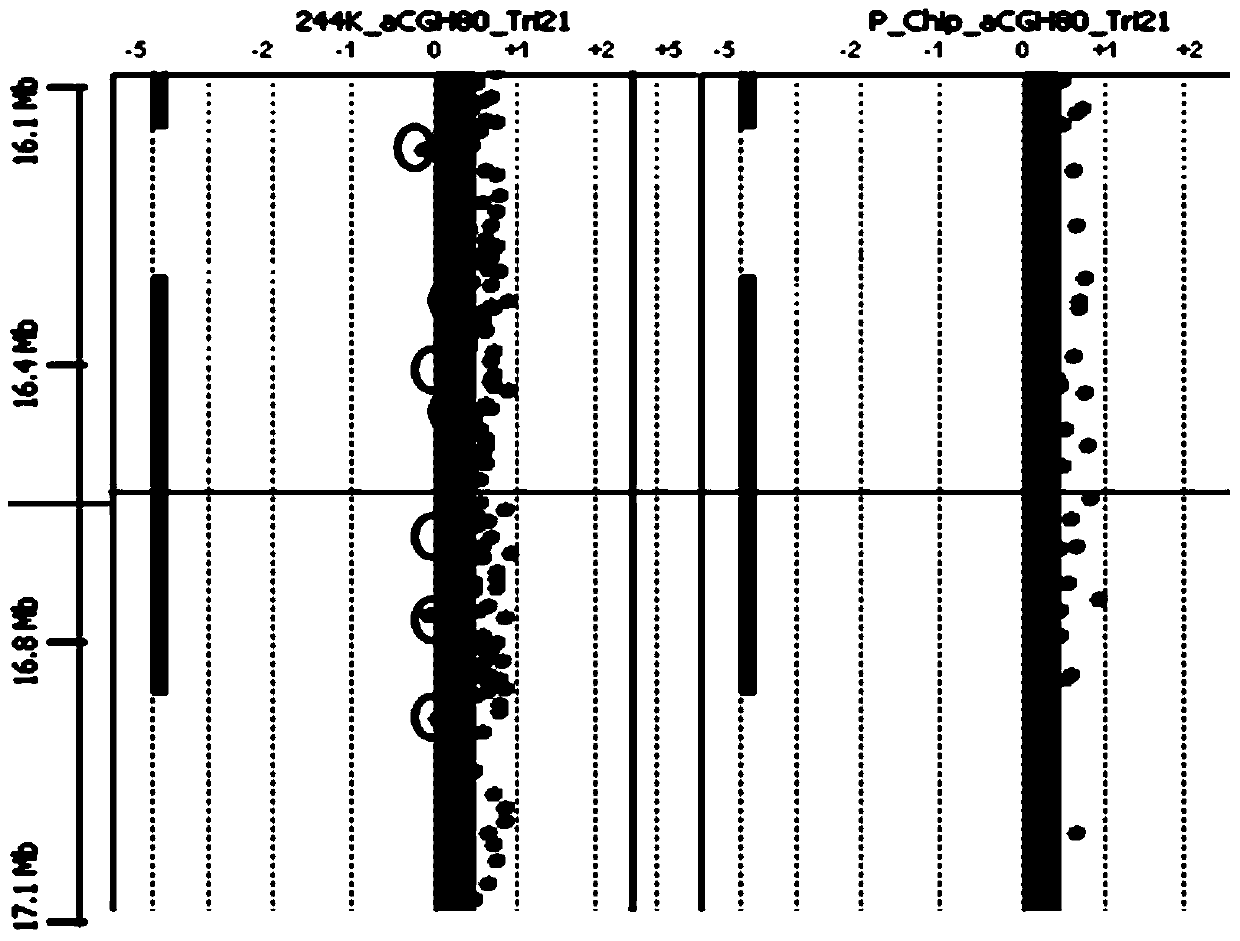

Fetal DNA (deoxyribonucleic acid) chip and application thereof

InactiveCN103740827AReduce background noiseEase of post-analysisBioreactor/fermenter combinationsBiological substance pretreatmentsSolid phasesImage resolution

The invention discloses a fetal DNA (deoxyribonucleic acid) chip and an application thereof. The fetal DNA chip comprises a solid phase carrier and oligonucleotide probe lattices fixed on the solid phase carrier, wherein the oligonucleotide probes comprise oligonucleotide sequences corresponding to genes related to 125 common fetal genetic or birth defect diseases in the gestation period; the 125 diseases include 1q21.2 deletion or repetition, 1q41-q42 fragment deletion and the like. The fetal DNA chip can be used for constructing a prenatal genetic screening system, has the characteristics of parallel analysis and multiple analysis, can be used for simultaneously detecting genetic variation related to 125 diseases, has high pathogenic interval resolution and disease detection accuracy and good reliability, can be used for accurately predicting and molecularly diagnosing common genetic diseases and birth defects caused by gene copy number abnormity at the early stage of pregnancy, is suitable for clinical application, can be used for mainly monitoring and effectively intervening in fetuses with diseases, and is favorable for further reducing the incidence of birth defects.

Owner:SHENZHEN RES INST THE CHINESE UNIV OF HONG KONG

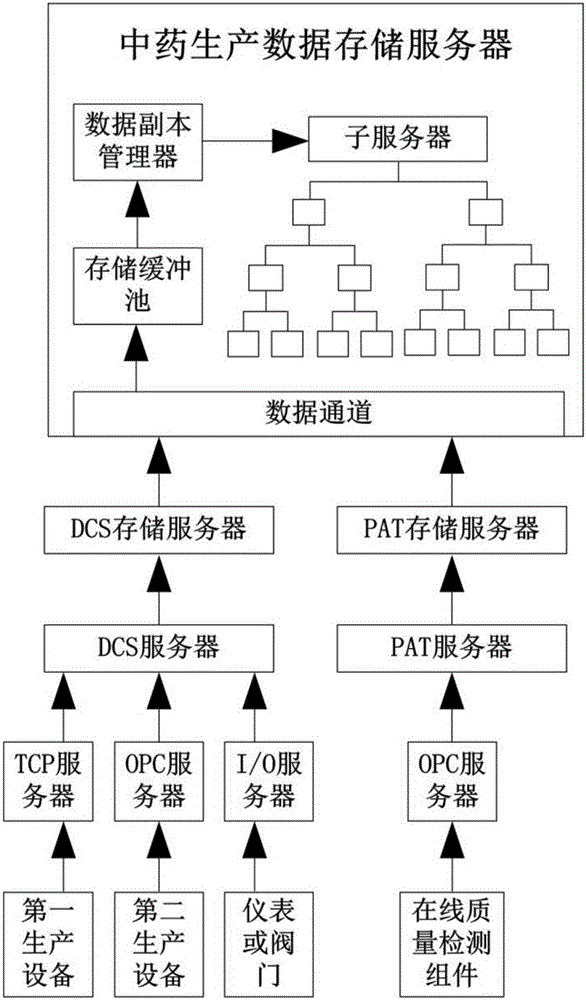

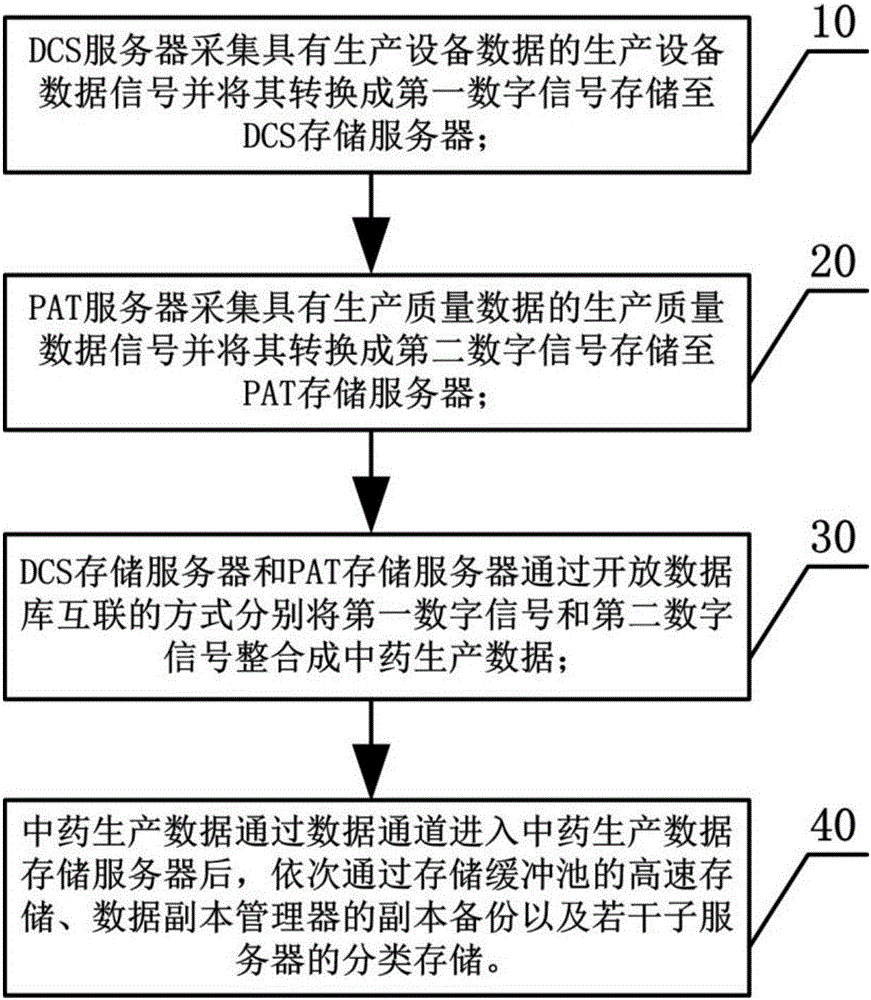

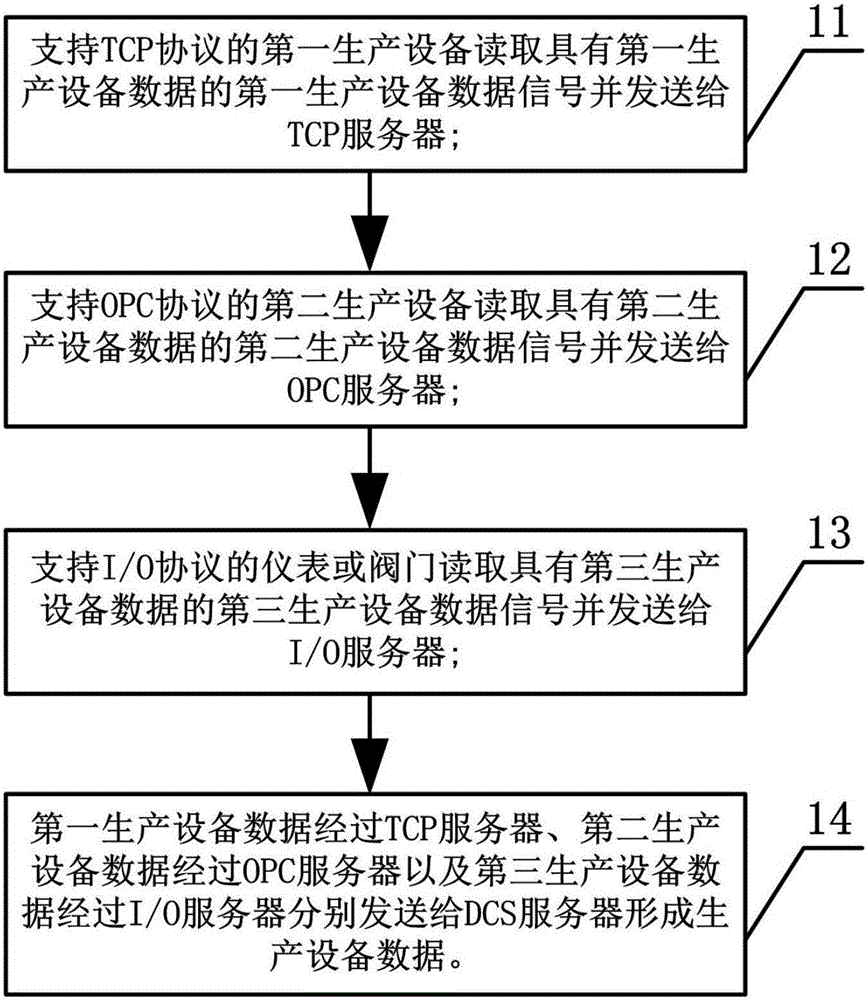

Processing method of traditional Chinese medicine production data

InactiveCN105897883AImplement copy backupRealize classified storageTransmissionDistributed control systemData signal

A processing method of traditional Chinese medicine production data disclosed by the present invention comprises the following steps of using a distributed control system (DCS) server to acquire the production equipment data signal possessing the production equipment data and transform the signal into a first digital signal and store in a DCS storage server; using a process analytical technology (PAT) server to acquire a production quality data signal possessing the production quality data and transform the signal into a second digital signal and store in a PAT storage server; using the DCS storage server and the PAT storage server to integrate the first digital signal and the second digital signal into the traditional Chinese medicine production data respectively in an open database connectivity manner; after the traditional Chinese medicine production data enters a traditional Chinese medicine production data storage server via a data channel, orderly using a storage buffer pool to carry out the high-speed storage, using a data copy management device to carry out the copy backup and using a plurality of sub-servers to carry out the classification storage, on the traditional Chinese medicine production data. The processing method of the present invention realizes the acquisition and storage of the traditional Chinese medicine production data, is convenient for the check, retrieval and later analysis of the traditional Chinese medicine production data, and is high in automation degree.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV +1

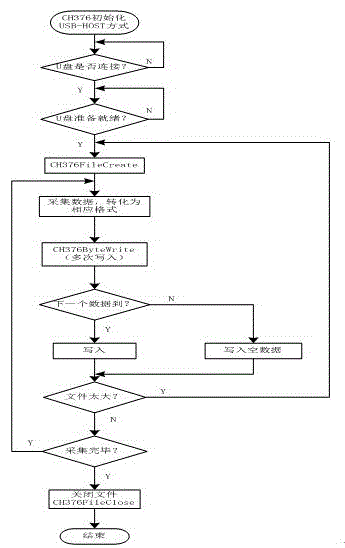

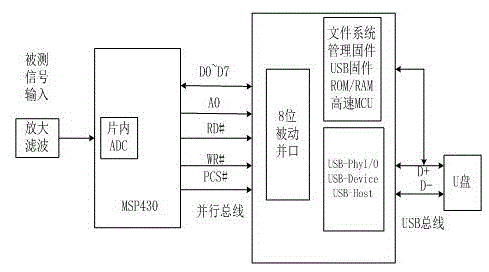

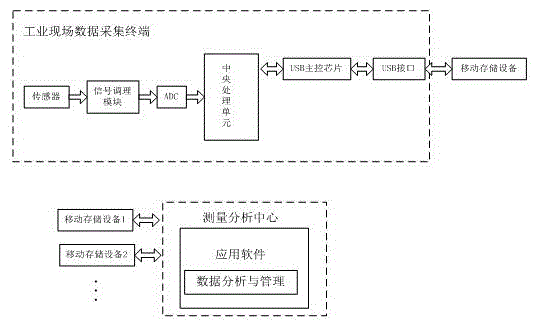

Distributed multi-terminal concurrent data acquisition and analysis system

InactiveCN105021221AFacilitate post-analysisEasy to carryMeasurement devicesData displayMass storage

The invention discloses a distributed multi-terminal concurrent data acquisition and analysis system. The system is formed by a measurement analysis system and data acquisition terminals, and a miniature distributed measurement and control system is formed. The task of each data acquisition terminal is to finish acquisition and storage of industrial on-site data; and the main task of the measurement analysis system is to be responsible for data analysis and management. Parameters of the plurality of data acquisition terminals are set through the measurement analysis system, and synchronous acquisition of the data is realized. The data acquisition terminals are externally connected high-capacity memories to enlarge storage capacity thereof. The system can realize synchronous acquisition and storage of on-site data of the same type of devices in different regions, carries out off-line data display, analysis and processing on the data in a mobile device in the measurement analysis system, and finds out and records the reasons of faults so as to provide reference for the subsequent analysis of the kind of device data. The system can realize synchronous acquisition, storage and analysis of multi-time and multi-occasion data, is convenient to carry and low in cost, and has good practical values and market prospect.

Owner:ANHUI NORMAL UNIV

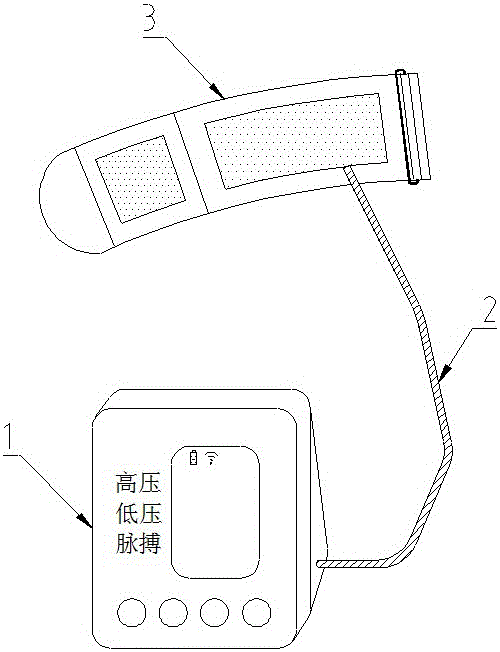

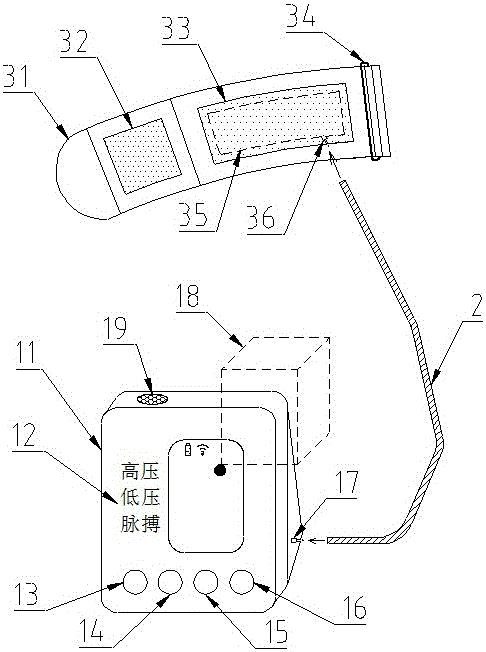

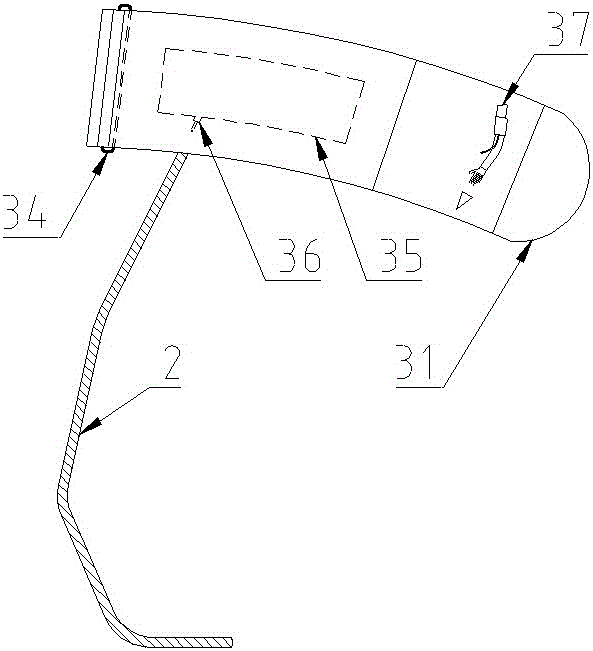

WiFi upper arm type intelligent electronic sphygmomanometer and using method thereof

InactiveCN106073740AAccurate measurement dataHigh level of integrationCatheterSensorsKey pressingOlder people

The invention discloses a WiFi upper arm type intelligent electronic sphygmomanometer. The WiFi upper arm type intelligent electronic sphygmomanometer comprises an electronic sphygmomanometer body, an air guide tube and an arm strap, wherein the electronic sphygmomanometer body comprises a shell; a display, a power key, a start / stop key, a storage key, a reading key, a first air guide nozzle and a loudspeaker are arranged on the outer surface of the shell; a functional circuit module is arranged inside the shell; a traction section, a hook surface, a loop surface, a metal ring and an indicating icon are arranged on the outer surface of the arm strap; an air bag is arranged inside the arm strap; a second air guide nozzle is arranged at the edge of the air bag; one end of the air guide tube is connected with the electronic sphygmomanometer body through the first air guide nozzle; and the other end of the air guide tube is connected with the arm strap through the second air guide nozzle. The invention further discloses a using method of the WiFi upper arm type intelligent electronic sphygmomanometer. The WiFi upper arm type intelligent electronic sphygmomanometer has the advantages of simplicity in operation, accurate measurement, automation and intelligence, and is quite suitable for patients suffering from disturbance of blood circulation and old people.

Owner:田曼丽

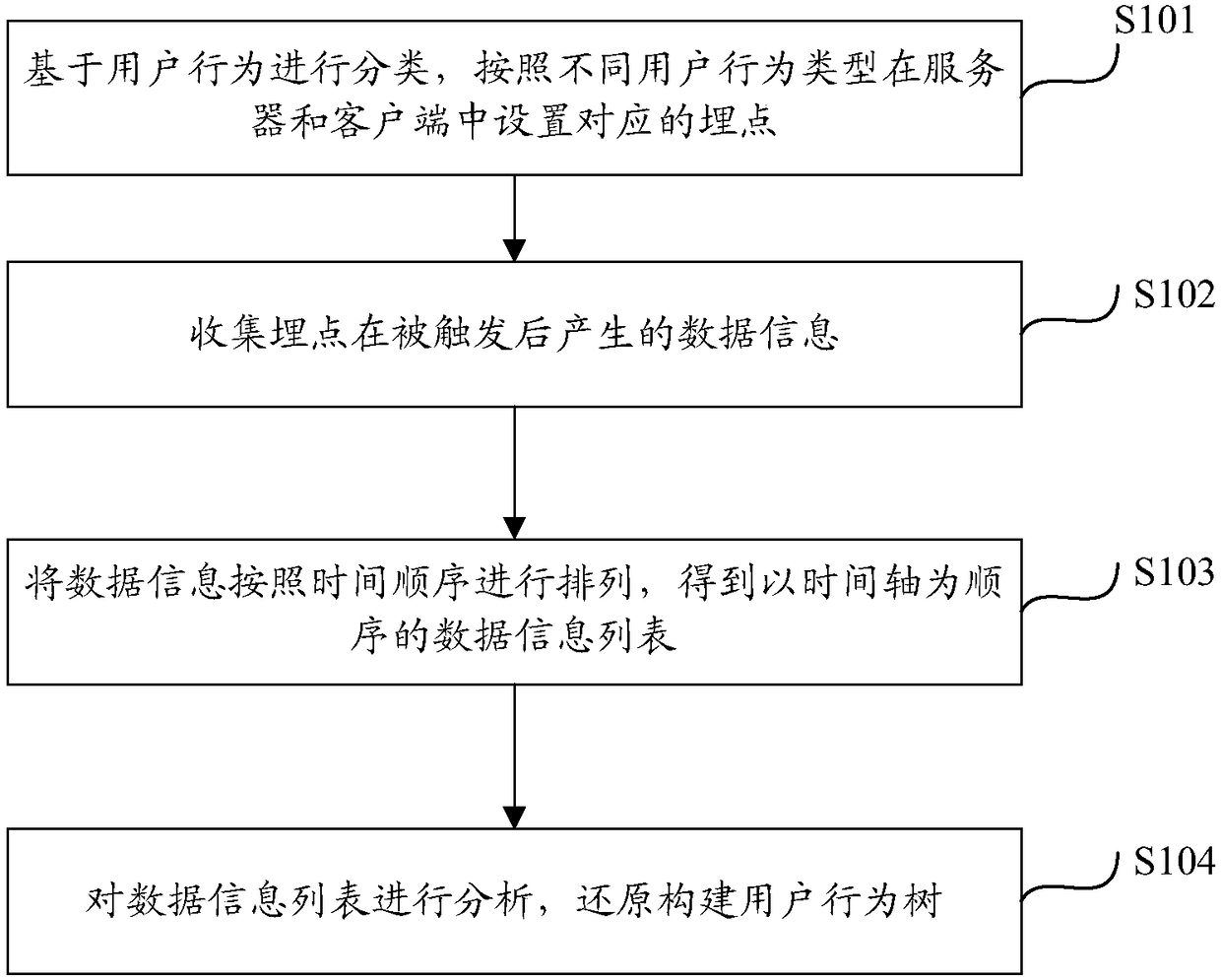

User behavior tree construction method and device

ActiveCN108574669ADoes not affect logicReduce workloadInternal/peripheral component protectionTransmissionData informationChronological time

The invention discloses a user behavior tree construction method and device. The method comprises the following steps: classifying based on user behaviors; setting corresponding burying points in a server and a client according to different user behavior types; collecting data information generated after the burying points are triggered; arranging the data information in a chronological order to obtain a data information list in an order of time axis; analyzing and restoring the data information list to construct a user behavior tree. By adoption of the method and the device in the invention,the data information of the user behaviors can be effectively collected; also, the collected data information is more accurate, which facilitates the later analysis. By analyzing and restoring the data information to construct the user behavior tree, the cost of code development and maintenance is reduced, and the work efficiency is improved.

Owner:ZHANGYUE TECH CO LTD

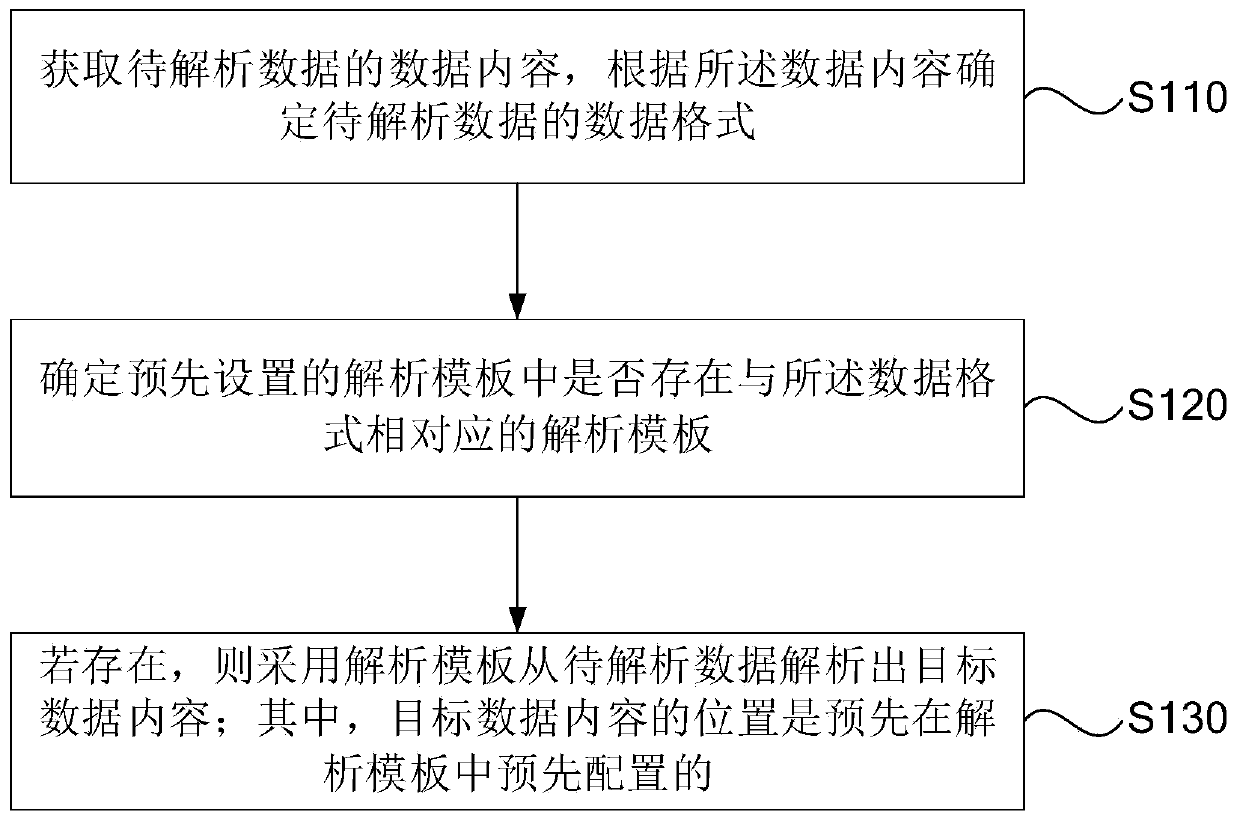

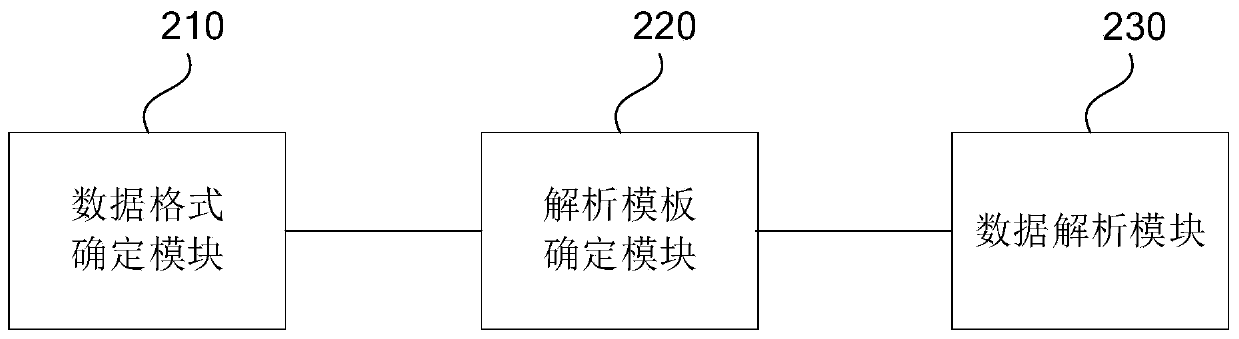

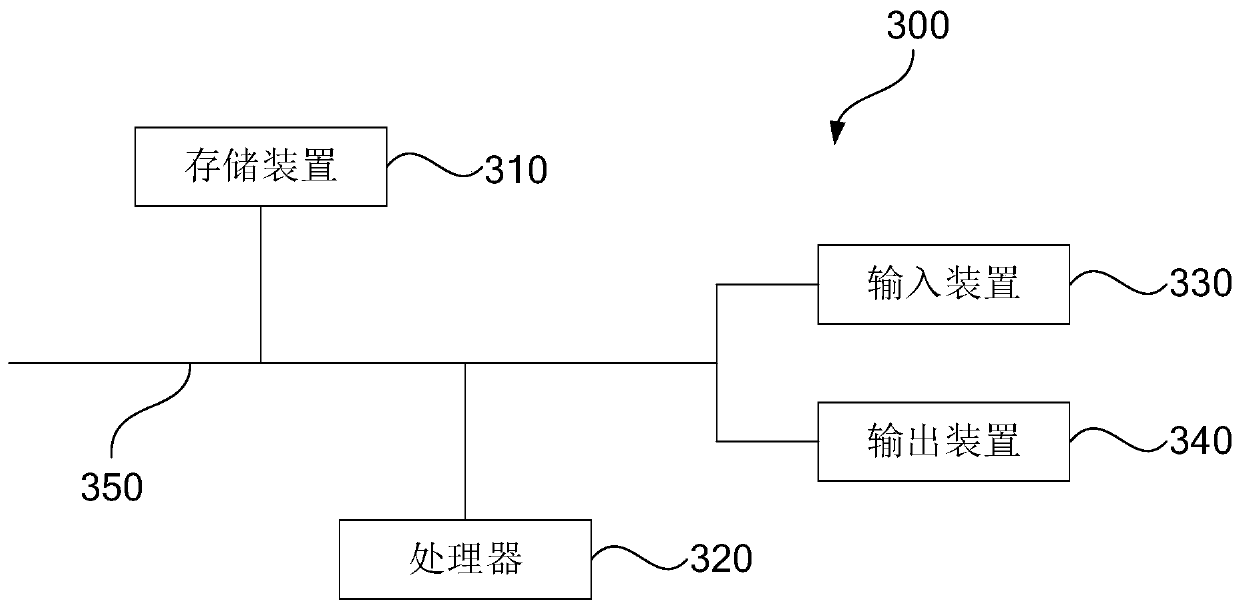

Data analysis method and device, storage medium and electronic device

PendingCN110765195AImprove efficiencyImprove data analysis qualityDatabase management systemsSpecial data processing applicationsData contentEngineering

The embodiment of the invention discloses a data analysis method and device, a storage medium and an electronic device. The method comprises the steps of obtaining data content of to-be-analyzed data,and determining a data format of the to-be-analyzed data according to the data content; determining whether an analysis template corresponding to the data format exists in preset analysis templates or not; if so, analyzing the to-be-analyzed data by adopting the analysis template to obtain the target data content; wherein the position of the target data content is pre-configured in the analysis template in advance. By implementing the technical scheme provided by the invention, the effect of improving the data analysis efficiency and the data analysis quality can be achieved.

Owner:RUN TECH CO LTD BEIJING

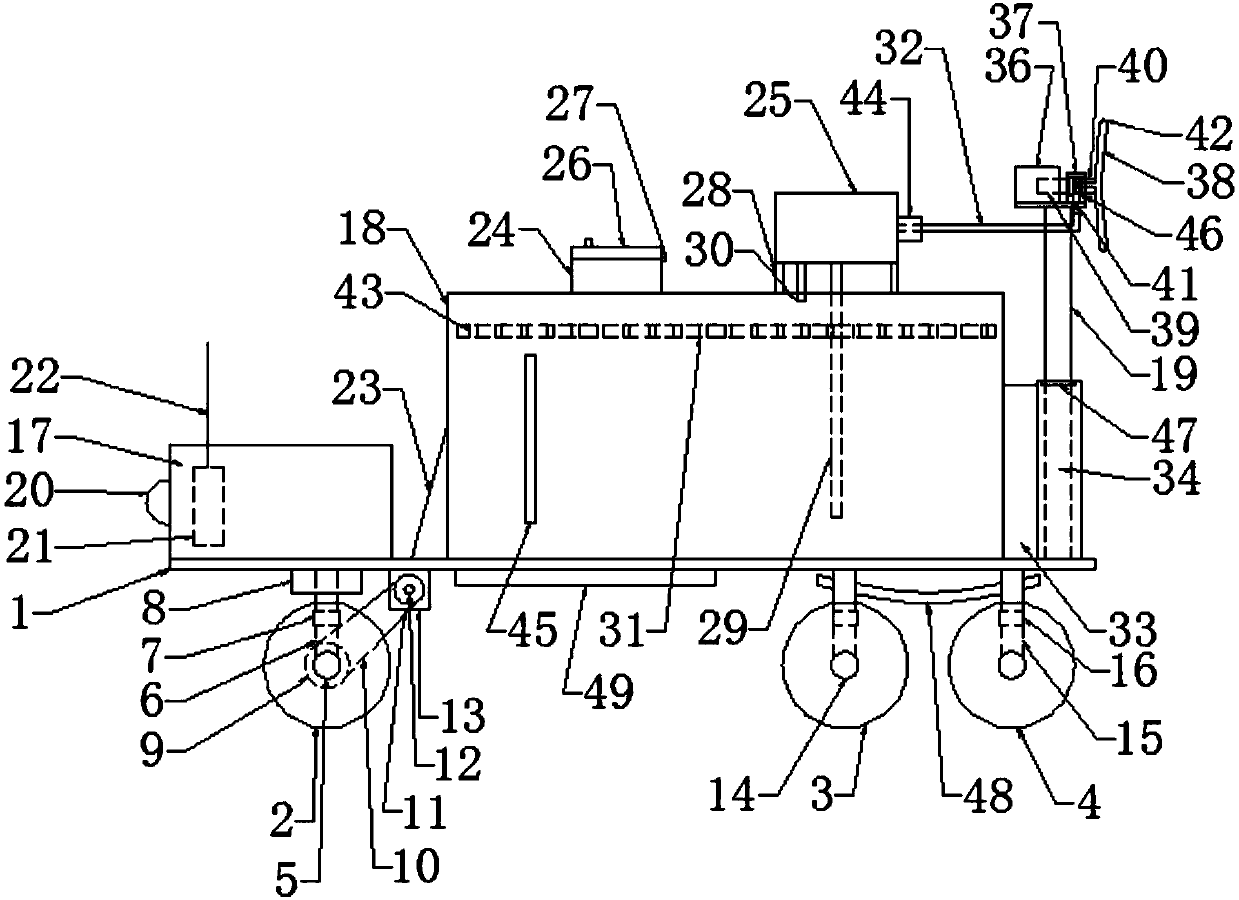

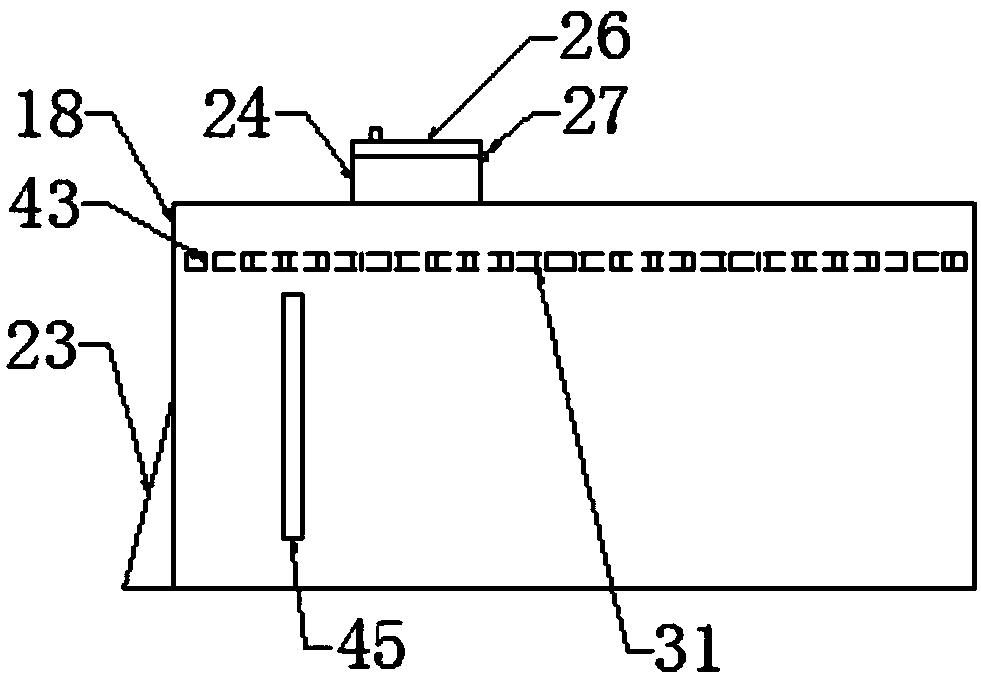

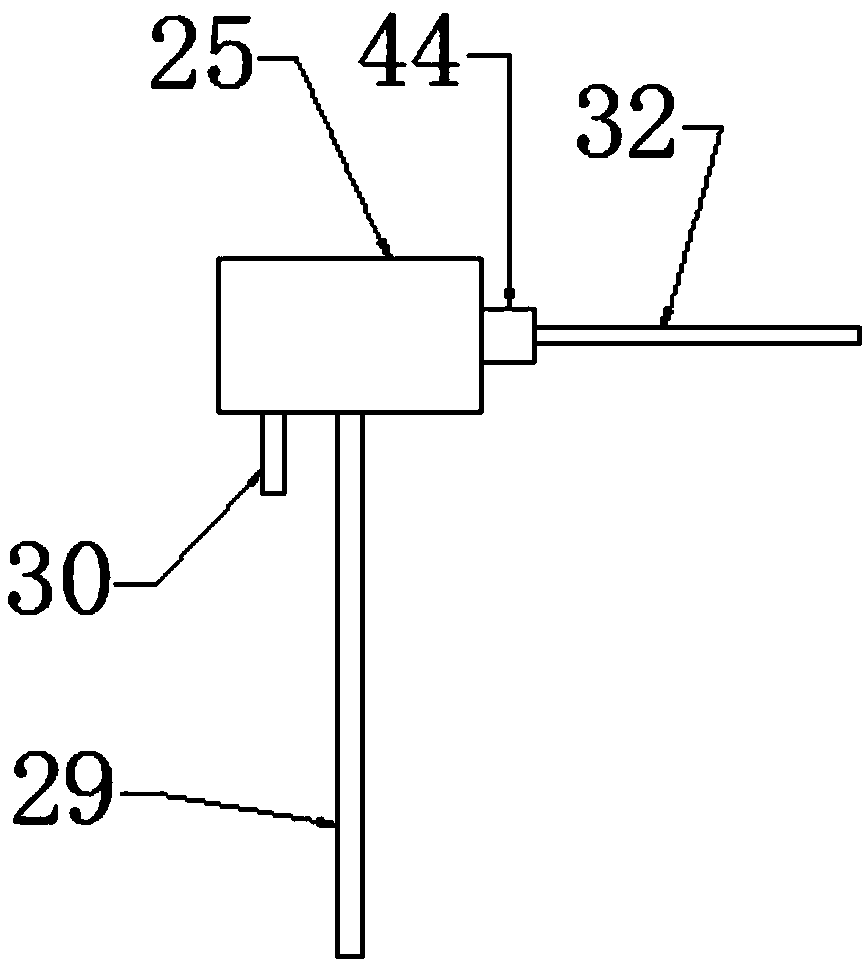

Apparatus for spraying inner wall of large pipe diameter

ActiveCN107737681AImprove securityImprove spraying effectSpraying apparatusDangerous environmentOperation safety

The invention discloses an apparatus for spraying an inner wall of a large pipe diameter. The apparatus comprises a holding platform, wherein the bottom of the holding platform is provided with a wheel I, a wheel II and a wheel III, the wheel I is arranged at one side of the bottom of the holding platform, the inner side of the wheel I is provided with a rotating shaft I, the top of the rotating shaft I is provided with a supporting rod I, the middle part of the supporting rod I is provided with a damping apparatus I, the top end of the supporting rod I is fixedly connected with the bottom ofa reversing apparatus arranged on the bottom of the holding platform, the middle part of the rotating shaft I is provided with a belt pulley I, the belt pulley I is connected with a belt pulley II ina driving manner by virtue of a belt, the belt pulley II is arranged at one end of a rotating shaft II, the other end of the rotating shaft II is arranged at one side of a motor I arranged at the bottom of the holding platform in a penetrating manner and extends into the motor I. The apparatus has the beneficial effects that the spraying efficiency is increased, the operation personnel can be prevented from working in a dangerous environment, and the operation safety is improved.

Owner:青岛北船管业有限责任公司

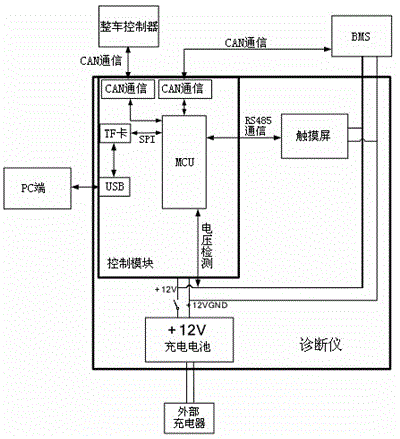

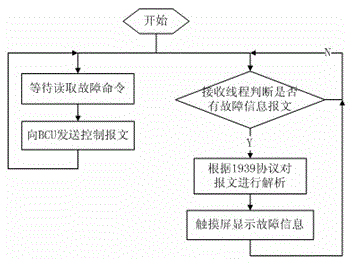

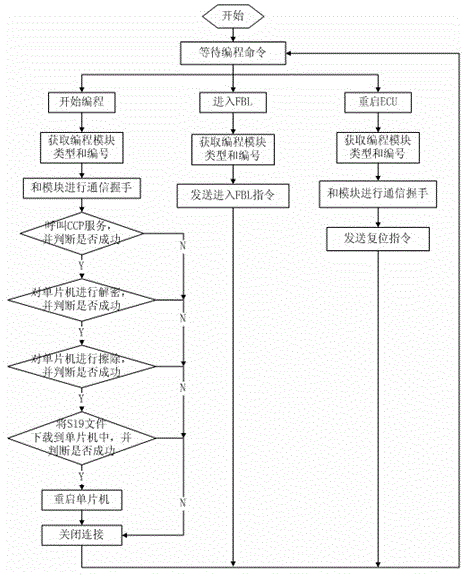

Portable battery management system diagnosis apparatus and working method thereof

InactiveCN105486951ARealize parameter configurationEasy program updateElectrical testingElectrical batteryWorking set

The invention discloses a portable battery management system diagnosis apparatus, which comprises a control module. The control module comprises a micro-control unit for receiving information, processing data and sending signals. The micro-control unit is connected with a TF storage card for storing battery information, complete vehicle information and fault information through a serial peripheral interface; the micro-control unit is also connected with a first path of CAN communication for carrying out information interaction with a BMS (battery management system), and a second CAN communication for carrying out information interaction with a vehicle control unit; and the TF storage card is connected with a USB interface for connecting with an external computer. The portable battery management system diagnosis apparatus has the advantages of being small in size, convenient to hold and convenient for on-site diagnosis and debugging. The invention also discloses a working method of the portable battery management system diagnosis apparatus.

Owner:ANHUI RNTEC TECH CO LTD +1

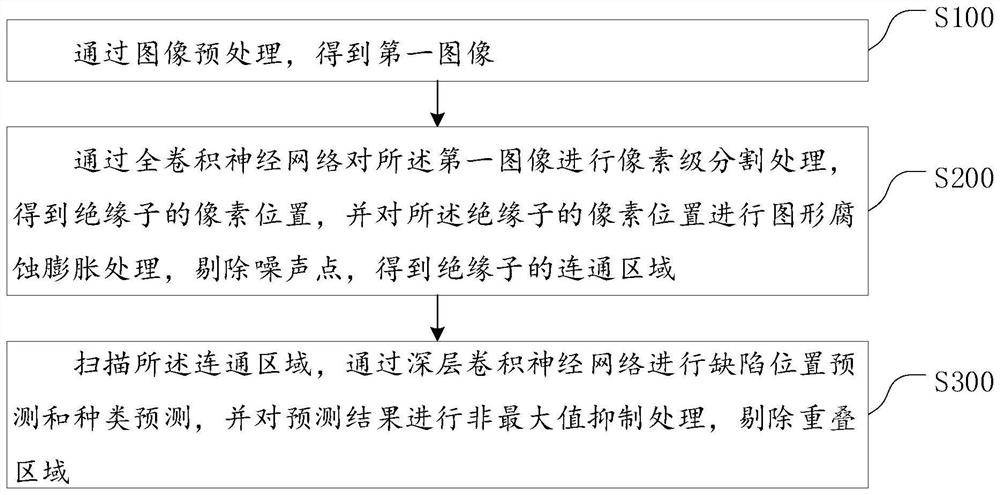

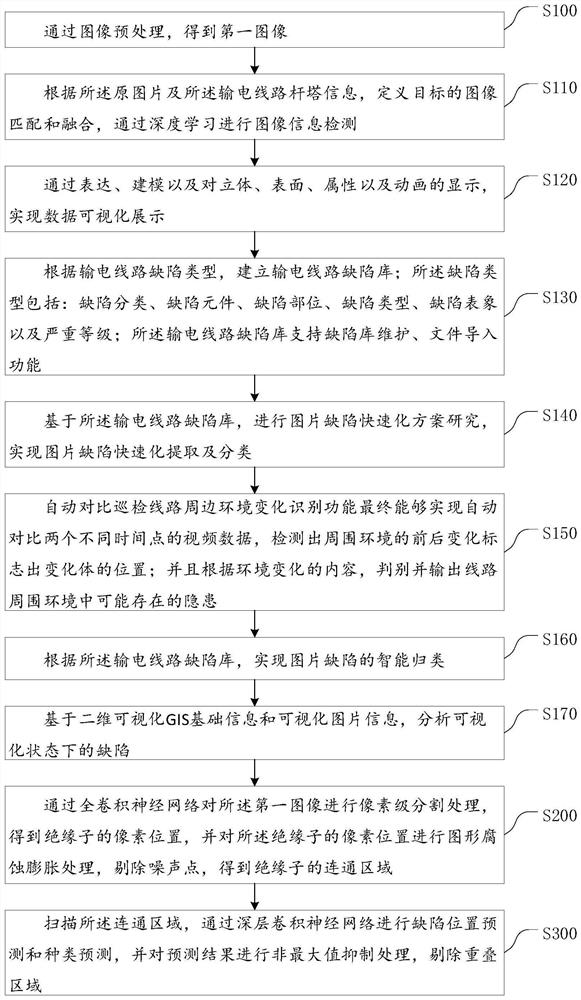

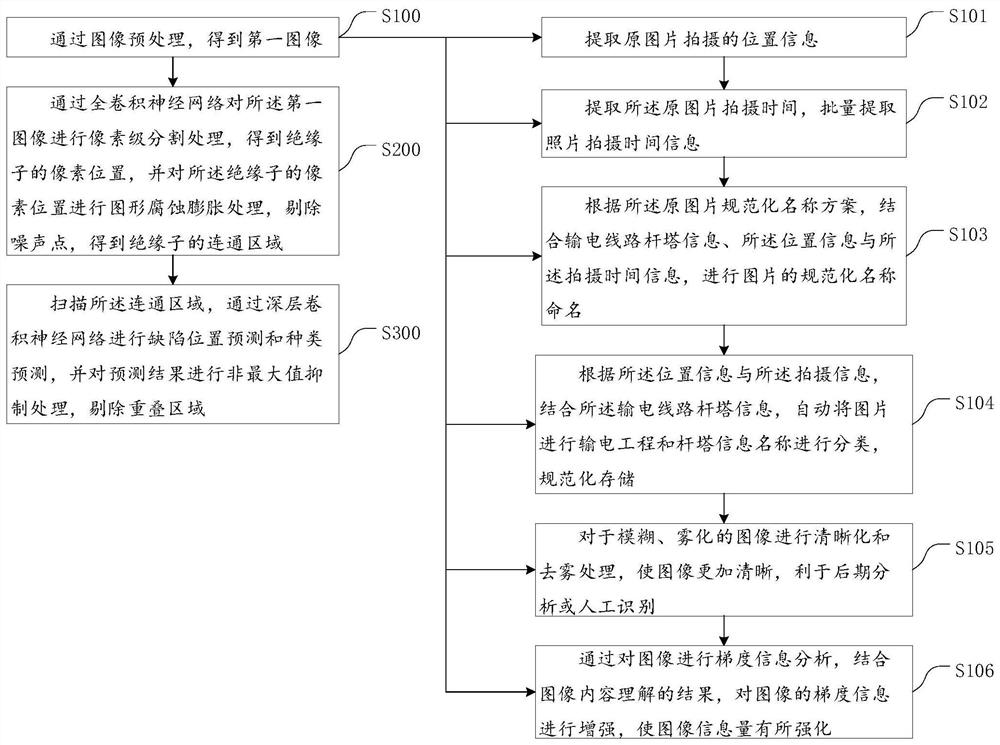

Image recognition method and system for power transmission line machine patrol

InactiveCN111899219AFacilitate post-analysisFacilitate manual identificationImage enhancementImage analysisUncrewed vehicleEngineering

The invention provides an image recognition method for power transmission line machine patrol. The method comprises the steps of obtaining a first image through image preprocessing; carrying out pixel-level segmentation processing on the first image through a full convolutional neural network to obtain a pixel position of an insulator, carrying out pattern corrosion expansion processing on the pixel position of the insulator, and removing noise points to obtain a connected region of the insulator; scanning the connected region, carrying out defect position prediction and type prediction through a deep convolutional neural network, carrying out non-maximum suppression processing on a prediction result, and removing an overlapping region. According to the image recognition method for power transmission line machine patrol, the image technology and the space technology are used as basic technical standards, the unmanned aerial vehicle patrol maintenance management level of the power transmission line is improved, convenient maintenance is achieved, the unmanned aerial vehicle line patrol management efficiency is improved, and the patrol cost is reduced.

Owner:广州中科智云科技有限公司

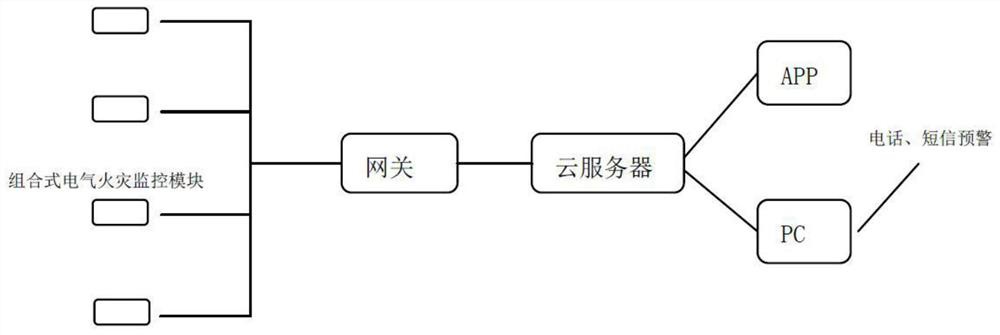

Intelligent safety monitoring method and system based on temporary electricity utilization of constructional engineering

PendingCN113689653ATimely warningEarly warning is accurateMeasurement devicesFire alarm electric actuationAlarm stateSwitch box

The invention discloses an intelligent safety monitoring method and system based on temporary power utilization of constructional engineering, and the method comprises the steps: carrying out the real-time monitoring and alarm of a general distribution box, a distribution box and a switch box of a temporary power utilization network, and if the monitored data reach an alarm state, actuating an outlet linkage loop switch, so a corresponding fault loop is automatically cut off, and the loss is reduced to the minimum. Meanwhile, monitored data are transmitted to a background system for access, the data are analyzed and compared, later-period real-time query and manual remote intervention of the data are achieved, and the purpose of real-time early warning is achieved. According to the invention, electricity utilization hidden dangers caused by complex on-site working condition environment are solved, so that electricity utilization conditions which are not illegal according to regulations are not hidden. Hidden hidden dangers which cannot be checked are exposed, early warning is conducted in time, the hidden hidden dangers are solved in time, and loss is reduced.

Owner:CHINA CONSTR FOURTH ENG DIV INSTALLATION ENG +1

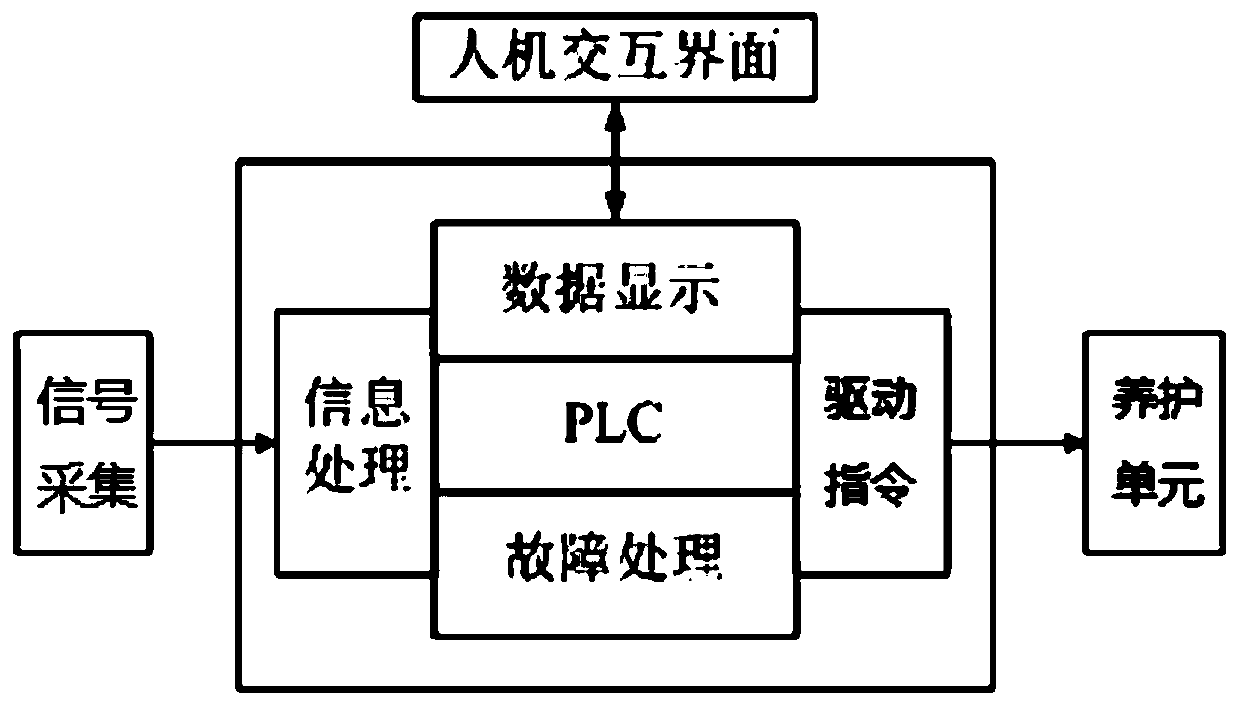

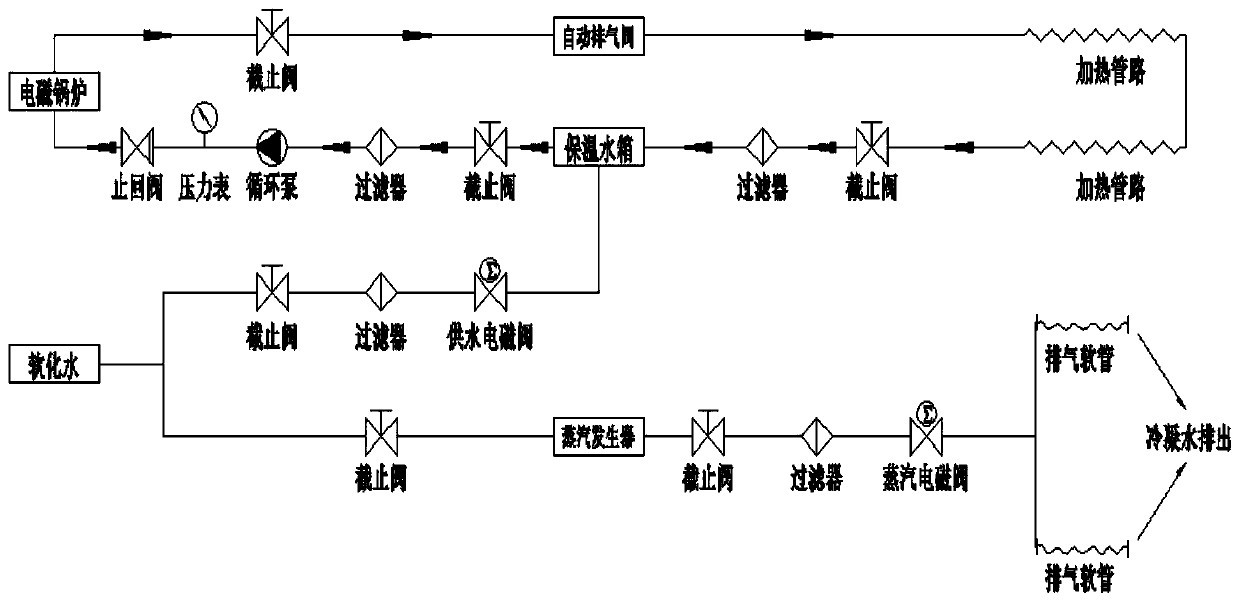

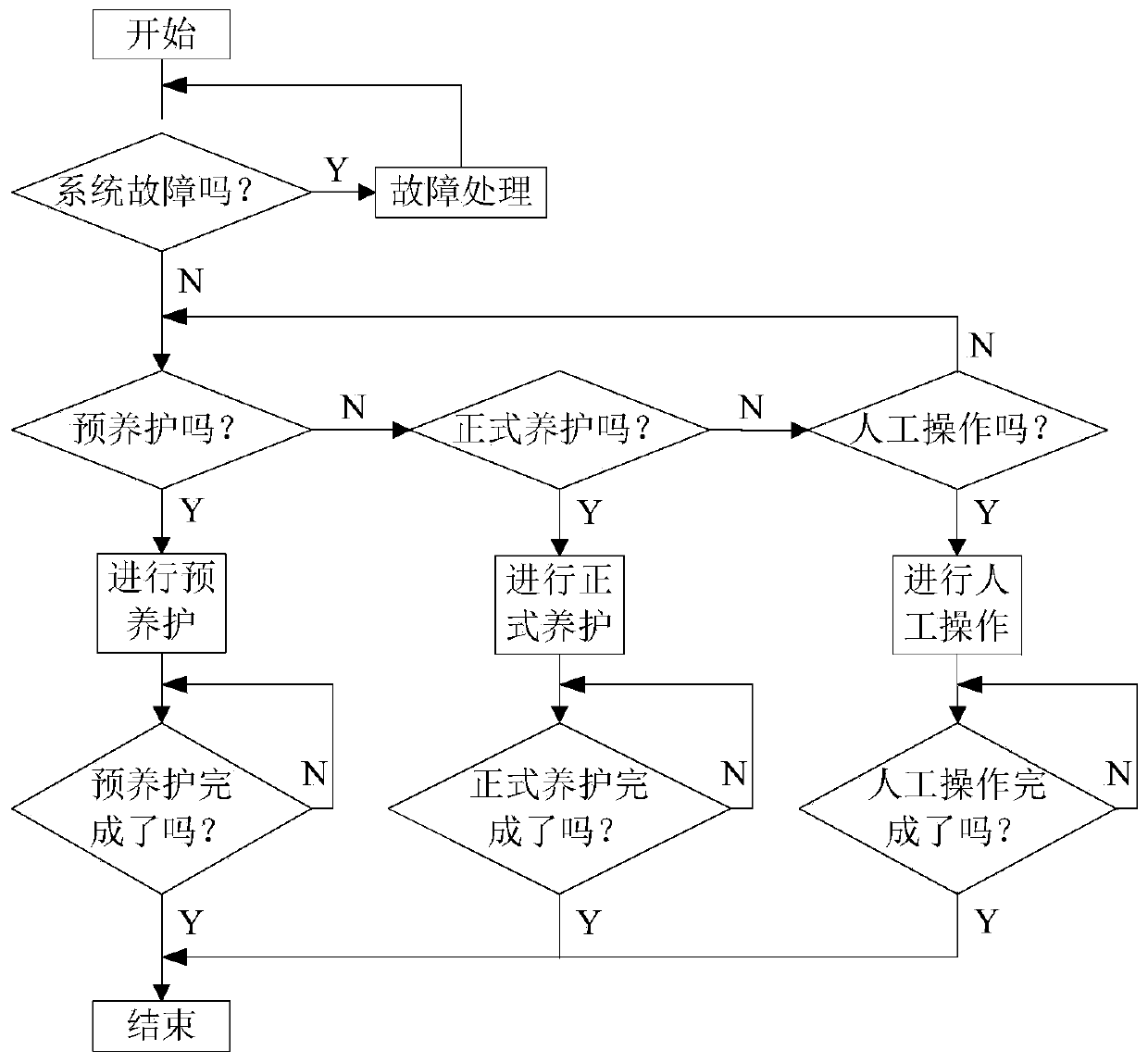

Control system and method for fixed mold table intelligent maintenance unit

InactiveCN110116452AQuality assuranceAvoid crackingScale removal and water softeningAuxillary shaping apparatusSoftened waterControl system

The invention relates to the technical field of concrete prefabricated slab production and provides a control system and method for a fixed mold table intelligent maintenance unit. The control systemcomprises a maintenance unit, a PLC, a human-computer interaction interface and signal acquisition equipment. The maintenance unit comprises softened water equipment, an electromagnetic boiler, a circulating water pump, a heating pipe, a steam generator and an exhaust hose. According to the control system, heating and humidification are controlled in a separated manner, and the temperature, humidity and temperature rise and fall rates are precisely controlled; the time is strictly controlled, the phenomenon that the surface has cracks due to severe temperature change can be prevented, and theproduct quality is guaranteed; electric equipment is adopted, no harmful gas such as nitrogen gas and oxide gas is generated in the process, and quite high environmental protection performance is achieved; an almost closed heating pipe system is adopted, water consumption caused by heating is little, and only a certain amount of water is consumed in the product humidifying process; and the final condensate water is collected and can be utilized cyclically, and water resources can be effectively saved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

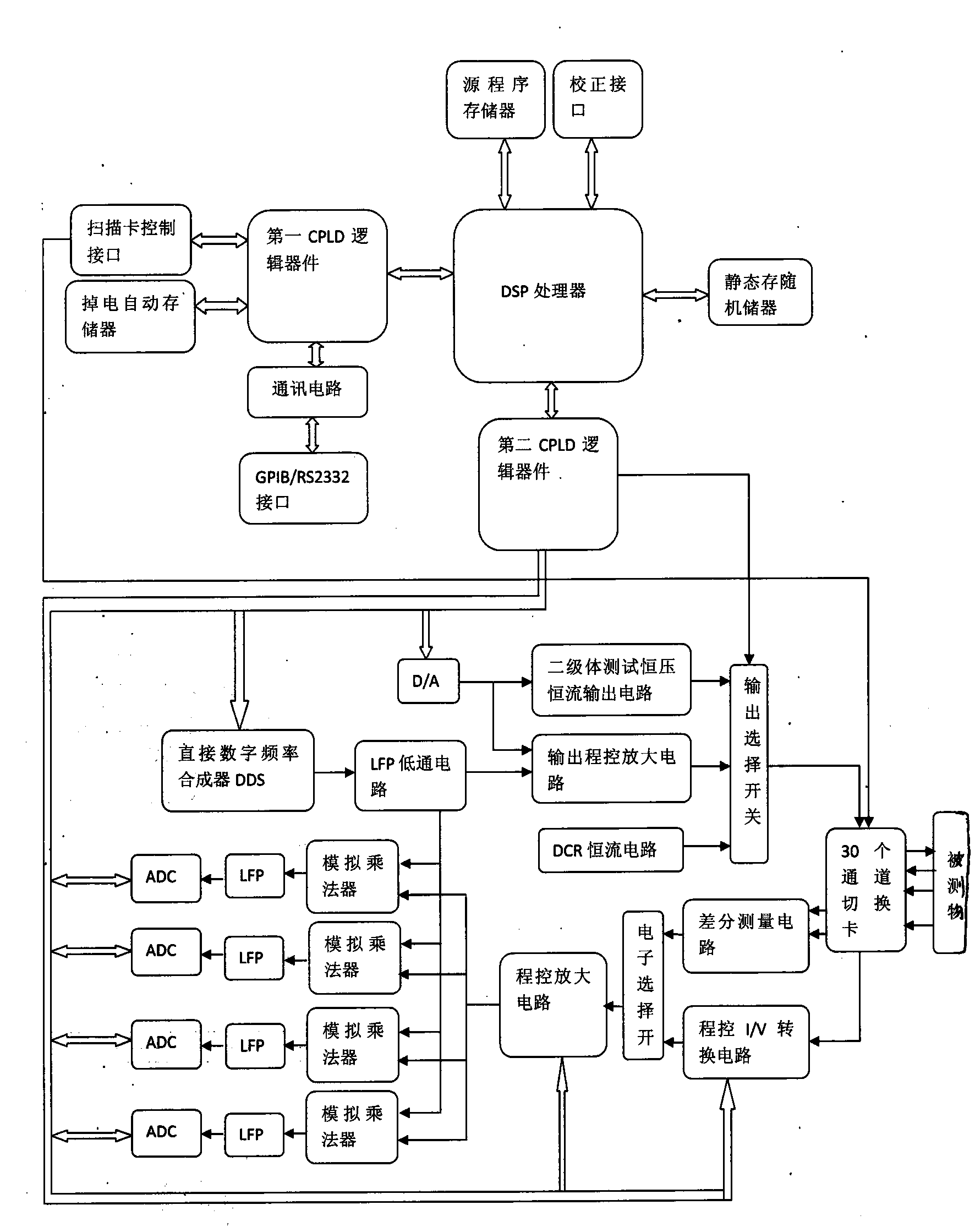

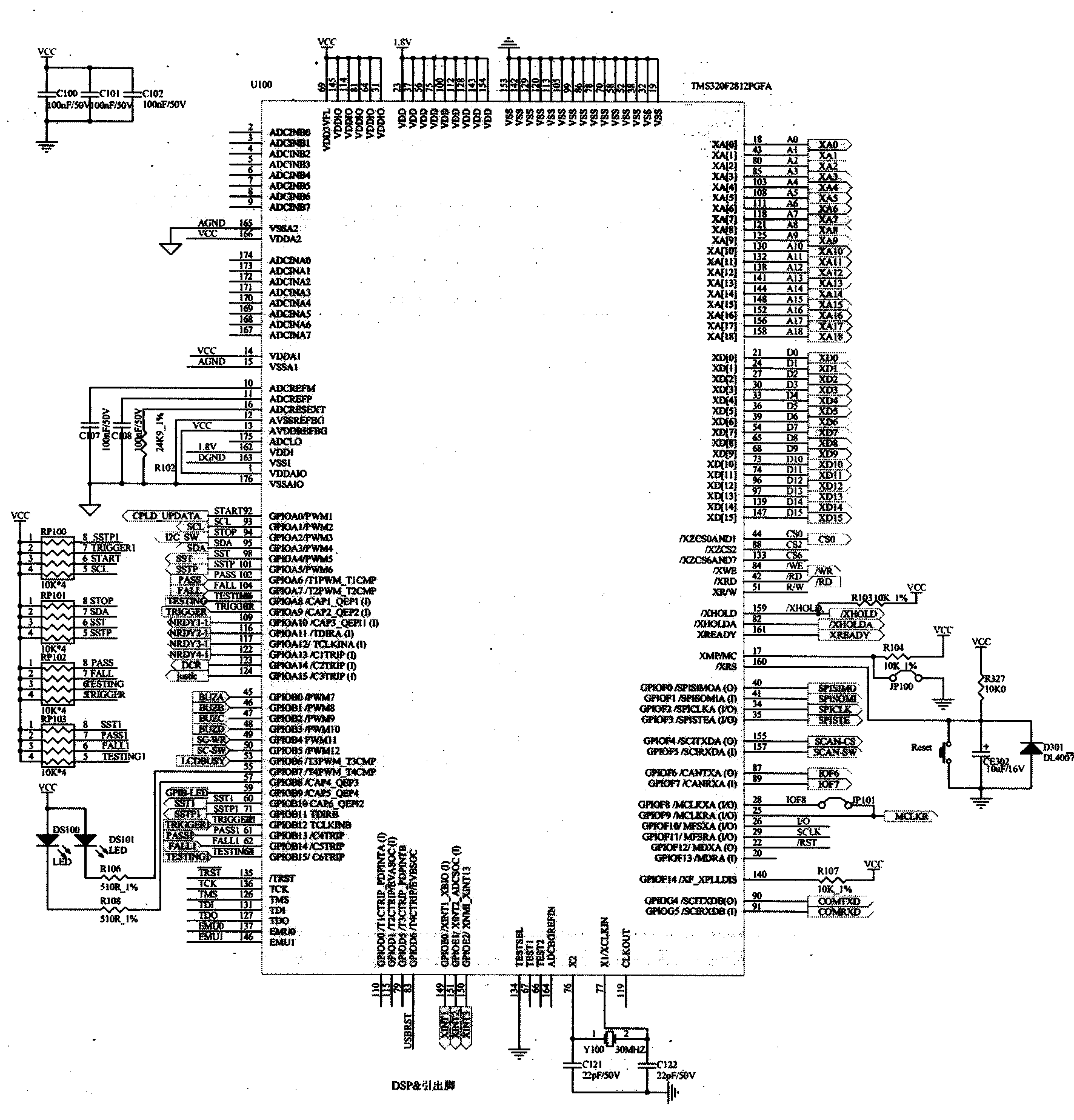

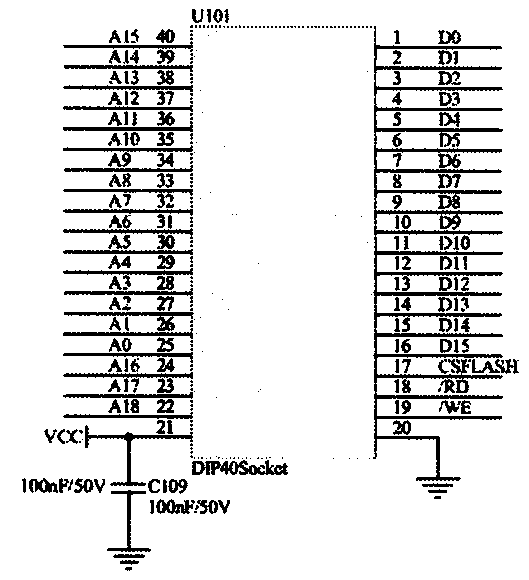

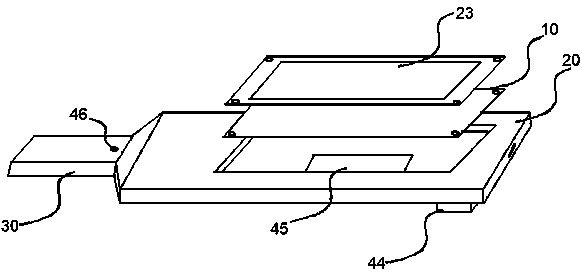

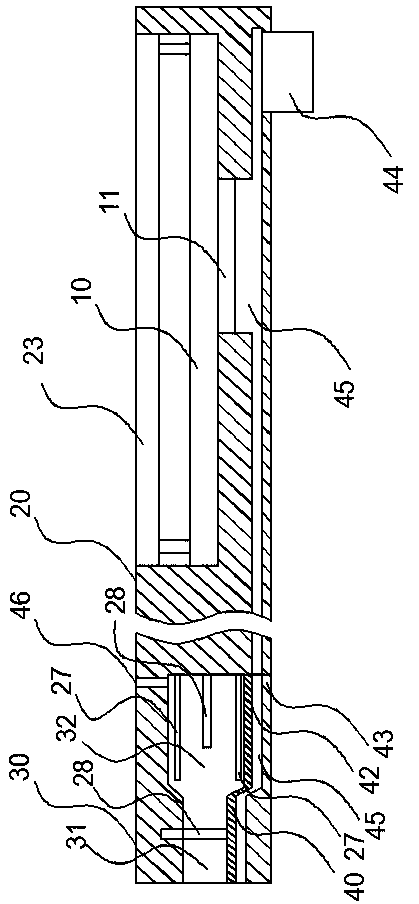

Capacitive touch sensor tester

The invention relates to a capacitive touch sensor tester which comprises a DSP, a source program memorizer, a correcting interface, a static random memorizer, a first CPLD and a second CPLD. Signal output and feedback are achieved, the first CPLD is connected with a scanning card control interface, a power-down automatic memorizer and a communication circuit to achieve signal output and feedback, and the second CPLD is respectively connected with a DDS, a programmable amplifying circuit, a programmable I / V conversion circuit, an output selection switch and a digital-to-analog conversion D / A to achieve signal transmission. The DSP sends out measuring signals, signals obtained by measuring a tested object by a scanning card are transmitted to a programmable amplifier to be converted into voltage signals suitable for being measured, a main LFP low-pass circuit converts analog signals into digital signals through an ADC, impedance, inductance values, capacitance and the like with the high activity accuracy are processed through the DSP, testing is efficient and fast, and observation, metering and later analysis are facilitated.

Owner:苏州茂鼎电子科技有限公司

Sleeping posture recorder

InactiveCN104720820AConvenient researchEasy to analyzeDiagnostic recording/measuringSensorsMicrocomputerPostural orientation

A sleeping posture recorder comprises a mattress, a pressure senor, a controller and a microcomputer. The pressure sensor is arranged in the mattress. The controller is connected with the pressure sensor and the microcomputer. According to the sleeping posture recorder, a sleeping posture image and a sleeping posture changing image can be seen conveniently, detailed postures pictures and pressure values of various pressure measuring points are in images, and sleeping postures can be studied and analyzed conveniently.

Owner:赵君雄

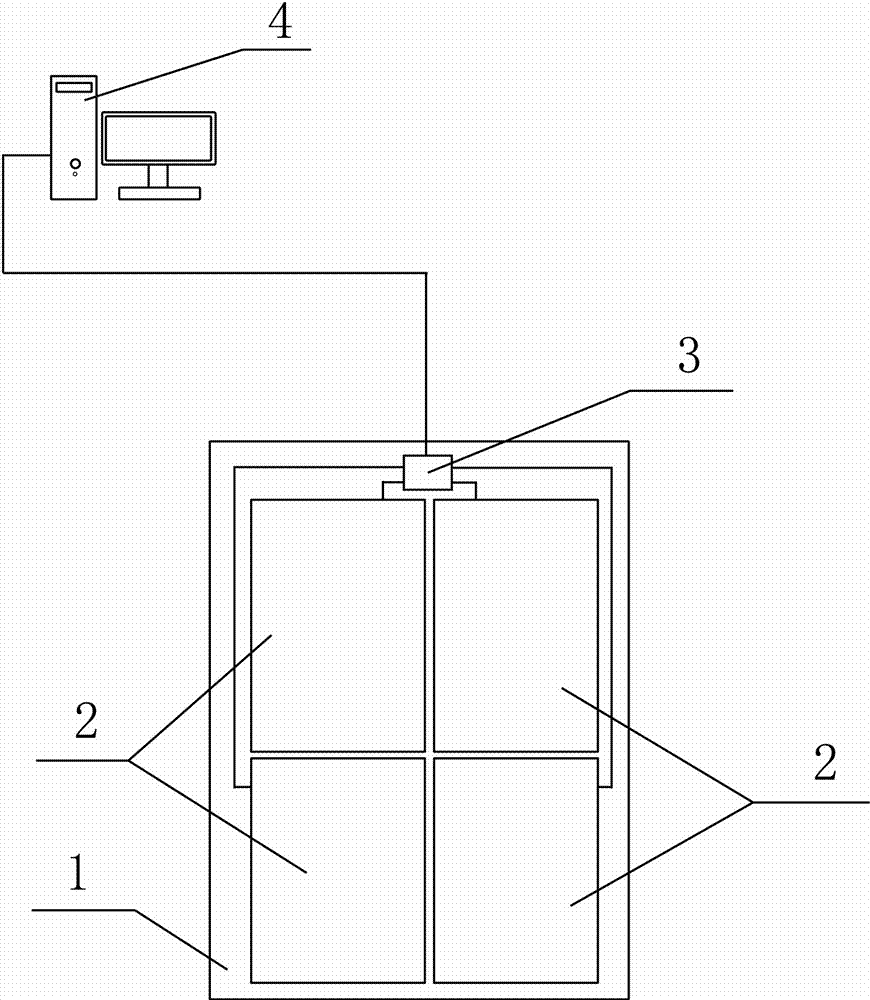

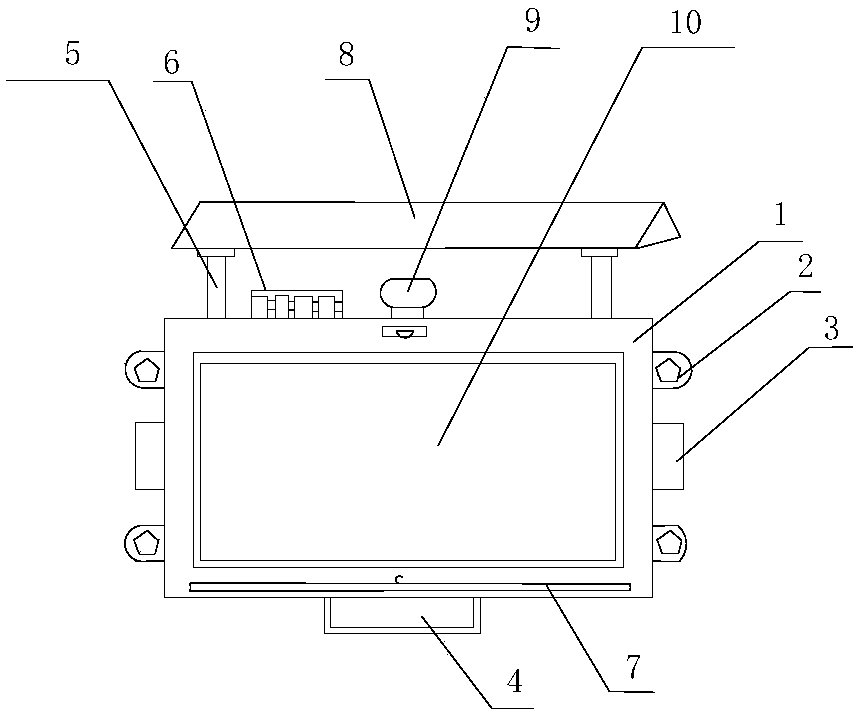

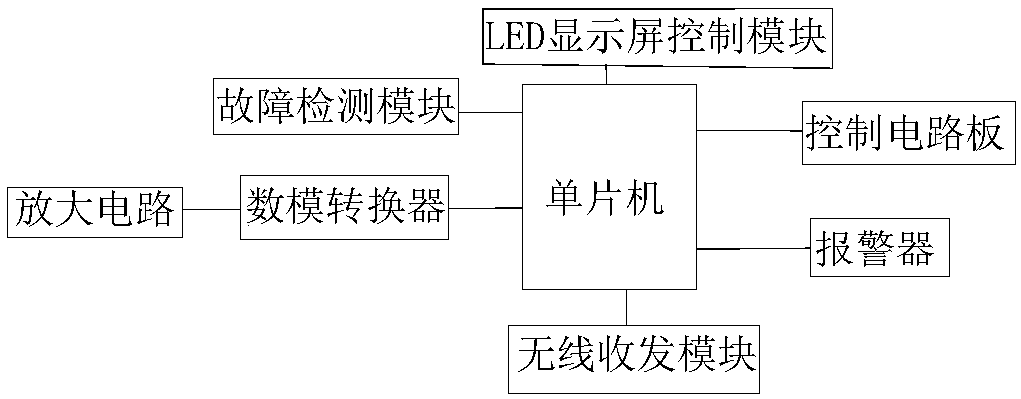

LED display screen capable of remotely adjusting pictures and colors

InactiveCN107945681AEasy to adjustFacilitate post-analysisStatic indicating devicesTransmissionLine sensorLED display

The invention discloses an LED display screen capable of remotely adjusting pictures and colors. The LED display screen capable of remotely adjusting the pictures and the colors comprises an LED display screen fixing frame and a control box body, the control box body is arranged at the bottom of the LED display screen fixing frame, an amplifying circuit, a digital analog converter and a single chip microcomputer which are orderly connected are arranged in the control box body, an LED display screen control module, a failure detection module, a wireless transceiver module and an alarm apparatussimultaneously connected with the single chip microcomputer are further arranged in the control box body, the LED display screen is arranged on the front surface wall of the LED display screen fixingframe and connected with the LED display screen control module, and a storage battery box and a light sensor are arranged on the top of the LED display screen fixing frame. By the structure above andthe wireless transceiver module, the pictures and the colors of the LED display screen are remotely adjusted, and the adjustment is simpler and more convenient.

Owner:重庆锐虎光电科技有限公司

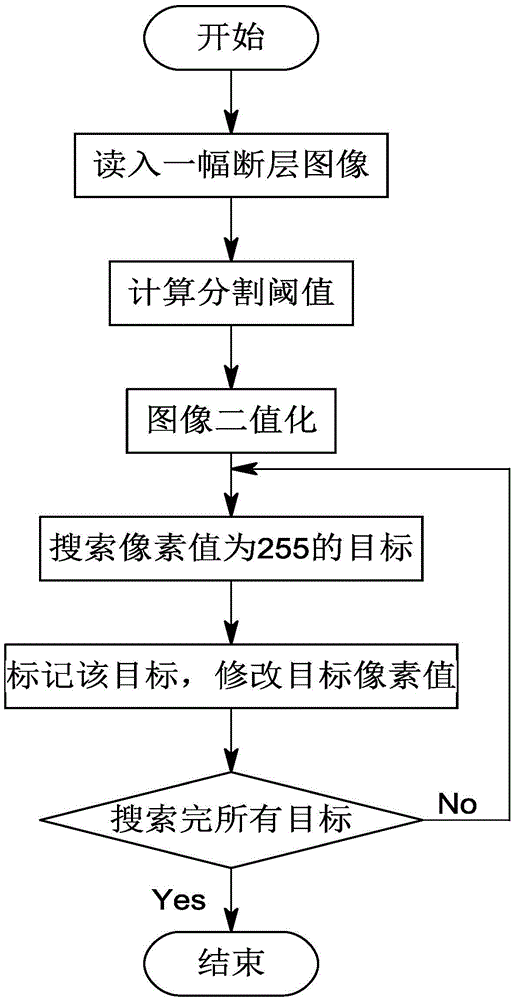

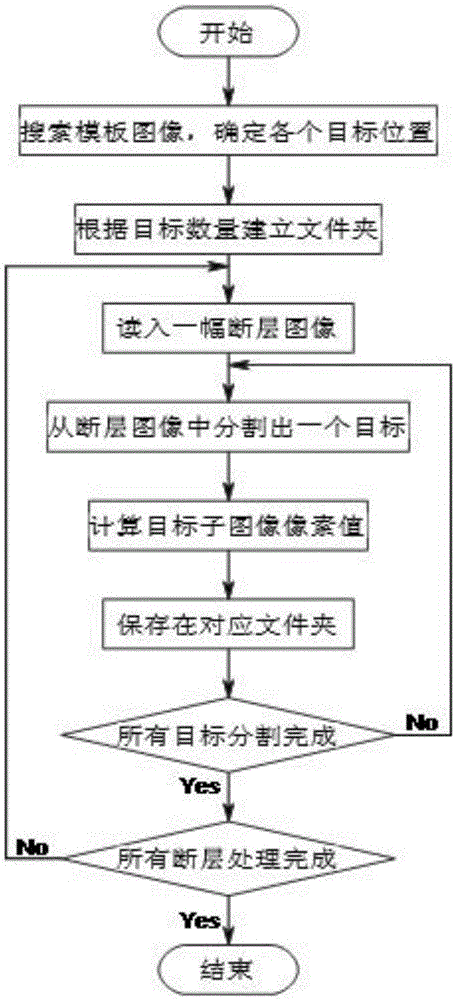

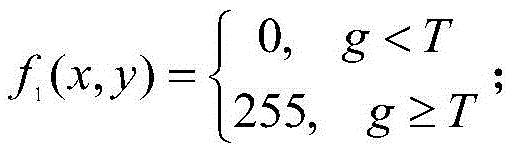

Method for dividing industrial CT image comprising multiple columnar targets

ActiveCN105654489ARun fastImprove work efficiencyImage enhancementImage analysisComputer graphics (images)Computer vision

The invention discloses a method for dividing an industrial CT image comprising multiple columnar targets. The method comprises the following steps: making a template; marking targets in the template image; automatically performing target division of all CT images according to the template; and storing the divided targets in different catalogues. According to the method, all steps are automatically finished by a computer, errors caused by human factors are avoided, the target images are automatically stored in files to facilitate later management, the operation speed is high, and the working efficiency is remarkably improved; moreover, manual operation is reduced, and the labor cost is reduced; meanwhile, the division is accurate, and the cross-section images of the same target are divided into the equal size while the target positions are the same so as to facilitate later analysis and three-dimensional reconstruction and avoid difference caused by manual division; and moreover, an effect that the backgrounds of the divided sub-images are all black unavailable by manual division is realized, which is equivalent to the removal of background noise in three-dimensional reconstruction so as to highlight the target.

Owner:重庆真测科技股份有限公司 +1

Method and device for washing and seal detecting of railway vehicle braking lines

ActiveCN102401725BEasy to cleanEasy to transportMeasurement of fluid loss/gain rateHollow article cleaningMicrocomputerSolenoid valve

The invention relates to a method and a device for washing and seal detecting of railway vehicle braking lines. Air inlet lines and air outlet lines are communicated with each other at the inlet end and the outlet end of each braking line, an air inlet solenoid valve is arranged on each air inlet line, a plugging solenoid valve is connected with each air outlet line correspondingly, a pressure sensor used for detecting the air pressure in the line is arranged on each of the air outlet lines, and the air inlet solenoid valves, the plugging solenoid valves and the pressure sensors are respectively connected with a microcomputer. The microcomputer controls the opening and closing of the air inlet solenoid valves and air outlet solenoid valves according to the detected air pressure in the lines so as to complete the air inflation, exhausting and pressure maintaining process of the braking lines and merge line washing equipment and seal detecting equipment into a whole to complete the line washing and the seal detecting at one time; and the operation is simple, few equipment is required, and the cost is low; and the equipment operation is controlled by the microcomputer automatically, so that the labor intensity of workers is lowered, and the line washing and the quality as well as the precision of the sealing property detection can be ensured.

Owner:CRRC QINGDAO SIFANG CO LTD

Device and method for measuring liquid density and viscosity on basis of quartz crystal microbalance

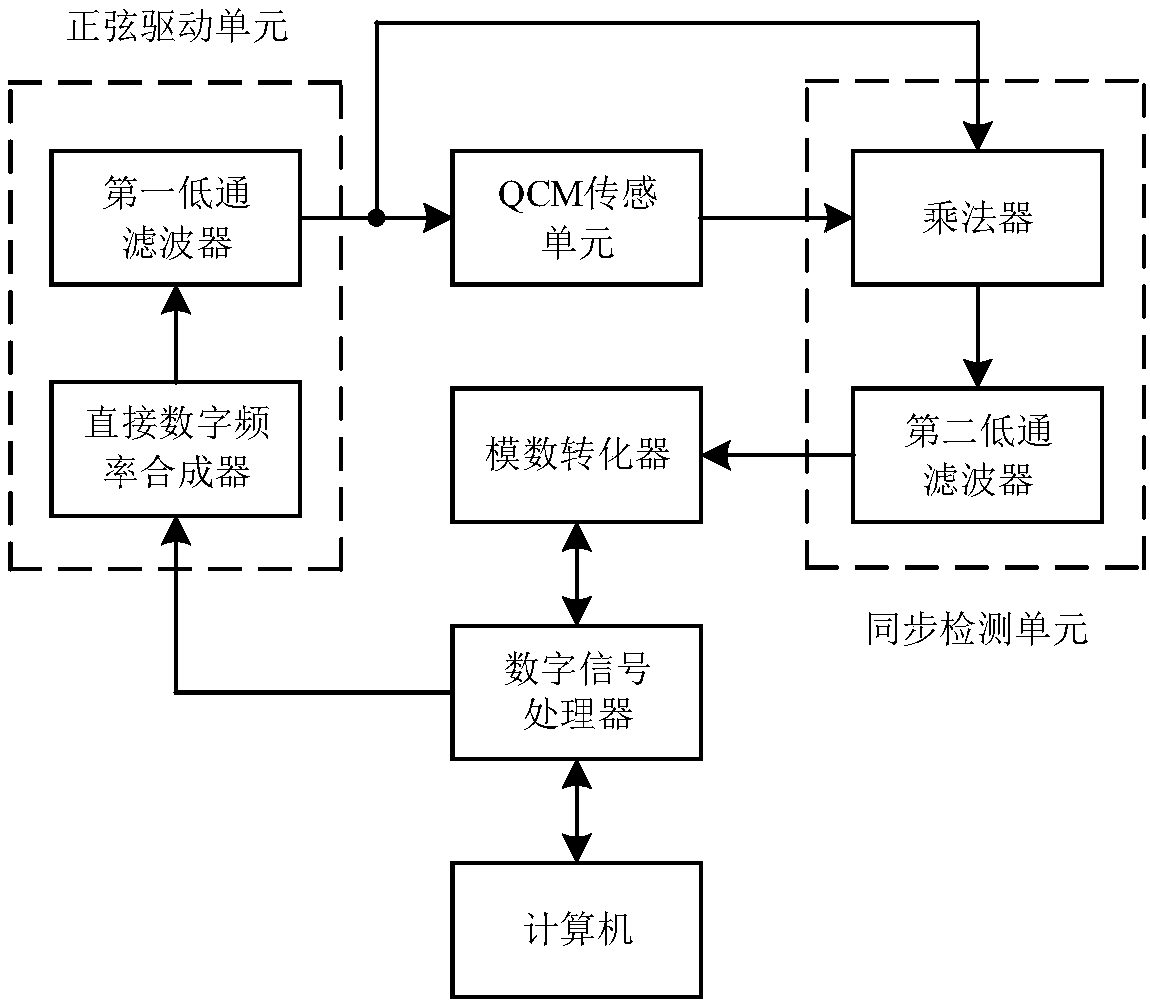

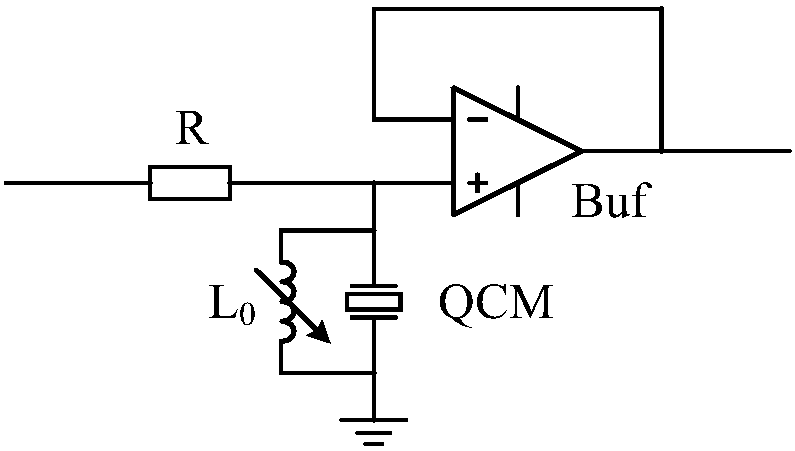

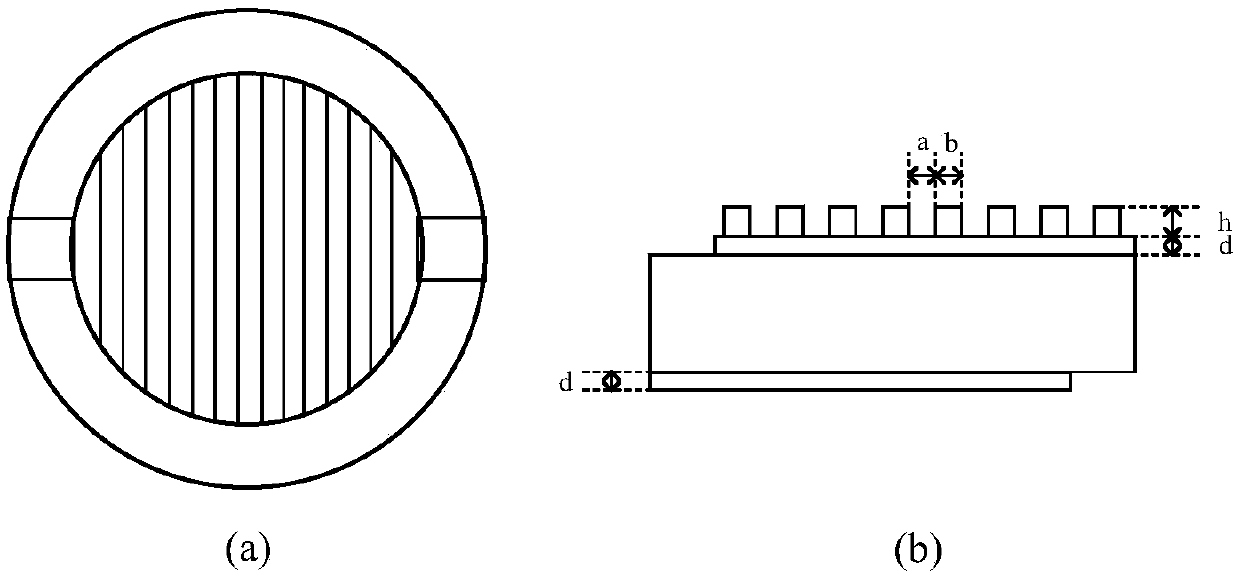

PendingCN107643227AFacilitate post-analysisEasy to handleFlow propertiesMaterial weighingPeak valueAlternating current

The invention discloses a device and method for measuring liquid density and viscosity on the basis of a quartz crystal microbalance. The device comprises a sine driving unit, a QCM (Quartz Crystal Monitor) sensing unit, a synchronous detection unit, an analog-digital converter, a digital signal processor and a computer, wherein the sine driving unit is used for generating a sine frequency scanning signal; the QCM sensing unit is driven by the sine frequency scanning signal and used for sensing and testing a liquid; the density and the viscosity of the liquid are converted into alternative-current voltage signals; the synchronous detection unit is used for converting alternative-current voltage signals output from the QCM sensing unit into direct-current voltage signals corresponding to conductive variation of a QCM; the analog-digital converter is used for performing analog-digital conversion on the direct-current voltage signals; the digital signal processor is used for extracting anelectric conductivity peak of a digital signal and a serial connection resonant frequency of the peak; the computer is used for calculating the output of the digital signal processor to obtain the density and the viscosity of the liquid. The device disclosed by the invention is small in size, high in integration degree, simple in measurement process and accurate in measurement result.

Owner:NANJING UNIV OF SCI & TECH

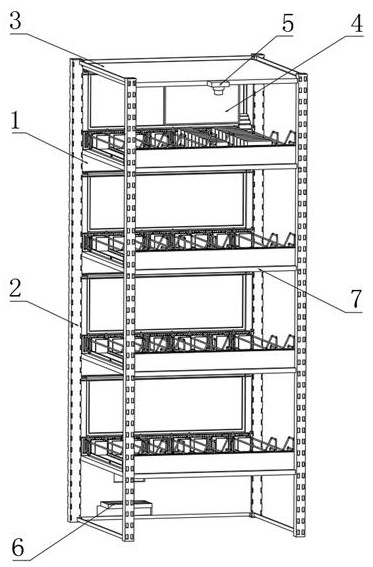

Intelligent goods shelf system based on RFID technology

PendingCN114176368AConvenient and timely replenishmentFacilitate post-analysisRacksRecord carriers used with machinesMechanical engineeringEmbedded system

The invention discloses an intelligent goods shelf system based on an RFID technology, which comprises a back plate, supporting rods are mounted at the end parts of the two sides of the back plate, a top plate is mounted at the top of the back plate, a display screen is mounted at the rear end position of the bottom of the top plate, a camera is mounted on the front end surface of the top plate, and a display screen is mounted at the rear end position of the top plate. According to the invention, one side of the commodity, which is pasted with the RFID tag, is attached to the stainless steel laminate, a signal can be shielded and cannot be sensed, the signal can be captured by the antenna after the commodity is taken by a user, the commodity can be regarded as being taken, corresponding information is sent to the display screen, corresponding content is displayed, a salesperson does not need to explain one by one, and the service life of the salesperson is prolonged. Meanwhile, the pushing spring can push the commodities forwards, timely replenishment of the commodities is facilitated, the camera recognizes the hand action of the customer taking the commodities and records corresponding taking data, the recorded data can analyze the condition that the commodities are taken by the customer, the taking data of the commodities can be provided for merchants, and later analysis and application work are facilitated.

Owner:杭州座头鲸科技有限公司

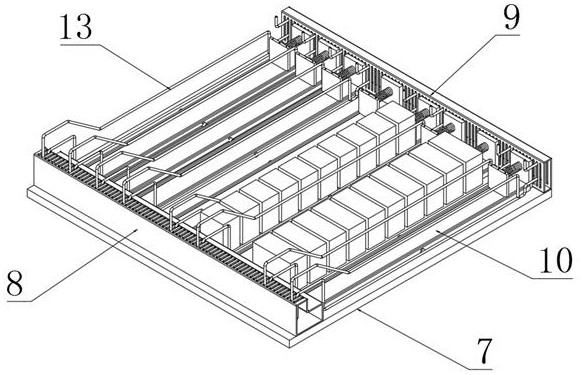

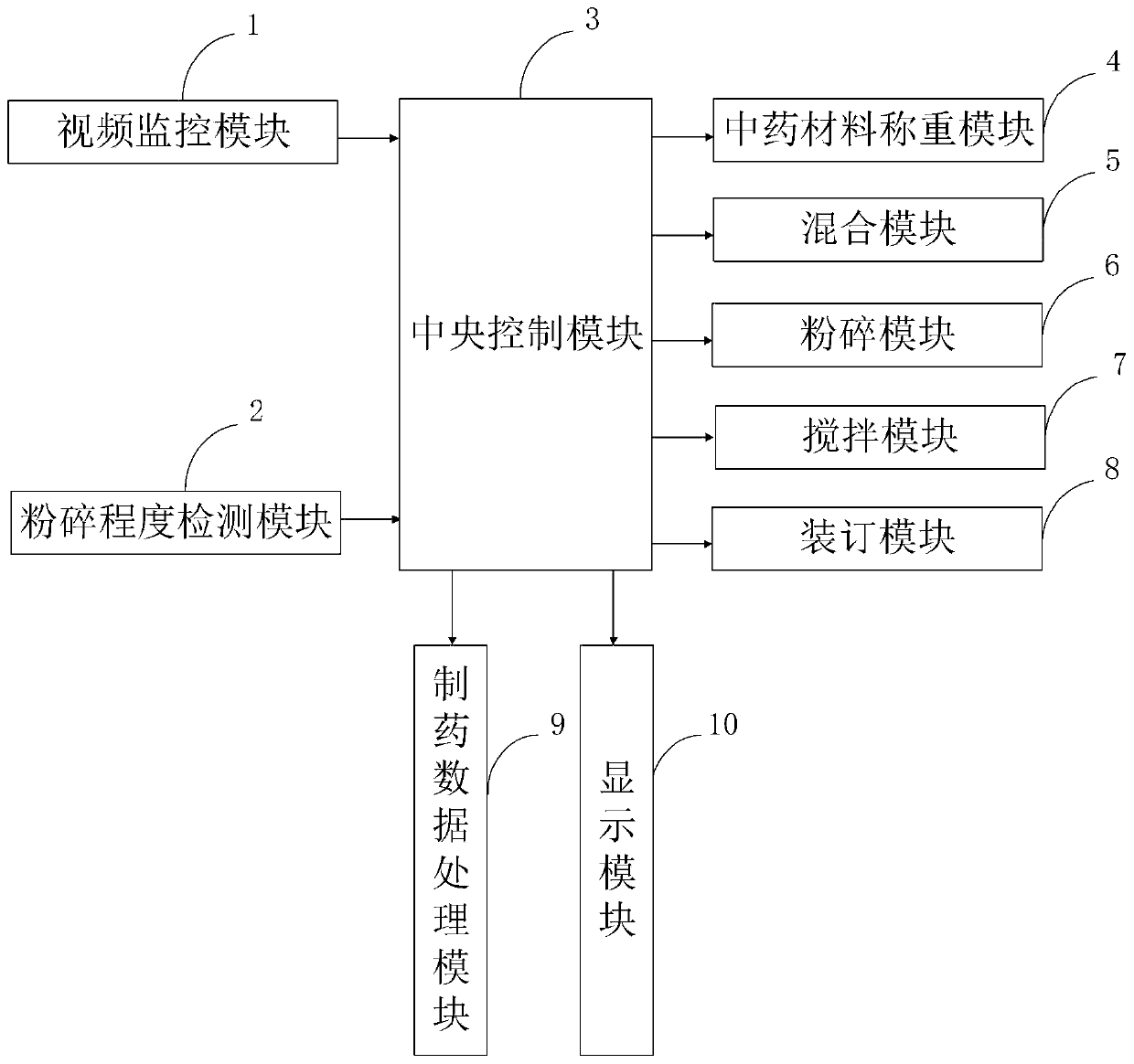

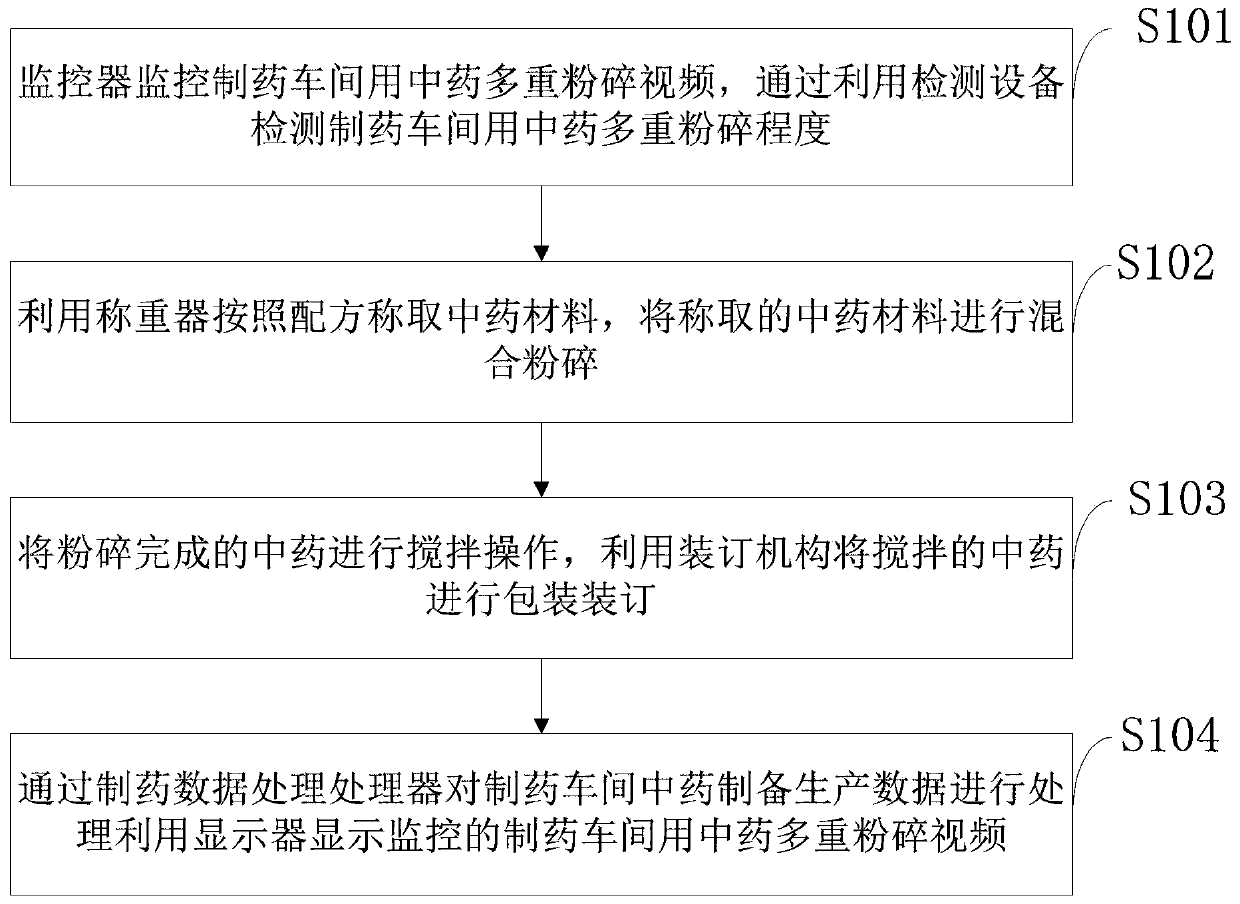

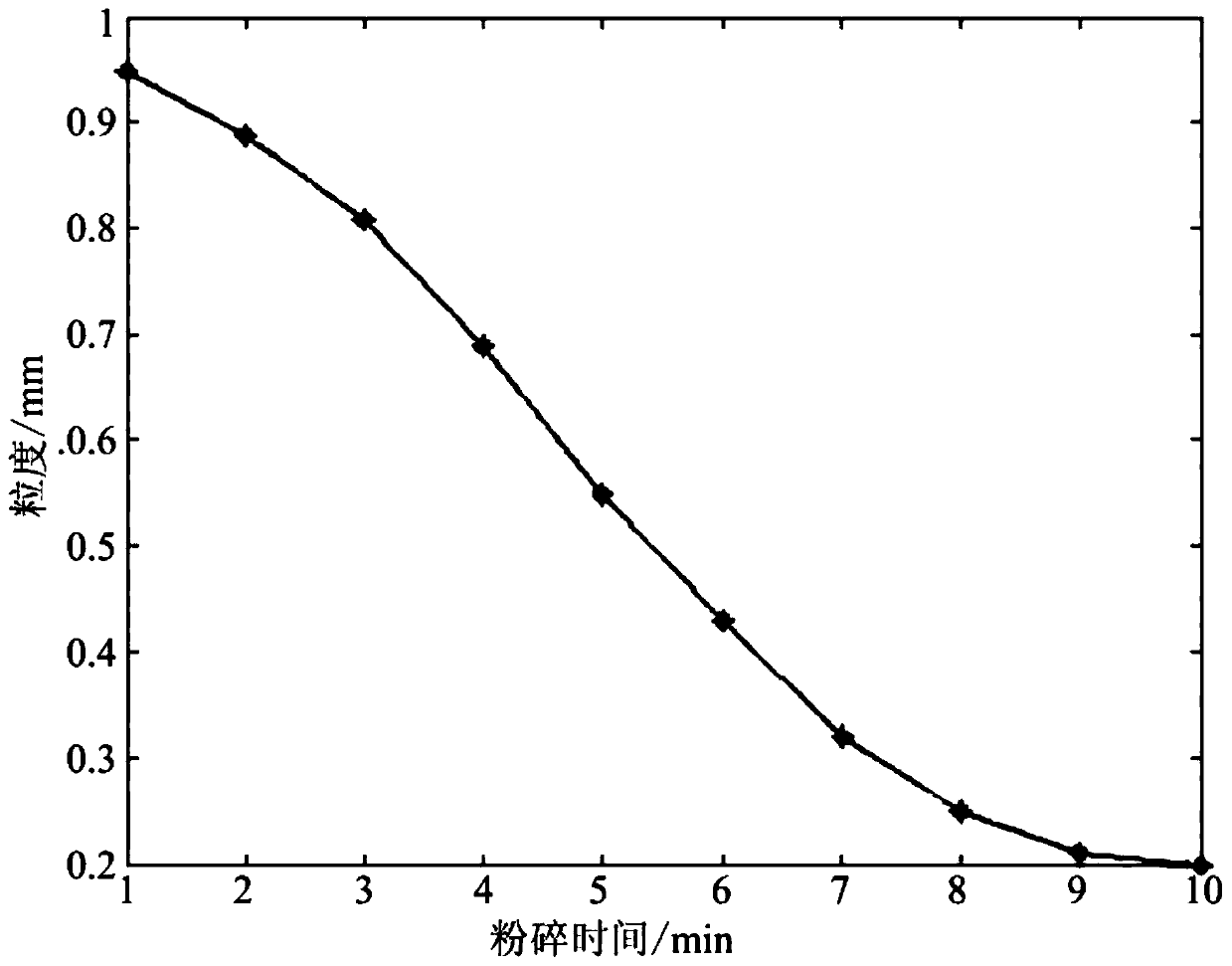

Traditional Chinese medicine multiple crushing control system and method for pharmaceutical workshop

InactiveCN110947505AGuaranteed accuracy and validityHigh speed storageGrain treatmentsMedicinal herbsProcess engineering

The invention belongs to the technical field of traditional Chinese medicine multiple crushing control, and discloses a traditional Chinese medicine multiple crushing control system and method for a pharmaceutical workshop. The traditional Chinese medicine multiple crushing control system for the pharmaceutical workshop comprises a video monitoring module, a crushing degree detection module, a central control module, a traditional Chinese medicine material weighing module, a mixing module, a crushing module, a stirring module, a binding module, a pharmaceutical data processing module and a display module. The crushing degree of traditional Chinese medicine materials is accurately judged through the crushing degree detection module, effectiveness and accuracy of the crushing degree judged result are ensured, meanwhile, high-speed storage, copy backup and classified storage of traditional Chinese medicine production data are achieved through the production data processing module, data processing is high in automatic degree, viewing, retrieval and later analysis of traditional Chinese medicine production data are convenient, and data management is convenient.

Owner:GANSU UNIV OF CHINESE MEDICINE

Water quality detector based on open source hardware

PendingCN110244014AAchieve measurement speedAchieve precisionTesting waterMaterial resistanceWater qualityMeasurement precision

The invention discloses a water quality detector based on open source hardware, and relates to the technical field of detection. The water quality detector comprises a processing unit, and a TDS measuring circuit, a PH measurement circuit and an output unit which are connected to the processing unit, wherein the TDS measurement circuit comprises a probe; and the PH detection circuit comprises an electrode. The processing core uses the open source hardware, and under a condition of uniform interface, the overall measuring speed, precision, stability, communication reliability and the like can be realized along with the upgrade of the open source software by replacing the processing core mode, and the overall manufacturing cost is reduced by reducing the cost of product testing. The water quality detector is low in price, practical, convenient and higher in measurement precision, and can be applied to the water quality detection of the fields such as domestic water, food processing, chemical enterprises, swimming pools, environment monitoring, water culture and the like, especially to the non-professional fields.

Owner:SHIJIAZHUANG INST OF RAILWAY TECH

Natural gas sampling device and method thereof

InactiveCN109115564AQuality improvementFacilitate post-analysisWithdrawing sample devicesInlet valveEngineering

The invention discloses a natural gas sampling device and a method thereof, which belong to the field of gas sampling. The device comprises a tubular sampling probe, wherein a sampling port is inserted into a natural gas pipe at one end, and a safety bottle is connected with the other end; a heating assembly for heating the tubular sampling probe and the safety bottle; a sampling pump connected tothe safety bottle through a first pipeline; and a sampling air bag, wherein the sampling air bag is detachably connected to the sampling pump through a second pipeline, and the sampling air bag is provided with an intake valve and an outlet valve. The natural gas sampling device provided by the invention can avoid the clogging of the sampling port, and the obtained sample has the advantages of good quality and convenient usage, and is suitable for large-scale popularization and application.

Owner:PETROCHINA CO LTD

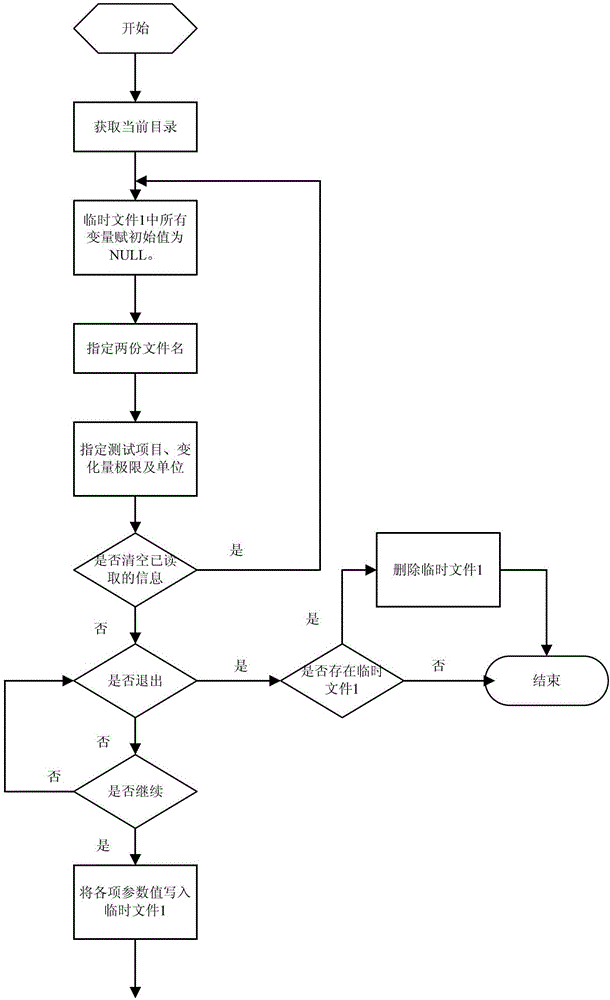

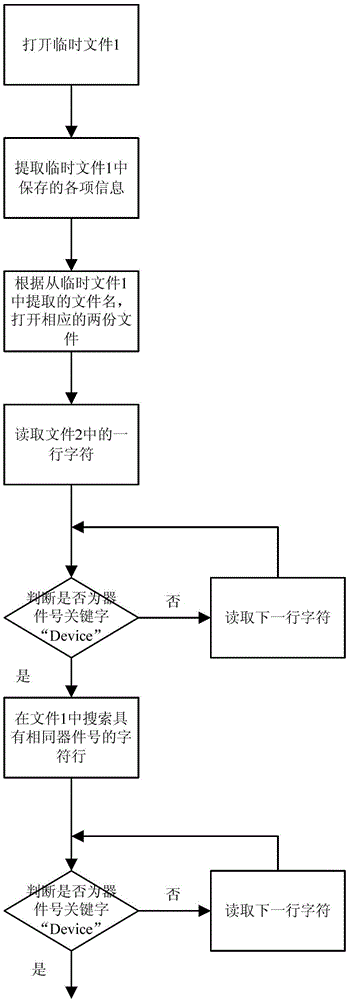

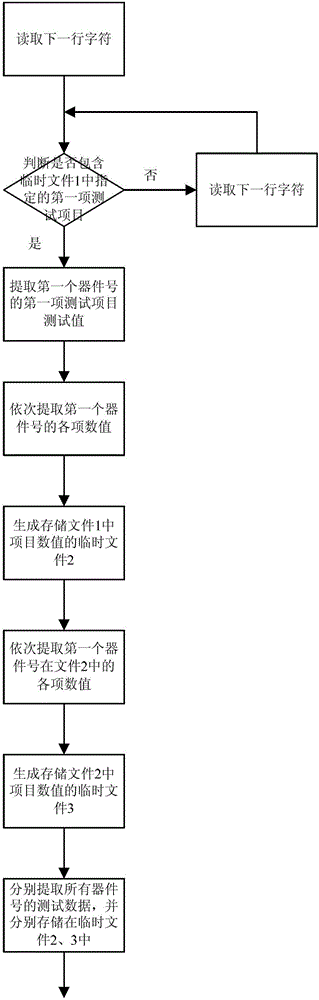

A method for processing integrated circuit test data

ActiveCN103116617BEasy to operateImprove stabilitySpecial data processing applicationsWork periodComputer science

The invention discloses a processing method of integrated circuit testing data. Calculation and discretion of corresponding test item variation quantity are carried out on any two files according to appointed test items, vibration quantity limitation and limitation units. Two appointed files are searched automatically according to recorded parameters to generate a corresponding test item variation quantity aggregate report form of all devices, and the corresponding test item variation quantity aggregate report form is judged according to limitation value. If some items are not qualified, a non-qualified report form is automatically generated. According to the processing method of the integrated circuit testing data, working time is greatly shortened, accuracy of variation quantity calculation is improved, working efficiency is improved, and the problem that no corresponding data analyzing tool exists in the field of integrated circuit testing is solved.

Owner:BEIJING MXTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com