Method and device for washing and seal detecting of railway vehicle braking lines

A rail vehicle and seal detection technology, applied in chemical instruments and methods, cleaning methods and utensils, and by measuring the acceleration and deceleration rates of fluids. Problems such as troublesome equipment transportation, to achieve the effect of specific and detailed output results, low cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

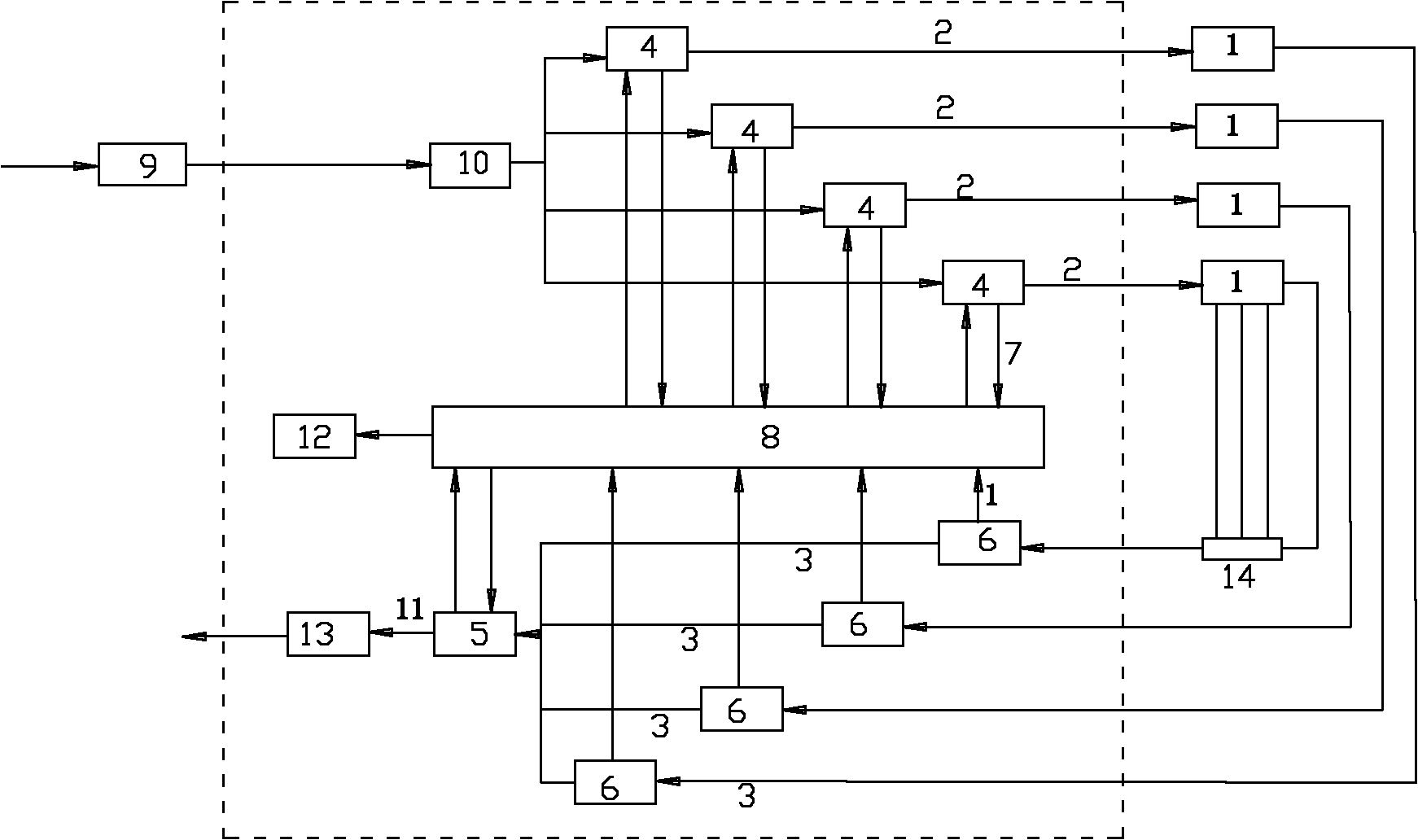

[0029] The following structural drawings and specific implementations further describe the present invention in detail:

[0030] Such as figure 1 As shown, a plurality of brake pipelines 1 for vehicle braking run through the bottom of the rail vehicle, and this embodiment takes four brake pipelines 1 as an example for detailed description.

[0031] The rail vehicle brake pipeline cleaning and sealing detection device includes an air compressor 9 for supplying high-pressure air to the intake pipe 2, and an air filter is connected between the air compressor 9 and the intake pipe 2 10. It is used to filter the impurities blown into the intake pipeline 2 to ensure that the pipeline is not recontaminated by external air during the cleaning and sealing test process, so as to ensure that the cleanliness of the brake pipeline 1 meets the design requirements of rail vehicles .

[0032] Matching with the brake pipe 1, four air intake pipes 2 and four air outlet pipes 3 are provided in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com