Combustion-heated heating ball

A sphere, combustible material technology, applied in the direction of combustion chamber, combustion method, combustion equipment, etc., can solve the problems of undiscovered patent documents, slag sticking at the mouth of ladle and ladle, consumption of large energy, etc., to save centralized heating time. , save energy, improve the effect of heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

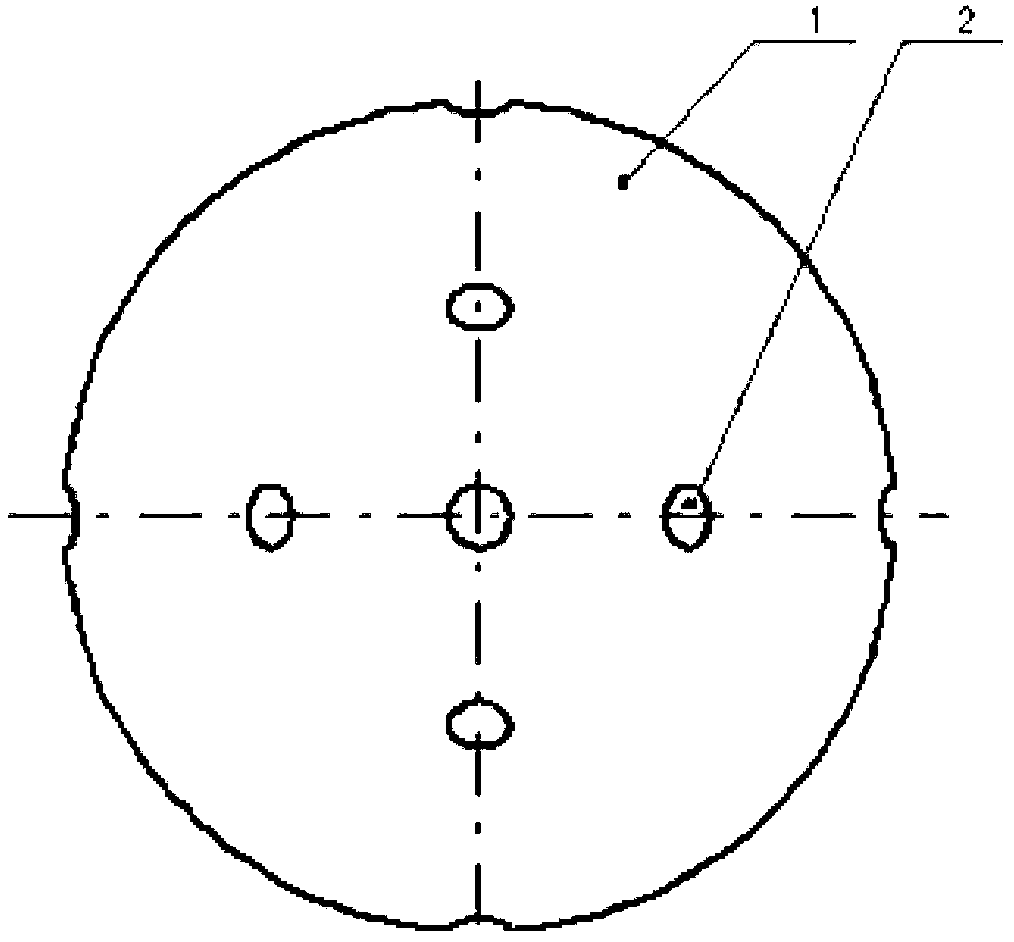

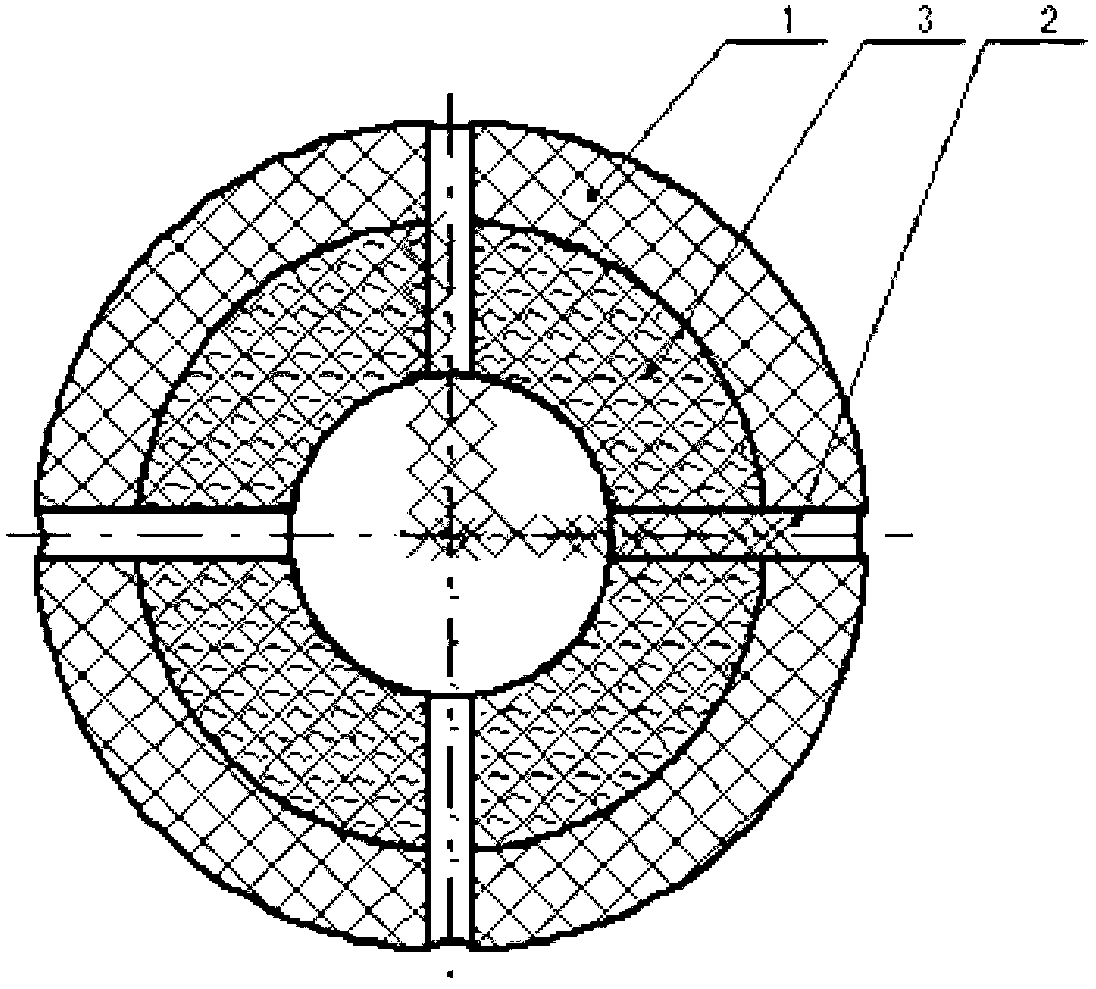

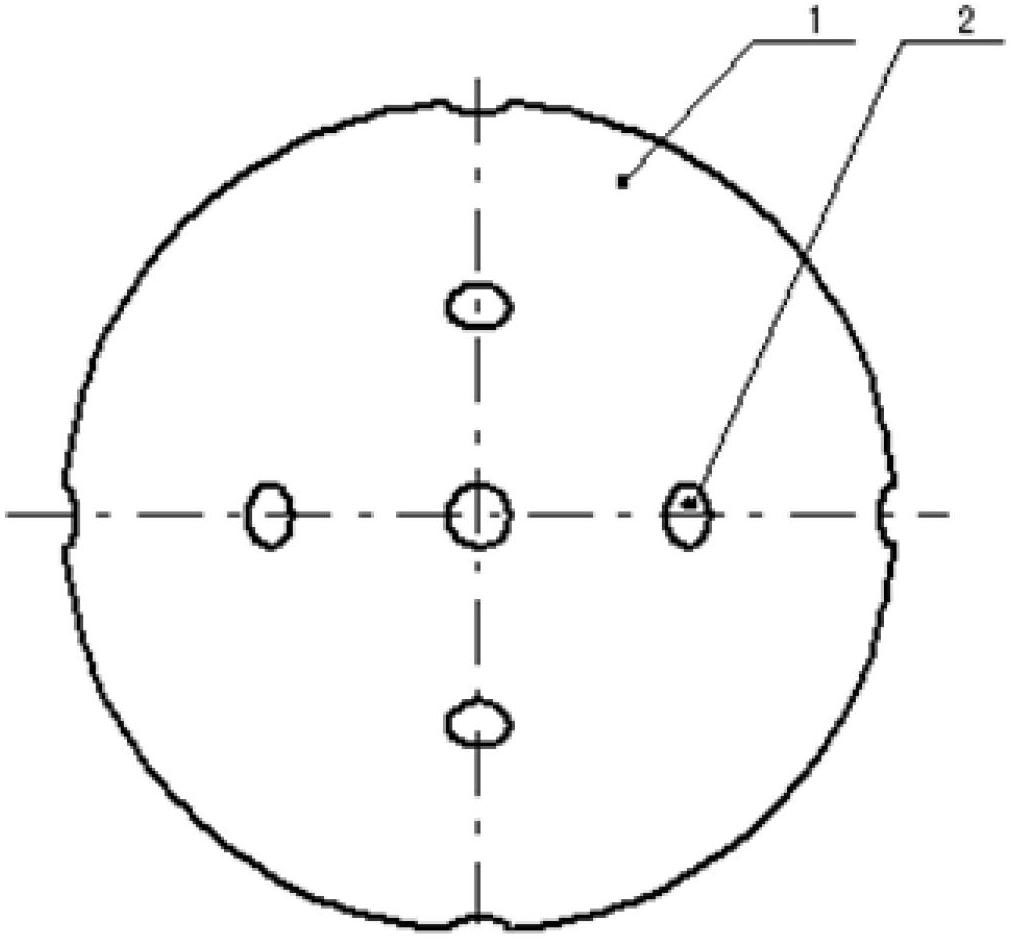

[0024] A heating ball. The ball of the heating ball is a hollow sphere composed of two layers of materials: an outer layer of refractory material layer 1 and an inner layer of combustible material layer 3. The outer layer of refractory material layer and the inner layer of combustible material layer are arranged concentrically. It can be arranged non-concentrically, and it is concentrically arranged in the accompanying drawings of this embodiment; in order to increase air permeability and transfer heat, a centripetal heating through-hole 2 is formed on the sphere.

[0025] The refractory material layer is a high temperature resistant material, using silicon oxide, high alumina, silicon carbide, corundum, magnesium, magnesium calcium, zirco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com