Intelligent constant-temperature injection mold

An injection mold and constant temperature technology, which is applied in the field of intelligent constant temperature injection molds, can solve the problems of slow heat dissipation, achieve the effects of slowing down the temperature drop, accelerating the reaction speed, and increasing the heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

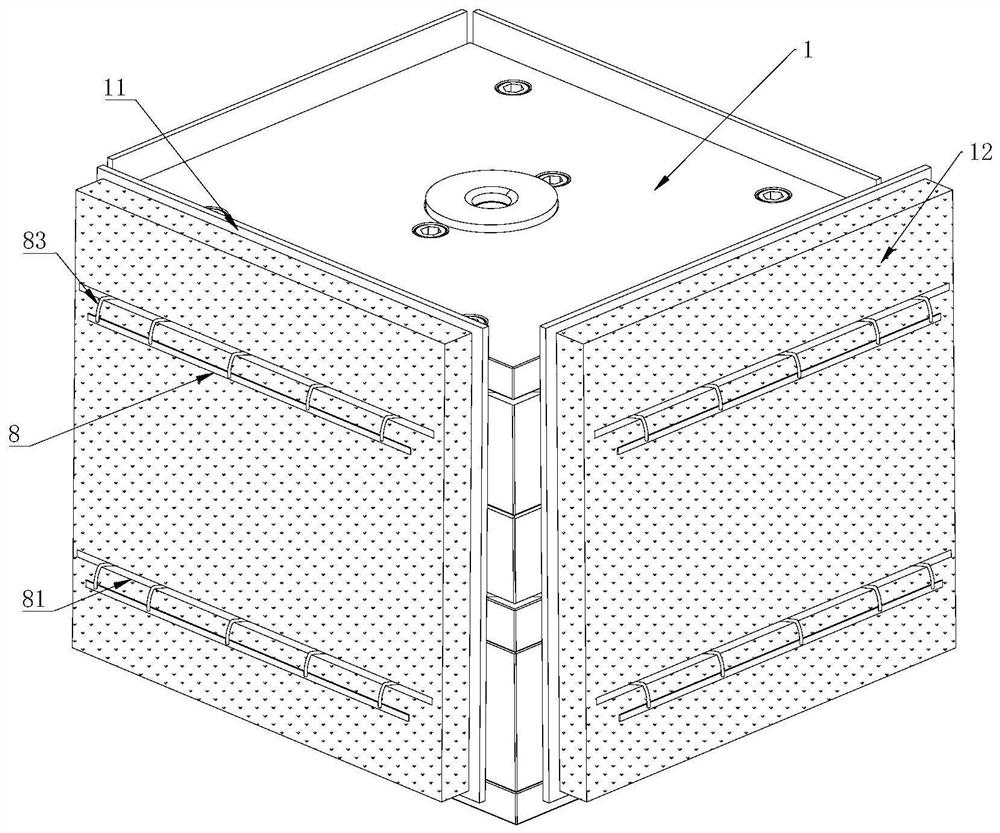

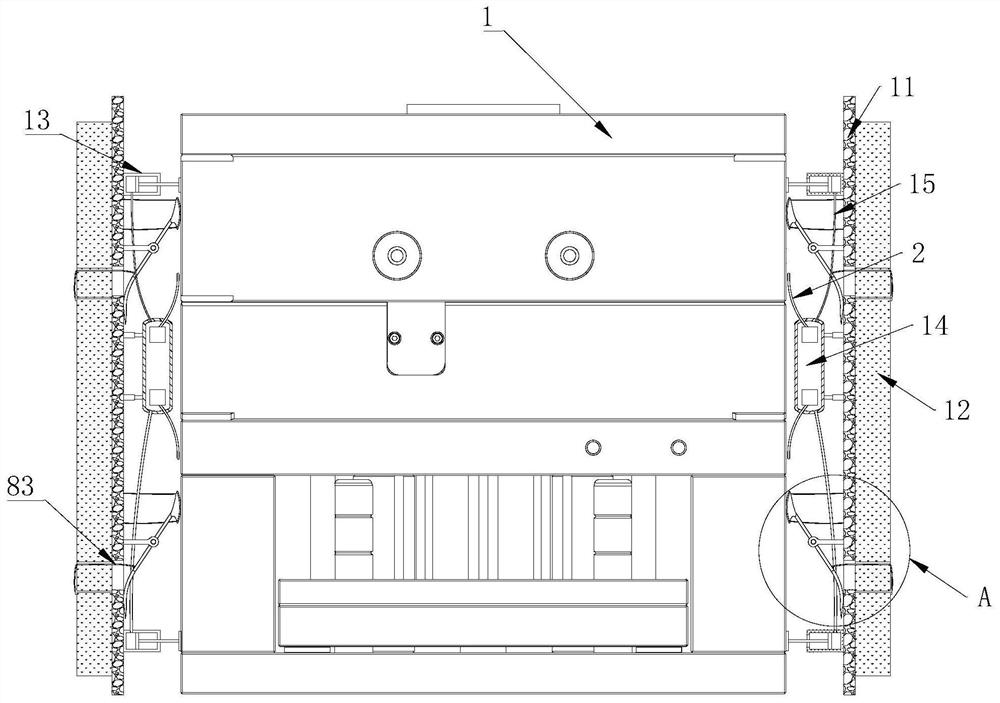

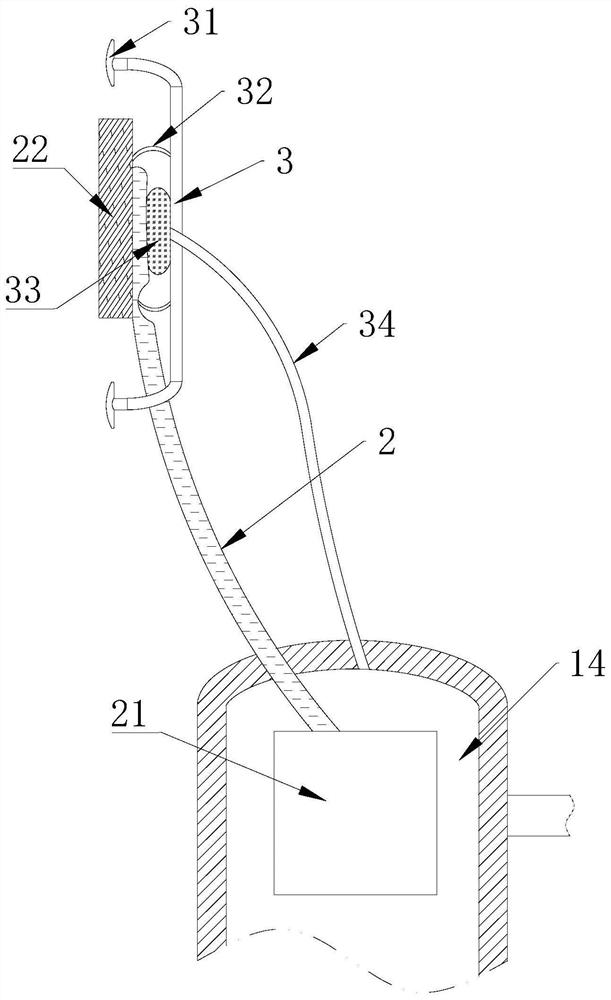

Image

Examples

Embodiment 2

[0039] see Figure 7 As shown in Comparative Example 1, as another embodiment of the present invention, the bottom of the fan flexible board 7 is fixed on the side close to the body 1 with a first flexible pad 9; the fan fan flexible board 7 The other side of the fan is fixedly connected with a second flexible pad 91; by being provided with a first flexible pad 9 and a second flexible pad 91 at the bottom of the fan flexible board 7, it is possible to reduce the contact between the fan flexible board 7 and the thermal insulation and flame retardant. When the side walls of the material 12 are in contact, the scratch problem caused to the inner wall of the heat-insulating and flame-retardant material 12 can be reduced, and at the same time, the problem of wear at the end of the fan-wind flexible plate 7 can be reduced, which can increase the resistance of the fan-wind flexible plate 7 to the heat-insulation and flame-retardant material 12. air tightness.

[0040] The bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com