Nano phase-change constant-temperature culture dish and manufacturing method thereof

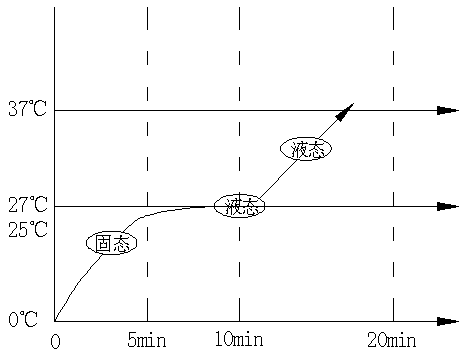

A technology of constant temperature culture and petri dish, which is applied in the field of nano-phase change constant temperature petri dish and its production, can solve the problems of lack of heat preservation, accidental loss of microorganisms or biological cells, and the growth of culture is easily affected by changes in the external environment, etc. The effect of slowing down the rate of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

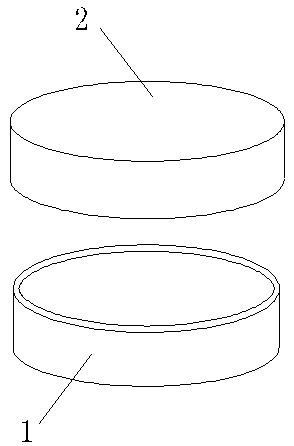

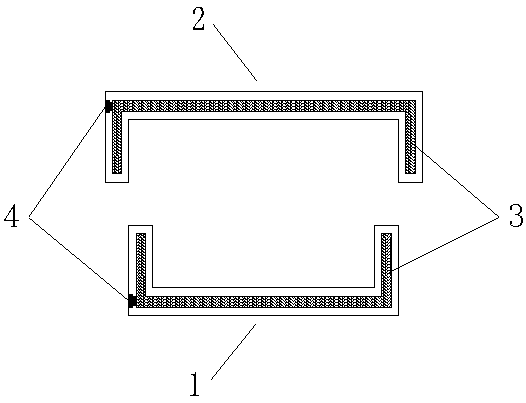

[0017] Such as figure 1 , the product of the present invention is a nano phase change constant temperature culture dish, which is composed of a culture dish 1, a culture dish cover 2, a nano phase change constant temperature capsule material 3 and a liquid injection sealing port 4, referring to figure 1 figure 2 , its production and processing method is described as follows:

[0018] 1: The petri dish 1 and the petri dish cover are produced by injection molding 2: Put the special injection mold for making the petri dish on the injection molding machine, and evenly mix nano-aluminum nitride powder into the PP plastic particles in a proportion of 2-5%, acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com