Temperature control system and method for hot-rolled thin strip steel production

A temperature control system and thin strip steel technology, applied in metal rolling, temperature control, metal rolling, etc., can solve the problems of low temperature and thermal history, affect customers' deep processing, and high strength, so as to reduce the temperature drop rate and highlight the essence Sexual characteristics, the effect of improving tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

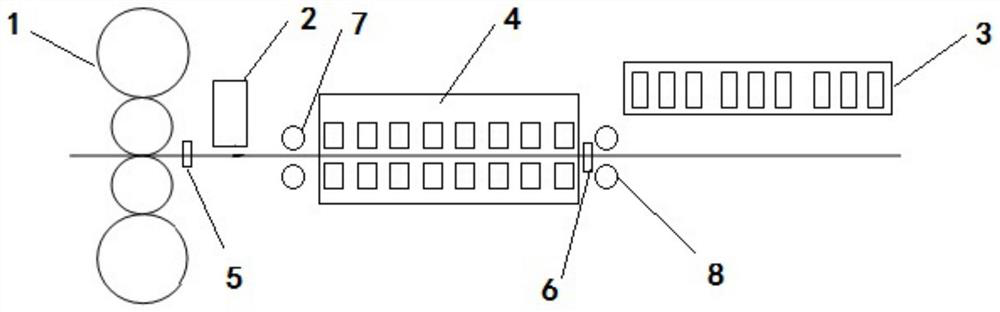

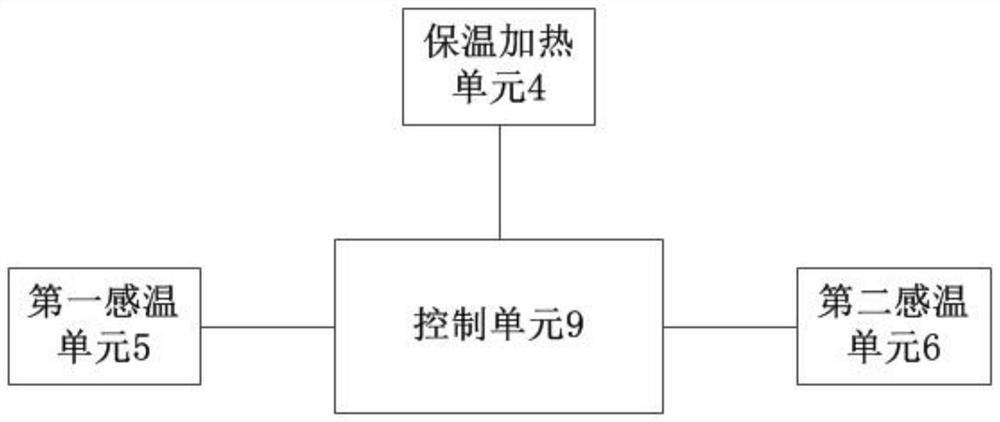

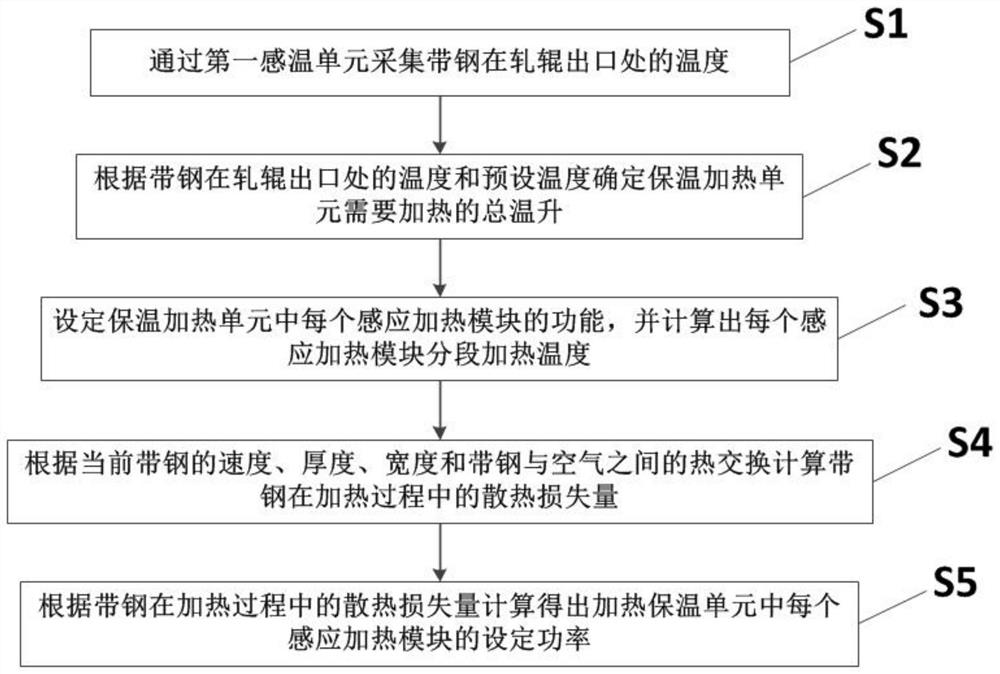

[0037] Such as figure 1 A temperature control system for the production of hot-rolled thin strip is shown, including a hot-rolled thin-strip production line, in which a roll 1 and a width and thickness gauge 2 are sequentially arranged along the rolling direction of the strip and laminar flow cooling device 3. This system is based on the hot-rolled thin strip steel production line, including: heat preservation heating unit 4, first temperature sensing unit 5, second temperature sensing unit 6, first pinch roll 7, second pinch roll 8 and control unit 9, the first A temperature sensing unit 5 is set at the exit end of the roll 1, and the first pinch roll 7, the heat preservation heating unit 4, the second temperature sensing unit 6, and the second pinch roll 8 are successively arranged at the width measuring point along the rolling direction of the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com