Rolling compaction process based on asphalt mixed material compaction characteristic

A technology of asphalt mixture and solid characteristics, which is applied in the field of coagulation pavement, roads, climate change adaptation, etc. Influence and other problems, to achieve the effect of easy guarantee of compaction, increase of initial compaction, and increase of appearance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0054] A rolling process based on the compaction characteristics of asphalt mixture, comprising the steps of:

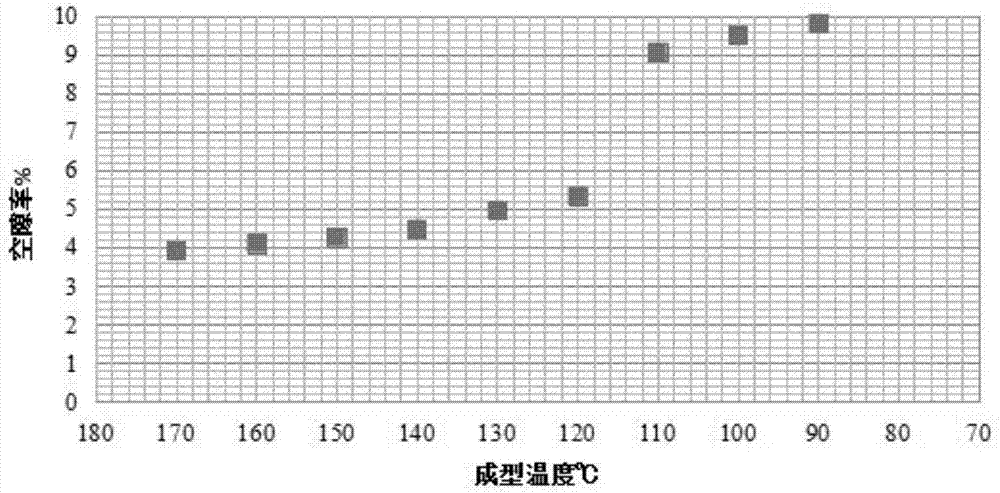

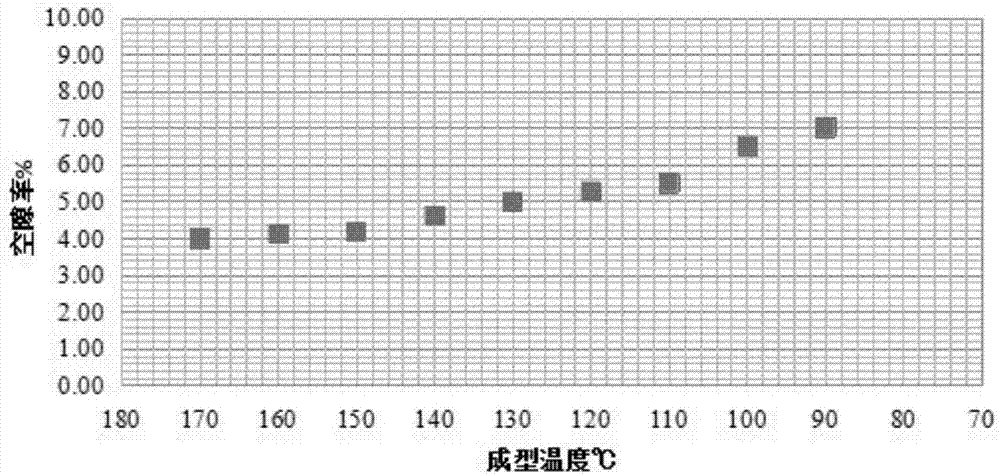

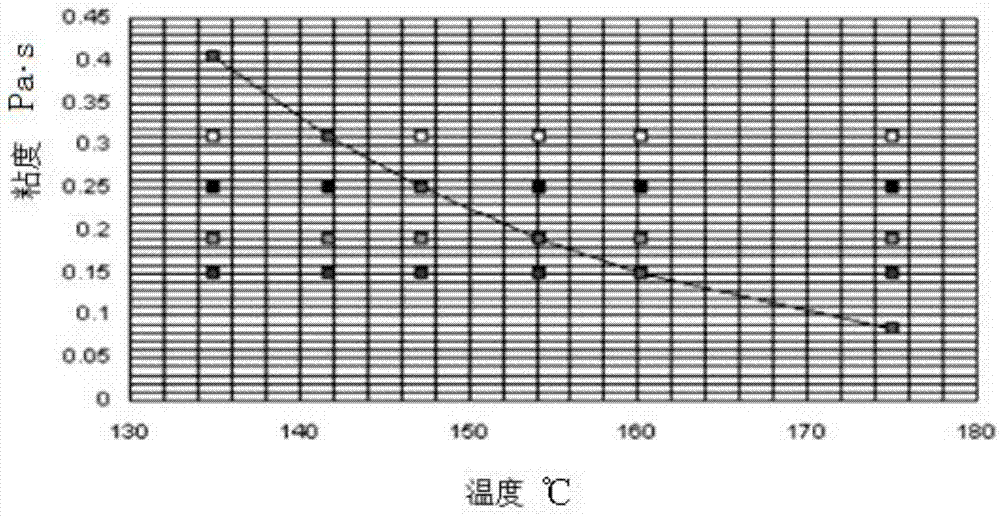

[0055] 1. Determine the initial pressure temperature of asphalt mixture:

[0056] Determine the initial pressure temperature of asphalt mixture according to actual engineering experience or viscosity-temperature curve.

[0057] The asphalt mixture is rubber powder modified asphalt mixture, and the initial pressure temperature is set at 170°C based on actual engineering experience.

[0058] The initial pressure temperature of SBS I-D modified asphalt mixture is set at 170°C according to actual engineering experience.

[0059] The initial pressure temperature of 70A road petroleum asphalt mixture is determined according to the visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com