Electric silicon oil clutch water pump

A water pump and water pump body technology, applied in the control of coolant flow, engine components, machines/engines, etc., can solve the problems of limited service life, low accuracy, waste of energy, etc., and achieve large driving torque, rapid response, and extended The effect of pump life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

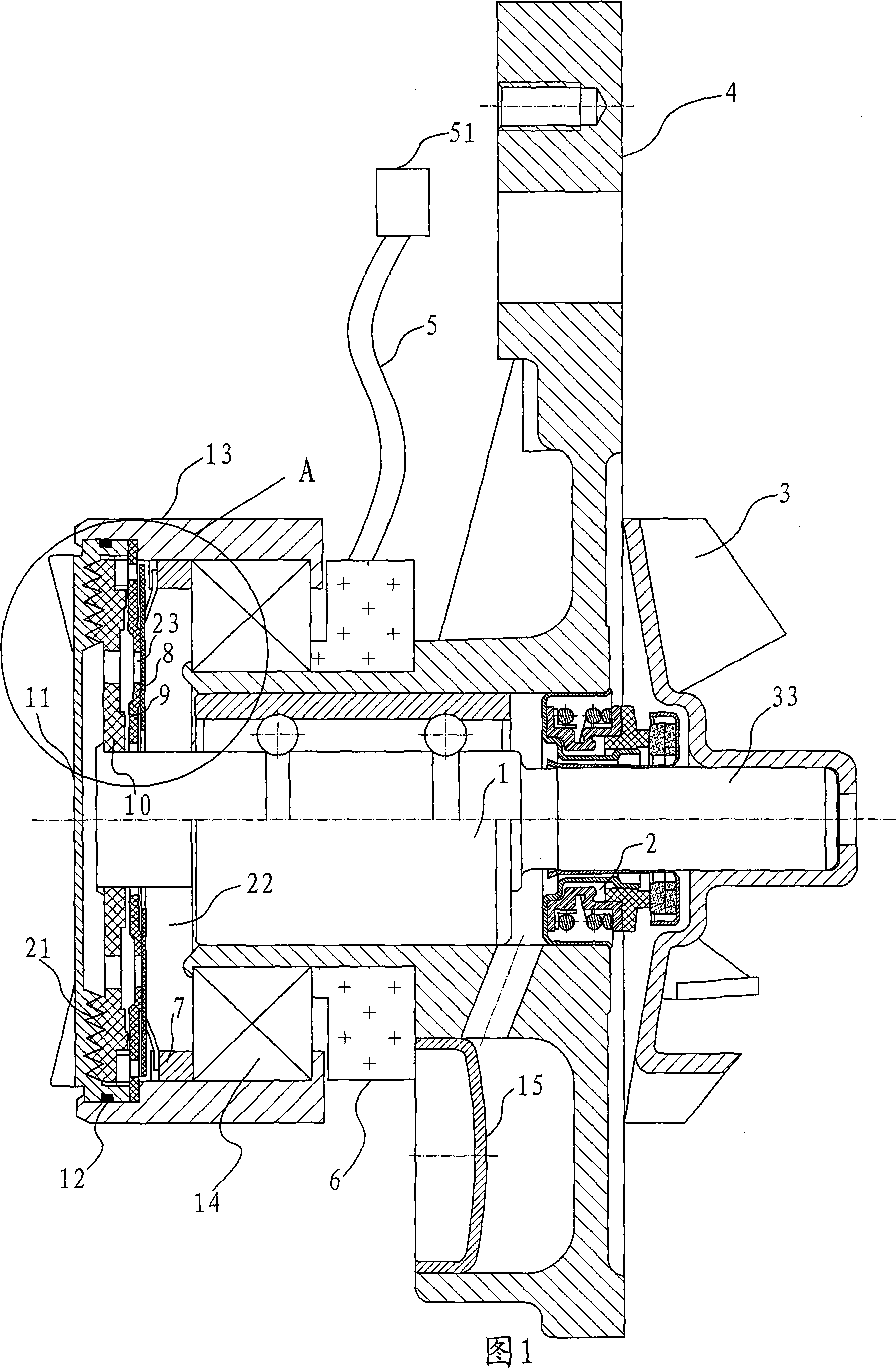

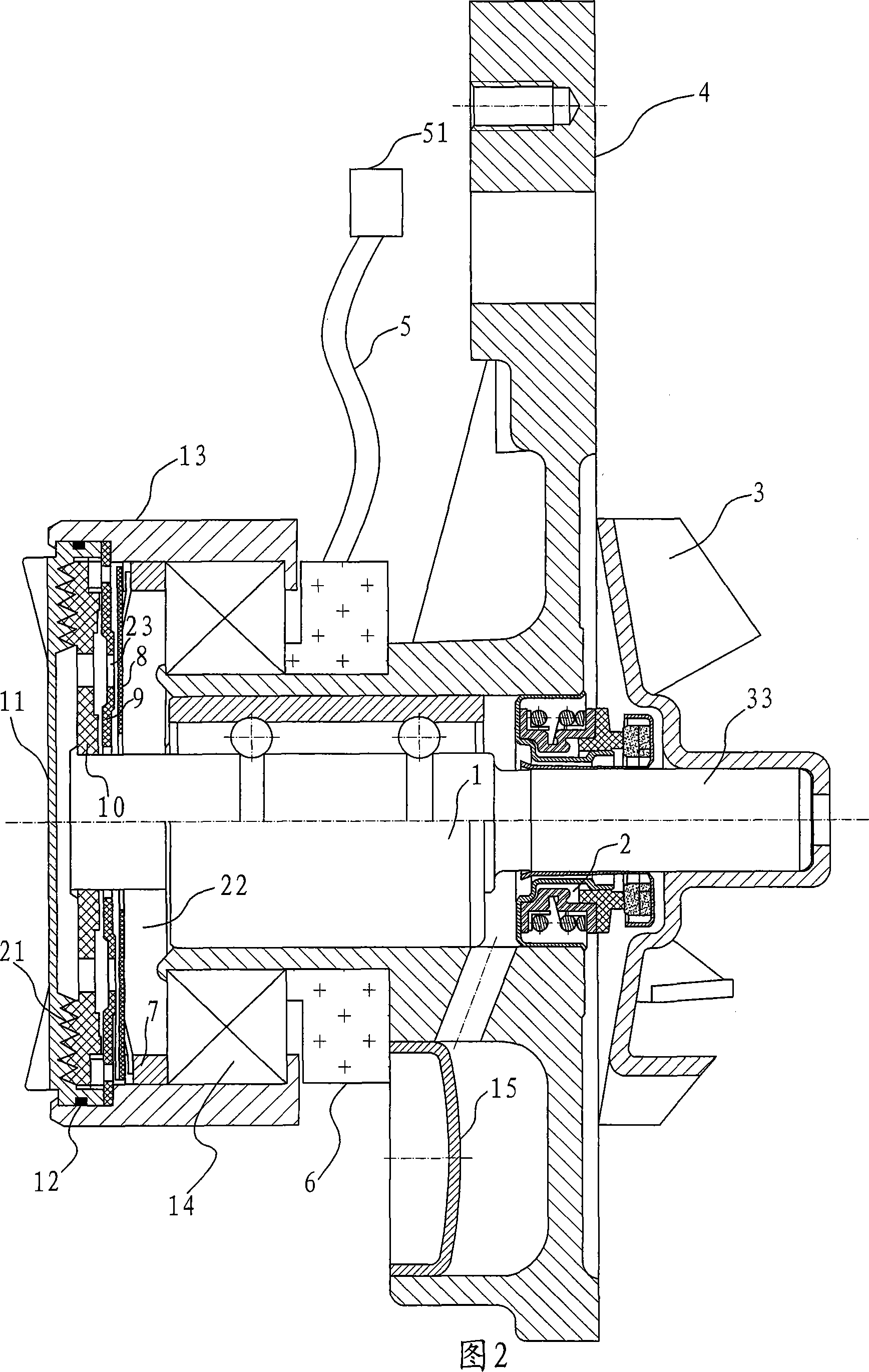

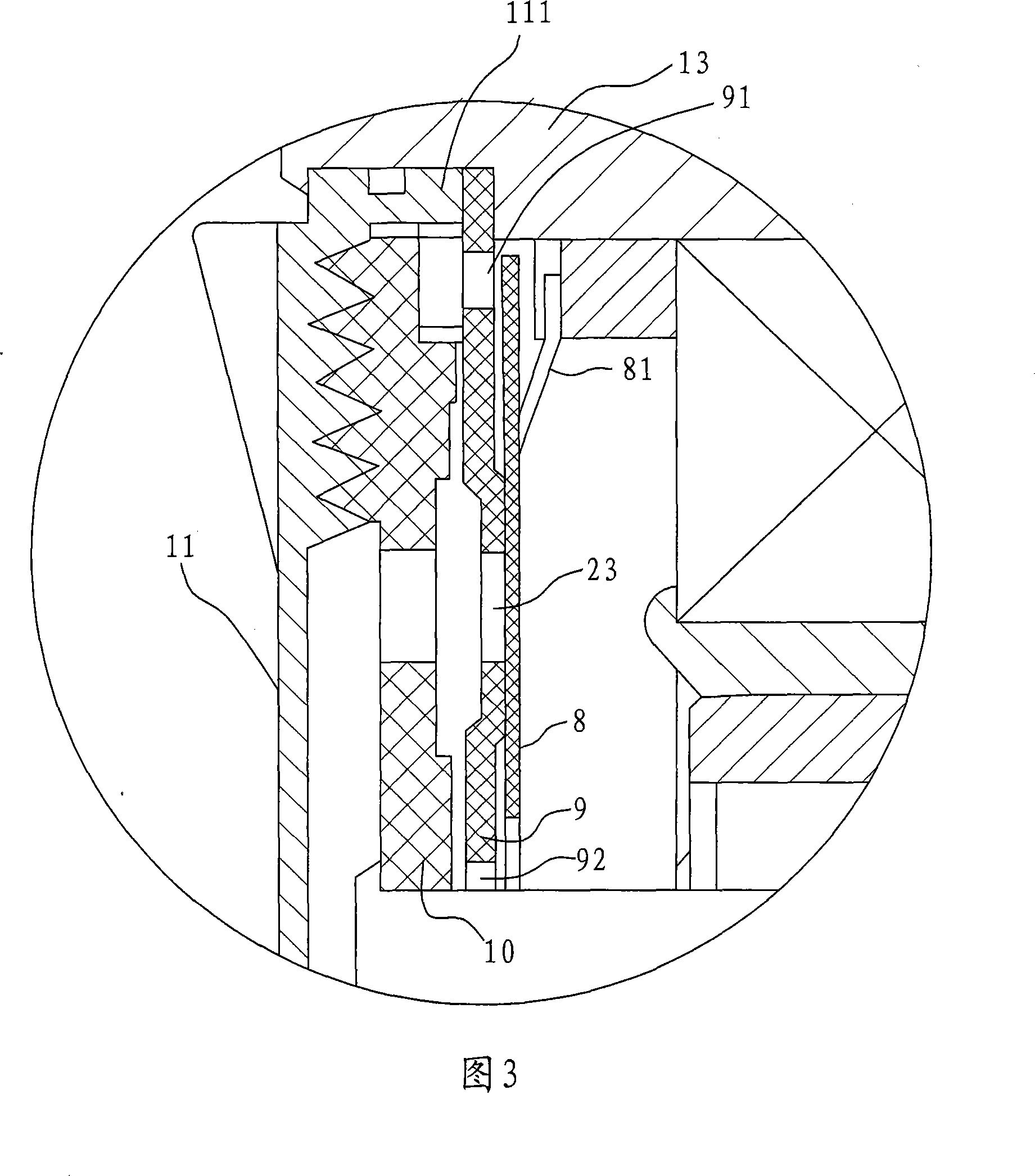

[0016] Embodiment: Referring to Figure 1, the electronic silicone oil clutch water pump in this embodiment includes a shaft coupling bearing 1, a water seal 2, an impeller 3, a water pump body 4, a wiring harness 5, a coil 6, an iron core 7, a valve plate 8, a storage Oil cover 9, active plate 10, front cover 11, sealing ring 12, pulley housing 13, bearing 14 and silicone oil. There is a water seal 2 between the shaft bearing 1 and the water pump body 4, the impeller 3 is fixed on the shaft of the shaft coupling bearing 1, the blocking cover 15 is fixed on the water pump body 4; the coil 6 is fixed on the water pump body 4, and is connected to the engine through the wire harness 5 The electronic control unit 51; the pulley housing 13 is fixed on the water pump body 4 through the bearing 14, the iron core 7 and the oil storage cover 9 are fixed in the pulley housing 13, the valve plate 8 is located between the iron core 7 and the oil storage cover 9, The active plate 10 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com