Changeable flange joint

A technology of variable flanges and threaded pipes, applied in the direction of flange connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as waste, difficulty in ensuring cleanliness, and inability to reuse materials, etc., to achieve reliable connections, The effect of convenient on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

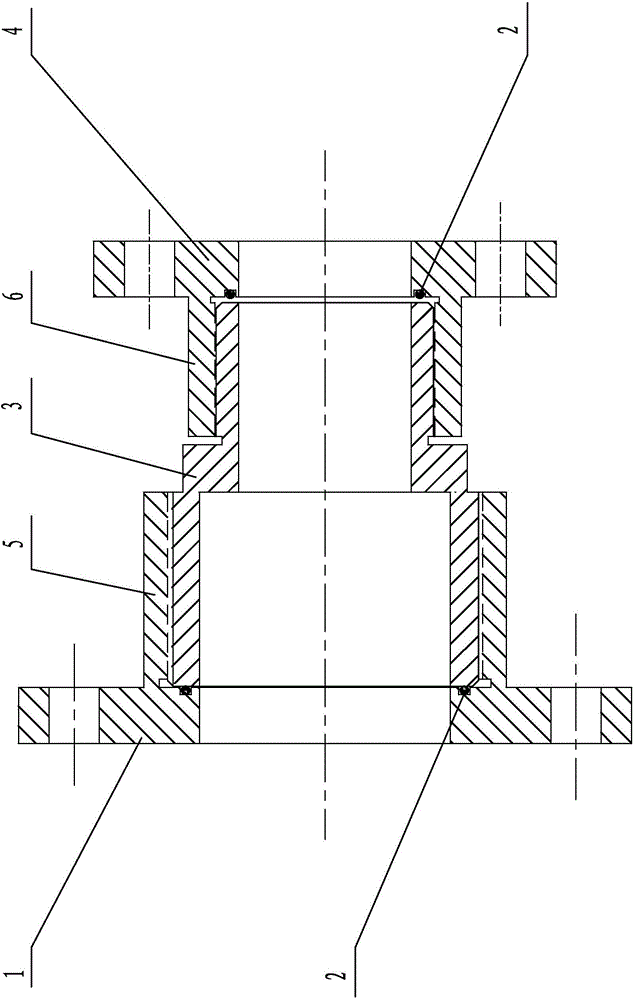

[0014] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0015] The variable flange joint of the present invention is mainly composed of a large flange 1, a small flange 4, a double-ended threaded pipe joint 3, a large-diameter threaded pipe 5, a small-diameter threaded pipe 6 and a sealing ring 2.

[0016] The large-diameter threaded pipe 5 is coaxially arranged at the bottom of the large flange 1 (non-sealing surface) and forms a whole with it (constituting a non-standard part), and the small-diameter threaded pipe 6 is coaxially arranged at the bottom of the small flange 4 end (non-sealing surface) and form a whole with it (constituting a non-standard part), the large-diameter threaded pipe 5 and the small-diameter threaded pipe 6 both adopt internal pipe threads; the two ends of the double-ended threaded pipe joint 3 are respectively large The threaded end and the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com