Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

A pulp and copper card technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, papermaking, textiles and papermaking, etc., can solve the problems of pulp yellowing, poor pulp quality stability, and unfavorable high-quality stability requirements, etc. Achieve the effect of reducing energy consumption of refining, avoiding excessive production and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

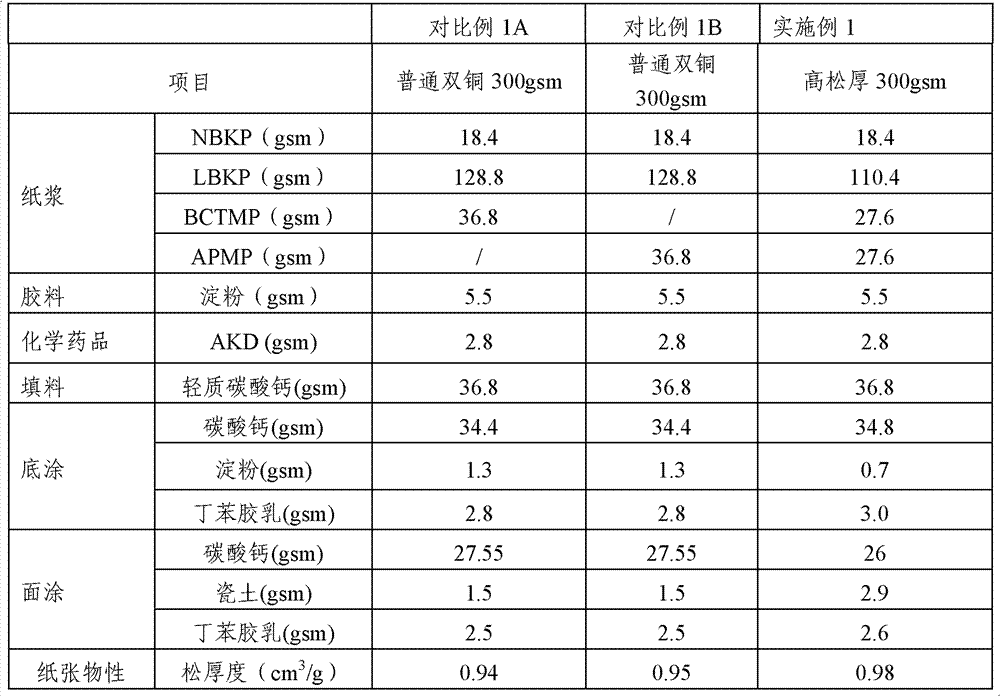

Embodiment 1 and comparative example 1A、1B

[0048] Embodiment 1 and comparative examples 1A, 1B: copper card

[0049] 1. The raw materials and dosage are shown in Table 1: NBKP is bleached kraft softwood pulp (freeness control in Canada is 430±20ml), LBKP is bleached kraft hardwood pulp (freeness control in Canada is 400±20ml), and BCTMP is chemical heat Refining mechanical pulp (250ml of Canadian freeness control), APMP is alkaline hydrogen peroxide mechanical pulp (250ml of Canadian freeness control).

[0050] 2. Preparation method:

[0051] 1) Base paper preparation: Dilute the pulp with water to a slurry with a mass concentration of 5%, centrifuge 5 times, then refine the pulp, add chemicals and fillers, mix well, spray the mixture on the forming net, then dehydrate and dry , apply glue on the surface, then dry, curl into paper, and make base paper. The dust point of base paper should be ≤5ppm;

[0052] 2) Coating coating: according to the formula, apply the primer and top coating on the base paper thinly and even...

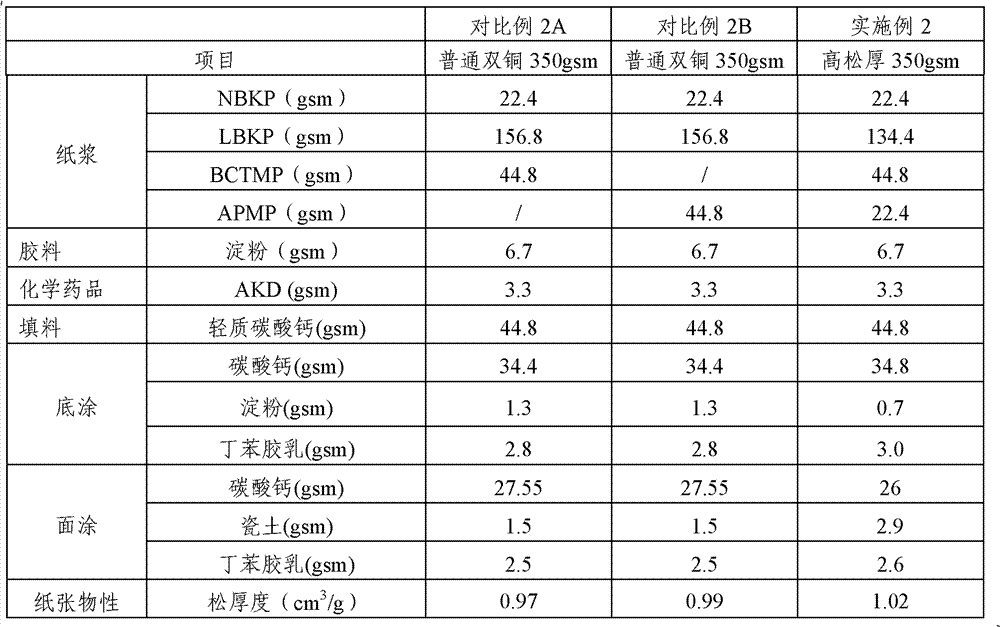

Embodiment 2 and comparative example 2A、2B

[0058] Embodiment 2 and comparative examples 2A, 2B: copper card

[0059] 1. The raw materials and dosage are shown in Table 2: the Canadian freeness of NBKP is controlled at 430±20ml, the Canadian freeness of LBKP is controlled at 400±20ml, the Canadian freeness of BCTMP is 350ml, and the Canadian freeness of APMP is 350ml.

[0060] 2. Preparation method:

[0061] 1) Base paper preparation: Dilute the pulp with water to a slurry with a mass concentration of 10%, centrifuge 4 times, then refine the pulp, add chemicals and fillers, mix well, spray the mixture on the forming net, then dehydrate and dry , apply sizing material on the surface, then dry, curl into paper, and make base paper. The dust point requirement of base paper is ≤5ppm;

[0062] 2) Coating coating: according to the formula, apply the primer and top coating on the base paper thinly and evenly through the coating machine, then dry it, roll it into a roll on the winder, and then send it to super calendering Car...

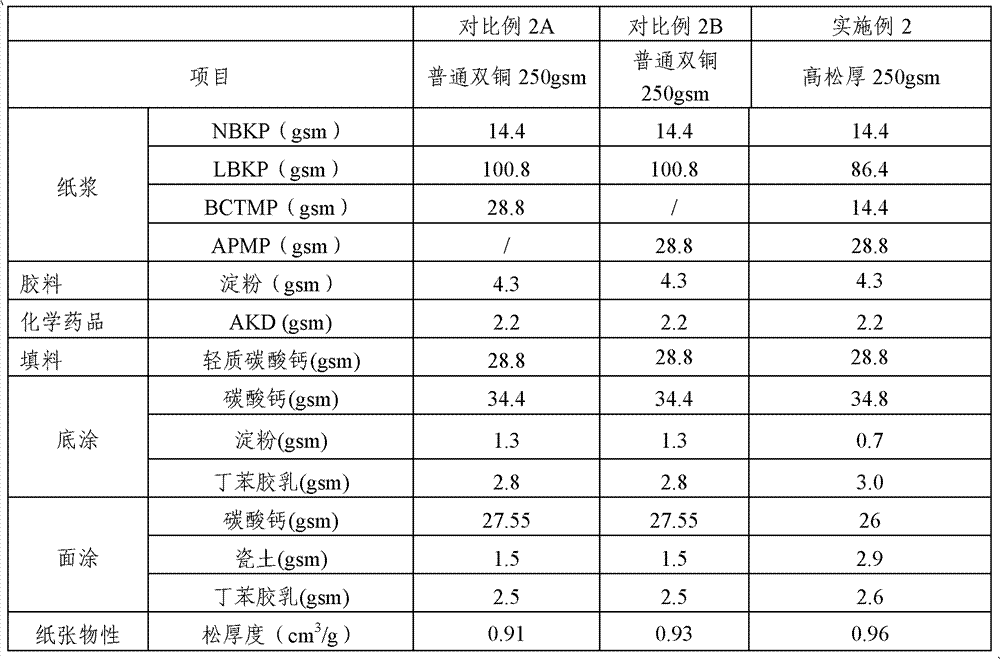

Embodiment 3 and comparative example 3A、3B

[0068] Embodiment 3 and comparative examples 3A, 3B: copper card

[0069] 1. See Table 3 for raw materials: the Canadian freeness of NBKP is controlled at 430±20ml, the Canadian freeness of LBKP is controlled at 400±20ml, the Canadian freeness of BCTMP is 250ml, and the Canadian freeness of APMP is 250ml.

[0070] 2. Preparation method:

[0071] 1) Base paper preparation: Dilute the pulp with water to a slurry with a mass concentration of 30%, centrifuge three times to remove iron wires and stones, then refine the pulp, add chemicals and fillers, mix well, and spray the mixture on the forming wire , then dehydrated, dried, applied glue on the surface, dried again, curled into paper, and made into base paper. The dust point of base paper is required to be ≤5ppm;

[0072] 2) Coating coating: according to the formula, apply the primer and top coating on the base paper thinly and evenly through the coating machine, then dry it, roll it into a roll on the winder, and then send it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com