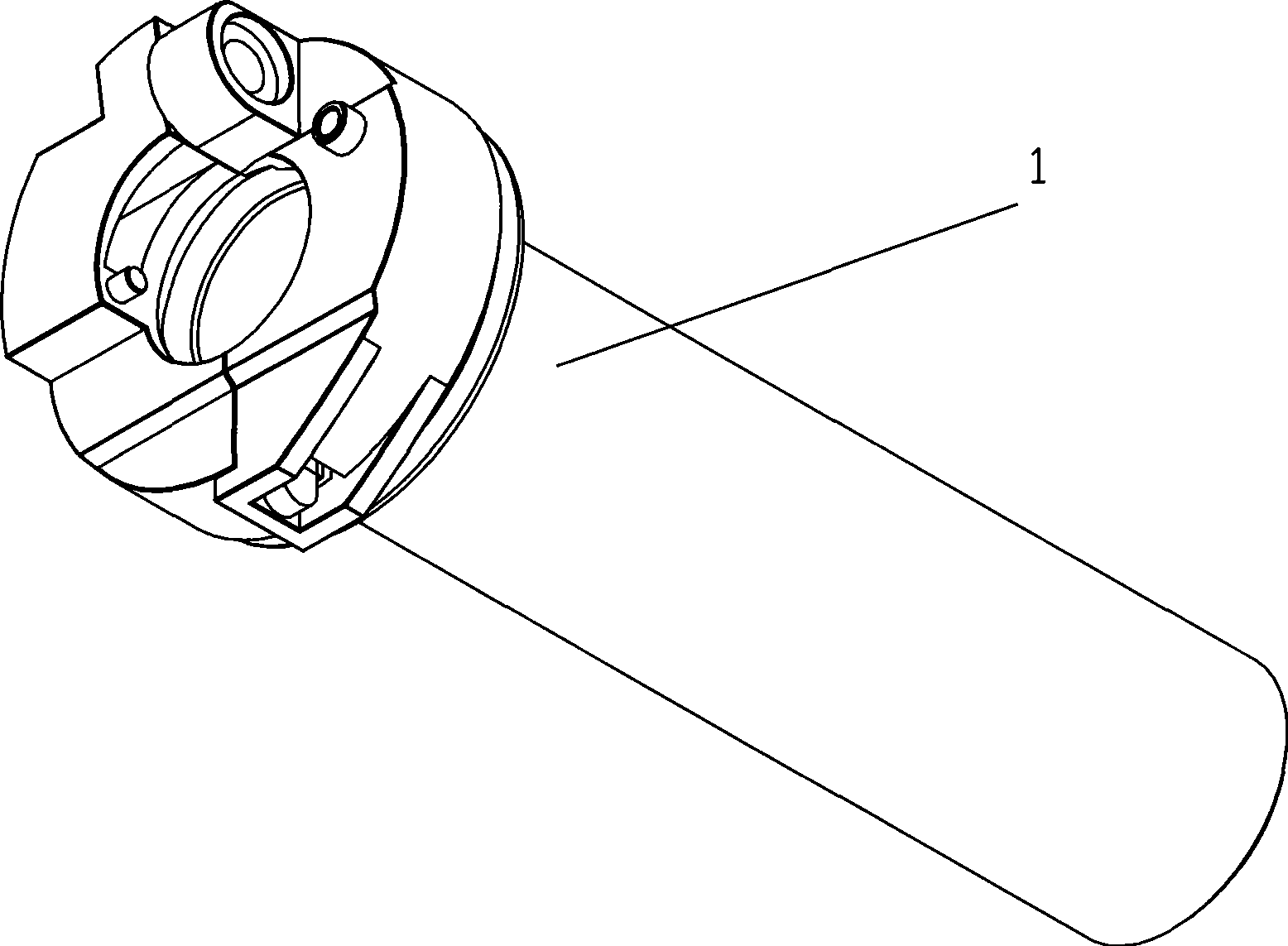

Engine for hybrid power motorcycle and electric motor integrated controlling speed regulating handle

A technology of hybrid power and motorcycles, applied in bicycle control systems, bicycle accessories, transportation and packaging, etc., to achieve the effect of simple structure design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

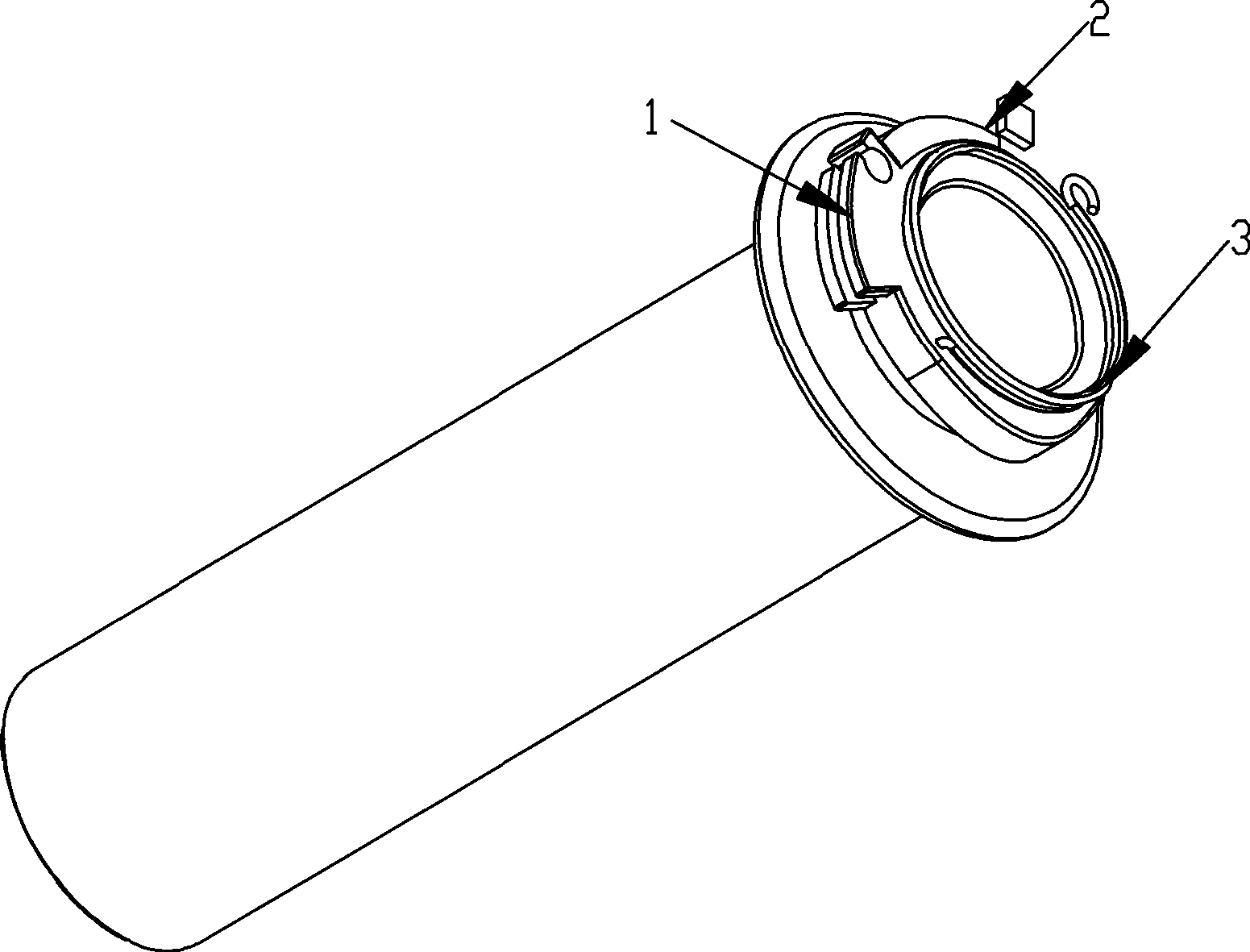

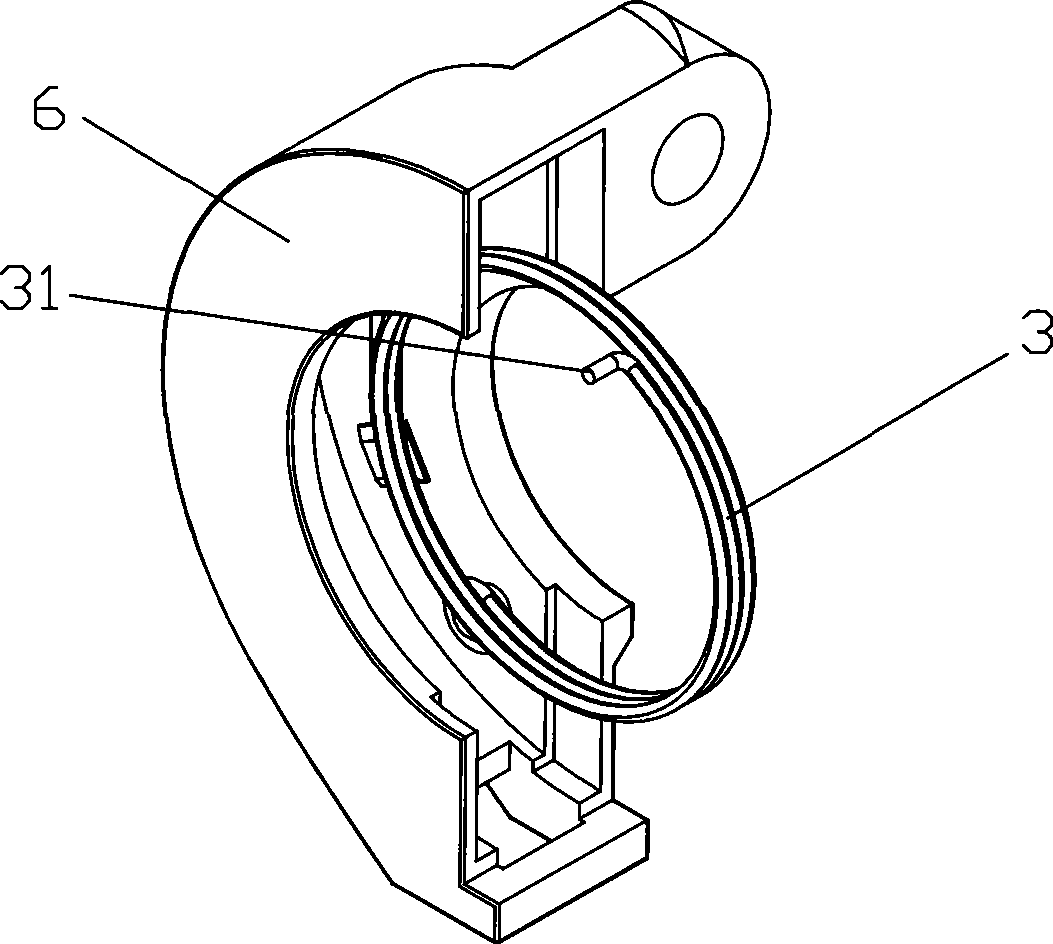

[0027] Firstly, the switching speed V is calculated according to the control strategy of the hybrid motorcycle and the structural configuration of the vehicle. 0 and the corresponding speed N of the engine 0 ; Then according to the operating characteristics of the motor and the engine, calculate the turn to control the motor drive to accelerate to the speed V 0 The corresponding rotation angle α 0 , the engine speed is N 0 The corresponding throttle opening (that is, the lift of the carburetor needle); and then calculate the parameters of the parabola at the 8 positions of the winding shaft on the handlebar, the relative position, and the free length L of the throttle cable according to the above data and other relevant known parameters. 、α 1 , V 1 and other parameters.

[0028] The model of the handle is determined according to the calculated relevant parameters, correspondingly the parameters of other components (such as the position of the Hall element mounting hole, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com