Method for preparing chitosan through chitin liquefaction

A technology for liquefying chitosan and oxidizing chitosan, which is applied in the production of bulk chemicals and can solve problems such as environmental pollution of chitosan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

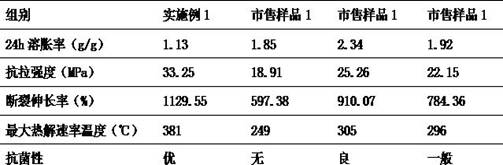

Examples

Embodiment 1

[0025] A kind of chitin liquefaction prepares the method for chitosan, it passes through following processing steps:

[0026] 1) Degradation of chitin

[0027] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0028] b. Add hydrogen peroxide to the squid fan-shaped bone powder obtained in step a, rapidly heat up to 120°C hydrogen peroxide detonation point, and process to obtain oxidized chitosan; wherein the hydrogen peroxide has a concentration of 67%, soak the squid fan-shaped bone powder in hydrogen peroxide before heating 2.5 hours;

[0029] 2) Enzymolysis

[0030] Adding the oxidized chitosan obtained in step b to a composite protease, enzymatically hydrolyzing it for 10 h under the action of ultrasonic waves, centrifuging and taking the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline protease and deacetylase, The mass percentage of...

Embodiment 2

[0034] A kind of chitin liquefaction prepares the method for chitosan, it passes through following processing steps:

[0035] 1) Degradation of chitin

[0036] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0037] b. add the squid fan-shaped bone powder obtained in step a to hydrogen peroxide, rapidly heat up to the detonation point of hydrogen peroxide at 100°C, and the treatment is completed to obtain oxidized chitosan; wherein, the hydrogen peroxide has a concentration of 60%, soak squid in hydrogen peroxide before heating Fan-shaped bone meal 2h;

[0038] 2) Enzymolysis

[0039] Adding the oxidized chitosan obtained in step b to a composite protease, enzymatically hydrolyzing it for 10 h under the action of ultrasonic waves, centrifuging and taking the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline protease and deacetylase, The m...

Embodiment 3

[0043] A kind of chitin liquefaction prepares the method for chitosan, it passes through following processing steps:

[0044] 1) Degradation of chitin

[0045] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0046] b. Add hydrogen peroxide to the squid fan-shaped bone powder obtained in step a, and rapidly heat up to 150°C hydrogen peroxide detonation point, and the treatment is completed to obtain oxidized chitosan; wherein, the hydrogen peroxide has a concentration of 70%, soak squid fan-shaped in hydrogen peroxide before heating Bone meal 3h;

[0047] 2) Enzymolysis

[0048] Add the oxidized chitosan composite protease obtained in step b, enzymolyze it for 12 hours under the action of ultrasonic waves, centrifuge and take the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline protease and deacetylase, Its alkaline protease and deacetyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com