Patents

Literature

36results about How to "Electrolytic smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

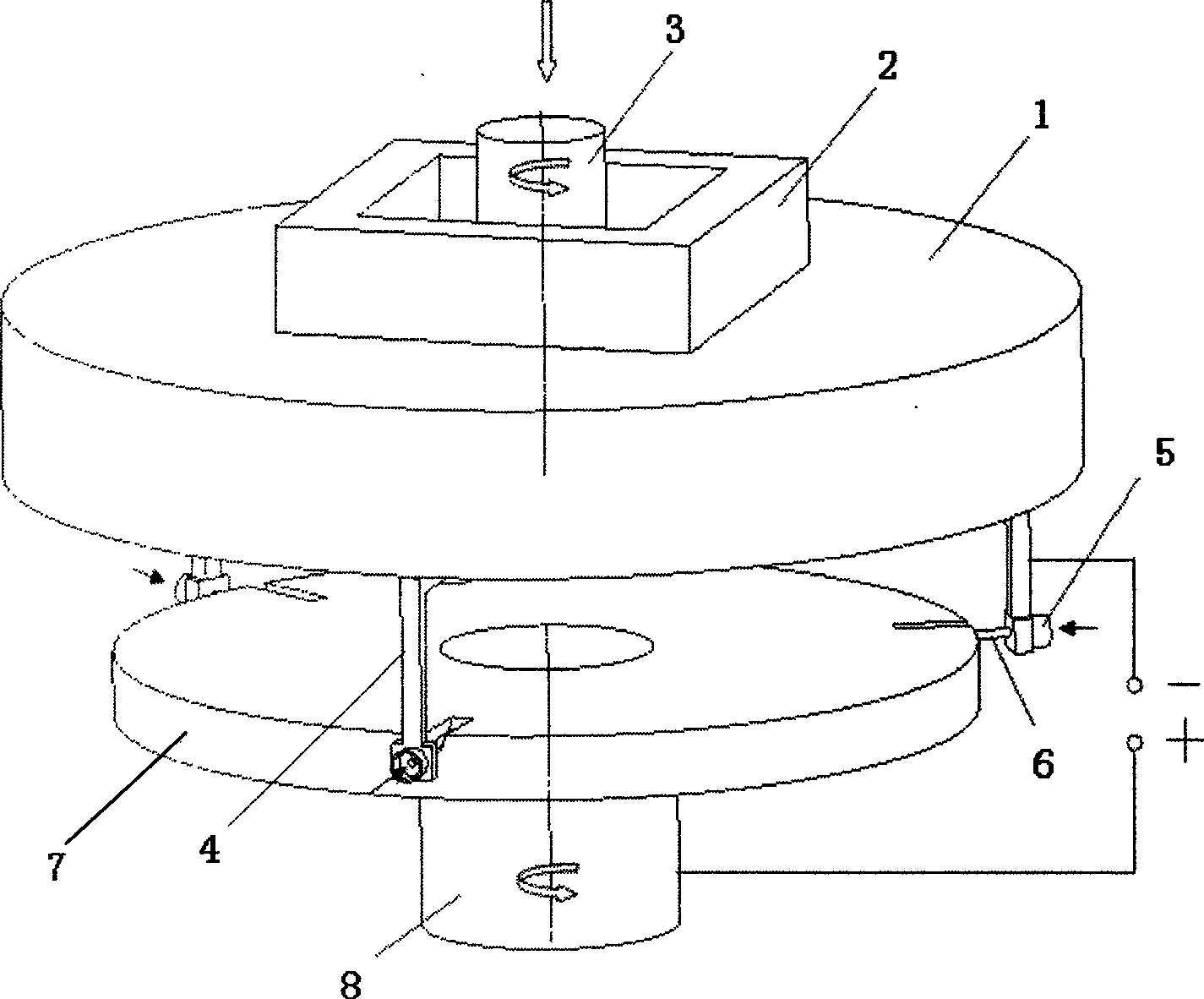

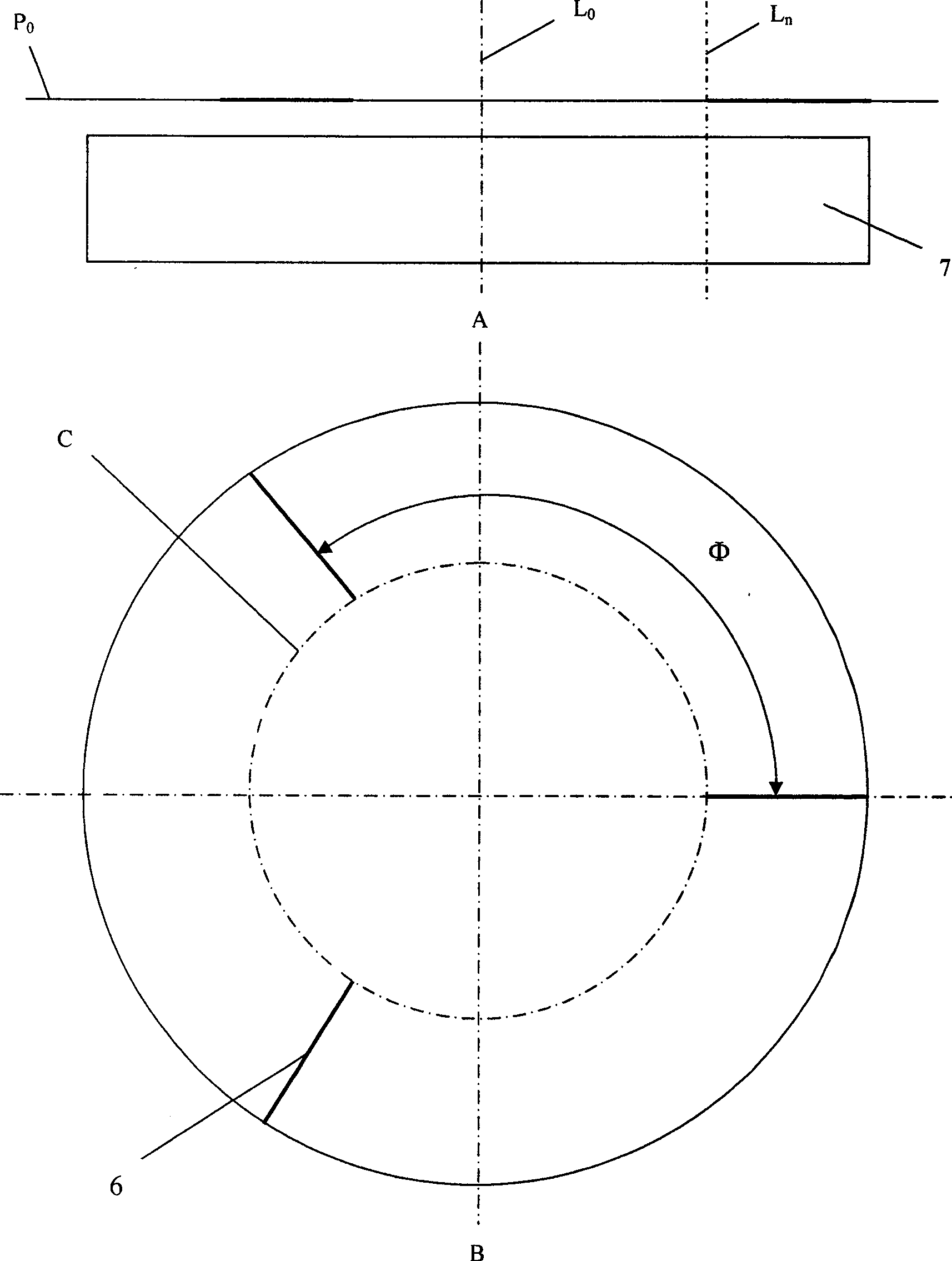

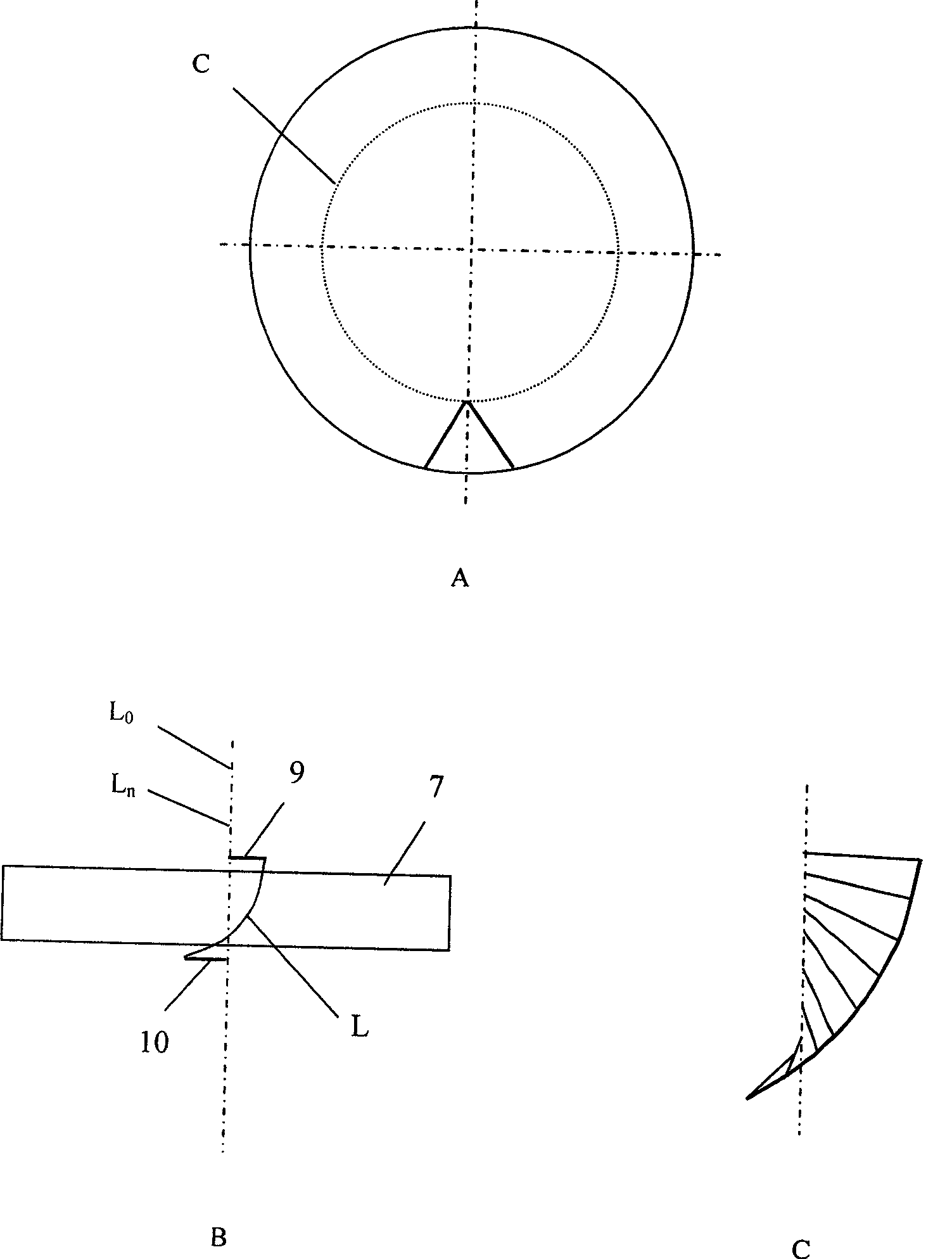

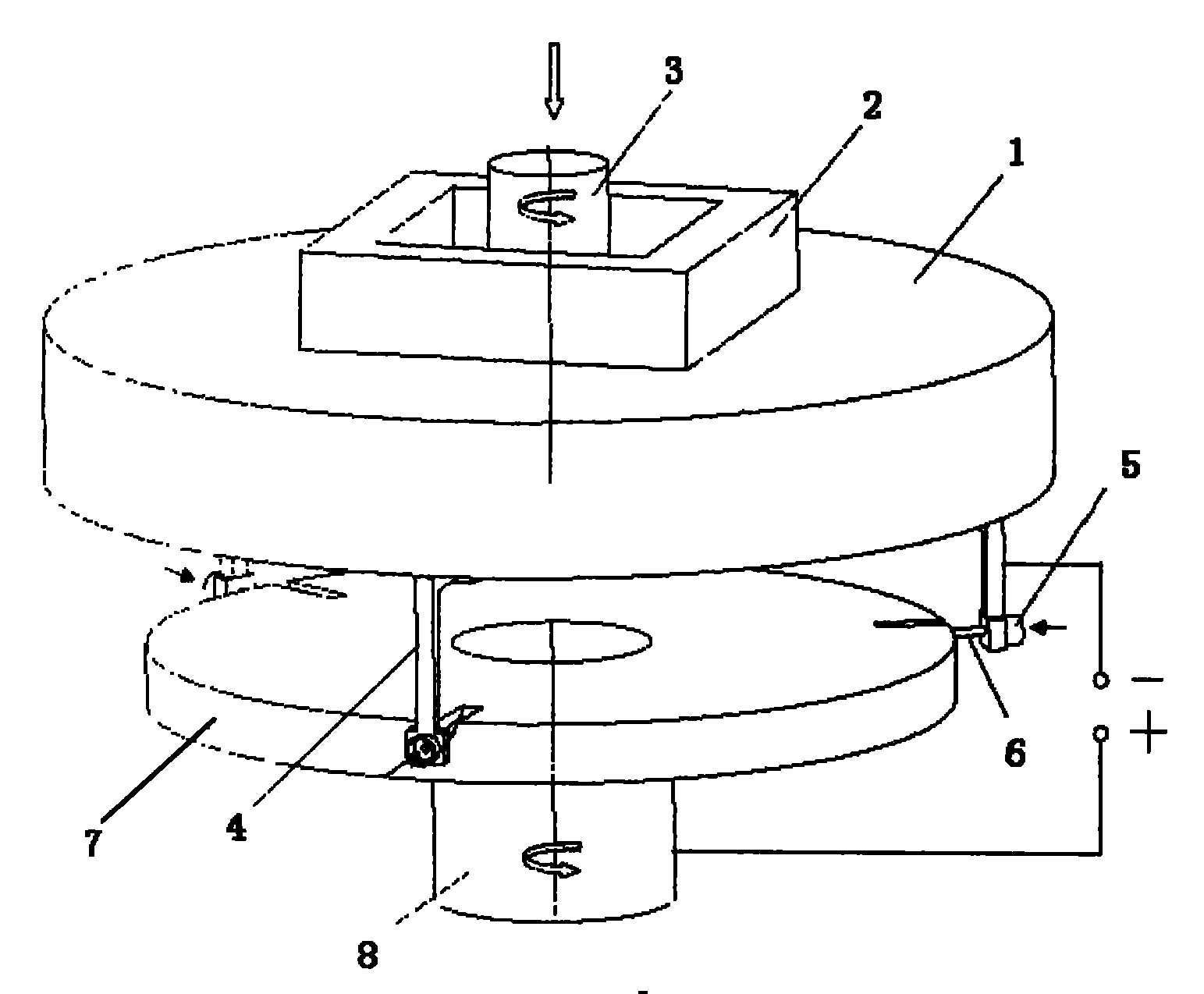

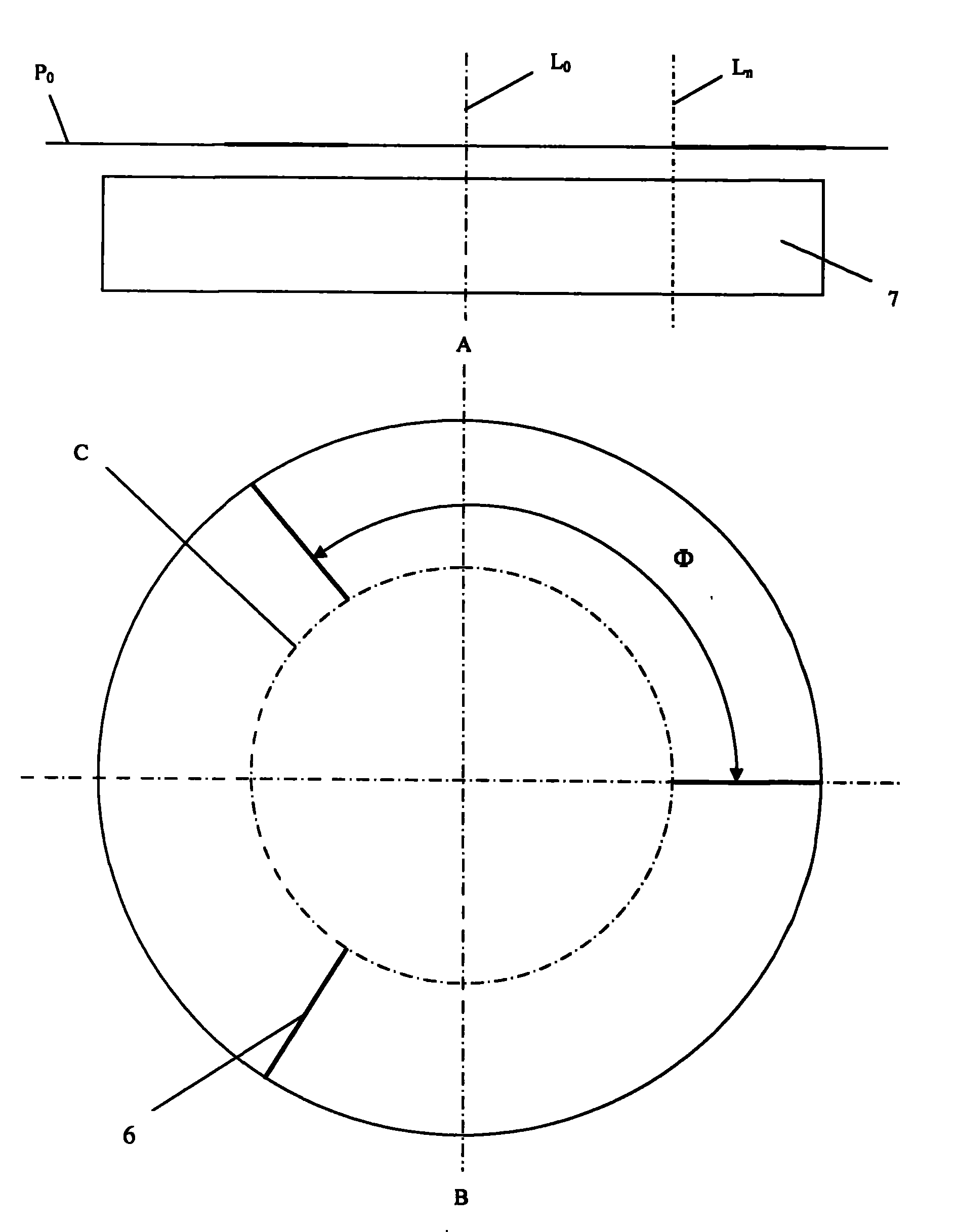

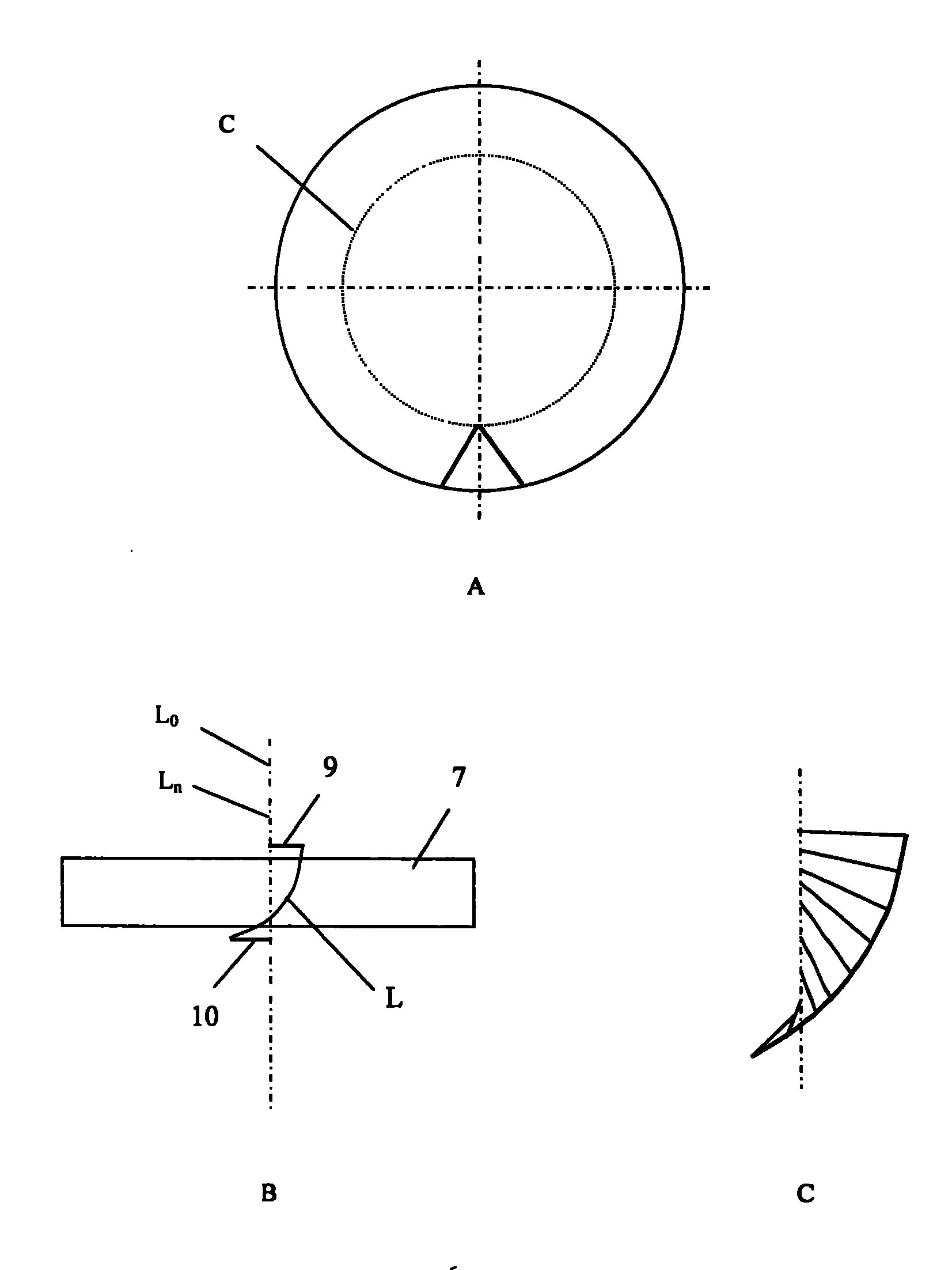

Multi-electrode spiral feeding integral blade wheel inter-blade passage electrolytic machining method

InactiveCN101508047AImprove processing efficiencyShorten the manufacturing cycleImpellerMachining process

The invention relates to an electrolytic machining method for multi-electrode screw feeding integral impeller flow passages, and belongs to the technical field of electrolytic machining. The method adopts a plurality of tool electrodes which are positioned on the same plane and arranged on an electrolytic machining clamp. In the machining process, a translation stage of a machine tool drives the plurality of the tool electrodes to simultaneously feed linearly along the axes direction of an impeller blank, and a turn table on the translation stage drives the plurality of the tool electrodes to rotate; meanwhile, the impeller blank rotates around the axes of the impeller blank, and the tool electrodes perform electrolytic machining along a motion trail determined by the resultant motion. The electrodes and the impeller blank keep a small clearance; electrolyte flows out at a high speed from gaps of the tool electrodes to continuously take away products of electrolysis; and a plurality of impeller flow passages are machined finally. The number and distribution positions of the tool electrodes can be adjusted to meet machining requirements of integral impellers in different types. Because the plurality of the electrodes are adopted to perform machining simultaneously, the machining efficiency for the integral impeller is greatly improved, and the rotation of the electrodes makes machining allowance more even at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

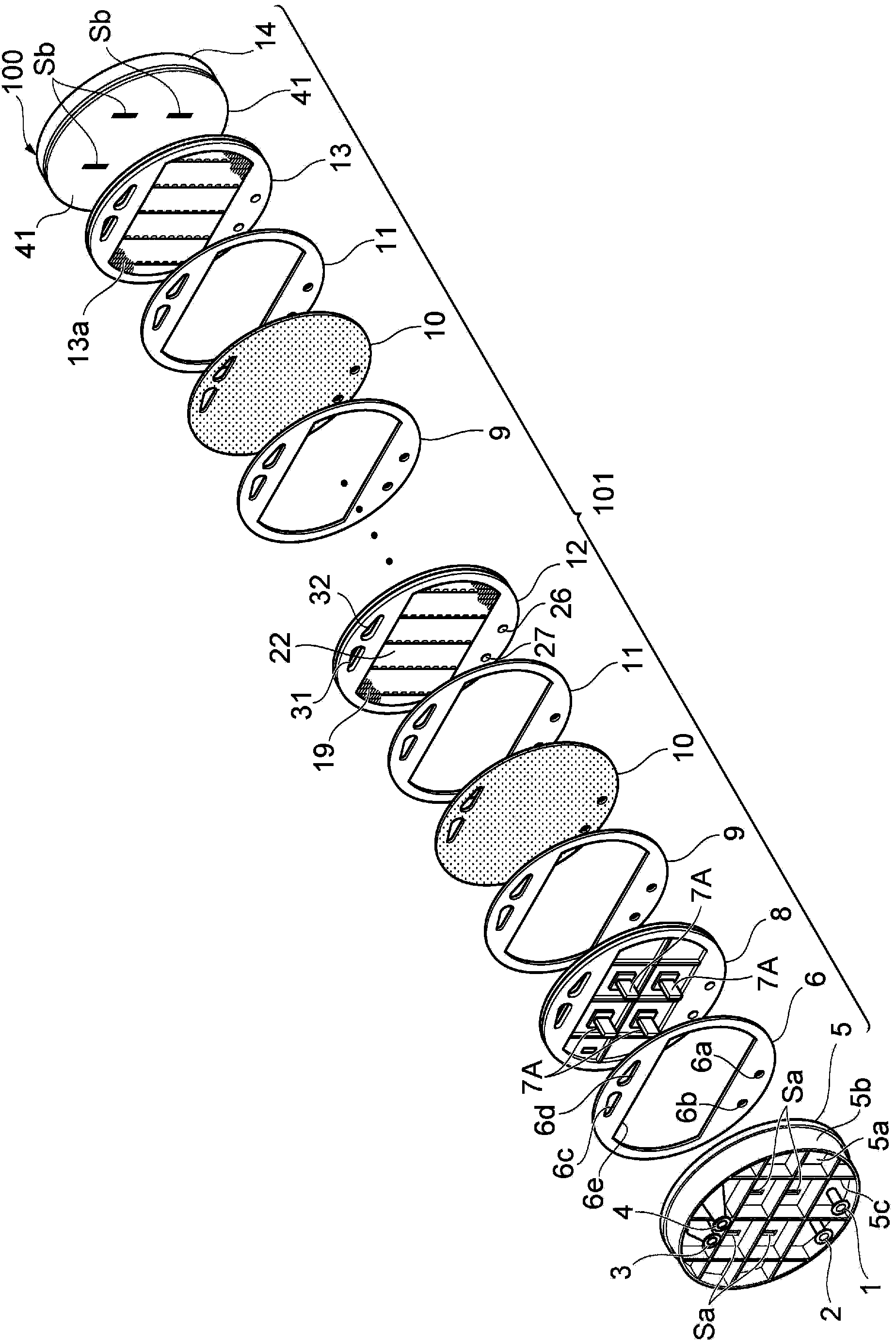

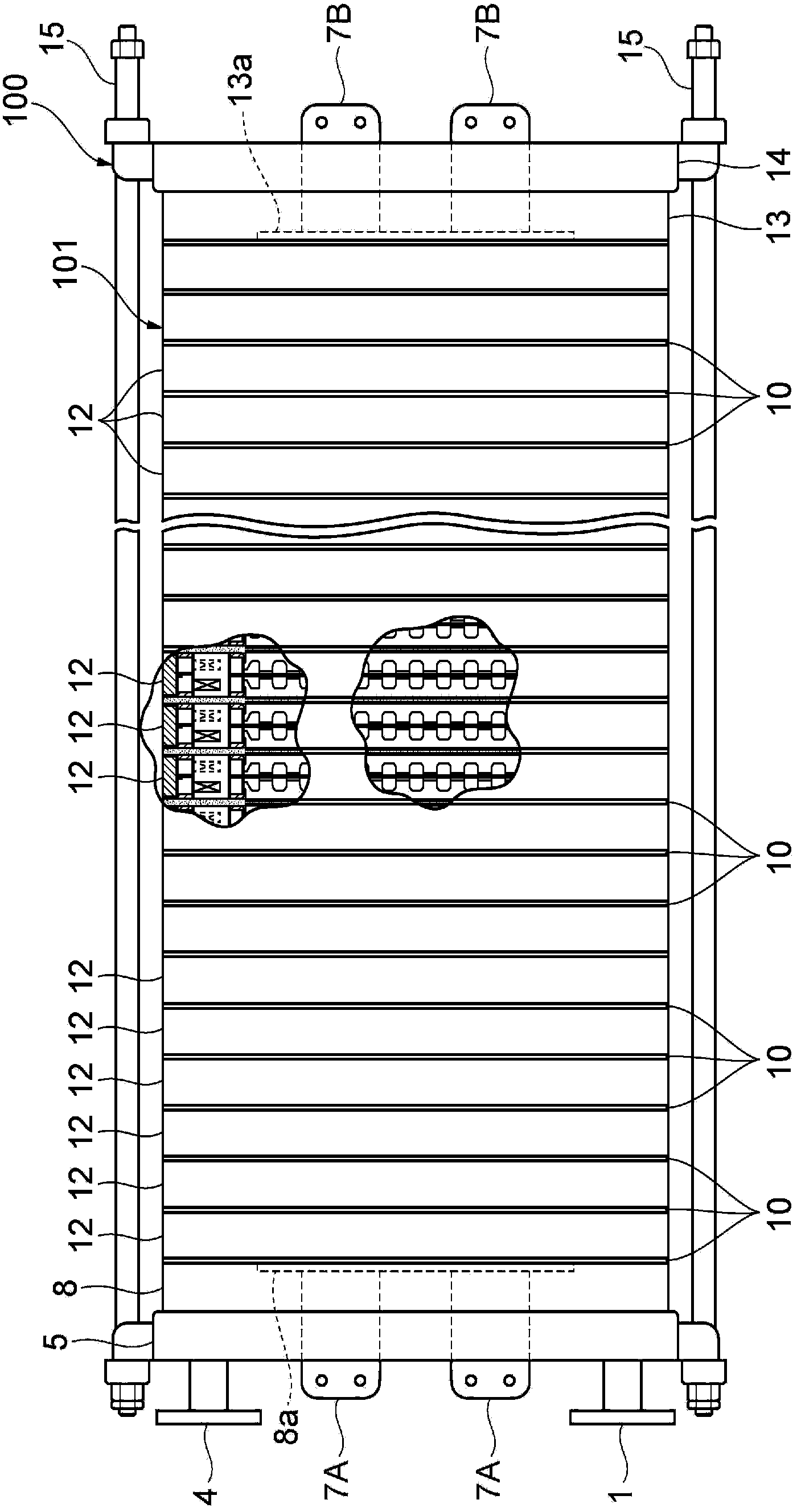

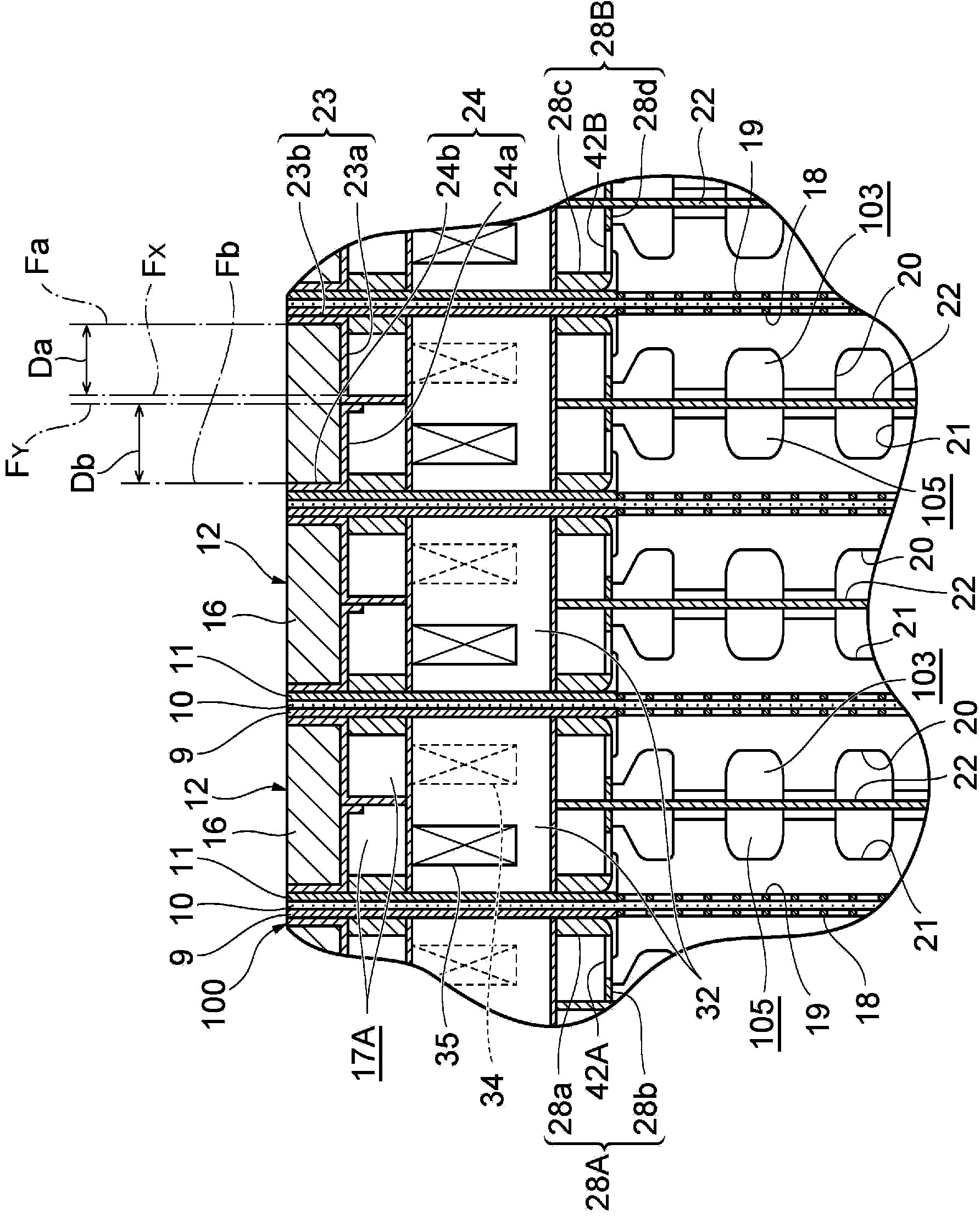

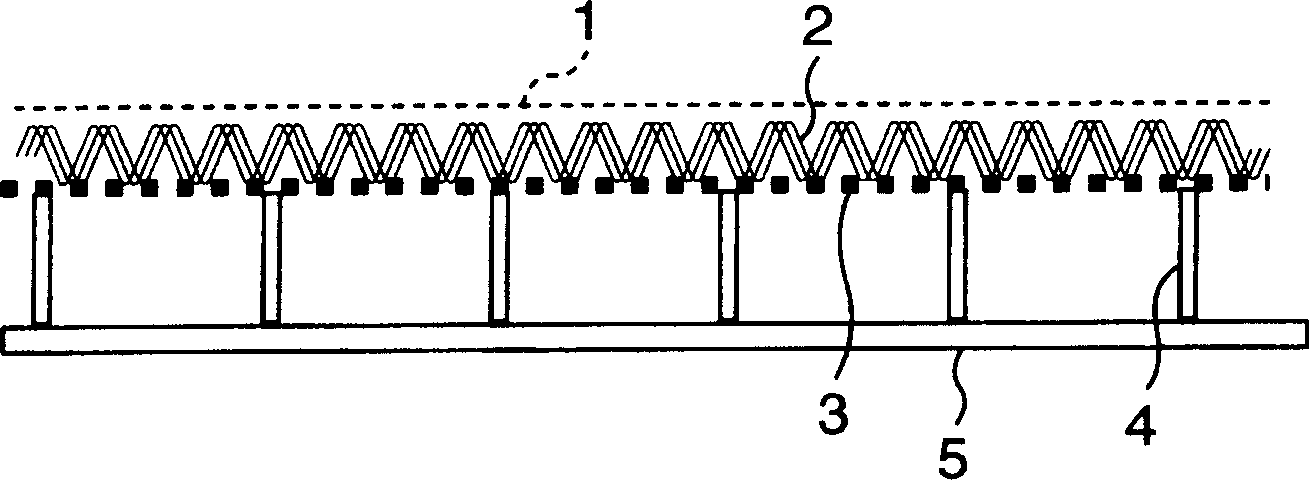

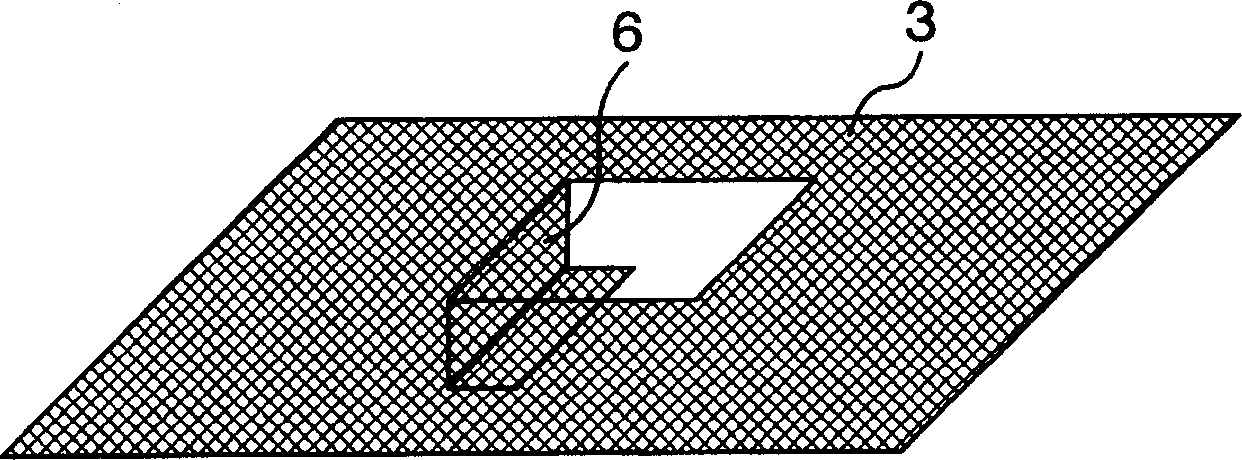

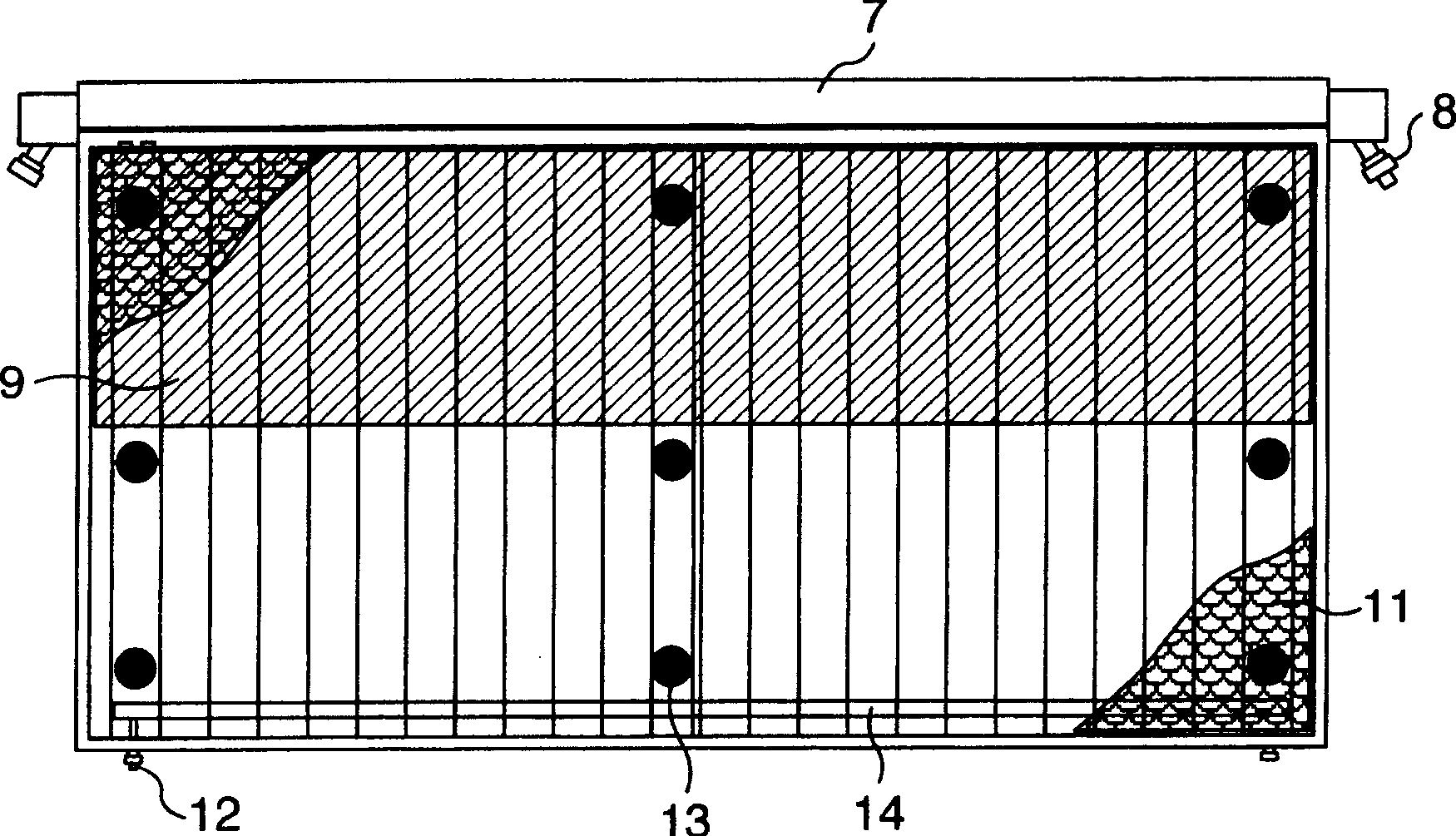

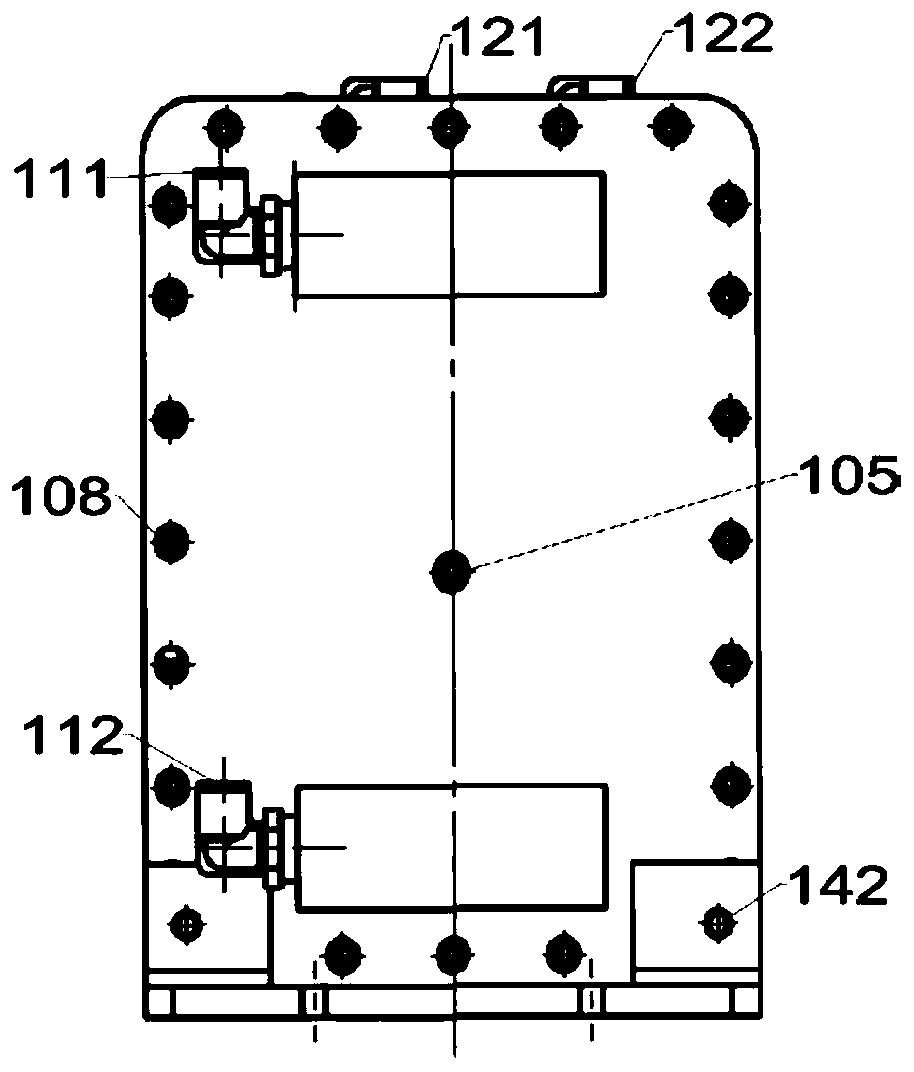

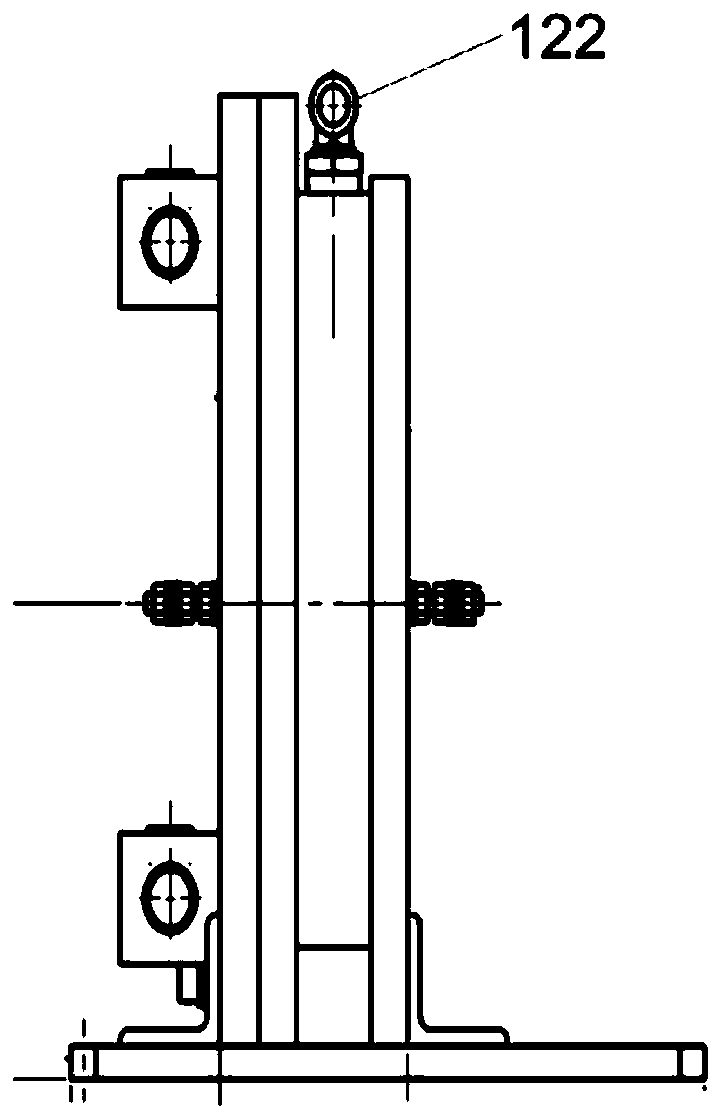

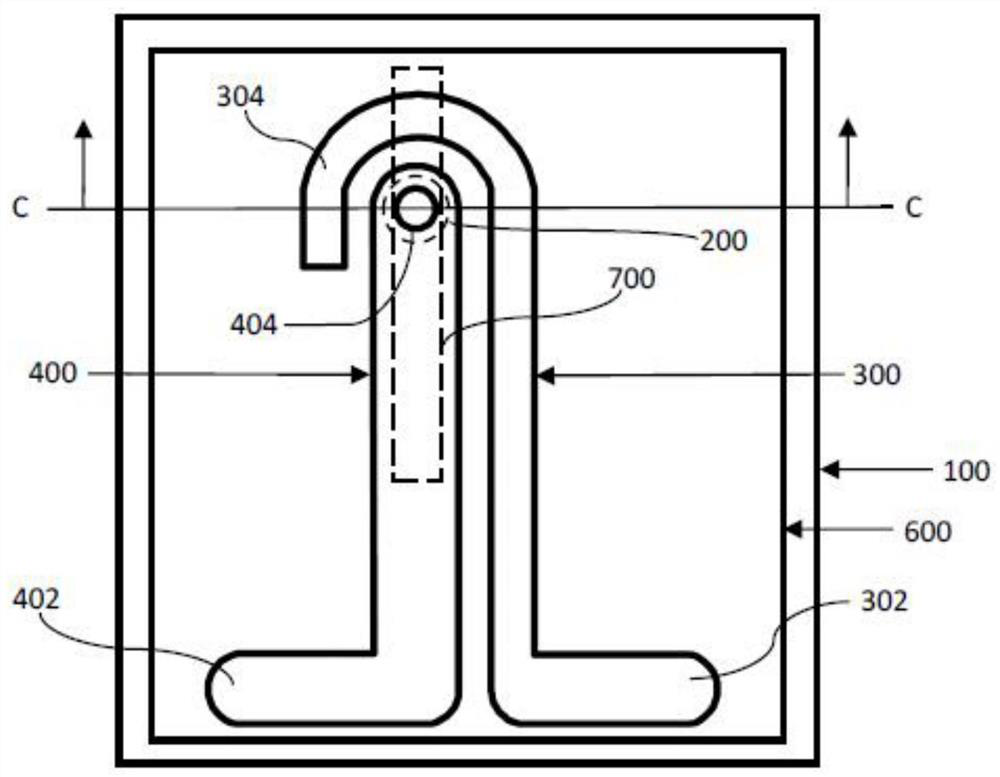

Bipolar alkaline water electrolysis unit and electrolytic cell

ActiveCN104364425AEasy to installElectrolytic smoothCellsElectrode shape/formsAlkaline waterHydrogen

A bipolar alkaline water electrolysis unit (12) which is built in an electrolytic cell (100) for the purpose of obtaining oxygen and hydrogen by electrolyzing an electrolysis solution that is composed of alkaline water. This bipolar alkaline water electrolysis unit (12) is provided with: a positive electrode (18) for the generation of oxygen; a negative electrode (19) for the generation of hydrogen; a conductive partition wall (22) for separating the positive electrode and the negative electrode from each other; and an annular outer frame (16) which surrounds the conductive partition wall (22). A passage part for a gas and the electrolysis solution is provided above the conductive partition wall (22) and / or the outer frame (16), while a passage part for the electrolysis solution is provided below the conductive partition wall (22) and / or the outer frame (16).

Owner:ASAHI KASEI KK

Bipolar zero-gap electrolytic cell

InactiveCN1717507AAvoid vibrationElectrolytic smoothCellsElectrode shape/formsInternal pressureTitanium metal

A bipolar zero-gap electrolytic cell comprising an anode comprising an anode substrate constituted of a titanium expanded metal or titanium metal net of 25 to 70% opening ratio, which anode after coating the substrate with a catalyst has a surface of 5 to 50 mum unevenness difference maximum and has a thickness of 0.7 to 2.0 mm. In this electrolytic cell, the possibility of breakage of ion exchange membrane is low, and the anolyte and catholyte have a concentration distribution falling within given range. With this electrolytic cell, stable electrolysis can be performed for a prolonged period of time with less variation of cell internal pressure.

Owner:ASAHI KASEI KK

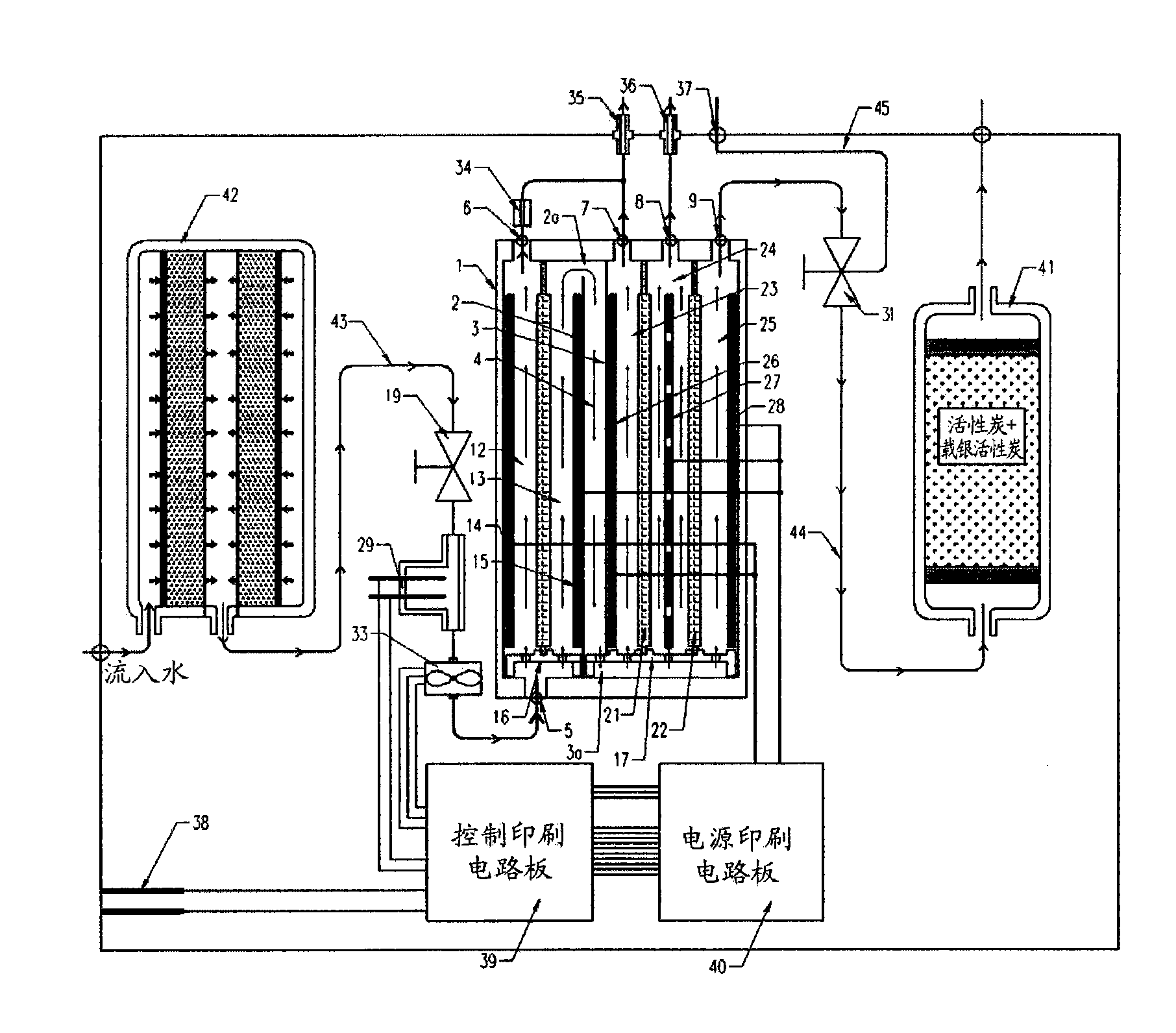

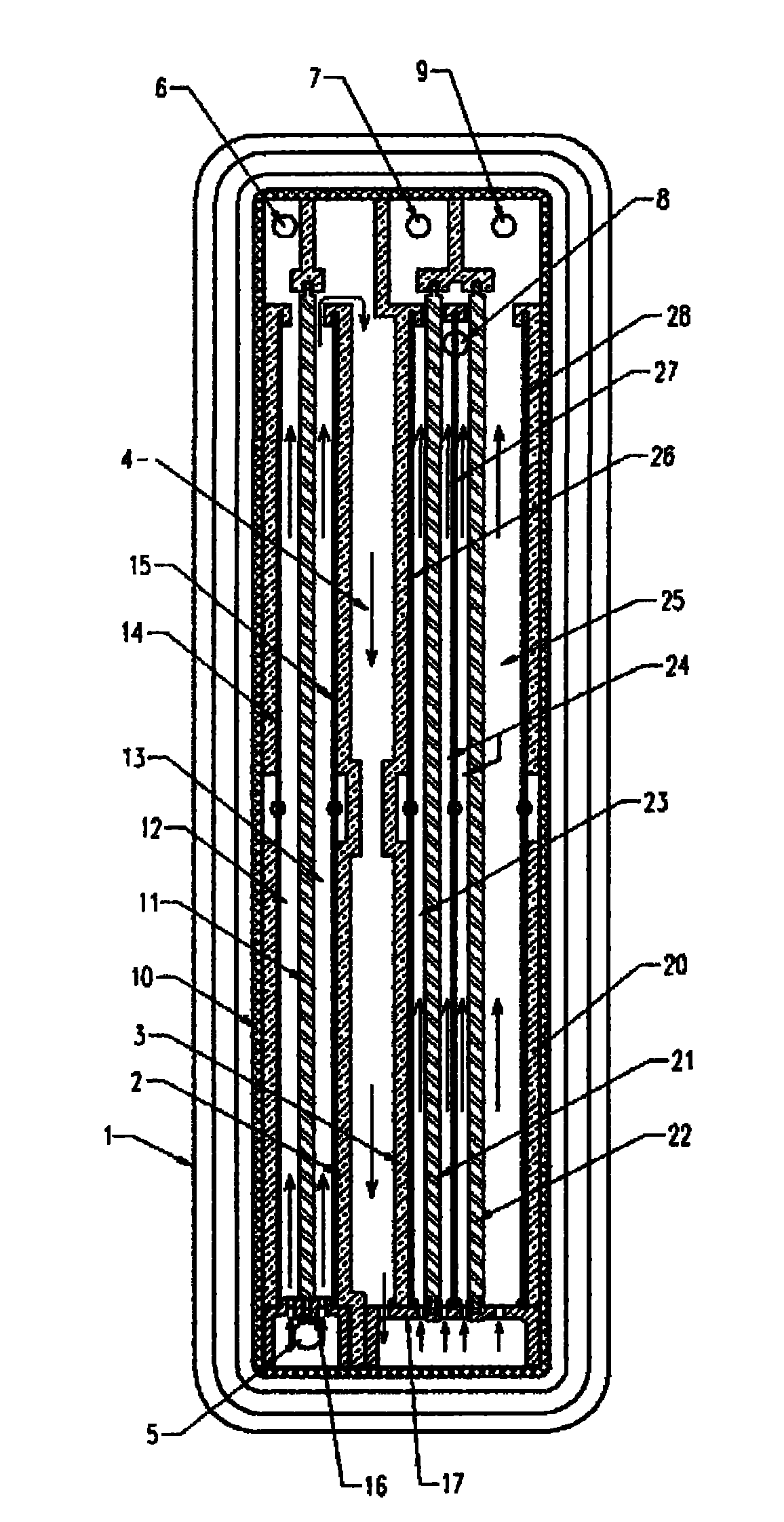

Electrolytic water purifier capable of automatically controlling applied voltage based on water inflow change

InactiveCN101870532AElectrolytic smoothReduce consumptionMultistage water/sewage treatmentWater treatment locationAlkaline waterAcid water

The present invention is about an electrolytic water purifier capable of automatically controlling applied voltage based on water inflow change, comprising an electrolytic part through a primary electrolytic tank divided into a primary acid water production electrode chamber and an alkaline water production electrode chamber and a secondary electrolytic tank divided into a secondary acid water electrode chamber, a strong alkaline water production electrode chamber and a weak alkaline water production motor chamber for twice electrolysis so as to respectively obtain three electrolytic ion water of strong alkaline water, acid water and weak alkaline water, wherein the electrolytic water purifier further comprises a flow sensor installed at the water inlet pipeline of the electrolytic part for detecting the water inflow flowing through a water valve, and a control part inputting the water inflow value detected by the flow sensor so as to automatically control the applied voltage of the electrolytic part based on the flow change. Therefore, the invention provides an electrolytic water purifier automatically controlling the applied voltage to maintain electrolysis stably all the time based on the water inflow change flowing into the electrolytic tank.

Owner:汉纽木股份有限公司 +1

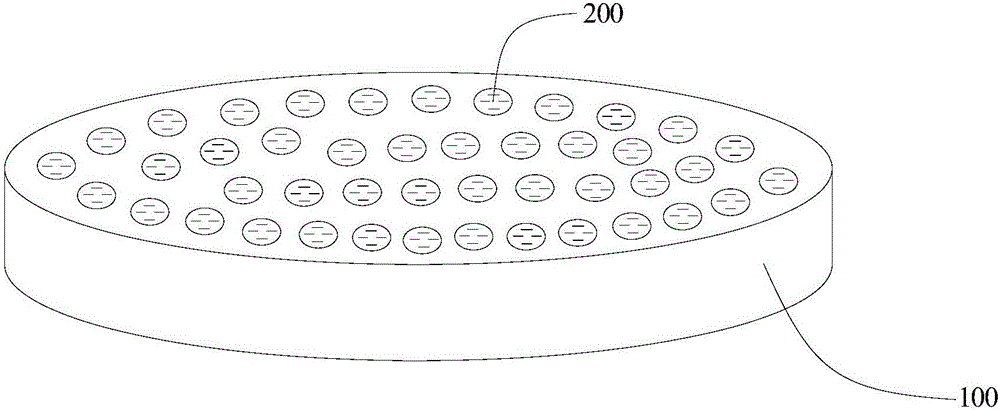

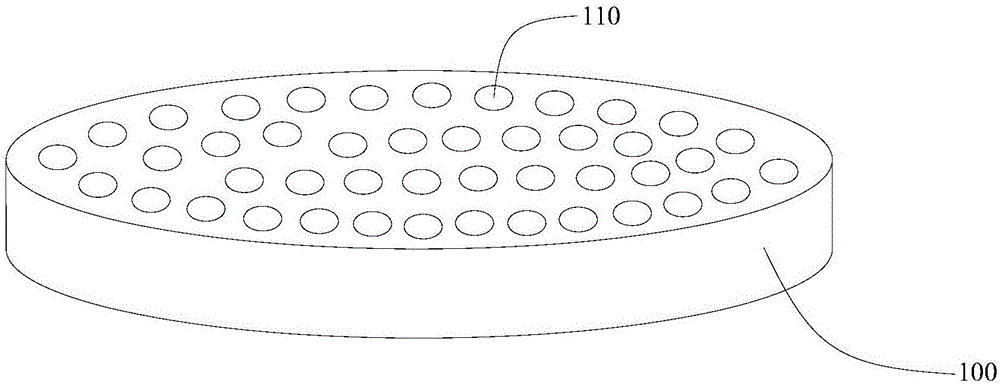

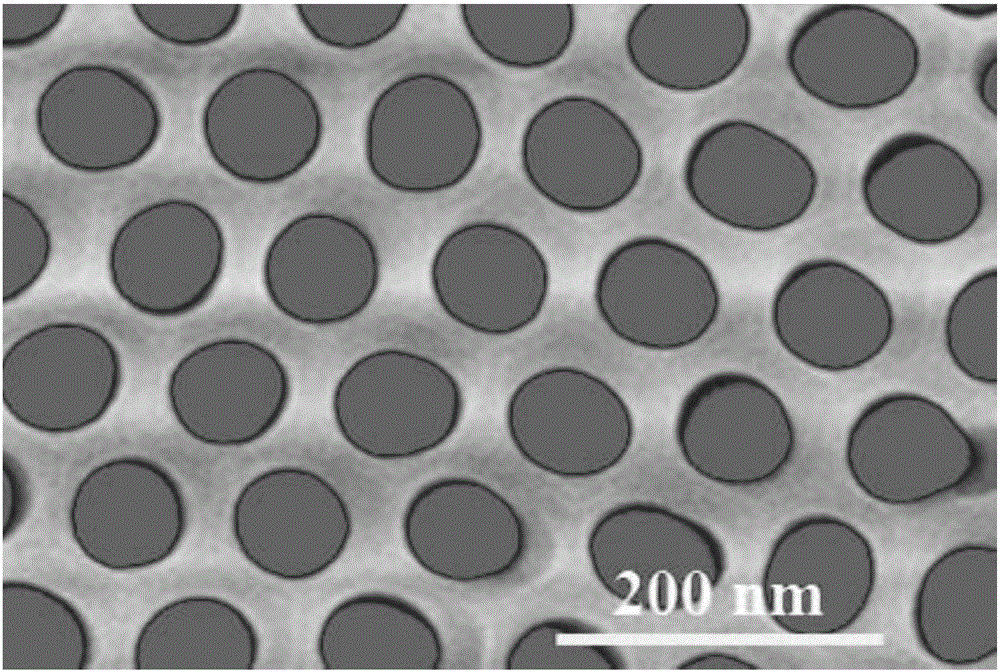

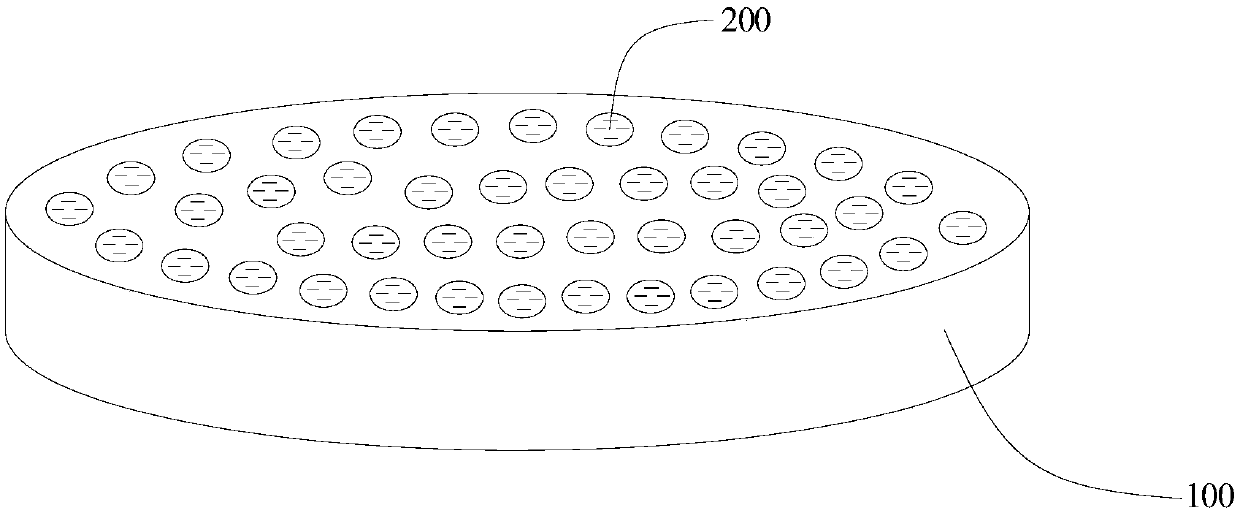

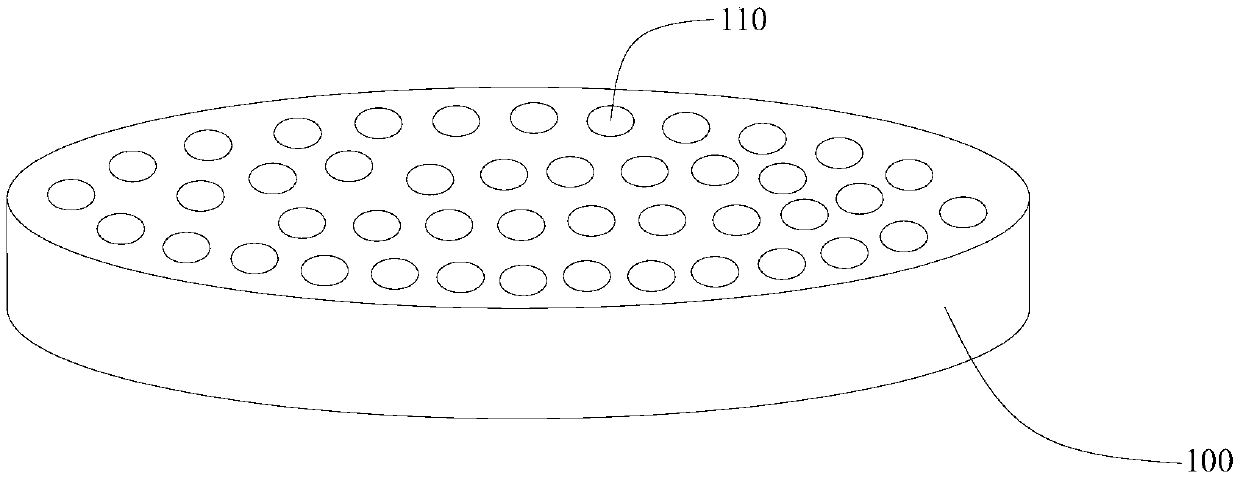

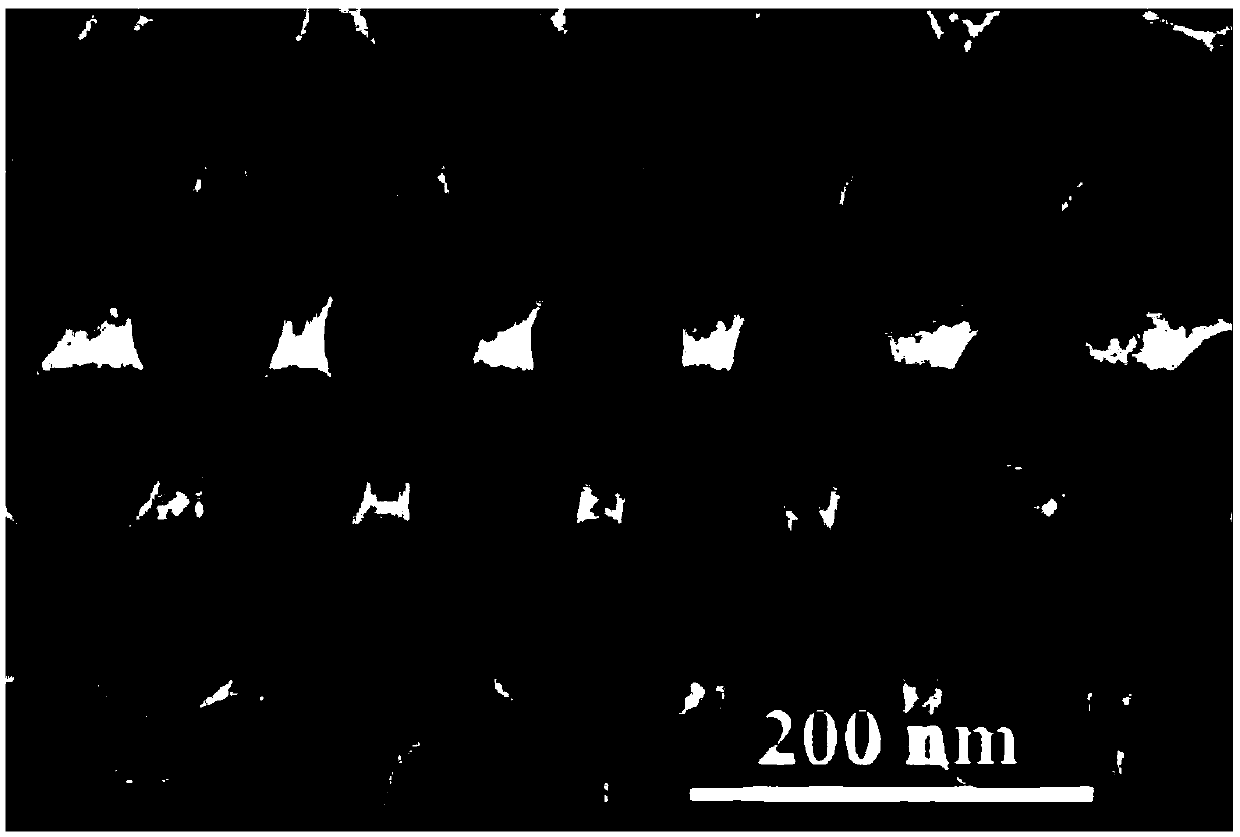

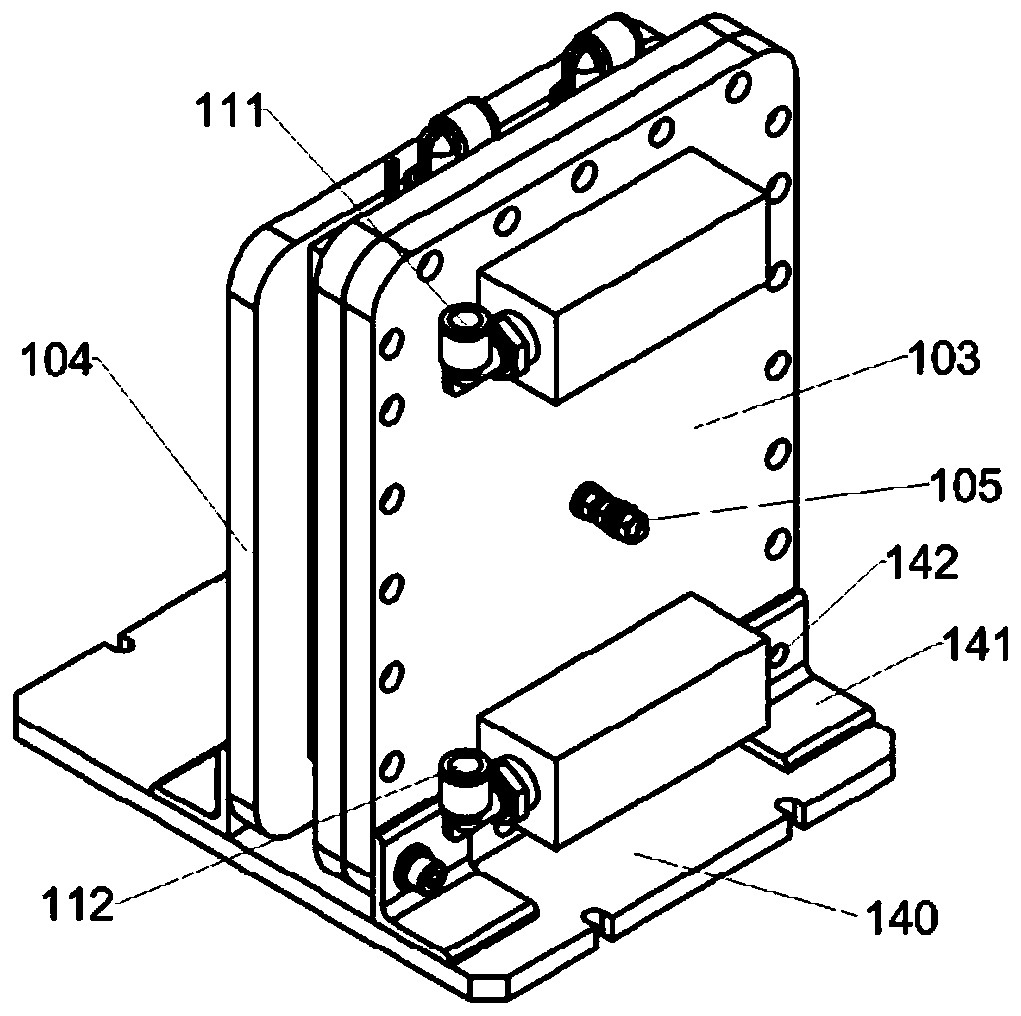

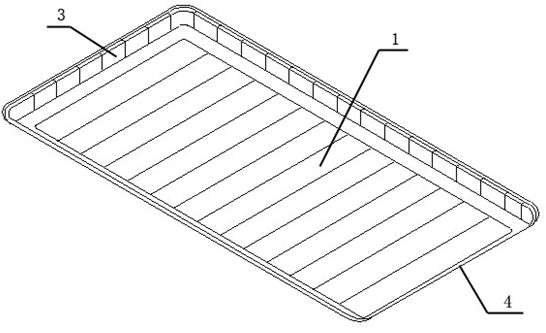

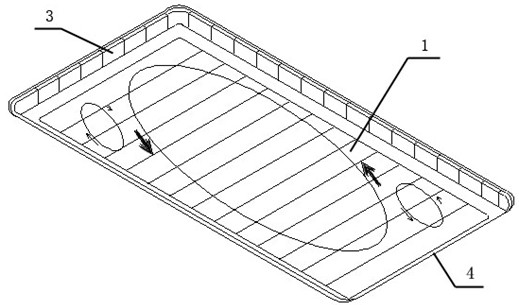

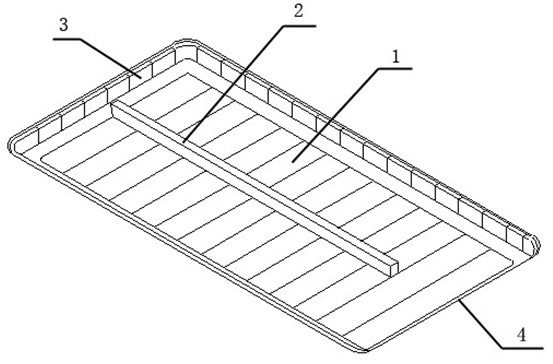

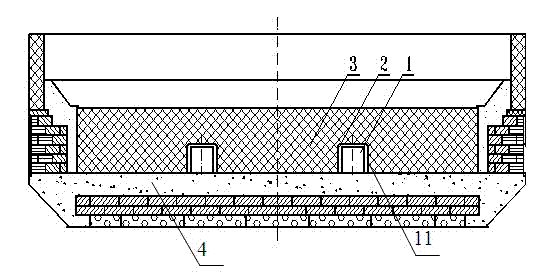

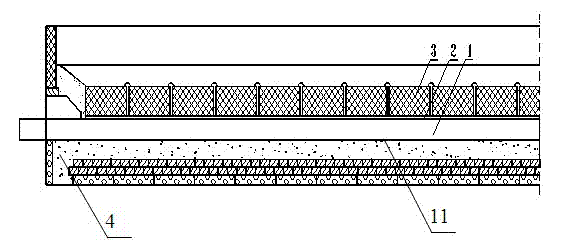

Phase change heat conducting fin, manufacturing method thereof, and manufacturing device of porous alumina framework

ActiveCN106497519AImprove thermal conductivityImprove adsorption capacitySurface reaction electrolytic coatingHeat-exchange elementsHeat conductingInterfacial thermal resistance

The invention discloses a phase change heat conducting fin. The phase change heat conducting fin comprises a porous alumina framework. Organic phase change material is filled in holes of the porous alumina framework. The phase change heat conducting fin uses the porous alumina framework as a heat conducting framework filled with the organic phase change material inside. On the premise that the phase change heat conducting fin has high thermal conductivity, the organic phase change material fills interface gaps through phase change at lower temperature, and then greatly reduces interface thermal resistance, and thereby is an ideal thermal interface material applied to heat dissipation devices and the like. The invention further discloses a preparation method of the phase change heat conducting fin. The preparation method has the advantages of being simple in process, easy to operate, high in yield, gentle in reaction condition, low in energy consumption and the like, and is suitable for industrialized mass production. The invention further discloses a manufacturing device of the porous alumina framework. The manufacturing device of the porous alumina framework can guarantee good and stable proceeding of the electrolytic process of the porous alumina framework.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

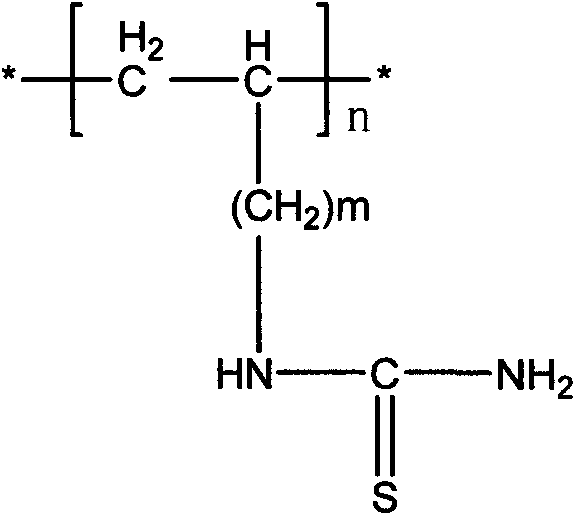

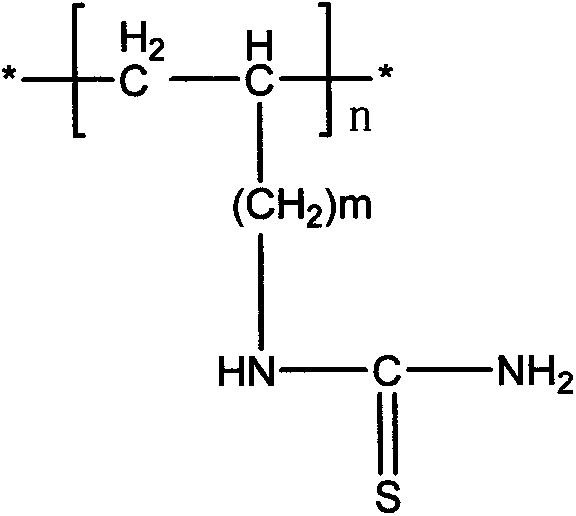

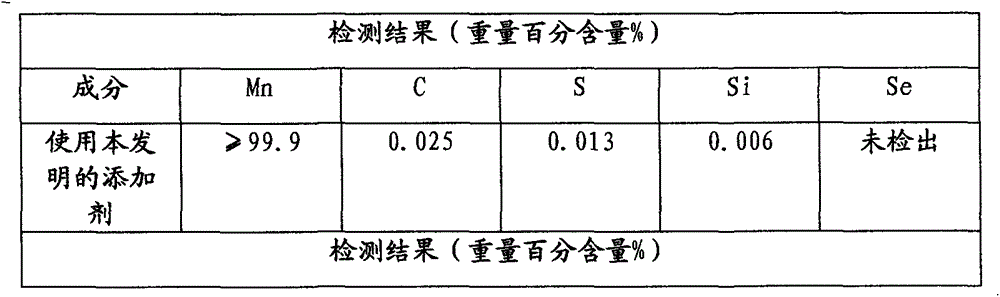

Method for environmentally friendly and efficiently producing electrolytic manganese metal

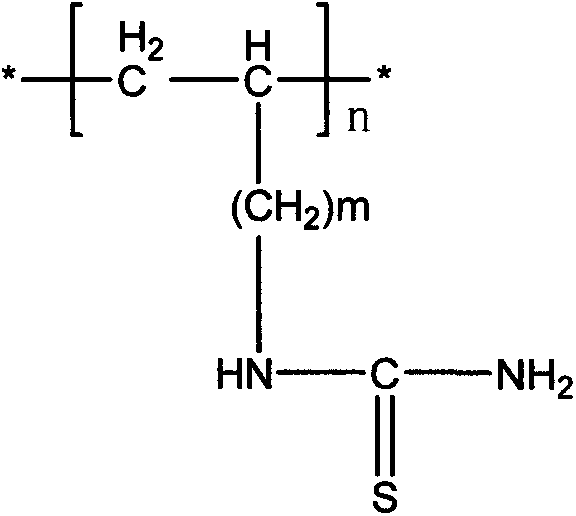

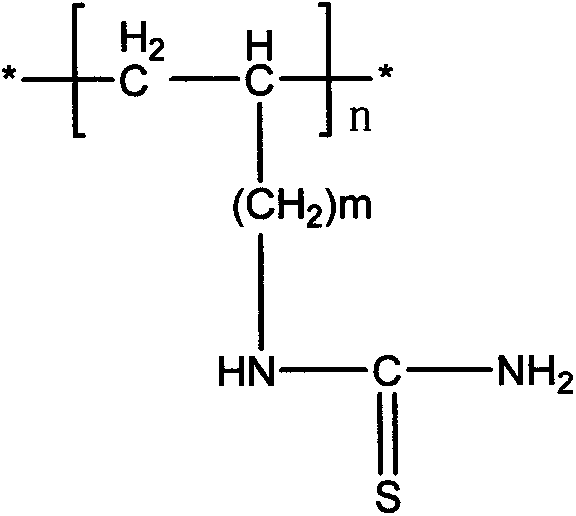

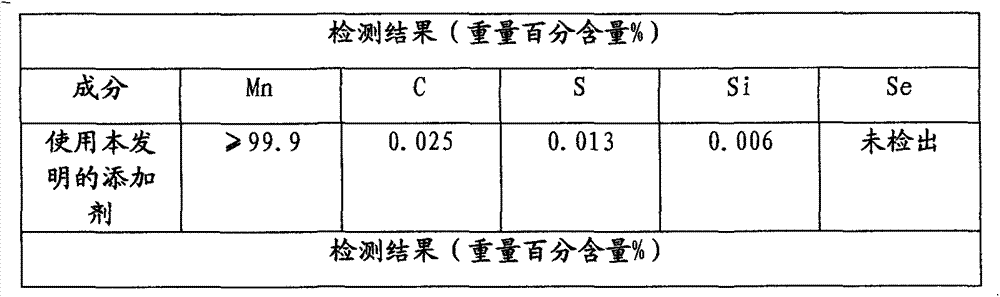

ActiveCN103173786AHigh temperature toleranceReduced current efficiencyPhotography auxillary processesSolubilityEnvironmental resistance

The invention belongs to the technical field of chemical production and provides a method for efficiently producing electrolytic manganese metal in an environment-friendly manner. The method provided by the invention takes a vinyl polymer hooked with a thiourea side group as an electrolysis additive, and the electrolysis additive is added into electrolyte containing manganese sulphate and ammonium sulphate for the production of electrolytic manganese, wherein the content of the electrolysis additive in the electrolyte is controlled to be 10-120mg / L. The electrolysis additive is an environment-friendly and non-toxic polymer and can be used for replacing the existing widely applied poisonous or pollutional selenium dioxide and sulphur dioxide; the electrolysis additive is low in solubility and cannot be accumulated in the electrolyte, a production process operation is simple, manganese metal electrolysis efficiency is high, the product purity is high, an electrolysis process is stable, purity requirement to the electrolyte is lower, and electrolytic manganese metal production difficulty and cost are reduced, so that the method provided by the invention has higher popularization and application values.

Owner:云南江南锰业股份有限公司

Cryolite production process

The invention relates to a cryolite production process, which comprises: 1) preparing a slurry; 2) carrying out a reaction; and 3) filtering, carrying out water washing, separating to obtain a mother liquor, a cryolite crude product and a washing liquid, and respectively treating. According to the present invention, the process is simple, and the performances of the prepared cryolite are excellent; the produced cryolite has characteristics of stable electrolysis, slow shrinkage and mild molecular ratio change, and can stably maintain the electrolyte components; the sodium absorption on the cathode is uniform so as to prolong the service life of the electrolytic cell; the electrolysis temperature is reasonable and is changed little so as to be easily controlled; the volatilization loss is low, and the site operating conditions can be effectively improved; and with the production process, the consumption of sodium fluoride or soda ash can be substantially saved, the production cost can be reduced, the used adding method is simple, and the operation is easy to perform.

Owner:CHANGNING HUAJUN RENEWABLE RESOURCES

Method for preparing Al-Li alloy through molten salt electrolytic method

A method for preparing Al-Li alloy through a molten salt electrolytic method includes following steps: (1) uniformly mixing potassium fluoride, calcium fluoride, barium fluoride or lithium chloride and lithium fluoride to obtain the mixed material; (2) putting the mixed material in an electrolytic tank and heating the electrolytic tank to a temperature higher than the mixed electrolyte melting point of 10-100 DEG C; adding lithium oxide in the electrolytic tank and uniformly mixing to obtain the liquid mixed electrolyte; electrifying the electrolytic tank for electrolysis with the current density of 0.05-0.4A / cm[2] and the electrolysis time of 0.6-2.5h. The method adopts the lithium oxide as the electrolysis material and the electrolysis process does not generate the chlorine and other harmful gases.

Owner:NORTHEASTERN UNIV LIAONING

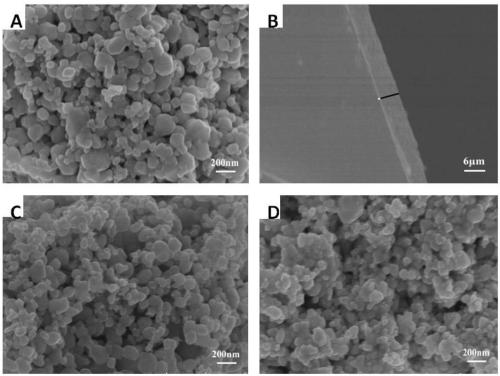

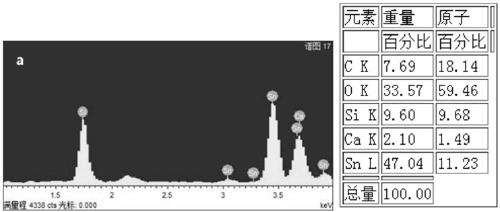

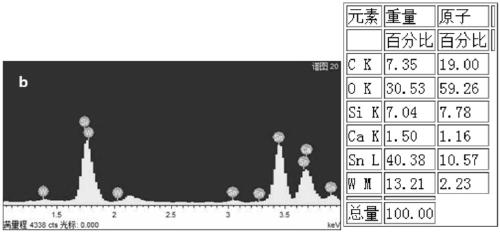

Molecular level iridium catalyst modified wo3 composite photoanode and its application

ActiveCN106801231BImprove transmission efficiencyImprove separation efficiencyLight-sensitive devicesPhotovoltaic energy generationIridiumSemiconductor materials

Owner:LIAONING UNIVERSITY

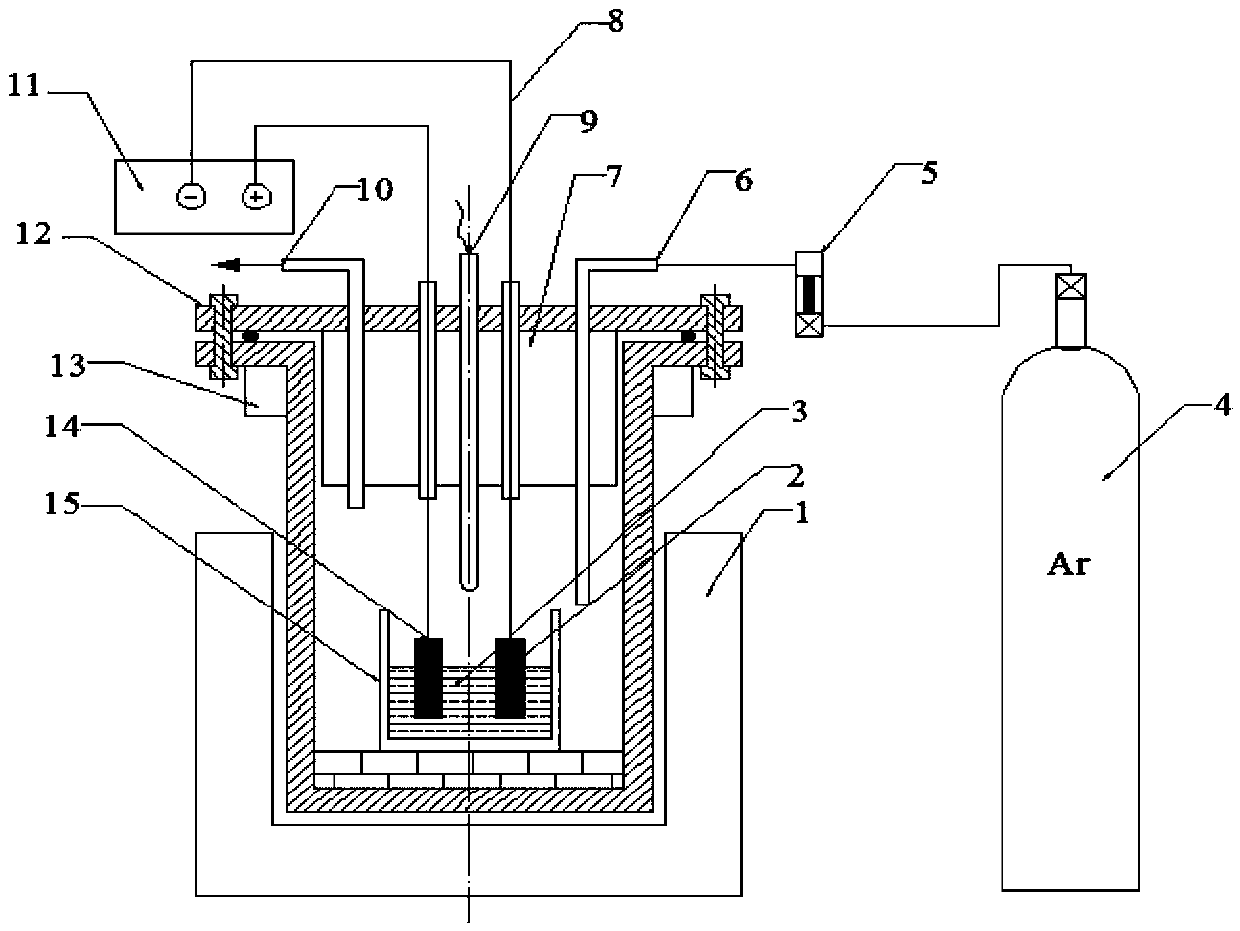

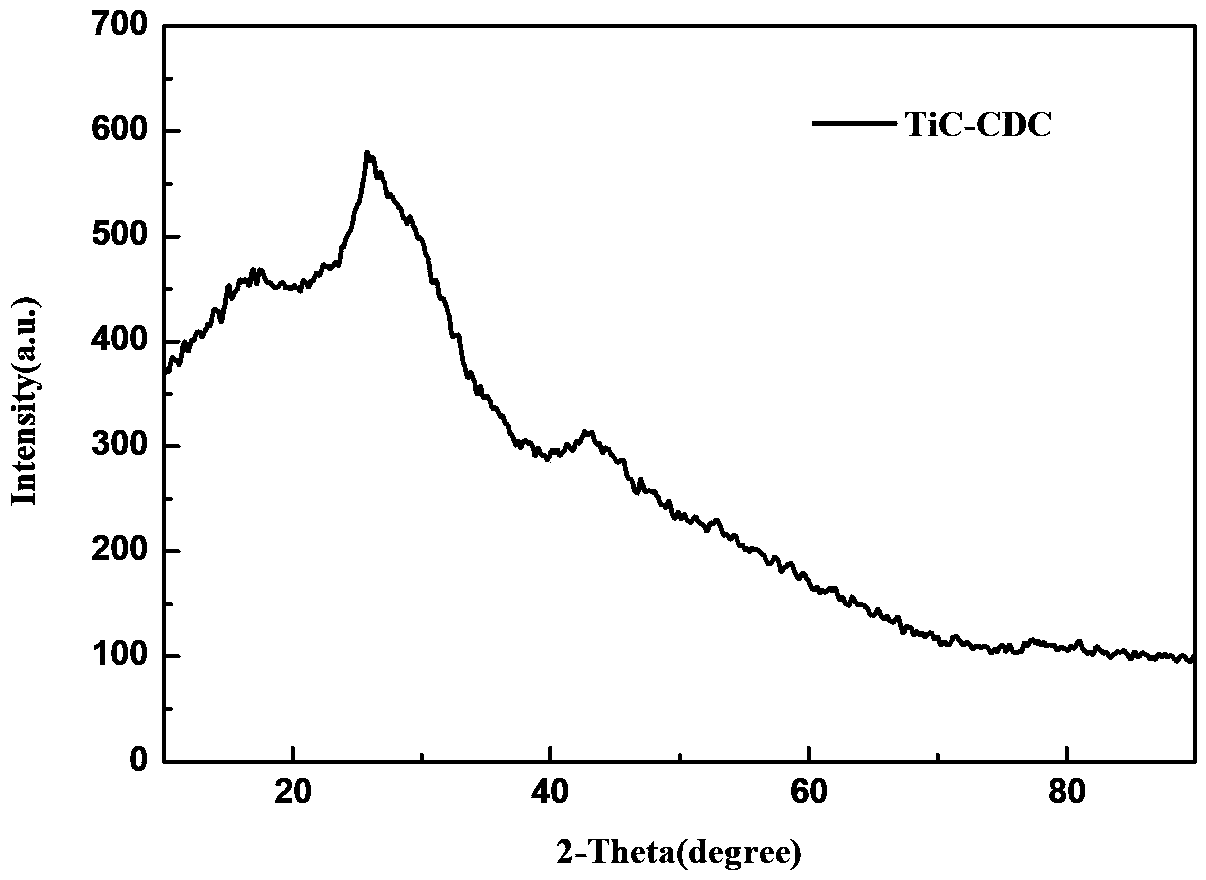

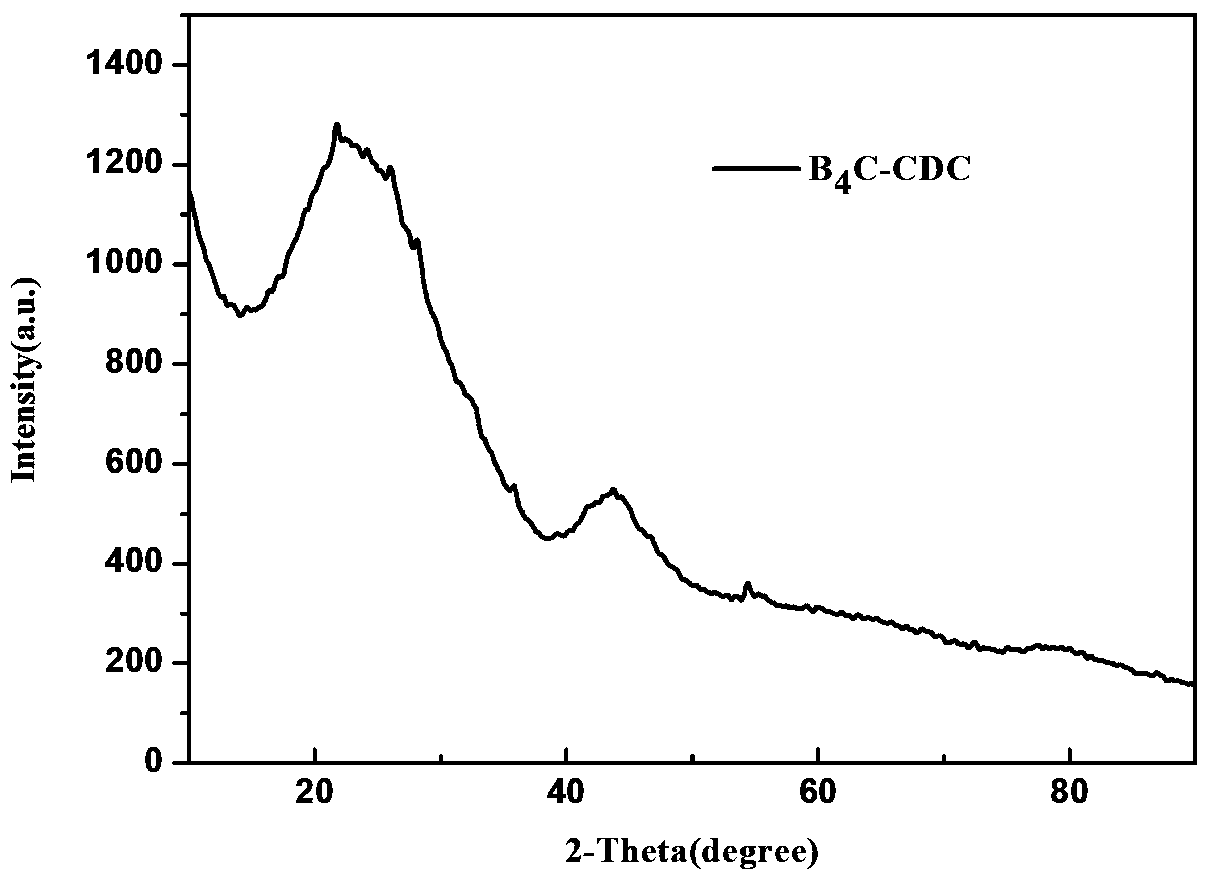

A method for preparing carbide-derived carbon by molten salt electrolysis

InactiveCN103436904BHigh purityUniform pore size distributionElectrolysis componentsCarbon preparation/purificationElectrolysisRaw material

The invention discloses a method for preparing carbide derived carbon by a fused salt electrolysis method. The method mainly comprises the steps that metal carbide serves as a raw material, and is subjected to die pressing sintering to form a metal carbide sheet to serve as an anode; by taking fused salt as an electrolyte, and a high-purity and high-density graphite rod as a cathode, fused salt electrolysis is performed in an electrolysis furnace in an argon atmosphere with the electrolysis temperature of 400-1300 DEG C, the electrolysis voltage of 1.8-3.2V, and the electrolysis time of 2-60h; after the electrolysis, an anode product is taken out, and subjected to water washing, ultrasonic-assisted pickling, water washing and drying treatment; and the carbide derived carbon is prepared. According to the method, the low-cost metal carbide can serve as the raw material for preparing the carbide derived carbon by the fused salt electrolysis method, so that a preparation technology is simplified; the cost is lowered; and the prepared carbide derived carbon serves as an electrode material of a supercapacitor, and has high specific capacity and good cycling stability.

Owner:YANSHAN UNIV

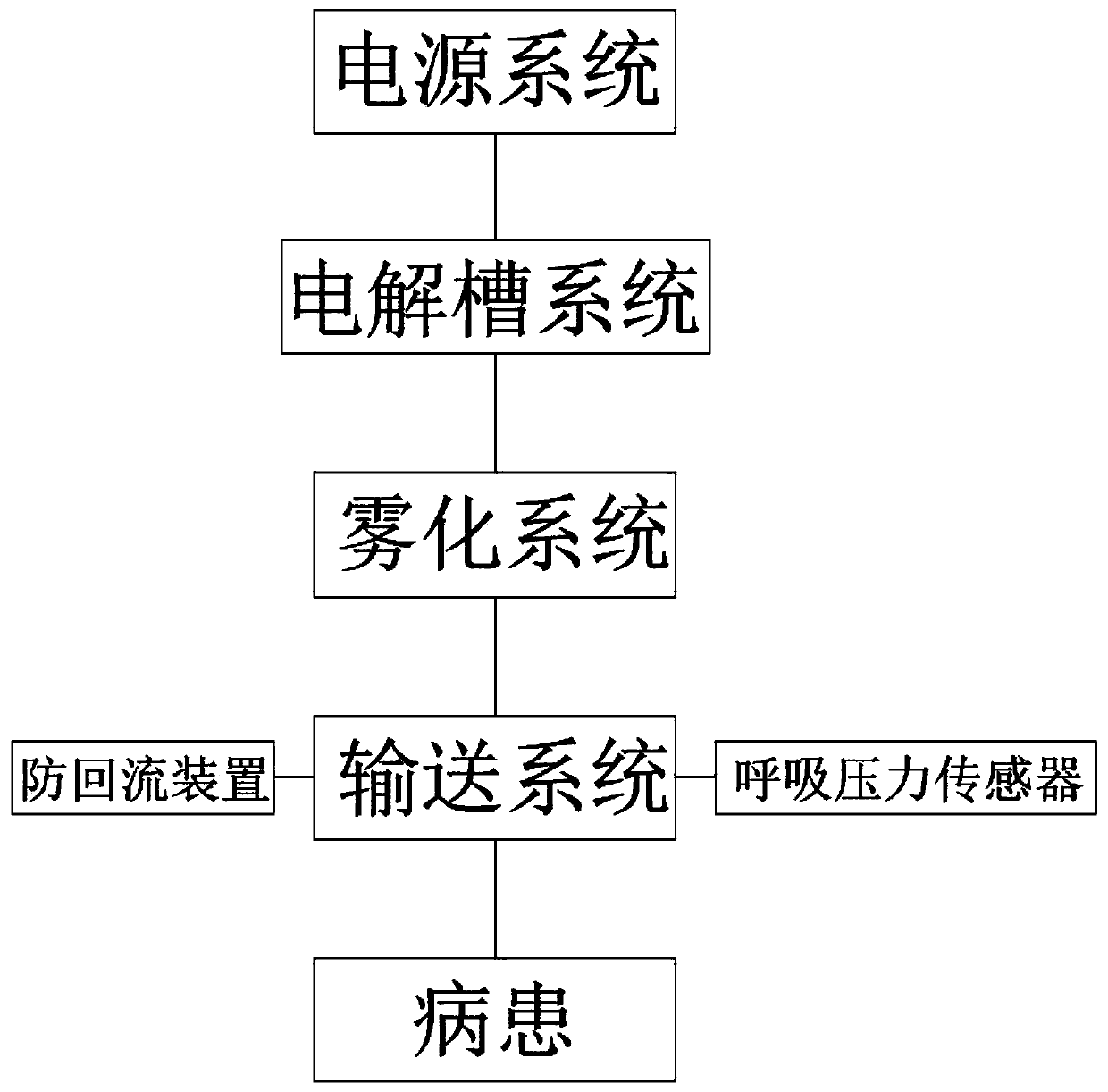

High-efficiency and stable medical oxyhydrogen atomizer

PendingCN111359064AHigh rate of hydrogen and oxygen productionThe dose of hydrogen and oxygen does not decayGrapheneMedical devicesIntelligent control systemBreathing system

The invention discloses a high-efficiency and stable medical oxyhydrogen atomizer. The atomizer comprises a power supply system, the power supply system supplies power to an electrolytic tank system,the electrolytic tank system is correspondingly connected to an atomizing system, the atomizing system is correspondingly connected to a conveying system, and the conveying system, the atomizing system and the electrolytic tank system are uniformly correspondingly electrically connected to an intelligent control system; the conveying system correspondingly communicates with patients; and the conveying system is correspondingly provided with a back-flow prevention device and a breathing pressure sensor. The high-efficiency and stable medical oxyhydrogen atomizer of the present invention is applied to the treatment of respiratory diseases, especially to the treatment of lung diseases, and the atomized hydrogen and drugs act on the human body directly through the inhalation of the airway.

Owner:玻尔量子(厦门)科技有限公司

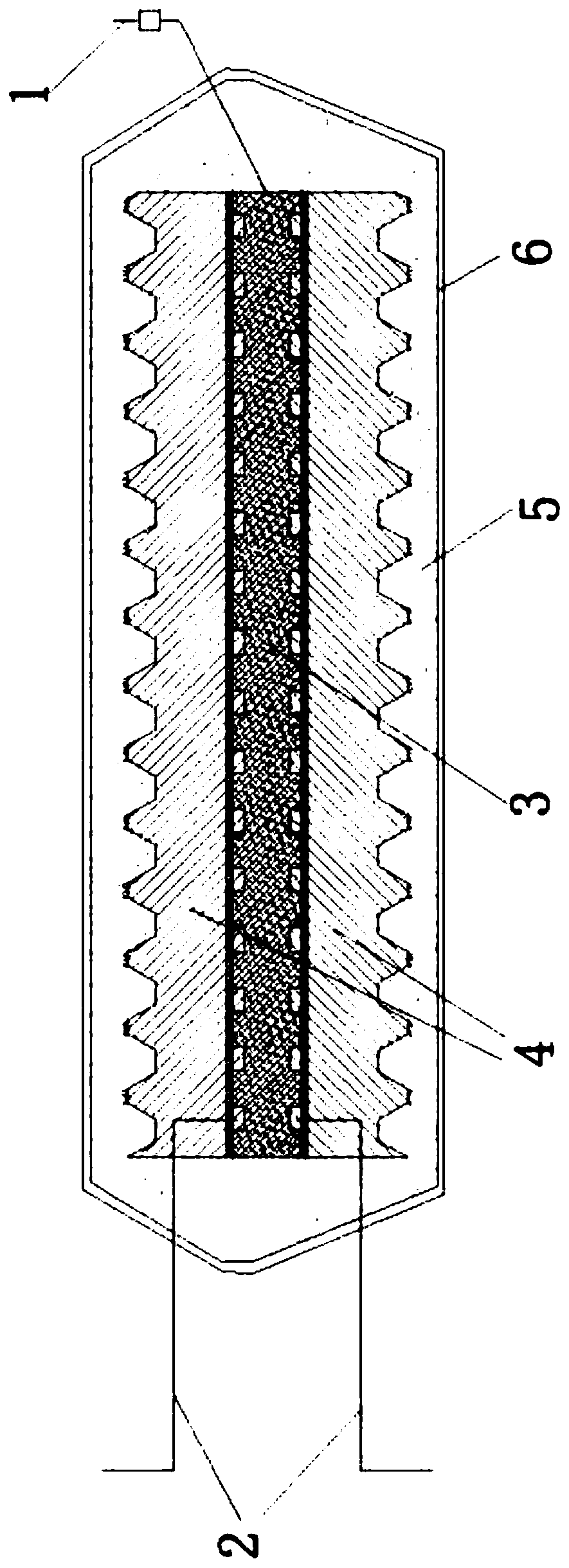

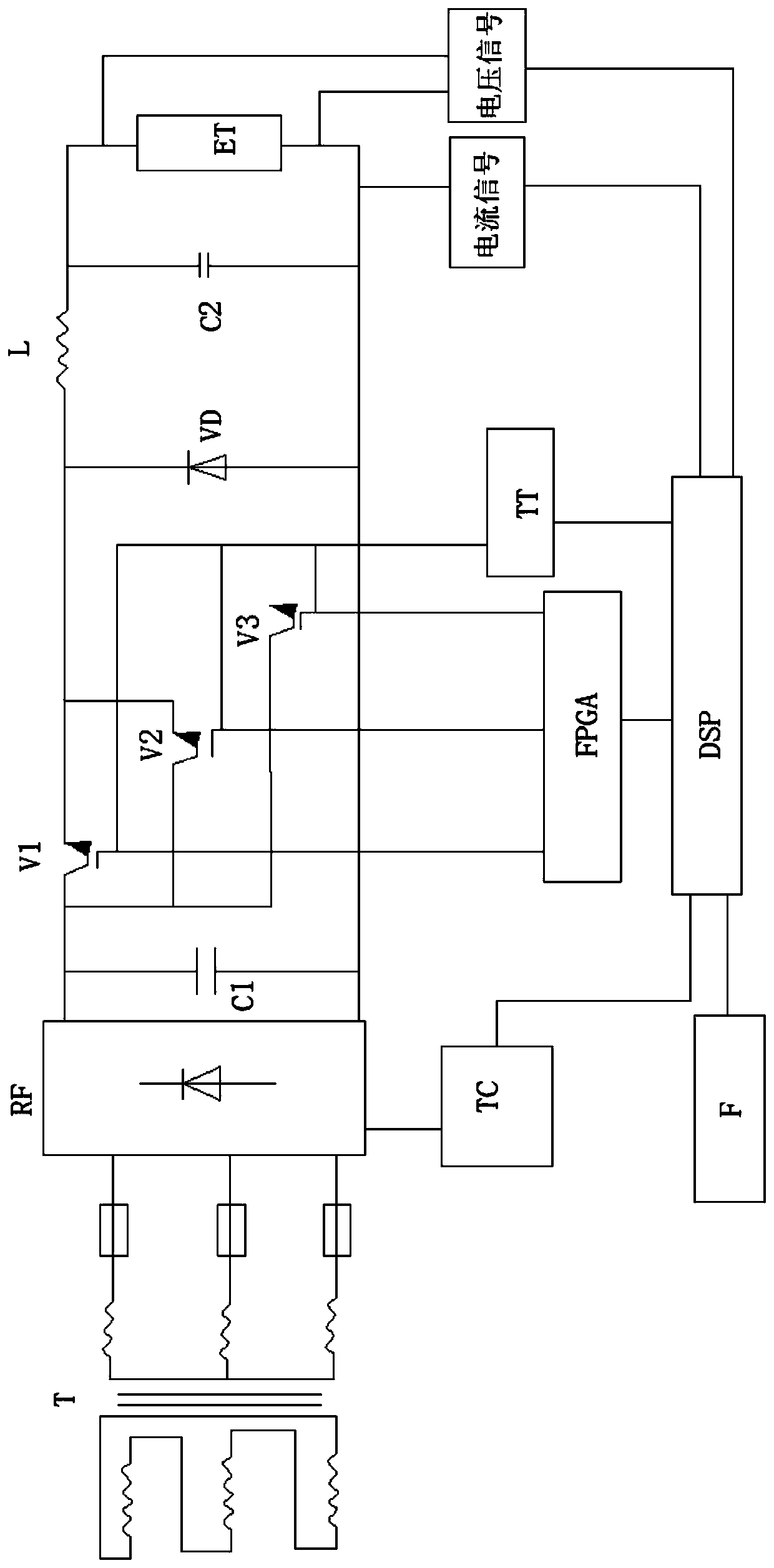

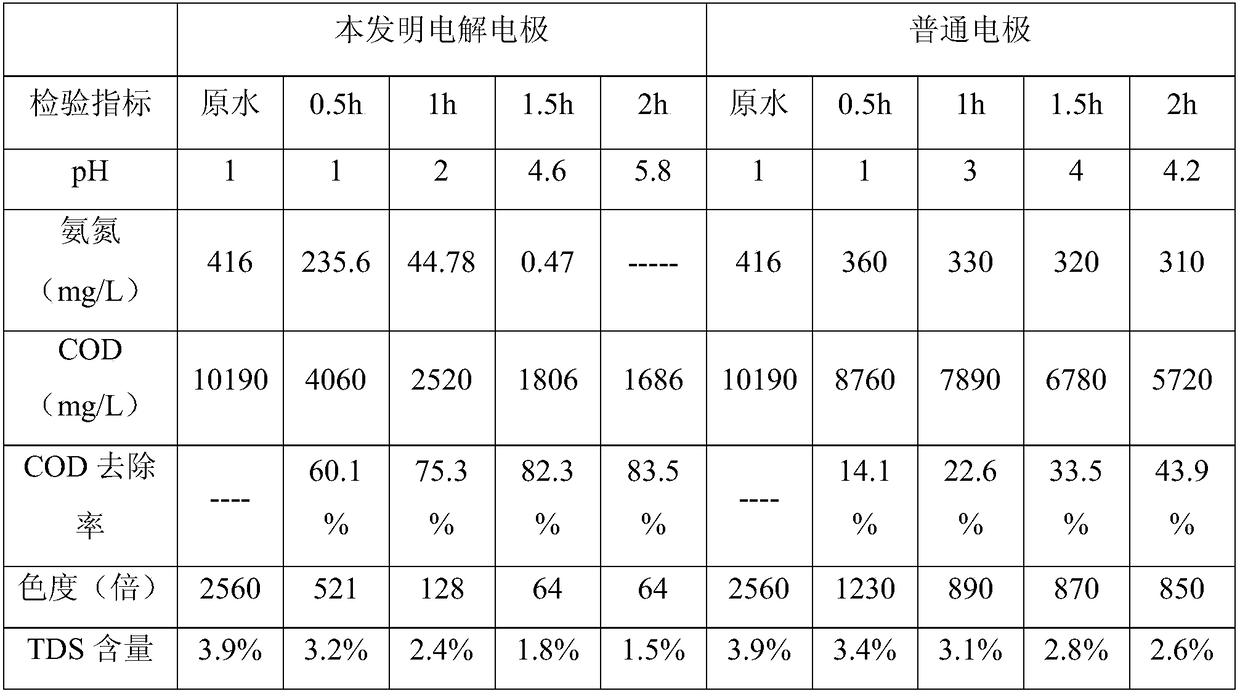

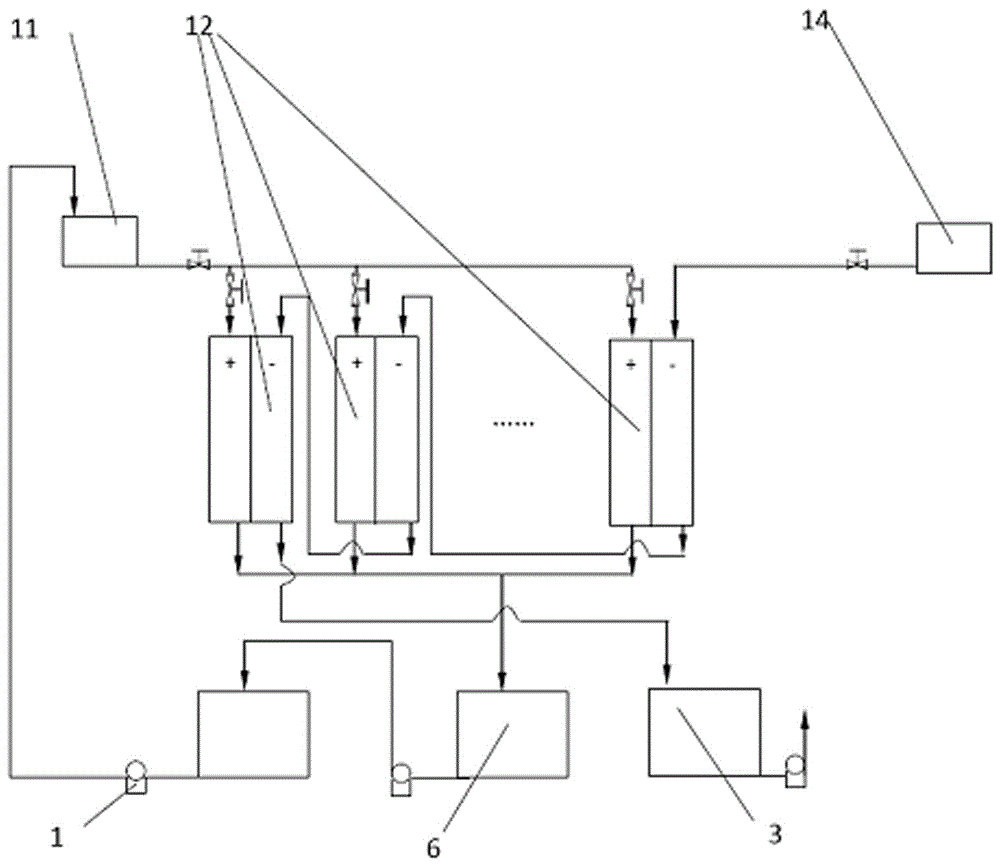

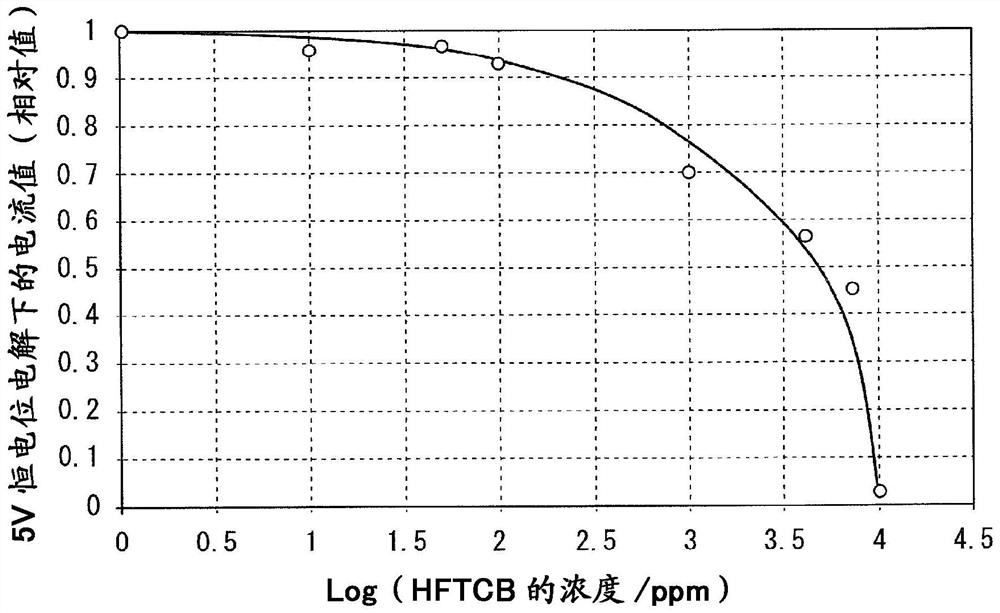

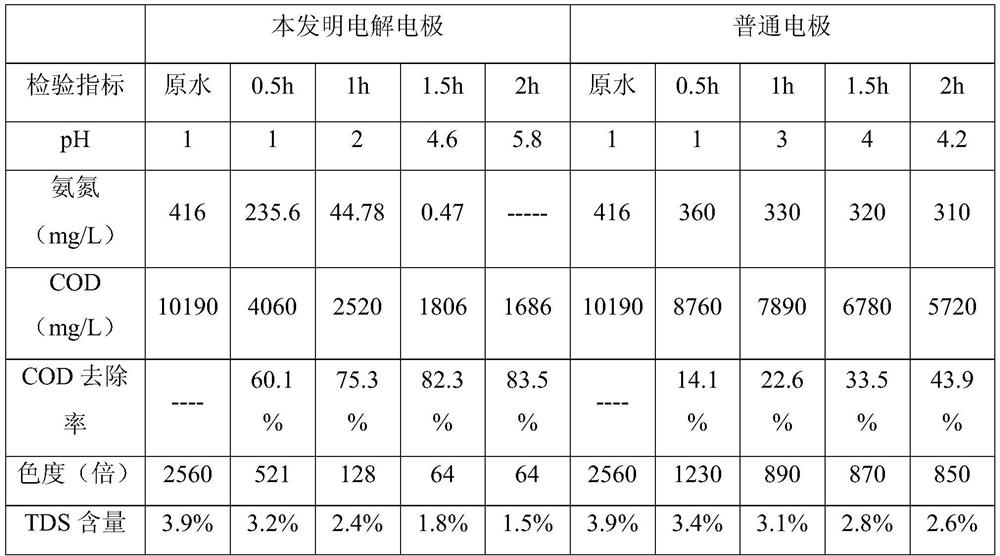

High-salt and high-COD wastewater electrolysis electrode and electrolytic oxidation treatment method

ActiveCN108264134AImprove antioxidant capacityImprove bindingWater treatment parameter controlWater/sewage treatmentIridiumRare earth

The invention discloses a high-salt and high-COD wastewater electrolysis electrode and an electrolytic oxidation treatment method. The electrolysis electrode comprises a titanium plate matrix and a plating located on the surface of the titanium plate matrix; and the plating is an alloy of metal ruthenium, metal iridium and rare earth. Electrolysis electrodes are uniformly arranged at a certain interval in wastewater, one of two adjacent electrolysis electrodes serves as an anode, the other electrolysis electrode serves as a cathode, the anode is connected with the anode of an electrolysis power supply, and the cathode is connected with the cathode of the electrolysis power supply which is a direct-current pulse power supply. The electrolysis electrode disclosed by the invention is high inoxidation resistance, firm in combination of the plating and the titanium plate, incapable of generating spots or falling off within 5 years if being normally used, high in electrolysis oxidation efficiency 1.5 times as high as that of a common electrode during wastewater treatment, low in power consumption, stable in electrolysis as well as voltage and current in an electrolysis process due to the adoption of the constant direct-current pulse power supply, capable of effectively removing COD, ammonium, nitrogen and chloride ions in wastewater and particularly suitable for electrolysis oxidation treatment of high-salt and high-COD wastewater.

Owner:SHIJIAZHUANG YUANSHENGYUAN ENVIRONMENTAL

Pure cryolite production technology without wastewater discharge

InactiveCN108975369AImprove performanceElectrolytic smoothAluminium fluoridesAmmonium chlorideSlurrySodium fluoride

The invention discloses a pure cryolite production technology without wastewater discharge. The technology comprises the following steps of (1) slurry production, (2) reaction, (3) entrifugal separation, (4) purification, (5) sedimentation, (6) alkalization and (7) wastewater treatment. The technology is simple, and a finished product cryolite has excellent performance; the cryolite produced through the pure cryolite production technology without wastewater discharge is electrolyzed smoothly, shrinkage is low, molecular ratio change is gentle, and the pure cryolite production technology without wastewater discharge is beneficial to stably maintaining an electrolyte component; a cathode absorbs sodium evenly, which is beneficial to prolonging the service life of an electrolytic cell; an electrolysis temperature is reasonable, little in change and easy to control; volatilization loss is little, and field operation conditions can be effectively improved; by means of the pure cryolite production technology without wastewater discharge, a large amount of sodium fluoride or sodium carbonate can be saved, the production cost is reduced, an adding method is used and is simple, and operation is easy; moreover, according to the pure cryolite production technology, no wastewater is discharged, and ammonium chloride is a by-product.

Owner:衡东合兴化工有限责任公司

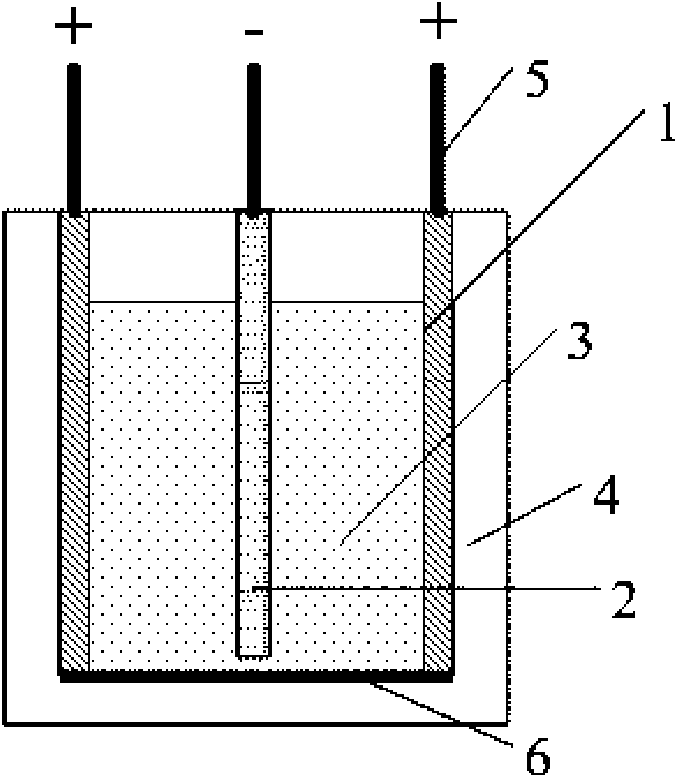

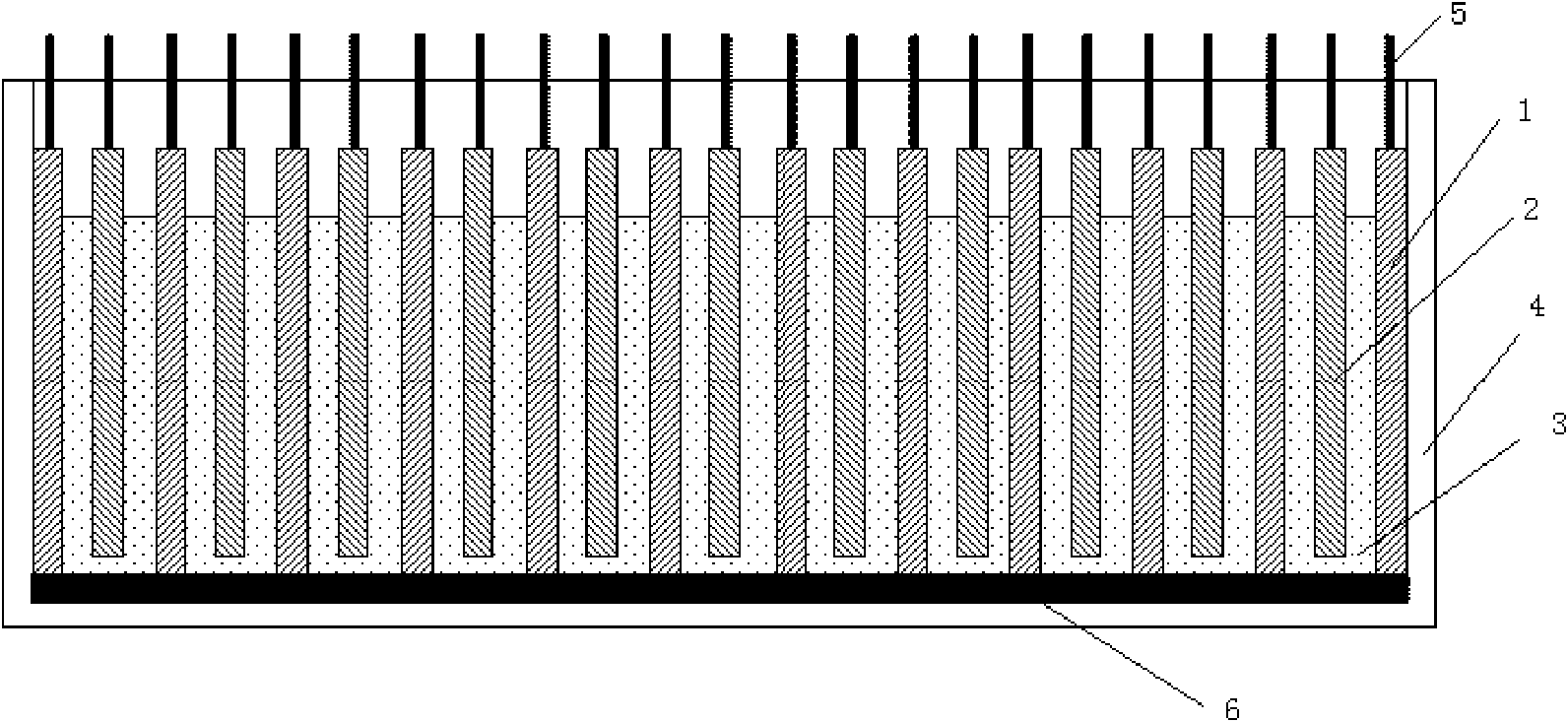

Device for continuous electrolytic reduction of trivalent europium

InactiveCN105862058AConvenient individual control of current densityElectrolytic smoothCellsRare earthAcid concentration

The invention discloses a device for continuous electrolytic reduction of trivalent europium. The device comprises electrolytic cells, a catholyte overhead tank, an anolyte overhead tank, a catholyte collection tank, an anolyte collection tank and a rare earth liquid tank. According to the device, cathode chambers among the electrolytic cells communicate with one another in a series connection mode, and catholyte flows from the cathode chamber of the previous electrolytic cell to the cathode chamber of the next electrolytic cell and is reduced step by step; anode chambers of the electrolytic cells do not communicate with one another, anolyte in the anode chambers flows independently, and the flow is independently controlled. The electric current density of the electrolytic cells and the acid concentration of the catholyte and the anolyte in the electrolytic cells can be independently controlled, and therefore electrolysis of the electrolytic cells is stable, and the reduction effect is good.

Owner:GUANGDONG INST OF RARE METALS

Method for continuous electrolytic reduction of three-valence europium

ActiveCN105780042AConvenient individual control of current densityElectrolytic smoothCellsTime rangeAcid concentration

The invention relates to a method for continuous electrolytic reduction of three-valence europium. The method includes the steps that anode liquor is added into all electrolytic cell anode chambers, and cathode liquor is added into a first electrolytic cell cathode chamber; then the cathode liquor sequentially flows from the first electrolytic cell cathode chamber to a next electrolytic cell cathode chamber until entering the Nth cathode chambers, wherein the flow ratio of the cathode liquor to the anode liquor is 0.1 -10:1, the standing time ranges from 0.5 hours to 2 hours, and the density of electric current in all electrolytic cells ranges from 100 A / m<2> to 1600 A / m<2>; anode liquor flowing out from all electrolytic cell anode chambers is collected and returns to all electrolytic cell anode chambers according to flow after ingredients are merged and mixed; and cathode liquor flowing out from the last electrolytic cell cathode chamber is material liquid obtained after reduction. By means of the method for continuous electrolytic reduction of three-valence europium, the electric current density of all electrolytic cells and the acid concentration of the cathode liquor and the anode liquor in single electrolytic cells can be conveniently and independently controlled, electrolysis of the electrolytic cells is stable, and the reduction effect is good.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

A phase-change thermal conductive sheet and its manufacturing method, and a device for manufacturing a porous alumina skeleton

ActiveCN106497519BImprove thermal conductivityImprove adsorption capacitySurface reaction electrolytic coatingHeat-exchange elementsHeat conductingInterfacial thermal resistance

The invention discloses a phase change heat conducting fin. The phase change heat conducting fin comprises a porous alumina framework. Organic phase change material is filled in holes of the porous alumina framework. The phase change heat conducting fin uses the porous alumina framework as a heat conducting framework filled with the organic phase change material inside. On the premise that the phase change heat conducting fin has high thermal conductivity, the organic phase change material fills interface gaps through phase change at lower temperature, and then greatly reduces interface thermal resistance, and thereby is an ideal thermal interface material applied to heat dissipation devices and the like. The invention further discloses a preparation method of the phase change heat conducting fin. The preparation method has the advantages of being simple in process, easy to operate, high in yield, gentle in reaction condition, low in energy consumption and the like, and is suitable for industrialized mass production. The invention further discloses a manufacturing device of the porous alumina framework. The manufacturing device of the porous alumina framework can guarantee good and stable proceeding of the electrolytic process of the porous alumina framework.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

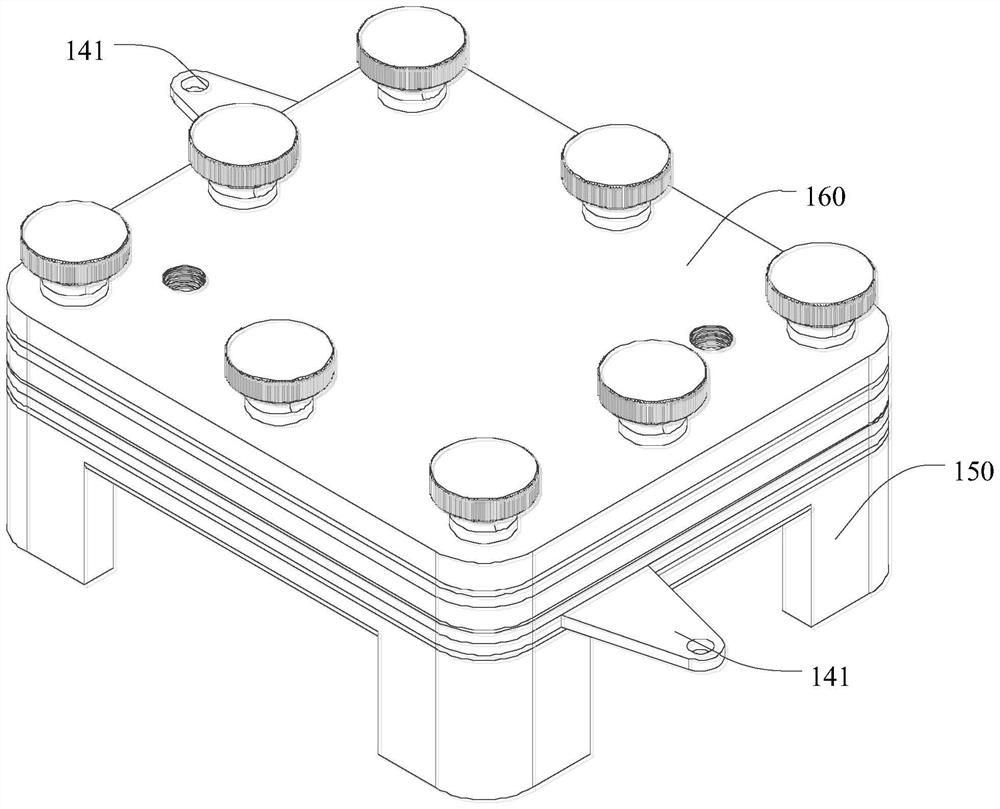

Small-scale water electrolysis apparatus and system thereof

PendingCN110862125ASimplify the structure of the electrolyzerSimplified stable electrolysisCellsWater/sewage treatmentElectrolytic cellWater tanks

The invention discloses a small-scale water electrolysis apparatus and a system thereof. The small-scale water electrolysis apparatus comprises an anode chamber, a cathode chamber, and an electrolyticmembrane, and further comprises a first electrolytic cell outer frame and a second electrolytic cell outer frame, wherein the electrolytic membrane and the first electrolytic cell outer frame forms the anode chamber, the electrolytic membrane and the second electrolytic cell outer frame forms the cathode chamber, the upper part of one side, opposite to the electrolytic membrane, of the anode chamber is provided with a first water inlet and a first water outlet, and the top of the cathode chamber is provided with an electrolyte inlet and an electrolyte outlet. The electrolyzed water with a specified pH can be continuously manufactured and the electrolyzed water with a relatively low concentration of un-decomposed brine is provided by combining the above-mentioned small-scale water electrolysis apparatus with a circulating water tank and an electrolyte circulating tank. The small-scale water electrolysis apparatus and the system thereof provided by the invention can meet various practical use requirements, the electrolytic cell structure is simple, the water production cost is low, the work applicability is strong, the scale is small, and thereby strong practicability and broad market application prospects are achieved.

Owner:诺枫瀛(上海)科技有限公司

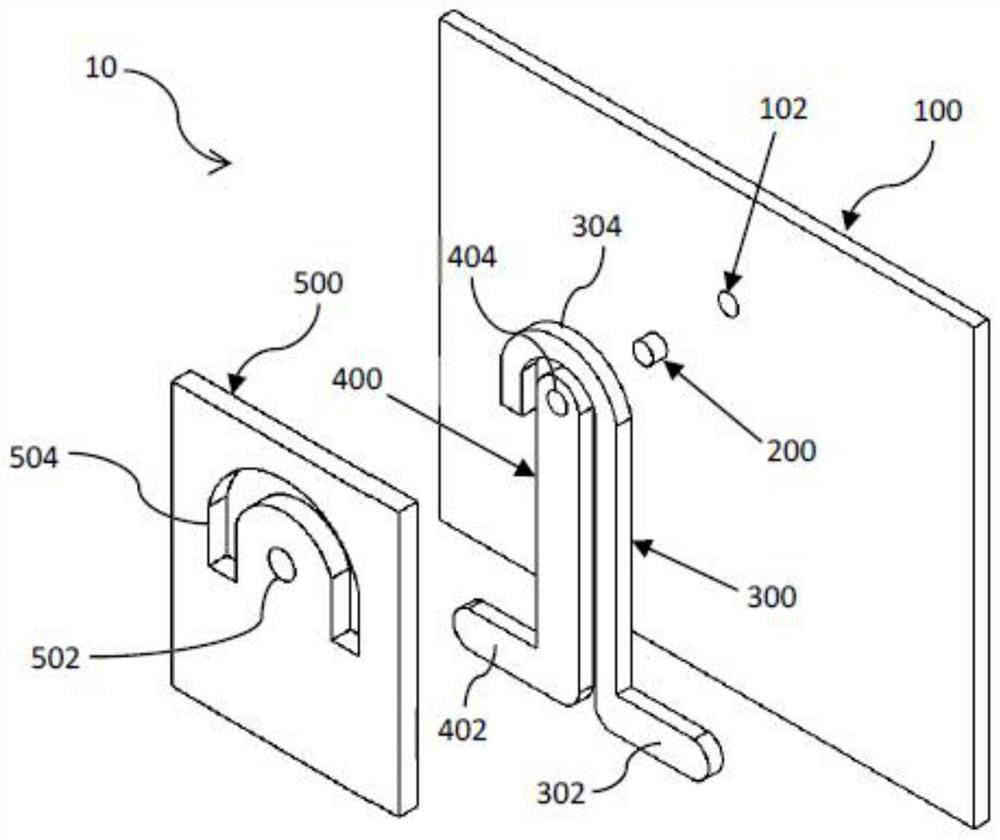

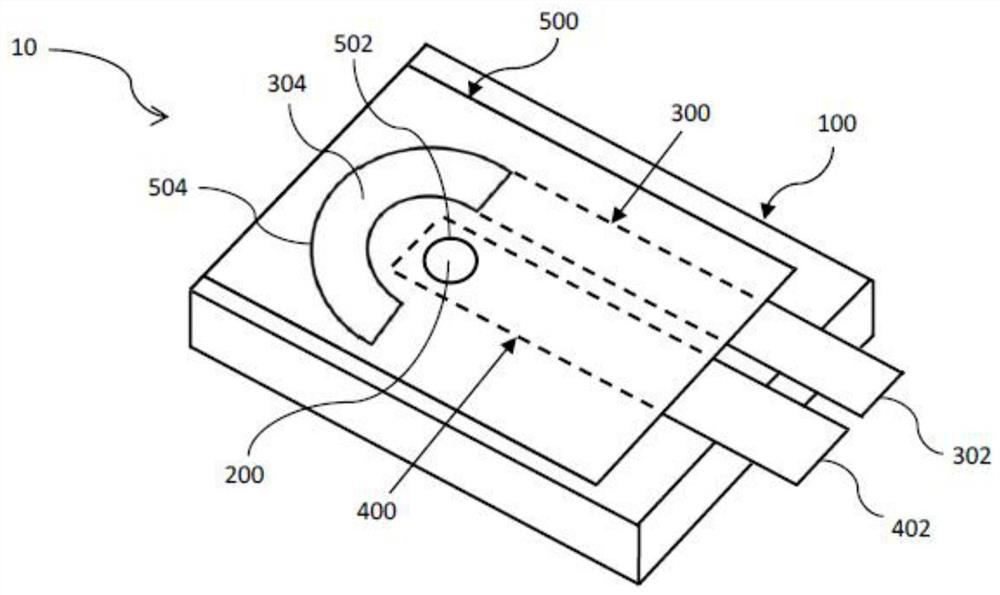

An electrolytic membrane valve and its manufacturing method

InactiveCN107869613BAvoid it happening againGuaranteed pass efficiencyValve arrangementsChemical physicsElectrolysis

Owner:山西云锦成文化投资有限公司

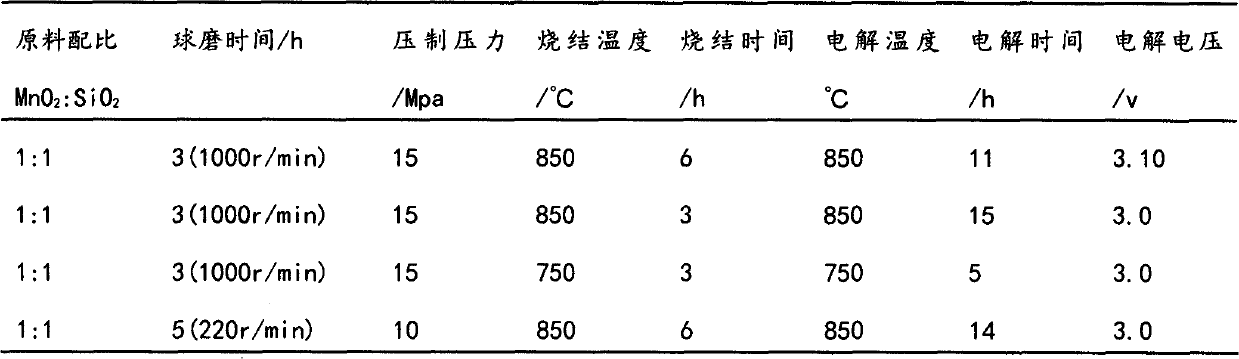

Preparation method of silicon-manganese alloy

The invention relates to a preparation method of an alloy, in particular to a preparation method of a silicon-manganese alloy. The preparation method comprises the steps of: preparing a cathode; pretreating a melting salt; pre-electrolyzing; electrolyzing; and washing and drying. The invention has the advantages as follows: all materials are green and pollution-free products; the electrolyzing process is stable and can not generate toxic and harmful gases or substances, the main generated gas is O2; the electrolyzing temperature is lower than the melting point of the alloy; the energy consumption is lower than that in the traditional technology and the serious situation that our country is short of the high-level manganese ore is made up; the electricity consumption is reduced; the reducing agent such as coke does not need to be added in the electrolyzing process so as to reduce the cost; and the process is stable and the compositions of the product can be controlled by regulating proportion of the metal oxide and process parameters.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A production process of pure cryolite

InactiveCN108996531AImprove performanceElectrolytic smoothAluminium fluoridesAmmonium chlorideElectrolysisWastewater

A production process of pure cryolite is disclosed. The process includes 1) pulping, 2) reaction, 3) centrifugal separation, 4) purification, 5) precipitation and 6) wastewater treatment. The processis simple and the produced cryolite is excellent in performance. The produced cryolite is stable in electrolysis, low in shrinkage, and smooth in molecular ratio change, and facilitates electrolyte stabilization. A cathode absorbs sodium evenly, thus prolonging the service lifetime of an electrolysis cell. An electrolysis temperature is reasonable, small in change and easy to control. Volatilization loss is low and on-site operation conditions can be effectively improved. The process can save a high amount of sodium fluoride or sodium carbonate, and reduces the production cost, and an additionmethod is simple and easy to operate. The process is free of wastewater emission and produces ammonium chloride as a byproduct.

Owner:衡东合兴化工有限责任公司

A method for environmentally friendly and efficient production of electrolytic manganese metal

ActiveCN103173786BHigh temperature toleranceReduced current efficiencyPhotography auxillary processesSolubilityThiourea

The invention belongs to the technical field of chemical production and provides a method for efficiently producing electrolytic manganese metal in an environment-friendly manner. The method provided by the invention takes a vinyl polymer hooked with a thiourea side group as an electrolysis additive, and the electrolysis additive is added into electrolyte containing manganese sulphate and ammonium sulphate for the production of electrolytic manganese, wherein the content of the electrolysis additive in the electrolyte is controlled to be 10-120mg / L. The electrolysis additive is an environment-friendly and non-toxic polymer and can be used for replacing the existing widely applied poisonous or pollutional selenium dioxide and sulphur dioxide; the electrolysis additive is low in solubility and cannot be accumulated in the electrolyte, a production process operation is simple, manganese metal electrolysis efficiency is high, the product purity is high, an electrolysis process is stable, purity requirement to the electrolyte is lower, and electrolytic manganese metal production difficulty and cost are reduced, so that the method provided by the invention has higher popularization and application values.

Owner:云南江南锰业股份有限公司

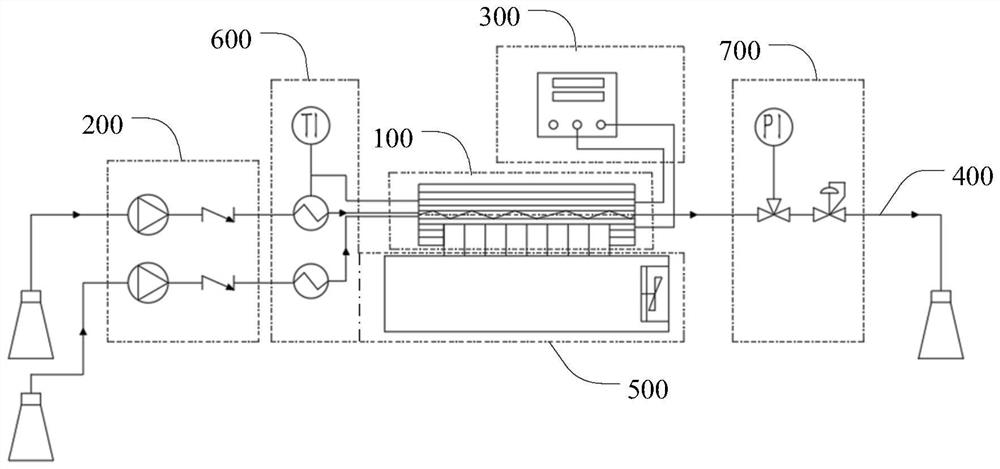

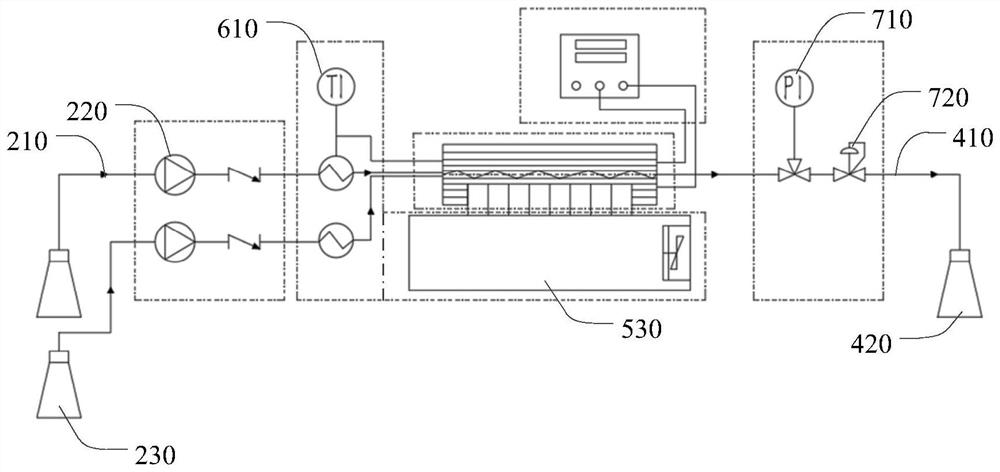

Continuous flow micro-electrolytic tank system device

PendingCN113604825AStabilizationGood electrolysis effectCellsMachines using electric/magnetic effectsContinuous flowElectrochemical response

The invention discloses a continuous flow micro-electrolytic tank system device, which comprises: a reaction module, a feeding module, a power supply module, a material receiving module and a heat exchange module; the reaction module forms a reaction flow channel with a feeding hole and a discharging hole, and the reaction module discharges to perform electrochemical reaction on a material in the reaction flow channel to generate a reaction product; the feeding module is used for driving a material to flow through the reaction flow channel; the power supply module is electrically connected with the reaction module; the material receiving module is used for receiving a reaction product flowing out of the reaction flow channel; and the heat exchange module is connected with the reaction module and is used for exchanging cold energy or heat energy generated by the reaction module with the outside. According to the technical scheme, the material in a material tank is continuously fed into the reaction module through the feeding module, and the product after the reaction of the reaction module is continuously conveyed into a product tank, so that the reaction electrolyte can be stably treated, and the end-to-end production of the material and the product can be realized by combining with other continuous flow reaction or separation and purification steps.

Owner:SHENZHEN E ZHENG TECH

A method for continuous electrolytic reduction of trivalent europium

ActiveCN105780042BConvenient individual control of current densityElectrolytic smoothCellsTime rangeAcid concentration

The invention relates to a method for continuous electrolytic reduction of three-valence europium. The method includes the steps that anode liquor is added into all electrolytic cell anode chambers, and cathode liquor is added into a first electrolytic cell cathode chamber; then the cathode liquor sequentially flows from the first electrolytic cell cathode chamber to a next electrolytic cell cathode chamber until entering the Nth cathode chambers, wherein the flow ratio of the cathode liquor to the anode liquor is 0.1 -10:1, the standing time ranges from 0.5 hours to 2 hours, and the density of electric current in all electrolytic cells ranges from 100 A / m<2> to 1600 A / m<2>; anode liquor flowing out from all electrolytic cell anode chambers is collected and returns to all electrolytic cell anode chambers according to flow after ingredients are merged and mixed; and cathode liquor flowing out from the last electrolytic cell cathode chamber is material liquid obtained after reduction. By means of the method for continuous electrolytic reduction of three-valence europium, the electric current density of all electrolytic cells and the acid concentration of the cathode liquor and the anode liquor in single electrolytic cells can be conveniently and independently controlled, electrolysis of the electrolytic cells is stable, and the reduction effect is good.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Multi-electrode spiral feeding integral blade wheel inter-blade passage electrolytic machining method

InactiveCN101508047BImprove processing efficiencyShorten the manufacturing cycleImpellerElectrolysis

The invention relates to an electrolytic machining method for multi-electrode screw feeding integral impeller flow passages, and belongs to the technical field of electrolytic machining. The method adopts a plurality of tool electrodes which are positioned on the same plane and arranged on an electrolytic machining clamp. In the machining process, a translation stage of a machine tool drives the plurality of the tool electrodes to simultaneously feed linearly along the axes direction of an impeller blank, and a turn table on the translation stage drives the plurality of the tool electrodes torotate; meanwhile, the impeller blank rotates around the axes of the impeller blank, and the tool electrodes perform electrolytic machining along a motion trail determined by the resultant motion. The electrodes and the impeller blank keep a small clearance; electrolyte flows out at a high speed from gaps of the tool electrodes to continuously take away products of electrolysis; and a plurality of impeller flow passages are machined finally. The number and distribution positions of the tool electrodes can be adjusted to meet machining requirements of integral impellers in different types. Because the plurality of the electrodes are adopted to perform machining simultaneously, the machining efficiency for the integral impeller is greatly improved, and the rotation of the electrodes makes machining allowance more even at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for inhibiting voltage swing of aluminum reduction cell and baffle wall-carrying cathode of aluminum reduction cell

The invention discloses a method for inhibiting voltage swing of an aluminum reduction cell and a baffle wall-carrying cathode of the aluminum reduction cell. The method comprises the following steps of: arranging a baffle wall inside a cathode groove of the aluminum reduction cell, and connecting one end of the baffle wall with a carbon block at the lateral part of a flue with the other end being 1-1.5m far away from the lateral part of an aluminum tapping end. By the arrangement of the baffle wall in the groove of the aluminum reduction cell, recirculating flow of molten aluminum is blocked and interface fluctuation of the molten aluminum is inhibited, thus effectively inhibiting the voltage swing of the aluminum reduction cell, stabilizing the electrolytic process and achieving the purpose of reducing polar distance, voltage and energy consumption. In addition, the method and the apparatus provided by the invention are easy to operate and realize, and can be widely applied in present common aluminum reduction cells.

Owner:GUIYANG AL-MG DESIGN & RES INST

Aluminum electrolysis cell with end face electricity outgoing

The invention discloses an aluminum electrolysis cell with end face electricity outgoing, is used for solving the problems that because a conventional aluminum electrolysis cell generates electricity from side faces, a large number of cell circumference busbars are required to be constructed, the investment cost is greatly increased, the cell separation distance is relatively large and the land occupation area is increased, and at the same time, the side face electricity outgoing makes the horizontal current quite large and is not conducive to electrolysis cell stability; the aluminum electrolysis cell includes a cathode carbon block and a cathode bar, the cathode carbon block is provided with a bar groove, the bar groove is internally provided with the cathode bar along the length direction, the bar groove passes through a cell shell at an electricity outgoing side of the electrolysis cell. The aluminum electrolysis cell is used for industrial production of metal aluminum.

Owner:GUIYANG AL-MG DESIGN & RES INST

Cryolite production process without discharge of waste water

InactiveCN108821320AImprove performanceElectrolytic smoothAluminium fluoridesAmmonium chlorideSlurryEngineering

The invention discloses a cryolite production process without discharge of waste water, which includes the steps of: 1) preparing slurry; 2) performing reactions; 3) performing centrifugal separation;4) eluting and drying a cryolite crude product separated in the step 3) to prepare a cryolite product; 5) precipitating the cryolite product; 6) alkalizing the cryolite product; and 7) waste treatment: cooling discharged water from an alkalization tank in the step 6) to normal temperature, adding the water into an ammonia separation kettle, adding hydrochloric acid to control content of free ammonia in clear liquid to be less than 1.3%, pH being 6.5-7.1, so that the hydrochloric acid is reacted with the free ammonia (NH3) to generate ammonium chc loride and is reacted with free sodium ions togenerate NaCl, adding ammonium sulfate or ammonium nitrate, as an anionic exciting agent, according to 8-11 wt% of total salt weight, and uniformly adding solid NaCl on the basis of 100% of the content of ammonium chloride to crystallize and separate-out the ammonium chloride under effect of the anionic exciting agent, while the NaCl is rapidly dissolved in water to obtain brine until the ammonium chloride is completely separated out and the brine is saturated, finally performing solid-liquid separation with a centrifuge to obtain the ammonium chloride, the brine returning to the step 2).

Owner:衡东合兴化工有限责任公司

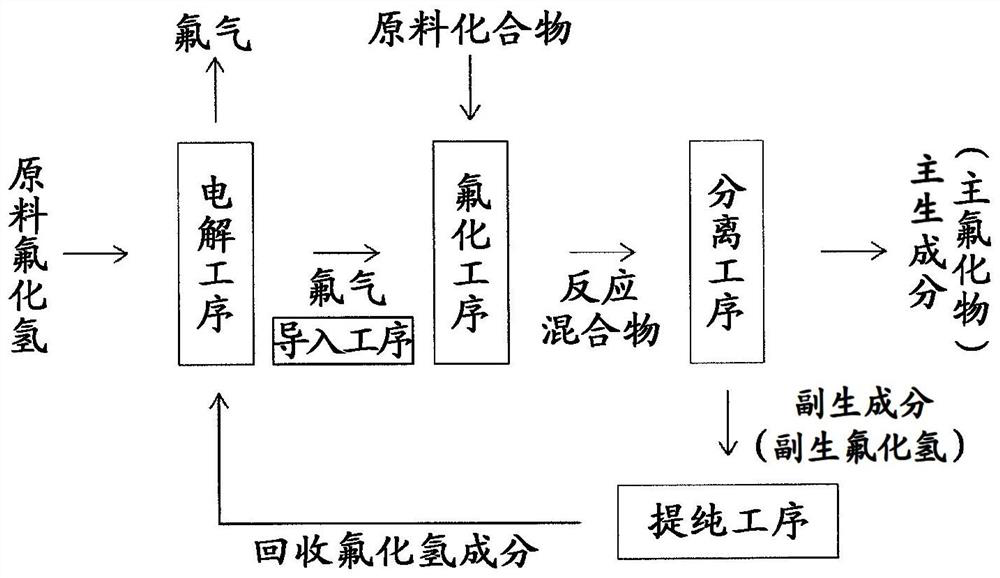

Fluorine gas production method

PendingCN113906165ALess prone to performance degradationElectrolytic smoothIon-exchange process apparatusGas treatmentHydrogen fluorideElectrolytic agent

Provided is a fluorine gas production method, which makes it possible to re-use a byproduct hydrogen fluoride, which is a byproduct produced during the production of a fluoride, i.e., a desired component, by reacting a raw material compound with a fluorine gas to fluorinate the raw material compound, as a raw material for the production of a fluorine gas by an electrolysis method. The fluorine gas production method comprises: a fluorination step of producing a reaction mixture comprising a main product fluoride, which is a desired component produced by fluorinating a raw material compound, and a byproduct hydrogen fluoride, which is produced as a byproduct; a separation step of separating the reaction mixture to produce a main product component containing the main product fluoride and a byproduct component containing the byproduct hydrogen fluoride; a purification step of purifying the byproduct component to produce such a recycled hydrogen fluoride component that the concentration of an organic substance contained in the byproduct component is decreased and the concentration of the byproduct hydrogen fluoride is increased; an electrolysis step of carrying out an electrolysis procedure using the recycled hydrogen fluoride component as at least a portion of an electrolyte solution to produce a fluorine gas; and an introduction step of introducing the fluorine gas produced in the electrolysis step into a reaction field for fluorination in the fluorination step.

Owner:RESONAC CORPORATION

A high-salt and high-cod wastewater electrolysis electrode and electrolytic oxidation treatment method

ActiveCN108264134BImprove antioxidant capacityImprove bindingWater treatment parameter controlWater/sewage treatmentIridiumAlloy

The invention discloses a high-salt and high-COD wastewater electrolysis electrode and an electrolytic oxidation treatment method. The electrolysis electrode comprises a titanium plate matrix and a plating located on the surface of the titanium plate matrix; and the plating is an alloy of metal ruthenium, metal iridium and rare earth. Electrolysis electrodes are uniformly arranged at a certain interval in wastewater, one of two adjacent electrolysis electrodes serves as an anode, the other electrolysis electrode serves as a cathode, the anode is connected with the anode of an electrolysis power supply, and the cathode is connected with the cathode of the electrolysis power supply which is a direct-current pulse power supply. The electrolysis electrode disclosed by the invention is high inoxidation resistance, firm in combination of the plating and the titanium plate, incapable of generating spots or falling off within 5 years if being normally used, high in electrolysis oxidation efficiency 1.5 times as high as that of a common electrode during wastewater treatment, low in power consumption, stable in electrolysis as well as voltage and current in an electrolysis process due to the adoption of the constant direct-current pulse power supply, capable of effectively removing COD, ammonium, nitrogen and chloride ions in wastewater and particularly suitable for electrolysis oxidation treatment of high-salt and high-COD wastewater.

Owner:SHIJIAZHUANG YUANSHENGYUAN ENVIRONMENTAL

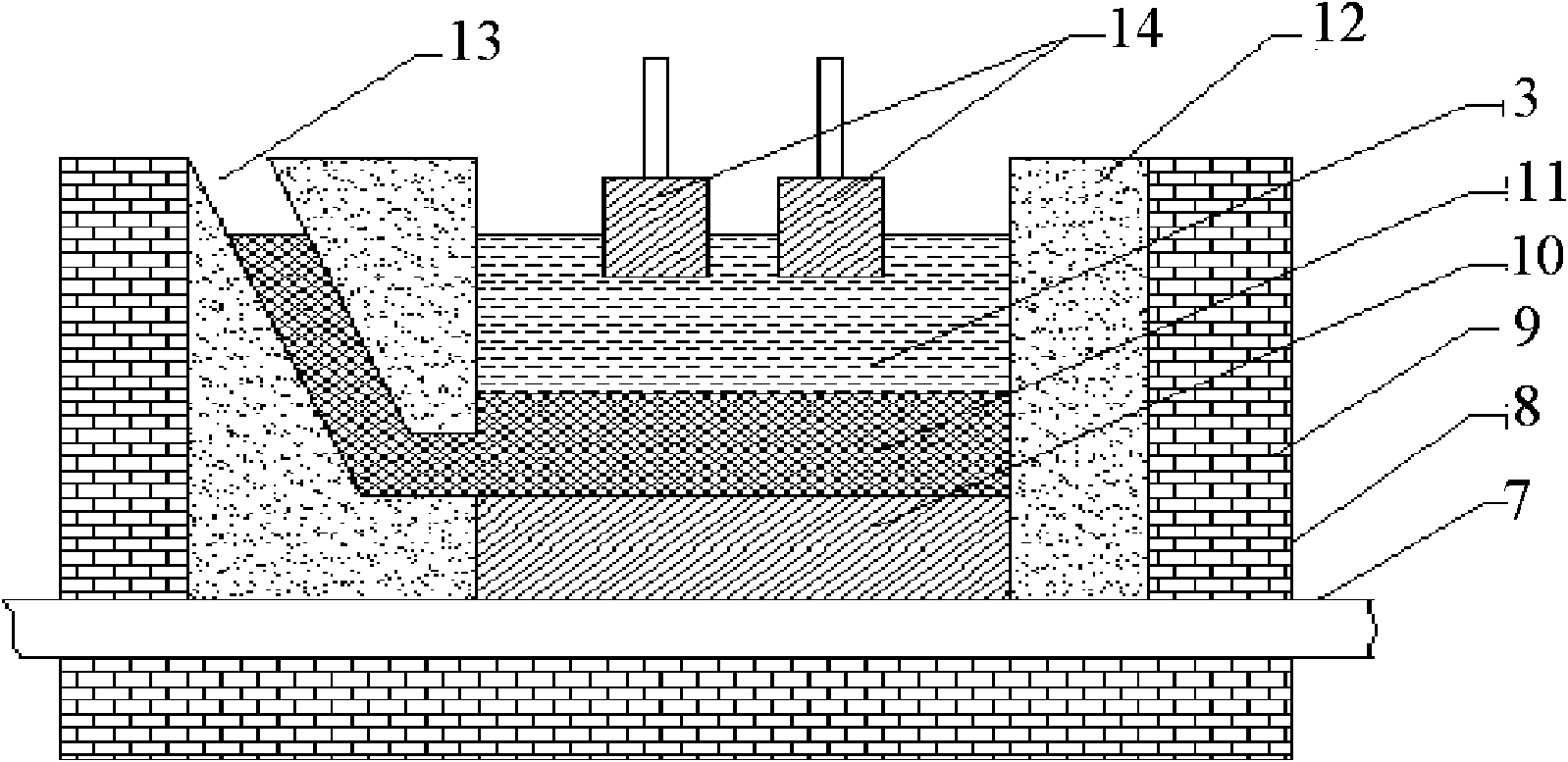

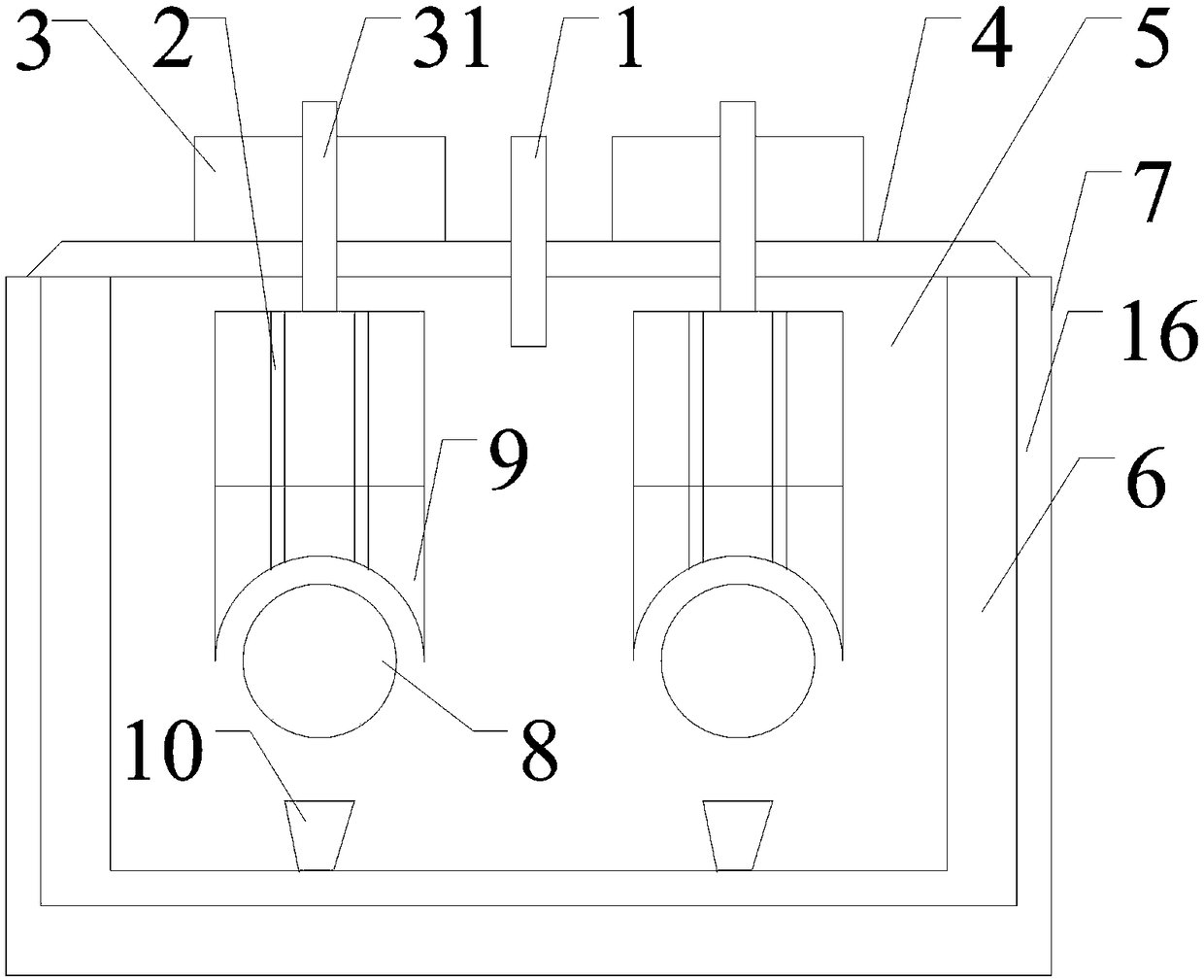

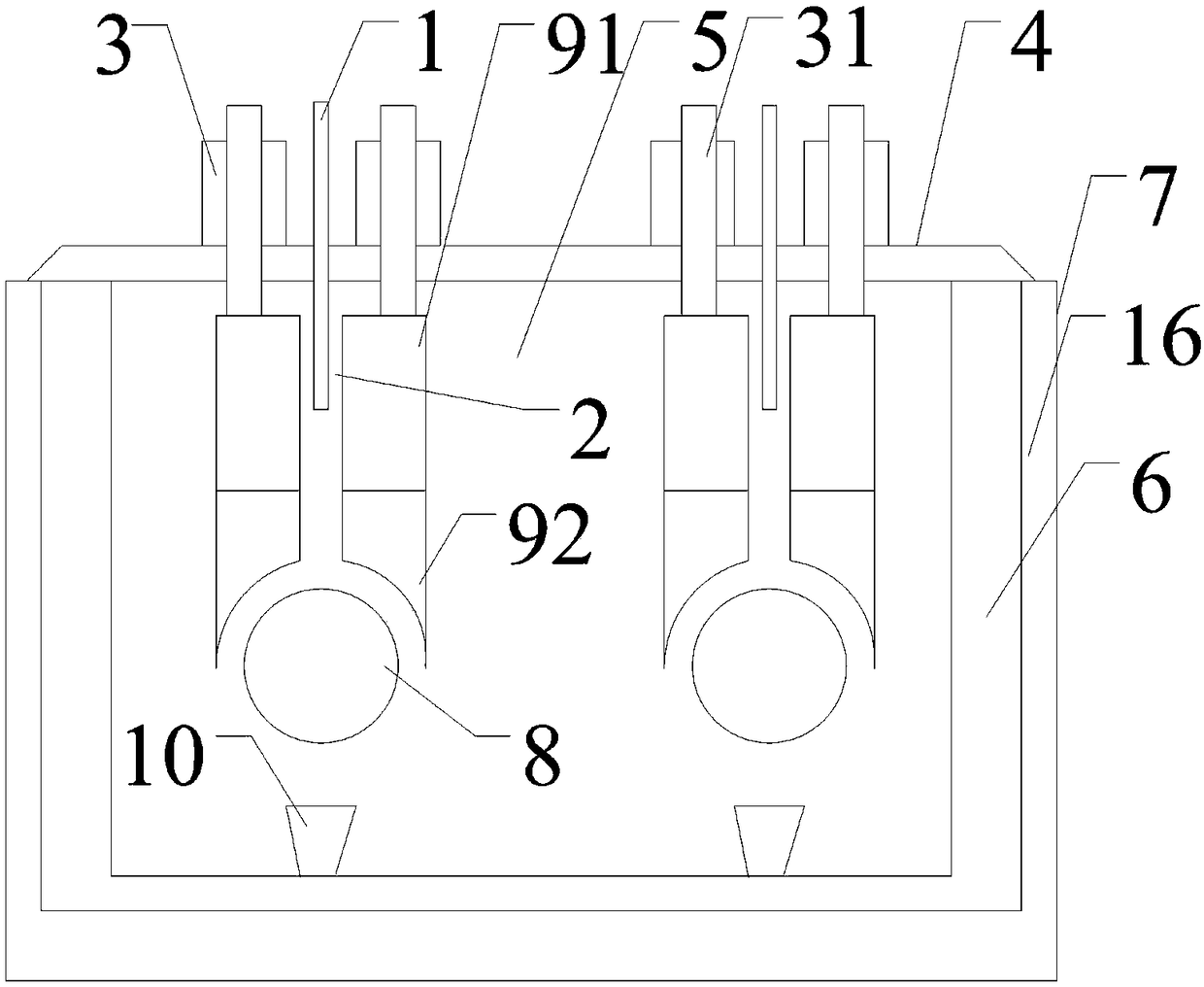

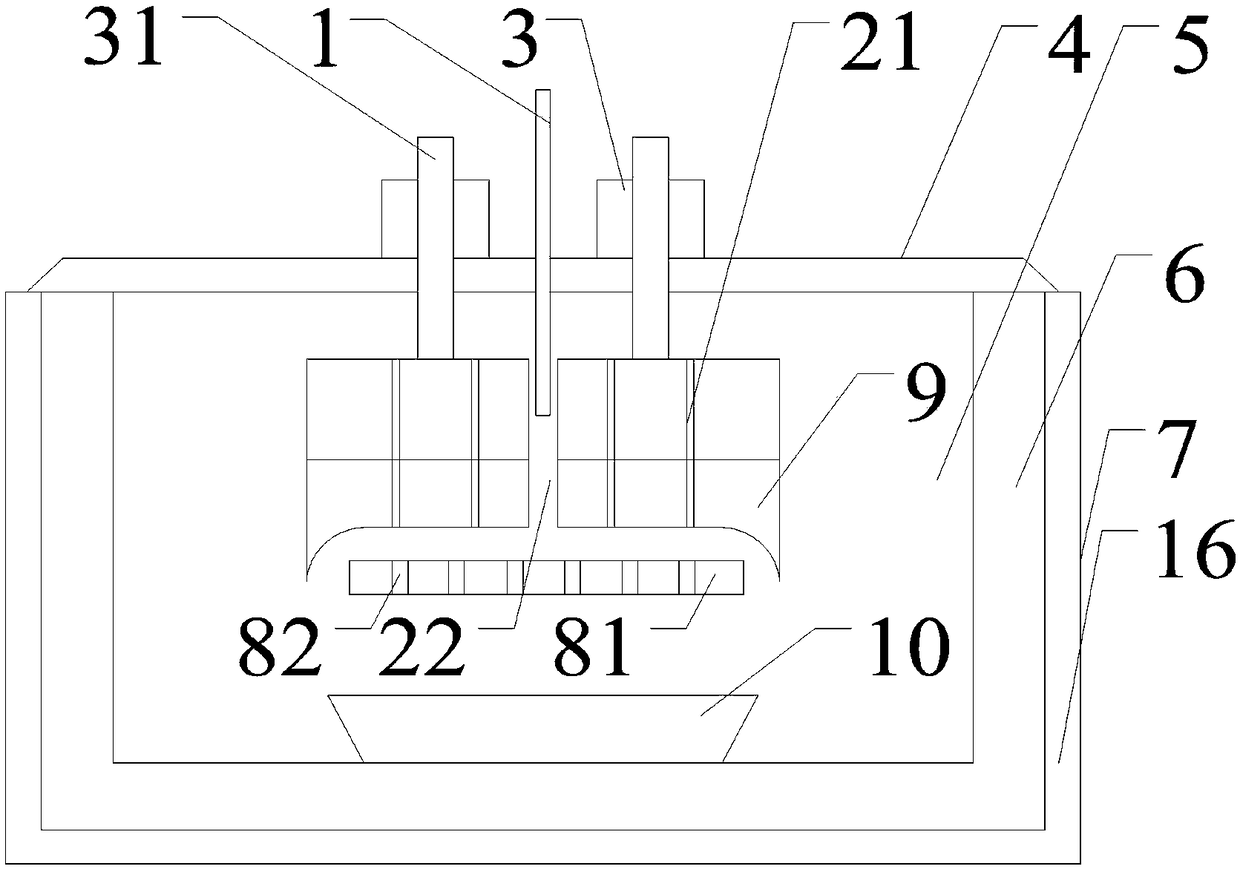

electrolytic furnace

The invention discloses an electrolytic furnace. The electrolytic furnace comprises a shell (7), a heat preservation layer (16), a furnace wall (6) and a hearth (5) from outside to inside. The hearth (5) with an opening in the top is formed in a cavity in the furnace wall (6); an anode adjusting component (3), the heath (5), an anode (9) and a cathode (8) are arranged from top to bottom; the cathode (8) is located in the hearth (5), and at least one end penetrates the furnace wall (6), the heat preservation layer (16) and the shell (7) and stretches out of the shell (7); the anode (9) stretches into the hearth (5) from the top of the hearth (5), and an electrolytic work pair is formed by the anode (9) and the cathode (8); the anode adjusting component (3) controls the anode (9) to move; and the anode (9) is provided with an exhaust channel (2). The electrolytic furnace has the beneficial effects that during electrolytic operation, generated gas can be conveniently escaped, anode uniform consumption and electrolytic technology parameter control is convenient, discharging is convenient, the anode utilization rate is high, the staying time of products in the electrolytic reaction area is short, the yield is high, and the product quality is more uniform.

Owner:GANZHOU KELI RARE EARTH NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com