Method for inhibiting voltage swing of aluminum reduction cell and baffle wall-carrying cathode of aluminum reduction cell

An aluminum electrolytic cell and voltage pendulum technology, applied in the field of aluminum electrolysis, to achieve the effects of easy operation and realization, reduced energy consumption, and reduced pole distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Both the partition wall and the cathode carbon block will be immersed in the aluminum liquid at about 1000°C, and they will often contact the electrolyte liquid. Therefore, the partition wall must be able to withstand high temperature, and the material will not dissolve into the aluminum liquid. Choose carbon block as the partition wall, as follows:

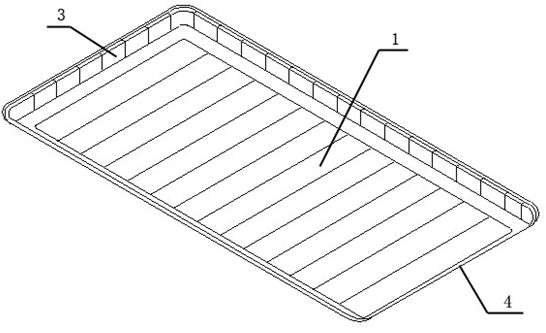

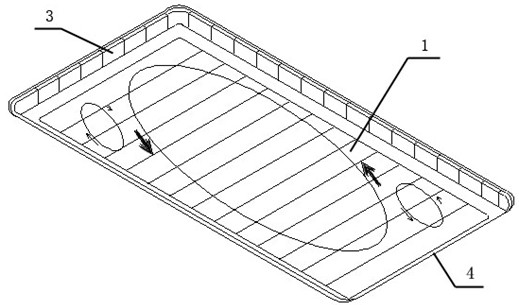

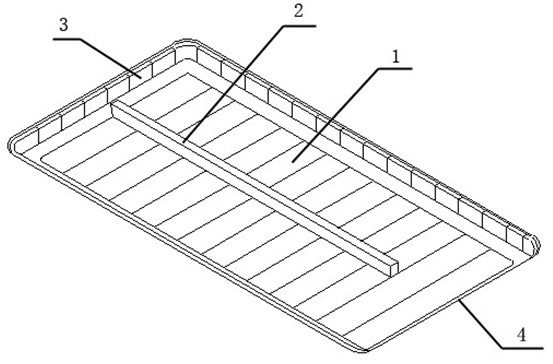

[0021] Such as Figure 4 and 5 As shown in the aluminum electrolytic cell, there are two rows of prebaked anodes 5, and the gap between the two rows of anodes 5 is generally 200 mm. Make the vertical partition wall 2 and the cathode carbon block 6 into a whole to form the tank chamber 1 (because the specific gravity of the carbon block is less than 2.3, it is necessary to make the vertical partition wall 2 and the cathode carbon block into a whole to prevent floating), the vertical partition wall 2. Arranged along the middle seam of the anode, one end of the longitudinal partition wall 2 is connected to the si...

Embodiment 2

[0023] Embodiment 2: Use silicon carbide, sintered corundum or titanium boride to make a strip-shaped partition wall 2, place the partition wall 2 in the groove chamber 1, place it along the middle slit of the anode, and connect one end of the partition wall 2 to the carbon at the side of the flue Block 3, the other end is 1.5 meters away from the carbon block 4 at the side of the aluminum outlet, and the height of the partition wall 2 is 5cm lower than the liquid aluminum interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com