Method for environmentally friendly and efficiently producing electrolytic manganese metal

An electrolytic manganese metal, high-efficiency technology, applied in photography technology, instruments, photography auxiliary technology and other directions, can solve the problems of unstable electrolysis process, low electrolysis efficiency, inconvenient use, etc., to achieve stable electrolysis process, high electrolysis efficiency, and reduce difficulty. and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

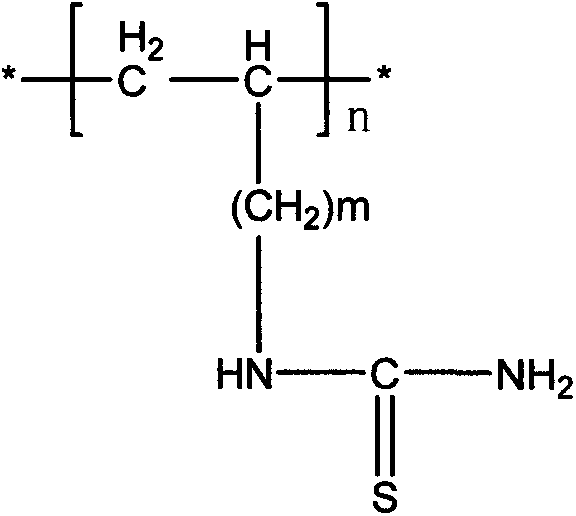

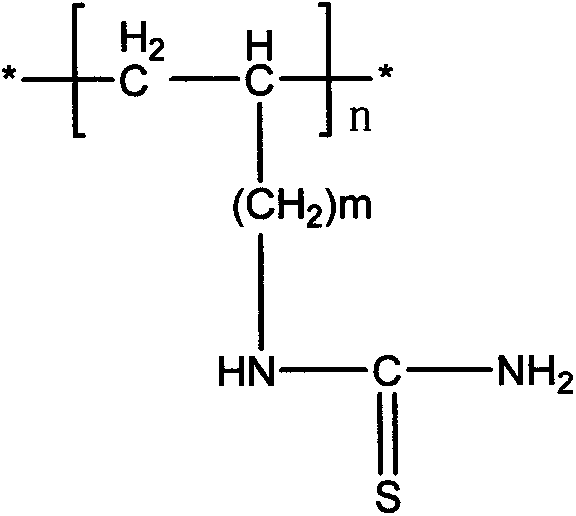

[0035] The above-mentioned polymer (m=1, number average molecular weight 8000) was used as an additive, and the content of the additive in the electrolyte solution was 35 mg / L.

[0036] This additive for high-efficiency production of selenium-free electrolytic manganese can be directly used in existing SeO 2 or SO 2 Application on the electrolysis production equipment as additive, use the production process condition of the present invention to be (1) electrolytic solution replenishment processing section: qualified solution requires manganese content to be 32-38g / L, ammonium sulfate content at 90-110g / L, pH control At 6.5-6.8. (2) Electrolysis section: the manganese content in the electrolytic cell is required to be 15-20g / L, the ammonium sulfate content to be 90-110g / L, and the pH to be controlled at 7.5-8.0. The bath temperature is 38-50°C; the electrolysis cycle is 24 hours, and the current density is 350-450A / m 2 .

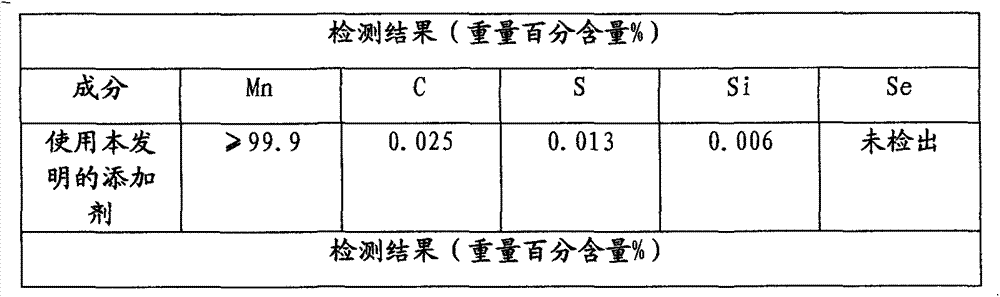

[0037] The production test in the electrolytic mang...

Embodiment 2

[0039] The above polymer (m=1, number average molecular weight 60,000) was used as an additive, and the content of the additive in the electrolyte solution was 20 mg / L.

[0040] This additive for high-efficiency production of selenium-free electrolytic manganese can be directly used in existing SeO 2 or SO 2 Application on the electrolysis production equipment as additive, use the production process condition of the present invention to be (1) electrolytic solution replenishment processing section: qualified solution requires manganese content to be 32-38g / L, ammonium sulfate content at 90-110g / L, pH control At 6.5-6.8. (2) Electrolysis section: the manganese content in the electrolytic cell is required to be 15-20g / L, the ammonium sulfate content to be 90-110g / L, and the pH to be controlled at 7.5-8.0. The bath temperature is 38-50°C; the electrolysis cycle is 24 hours, and the current density is 350-400A / m 2 .

[0041] Tested in the electrolytic manganese plant, the elec...

Embodiment 3

[0043] The above-mentioned polymer (m=0, number average molecular weight 35,000) was used as an additive, and the content of the additive in the electrolyte solution was 15 mg / L.

[0044] This additive for high-efficiency production of selenium-free electrolytic manganese can be directly used in existing SeO 2 or SO 2 Application on the electrolysis production equipment as additive, use the production process condition of the present invention to be (1) electrolytic solution replenishment processing section: qualified solution requires manganese content to be 32-38g / L, ammonium sulfate content at 90-110g / L, pH control At 6.5-6.8. (2) Electrolysis section: the manganese content in the electrolytic cell is required to be 15-20g / L, the ammonium sulfate content to be 90-110g / L, and the pH to be controlled at 7.5-8.0. The bath temperature is 38-50°C; the electrolysis cycle is 24 hours, and the current density is 350-430A / m 2 .

[0045] The electrolytic manganese factory conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com