Catalyst composition for ethylene oligomerization and preparation method and application thereof

A technology of ethylene oligomerization and catalyst, applied in the direction of catalysts, catalytic reactions, hydrocarbons, etc., can solve the problems of long duration of high activity, blockage of pipelines, high temperature tolerance, etc., to achieve reduced deactivation rate, temperature tolerance High acceptability and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

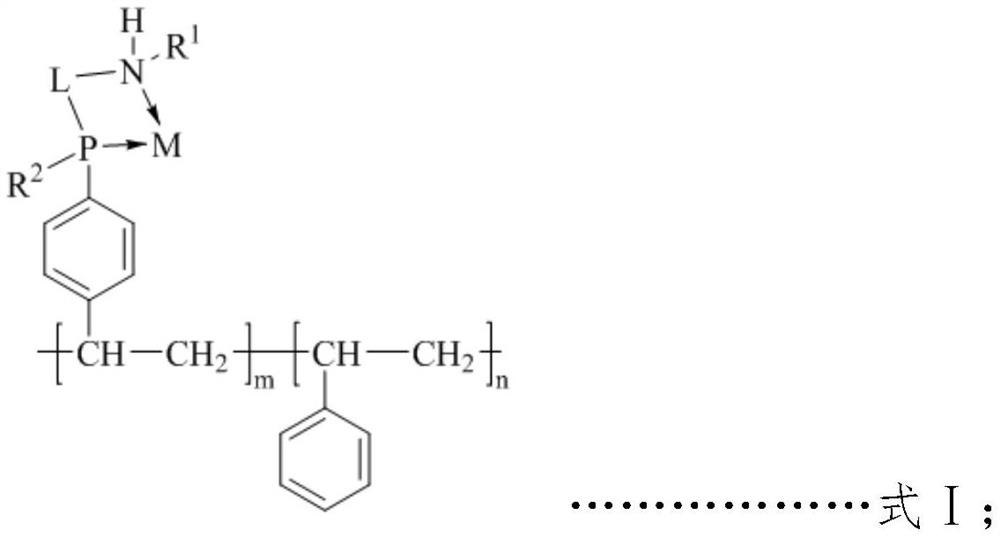

[0042] Preparation of self-supporting chromium complexes:

[0043] (1) under nitrogen protection, utilize basic alumina column to remove the polymerization inhibitor in styrene;

[0044] (2) Under anhydrous and oxygen-free conditions, using N,N-dimethylformamide (DMF) as a solvent, the phosphine nitrogen ligand monomer containing terminal double bonds, styrene and initiator azobisisobutyronitrile (AIBN) mixed at 1:0.1:0.005;

[0045] (3) Heating at 100°C for 24 hours, removing the solvent under reduced pressure to form a solid powder, washing and vacuum drying to obtain a self-supported phosphine nitrogen ligand;

[0046] (4) Combine the self-supported phosphine nitrogen ligand with CrCl 3 (THF) 3 Mix in toluene, react at 60°C for 24 hours, filter in a glove box, and vacuum dry to obtain the target complex, the structure of which is shown in formula III.

[0047] Catalyst configuration: freshly prepare 20 mL of toluene solution of the self-supporting metal complex shown in...

Embodiment 2

[0054] Preparation of self-supporting chromium complex: same as Example 1.

[0055] Catalyst configuration: with embodiment 1.

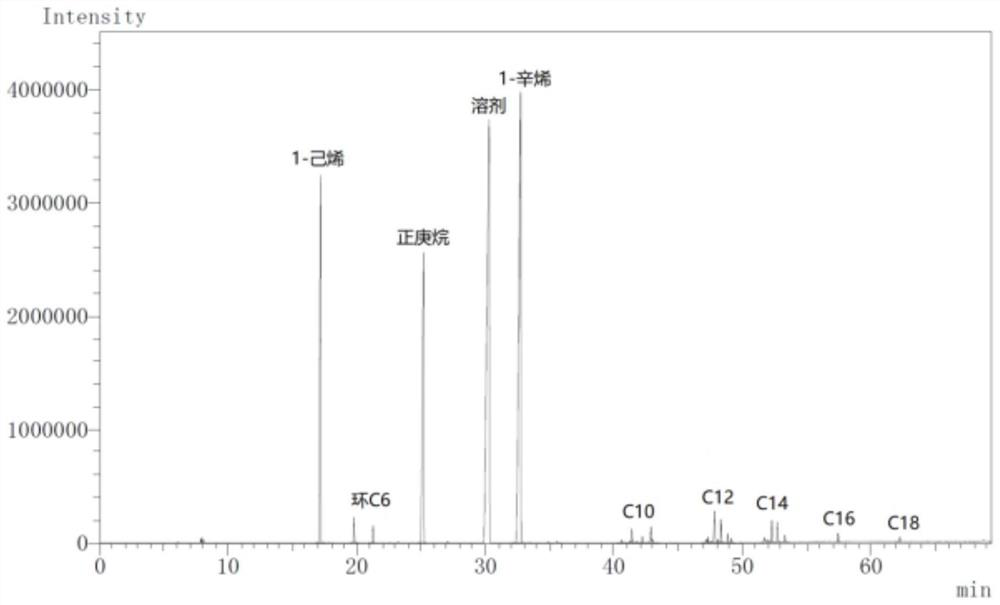

[0056] Ethylene oligomerization: the amount of co-catalyst methylaluminoxane was reduced to 5000 μmol (10 wt% toluene solution), and other conditions were the same as in Example 1. The catalyst activity calculated by the internal standard method was 12.3×10 6 g / (mol Cr h), the product composition is recorded in Table 1, and the gas chromatographic analysis of the product is shown in the attached figure 1 .

Embodiment 3

[0058] Preparation of self-supporting chromium complex: same as Example 1.

[0059] Catalyst configuration: with embodiment 1.

[0060] Ethylene oligomerization: the amount of co-catalyst methylaluminoxane was reduced to 4000 μmol (10 wt% toluene solution), and other conditions were the same as in Example 1. The catalyst activity calculated by the internal standard method was 8.5×10 6 g / (mol Cr h), the product composition is recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com